Vetter Oil water debris aspirator User Manual

Emergency Pneumatics.

Operating instructions

VETTER Oil-Water-Debris Aspirator

Article No. 9987011304 | © Vetter GmbH I 09/14 I Changes and errors excepted.

Vetter Oil-Water-Debris Aspirator

Contents

1. Important preliminary remarks ....................................3

2. Description of the product ........................................3

2.1 Scope of delivery ...........................................3

2.2 Optional accessories ........................................4

2.3 Area of application ..........................................4

2.4 Correct use according to regulations ........................4

2.5 Safety information ..........................................4

3. Preparing the product for use .....................................5

3.1 Preparations for operation ..................................5

4. Operating instructions ............................................5

4.1 Aspiration of liquids ........................................5

4.2 Aspiration of strongly contaminated liquids .................5

4.3 Aspiration of dust ...........................................6

4.4 Care and maintenance ......................................6

5. Taking the product out of operation ...............................6

6. Elimination of defects .............................................7

7. Technical data ....................................................7

8. Resistance Guide ..................................................8

9. Spare parts lists ...................................................8

9.1 Motor head .................................................9

9.2 Adapter for Oil-Water-Debris Aspirator ....................11

9.3 Trolley, GF-Polyester ......................................12

9.4 Suction hose .............................................13

Page 2/15

9.5 Suction pipe, stainless steel (2 parts) ......................13

9.6 Narrow space nozzle ...................................... 13

9.7 Ground nozzle 370 mm ................................... 13

EC Conformity Declaration (available on demand) ...................14

1. Important preliminary remarks

Only a knowledge and exact adherence to this operating manual will guarantee correct and perfect operation, achieve the best

possible use and uphold claims made within the framework of the

Vetter warranty.

Vetter Oil-Water-Debris Aspirators must only be used by trained,

reliable sta. Operational usage of the Oil-Water-Debris Aspirator

is to be made under the condition that operators have an exact

knowledge of this operating manual and that they observe all the

information contained in it.

The operating instructions given here are to be regarded as part

of the product and are to be kept for the complete life duration of

the product. In case the product should be passed on to a successive user then the operating instructions must also be included.

2. Description of the product

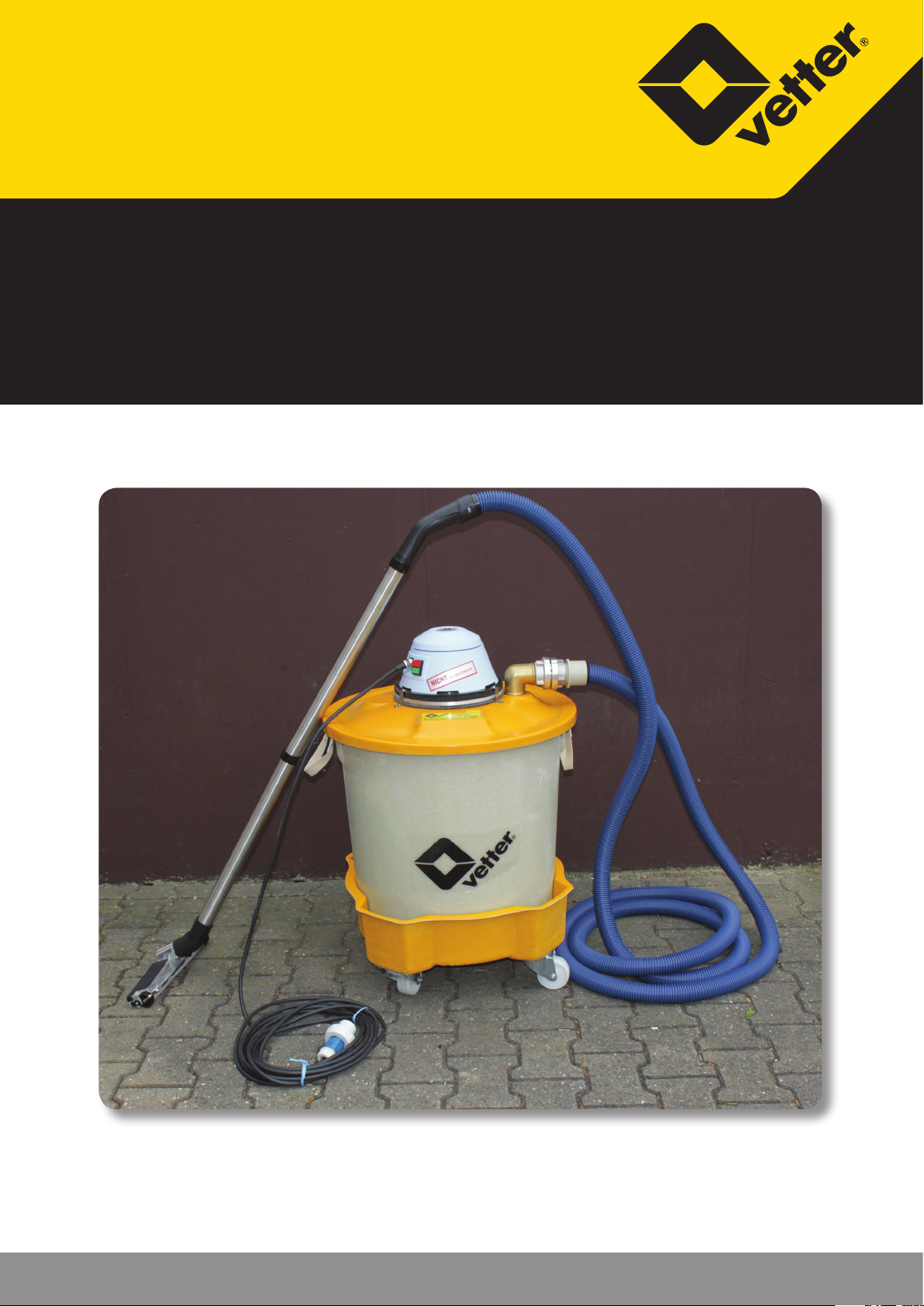

2.1 Scope of delivery

Article No. Description Qty.

2200000804

2200000301 Motor head, 240 V / 50 Hz / 1000 Watt 1

2200000701 Adapter, OWA, GRP-Polyester 1

2230004500 Container, 100 l, GRP-Polyester 1

2200000600 Filter cartridge (no illus.) 1

2230022900

2230001100 Trolley, GRP-Polyester 1

Oil-Water-Debris Aspirator set

Basic equipment consisting of:

Accessories aspirators, consisting of:

Suction hose, oil resistant, 6 m, incl. curved

connecting pipe and adapter suction hose,

blue incl. coupling Storz 38

Suction pipe (2 parts)

Narrow space nozzle

Ground nozzle

1

Page 3/15

Vetter Oil-Water-Debris Aspirator

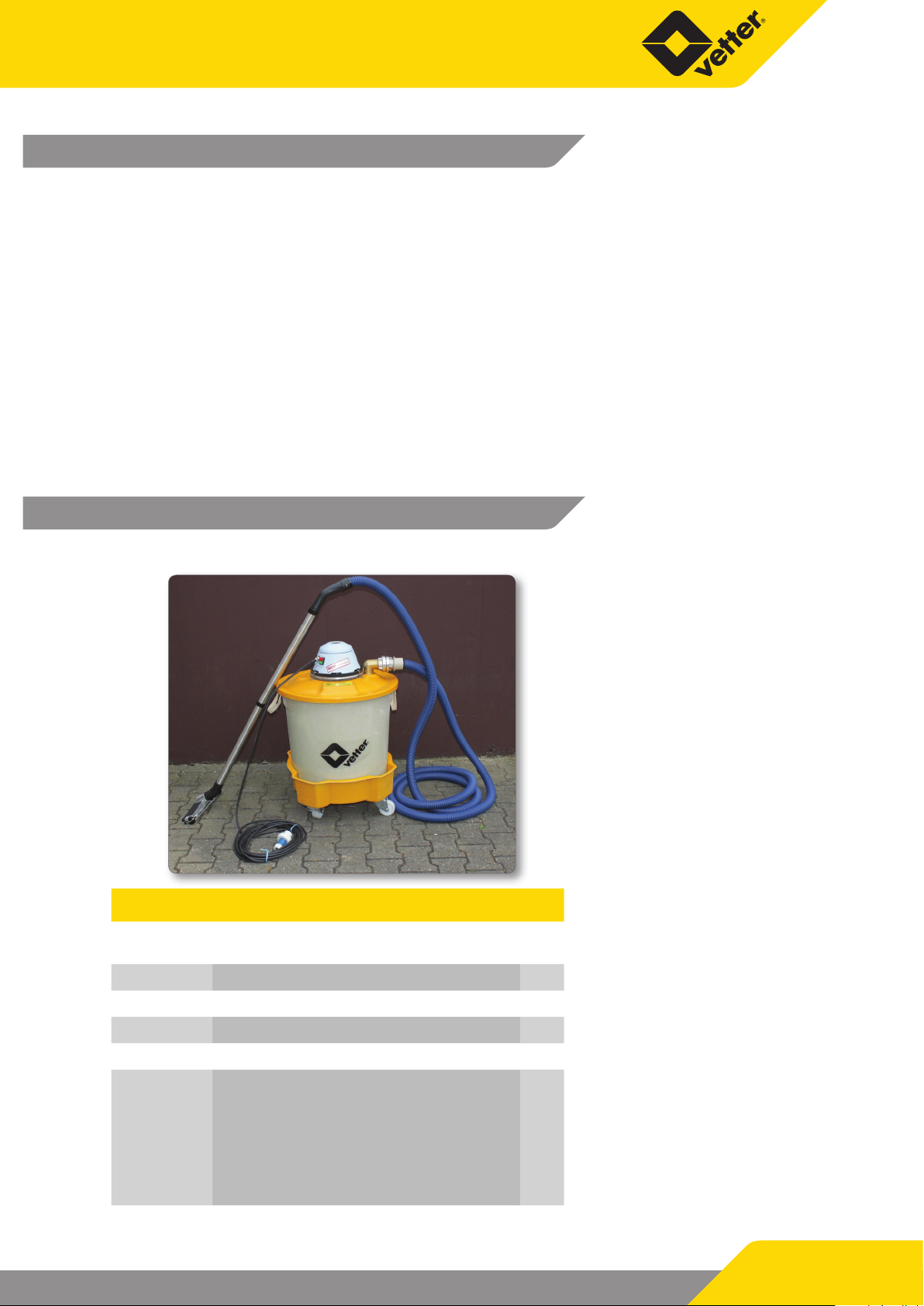

2.2 Optional accessories

Article No. Description

2230025400 Safety switch PRCD-S

If in an exceptional case it is necessary to provide the power sup-

Never turn on with

gloves or other insulating materials.

ply from other feed points (external network, e.g. public power

supply), the re brigade accident prevention regulations stipulate

the use of PRCD-S type portable residual current devices.

2.3 Area of application

The Vetter Oil-Water-Debris Aspirator can be used for the aspiration of water, oil, non-aggressively acting liquids and non-aggressively acting dust. Both mobile and stationary operation is possible

depending on the task involved.

2.4 Correct use according to regulations

The mains power supply line is to be protected against damage.

The aspirator is only allowed to be used when the connection line

is in a perfect condition. The aspirator is set to a operating voltage

of 240 V/ 50 Hz at the manufacturer.

The mains power plug is to be removed

before any cleaning, maintenance and

repair work is carried out.

2.5 Safety information

All pertinent, public work protection and accident prevention regulations are to be observed as well as the generally recognized

regulations for the eld of technology. The necessary work protection clothing is to be worn during operation.

Attention! Danger of Explosion!

Vetter Permanent Aspirators are not

protected against explosion owing to their

operational principle (vacuum cleaner).

Page 4/15

It must not be used for aspiration of highly inammable liquids or

liquid mixtures (with a ash point below 21°C). Vetter Permanent

Aspirators must not be used in Explosion Protected Zones (0).

Explosion Protected Zones are, according to the German Regulations for inammable Liquids (German abbreviation: VbF), explosion endangered areas in which there is a constant or permanent

explosive atmosphere caused by inammable gasses, vapours or

mist.

All Vetter Permanent Aspirators are suitable for liquid aspiration.

Acids, caustic solutions and aggressively

acting solvents can form mixtures which

are a danger to health and therefore

must not be aspirated.

Dust can also be aspirated with the Vetter Oil-Water-Debris Aspirator. In agreement with the Trade Association we would like to

expressively point out that in this connection, this aspirator must

not be used for the aspiration of dust which is hazardous to health.

3. Preparing the product for use

3.1 Preparations for operation

Place the container into the trolley if there is a trolley available for

mobile operation. When using the adapter make certain that the

adapter sealing on edge of the container seals correctly. Check to

see if the motor head is seated correctly in the adapter opening.

Connect the suction hose into the suction coupling. Connect the

cylindrical suction pipe (with a yellow shrink-t hose) to the angled connection pipe, then connect the second suction pipe (conical end ) to the cylindrical suction pipe. Join the liquid ground

nozzle, dual-purpose ground nozzle or oating suction collector

(depending of the task involved) to the suction pipe. Connect the

mains power plug to a correctly installed protection contact socket.

4. Operating instructions

4.1 Aspiration of liquids

Switch on the suction turbine and start suction cleaning. If the

maximum capacity level in the container is reached then the

swimmer will block the suction opening of the motor head. Suction is then interrupted.

Switch o the suction turbine. If a second or third container with

a lid is available then the complete adapter with suction turbine

and suction hose can be xed to another container and suction

cleaning continued as already described. The container which is

full should be sealed with the lid and made available for emptying.

4.2 Aspiration of strongly contaminated liquids

Even when the liquid to be aspirated is strongly contaminated it is

not necessary to use an additional lter cage.

Page 5/15

Vetter Oil-Water-Debris Aspirator

4.3 Aspiration of dust

The lter cartridge ( Item No.: 2200 0006 00) must be inserted before

operation. Loosen the three motor clamps and withdraw the motor

head out of the adapter.

Avoid damage when depositing and storing the

motor head.

Insert the lter cartridge into the adapter. Place the motor head into the

adapter and x it with the three motor clamps. Make certain that the

lter cartridge and the motor head are perfectly seated and sealed. The

Oil-Water-Debris Aspirator can now be used for the aspiration or neutral

dust.

If, for example, there is a decrease in suction power, clean the lter cartridge or, if necessary, exchange it for a new one.

Liquids must not be aspirated if the lter

cartridge is used because this considerably

decreases the suction power and also inhibits

the correct operation of the swimmer ball.

4.4 Care and maintenance

Any special maintenance measures are not required owing to the sturdy construction of the Vetter aspirator. The swimmer oat housing on

the motor head and the swimmer oat are to be regularly checked for

dirt and foreign bodies and manually cleaned if necessary. The motor

head, swimmer oat housing and the suction hoses are not, under any

circumstances, to be cleaned with a hot water high pressure cleaner,

as for example can be done with the containers. This cleaning must be

done manually with a cloth or brush. Observe the safety regulations. The

motor head with the suction turbine is maintenance-free and does not

therefore require any special maintenance.

5. Taking the product out of operation

The disposal of used electrical and electronic equipment (applicable

in the countries of the European Union and other European countries

with a separate collection system for these items) in accordance with the

electrical and electronic equipment act (ElektroG) of 24th March 2005,

implementing the EC guidelines 2002/96/EC on electrical and electronic

equipment (“WEEE guidelines“).

Page 6/15

This symbol on the product or its packaging means that the electronic

components of this product are not to be treated as normal household

waste but must be returned to the manufacturer for recycling (free

delivery).

6. Elimination of defects

Defect Cause Remedy

Suction motor

does not run

Suction motor runs

but equipment

does not suction

Suction motor

runs but suction

power too low

*only by a qualied electrician

Should the defect remain despite the above information then contact an authorized representative or Vetter GmbH.

Protector switch has cut oReactivate protector.

Call specialist if it switches o again.

No voltage at the mains Check socket

Connection cable defec-

tive

Motor defective Exchange motor*

Float ball has closed the

suction opening

Suction line is blocked Clean suction line

Motor head turbine is

defective

Equipment draws outside

air

Sealing is defective Change sealing

Suction line is blocked Clean suction line

Suction height is too large Position equipment to suction height

Exchange cable*

Switch o motor, release oat ball

Carry out maintenance*

Check the adapter and motor head

for correct seating

7. Technical data

Set Oil-Water-Debris Aspirator Art.Nr.: 2200000804

Unit Data

Suction power (air)

Suction power (water)

Vacuum pressure

Current consumption of motor head Amps 4.6

Power consumption of motor head Watts 1,000

Voltage of motor head V/Hz 240/50/60

Capacity of container

Dimensions of aspirator base equipment

(LxWxH)

Weight (set for base equipment), ca.

Noise level dBA 84.4

l/min. 3,030

cu.ft./min. 107

l/min. 160

cu.ft./min. 5.7

mm WS 2,392

psi 3.5

l 100

cu.ft. 3.53

cm 86 x Ø 62

inch 34 x Ø 25

kg 30

lbs 66

Protection class : I

Protection category : IP 44

All rights reserved for technical changes within the scope of product improvement.

Page 7/15

Vetter Oil-Water-Debris Aspirator

8. Resistance Guide

Detailed information about the chemical resistance please nd in the appendix!

9. Spare parts lists

4

5

1

2

3

7

6

Page 8/15

1. Motor head with suction turbine

2. Adapter Oil-Water-Debris Aspirator

3. Trolley

4. Suction hose

5. Suction pipe, stainless steel (2 parts)

6. Narrow space nozzle

7. Ground nozzle

9.1 Motor head

Page 9/15

Loading...

Loading...