Page 1

Emergency Pneumatics.

Operating Instructions

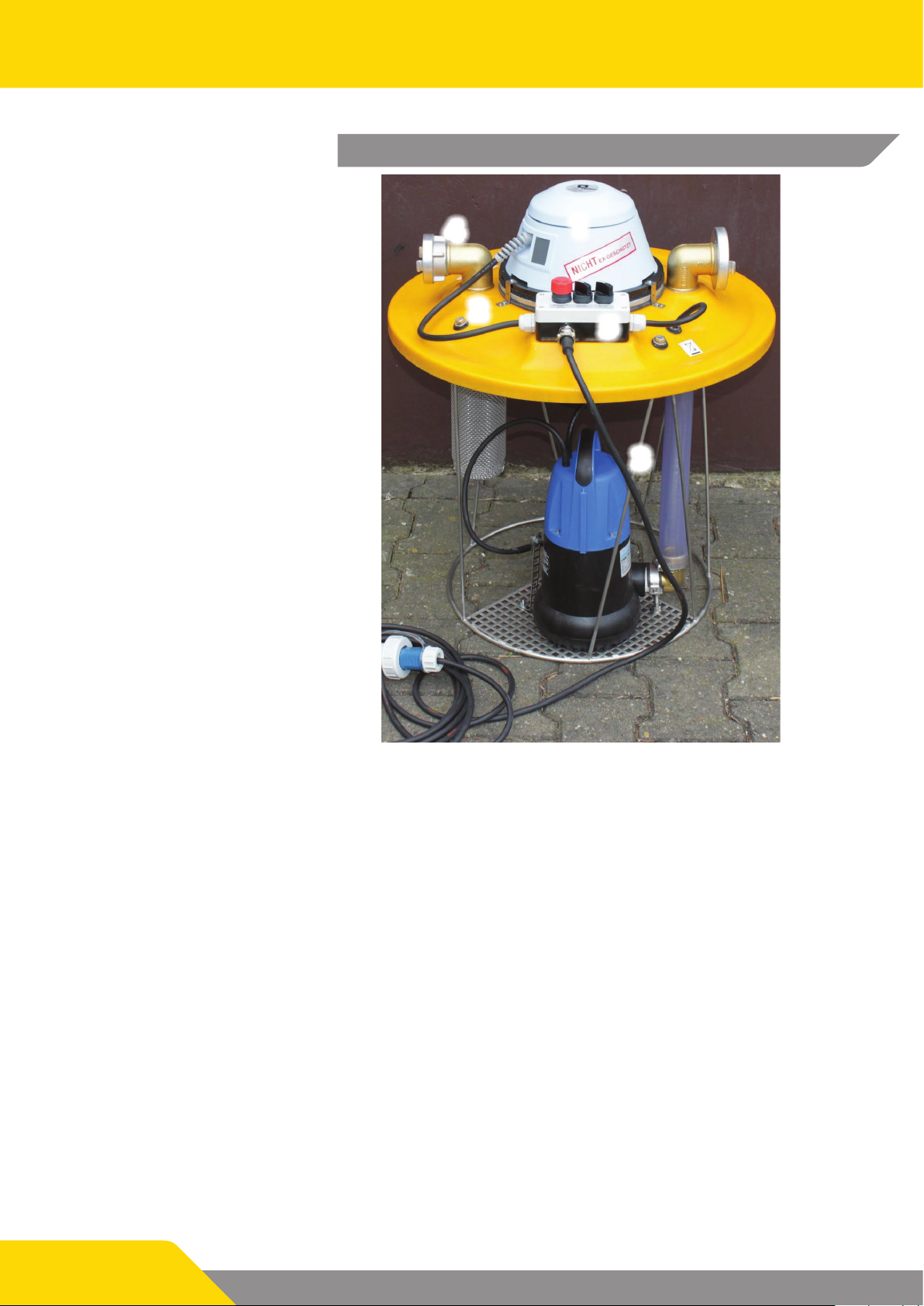

VETTER Permanent Aspirator

Article No. 9987011205 | © Vetter GmbH I 09/14 I Changes and errors excepted.

Page 2

Vetter Permanent Aspirator

Contents

1. Important preliminary remarks ....................................3

2. Description of the product ........................................3

2.1 Scope of delivery ...........................................3

2.2 Optional accessories ........................................4

2.3 Area of application ..........................................4

2.4 Correct use according to regulations ........................4

2.5 Safety information ..........................................4

3. Preparing the product for use .....................................5

3.1 Preparations for operation ..................................5

3.2 Emergency switch ..........................................5

4. Operating instructions ............................................6

4.1 Operation mode: Suction ...................................6

4.2 Operation mode: Pump .....................................6

4.3 Operation mode: Suction and Pumping .....................6

4.4 Aspiration of strongly contaminated liquids .................7

4.5 Care and maintenance ......................................7

5. Taking the product out of operation ...............................7

6. Elimination of defects .............................................8

7. Technical data ....................................................9

8. Spare parts lists ................................................. 10

8.1 Motor head ............................................... 11

8.2 Adapter with cover and pump holder ..................... 13

8.3 Suction line ...............................................14

8.4 Pump with pressure line ..................................15

Page 2/20

8.5 Switch panel ..............................................16

8.6 Suction hose .............................................17

8.7 Suction pipe, stainless steel (2 parts) ......................17

8.8 Narrow space nozzle ...................................... 17

8.9 Ground nozzle 370 mm ................................... 17

8.10 Trolley for Permanent Aspirator, GF-Polyester ..............18

9. Resistance Guide ................................................18

EC Conformity Declaration (available on request) ...................19

Page 3

1. Important preliminary remarks

Only a knowledge and exact adherence to this operating manual will

guarantee correct and perfect operation, achieve the best possible use

and uphold claims made within the framework of the Vetter warranty.

Vetter Permanent Aspirators must only be used by trained, reliable sta.

Operational usage of the Permanent Aspirator is to be made under the

condition that operators have an exact knowledge of this operating manual and that they observe all the information contained in it.

The operating instructions given here are to be regarded as part of the

product and are to be kept for the complete life duration of the product.

In case the product should be passed on to a successive user then the

operating instructions must also be included.

2. Description of the product

2.1 Scope of delivery

Article No. Description Qty.

2210001303

2210001101 Suction and pump unit 1

2230004500 Container, 100 l, GRP-Polyester 1

2230010501 Filter cage 1 1/2" OT 1

2230022900

2230001100 Trolley, GRP-Polyester 1

Permanent Aspirator set

basic equipment consisting of:

Accessories aspirators, consisting of:

Suction hose, oil resistant, 6 m, incl. curved connecting pipe

and adapter suction hose, blue incl. coupling Storz 38

Suction pipe (2 par ts)

Narrow space nozzle

Ground nozzle

1

Page 3/20

Page 4

Vetter Permanent Aspirator

Never turn on with

gloves or other insulating materials.

2.2 Optional accessories

Article No. Description

2230025400 Safety switch PRCD-S

If in an exceptional case it is necessary to provide the power supply from other feed points (external network, e.g. public power

supply), the re brigade accident prevention regulations stipulate

the use of PRCD-S type portable residual current devices.

2.3 Area of application

The Vetter Permanent Aspirator can be used for the aspiration of

water, oil and non-aggressively acting liquids. Both mobile and

stationary operation is possible depending on the task involved.

2.4 Correct use according to regulations

The mains power supply line is to be protected against damage.

The aspirator is only allowed to be used when the connection line

is in a perfect condition. The aspirator is set to a operating voltage

of 240 V/ 50 Hz at the manufacturer.

The mains power plug is to be removed

before any cleaning, maintenance and

repair work is carried out.

2.5 Safety information

All pertinent, public work protection and accident prevention regulations are to be observed as well as the generally recognized

regulations for the eld of technology. The necessary work protection clothing is to be worn during operation.

Attention! Danger of Explosion!

Vetter Permanent Aspirators are not

protected against explosion owing to their

operational principle (vacuum cleaner).

It must not be used for aspiration of highly inammable liquids or

liquid mixtures (with a ash point below 21°C). Vetter Permanent

Aspirators must not be used in Explosion Protected Zones (0).

Page 4/20

Explosion Protected Zones are, according to the German Regulations for inammable Liquids (German abbreviation: VbF), explosion endangered areas in which there is a constant or permanent

explosive atmosphere caused by inammable gasses, vapours or

mist.

All Vetter Permanent Aspirators are suitable for liquid aspiration.

Page 5

Acids, caustic solutions and aggressively

acting solvents can form mixtures which

are a danger to health and therefore

must not be aspirated.

Dust cannot be aspirated with the Vetter Permanent Aspirator. In

agreement with the Trade Association we would like to expressively point out that in this connection, this aspirator must not be

used for the aspiration of dust and dust which is hazardous to

health.

3. Preparing the product for use

3.1 Preparations for operation

Place the container into the trolley if there is a trolley available for

mobile operation. When using the adapter make certain that the

adapter sealing on edge of the container seals correctly. Use the

lter cage when aspirating.

Connect the pressure coupling (Storz C) to the blocking valve. It is

to be opened before pumping begins and closed when pumping

has nished. This stops the pumped liquid from owing back after

pumping has nished.

In order to pump out, connect a normal re service hose having a

Storz C coupling to the blocking valve Size C. Lay out the hose so

that it is not bent. The re service hose should not be longer than

necessary to achieve maximum pump performance. Check to see

if the motor head is perfectly seated in the adapter opening.

Connect the suction hose to the suction coupling for suctioning

o. Connect the bent pipe rst and then connect the 2-part suction pipe to the previously mounted suction hose. Depending

on the type of use, push the ground nozzle or the narrow crevice

nozzle onto the suction pipe. Connect the mains power plug to a

correctly installed protection contact socket.

3.2 Emergency switch

The Permanent Aspirator is equipped with an emergency switch

according the regulations from the German Association for Electrical Engineering (VDE). If the emergency switch is activated before work begins then it can be deactivated by turning in the direction of the arrow (clockwise).

Page 5/20

Page 6

Vetter Permanent Aspirator

4. Operating instructions

4.1 Operation mode: Suction

Set the „ASPIRATOR“ switch on the panel to „ON“ and leave the

„PUMP“ switch set to „OFF“. The blocking valve, Size C, remains

closed.

The liquid is suctioned. When the container reaches full capacity, the swimmer ball will block the suction opening of the motor

head. The suction sequence is interrupted. Switch the equipment

„OFF“ using the „ASPIRATOR“ switch. Empty the tank or pump out

at another position.

4.2 Operation mode: Pump

Only pumping out takes place, the suction turbine remains switched o. Connect the pressure hose, making sure it has no bends,

to the blocking valve (Size C). Set the „PUMP“ switch on the panel

to „ON“. Open the blocking valve (Size C). The container is now automatically emptied. The dredging pump automatically switches

o after completion of the emptying process. Set the „PUMP“

switch to „OFF“- Close the blocking valve (Size C) and decouple

the pressure hose.

4.3 Operation mode: Suction and Pumping

Connect the pressure hose as described before and open the blocking valve (Size C). Set both switches to „ON“. The liquid is suctioned and pumped out at the same time. The dredger pump is

automatically switched on and o by the swimmer switch depending on the level of liquid in the container.

With large feed amounts, the capacity for

the suctioned liquid exceeds the

pumping capacity: The swimmer ball

then closes the suction opening of the

motor head. The suction sequence is

automatically interrupted.

Switch o the suction turbine by setting the „ASPIRATOR“ switch

on the panel to o. Due to the fact that the liquid is further pumped, the swimmer ball is released after a short time (about 15 secs)

from the suction opening of the motor head. Switch on the motor

head again. The suction capacity is to be matched to the feed capacity by feeds over 4 m. To do this, proceed as follows:

1.) Withdraw the ground nozzle out of the liquid to be suctioned

before the container is lled and the swimmer ball closes the

suction opening. Only pumping takes place.

Page 6/20

or:

Page 7

2.) Interrupt the suction sequence by briey switching o the

suction turbine if the level is the same. By doing this, the

pumping sequence is not interrupted. Switch the suction turbine on again as soon as the level of liquid in the container has

correspondingly sunk.

4.4 Aspiration of strongly contaminated liquids

The Permanent Aspirator is equipped with a collection lter cage

in order to protect the feed pump. To empty the lter cage, turn

it counter clockwise and take it out of the holder. Empty the lter

cage and re-insert. Remember that with strongly contaminated liquids it should be regularly emptied because if it is full it will greatly reduce the suction power.

4.5 Care and maintenance

Any special maintenance measures are not required owing to the

sturdy construction of the Vetter aspirator. The suction hoses are

not, under any circumstances, to be cleaned with a hot water high

pressure cleaner, as for example can be done with the containers.

The motor head with the suction turbine is maintenance-free and

does not therefore require any special maintenance.

5. Taking the product out of operation

The disposal of used electrical and electronic equipment (applicable in the countries of the European Union and other European countries with a separate collection system for these items)

in accordance with the electrical and electronic equipment act

(ElektroG) of 24th March 2005, implementing the EC guidelines

2002/96/EC on electrical and electronic equipment (“WEEE guidelines“).

This symbol on the product or its packaging means that the

electronic components of this product are not to be treated as

normal household waste but must be returned to the manufacturer for recycling (free delivery).

Page 7/20

Page 8

Vetter Permanent Aspirator

6. Elimination of defects

Defect Cause Remedy

Suction motor

does not run

Suction motor

runs but equipment does not

suction

Conveyor pump

power is too low

Suction motor

runs but suction

power is too low

Conveyor pump

does not work

Conveyor pump

runs but there is

no feed

*only by a qualied electrician

Should the defect remain despite the above information then contact an authorized

representative or Vetter GmbH.

Shut-o switch is o Turn the switch on. Call

a qualied electician if

switch cuts o again.

No mains voltage Check socket

Connection cable defective Replace cable*

Motor is defective Exchange motor*

Emergency switch is

pressed

Float ball has closed the

suction opening

Suction line is blocked Clean suction line

Motor head turbine is

defective

Pump is blocked Clean pump

Conveying height is too

high

Equipment is drawing air

from outside

Sealing is defective Exchange sealing

Suction line is blocked Clean suction line

Suction height is too great Place the equipment to

Filter basket is blocked Empty lter basket

Float switch is interlocked Release oat switch

Connection cable defective Replace cable*

Pump wheel blocked by dirt Clean pump and wheel

Pump motor defective Exchange pump*

Pump blocked Clean pump

Ventilation hole blocked (in

the lifting tube of the pump

under the ap trap or at the

side of the pump)

Pressure hose is bent Take out the bend in

Shut-o unit Size C is closed Open shut-o unit

Pump is defective Exchange pump*

Unlock the emergency

switch

Switch o motor, re-

lease oat ball

Carry out maintenance*

Reduce height die-

rence

Check the adapter and

motor head for correct

seating

suction level

Clean ventilation hole

the hose

Page 8/20

Page 9

7. Technical data

Set Permanent Aspirators Art.-Nr: 2210001303

Unit Data

Suction power (air)

Suction power (water)

Vacuum pressure

Delivery capacity of pump

Delivery height of pump

Current consumption of motor head Amps 4.6

Current consumption of pump Amps 3.4

Power consumption of motor head Watts 1.000

Power consumption of pump Watts 800

Voltage of motor head * V/Hz 240/50/60

Voltage of pump * V/Hz 240/50

Capacity of container

Dimensions of aspirator base equipment

(LxWxH)

Weight (set for base equipment), ca.

Noise level dBA 84.9

l/min. 3,030

cu.ft./min. 107

l/min. 160

cu.ft./min. 5.7

mm WS 2,392

psi 3.5

l/min. 260

cu.ft./min. 9.2

m 11

ft. 18

l 100

cu.ft. 3.53

cm 86 x Ø 62

in. 34 x Ø 25

kg 35

lbs 77

Protection class : I

Protection category : IP 44

All rights reserved for technical changes within the scope of product improvement.

Page 9/20

Page 10

Vetter Permanent Aspirator

8. Spare parts lists

4

1

2

5

3

1. Motor head with suction turbine

2. Adapter with cover and pump holder

3. Pump with pressure line

4. Suction line

5. Switch panel

Page 10/20

Page 11

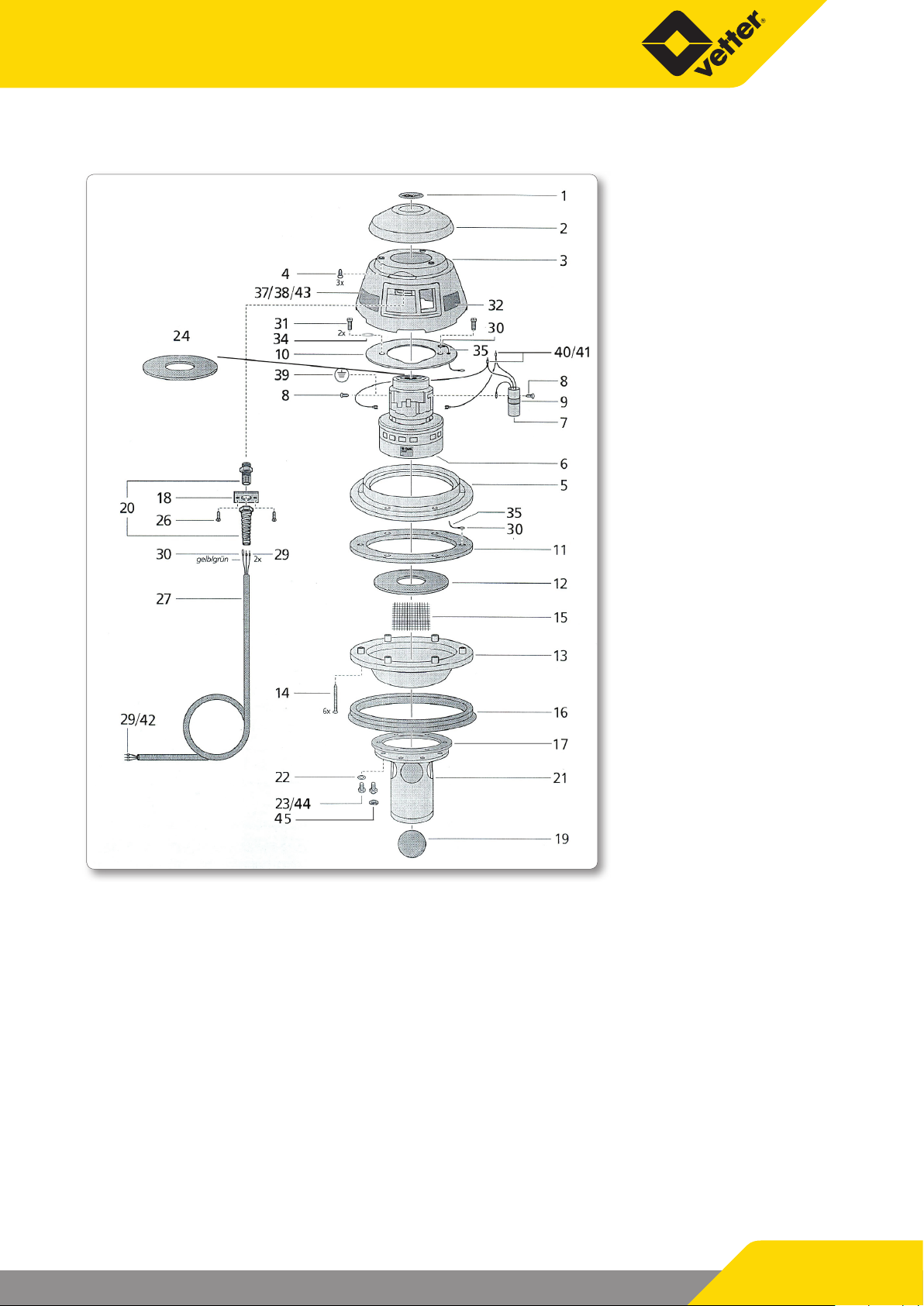

8.1 Motor head

Page 11/20

Page 12

Vetter Permanent Aspirator

Pos.: Article No. Description Qty.

1 2230 0004 00 Label "VETTER" 1

2 2220 0002 00 Turbine upper housing cover 1

3 2220 0003 00 Turbine upper housing, blue 1

4 2230 0073 00 Pan-head tapping screw, cross headed 3

5 2220 0004 00 Securing ring, PVC 1

6 2230 0074 00 Turbine 1000 Watt, 240 Volt 1

7 2230 0064 00 Capacitor 800/1000/1200 Watt BV 0.450/60 1

8 1700 0045 00 Slotted screw M 5 x q16, galv. DIN 84 2

9 2230 0066 00 Securing clip for capacitor, 16 mm diam. 1

10 2230 0077 00 Insulation disk, ST 37, diam. 190 mm x 102 mm 1

11 2230 0078 00 Rubber sealing ring 195/245 diam. x 15 1

12 2230 0079 00 Sealing made of cellular rubber, black 140x59x4 mm 1

13 2230 0080 00 Turbine head 1

14 2230 0081 00 Pan-head tapping screw, cross headed, 4.8 x 50 6

15 2230 0082 00 Wire cloth (1.4301), machine width 6.3 mm 1

16 2230 0083 00 Sealing rubber for turbine head 1

17 2230 0148 00 Sealing 150x59x4mm, 130 mm, 8 holes 8 mm 1

18 2230 0067 00 PVC plate for PG screw, gray 1

19 2230 0002 00 Sponge rubber ball 1

20 2230 0086 00 Cable screw tting BS 11 1

21 2220 0001 00 Swimmer ball housing 1

22 1481 0097 00 U-washer 12.0 x 6.4 x 1.6 mm, stainless steel A2 9

23 2230 0053 00 Screw M 6 x 12, A 2, DIN 933 8.8 7

24 2230 0085 00 Sealing made of cellular rubber, black 140x100x4 mm 1

26 2230 0076 00 Counter sunk screw, cross headed 3.5x9.5 DIN 7982 2

27 2230 0032 00 Cable HO7 RNF 3G 1.5, product sold by meter 0,8

29 1700 0174 00 Core end sleeves, insulated, 1.5 sq mm- 8mm red 2

30 2230 0126 00 Cable shoe 1 mm 6

31 2230 0107 00 Pan-head tapping screw, cross headed, 4.2 x 19 4

32 2230 0102 00 PVC plate for covering switch, gray, 27x38x3mm 1

34 2230 0108 00 Toothed disk, internal tooth DIN 6798 4

35 2230 0068 00 Ground cable SIF 1.5 GR/YEL, meter 0,3

37 2230 0007 00 Label " NOT EXPLOSION PROTECTED", 120x30 mm 1

38 2230 0087 00 Label „Motorkopf Gerätetyp“ 1

39 2230 0071 00 Protection conductor label 1

40 2230 0003 00 Butt joiner 2

41 1700 0172 00 Shrink t sleeve 142/21-064 DN 06 3:1 PB, meter 0,12

42 2230 0120 00 Flat sleeve, red 0.5 qmm-1 sq mm /6.3x08 1

43 1700 0351 00 Label "Elektroschrott" 1

45 2230 0054 00 Nut m 6, A2, DIN 934 1

45 1700 0212 00 Nut M 6, self-locking, A2 1

2230 0121 00 Thread rod M 6, V2A 0,03

Page 12/20

Page 13

8.2 Adapter with cover and pump holder

6

3

7

4

8

5

11-12

9

10

1

6-10

2

Pos.: Article No. Description Qty.

1 2210 0009 01 Adapter-PA, GRP, 4 layer, bare 1

2 2210 0002 00 Pump cage for Permanent Aspirator 1

3 2230 0100 00 Leaf spring 15 x 0.6 mm, Z-Form, raw, blank 3

4 2230 0018 00 Slotted screw M 4 x 12 6

5 1700 0170 00 Nut M 4, self locking 8

6 2230 0043 00 Screw M 8 x 50 4

7 2230 0023 00 Washer 20x8.5x1.5 mm 9

8 2230 0038 00 Rubber squeeze nipple 9

9 1700 0168 00 Nut M 8 6

10 2230 0044 00 Nut M 8, self locking 4

11 2230 0030 00 Label " PA " 1

12 2230 0190 00 Label - Protection type IP 44 1

Pressure line

Pos.: Article No. Description

1 2230 0005 00 Foam rubber sealing ring 1.85 m

Suction line

1

Page 13/20

Page 14

Vetter Permanent Aspirator

Grounding cable/Adapter/Pump cage

4 - 5

1

3

2

4 - 5

3

2

1

Pos.: Article No. Description Qty.

1 2230 0175 00 Eyelet for grounding cable 2

2 2230 0176 00 Winch wire 0,54

3 2230 0177 00 Cable lug 6

4 2230 0178 00 Hexagon screw 4

5 1700 0212 00 Nut M 6, self locking, A 2 4

8.3 Suction line

2

1

3

4

5

Pos.: Article No. Description Qty.

1 2230 0039 00 Fixed coupling Storz 38, 1 1/4" AG 1

2 2230 0035 00 Angle 90°, 1 1/4" IG, brass 1

3 2230 0175 00 Eyelet for grounding cable 1

4 2230 0037 00 Double nipple 1 1/4" AG, brass 1

5 2230 0149 00 Reducing sleeve 1 1/4" IG - 1 1/2" IG,brass 1

Page 14/20

Page 15

8.4 Pump with pressure line

12

10

8

9

8

6

11

1

3

4

2

5

13

14151617

6

7

Pos.: Article No. Description Qty.

1 2230 0050 00 Automatic drainage immersion pump 1

2 2230 0150 00 Angle 90°, 1 1/4" AG-AG 1

3 2230 0055 00 Pipe clamp A2, 20/1. rubber 1

4 1700 0168 00 Nut M 6, A2 6

5 1481 0098 00 Locking screw M 8 x 30 1

6 2230 0110 00 Hose clamp SG 12 mm/32-50 2

7 2210 0003 00 PVC hose 38x5 mm,transparent 0,37

8 2230 0037 00 Double nipple 1 1/4" AG, brass 3

9 2230 0052 00 Nonreturn clap 1

10 2230 0175 00 Eyelet for grounding cable 1

11 2230 0035 00 Angle 90°, 1 1/4" IG, brass 1

12 2230 0041 00 C-xed coupling 1 1/4" AG 1

13 2210 0005 00 Float holder 1

14 2230 0125 00 Pipe clamp Size 12/15 1

15 2230 0053 00 Screw M6 x 12 2

16 2230 0023 00 Body disk 20x8.5x1.25 1

17 2230 0054 00 Nut M 8, A 2 2

Page 15/20

Page 16

Vetter Permanent Aspirator

8.5 Switch panel

4

5

3

2

16

6

8

7

9

10

9

11

10

7

9

17

12

13

14

1

1

18

15

Article No. / Pos.: Description Qty.

2230025500 Switch panel, consisting of: 1

1 Treble housing, upper and lower part 1

2 Screwed cable gland 1

3 Counter nut 1

4 Lug for grounding cable 1

5 Flat sealing ring 1

6 Connection 2

7 Nut BET 2

8 Line distributer quadruple 1

9 Connecting ange 3

10 Shutter 2

11 Break contact 1

12

13 Rotary switch (Illustration dierent) 2

14 Emergency stop-button 1

15

16 Protective Plug 1

17 Wire m 10

18 Cellular rubber gasket 1

Label electrical switch „MPS, PS“ ON/OFF

(Illustration dierent)

Label electrical switch „MPS,PS“ Aspirator/Pump

(Illustration dierent)

1

1

Page 16/20

Page 17

8.6 Suction hose

1

2

Pos.: Article No. Description

1 2230023000

2 2230022800

Suction hose, 6 m, oil resistant,

including curved connecting pipe

Adapter Suction hose Aspirators

incl. Coupling Storz 38

8.7 Suction pipe, stainless steel (2 parts)

Article No. Description

2230024500 Suction pipe, stainless steel (2 parts)

8.8 Narrow space nozzle

Article No. Description

2230024600 Narrow space nozzle

8.9 Ground nozzle 370 mm

Article No. Description

2230024700 Ground nozzle 370 mm

Page 17/20

Page 18

Vetter Permanent Aspirator

8.10 Trolley for Permanent Aspirator, GF-Polyester

3

6

1

2

Pos.: Article No. Description

1 2230 0012 01 Trolley for OWA/PA, GRP, bare

2 2230 0020 00 Guiding roller

3 1700 0167 00 Screw M 8 x 16, hexagon, galv.

4 1700 0168 00 Nut M 8 A2

5 2230 0022 00 Toothed washer M 8, galv.

6 2230 0023 00 Washer 20x 8.5, A 2

9. Resistance Guide

5

4

Detailed information about the chemical resistance please nd in

the appendix!

Page 18/20

Page 19

EC Conformity Declaration (available on request)

in terms of the EC Directive 2006/42/EC

We

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

53909 Zülpich

hereby declare that the aspirators

OWS for aspirating and temporary storage of liquids

PS for aspirating and pumping of liquids

Serial no.: ______________

Design: ______________

(see ratings plate, to be completed by customer)

complies with the following pertinent regulations in its standard design:

Directive 2006/42/EC

National standards, harmonised standards, technical specications employed:

EN 60335-1 (2003) = DIN VDE 0700-1 (2004)

DIN EN 60335-2-69 (2009)

Authorised representative for the compilation of technical documents:

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

53909 Zülpich

This EC Conformity Declaration was issued:

Zülpich, 27.06.2014

(Place, Date, Signature)

Page 19/20

Page 20

Chemical resistance list Suction hose

The information is based on laboratory examinations,

empirical values and is inuenced by variable factors

such as the temperature, intensity and the contact

time.

This resistance list was compiled based on the above

aspects. The information corresponds to today‘s state

of our knowledge and should be taken as typical values.

Chemical resistance

+ Resistant, no corrosion is expected

Slight eect of the medium is to be expected, but

+/-

still commercially tenable

Cannot be used permanently, occasional use pos-

-

sible

u Unstable, use is not recommended

Experiences available on the following media (each at room temperature):

Medium PP

Acetic acid, 1%

Acetophenone

Acetyl chloride

Acid sodium carbonate

Ammonium hydroxide, 10 %

Ammonium nitrate saturated solution

Ammonium phosphate

Aniline

Anti-free additive

Benzaldehyde

Benzyl chloride

Beverages, also alcoholic

Butyl acetate

Calcium acetate

Calcium hydroxide

Carbon tetrachloride

Chromium acid

Cleaning agent, high conc., up to 45 °C

Cleaning agent, normal conc. up to 25 °C (soap solution, P-3 alkali, dishwasher agents, etc.)

Cyclohexane, cyclohexanone, cyclohexanol

Detergent for textiles, normal leaching concentrations

Dichlorethane, dichloromethane

Diesel fuel

Diethylenglycol, 50%

Dioxane

Dishwasher agent, normal conc.

Ethanol

Ethyl acetate

Ethylene glycol

Formaldehyde, 20%

Formic acid, 30 %

Glycerine

Glycol

Greases and oils, acid-free from natural and mineral oil basis

Heating oil, EL

Heptane

Hydrochloric acid, 0.5% - 1%

+

u

u

+

+/-

+

+

u

+

u

u

+

u

u

u

u

u

+

u

+

u

+

+/-

u

+

+

u

+

+/-

u

+

+

+

+

u

u

-

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

Page 1/2

Page 21

Chemical resistance list Suction hose

Isopropanol

Lactic acid

Liquid fertiliser

Methyl ethyl ketone

Methylene chloride

Nitric acid, 3%

Oil and greases, acid-free from natural and mineral oil basis

Petroleum

Phenol

Phosphoric acid, 10%

Polyglycols

Potassium carbonate, 30% potash

Potassium chloride

Potassium hydroxide, 20%

Propylene glycol

Pyridine

Silage euents

Sodium borate

Sodium hydrogenphosphate

Sodium hydroxide, 10%

Sodium hydroxide, 20%

Sodium nitrate

Sodium perborate hydrate

Sodium sulphate

Sulphur dioxide (ue gas scrubbing)

Sulphuric acid, 3%

Synthetic based oils

"Fuel economy engine oil for vehicles" (chlorinated phosphate ester, etc.)

Tetrachlorohydrocarbons

Tetrahydrofuran

Toluene

Trichloroethene

Tri-sodium phosphate

Uric acid

Water:

- Boiler feedwater

- Carbonated

- Condensate

- Cooling water

- Distilled

- Drainage water

- Fire-extinguishing water

- Heater water

- Lime water

- Ocean water

- Sea water (North Sea, Baltic Sea)

- Swimming pool water, chlorous, up to 2 mg / l

+/-

u

+

u

u

u

+

u

u

u

+

+

+

+/-

u

u

+

+

+

+

+

+

u

u

u

u

u

u

u

+

+

+

+

+

+

+

+

+/+/-

-

-

-

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

-

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

-

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

-

-

www.vetter.de

Page 2/2

Page 22

Chemical resistance list Products made of breglass-reinforced polyester

The information is based on laboratory examinations,

empirical values and is inuenced by variable factors

such as the temperature, intensity and the contact

time. Exposure time 7 days

This resistance list was compiled based on the above

aspects. The information corresponds to today‘s state

of our knowledge and should be taken as typical values.

Chemical resistance

A High resistance

Resistant

B

C Limited resistance

D Unstable or highly emollient

Not tested

Experiences are available on the following media (each at room temperature unless stated otherwise):

Medium GRP

Aceit acid, conc.

Acetaldehyde

Acetic acid 10 %

Acetic acid 25 %

Acetic acid 75 %

Acetic acid anhydride

Acetic acid ethyl ester

Acetic acid, vapours

Acetone

Acetylene

Adiponitrile

Aero Hydraulic HFA

Aero Mobile HFA

Aero Safe 2300 W

Aero Shell-Fluid No. 7

Air Hydraulic

Aircraft AA

Alcohol

Alum

Aluminium chloride

Aluminium uoride

Aluminium sulphate

Alvania EP Grease 2

Ammonia

Ammonia, aqueous

Ammonia, gaseous, cold

Ammonia, gaseous, hot

Ammonium carbonate

Ammonium chloride

Ammonium hydroxide

Ammonium nitrate

Ammonium sulphate

Amocool Soluble 3%

Amyl acetate

Amyl alcohol

Andol, 4,5 HL 36

B

B

A

B

B

C

B

D

B

A

A

A

A

A

B

A

A

A

A

A

B

B

B

C

A

A

A

A

A

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

C

B

Page 1/13

Page 23

Chemical resistance list Products made of breglass-reinforced polyester

Aniline

Aniline dyes

APL 731 - Shell

APL 742 - Shell

Apresslube 79

Aqua regia

Aral - BV - CMS

Aral - GFY/4017

Aral - HDK

Aral - HDY

Aral - HFX

Aral - HFY

Aral - HFY/3077

Aramco crude oil

Arctis

Aroclor

Arsenic

ASTM fuel no. 1

ASTM fuel no. 2

ASTM fuel no. 3

ASTM oil no. 1

ASTM oil no. 2

ASTM oil no. 3

ATE-blue brake uid

ATF 200 Mobil

Automatic transm. Fluid

Bacharquero crude oil

Barium chloride

Barium salts

Battery acid

BC 48

Becroson KSM

Beer

Benzaldehyde

Benzol

Benzyl alcohol

Benzyl chloride

Benzyne, ligroin, naphtha

Bichloride of mercury

Bitumen

Blast gas

BM 68 concentrate

Borax

Boric acid

BP-Öl HP 0

BP-ÖL Hy S 35

C

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

B

Vetter GmbH

A Unit of IDEX Corporation

C

B

C

B

A

B

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

A

www.vetter.de

A

A

Page 2/13

Page 24

Chemical resistance list Products made of breglass-reinforced polyester

The information is based on laboratory examinations,

empirical values and is inuenced by variable factors

such as the temperature, intensity and the contact

time. Exposure time 7 days

This resistance list was compiled based on the above

aspects. The information corresponds to today‘s state

of our knowledge and should be taken as typical values.

Chemical resistance

A High resistance

Resistant

B

C Limited resistance

D Unstable or highly emollient

Not tested

Experiences are available on the following media (each at room temperature unless stated otherwise):

Medium GRP

BP-Öl HY S 45

Brega crude oil

Bromine

Bromobenzene

Butane, dry

Butane, moist

Butanol

Butyl acetate

Butyl alcohol

Butyl stearate

Calcium chloride

Calcium hydroxide

Calcium hypochlorite

Calcium salts

Caltex low temp. oil

Calypso fat M 2

Calypso fat WJA

Carbolic acid

Carbolineum

Carbon dioxide, dry

Carbon dioxide, wet

Carbon disulphide

Carbon monoxide, hot

Carbonic acid

Castor oil

Castrol-Rustilo 209

Caustic lye 10%

Caustic lye 25 %

Caustic lye 50 %

Caustic potash

Caustic soda

Cherron spindle oil SX

Chlorinated solvent

Chlorine baths

Chlorine, dry

Chlorine, wet

Chloroacetic acid

A

B

C

C

B

B

A

C

A

A

A

A

B

A

A

A

C

Vetter GmbH

A Unit of IDEX Corporation

A

D

Blatzheimer Str. 10 - 12

D-53909 Zülpich

B

B

B

B

B

C

C

B

B

C

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

Page 3/13

Page 25

Chemical resistance list Products made of breglass-reinforced polyester

Chlorobenzene

Chloroform

Chloroprene

Chlorosulphuric acid

Chromium acid

Cirkan 21

Citric acid

Citronella oil

Clavus 17

Clavus 27

Clophen

Coal tar oil

Coconut oil

Coke-oven gas

Copper chloride

Copper salts

Corn oil

Cottonseed oil

Creosote

Creosote from coal

Creosote from wood

Cupric sulphate

Cyclohexane

Cyclohexanol

Cyclohexanon

D.T.E. 23 Mobil

D.T.E. Heavy

DASCO IFR-2 hydr. uid

Delial suntan lotion

Dextro-tartaric acid

Diala

Dibenzylether

Dibutyl phthalate

Dichlorbutylene

Dichlorobenzene

Dicyclohexylamine

Diethanolamine

Diethyl sulfate

Diethylamine

Diethylsebacat

Dimethyl ether

Dimethyl formamide

Dimethylaniline

Dioctyl phthalate

Dioxolane

Dipentene

Diphenyl ether

C

C

C

B

D

A

B

A

A

A

A

A

B

B

B

A

A

A

Vetter GmbH

A Unit of IDEX Corporation

C

Blatzheimer Str. 10 - 12

B

B

B

B

C

B

B

A

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

Page 4/13

Page 26

Chemical resistance list Products made of breglass-reinforced polyester

The information is based on laboratory examinations,

empirical values and is inuenced by variable factors

such as the temperature, intensity and the contact

time. Exposure time 7 days

This resistance list was compiled based on the above

aspects. The information corresponds to today‘s state

of our knowledge and should be taken as typical values.

Chemical resistance

A High resistance

Resistant

B

C Limited resistance

D Unstable or highly emollient

Not tested

Experiences are available on the following media (each at room temperature unless stated otherwise):

Medium GRP

Dioctyl phthalate

Dioxolane

Dipentene

Diphenyl ether

Diphenylether

Diphyl (mixture of biphenyl and diphenyl ether)

Distilled spirits

Doaxane

Donaxine I 6

Dusarite water

Dusek I 150

E 100 - Hydraulic medium

Ecubsol-Widroamm 5.5

ED 60/70-Mobil oil

ED 66/11-Mobil oil

Elmodur

Energol CFS 100

Energol HDSAE - 20W/20

Energol HL 100

Energol HL 65

Energol HLP 100

Energol HP 20

Energol NRA - 31

Energol SHF 0202-7

Energol TH 100-HB

Ensis (motor oil 30)

Essential oils

Esstic 42

Esstic 55

Estic 45

Estor HD 10

Ethane

Ethanolamine

Ether

Ethyl acetate

Ethyl alcohol

Ethyl alcohol, denat.

A

A

C

B

A

A

A

A

A

A

A

A

A

A

C

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

B

B

C

C

B

B

www.vetter.de

Page 5/13

Page 27

Chemical resistance list Products made of breglass-reinforced polyester

Ethyl cellulose

Ethyl silicate

Ethylbenzene

Ethylchloride

Ethylene

Ethylene chloride

Ethylene chlorohydrin

Ethylene dibromide

Ethylene dichloride

Ethylene glycol

Ethylene mercaptan

Ethylene oxalate

Ethylenediamine

F 4 /Th. Goldschmidt)

F 4 hc (Th. Goldschmidt)

Fatty acids

FC - 75 (Flourchamical)

FC - 77 (Flourchemical)

Flowrex E

Flue gas

Fluid 200 y Mobil transformer

Fluid 4 Aero Shell

Fluorobenzene

Flurfural

Formaldehyde

Formamide: pure

Formic acid

FR 1 (Mosanto)

FR Fluid

Frigen /Freon) no. 11

Frigen /Freon) no. 113

Frigen /Freon) no. 12

Frigen /Freon) no. 14

Frigen /Freon) no. 21

Frigen /Freon) no. 22

Frigus

Furan, furfurane

Fyrquel 220

Fyrquel 220 (80 degrees)

Gasoline 504

Gasoline DK 305

Gasoline FKL

Gasoline FKM

Gasoline TU 504

Gasoline Vitam DH

Gelantine

Generator gas

A

A

C

C

B

C

C

C

D

A

A

B

A

C

C

B

B

B

B

A

B

B

B

Vetter GmbH

A Unit of IDEX Corporation

B

Blatzheimer Str. 10 - 12

C

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

A

A

Page 6/13

Page 28

Chemical resistance list Products made of breglass-reinforced polyester

The information is based on laboratory examinations,

empirical values and is inuenced by variable factors

such as the temperature, intensity and the contact

time. Exposure time 7 days

This resistance list was compiled based on the above

aspects. The information corresponds to today‘s state

of our knowledge and should be taken as typical values.

Chemical resistance

A High resistance

Resistant

B

C Limited resistance

D Unstable or highly emollient

Not tested

Experiences are available on the following media (each at room temperature unless stated otherwise):

Medium GRP

Genrex 24

Glacial acetic acid (conc.), pure

Glucose

Glue

Glycerine

Glycol

Hassi Masurad

Heating oil

Hexane

Hydran 21

Hydran 25

Hydraulic HBN PC

Hydraulic L

Hydraulic M 4174

Hydraulic MW 30

Hydraulic STDL/C

Hydraulubric X

Hydrazinobenzene

Hydrazol 45

Hydrit B 111

Hydro 5025

Hydrobromic acid, aqueous

Hydrochloric acid <65 degrees C.

Hydrochloric acid >65 degrees C.

Hydrochloric acid, concentrated

Hydrouoric acid

Hydrogen cyanide

Hydrogen uoride

Hydrogen uoride, cold < 65%

Hydrogen uoride, cold > 65%

Hydrogen uoride, hot < 65%

Hydrogen uoride, hot > 65%

Hydrogen gas, cold

Hydrogen gas, hot

Hydrogen sulde, cold

Hydrogen sulde, dry, cold

C

A

A

A

A

A

B

C

C

C

C

B

B

B

A

A

C

C

A

B

A

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

Page 7/13

Page 29

Chemical resistance list Products made of breglass-reinforced polyester

Hydrogen sulde, dry, hot

Hydrogen sulde, hot

Illuminating gas

Inavol 3045

Iron chloride

Iron sulphate

Isobutyl alcohol

Isopropyl chloride

Isopropyl ether

Jatol-special hydraulic 54,8/50

Jatol-special hydraulic ES 7,7/50

Jatol-special hydraulic L2,7/50

Jatol-special hydraulic M3,5/50

kd oil

Kenlube B-521

Kerosenes

KH 60

Klosterfrau spirit of melissa

Lactic acid, cold

Lactic acid, hot

Lard

Lead acetate

Lead nitrite

Linseed oil

Lubricating oil

Lubricor hydraul. B 14

Macoma 68

Magnesium chloride

Magnesium hydrate

Magnesium salts

Magnesium sulphate

Maleic acid

Maleic acid anhydride

Malic acid

Mamellin

Mercury

Meropa Lubricant 2

Methacrylic acid methyl ester

Methanol

Methyl alcohol

Methyl ethyl ketone

Methyl salicylate

Methylene chloride

Methylglycol acetate

C

A

A

A

B

B

A

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

A

A

C

C

A

C

D

D

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

Page 8/13

Page 30

Chemical resistance list Products made of breglass-reinforced polyester

The information is based on laboratory examinations,

empirical values and is inuenced by variable factors

such as the temperature, intensity and the contact

time. Exposure time 7 days

This resistance list was compiled based on the above

aspects. The information corresponds to today‘s state

of our knowledge and should be taken as typical values.

Chemical resistance

A High resistance

Resistant

B

C Limited resistance

D Unstable or highly emollient

Not tested

Experiences are available on the following media (each at room temperature unless stated otherwise):

Medium GRP

Methylpyrrolidone

Milk

Mineral oil

Mineral oil

Mipolan mass 5319

Mirbane oil

Molub Alloy 601

Molub Alloy 602

Molub Alloy 603

Molykote A

(Mono)chlorobenzene

Monoethanolamine

Motor (engine) oils

Motor oil 20W/20

Motor oil 30

Motor oil W 10

Mustard

Nac H 402

Nac H 404

Naphtha

Naphthalene

Naptolen ZD

Natural gas

Nickel Chloride

Nickel salts

Nickel sulphate

Nitric acid, diluted

Nitrobenzene (mirbane oil)

Nuto 022 H

Nuto H 36

Nuto H 44

Nyvac no. 20

Ocean water, 5%

O-chloronaphthalene

Oel-Sythesco CH 33

Oleic acid

Olesimon 803

D

A

A

A

C

A

A

A

A

A

A

A

A

A

B

C

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

A

A

C

A

www.vetter.de

Page 9/13

Page 31

Chemical resistance list Products made of breglass-reinforced polyester

Olex SHF 0300

Olex SHF 0303

Olex SHF 0304

Olex SHF 0305

Olex SHF 0309

Olive oil

Oxalic acid

Oxo-C 4 -degassed

Oxygen, cold

Ozone

P 1962 (corrosion protection)

P 2614 concentrate

PAGB 5

Palmitic acid

Panaclor 85

Paran

Paran oil

Pena Pura HD 30

Pena Pura HD Super SAE 10

Pena Pura HD Super SAE 30

Pena Pura HDSAE 10 W

Pen-o-Led EP 2

Pentosin-Super Fluid

Perchloroethylene 50 degrees C.

Perfekthion S

Petroleum

Petroleum ether

Phenol

Phenylbenzene

Phosphoric acid (conc.)

Phosphoric acid, cold < 45 %

Phosphoric acid, cold > 45 %

Phosphoric acid, hot

Phosphorus trichloride

Phthalic anhydride

Picric acid, aqueous

Picric acid, melted

Piperidine

Potassium bisulfate

Potassium chloride

Potassium cyanide

Potassium hydroxide

Potassium sulphate

A

A

B

B

A

A

C

A

C

C

A

A

B

C

A

A

A

A

C

A

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

Page 10/13

Page 32

Chemical resistance list Products made of breglass-reinforced polyester

The information is based on laboratory examinations,

empirical values and is inuenced by variable factors

such as the temperature, intensity and the contact

time. Exposure time 7 days

This resistance list was compiled based on the above

aspects. The information corresponds to today‘s state

of our knowledge and should be taken as typical values.

Chemical resistance

A High resistance

Resistant

B

C Limited resistance

D Unstable or highly emollient

Not tested

Experiences are available on the following media (each at room temperature unless stated otherwise):

Medium GRP

Progil oil

Propane

Propanol 50 degrees C

Propyl alcohol

Prosol ZD

Pydraul 150

Pydraul 280

Pydraul 312

Pydraul 625

Pydraul A 200

Pydraul AC

Pydraul E

Pydraul F 9

Pyrogard 43

Pyrrole

Quaker 8211 M oil

Regal oil B

Renolin 2

Renolin B 15

Renolin MR 20

Renolin NF 2

Renolin NF 4

Salicylic acid

Shell Emulion M 2

Shell IYO

Shell JPH

Shell JPL

Silver nitrate(V)

Skydrol 500 B (60 degrees C.)

Soap solutions

Sodium carbonate

Sodium carbonate

Sodium chloride

Sodium cyanide

Sodium dichromate

Sodium hydroxide

Sodium hypochlorite

B

A

A

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

A

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

B

A

A

A

A

B

B

A

Mail: vetter.rescue@idexcorp.com

www.vetter.de

Page 11/13

Page 33

Chemical resistance list Products made of breglass-reinforced polyester

Sodium nitrate

Sodium phosphate

Sodium silicate

Sodium sulde

Sodium sulphate

Sodium thiosulfate

Somentor F

Somentor N 35

Somentor W 20

Somentor W 26

Son low 3

Soy bean oil

Spindle oil

Spinesso 34

Spruce turpentine

Stearic acid

Styrol

Sugar beet juice

Sulfate of zinc

Sulfurous acid

Sulphur chloride

Sulphur dioxide

Sulphur trioxide

Sulphuric acid 10%

Sulphuric acid 25%

Sulphuric acid 50%

Sulphuric acid 75%

Sulphuric acid 96%

Sulphuric acid, concentrated

Sulphuric acid, smoking

Tannic acid

Tar

Tartaric acid

Tetrachlorohydrocarbons

Tetracloroethylene

Tetrahydrofuran

Thioglycolic acid

Tin chloride

Toluene 20 degrees C. C

Transmission oil

Tributyl phosphate

Trichlorobenzene C

Triethanolamine

A

A

A

A

A

A

A

A

A

A

C

A

A

C

B

B

A

A

A

C

D

D

D

A

A

Vetter GmbH

A Unit of IDEX Corporation

C

C

Blatzheimer Str. 10 - 12

D-53909 Zülpich

A

Germany

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

Page 12/13

Page 34

Chemical resistance list Products made of breglass-reinforced polyester

The information is based on laboratory examinations,

empirical values and is inuenced by variable factors

such as the temperature, intensity and the contact

time. Exposure time 7 days

This resistance list was compiled based on the above

aspects. The information corresponds to today‘s state

of our knowledge and should be taken as typical values.

Chemical resistance

A High resistance

Resistant

B

C Limited resistance

D Unstable or highly emollient

Not tested

Experiences are available on the following media (each at room temperature unless stated otherwise):

Medium GRP

Triphenylmethane 21

Turpentine

Turpentine oil

Ucon-Hydrolube z 75 CP

Univis J 43 (Esso)

Univol 42 (Esso)

Ursa oil P 20

Vacra-Heary oil

Vacuoline BB

Vegetable oil

Venegar

Waste-water

Water (ocean water)

Water peroxide

Water up to 100 degrees C.

Water up to 80 degrees C.

Water, dist. 50 degrees C.

Water; cold

Wood oil

Wool grease

Wüf 265

Wyrol H-40

Xylene

Zinc salts

B

B

A

B

A

A

A

C

C

B

A

B

B

A

Vetter GmbH

A Unit of IDEX Corporation

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

Page 13/13

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

www.vetter.de

Page 35

Place your trust in emergency pneumatics!

We are the company who can help you, nd a solution to your problem!

Vetter GmbH

A Unit of IDEX Corporation

Sales

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

www.vetter.de

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

Article No. 9987011205 | © Vetter GmbH I 09/14 I Changes and errors excepted. | Made in Germany

Loading...

Loading...