Page 1

VESTIL MANUFACTURING CORPORATION

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-7586 • Fax (260) 665-1339

E-mail: sales@vestil.com • www.vestil.com

Drum Handling Equipment

Contents

Warnings and Safety Instructions ................ 1

Replacement Parts and Receiving .............. 1

Revised 10-07

A company dedicated to solving ergonomic and

material handling problems since 1955

.

INSTRUCTION

GUIDE

DELUXE ROTATING DRUM CART • RDC-1000

DRIP PAN INSTALLATION INSTRUCTIONS

What you will need .......................................... 1

Installation Instructions ................................... 1

WARNINGS & SAFETY INSTRUCTIONS

• Ensure that all employees understand and follow

the following instructions.

• Failure to read and understand these instructions

before assembling the unit constitutes a misuse of

the product. All persons involved in performing this

task must be familiar with this material.

• Maintenance and repairs are to be done only by

personnel qualified to perform the required work.

Consideration will not be given for warranty repair

charges without prior written authorization from the

manufacturer.

REPLACEMENT PARTS

We take pride in using quality parts on the equipment

we manufacture. We are not responsible for equipment

problems resulting from the use of unapproved replacement

parts.

To order replacement or spare parts for this

equipment, contact the factory.

In any communication with the factory please be

prepared to provide the model and serial number of the unit.

RECEIVING INSTRUCTIONS

It is possible that this unit could incur damage during

transit.

Inspect the parts and packaging closely when it

arrives.

either the packaging or to the unit when it is being received,

immediately make a note of it on the packing slip!

upon its arrival to ensure that there is no concealed damage

or to enable a timely claim with the carrier for freight damage.

ordered.

If you see evidence of damage or rough handling to

It is important that you remove the unit’s packaging

Also verify that the unit and its specifications are as

DRIP PAN INSTALLATION INSTRUCTIONS

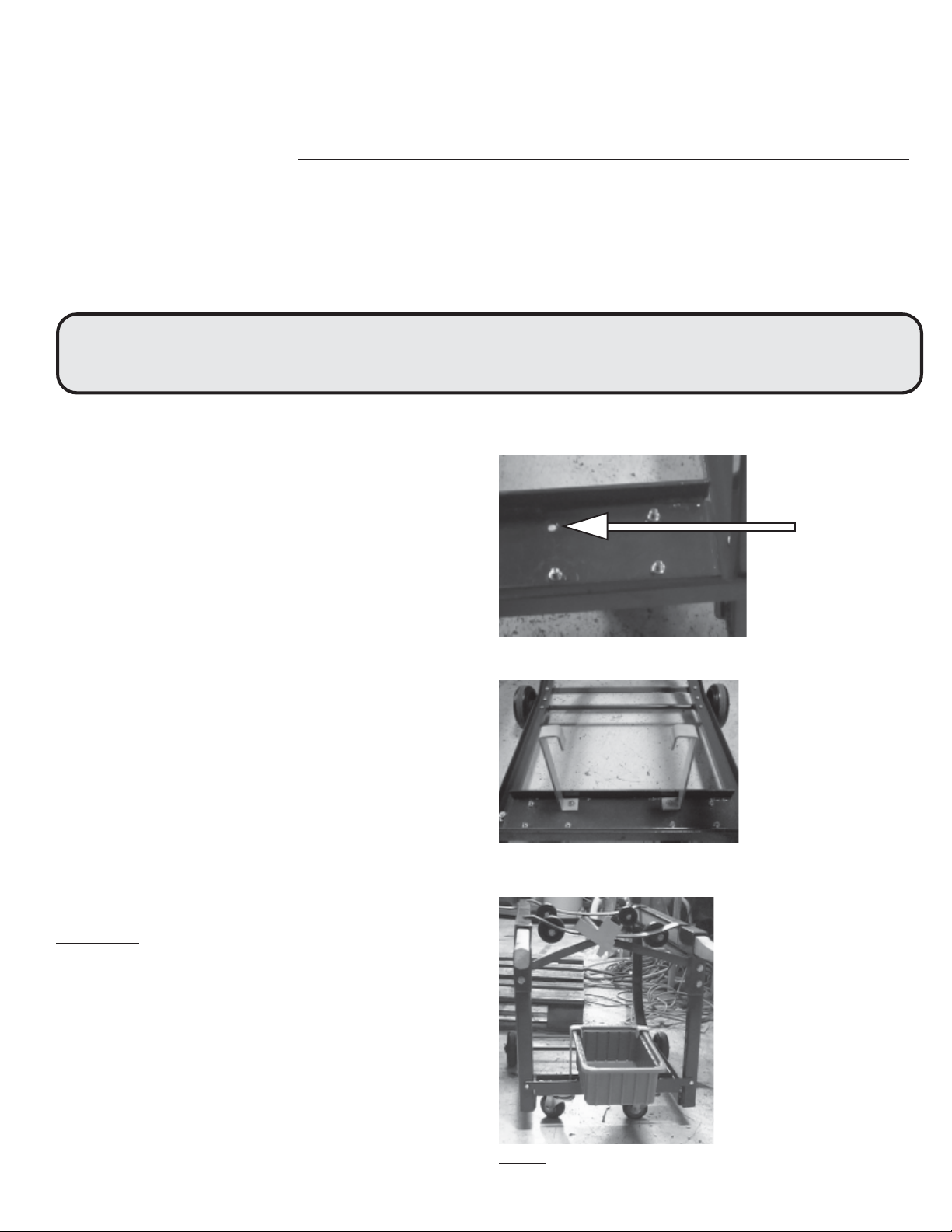

STEP ONE

Remove rear

inside nut and

bolt from both

swivels casters.

STEP TWO

Using original nuts and

bolts, install drip pan

brackets.

STEP THREE

Tilting drip pan forward

slightly to clear bracket

fingers, slide drip pan into

brackets.

Slide drip pan in or out to

align with spout of drum.

FOR DRIP PAN INSTALLATION,

YOU WILL NEED:

1. Phillips Screwdriver

2. Crescent Wrench

Approximate installation time: 10 minutes

NOTE: All drip pan installations use existing hardware from the

front swivel casters of the unit. (No hardware is shipped with

the brackets.)

Loading...

Loading...