Page 1

VESTIL MANUFACTURING CORPORATION

2999 North Wayne St., Angola, IN 46703

Phone (260) 665-7586 • Fax (260) 665-1339

E-mail: sales@vestil.com • www.vestil.com

Revised 11-07

A company dedicated to solving ergonomic and

material handling problems since 1955

.

Fork Truck Attachments

OWNER’S

MANUAL

PALLET DUMPER / RETAINER

PAL-D/R

Contents

Safety Instructions for the Operator ................ 2

Installation Instructions.................................... 2

Operation Instructions ..................................... 2

Loading Instructions ........................................ 2

FAILURE TO READ AND COMPLY WITH OWNER'S MANUAL MAY RESULT IN ACCIDENT, LOSS, DAMAGE, INJURY OR DEATH!

Routine Maintenance .......................................3

Location of Center of Gravity............................4

Safety Label Identification ................................ 5

Warranty........................................................... 6

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

• Read and understand the owner’s manual before using the

pallet dumper/retainer.

• Ensure that all safety and warning labels stay in place and

are legible. See the labels page in this manual.

• Observe all applicable OSHA laws regulating the use of this

Fork Truck Attachment.

• Secure the pallet dumper/retainer to the forklift mast using

the provided restraint strap before use.

• Never operate the pallet dumper / retainer unless you are

watching it.

• Never use the pallet dumper / retainer if the cradle is in need

of repairs or in the case of a malfunction.

• Do not stand below any part of a raised pallet dumper /

retainer.

• Never exceed the 2000 pound maximum loading capacity of

the pallet dumper/retainer.

• Consult factory for uneven loading or overhung loading.

• Not to be used as a personnel lift.

•

WARNING

of structural load.

• Fork truck manufacturers are to be consulted when

accessories are used that affect the truck’s capacity and safe

operation. The unit’s load-loss and center-of-gravity will be

made available on request. See OSHA 1910.178(a)5.

: Never use the platform to lift or support any type

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected prior to

shipment. However, it is possible that the unit may incur

damage during transit. If damage is noticed when unloading,

make a note of it on the BILL OF LADING. Remove all packing

and strapping material, then inspect the unit again for damage.

IF DAMAGE IS EVIDENT, FILE A CLAIM WITH THE CARRIER

IMMEDIATELY!

• When elevation is not required, always transport the

pallet in the lowered position.

• Always transport pallet only in horizontal position when

fork truck is moving.

• Do not allow pallet to impact the floor, ground, or dumping

station etc., or there may be damage to the unit.

• Remove pallet and all loads before working on unit.

• Consult factory if adding or performing any modification

to the original equipment.

• Use only maintenance parts supplied or approved by the

manufacturer.

PAL-D/R

1

Page 2

SAFETY INSTRUCTIONS FOR THE OPERATOR

1.) Please read all instructions THOROUGHLY before attempting to operate your new pallet dumper/retainer.

2.) The model PAL-D/R has a maximum capacity rating of 2,000 pounds. DO NOT exceed this rating as the unsafe

condition that may result could cause damage or excessive wear, or make the unit awkward to handle.

3.) When operating, loading, unloading, or maintaining your pallet dumper/retainer, always use care and good judgement,

have good footing and a firm hold. Keep hands and loose clothing etc., away from all moving parts. Never allow anyone

to be below any part of a raised pallet dumper/retainer. Read operating instructions before operation.

CAUTION

•

•

CAUTION

maintenance personnel if you notice damage to any part of carrier.

: Keep the pallet dumper/retainer level or slightly tilted back toward the fork truck.

: Never use the carrier if it is in need of repairs or if it seems to be malfunctioning. Notify your supervisor or

INSTALLATION INSTRUCTIONS

1.) With the unit sitting on the floor, lower the forks of the fork truck, aligning them with the fork pockets on the PAL-D/R.

2.) Slowly move the fork truck forward until the forks are fully inserted into the fork pockets.

3.) Secure the PAL-D/R to the fork truck by looping the restraining strap around the fork carriage so there is no slack and

fastening it back to itself with the hook.

OPERATION INSTRUCTIONS

1.) With the PAL-D/R properly installed on the fork truck, adjust the mast height so the pallet support forks are aligned with

the pallet opening.

2.) Slowly move the fork truck forward until the PAL-D/R forks are completely through the pallet and the pallet retaining

angles have cleared the pallet end.

3.) Raise the forks slightly so the pallet retaining angle is above the top of the pallet. DO NOT lift the pallet off of the floor

yet.

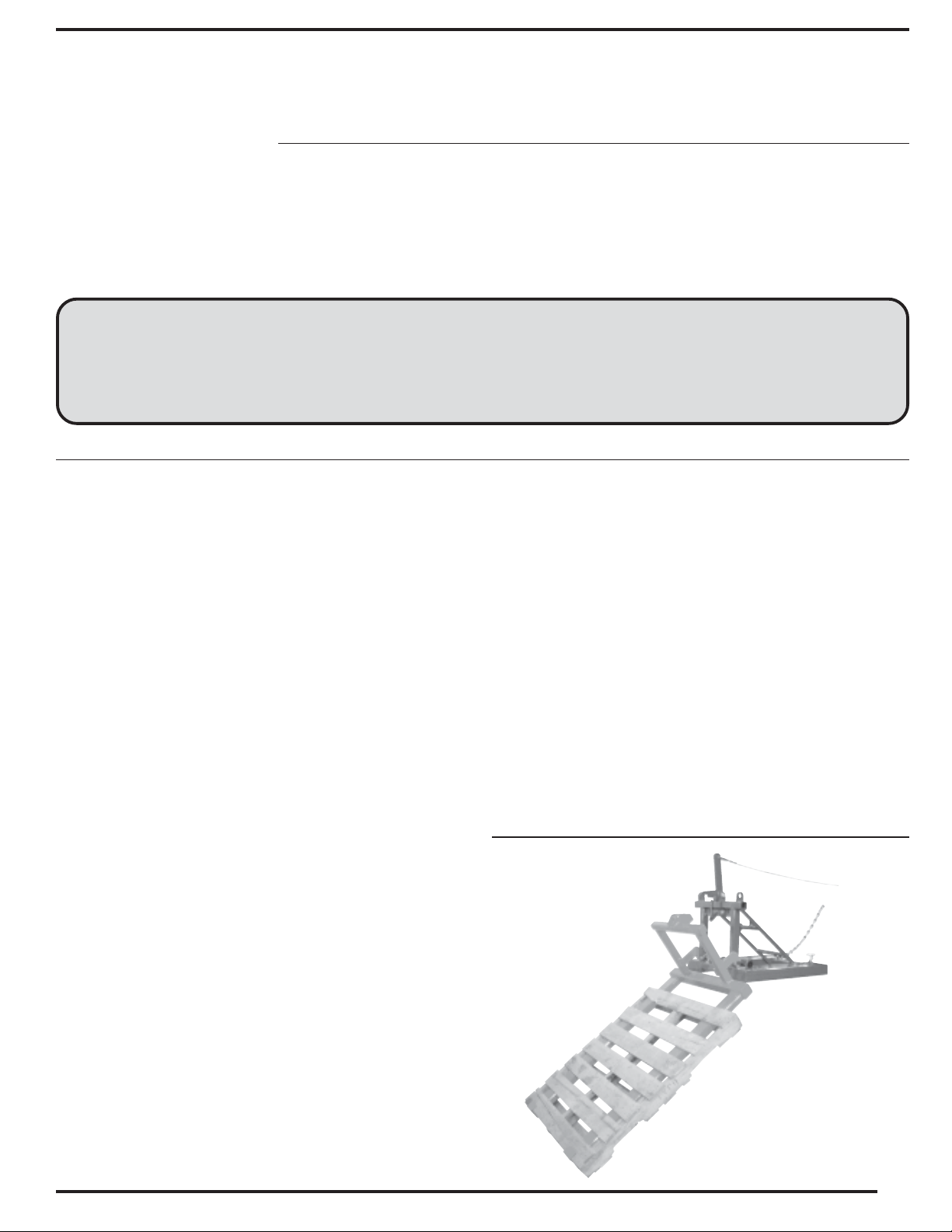

4.) Carefully move the fork lift backwards an inch or two to lock the pallet into the retaining angle. See Figure 1.

5.) When elevation is not required, always transport the pallet in the lowered position.

AT THE DUMPING AREA:

6.) Raise the fork mast so that the unit is above the dumping area, making sure the mast is high enough so that when the

pallet is dumped, neither the unit or the pallet hit any structure below it.

7.) When in place, pull the release lever to dump the forks.

8.) To re-latch the fork carriage, slowly lower the unit to the floor. When the front edge touches the floor, slowly (and

carefully) move the fork truck backwards while lowering the forks. When the unit is on the floor, the latch will re-engage

the latch pin.

•

Caution:

9.) Insure that the pallet is still secure in the pallet retaining angles before proceeding.

• Caution:

•

Caution:

unit.

If latch does not re-engage, make sure the release cable is not pulled.

Inspect the pallet before using. A damaged pallet may cause damage or personal injury.

Do not let any part of the unit or pallet hit the floor or dumping station while dumping. Doing so can damage the

Figure 1

Retaining

Hook

LOADING INSTRUCTIONS

1.) The PAL-D/R should be loaded with a secure and evenly-distributed load.

2.) The PAL-D/R is not intended to be used with a load that overhangs the pallet. Contact the factory for overhung load

applications.

3.) The load should never exceed the center of gravity or capacity on the fork truck’s dataplate.

2

Page 3

ROUTINE MAINTENANCE & SAFETY CHECKS

BEFORE EACH USE INSPECT FOR THE FOLLOWING:

1.) Proper operation of the securing chain’s snap.

2.) Obvious damage to, or structural deformation.

3.) Wear or damage to the pallet carriage.

4.) Wear or possible damage to the pallet retaining fingers/stops.

INSPECT MONTHLY FOR:

1.) Inspect all moving parts, framework, and contact areas for signs of wear, fatigue or loosening. Tighten, adjust or replace

parts as necessary to prevent failure and maintain proper functions.

2.) Worn, loose, or damaged hardware on the safety chains/restraining strap and hinges.

3.) Damage to the fork pockets.

4.) The overall condition of the unit.

5.) The integrity of the welds at all joints.

6.) Overall squareness and rigidness of the platform.

7.) Information and warning labels being in place and in good condition.

8.) The need to clean off rust, dirt and debris.

• Maintenance and repairs are to be done only by personnel qualified to perform the required work.

•

Caution:

authorization for changes to the equipment could void the warranty.

Do not perform any modifications to the platform without the manufacturer’s approval. Failure to receive

3

Page 4

LOCATION OF CENTER OF GRAVITY

HCG: 37-1/4”

VCG: 5-1/2”

LOST LOAD: 340 LBS.

LOAD CENTER: 63-3/4”

(Effective thickness equals the total fork length minus the fork tube length.)

4

Page 5

SAFETY LABEL IDENTIFICATION

• Product safety signs or labels should be periodically inspected and cleaned by the product users as necessary to maintain

good legibility for safe viewing distance — ANSI 535.4 (10.21). Contact the manufacturer for replacement labels.

569

VESTIL MANUFACTURING

569

CORPORATION

Phone (260) 665-7586 • Fax (260) 665-1339 E-mail: sales@vestil.com • www.vestil.com

207

MODEL/MODÉL/MODÈL ___________

CAPACITY ___________________ lbs.

CAPACIDAD/CAPACITÉ ________ kgs.

SERIAL/SERIE/SÉRIE _____________

VESTIL MANUFACTURING CORPORATION

sales@vestil.com • www.vestil.com

207

REV 09/03

577

VESTIL

MANUFACTURING

CORPORATION

Phone (260) 665-7586 • Fax (260) 665-1339

E-mail: sales@vestil.com • www.vestil.com

!

WARNING ADVERTENCIA

SECURELY ATTACH

the safety locking

device to the forklift

VESTIL MANUFACTURING CORPORATION • Phone (260) 665-7586 • Fax (260) 665-1339 • sales@vestil.com • www.vestil.com

577

!

SUJETE CON SEGURIDAD

el seguro de cierre

a la transpaleta

!

AVERTISSEMENT

ATTACHER SOLIDEMENT

le dispositif d’arrêt automatique

au chariot élévateur

525

525

5

Page 6

PRODUCT WARRANTY

90-DAY YEAR LIMITED WARRANTY

The manufacturer warrants for the original purchaser against defects in materials and workmanship under normal use one

year after date of shipment (not to exceed 6 months after date of manufacture). Any part that is determined by the

manufacturer to be defective in material or workmanship and returned to the factory, shipping costs prepaid, will be, as the

exclusive remedy, repaired or replaced at our option. Labor costs for warranty repairs and/or modifications are not covered

unless done at manufacturer’s facilities or pre-approved in advance by the manufacturer. Any modifications performed

without written approval of the manufacturer may void warranty. This limited warranty gives purchaser specific legal rights

which vary from state to state.

All specifications are subject to change without notice.

LIMITATION OF LIABILITY

To the extent allowable under applicable law, the manufacturer’s liability for consequential and incidental damages is

expressly disclaimed. The manufacturer’s liability in any event is limited to, and shall not exceed, the purchase price paid.

Misuse or modification may void warranty.

Warranty does not cover labor or consequential damages including, but not limited to, business interruption costs, lost

profits, or lost business opportunities.

WARRANTY DISCLAIMER

The manufacturer has made a diligent effort to accurately illustrate and describe their products. However, such illustrations

and descriptions are for the sole purpose of identification, and do note express or imply a warranty that the products are

merchantable or fit for a particular purpose, or that the products will necessarily conform to the illustrations or descriptions.

The provisions of the warranty shall be construed and enforced in accordance with the Uniform Commercial Code and laws

as enacted in the State of Indiana.

DISPOSITION

Our company will make a good faith effort for prompt correction or other adjustment with respect to any product that proves

to be defective within the Limited Warranty Period. Warranty claims must be made in writing within said year.

6

Loading...

Loading...