Page 1

VESTIL MANUFACTURING CORPORATION

P.O. Box 507., Angola, IN 46703 USA

Phone (260) 665-7586 • Fax (260) 665-1339

E-mail: sales@vestil.com • www.vestil.com

Loading Dock Equipment

Revised 04-06

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNER'S

MANUAL

RR-Series Mechanical Docklevelers

Contents

Warnings & Safety Instructions ....................... 1

Replacement Parts .......................................... 1

Receiving Instructions ..................................... 1

WARNINGS & SAFETY INSTRUCTIONS

Ensure that all employees understand and follow the

following.

• When working on the dockleveler, barricade it off to

traffic from on the dock and on the approach.

• Always brace leveler securely in the “UP” position

when performing maintenance work.

• Always brace lip in extended position when working on

lip or leveler.

• Check toe guards to ensure they are functional.

• When testing dockleveler be certain everyone is clear

from the swinging lip.

• When operating leveler, do not walk on lip.

• Return dockleveler to level, supported position after

maintenance or use is completed.

• Do not leave any cargo or equipment on deck of

dockleveler.

• Do not drive a fork truck or other material handling

equipment on dockleveler to bring deck down to the

truck bed.

• Monthly visual inspection of the dockleveler shall be

made to verify that there are no missing or damaged

components including toe guards.

WHEN ORDERING REPLACEMENT PARTS

We take pride in using quality parts on the equipment we

manufacture. We are not responsible for equipment

problems resulting from the use of unapproved

replacement parts.

To order replacement or spare parts for this equipment,

contact the factory.

In any communication with the factory please be

prepared to provide the machine’s serial number, which is

indicated on the machine dataplate.

Warranty ........................................................... 1

Operation Instructions ...................................... 2

Adjusting Instructions ....................................... 3

Parts List ............................................................. 4

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to

shipment. However, it is possible that the unit could incur

damage during transit.

Inspect the unit closely when it arrives.

evidence of damage or rough handling to either the

packaging or to the product when it is being unloaded,

immediately make a note of it on the Bill Of Lading!

It is important that you remove the product’s packaging

upon its arrival to ensure that there is no concealed

damage or to enable a timely claim with the carrier for

freight damage.

Also verify that the product and its specifications are as

ordered.

If you see

LIMITED WARRANTY

We warrant that this dockleveler is to be free from

defects for one (1) year from date of shipment.

We will bear the cost of repairing or replacing, at our

option, any defect. We will issue a Return Goods

Authorization Number for a return or a Purchase Order

Number for a repair. We do not cover costs for jobsite

labor, loss of use, or any consequential damages. To be

covered by our warranty, equipment must be installed and

maintained in accordance with the guidelines of this

manual and operated within the rated capacity. Periodic

lubrication and adjustment are the responsibility of the

owner.

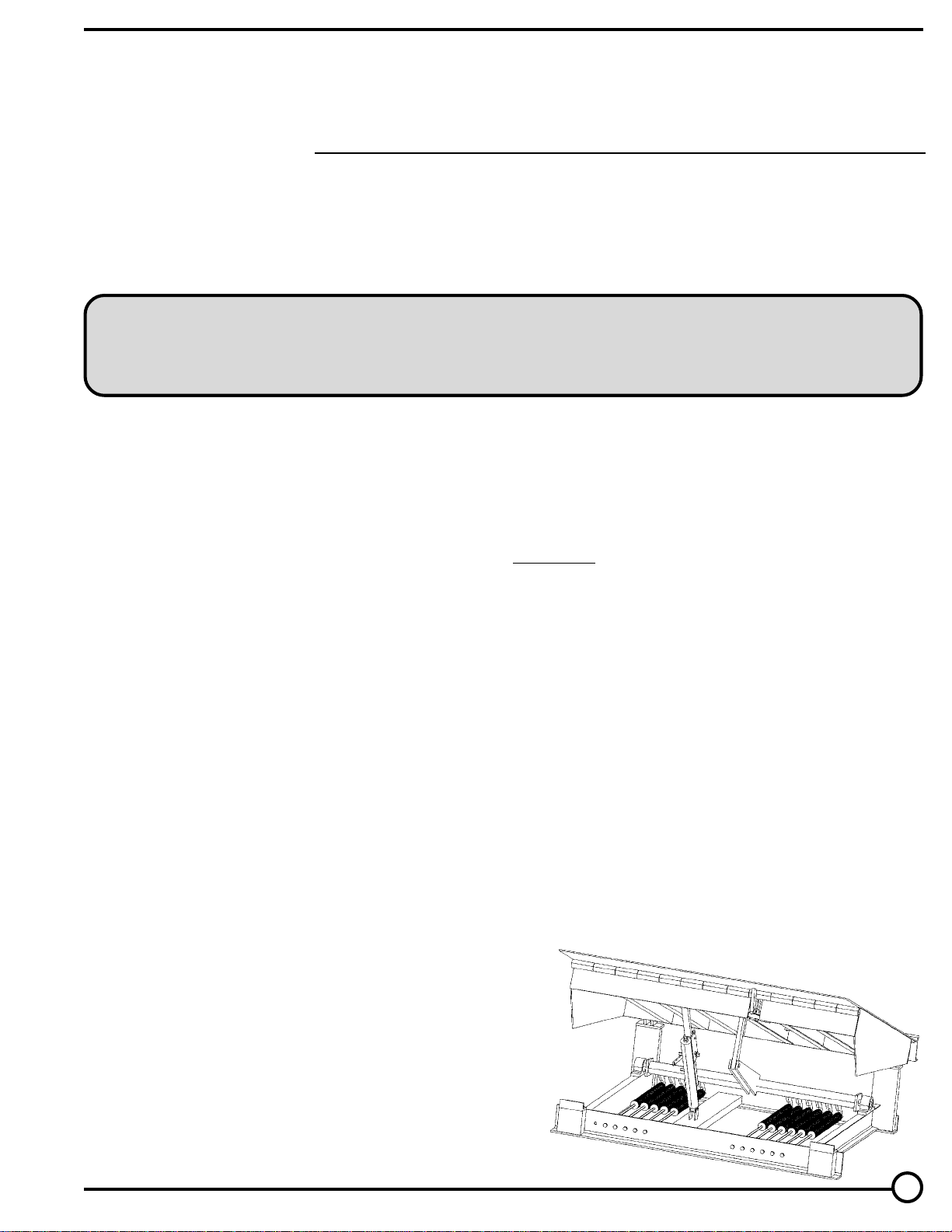

RR-Series

Mechanical Dockleveler

1

Page 2

OPERATING INSTRUCTIONS

• After truck is spotted against bumpers the dockleveler user chocks the truck wheels on both

sides.

• The user now looks at the cargo area of the truck to see if there is ample room for the

dockleveler lip to go onto the trailer.

• The lip will require about twelve inches (12”) beyond the bumper for the standard sixteen inch

(16”) lip.

• If there is not sufficient clear distance to put the lip, the area needs to be cleared manually or

with a fork truck. Before a fork truck is driven on the dockleveler deck the user should verify the

lip is in the vertical position securely behind the lip keepers. If the deck is below dock height the

user brings the dockleveler up above the dock floor by releasing the deck using the pull in the

rear center of the deck. Release pull as soon as deck is a few inches above floor height then

walk on deck to bring it back to the level supported position.

• After the lip contact area is clear the user goes to the rear of the deck and pulls the release after

verifying that no one will be hit by the raising deck and the extending lip. The deck comes up

and the lip extends automatically. The user releases the pull and promptly walks on the deck

which brings it down until the lip is on the truck bed. (DO NOT WALK ON LIP). Loading/

unloading may now commence.

• If the dockleveler is equipped with optional safety legs they need to be retracted if the trailer is

below floor height. Retract safety legs by pulling ring at rear of leveler. Release safety legs

immediately after lip comes to rest on trailer. Do not leave any cargo or equipment on the

dockleveler deck at any time.

• When loading/unloading is complete the dockleveler can be taken out of the truck by pulling the

recessed handle releasing the deck until the lip clears the truck. Wait for the lip to completely

retract and then walk on the deck until it comes back to the floor height. Check to be sure the

lip is behind the keepers. The overhead door of a trailer and/or the building may now be closed

and the wheel chocks removed.

• If the truck departs prior to removing the lip from the trailer the lip will fall to the down position.

The lip may or may not be in the keepers. The user must release the deck to a few inches above

floor height, allow the lip to fully retract and walk on the deck to bring the lip down to rest behind

the keepers. Visual inspection is necessary.

2

Page 3

ADJUSTING INSTRUCTIONS

(Review Safety Precautions before doing any work.)

The key to long term, dependable use of your dockleveler is proper maintenance.

Prior to doing adjustments on your dockleveler you need to grease and oil the friction points plus

clean all debris from leveler.

Cleaning is the first step. Remove all debris from the pit. Clean the lip hinge and the lip operating

mechanism. Wipe dirt and/or material from ratchet mechanism including the ratchet and paw. Clean

deck hinge.

Zerk fittings to be greased (lithium base preferred) as follows:

1. Lip hinge

2. Pillow block at ends of trunion

3. Rotating cam in center of dockleveler deck

4. If unit is equipped with safety stops grease both sides

Oil all moving parts liberally. The only exception is the ratchet bar and the locking paw which should

not be oiled. Use a grafite base oil. Oiling is required every thirty (30) days. Oil hooking point at the

end of the springs.

There are two primary adjustments required on your dockleveler as follows:

Lip Extending Mechanism

The lip is extended by the lip cable and the lip counterbalance spring. The function sequence should

be as follows: The deck comes up making the lip cable taught pulling the lip out with the assistance of

the counterbalance spring. The lip is momentarily held in the extended position by the two hydraulic

dampers.

It is important to know how much tension to put on the lip assist spring. You want the maximum force

you can get and still have the lip fall back to the vertical position.

Repeat the following sequence until the lip doesn’t fall back to the vertical position. Grab the lip end

and manually extend lip. Release the lip. If it falls to the vertical position tighten spring nut clockwise.

When lip doesn’t come down to vertical position you have went too far and you need to back off the

nut slightly.

Deck Raising Mechanism

It is important to know how much counterbalance force you need to achieve proper operation.

When making your counterbalancing adjustments, take up on all springs approximately the same

amount.

Your deck needs to come up with enough speed to provide the momentum to extend the lip as

previously outlined. If the lip doesn’t extend when the deck comes up you need more

counterbalancing force. Back off on counterbalance springs by turning the bolts counter clockwise.

Other causes of malfunction are as follows:

1. Platform hitting sides of pit

2. Bent ratchet bar

3. Worn ratchet or paw teeth

4. Broken activating cable

3

Page 4

PARTS LIST

6

11

12

13

14

15

ITEM NO.

1

2

3

4

5

6

7

8

N/S

9

10

11

12

13

14

15

17

18

19

20

21

22

N/S

N/S

N/S

N/S

N/S

N/S

N/S

N/S

1

19

PART NUMBER

D-COMP

D-TR

D-TRPB

D-CBS

D-CBSB-**

D-URP

D-LRP

D-REL-CH

D-REL-RF-KIT

D-UTLP

D-LTLP

D-UPLP

D-CY

D-W

D-TPIN

D-CTP

D-TC

D-SS

D-BPIN

D-LR

D-LS

D-LAM

HNG-CST

DM2-6-HP

DM2-7-HP

D-LAM-LP

DM2-**-**-20,000LA

DM2-**-**-50,000LA

DM2-**-TTG

D-ES-SPG

20

17

2

3

10

4

18

21

5

22

7

8

DESCRIPTION

Ratchet Hold Down Assembly (38 lbs.)

Trunion

Trunion Pillow Block Bearings

Counter Balance Springs

Spring Bolt (must have dock model #)

Upper Ratchet Pin

Lower Ratchet Pin

Release Chain

Release Chain Retrofit Kit with Rollers

Upper Trunion Link Pin

Lower Trunion Link Pin

Upper Link Pin (lip kick mech.)

Lip Cylinder (shock absorbers)

Washer

Top Cylinder Pin

Cotter Pin

Lip Trip Cable with Spring

Spring Shackle

Bottom Cylinder Pin

Lip Rod

Lip Spring

Complete Lip Actuating Mechanism

Hinge Block (Casting Weldment)

Hinge Pin for 6’ Wide Leveler

Hinge Pin for 7’ Wide Leveler

Lip Post for Actuating Mech.

Lip Assembly (Must have length + width)

Lip Assembly (Must have length + width)

Telescopic Toe Guard (Must have model number)

Emergency Stop Return Spring

9

4

Page 5

Loading...

Loading...