Page 1

T & S Equipment Company

2999 North Wayne St., Angola, IN 46703

Ph: 260-665-9521 Fax: 260-665-1339

E-mail: sales@tseq.com • www.tseq.com

Gantries and Jib Cranes

Contents

Safety Precautions .......................................... 1

Receiving Instructions ..................................... 1

Warranty.......................................................... 1

Revised 05-02

A company dedicated to solving ergonomic and material

handling problems since 1955

.

OWNER'S

MANUAL

OVERHEAD LOAD LIFTER

MODEL OLA

Operation ......................................................... 2

Inspection Instructions ..................................... 2

Warning Label Identification ............................. 3

SAFETY PRECAUTIONS

Read owner's manual completely before operating unit!

Before operating the pallet lifter, read and understand

this owners manual to insure safe operation. Inspect

before each use for damage parts or components.

Make sure all warning labels are in good condition and

are followed when operating.

This Overhead Pallet Lifter is to be used in conjunction

with an overhead hoist with the proper capacity only.

The pallet lifter weight needs to be added into the total

weight of the load. DO NOT stand under the lifter when

in use.

• Never exceed the maximum capacity printed on lifter!

• Check for damage and be sure all hardware is tight

before each use.

• Never move or load unless both adjustment pins are

fully inserted.

• Stand clear of load while loading and unloading.

• Never adjust height when loaded.

• Never stand under load.

• Keep clear of electrical wires or any other electrical

equipment.

• Make sure all operator safety labels are in place.

the unit again for damage. IF DAMAGE IS EVIDENT,

FILE A CLAIM WITH THE CARRIER IMMEDIATELY!

WARRANTY

This product is warranted for 1 year from date of

purchase to be free of manufacturing defects in material

and workmanship.

This warranty does not cover normal wear of

parts or damage resulting from any of the following:

negligent use or misuse of the product, use or application

contrary to installation instructions, or disassembly,

repair or alteration by any person prior to authorization

from a factory representative.

RECEIVING INSTRUCTIONS

Every unit is thoroughly inspected prior to

shipment. However, it is possible that the unit may incur

damage during transit. If damage is noticed when

unloading, make a note of it on the BILL OF LADING.

Remove all packing and strapping material, then inspect

OVERHEAD LOAD LIFTER

MODEL OLA

1

Page 2

OPERATION

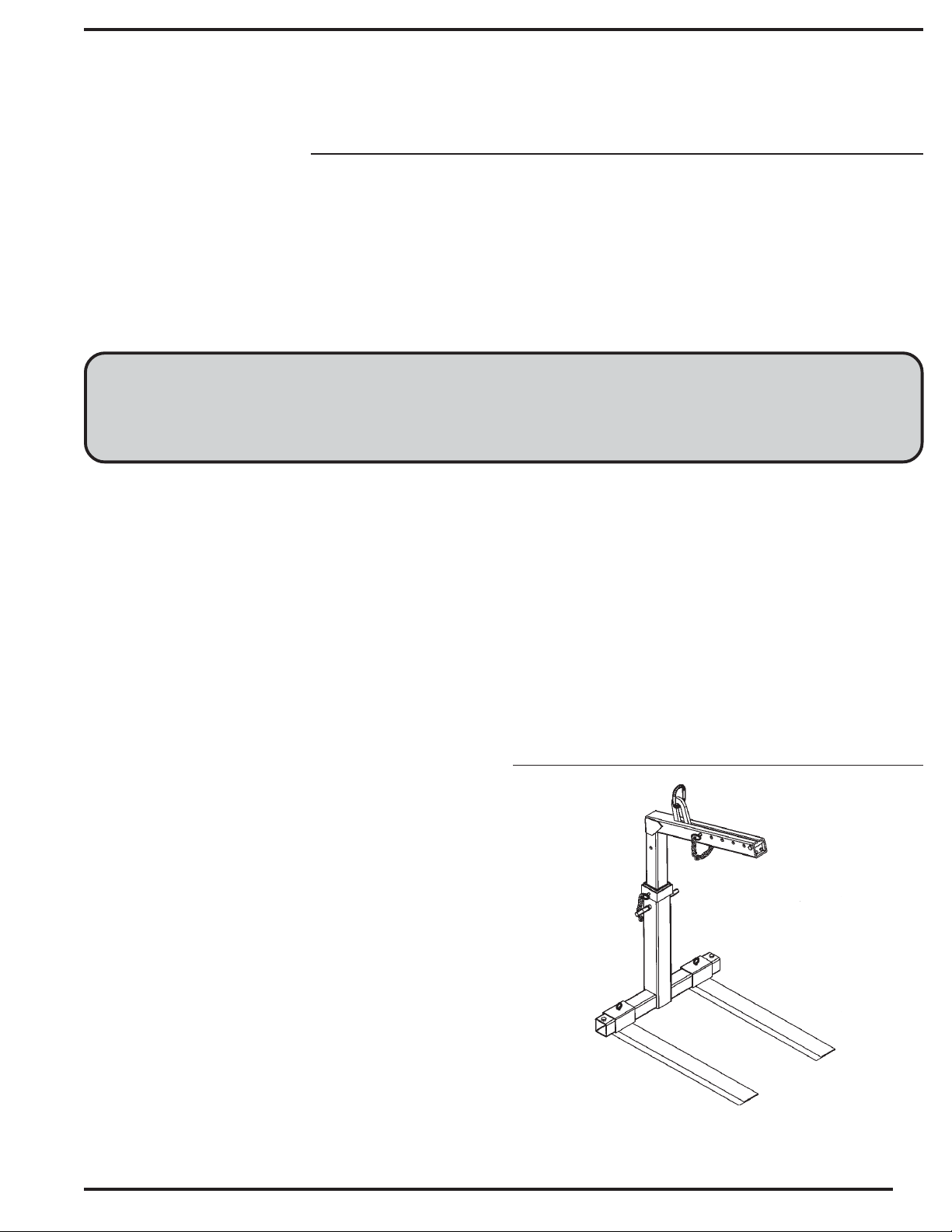

This lifter is designed to be used in conjunction with

closed bottom skids. Loads used wit this lifter needs to

be secure on the skid and symmetrically distributed on

the skid. Loose items falling off the pallet midair can

cause the center of gravity to shift and cause the entire

load to dump.

Place the forks of the pallet lifter through the pallet fork

slots until the forks are fully inserted. If the inside

clearance height needs to be adjusted, remove the rear

pin and either set the height with a hoist hooked into the

bail or by hand. After setting the height, replace the pin

and install the safety pin. Models with the adjustable

fork width option can set the fork width by loosening the

retainer bolts on the top of each fork and sliding the

forks to the desired width. The forks must be set the

same distance from the center in order to insure proper

balance. After the forks have been set retighten the

retaining bolts securely.

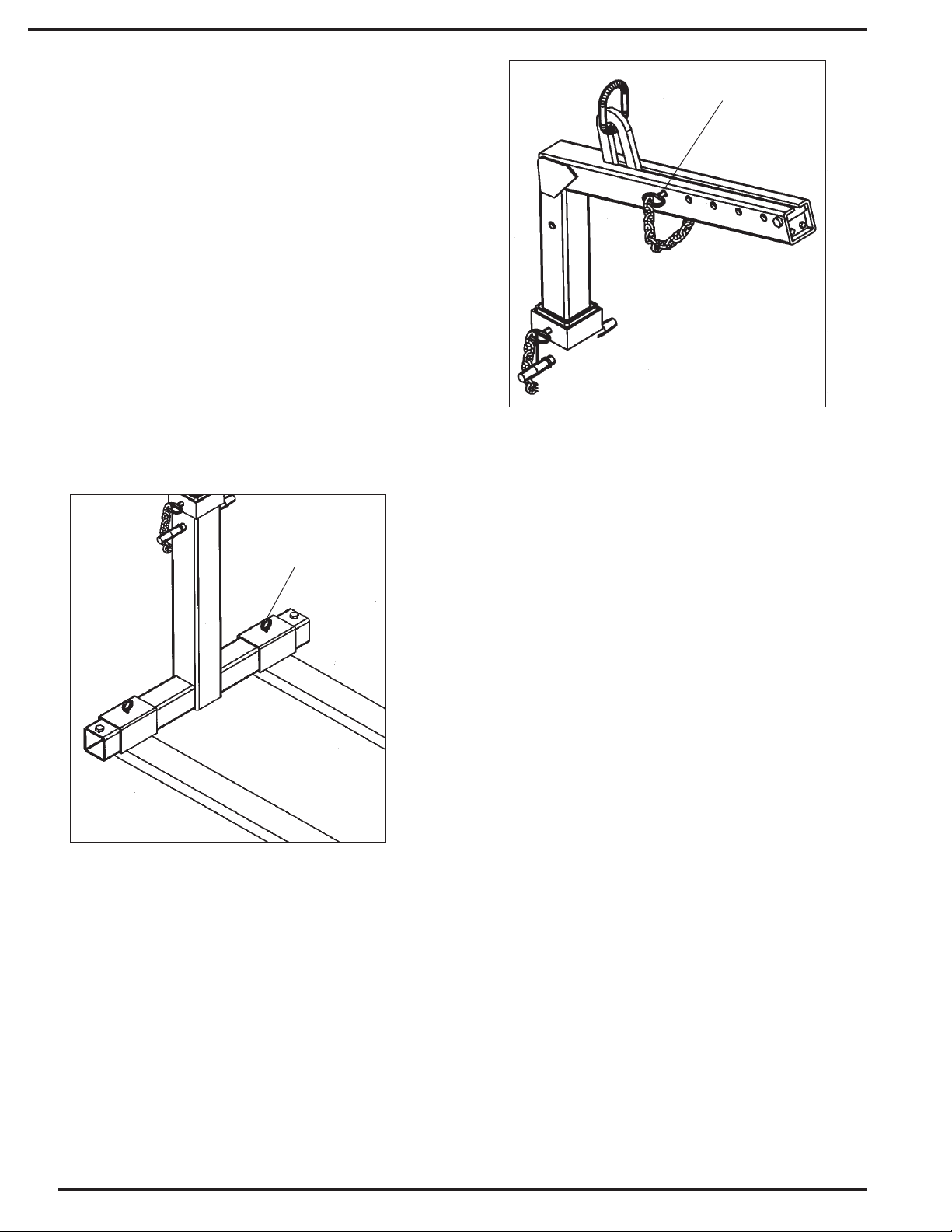

Fork Retaining Bolt

Bail Restraint Pin

Using the overhead hoist, pick up the pallet lifter and

load slowly to check for load balancing and stability. If

the load is not balanced position the pallet on the forks

and retry. Never extend the pallet past the edge of the

forks. Never extend the pallet past the edge of the forks.

If the pallet center balance is off enough, the bail stop

pin may need to be repositioned.

Set the bail restraint pin so that the bail will stop at

approximately the center of the load. Be sure all pins

are in place and the safety pins are inserted into the

pins. Connect the hoist hook through the bail pickup

loop on the pallet lifter. Be sure that the hoist has a

safety latch to insure the hook cannot slide off the bail.

When moving the pallet lifter empty, the bail will return

to the lower position. To be sure the bail does not slide

forward, place the bail adjustment pin into the first hole

position (first hole on the lower end).

When trying to position the pallet lifter with the load, use

the handles located on the rear of the unit. Never place

your feet underneath the unit when positioning the

load. To remove the pallet from the lifter, place the load

on the ground and with the lifter slightly raised remove

the pallet lifter from the rear of the pallet. When the

weight of the pallet has been removed from the forks,

the pallet lifter bail will slide back and allow the lifter to

balance when unloaded.

INSPECTIONS

As with all equipment, frequent inspections should be

preformed on this unit to insure safe operation. The

intervals of inspection should be determined by the

frequency of use. Inspect for cracked welds, worn or

damaged components or torn or damaged warning

labels. This lifter is built in accordance with ASME

B30.20. A copy of this standard can be attained from

ASME. Guidelines for testing and inspections are given

in this standard.

2

Page 3

WARNING LABEL IDENTIFICATION

MAKE SURE ALL WARNING LABELS ARE IN PLACE!

2

1

3

*Product safety signs or labels should be

periodically inspected and cleaned by the

product users as necessary to maintain

good legibility for safe viewing distance . . .

ANSI 535.4 (10.21)

Contact manufacturer for replacement labels if needed.

!

CAUTION

1

BAIL STOP PIN MUST BE PLACED IN THE

HOLE THAT WILL STOP THE BAIL OVER

CENTER OF THE LOAD. FAILURE TO DO THIS

MAY RESULT IN LOAD DUMPING.

T&S Equipment Company

Phone (219) 665-9521 Fax (219) 665-1339

2

!

CAUTION

CONSULT OWNERS MANUAL BEFORE USE

3

!

CAUTION

BAIL ADJUSTMENT PIN MUST BE

PLACED IN FIRST HOLE WHILE MOVING

PALLET LIFTER WHEN EMPTY

T&S Equipment Company

Phone (260) 665-9521 • Fax (260) 665-1339 • www.tseq.com

386

387

388

3

Page 4

Material Handling Problem Solvers

Scissor Lift Table

Pallet Server

XII

I

High Rise Lift

XI

Mobile Lift & Tilt

Work Stand

Time is money.

X

Increased productivity

equals greater profitability,

cost minimization and worker

IX

compatibility. Ergonomic

products will assist you

with your production and

safety goals.

VIII

VII

VI

II

III

VI

V

45° Container Tilter

Ground Lift Tilter

Copyright 2002 T&S Equipment Company

4

Loading...

Loading...