Page 1

Emergency Pneumatics.

Operating Instructions

ART Lite Pod

Article No. 9987050101 | © Vetter GmbH I 07/14 I Changes and errors excepted.

Page 2

ART Lite Pod

Contents

1. Important preliminary remarks ....................................3

2. Marking ..........................................................3

3. Product description ...............................................4

3.1 Set compilation .............................................4

3.2 Scope of application ........................................5

3.3 Check the equipment .......................................6

3.4 Safety instructions ..........................................6

4. Preparing for use ..................................................7

4.1 Mission preparation ........................................7

5. Operating instructions ............................................8

5.1 Assembling the ART Lite Pod ...............................8

5.2 Dismantling ................................................9

5.3 Care, maintenance, storage .................................9

6. Documentation ................................................. 10

7. Guarantee ......................................................10

8. Technical Data .................................................11

8.1 Technical Data ........................................... 11

9. Spare parts ART Lite Pod Litepod ................................12

EC Conformity Declaration .........................................13

Page 2/14

Page 3

1. Important preliminary remarks

Solely the knowledge of and exact abidance with these operating instructions guarantee proper and appropriate deployment, bring the greatest

possible benets and secure any claims in the frame of the Vetter guarantee.

ART Lite Pod and accessories may be utilised solely by instructed and reliable persons. Every deployment/operation of the ART Lite Pod and its accessories assumes exact knowledge of and compliance with these operating

instructions.

Consider these operating instructions as a component of the product and

retain them during the product life cycle. If the product is transferred, pass

on the operating instructions to the subsequent user.

If the equipment will be sold in or passed on to another country the reseller

must provide the instructions for the use, the maintenance, the regularly

scheduled checks and the corrective maintenance in the language of the

other country.

The anchoring devices will be tested in accordance with EN 795 and are

intended for use by an individual person with the energy absorbers in accordance with EN 355 and a connector as per EN 354.

2. Marking

Manufacturer Vetter GmbH

Product name ART Lite Pod,

Type and Model ART Lite Pod

Serial no. e.g. 01121234

01121234

01 = Month of manufacture January

12 = Year of manufacture 2012

1234 = Consecutive no.

EN Standard/Year/Class EN 795:1996

CE mark and Reference no. of the acredited

laboratory, which is intervened with the

type test/Contact

-0158

DEKRA EXAM GmbH

Prüaboratorium für

Bauteilsicherheit-Seilprüfstelle

Dinnendahlstr. 9

D-44809 Bochum

Code number: : 0158

Symbol, which demands to read the operating instructions

Max. number of persons 1 Person

Page 3/14

Page 4

ART Lite Pod

3. Product description

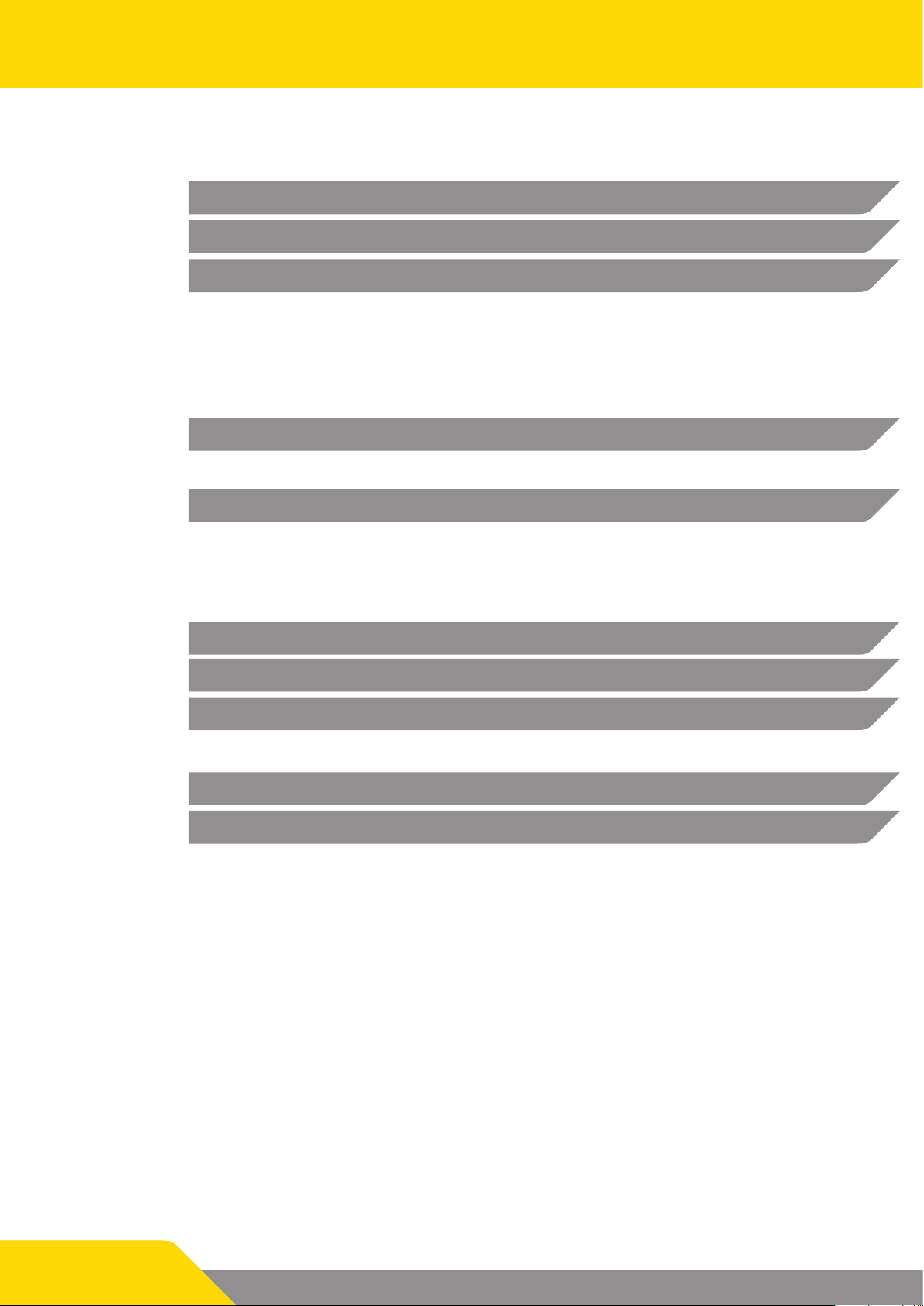

9 The ART Lite Pod comprises 5-cm (2 inch) thick round tubes

made of high-strength aluminium (6061-T6) and was powder

coated to guarantee the durability and a long service life.

9 The ART Lite Pod can be adjusted from 183 - 305 cm

(72 - 120 inch).

9 Use solely the silver eyelet for the fall safeguard. The pink eye-

let must not be used for this type of use! The silver eyelet is

permanently xed and is used as a slinging point as the personal fall safeguard.

9 The head plate of the ART-LP has two drill holes with 2.5 cm

(1 inch) diameter to guy the construction.

9 The drill holes in the struts are numbered to ease precise

alignment.

9 Red markings on the struts mark the maximum extension

length.

9 Secure the ART-LP by attaching the safety chain

9 The ART Lite Pod tripod struts are secured by the base plates

against sinking in. The load distribution makes the tripod stable and safe.

3.1 Set compilation

Set compilation ART Lite Pod

Article No. 7200011101

Article No. Product description Quantity

Strut, adjustable from

7200033800

1830 - 3050 mm

(72 - 120 inch)

3

Page 4/14

Page 5

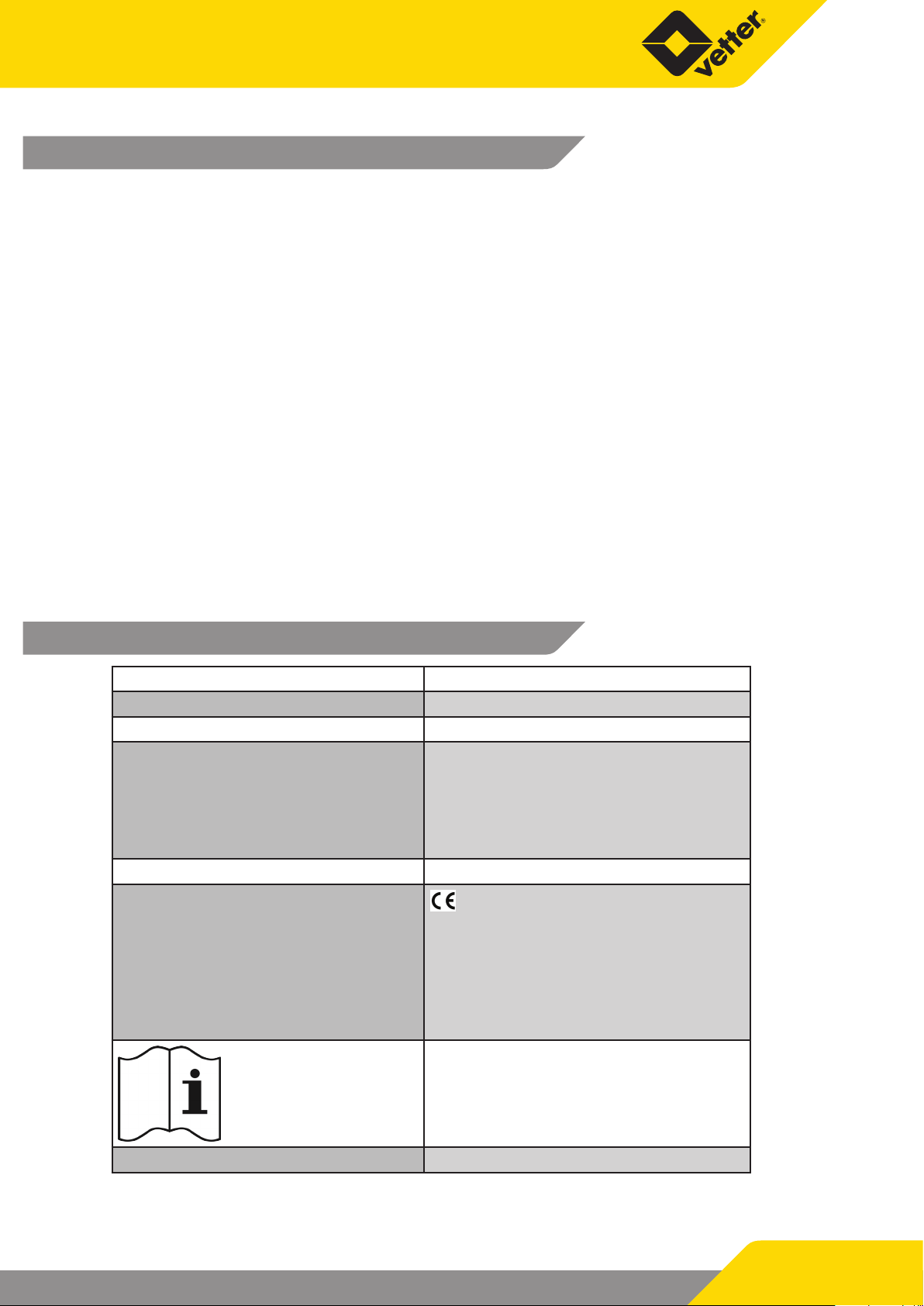

7200033900

Head attachment for

Tripod, light

ARL base plate 6”

150 mm (6 inch)

1

7200035500

7200035600

The base plates have

to be secured to each

other with a safety

chain against slipping.

Safety chain with quick

release fastener

3

1

Solely a body harness in accordance with EN 361 is permitted to be used in this personal protective equipment

system!

Additional accessories:

Article No. Description

7200011200 ART-LPC carrying case 1

3.2 Scope of application

The ART Lite Pod with its light weight and its small pack size is ideal for use in shaft, height, ditch and mountain rescue operations.

As an anchor construction the rescuer can, for example, secure it

while accessing a shaft, when rappelling from buildings or in the

mountains.

The equipment is allowed to be used solely within the stipulated

conditions of use and for the intended application.

Page 5/14

Page 6

ART Lite Pod

3.3 Check the equipment

Please make sure that:

9 The carabiner snap hooks do not exhibit any signs of dama-

ges.

Visual inspection

Carabiner snap hooks

Performance test

Headpiece for tripod Visual inspection

Base plate for tripod Visual inspection

9 The carabiner snap hooks are not bent.

9 The thumbscrew threads are clean and do not show any

signs of damages.

9 The bolts of the movable leg are present and tightly seated.

Please make sure that:

9 The movable leg is under spring tension.

9 The thumbscrew can be turned without any resistance

9 The swivel closure returns to its blocking position.

Please make sure that:

9 The headpiece is clean

9 The headpiece, the coupling ring and the eyelets along with

the securing pins are not bent

9 The nuts of the rigid eyelet are tightened with 34 Nm (301

lbf in) and the pink eyelet with 75 Nm (664 lbf in)

Please make sure that:

9 The base plates are clean

9 The base plates, the eyelets and the securing pins are not

bent

Please make sure that:

Safety chain for tripod Visual inspection

Tripod supports Visual inspection

9 The safety chain is clean

9 The safety chain including the carabiner hooks is not bent

Please make sure that:

9 All supports and cylinders (extendible part of the support)

are clean

9 No supports and cylinders are bent

9 All cylinders glide smoothly in the supports

9 The securing pins on the supports are not bent or damaged

3.4 Safety instructions

The ART Lite Pod may be used solely by qualied and trained persons who are familiar with corresponding

devices and situations! Only those persons are authorised from whom it can be expected that they perform their work reliably. Persons whose responsiveness is inuenced by, for example, drugs, alcohol, use of

medicines or illness are not authorised since these factors impair safety. People who are not involved are

not permitted to stay in the work area and must be instructed to leave the work area.

During deployment, compliance with all relevant accident prevention and occupational safety regulations

is mandatory.

Page 6/14

Page 7

Before deployment, make sure that the ART Lite Pod is complete and in

a awless condition. Please ensure that all parts of the system are in

awless condition. Even just one defective part can impair the reliable

functioning of the entire system. The ART Lite Pod must not be used if

there are signs of damage or if you have doubts about the awless condition.

If the equipment has been stressed by a fall, the written consent of an expert person is required before the equipment can be deployed again.

A plan must be available about the rescue measures and the plan must be

taken into consideration when working on possible emergencies.

Do not make any modications or undertake any supplements on the

equipment without prior, written consent from the manufacturer. Likewise,

perform corrective maintenance only in compliance with the measures stated by the manufacturer.

If you have any specic questions or doubts about the safety of the ART Lite

Pod, please get in touch with Vetter GmbH.

Caution! Check and if applicable re-tighten all

threaded connections before the deployment!

4. Preparing for use

4.1 Mission preparation

9 Check the local circumstances and adapt the strut length accordingly.

9 Get all parts of the set plus the accessories such as the karabiner snap

hooks, guide pulleys and cable winches ready.

9 Please make absolutely sure that there is sucient space underneath

the user before each deployment to denitely exclude any possibility of

an impact on the ground or on another obstacle in case of a fall.

9 Please also note that the free fall is restricted to the minimum.

9 Make sure the slinging point is above the user.

9 The following hazards can impair the functioning of the equipment and

must always be avoided: e.g., extreme temperatures, stress on the connectors due to sharp edges, slack ropes, eects of chemicals, electrical

inuences, cuts, abrasion, climatic impacts, oscillating motions during

falling.

Page 7/14

Page 8

ART Lite Pod

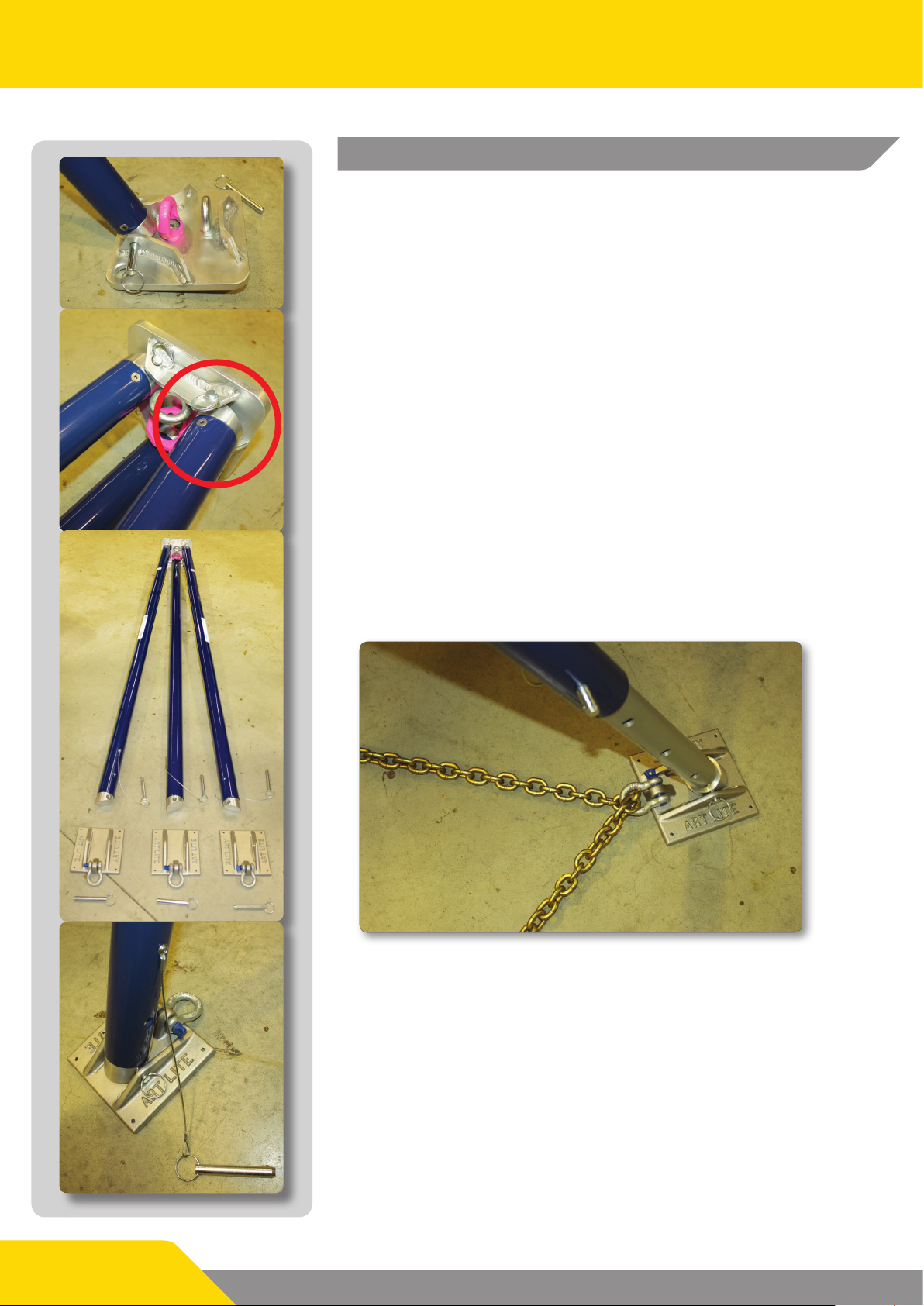

Fig. 1

Fig. 3

Fig. 2

5. Operating instructions

5.1 Assembling the ART Lite Pod

9 First use the bolts on the head piece to attach the struts to the

non-extendible side as can be seen in Figs 1 + 2. Make sure

that the chamfered side of the strut head faces the outside.

(See marking)

9 Then fasten the extendible strut ends with the bolts to the

base plate (Fig. 3). While doing so, make sure the eyelets of

the plates and the chamfered side of the strut ends are facing

towards the inside (Fig. 4).

9 The base plates can be secured against slipping with faste-

ning elements that are suitable for the substrate.

9 To correspondingly adjust the height of the struts to the de-

ployment situation, extend the struts manually and arrest

them at the desired height using the bolts. The numbering of

the holes helps with the orientation.

9 Finally, the tripod needs to be secured against slipping/splay-

ing with the provided chain. To accomplish that, lead the

chain through the rings (Fig. 5) and clamp the chain accordingly. After that, hook the chain lock together. (Fig. 6)

Fig. 4

Page 8/14

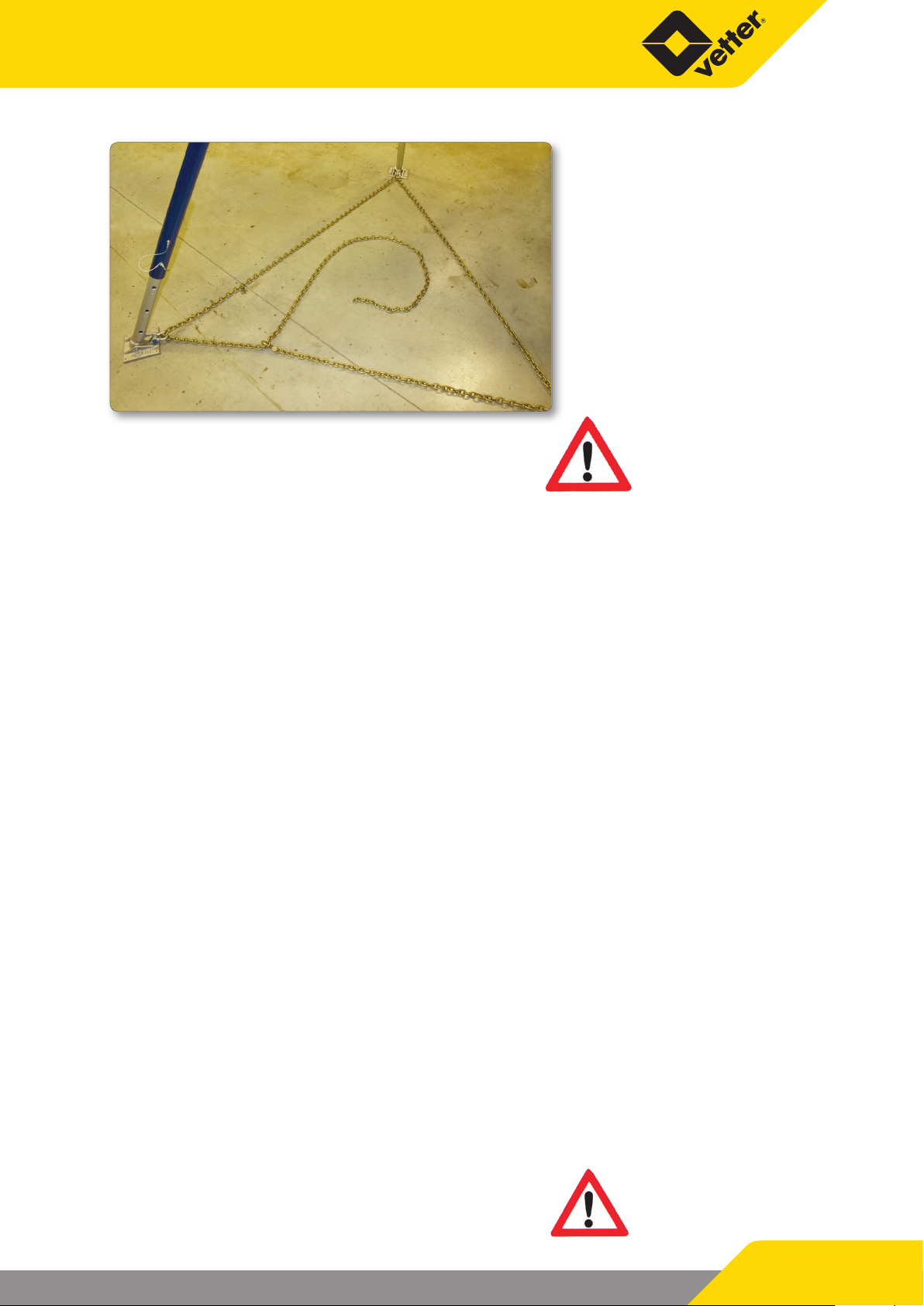

Fig. 5

Page 9

Fig. 6

Use suitable measures to secure the base plate

against slipping! (E.g. nails, screws)

5.2 Dismantling

Dismantle in the reverse order of setup.

5.3 Care, maintenance, storage

The user‘s safety depends on the eectiveness and the durability of the

equipment.

Store all the equipment together in the packing bag in a cool and dry location. Protect the equipment against sharp edges, direct heat, moisture,

vibrations and ultraviolet degradation!

Have an expert undertake a visual inspection and performance test of the

ART Lite Pod and the accessories and check them for completeness and intactness while precisely following these instructions before and after each

use and/or deployment but in any case at least once annually.

1. Pull the piston out of the strut tube.

2. Free the tripod and the accessories from dirt by washing with a washing brush and detergent and, if heavily soiled, possibly also with a

high-pressure jet cleaner.

3. Check the tripod and accessories for damages, completeness and

functioning!

4. Locking - Smoothness of operation and functioning

5. Reassemble the piston and strut tube and check for awless functioning and smoothness of operation.

6. The accessories - head plate and base plates also need to be regularly

inspected!

7. Above all, make sure that all adjusting bolts, securing pins, nuts and

locks are present and work awlessly!

8. Also check the legibility of the product identication!

Tighten the pink eyelet with 75 Nm (664 lbf in) and

the nut of the rigid eyelet with 34 Nm (301 lbf in)!

Page 9/14

Page 10

ART Lite Pod

6. Documentation

Perform and document the individual tests in accordance with the test instructions in these operating instructions. The documentation must include the points listed below and could look like this:

DOCUMENTATION OF THE EQUIPMENT

Product

Type and model/identication

Serial number

Year of construction

Trade name

Dealer

Address

Telephone and fax no.

E-mail

Date of purchase

Application

Date of the rst usage

Other important tasks

SEQUENCE OF THE REGULARLY SCHEDULED TESTS AND CORRECTIVE MAINTENANCE

Date Reason for pro-

cessing (regularly

scheduled test or

corrective maintenance)

The institution to which the user belongs is responsible for the documentation and the entry of the required

statements.

Damages found,

performed corrective maintenance

and other important

tasks

Name and signature

of the expert

Date of the next test

7. Guarantee

We cover material and defects in workmanship of all Airshore products with a warranty of 2 years from the date of

purchase. Airshore products which come under this warranty will be repaired or replaced after a corresponding

inspection. Warranty claims are managed by our contract dealers or Vetter GmbH.

Damages caused by incorrect or impermissible handling are not covered by this

warranty!

Page 10/14

Page 11

8. Technical Data

8.1 Technical Data

ART Lite Pod

Material Aluminium

Expansion diameter

Deployment height

Installation height

Load-bearing capacity

at max. height of 305 cm (120 inch)

Load-bearing capacity

at height of 183 cm (72 inch)

Weight approx.

All rights reserved for technical changes within the scope of product improvement.

2.65 m

104.3 inch

183 - 305 cm

72 - 120 inch

≤ 350 cm

≤ 137.8 inch

318 kg (Safety factor 10:1)

701 lbs

454 kg (Safety factor 10:1)

1001 lbs

32 kg

70.5 lbs

Load-bearing capacity at:

0 - 45° = 4 t (4.4 US tons),

> 45° = 1.5 t (1.6 US tons)

Strut material:

The ART Lite Pod comprises 5 cm (2 inch) thick round tubes made

of high-strength aluminium (6061-T6) and was powder coated to

guarantee the durability and a long service life.

Page 11/14

Page 12

ART Lite Pod

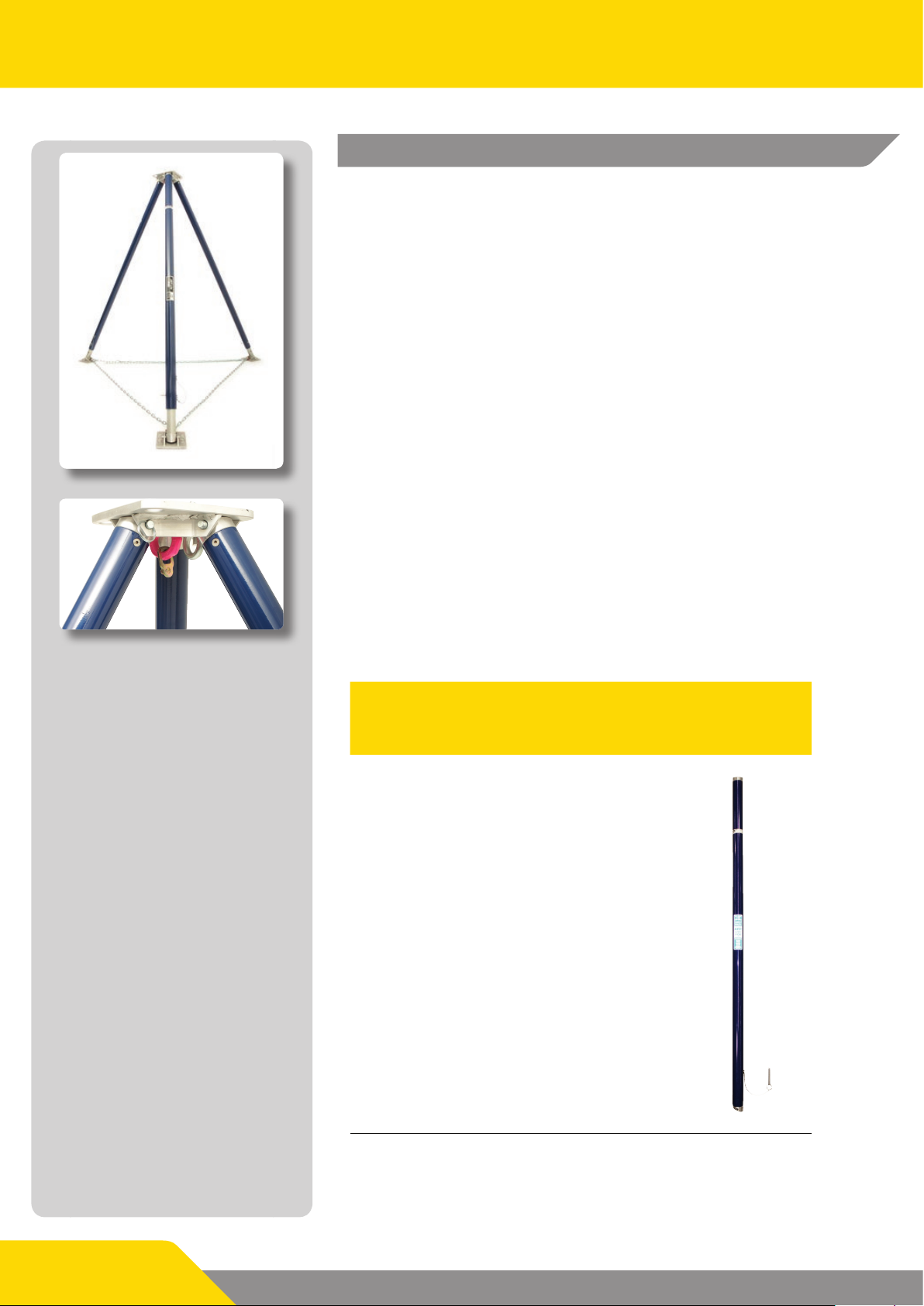

9. Spare parts ART Lite Pod Litepod

AIRSHORE LITE POD Parts List

Model Number: 368A062

ART-LPBC BARREL CLEVIS

K2-12WASHER WASHER

K2-500N HEX NUT

179A034 JAM NUT

267A066 WASHER

K2-1412 SCREWS

LOAD CAPACITIES

At 6 feet = 1,000lbs

At 10 feet = 700 lbs

10:1 SAFETY FACTOR

K2-1414BHSC SCREW

132A122 DECAL

107A049 BARREL

364A029

25' CHAIN w/GRAB HOOK

315A001 LANYARD

189A083

PIN

189A083 PIN

195A052 LITE POD LID

CW-58-EYE SWIVEL EYE

CW-12112EYE EYEBOLT

Load should always be

centered below top plate

ART-LPPR PISTON

ARL-LPPC

PISTON CLEVIS

K2-1412 SCREWS

189A083 PIN

ARL-BASEPLATE6

BASE PLATE

305A019

SHACKLE w/SCREW PIN

Page 12/14

Lite Pod should always be used

with the safety chain in place

AirShore products have precise assembly

specifications. Parts lists and diagrams are

for reference and part identification only.

Any and all modifications and repairs should be

performed only by factory trained personnel.

Form Part No. 172A304 Rev. 03

Page 13

EC Conformity Declaration

in accordance with Directive 89/686/EWG

Manufacturer name and address

Hurst Emergency Products

A Unit of IDEX Corporation

711 N. Post Road

Shelby, NC , USA 28150

We hereby declare, that the ART Lite Pod

Serial-No.: __________________

Model: __________________

(refer to equipment label, to be entered by the customer)

meets the following applied standards or other normative documents:

EN 795:1996

Authorised representative for the compilation of technical documents:

Vetter GmbH

Blatzheimer Str. 10 - 12

53909 Zülpich

GERMANY

Involved Notied Body during the EU type approval test:

DEKRA EXAM GmbH

Prüaboratorium für Bauteilsicherheit-Seilprüfstelle

Dinnendahlstr. 9

D-44809 Bochum

This EC Conformity Declaration was issued:

Zülpich, 10.12.2012

(Place, Date, Signature)

Page 13/14

Page 14

Place your trust in emergency pneumatics!

We are the company who can help you, nd a solution to your problem!

Vetter GmbH

A Unit of IDEX Corporation

Sales

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

www.vetter.de

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

Article No. 9987050101 | © Vetter GmbH I 07/14 I Changes and errors excepted. I Made in Germany

Page 15

Emergency Pneumatics.

Operating instructions addendum

Rope winch/Rescue lifting device

Article No. 9987061600 | © Vetter GmbH I 07/14 I Changes and errors excepted.

Page 16

Rope winch/Rescue lifting device

Contents

1. Important preliminary remarks ....................................3

2. Marking ..........................................................3

3. Product description ...............................................3

3.1 Set contents ................................................4

3.2 Scope of application ........................................4

3.3 Check the equipment .......................................5

3.4 Safety instructions ..........................................5

4. Preparing for use ..................................................7

4.1 Mission preparation ........................................7

5. Operating instructions ............................................8

5.1 Assembly of the rescue lifting device, AT200/3 ...............8

5.2 Dismantling .............................................. 10

5.3 Transport and shipping ................................... 11

6. Documentation ................................................. 12

7. Warranty ....................................................... 12

8. Technical Data ..................................................13

EU conformity declaration Rope winch/rescue lifting device ......... 14

Page 2/15

Page 17

1. Important preliminary remarks

Solely the knowledge of and exact following of these operating instructions guarantee proper and appropriate deployment, bring the greatest possible benets

and meet the requirements contained within the scope of the Vetter guarantee.

Only instructed and qualied specialists are permitted to use the AT200/3 winch.

Every deployment/operation of the winch and its accessories assumes exact

knowledge of and compliance with these operating instructions.

Consider these operating instructions as a component of the product and retain

them during the product life cycle. If the product is passed on, give the operating

instructions to the subsequent user.

If the equipment will be sold in or passed on to another country, the reseller must

provide the instructions for the use, maintenance, regularly scheduled checks and

corrective maintenance in the language of the other country.

The rescue lifting device was certied in accordance with EN 1496 Class B.

2. Marking

Manufacturer PROTECTA International

Product description Rescue lifting device AT200

Type and Model Rescue lifting device AT200

Rope length 20 m

Serial no. e.g. 1238286

Month of manufacture e.g. 12

Year of manufacture e.g. 12

EN Standard/Year/Class EN 1496 Class B

Maximum utilization load 136 kg max

3. Product description

The AT200/3 rescue lifting device can be used together with the tripod, light ART

Lite Pod. The rescue lifting device is made of galvanized steel and has a black epoxy coating. The rescue lifting device is equipped with a hold-back as well as with

a self-blocking brake. The stainless steel rope has a length of 20 m, a diameter of 5

mm and is equipped with a swivel snap hook.

The reduction ratio is 4.5:1. The mean lift is 10 cm / revolution.

There are two locking bolts on the device to attach the tripod to the rescue lifting

device.

Page 3/15

Page 18

Rope winch/Rescue lifting device

3.1 Set contents

Set Winch for ART Lite Pod, Item no. 7200040001

Item no. Name

7200000201

Winch for ART Lite Pod,

including bracket

1

7200039201

Role for wire rope incl.

snap hook

1

3.2 Scope of application

This rescue lifting device

9 must be used solely for the evacuation of one single person

9 must be used solely for evacuation and rescue work.

9 has a maximum service load of 136 kg

9 must not be put into operation if it has come into contact with chemical or

corrosive agents.

Use/deploy this lifting device to hoist persons only if the

person to be hoisted is secured against falling with

personal protective equipment at the same time!

The equipment is allowed to be used solely within the

stipulated conditions of use and for the intended

application.

Page 4/15

Page 19

3.3 Check the equipment

ATTENTION: Protective gloves and safety footwear must be worn also during

maintenance work to prevent injuries!

Make sure that:

Carabiner snap hooks

Rope Visual inspection

Strength of the rope

connection on the drum

Visual inspection

Functional check

Visual inspection

9 The snap hooks, especially the automatic locking system,

does not exhibit and damage.

9 The carabiner snap hook is not bent.

Make sure that:

9 The proper rotational movement of the pivot pin is en-

sured.

9 The moving parts are under spring tension and do not

block.

Make sure that:

9 The rope does not exhibit any indented points, torn th-

reads, uncoilings/untwists, bends, heat damage (welding

points), oxidations.

If any single one of these defects is noticed, immediately take

the lifting device out of service.

Make sure that:

9 The connector is correctly attached to the drum disc

(completely free of play) and that the rope end projects

more than 2 cm past the connector.

Do not use the lifting device if there are any doubts about

the awless rope attachment.

Make sure that:

Mounting hardware Visual inspection

9 The mounting hardware (bolts) is in awless condition.

If these checks leave any doubts, or if the winch has been exposed to a violent eort due to a fall, return it immediately to Vetter GmbH.

3.4 Safety instructions

The AT200/3 rescue lifting device may be used solely by qualied and trained persons who are familiar with

corresponding devices and situations! Only persons from whom it can be expected that they perform their work

reliably are approved. Persons whose responsiveness are inuenced by, for example, drugs, alcohol, use of medicines or illness are not permitted since these factors impair safety. People who are not involved are not permitted

to stay in the work area and must be instructed to leave the work area.

During deployment, compliance with all relevant accident prevention and occupational safety regulations is

mandatory.

During deployment, wear protective gloves and safety footwear to prevent injuries.

Before deployment, make sure that the AT200/3 rescue lifting device is complete and in a awless condition. Ple-

ase ensure that all parts of the system are in awless condition. Even if only one part is defective, the safe

and reliable functioning of the entire system can be impaired. The AT200/3 rescue lifting device must not be

used if there are signs of damage or if you have doubts about the awless condition.

Page 5/15

Page 20

Rope winch/Rescue lifting device

If the equipment has been stressed by a fall, the written consent

of an expert person is required before the equipment can be deployed again.

A plan of the rescue measures must be available and the plan

must be taken into consideration when working on possible

emergencies.

Do not make any modications or additions to the equipment without prior, written consent from the manufacturer. Likewise, perform corrective maintenance only in compliance with the measures stated by the manufacturer.

If you have any specic questions or doubts about the safety of

the AT200/3 rescue lifting device, please get in touch with Vetter

GmbH.

ATTENTION: Check and if applicable re-tighten all

threaded connections before the

deployment.

CAUTION:

9 Do not change cable and check that the cable in place is free

of damage. Otherwise, do not use the lifting device and contact Vetter GmbH.

9 Do not use the lifting device if it shows any signs of damage,

deformation or specic wear.

9 Do not modify the lifting device or any of its accessories.

9 Never install the lifting device on a dierent structure that

might be suspected of not being strong enough. This strength

shall include the possibility of an impact force due to inadvertent falling and must therefore be greater than 1000 daN

(approx. 1000 kg).

9 Never install the lifting device in a position that is liable to

cause the load to swing or turn.

Page 6/15

Page 21

4. Preparing for use

4.1 Mission preparation

9 Before using each time, carry out visual examination of the

lifting device and the other components of the evacuation

system and do not use it if there is any resulting doubt.

9 Check out the local circumstances and that the working area

is protected from any electrical, chemical, thermal or contamination risks.

9 Get the rescue lifting device, the guide roller and the snap

hook ready.

9 Make sure the area around the winch is clear of any obstacle

that could obstruct its operation or hinder repair work.

9 Also check that all the system components are compatible

with each other by verifying more particularly the utilization

limits indicated in the various instruction manuals.

9 Protect the lifting device and its support against any specic

risks related to use (projection of objects, sparks and ames,

corrosive atmospheres, etc.).

9 The following hazards can impair the functioning of the

equipment and must always be avoided: e.g., extreme temperatures, stress on the connectors due to sharp edges, slack ropes, eects of chemicals, electrical inuences, cuts, abrasion,

climatic impacts, oscillating motions during falling.

Page 7/15

Page 22

Rope winch/Rescue lifting device

5. Operating instructions

5.1 Assembly of the rescue lifting device, AT200/3

In the photographs in these operating instructions, protective gloves are not being

worn. This is only to make the pictures more understandable. Wearing protective

gloves and safety footwear is, however, mandatory when working on the AT200/3 rescue lifting device!

9 Pull out the bolts by pressing the button before attaching the winch to one of the support legs

of the ART Lite Pod tripod.

9 Then fasten the winch with the bolts to one of the support legs of the setup and secured ART

Lite Pod tripod.

9 Attach the snap hooks to the pink eyelet.

ATTENTION: Wear protective gloves! Danger of crushing when

opening and closing the snap hook.

Page 8/15

Page 23

9 Route the steel rope through the guide roller and put the guide roller on the snap hook.

9 Lock the snap hook by turning the lock.

9 The black crank handle on the winch must be pulled out and clinched!

ATTENTION: Wear protective gloves! Danger of crushing!

Page 9/15

Page 24

Rope winch/Rescue lifting device

TO LEAD THE CABLE OUT OF THE WINCH WINDING DRUM:

ATTENTION: Do not reach into the cable drum! Fingers could get pulled in

and crushed!

9 Turn the crank handle counter-clockwise until the carabiner can be connected to the rescue

harness anchorage point.

9 After connecting the carabiner to the rescue harness anchorage point, turn the crank handle

clockwise to activate the lifting movement. Lift the person until he/she can be grasped safely by

the intervention crew members. When there is no further risk of fall, detach the carabiner from the

harness anchorage point.

9 If it is necessary to lower the injured party, activate the lowering movement by turning the crank

handle counter-clockwise. The system has a built-in brake so that the descent will stop as soon

as action on the crank is ceased.

This winch must not be used as a personal lifting system unless the person being

winched is secured in parallel with fall arrest personal protective equipment.

5.2 Dismantling

Dismantle in the reverse order of setup.

5.3 Care, maintenance, storage

The user‘s safety depends on the eectiveness and the durability of the equipment.

Store all the complete equipment in a cool and dry location. Protect the equipment against sharp edges, direct

heat, moisture, vibrations and ultraviolet degradation!

Have a person authorised by PROTECTA International perform a visual inspection and performance test of the

AT200/3 rescue lifting device and accessories and have them checked for completeness and intactness before

and after each use and/or deployment but in any case at least once annually.

REGULARLY CHECK, AND MORE PARTICULARLY BEFORE INTERVENTION:

9 The general condition of the cable and in particular, any signs of crushing, broken strands, unstranding,

bends, swellings, thermal changes (welding) or oxidization. Any one of these defects should be considered

sucient to immediately decommission the winch.

9 The strength of the cable attachment to the drum. To do this, check that the attaching part is correctly secu-

red to the drum (total absence of play) and that the cable end protrudes more than 2 cm from the attaching

part. Do not use the winch if you are not sure about the correct attachment of the cable.

9 The condition of the carabiner, in particular its automatic closing and the correct rotation of its trunnion.

9 The condition of the attaching parts.

9 Above all, make sure that all adjusting bolts, securing pins, nuts and locks are present and work awlessly!

9 Also check the legibility of the product identication!

ATTENTION: Protective gloves and safety footwear must also be worn also

during maintenance work to prevent injuries!

Here also, do not reach into the cable drum! Danger of crushing!

If these checks leave any doubts, or if the winch has been exposed to a violent eort due to a fall, return it immediately to Vetter GmbH.

Page 10/15

Page 25

5.3 Transport and shipping

For transport, the black crank handle has to be closed again!

ATTENTION: Danger of crushing!

Page 11/15

Page 26

Rope winch/Rescue lifting device

6. Documentation

Perform and document the individual tests in accordance with the test instructions in these operating instructions. The documentation must include the points listed below and could look like this:

DOCUMENTATION OF THE EQUIPMENT

Product

Type and model/identication

Serial number

Year of manufacture

Trade name

Dealer

Address

Telephone and fax no.

E-mail

Date of purchase

Application area

Date of the rst usage

Other important tasks

SEQUENCE OF THE REGULARLY SCHEDULED TESTS AND CORRECTIVE MAINTENANCE

Date Reason for doing the work

(regularly scheduled test or

corrective maintenance)

Damages found, performed

corrective maintenance and

other important tasks

Name and address of the

expert

Date of the

next test:

The institution to which the user belongs is responsible for the documentation and the entry of the required

statements.

7. Warranty

We cover material and defects in workmanship on the AT200/3 rescue lifting device with a warranty of 2 years

from the date of purchase. Rescue lifting devices which come under this warranty will be repaired or replaced

after a corresponding inspection. Warranty claims are managed by our contract dealers or Vetter GmbH.

Damages caused by incorrect or impermissible handling are not covered by this

warranty!

The same „General Directives“ apply to this product as to standard products: The term of the warranty period in

case of damage is 2 years, and, as with any mechanical product, an unlimited lifetime is guaranteed if the product

is inspected and, if necessary, repaired annually.

Page 12/15

Page 27

8. Technical Data

AT200/3 rescue lifting device

Material winch

Rope length

Rope diameter 5 mm

Reduction ratio 4.5:1

Permissible max. load 136 kg / 1 Person

Breaking load of the system

Average lift 10 cm / Revolution

Temperature resistance -36 °C to +60 °C

Weight, approx. 9.15 kg

We reserve the right to make technical changes in the scope of product improvements.

The rescue lifting device is equipped with a hold-back and a self-blocking brake.

Galvanised steel with black epoxy

coating

20 m, stainless steel with swivel

snap hook

1.2 t

Page 13/15

Page 28

Rope winch/Rescue lifting device

EU conformity declaration Rope winch/rescue lifting device

Page 14/15

Page 29

Place your trust in emergency pneumatics!

We are the company who can help you, nd a solution to your problem!

Vetter GmbH

A Unit of IDEX Corporation

Sales

Blatzheimer Str. 10 - 12

D-53909 Zülpich

Germany

www.vetter.de

Tel.: +49 (0) 22 52 / 30 08-0

Fax: +49 (0) 22 52 / 30 08-590

Mail: vetter.rescue@idexcorp.com

Article No. 9987061600 | © Vetter GmbH I 07/14 I Changes and errors excepted. | Made in Germany

Loading...

Loading...