Vetter Lifting bags 1 bar User Manual

Emergency Pneumatics.

Operating Instructions

VETTER Lifting Bags 1.0 bar/14.5 psi

Article No. 9987013203 | © Vetter GmbH I 11/14 I Changes and errors excepted.

Vetter Lifting Bags 1.0 bar/14.5 psi

Contents

1. Important preliminary remarks ....................................2

2. Description of the product ........................................2

2.1 Scope of delivery ...........................................2

2.2 Additional accessories ......................................2

2.3 Application area ............................................3

2.4 The VETTER construction ....................................4

2.5 Correct handling and usage .................................6

2.6 Safety instructions ..........................................6

3. Preparing the product for use .....................................7

3.1 Preparations for operation ..................................7

3.2 Application instructions .....................................7

4. Operating Instructions ............................................8

4.1 Operation with compressed air bottle 200 bar or 300 bar .....8

4.2 Operation with other air supplies ..........................10

4.3 Dismantling of the lifting bag system after use .............10

4.4 Care and storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5 Repair instructions ........................................ 11

5. Elimination of defects ........................................... 11

6. Repetitive checks ............................................... 12

7. Technical data .................................................. 13

EC Conformity Declaration (available on request) ...................14

Page 1/15

1. Important preliminary remarks

Only knowledge and the exact observance of this operating manual guarantee correct and reliable operation, achieve the best possible usage

and ensure any claims made within the framework of the Vetter guarantee.

Only a person who has been instructed in the use of Vetter Lifting Bags,

using the manufacturer operating manual and the instructions from the

user, is to be given the operation task.

The disposal of discarded lifting bags is to be carried out according to

disposal regulations valid for the region.

The operating instructions given here are to be regarded as part of the

product and are to be kept for the complete life duration of the product.

In case the product should be passed on to a successive user then the

operating instructions must also be included.

2. Description of the product

2.1 Scope of delivery

Inventory check: Items

Description Qty.

Lifting bags, of the same type and size 2

Ination hoses, 5 m (16.4 ft.) in length 2

Air Cu 1 bar, deadman 1

Pressure regulator 200/300 bar 1

Packing bag 1

Set repair material 1

Operating instruction 1

Other set combinations are possible if required!

2.2 Additional accessories

Pos. Article No. Description

1600 0261 00

1

or 1600 0262 00

Pressure regulator 200/300 bar

US Version 4500 psi

(not compatible with below

mentioned compressed air

bottles)

2

3

1600 0108 00

1600 0199 00

Comp. air bottle 6 l / 300 bar

Comp. air bottle 9 l / 300 bar

Page 2/15

Vetter Lifting Bags 1.0 bar/14.5 psi

Pos. Article No. Description

4

5

6

1600 0091 00

1600 0145 00

1600 0120 00

Dual connector 300 bar

Pressure regulator

Adapter for compressor

2.3 Application area

Due to the high pressure point load, it is frequently not possible to use

winches or hydraulic lifting gear when dealing with heavy, unstable loads.

In such cases the advantages of Vetter lifting bags become very much apparent:

9 Very light

9 Low pressure point loading

9 Very at in design

9 Can be used in any position

As already known, air distributes itself evenly on all sides. The ideal shape of

a pressure container is spherical. With exible pressure containers, such as

the lifting bag, the top and bottom as well as sides bulge.

With lifting bags this bulging, especially of the top and bottom, could damage the bag when pressed against sharp objects and the bag may become cut, punctured or abraded.

Danger of damage to the pressurized walls of the

bag.

Page 3/15

2.4 The VETTER construction

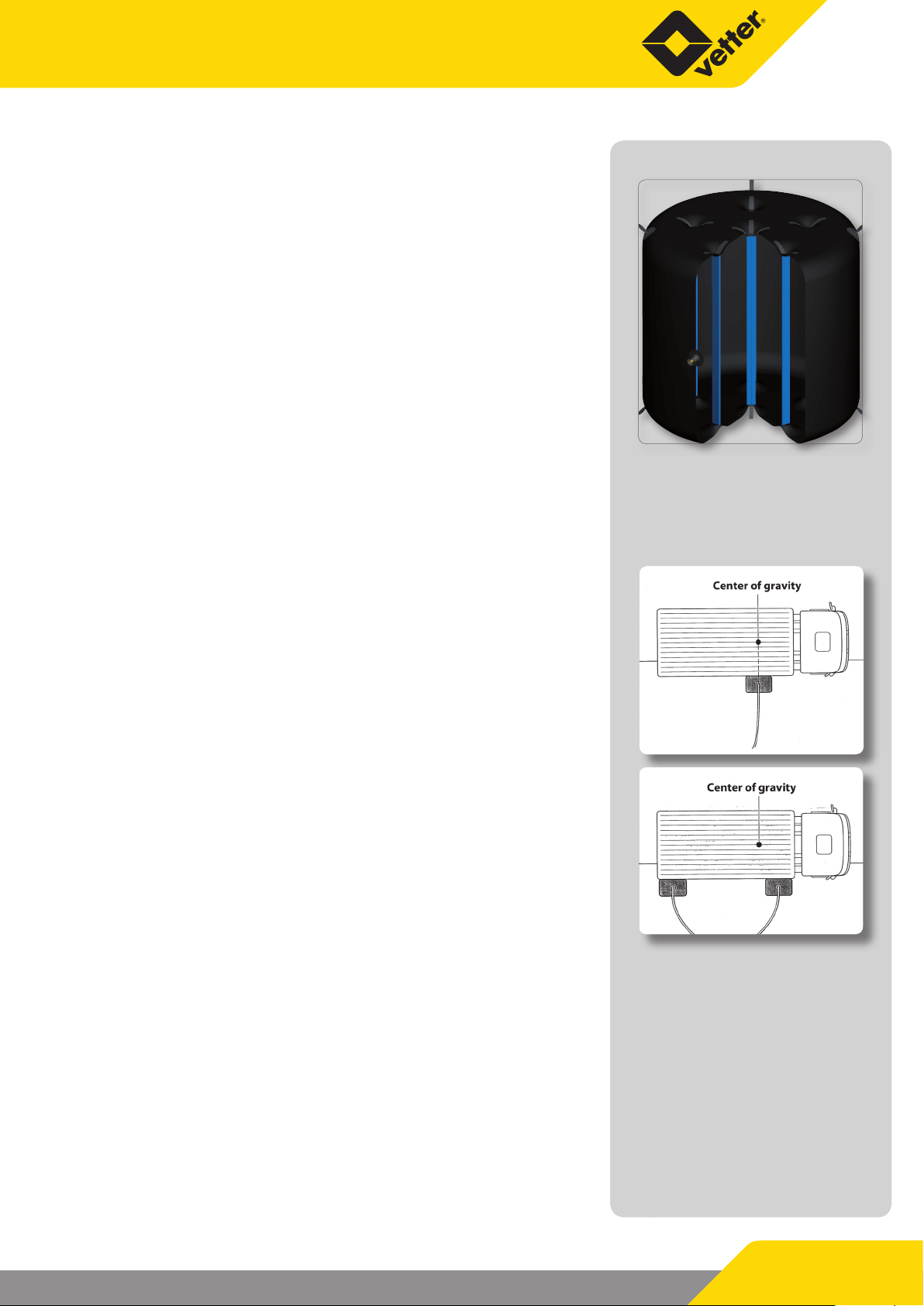

Bags which have a cylinder shape cannot bulge on the side because the material tensions evenly. This characteristic greatly reduces any damage to the side wall.

Owing the extensive use of internal harnesses, bulging of the top

and bottom is avoided. The strong, multi-layer and reinforced material avoids bag damage within the working area. The supporting

material of the lifting bag is made of ARAMIDE which is a very light

but tear-resistant articial bre.

The coating of the supporting material is made of NEOPRENE

which is a synthetic articial rubber. As opposed to material rubber, NEOPRENE has ideal characteristics for the lifting bag, e.g.:

9 High resistance to mineral oil and acid

9 High resistance to wear and has a long life cycle

9 Maintenance free

The exible lifting bags mould themselves to the shape of the

load to be lifted as opposed to hydraulic and pneumatic lifting

gear with their solid positioning plates. In connection with the

very low application pressure of only 1.0 kg/cm², loads can be lifted carefully.

Lifting bags, irrespective of the type, are unstable over the complete lifting distance! When using just one bag it must be positioned exactly under the load‘s centre of gravity otherwise load

movement cannot be avoided.

In practise, exact positioning is not possible!

If the use of one bag cannot be avoided then positioning stability

of the load is to be ensured. However, if two bags are used and if

one bag is placed to the front part and the other bag to the rear

part of the load then the centre of gravity will always be between

the two bags.

The basic condition for a stable, dierent control of both bags is

the separate independent control using the corresponding dual

controller.

Page 4/15

Loading...

Loading...