Page 1

01/11 rev. 10/26/2017 LM, MANUAL

LM-Series and LMS-Series Fork Truck Attachments

VESTIL MANUFACTURING CORP.

2999 North Wayne Street, P.O. Box 507, Angola, IN 46703

Telephone: (260) 665-7586 -or- Toll Free (800) 348-0868

Fax: (260) 665-1339

www.vestilmfg.com e-mail: info@vestil.com

LM-HRT &

LM-HRNT

LMS-EBT &

LMS-EBNT

Use and Maintenance Manual

LM-OBT &

LM-OBNT

LM-1T &

LM-1NT

LM-EBT &

LM-EBNT

Receiving instructions:

After delivery, remove the packaging from the product. Inspect the product closely to determine whether it

sustained damage during transport. If damage is discovered during the inspection, immediately record a

complete description of the damage on the bill of lading. If the product is undamaged, discard the packaging.

NOTE:

The end-user is solely responsible for confirming that product design, installation, use, and maintenance

comply with laws, regulations, codes, and mandatory standards applied where the product is used.

Table of Contents Table of Figures

Signal words……………………… 2 Fig. 1: LM-1T & -1NT Exploded Parts Diagrams, Parts Lists, Center of Gravity………… 3 - 6

Safe use recommendations……. 2 Fig. 2: LM-OBT & -OBNT Exploded Parts Diagrams, Parts Lists, Center of Gravity........ 7 - 10

Safety Recommendations……… 2 Fig. 3: LM-HRT & -HRNT Exploded Parts Diagram, Parts Lists, Center of Gravity…….. 11 - 14

Loading & Use Instructions…….. 23 - 25 Fig. 4: LM-EBT & -EBNT Exploded Parts Diagram, Parts Lists, Center of Gravity……... 15 - 18

Inspections & Maintenance…….. 25 - 26 Fig. 5: LMS-EBT-46 & -EBNT-46 Exploded Parts Diagram, Parts Lists, Centers……….

Labeling diagram…………..……. 27 of Gravity………………………………………………………………………………… 19 - 22

Limited Warranty………………… 28

Copyright 2017 Vestil Manufacturing Corp.

Page 2

01/11 rev. 10/26/2017 LM, MANUAL

SIGNAL WORDS

This manual classifies personal injury risks and situations that might cause property damage with “Signal

words”. Signal words indicate the seriousness of injuries that might result if a particular act or omission occurs.

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or

Identifies practices likely to result in product/property damage, such as operation that might

Safe Use Recommendations:

Vestil strives to identify all foreseeable hazards associated with the use of its products. However, material handling

is dangerous and no manual can address every possible risk. The most effective means for avoiding injury is for the

end user to apply sound judgment whenever using this device.

Material handling is dangerous. Improper or careless operation might result in serious personal

injuries. Acquire a copy of the latest version of ANSI B56.1, which is freely downloadable on www.ITSDF.org. Apply

all relevant portions of Part II “For the User”. The following recommendations are intended to complement the

guidance provided in B56.1.

Always use this boom in compliance with all rules applied to fork truck attachment at your worksite.

Failure to read and understand the instructions included in this manual before using or servicing the boom

constitutes misuse.

DO NOT use a damaged boom. Inspect the boom before each use according to the relevant inspection instructions

that appear on p. 25-26 to determine whether the boom is in normal operating condition.

DO NOT contact electrified wires with the boom.

DO NOT use the boom if the safety chain is damaged or missing. The only purpose of the safety chain is to prevent

the boom from sliding off of the forks—it is NOT intended or designed to bear the full load rating.

DO NOT lift the boom until it is securely connected to the carriage of the fork truck with the restraint strap.

DO NOT attempt to lift a load weighing more than the boom’s maximum rated load. Load ratings for all boom

variants appear on pages 4, 6, 8, 10, 12, 14, 16, 18, 20, and 22.

NEVER lift this boom over people.

DO NOT permit any person to stand beneath or travel under the boom or the load.

Inform everyone in the area that you are going to use the boom. Instruct them to stay clear of the boom and the

supported load during use.

DO NOT allow people to ride on either the boom or the load.

DO NOT use the boom if any product label (see p. 27) is unreadable, damaged, or missing. Contact Vestil to order

a replacement label(s).

ALWAYS apply proper (fork) lift operation practices learned during your training program.

Always make sure that shackle pins (see shackles in exploded parts diagrams, pp. 3-22) are secure before applying

a load to the load hook. Tighten the screw pin before each use.

Before raising the boom from the floor AND before attaching the load to the boom, tilt the fork lift mast away from

the boom to ensure that the boom will not slide towards the tips of the forks.

ALWAYS follow the loading and use instructions that appear on p. 23-25. Failure to properly position a load might

cause a dangerous degree of load swing when the boom is elevated.

Only use the boom to lift loads. DO NOT use the boom to drag items.

Transport loads with the bottom of the load and the forks as low as possible.

Drive suspended loads at low speed. Brake and turn slowly cautiously.

DO NOT modify the boom in any way. Modifications automatically void the limited warranty (see p. 28) and might

make the boom unsafe to use.

SERIOUS INJURY. Use of this signal word is limited to the most extreme situations.

SERIOUS INJURY.

MODERATE injury.

damage the boom.

Copyright 2016 Vestil Manufacturing Co. Page 2 of 28

Page 3

01/11 rev. 10/26/2017 LM, MANUAL

1

1

1

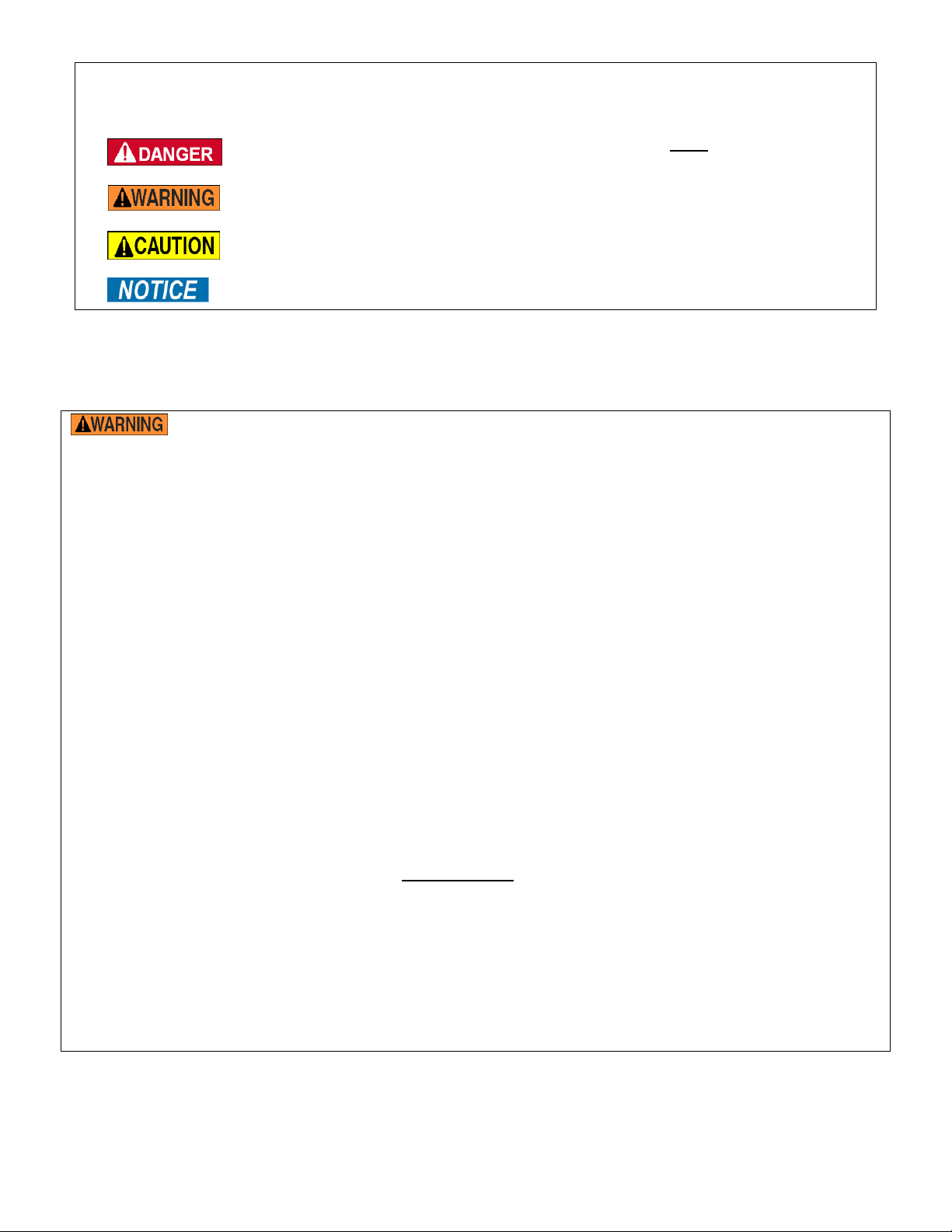

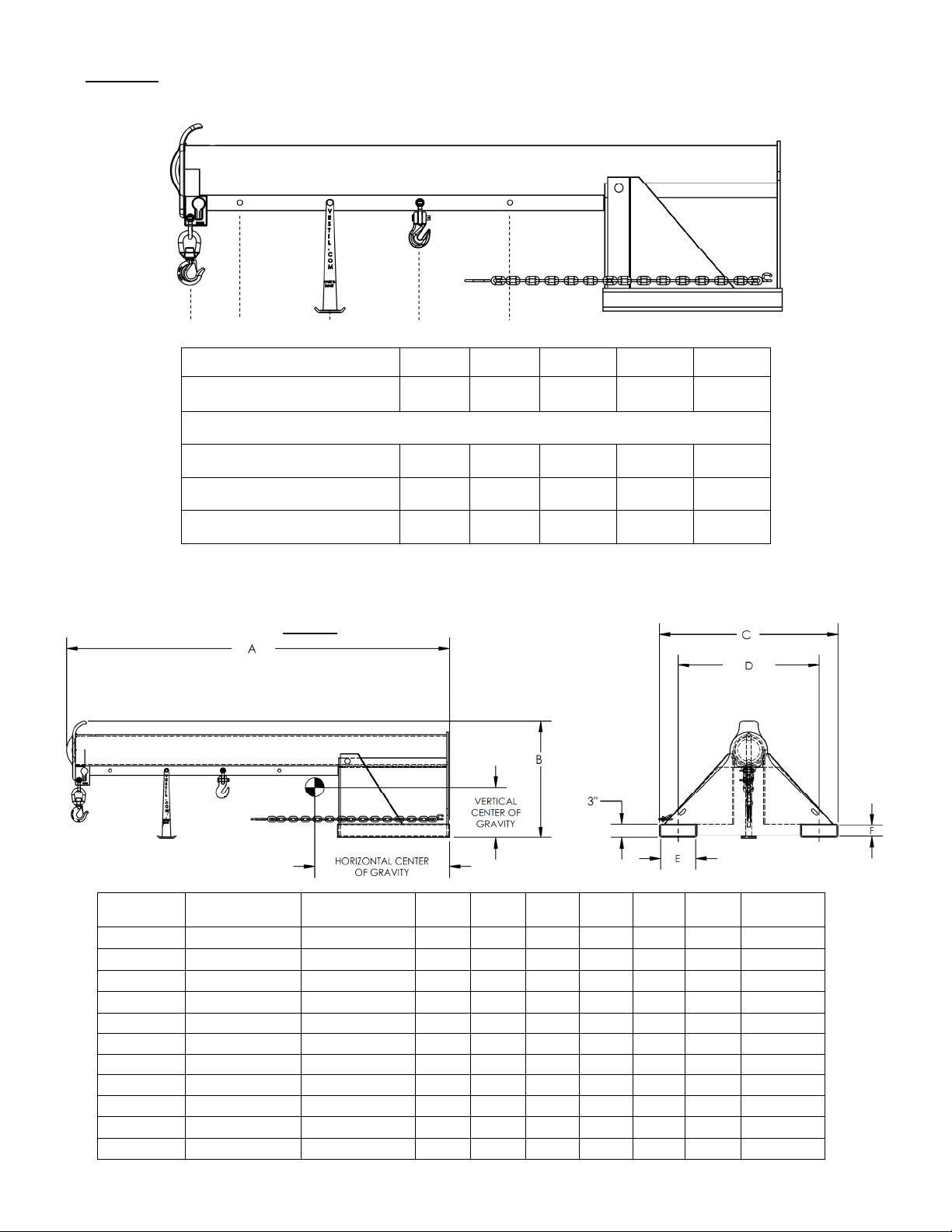

FIG. 1A: LM-1T-3-24 & LM-1T-4k Exploded Parts Diagram & Bill of Materials

FIG. 1B: LM-1T-6k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-176

1

08-514-111

08-514-177

08-514-178

2 08-514-261 Weldment, inner tube 1

3 08-014-134 Frame, front support leg casting 1

4 08-025-004 X-handle, locking bolt 1

5 08-145-001 Swivel hook, 2-ton 1

6 08-145-041 5/16” snap hook 1

7 08-145-010 1/2” shackle, 2-ton 1

8 99-145-037 5/16” chain 36” long 1

9 99-145-084 Lap link 1

10 99-645-019 2-ton hook and shackle 1

11 11211

12 36109 1/2” – 13UNC hex nut 1

Weldment, frame, boom/base, 4k:

LM-1T-4-11

LM-1T-4-24 & LM-1T-3-24

LM-1T-4-30

LM-1T-4-36

/2” -13UNC x 2” HHCS zinc-plated

bolt

Item Part No. Description Quantity

08-514-179

1

08-514-113

08-514-180

08-514-181

2 08-514-261 Weldment, inner tube 1

3 08-014-134 Frame, front support leg casting 1

4 08-025-004 X-handle, locking bolt 1

5 08-145-001 Swivel hook, 2-ton 1

6 08-145-002 Swivel hook, 3-ton 1

7 08-145-041 5/16” snap hook 1

8 08-145-010 1/2” shackle, 2-ton 1

9 99-145-019 5/8” 3.25-ton shackle 1

10 99-145-037 5/16” chain 36” long 1

11 99-145-084 Lap link 1

12 11211

13 36109 1/2” – 13UNC hex nut 1

Weldment, frame, boom/base, 6k:

LM-1T-6-11

LM-1T-6-24

LM-1T-6-30

LM-1T-6-36

/2” -13UNC x 2” HHCS zinc-plated

bolt

FIG. 1C: LM-1T-8k Exploded Parts Diagram & Bill of Materials

1

1

1

1

1

1

1

1

1

1

Item

Copyright 2016 Vestil Manufacturing Co. Page 3 of 28

Part No. Description Quantity

08-514-115

1

08-514-315

08-514-316

2 08-514-272 Weldment, inner tube 1

3 08-014-134 Frame, front support leg casting 1

4 08-025-004 X-handle, locking bolt 1

5 08-145-002 Swivel hook, 3-ton 1

6 08-145-005 Swivel hook, 5-ton 1

7 08-145-006 7/8” 6.5-ton shackle 1

8 08-145-041 5/16” snap hook 1

9 99-145-019 5/8” 3.25-ton shackle 1

10 99-145-037 5/16” chain 36” long 1

11 99-145-084 Lap link 1

12 11211

13 36110 1/2” – 13UNC zinc-plated hex nut 1

Weldment, frame, boom/base, 8k:

LM-1T-8-24

LM-1T-8-30

LM-1T-8-36

/2” -13UNC x 2” HHCS zinc-

plated bolt

1

1

1

1

Page 4

01/11 rev. 10/26/2017 LM, MANUAL

”

”

”

”

” (33.5 cm)

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

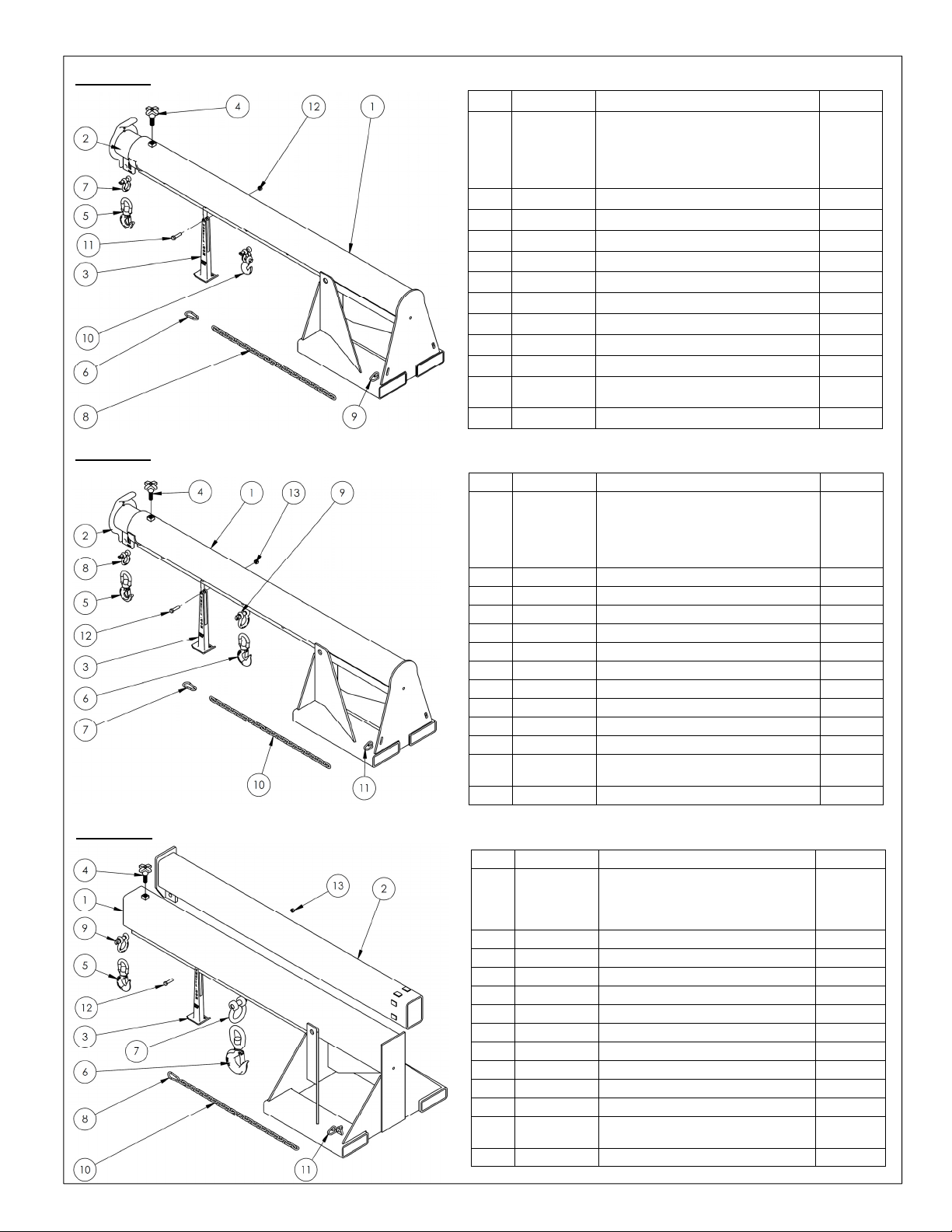

FIG. 1D: LM-1T- 4k, 6k & 8k Centers of Gravity and Maximum Load Ratings for

J I H G F E D C B A

Hook position A B C D E F G H I J

Distance from end of

boom in inches (cm)

Maximum rated load of a load suspended from a single hook located at the corresponding “Hook position”.

LM-1T-3-24

LM-1T-4k

LM-1T-6k

LM-1T-8k

Varying Load Attachment Point and Boom Extension Combinations

36”

91 cm

3000 lb.

1363 kg

4000 lb.

1820 kg

6000 lb.

2727 kg

8000 lb.

3636 kg

48”

122 cm

2750 lb.

1250 kg

3750 lb.

1705 kg

5000 lb.

2272 kg

6650 lb.

3022 kg

60”

152 cm

2500 lb.

1136 kg

3500 lb.

1590 kg

4500 lb.

2045 kg

6000 lb.

2727 kg

72”

183 cm

2250 lb.

1022 kg

3250 lb.

1477 kg

4000 lb.

1820 kg

5300 lb.

2409 kg

84”

213 cm

2000 lb.

909 kg

3000 lb.

1363 kg

3500 lb.

1590 kg

4650 lb.

2113 kg

96”

244 cm

1750 lb.

795 kg

2750 lb.

1250 kg

3000 lb.

1363 kg

4000 lb.

1820 kg

108”

274 cm

1500 lb.

681 kg

2500 lb.

1136 kg

2600 lb.

1181 kg

3500 lb.

1590 kg

120”

305 cm

1250 lb.

568 kg

2250 lb.

1022 kg

2300 lb.

1045 kg

3000 lb.

1363 kg

132”

335 cm

1000 lb.

454 kg

2000 lb.

909 kg

2000 lb.

909 kg

2600 lb.

1181 kg

144”

366 cm

750 lb.

340 kg

1750 lb.

795 kg

1800 lb.

818 kg

2200 lb.

1000 kg

The center of gravity of the boom changes as boom length changes. As shown in the diagram below, the

horizontal center of gravity may be located at any point from RHCG to EHCG:

Retracted horizontal center of gravity (RHCG): boom fully retracted and unloaded. RHCG is measured from

the “origin point” of the above diagram (edges of the fork pockets);

Extended horizontal center of gravity (EHCG): boom fully extended and unloaded. EHCG is also measured

from the “origin point” of the above diagram (edges of the fork pockets);

All other combinations of boom extension and load position produce a horizontal center of gravity located

somewhere between RHCG and EHCG.

FIG. 1E: LM-1T centers of gravity and dimensions

LM-1T-3-24 4813/16” (124 cm) 3211/16 (83 cm) 1313/16” (33.5 cm) 86-1511/4” 13” 32” 24” 257/8” 71/

LM-1T-4-11 51 in. (129.5 cm) 3315/16 in. (86.2 cm) 135/8” (34.6 cm) 86-1531/2” 13” 19” 11” 257/8” 71/

LM-1T-4-24 4813/16 in. (124.0 cm) 3211/16 in. (83.0 cm) 133/

LM-1T-4-30 477/16 in. (120.5 cm) 32 in. (81.3 cm) 1215/16” (32.9 cm) 86-1531/2” 13” 38” 30” 257/8” 71/

LM-1T-4-36 463/16 in. (117.3 cm) 315/16 in. (79.5 cm) 1211/16” (32.2 cm) 86-1531/2” 13” 44” 36” 257/8” 71/

LM-1T-6-11 477/16 in. (120.5 cm) 323/16 in. (81.8 cm) 125/8” (32.1 cm) 86-1531/2” 13” 19” 11” 257/8” 71/

LM-1T-6-24 4511/16 in. (116 cm) 313/16 in. (79.2 cm) 125/16” (31.3 cm) 86-1531/2” 13” 32” 24” 257/8” 71/

LM-1T-6-30 441/2 in. (113 cm) 309/16 in. (77.6 cm) 121/8” (30.8 cm) 86-1531/2” 13” 38” 30” 257/8” 71/

LM-1T-6-36 433/8 in. (110.2 cm) 2915/16 in. (76 cm) 1115/16” (30.3 cm) 86-1531/2” 13” 44” 36” 257/8” 71/

LM-1T-8-24 531/4 in. (135.3 cm) 347/16 in. (87.5 cm) 135/8” (34.6 cm) 845/8-1491/8” 111/2” 32” 24” 269/16” 71/

LM-1T-8-30 531/4 in. (135.3 cm) 347/16 in. (87.5 cm) 135/8” (34.6 cm) 845/8-1491/8” 111/2” 38” 30” 269/16” 71/

LM-1T-8-36 531/4 in. (135.3 cm) 347/16 in. (87.5 cm) 135/8” (34.6 cm) 845/8-1491/8” 111/2” 44” 36” 269/16” 71/

= Center of gravity

Model

Extended horizontal

center of gravity

Copyright 2016 Vestil Manufacturing Co. Page 4 of 28

Retracted horizontal

center of gravity

Vertical center of

gravity

16

A B C D E F G

86-1531/2” 13” 32” 24” 257/8” 71/

2

2

2

2

2

4

4

4

4

4

4

4

21/

21/

21/

21/

21/

21/

21/

21/

21/

21/

21/

21/

2

2

2

2

2

4

4

4

4

4

4

4

Net

weight

434.4 lb.

404.7 lb.

429.3 lb.

447.4 lb.

465.4 lb.

452.7 lb.

477.4 lb.

497.0 lb.

516.5 lb.

665.3 lb.

688.5 lb.

711.7 lb.

Page 5

01/11 rev. 10/26/2017 LM, MANUAL

tem

1

1

1

1

FIG. 1F: LM-1NT-4k Exploded Parts Diagram & Bill of Materials

I

Part No. Description

1

2 08-014-134 Frame, front support leg casting 1

3 08-145-001 Swivel hook, 2-ton 1

4 08-145-041

5 08-145-010

6 99-145-037

7 99-145-084 Lap link 1

8 99-645-019 2-ton hook and shackle 1

9 11211

10 36109 1/2in. – 13 UNC hex nut 1

08-514-319

08-514-128

08-514-320

08-514-321

Weldment, frame, boom/base:

LM-1NT-4-11

LM-1NT-4-24

LM-1NT-4-30

LM-1NT-4-36

5

/16” snap hook

1

/2” 2-ton shackle

5

/16” chain 36” long

/2in. – 13 UNC x 2in. HHCS zinc-

plated bolt

FIG. 1G: LM-1NT-6k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-322

1

08-514-129

08-514-323

08-514-324

2 08-014-134

3 08-145-001 Swivel hook, 2-ton 1

4 08-145-002 Swivel hook, 3-ton 1

5 08-145-041

6 08-145-010

7 99-145-019 5/8” 3.25-ton shackle 1

8 99-145-037

9 99-145-084 Lap link 1

10 11211

11 36109 1/2in. – 13 UNC hex nut 1

Weldment, frame, boom/base:

LM-1NT-6-11

LM-1NT-6-24

LM-1NT-6-30

LM-1NT-6-36

Frame, front support leg

casting

5

/16” snap hook

1

/2” 2-ton shackle

5

/16” chain 36” long

/2in. – 13 UNC x 2in. HHCS

zinc-plated bolt

Quantity

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

FIG. 1H: LM-1NT-8k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-130

1

08-514-317

08-514-318

2 08-014-134

3 08-145-002 Swivel hook, 3-ton 1

4 08-145-005 Swivel hook, 5-ton 1

5 08-145-006 7/8” 6.5-ton shackle 1

6 08-145-041

7 99-145-019 5/8” 3.25-ton shackle 1

8 99-145-037

9 99-145-084 Lap link 1

10 11211

11 36110

Copyright 2016 Vestil Manufacturing Co. Page 5 of 28

Weldment, frame, boom/base:

LM-1NT-8-24

LM-1NT-8-30

LM-1NT-8-36

Frame, front support leg

casting

5

/16” snap hook

5

/16” chain 36” long

/2in. – 13 UNC x 2in. HHCS

zinc-plated bolt

/2” – 13UNC zinc-plated hex

nut

1

1

1

1

1

1

1

1

Page 6

01/11 rev. 10/26/2017 LM, MANUAL

FIG. 1J: LM-1NT- 4k, 6k & 8k Centers of Gravity and Maximum Load Ratings

for Varying Load Attachment Points

HCG

VCG

Center of gravity has both a horizontal component and a vertical component. The vertical center of gravity

(VCG) lies along a horizontal line above the bottom edges of the fork pockets. Similarly, the horizontal center of

gravity (HCG) is located along a vertical line as shown in the diagram below.

E D C B A

Hook position A B C D E

Distance from end of boom in

inches (cm)

Maximum rated load of a load suspended from a single hook located at the

corresponding “Hook position”.

LM-1NT-4k

LM-1NT-6k

LM-1NT-8k

FIG. 1K: LM-1NT centers of gravity and dimensions

36”

91 cm

4000 lb.

1820 kg

6000 lb.

2727 kg

8000 lb.

3636 kg

48”

122 cm

3750 lb.

1705 kg

5000 lb.

2272 kg

6650 lb.

3022 kg

60”

152 cm

3500 lb.

1590 kg

4500 lb.

2045 kg

6000 lb.

2727 kg

72”

183 cm

3250 lb.

1477 kg

4000 lb.

1820 kg

5300 lb.

2409 kg

84”

213 cm

3000 lb.

1363 kg

3500 lb.

1590 kg

4850 lb.

2205 kg

Model

LM-1NT-4-11 2811/16” (72.9 cm) 1013/16” (27.5 cm) 811/2” 2711/16” 19” 11” 71/2” 21/2” 309.9 lb.

LM-1NT-4-24 2811/16” (72.9 cm) 1013/16” (27.5 cm) 811/2” 2413/16” 32” 24” 71/2” 21/2” 334.6 lb.

LM-1NT-4-30 2811/16” (72.9 cm) 1013/16” (27.5 cm) 811/2” 2413/16” 38” 30” 71/2” 21/2” 352.6 lb.

LM-1NT-4-36 2811/16” (72.9 cm) 1013/16” (27.5 cm) 811/2” 2413/16” 44” 36” 71/2” 21/2” 370.6 lb.

LM-1NT-6-11 27” (68.6cm) 1013/16” (27.5 cm) 811/2” 2413/16” 19” 11” 71/4” 21/4” 357.7 lb.

LM-1NT-6-24 27” (68.6cm) 1013/16” (27.5 cm) 811/2” 2413/16” 32” 24” 71/4” 21/4” 382.4 lb.

LM-1NT-6-30 27” (68.6cm) 1013/16” (27.5 cm) 811/2” 2413/16” 38” 30” 71/4” 21/4” 402.0 lb.

LM-1NT-6-36 27” (68.6cm) 1013/16” (27.5 cm) 811/2” 2413/16” 44” 36” 71/4” 21/4” 421.5 lb.

LM-1NT-8-24 301/8” (29.8 cm) 113/4” (29.8 cm) 801/8” 231/2” 32” 24” 71/4” 21/4” 488.4 lb.

LM-1NT-8-30 301/8” (29.8 cm) 113/4” (29.8 cm) 801/8” 231/2” 38” 30” 71/4” 21/4” 506.9 lb.

LM-1NT-8-36 301/8” (29.8 cm) 113/4” (29.8 cm) 801/8” 231/2” 44” 36” 71/4” 21/4” 525.4 lb.

Copyright 2016 Vestil Manufacturing Co. Page 6 of 28

Horizontal center

of gravity

Vertical center of

gravity

A B C D E F Net weight

Page 7

01/11 rev. 10/26/2017 LM, MANUAL

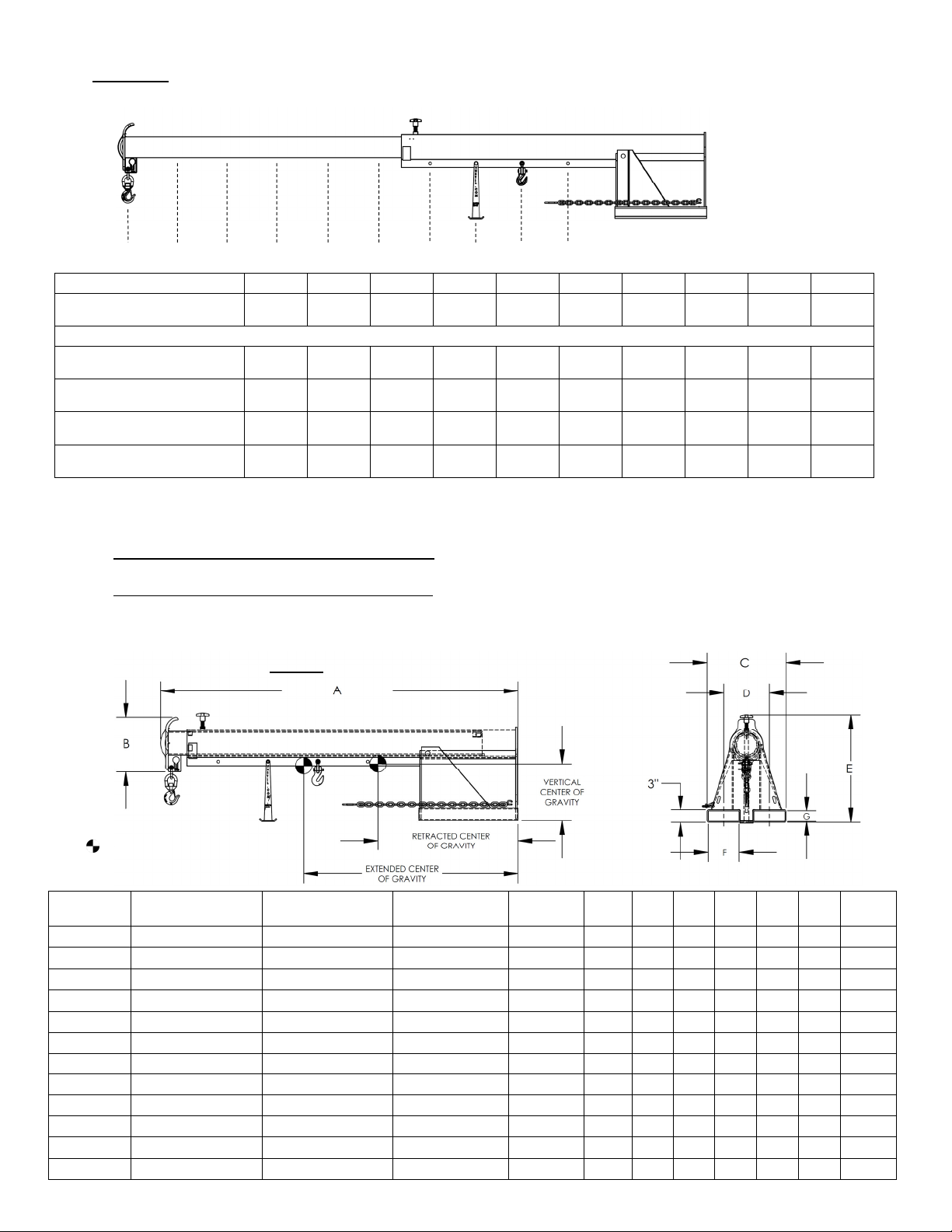

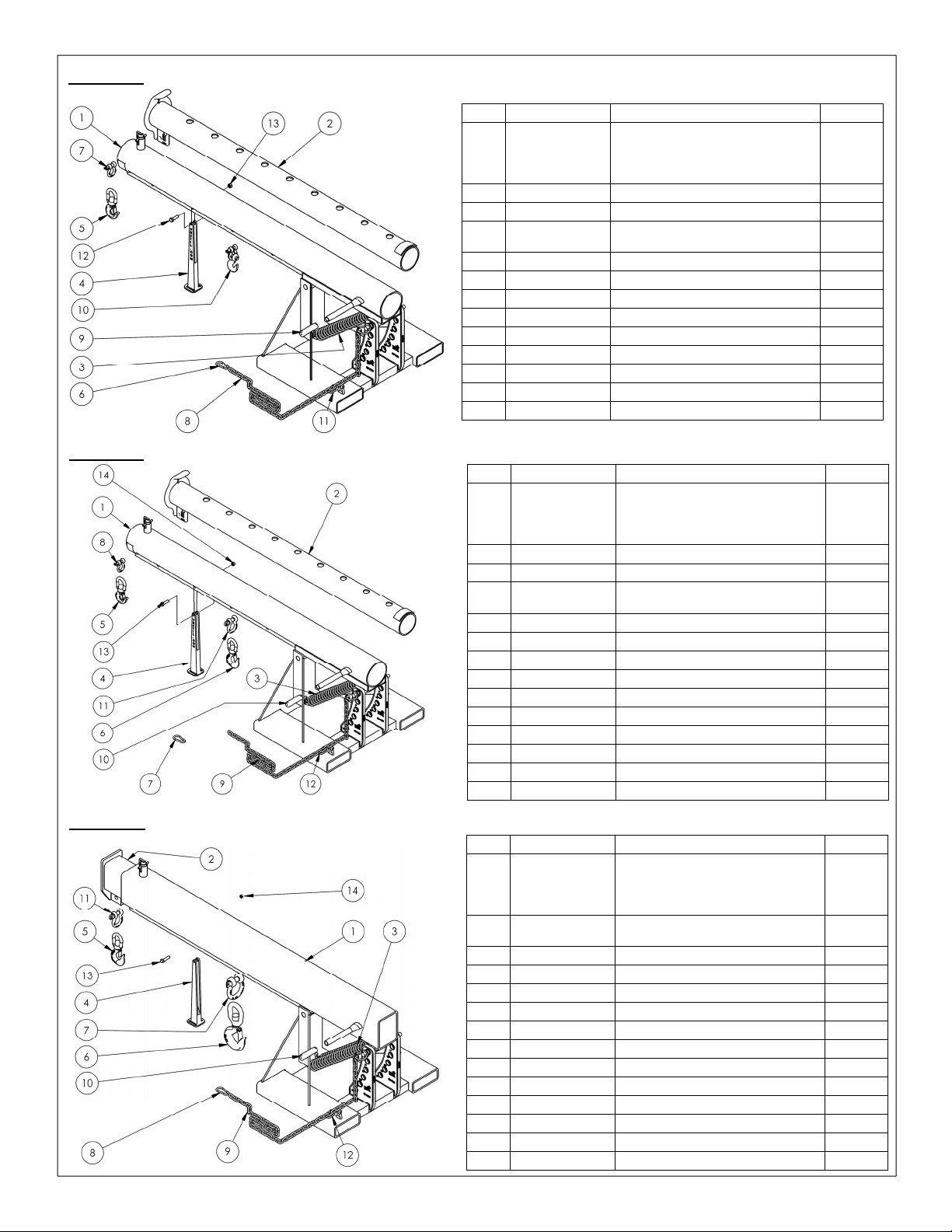

FIG. 2A: LM-OBT-3-24 & LM-OBT-4k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-119

1

08-514-298

08-514-299

2 08-514-293 Weldment, inner tube 1

3 01-146-006 Spring 1

4 08-014-069-001

5 08-145-001 Swivel hook, 2-ton 1

6 08-145-041 5/16” snap hook 1

7 08-145-010 1/2” 2-ton shackle 1

8 08-645-008 Boom chain and pin 1

9 13-025-023 11/8” i.d. red handle grip 1

10 99-645-019 2-ton hook and shackle 1

11 99-145-084 Lap link 1

12 11210 1/2” – 13UNC x 13/4” hex bolt 1

13 36110 1/2” – 13UNC zinc-plated hex nut 1

Weldment, frame, boom + base:

LM-OBT-4k-24 & LM-OBT-3-24

LM-OBT-4k-30

LM-OBT-4k-36

Frame, front supporting leg (small)

casting

FIG. 2B: LM-OBT-6k Exploded Parts Diagram & Bill of Materials

Item

1

2 08-514-293 Weldment, inner tube 1

3 01-146-006 Spring 1

4 08-014-069-001

5 08-145-001 Swivel hook, 2-ton 1

6 08-145-002 Swivel hook, 3-ton 1

7 08-145-041 5/16” snap hook 1

8 08-145-010 1/2” 2-ton shackle 1

9 08-645-008 Boom chain and pin 1

10 13-025-023 11/8” i.d. red handle grip 1

11 99-145-019 2-ton hook and shackle 1

12 99-145-084 Lap link 1

13 11210 1/2” – 13UNC x 13/4” hex bolt 1

14 36110 1/2” – 13UNC zinc-plated hex nut 1

Part No. Description Quantity

08-514-122

08-514-300

08-514-301

Weldment, frame, boom + base:

LM-OBT-6k-24

LM-OBT-6k-30

LM-OBT-6k-36

Frame, front supporting leg (small)

casting

FIG. 2C: LM-OBT-8k Exploded Parts Diagram & Bill of Materials

Item

1

2 08-014-069-001

3 08-514-310 Weldment, inner tube 1

4 01-146-006 Spring 2

5 08-145-002 Swivel hook, 3-ton 1

6 08-145-005 Swivel hook, 5-ton 1

7 08-145-006 7/8” 6.5-ton shackle 1

8 08-145-041 5/16” snap hook 1

9 08-645-008 Boom chain and pin 1

10 13-025-023 11/8” i.d. red handle grip 1

11 99-145-019 2-ton hook and shackle 1

12 99-145-084 Lap link 1

13 11211 1/2” – 13UNC x 2” hex bolt 1

14 36110 1/2” – 13UNC zinc-plated hex nut 1

Part No. Description Quantity

08-514-125

08-514-311

08-514-312

Weldment, frame, boom + base:

LM-OBT-8k-24

LM-OBT-8k-30

LM-OBT-8k-36

Frame, front supporting leg (small)

casting

1

1

1

1

1

1

1

1

1

1

1

1

Copyright 2016 Vestil Manufacturing Co. Page 7 of 28

Page 8

01/11 rev. 10/26/2017 LM, MANUAL

Load Attachment Point and

Boom Extension Combinations

” (36.4 cm)

”

” (36.4 cm)

”

” (35.4 cm)

”

” (34.8 cm)

”

” (33.8 cm)

”

” (33.2 cm)

”

” (32.5 cm)

”

cm)

”

cm)

”

cm)

”

FIG. 2D: LM-OBT- 4k, 6k & 8k Centers of Gravity and Maximum Load Ratings for Varying

J I H G F E D C B A

Hook position A B C D E F G H I J

Distance from mast

end of boom

Maximum rated load of a load suspended from a single hook located at the corresponding “Hook position”.

LM-OBT-3-24

LM-OBT-4k

LM-OBT-6k

LM-OBT-8k

36”

91 cm

3000 lb.

1363 kg

4000 lb.

1820 kg

6000 lb.

2727 kg

8000 lb.

3636 kg

48”

122 cm

2750 lb.

1250 kg

3750 lb.

1705 kg

5000 lb.

2272 kg

6650 lb.

3022 kg

60”

152 cm

2500 lb.

1136 kg

3500 lb.

1590 kg

4500 lb.

2045 kg

6000 lb.

2727 kg

72”

183 cm

2250 lb.

1022 kg

3250 lb.

1477 kg

4000 lb.

1820 kg

5300 lb.

2409 kg

84”

213 cm

2000 lb.

909 kg

3000 lb.

1363 kg

3500 lb.

1590 kg

4650 lb.

2113 kg

96”

244 cm

1750 lb.

795 kg

2750 lb.

1250 kg

3000 lb.

1364 kg

4000 lb.

1820 kg

108”

274 cm

1500 lb.

681 kg

2500 lb.

1136 kg

2600 lb.

1182 kg

3500 lb.

1590 kg

120”

305 cm

1250 lb.

568 kg

2250 lb.

1023 kg

2300 lb.

1045 kg

3000 lb.

1363 kg

132”

335 cm

1000 lb.

454 kg

2000 lb.

909 kg

2000 lb.

909 kg

2600 lb.

1181 kg

366 cm

750 lb.

340 kg

1750 lb.

795 kg

1800 lb.

818 kg

2200 lb.

1000 kg

The center of gravity of the boom changes as boom length changes. As shown in the diagram below, the horizontal

center of gravity may be located at any point from RHCG to EHCG:

Retracted horizontal center of gravity (RHCG): boom fully retracted and unloaded. RHCG is measured from the

“origin point” of the above diagram (edges of the fork pockets);

Extended horizontal center of gravity (EHCG): boom fully extended and unloaded. EHCG is also measured from

the “origin point” of the above diagram (edges of the fork pockets);

All other combinations of boom extension and load position produce a horizontal center of gravity located

somewhere between RHCG and EHCG.

FIG. 2E: LM-OBT centers of gravity and dimensions

144”

Model

LM-OBT-3-24 47” (119.4 cm) 323/8” (82.2 cm) 145/

LM-OBT-4-24 47” (119.4 cm) 323/8” (82.2 cm) 145/

LM-OBT-4-30 4513/16” (116.4 cm) 313/4” (80.6 cm) 1315/

LM-OBT-4-36 4411/16” (113.5 cm) 313/16” (79.2 cm) 1311/

LM-OBT-6-24 441/16” (112 cm) 3015/16” (78.6 cm) 135/

LM-OBT-6-30 43” (109.2 cm) 303/8” (77.2 cm) 131/

LM-OBT-6-36 42” (106.7 cm) 2913/16” (75.7 cm) 1213/

LM-OBT-8-24 5111/16” (131.3 cm) 35” (88.9 cm) 151/4” (38.7

LM-OBT-8-30 5111/16” (131.3 cm) 35” (88.9 cm) 151/4” (38.7

LM-OBT-8-36 5111/16” (131.3 cm) 35” (88.9 cm) 151/4” (38.7

Extended

horizontal center

of gravity

Copyright 2016 Vestil Manufacturing Co. Page 8 of 28

Retracted

horizontal center

of gravity

Vertical center of

gravity

16

16

16

16

16

16

16

A B C D E F G

865/8”-1465/8” 2711/

865/8”-1465/8” 2711/

865/8”-1465/8” 2711/

865/8”-1465/8” 2711/

865/8”-1465/8” 2711/

865/8”-1465/8” 2711/

865/8”-1465/8” 2711/

851/4”-1451/4” 287/8” 32” 24” 51/

851/4”-1451/4” 287/8” 38” 30” 51/

851/4”-1451/4” 287/8” 44” 36” 51/

32” 24” 6” 71/2” 21/2” 436.7 lb.

16

32” 24” 6” 71/2” 21/2” 433.9 lb.

16

38” 30” 6” 71/2” 21/2” 451.5 lb.

16

44” 36” 6” 71/2” 21/2” 469.1 lb.

16

32” 24” 6” 71/4” 21/4” 481.9 lb.

16

38” 30” 6” 71/4” 21/4” 501.1 lb.

16

44” 36” 6” 71/4” 21/4” 520.3 lb.

16

71/4” 21/4” 665.0 lb.

8

71/4” 21/4” 684.1 lb.

8

71/4” 21/4” 703.3 lb.

8

Net

weight

Page 9

01/11 rev. 10/26/2017 LM, MANUAL

5

1

5

1

1

7

5

5

1

1

FIG. 2F: LM-OBNT-4k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-132

1

08-514-302

08-514-303

2 01-146-006 Spring 1

3 08-014-069-001 Frame, front support leg (small) casting

4 08-145-001 Swivel hook, 2-ton 1

5 08-145-041

6 08-145-010

7 08-645-008 Assembly, boom chain and pin 1

8 13-025-023

9 99-145-084 Lap link 1

10 99-645-019 2-ton hook and shackle 1

11 11210

12 36110

Weldment, frame, boom + base

LM-OBNT-4-24

LM-OBNT-4-30

LM-OBNT-4-36

5

/16” snap hook

1

/2” 2-ton shackle

11/8” inner diameter red handle grip

1

/2” – 13UNC x 13/4” hex bolt

1

/2” – 13 zinc-plated hex nut

FIG. 2G: LM-OBNT-6k Exploded Parts Diagram & Bill of Materials

1

1

1

1

1

1

1

1

1

Item Part No. Description Quantity

08-514-134

1

08-514-304

08-514-305

2 01-146-006 Spring 1

3 08-014-069-001 Frame, front support leg (small) casting

4 08-145-001 Swivel hook, 2-ton 1

5 08-145-002 Swivel hook, 3-ton 1

6 08-145-041

7 08-145-010

8 08-645-008 Assembly, boom chain and pin 1

9 13-025-023

10 99-145-019

11 99-145-084 Lap link 1

12 11210

13 36110

Weldment, frame, boom + base

LM-OBNT-6-24

LM-OBNT-6-30

LM-OBNT-6-36

/16” snap hook

/2” 2-ton shackle

11/8” inner diameter red handle grip

/8” 31/4-ton shackle

/2” – 13UNC x 13/4” hex bolt

/2” – 13 zinc-plated hex nut

FIG. 2H: LM-OBNT-8k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-136

1

08-514-308

08-514-309

2 01-146-006 Spring 2

3 08-014-069-001 Frame, front support leg (small) casting

4 08-145-006

5 08-145-002 Swivel hook, 3-ton 1

6 08-145-041

7 08-145-005

8 08-645-008 Assembly, boom chain and pin 1

9 13-025-023

10 99-145-019

11 99-145-084 Lap link 1

12 11211

13 36110

Weldment, frame, boom + base

LM-OBNT-8-24

LM-OBNT-8-30

LM-OBNT-8-36

/8” 61/2-ton shackle

/16” snap hook

Swivel hook, 5-ton

11/8” inner diameter red handle grip

/8” 31/4-ton shackle

/2” – 13UNC x 2” hex bolt

/2” – 13 zinc-plated hex nut

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Copyright 2016 Vestil Manufacturing Co. Page 9 of 28

Page 10

01/11 rev. 10/26/2017 LM, MANUAL

FIG. 2J: LM-OBNT- 4k, 6k & 8k Centers of Gravity and Maximum Load

Ratings for Varying Load Attachment Points

Center of gravity has both a horizontal component and a vertical component. The vertical center of gravity

(VCG) lies along a horizontal line above the bottom edges of the fork pockets. Similarly, the horizontal center of

gravity (HCG) is located along a vertical line as shown in the diagram below.

E D C B A

Hook position A B C D E

Distance from end of boom in

inches (cm)

Maximum rated load of a load suspended from a single hook located at the

corresponding “Hook position”.

LM-OBNT-4k

LM-OBNT-6k

LM-OBNT-8k

FIG. 2K: LM-OBNT centers of gravity and dimensions

36”

91 cm

4000 lb.

1820 kg

6000 lb.

2727 kg

8000 lb.

3636 kg

48”

122 cm

3750 lb.

1705 kg

5000 lb.

2272 kg

6650 lb.

3022 kg

60”

152 cm

3500 lb.

1590 kg

4500 lb.

2045 kg

6000 lb.

2727 kg

72”

183 cm

3250 lb.

1477 kg

4000 lb.

1820 kg

5300 lb.

2409 kg

3000 lb.

1363 kg

3500 lb.

1590 kg

4850 lb.

2205 kg

78”

198 cm

Model

LM-1NT-4-24 263/4” (67.9 cm) 115/8” (29.5 cm) 807/8” 265/8” 32” 24” 51/2” 71/2” 21/2” 339.2 lb.

LM-1NT-4-30 263/4” (67.9 cm) 115/8” (29.5 cm) 807/8” 265/8” 38” 30” 51/2” 71/2” 21/2” 356.9 lb.

LM-1NT-4-36 263/4” (67.9 cm) 115/8” (29.5 cm) 807/8” 265/8” 44” 36” 51/2” 71/2” 21/2” 374.4 lb.

LM-1NT-6-24 263/4” (67.9 cm) 115/8” (29.5 cm) 807/8” 265/8” 32” 24” 51/2” 71/4” 21/4” 387.0 lb.

LM-1NT-6-30 263/4” (67.9 cm) 115/8” (29.5 cm) 807/8” 265/8” 38” 30” 51/2” 71/4” 21/4” 406.2 lb.

LM-1NT-6-36 263/4” (67.9 cm) 115/8” (29.5 cm) 807/8” 265/8” 44” 36” 51/2” 71/4” 21/4” 425.4 lb.

LM-1NT-8-24 301/4” (76.8 cm) 133/16” (33.5 cm) 791/2” 251/8” 32” 24” 411/16” 71/4” 21/4” 490.9 lb.

LM-1NT-8-30 301/4” (76.8 cm) 133/16” (33.5 cm) 791/2” 251/8” 38” 30” 411/16” 71/4” 21/4” 510.0 lb.

LM-1NT-8-36 301/4” (76.8 cm) 133/16” (33.5 cm) 791/2” 251/8” 44” 36” 411/16” 71/4” 21/4” 521.2 lb.

Horizontal

center of gravity

Vertical center

of gravity

A B C D E F G

Net

weight

Copyright 2016 Vestil Manufacturing Co. Page 10 of 28

Page 11

01/11 rev. 10/26/2017 LM, MANUAL

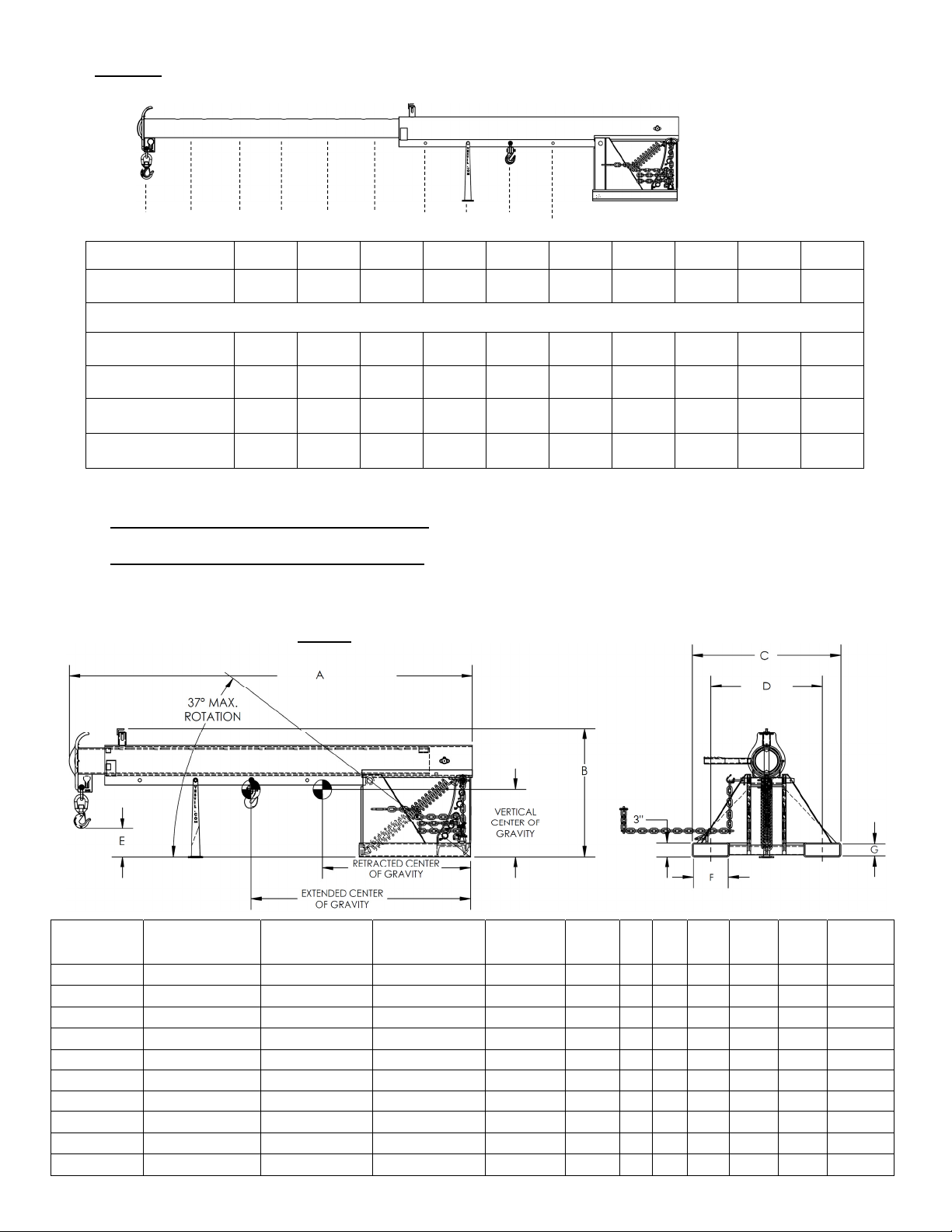

FIG. 3A: LM-HRT-4k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-005

1

08-514-337

08-514-339

2 08-025-004 X-handle, locking bolt 1

3 08-145-001 Swivel hook, 2-ton 1

4 08-145-010 1/2in. 2-ton shackle 1

5 08-145-041 5/16in. snap hook 1

6 99-145-037 5/16in. x 36in. chain 1

7 99-145-084 Lap link 1

8 99-645-019 2-ton hook and shackle 1

Assembly, frame, boom

LM-HRT-4k 24

LM-HRT-4k-30

LM-HRT-4k-36

1

1

1

FIG. 3B: LM-HRT-6k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-006

1

08-514-338

08-514-340

2 08-025-004 X-handle, locking bolt 1

3 08-145-001 Swivel hook, 2-ton 1

4 08-145-002 Swivel hook, 3-ton 1

5 08-145-010 1/2” 2-ton shackle 1

6 08-145-041 5/16” snap hook 1

7 99-145-019 5/8” 31/4-ton hook and shackle 1

8 99-145-037 5/16’ x 36” chain 1

9 99-145-084 Lap link 1

Assembly, frame, boom

LM-HRT-6k 24

LM-HRT-6k-30

LM-HRT-6k-36

1

1

1

Copyright 2016 Vestil Manufacturing Co. Page 11 of 28

Page 12

01/11 rev. 10/26/2017 LM, MANUAL

” (98.3 cm)

”

”

”

” (94.8 cm)

”

”

”

” (93.5 cm)

”

”

”

” (93.5 cm)

”

”

”

” (92.3 cm)

”

”

”

”

”

”

FIG. 3C: LM-HRT- 4k & 6k Centers of Gravity and Maximum Load Ratings for

Varying Load Attachment Point and Boom Extension Combinations

K J I H G F E D C B A

Hook position A B C D E F G H I J K

Distance from end

of boom

Maximum rated load of a load suspended from a single hook located at the corresponding “Hook position”.

LM-HRT-4-24

LM-HRT-6-24

The center of gravity of the boom changes as boom length changes. As shown in the diagram below, the horizontal center of

gravity may be located at any point from RHCG to EHCG:

Retracted horizontal center of gravity (RHCG): boom fully retracted and unloaded. RHCG is measured from the “origin point”

of the above diagram (edges of the fork pockets);

Extended horizontal center of gravity (EHCG): boom fully extended and unloaded. EHCG is also measured from the “origin

point” of the above diagram (edges of the fork pockets);

All other combinations of boom extension and load position produce a horizontal center of gravity located somewhere between

RHCG and EHCG.

30”

76 cm

4000 lb.

1820 kg

6000 lb.

2727 kg

36”

91 cm

3750 lb.

1705 kg

5000 lb.

2273 kg

42”

107 cm

3500 lb.

1590 kg

4500 lb.

2046 kg

48”

122 cm

3250 lb.

1477 kg

4000 lb.

1818 kg

54”

137 cm

3000 lb.

1363 kg

3500 lb.

1591 kg

60”

152 cm

2750 lb.

1250 kg

3000 lb.

1363 kg

66”

168 cm

2500 lb.

1136 kg

2600 lb.

1182 kg

FIG. 3D: LM-HRT centers of gravity and dimensions

72”

183 cm

2250 lb.

1022 kg

2300 lb.

1046 kg

78”

198 cm

2000 lb.

909 kg

2000 lb.

909 kg

84”

213 cm

1750 lb.

796 kg

1800 lb.

818 kg

90”

229 cm

1500 lb.

682 kg

1550 lb.

705 kg

Model

LM-HRT-4-24 133/16” (33.5 cm) 10” (25.4 cm) 3811/

LM-HRT-4-30 131/8” (33.3 cm) 101/4” (26 cm) 375/

LM-HRT-4-36 131/16” (33.2 cm) 101/4” (26 cm) 3613/

LM-HRT-6-24 133/16” (33.5 cm) 103/8” (26.4 cm) 3613/

LM-HRT-6-30 131/8” (33.3 cm) 103/8” (26.4 cm) 365/

LM-HRT-6-36 131/8” (33.3 cm) 103/8” (26.4 cm) 3513/16” (91 cm) 547/8”-947/8” 13” 44” 36” 71/

Extended

horizontal center

of gravity

Retracted

horizontal center

of gravity

Vertical center of

gravity

16

16

16

16

16

A B C D E F G

547/8”-947/8” 13” 32” 24” 71/

547/8”-947/8” 13” 38” 30” 71/

547/8”-947/8” 13” 44” 36” 71/

547/8”-947/8” 13” 32” 24” 71/

547/8”-947/8” 13” 38” 30” 71/

21/

21/

21/

21/

21/

21/

7913/

2

7913/

2

7913/

2

7913/

4

7913/

4

7913/

4

2

2

2

4

4

4

16

16

16

16

16

16

Net

weight

943.7 lb.

958.9 lb.

974.1 lb.

978.2 lb.

993.4 lb.

1008.6 lb.

Copyright 2016 Vestil Manufacturing Co. Page 12 of 28

Page 13

01/11 rev. 10/26/2017 LM, MANUAL

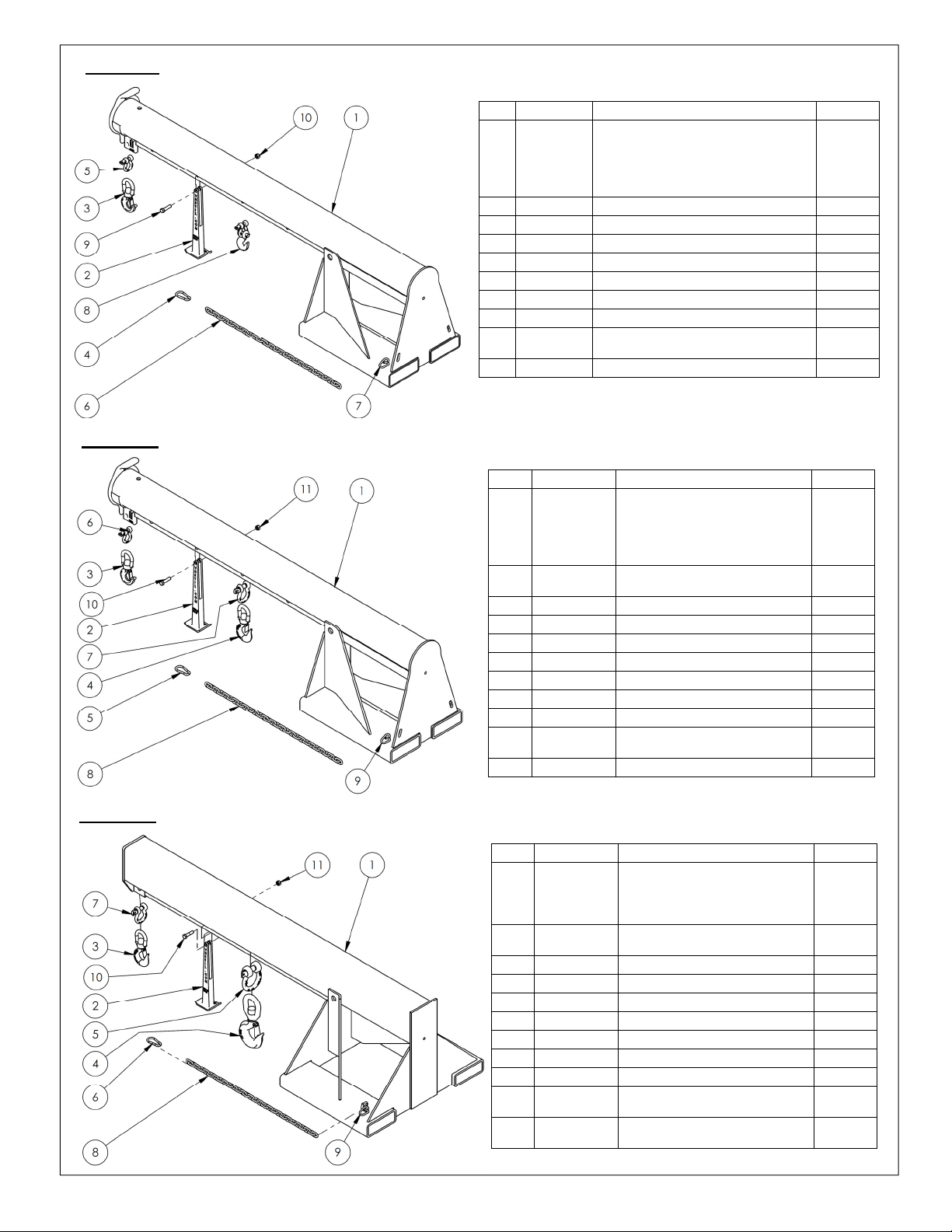

FIG. 3E: LM-HRNT-4k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-007

1

08-514-341

08-514-343

2 08-145-001 2-ton hook 1

3 08-145-010 Specialty hardware: 2-ton shackle 1

4 08-145-041 5/16in. snap hook 1

5 99-145-037 5/16in. x 36in. chain 1

6 99-145-084 Lap link 1

7 99-645-019 2-ton hook and shackle 1

Frame, boom + base weldment:

LM-HRNT-4-24

LM-HRNT-4-30

LM-HRNT-4-36

1

1

1

FIG. 3F: LM-HRNT-6k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

1 08-145-001 Swivel hook, 2-ton 1

2 08-145-010 1/2” 2-ton shackle 1

3 08-145-041 5/16” snap hook 1

4 99-145-037 5/16” chain 36” long 1

5 99-145-084 Lap Link 1

08-514-008

6

08-514-342

08-514-344

7 08-145-002 Swivel hook, 3-ton 1

8 99-145-019 5/8” 31/4-ton shackle 1

Frame, boom + base weldment:

LM-HRNT-6-24

LM-HRNT-6-30

LM-HRNT-6-36

1

1

1

Copyright 2016 Vestil Manufacturing Co. Page 13 of 28

Page 14

01/11 rev. 10/26/2017 LM, MANUAL

cm)

”

”

cm)

”

”

cm)

”

”

cm)

”

”

cm)

”

”

cm)

”

”

FIG. 3G: LM-HRNT- 4k & 6k Centers of Gravity and Maximum Load Ratings for

Varying Load Attachment Points

Hook position A B C D

Distance from end of boom in

inches (cm)

Maximum rated load in pounds (kg) of a load suspended from a single

hook located at the corresponding “Hook position”.

LM-HRNT-4k

LM-HRNT-6k

30”

76 cm

4000 lb.

1820 kg

6000 lb.

2727 kg

36”

91 cm

3750 lb.

1705 kg

5000 lb.

2045 kg

42”

107 cm

3500 lb.

1590 kg

4500 lb.

1727 kg

48”

122 cm

3250 lb.

1477 kg

4000 lb.

1363 kg

Center of gravity has both a horizontal component and a vertical component. The vertical center of gravity

(VCG) lies along a line 38 inches (~97 cm) from the bottom edges of the fork pockets. Similarly, the horizontal

center of gravity (HCG) is located 8 inches (~20cm) from the front edge of the vertical support.

D C B A

Model

LM-HRNT-4-24 85/8” (21.9 cm) 2811/16” (72.9

LM-HRNT-4-30 85/8” (21.9 cm) 2811/16” (72.9

LM-HRNT-4-36 85/8” (21.9 cm) 2811/16” (72.9

LM-HRNT-6-24 813/16” (22.4 cm) 277/8” (68.9

LM-HRNT-6-30 813/16” (22.4 cm) 277/8” (68.9

LM-HRNT-6-36 813/16” (22.4 cm) 277/8” (68.9

Copyright 2016 Vestil Manufacturing Co. Page 14 of 28

Horizontal center

of gravity

Vertical center of

gravity

A B C D E F G

503/8” 131/4” 32” 24” 71/

503/8” 131/4” 38” 30” 71/

503/8” 131/4” 44” 36” 71/

503/8” 131/4” 32” 24” 71/

503/8” 131/4” 38” 30” 71/

503/8” 131/4” 44” 36” 71/

21/

2

2

2

4

4

4

789/16” 882.3 lb.

2

21/

789/16” 897.5 lb.

2

21/

789/16” 912.7 lb.

2

21/

789/16” 916.6 lb.

4

21/

789/16” 931.8 lb.

4

21/

789/16” 947.0 lb.

4

Net

weight

Page 15

01/11 rev. 10/26/2017 LM, MANUAL

FIG. 4A: LM-EBT-4k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-169

1

08-514-263

08-514-170

08-514-171

2 08-514-261 Weldment, inner tube/boom: 1

3 08-025-004 X-handle, locking bolt 1

4 08-145-041

5 99-145-084 Lap link 1

6 99-145-037

7 08-145-001 Swivel hook, 2-ton 1

8 08-145-010

9 99-645-019 2-ton hook-and-shackle 1

Weldment, frame, base:

LM-EBT-4-11

LM-EBT-4-24

LM-EBT-4-30

LM-EBT-4-36

5

/16” snap hook

5

/16” chain 36” long

1

/2” 2-ton shackle

FIG. 4B: LM-EBT-6k Exploded Parts Diagram & Bill of Materials

FIG. 4C: LM-EBT-8k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-172

1

08-514-265

08-514-173

08-514-174

2 08-514-261 Weldment, inner tube/boom: 1

3 08-025-004 X-handle, locking bolt 1

4 08-145-041

5 99-145-084 Lap link 1

6 99-145-037

7 08-145-001 Swivel hook, 2-ton 1

8 08-145-010

9 08-145-002 Swivel hook, 3-ton 1

10 99-145-019

Weldment, frame, base:

LM-EBT-6-11

LM-EBT-6-24

LM-EBT-6-30

LM-EBT-6-36

5

/16” snap hook

5

/16” chain 36” long

1

/2” 2-ton shackle

5

/8” 31/4-ton shackle

Item Part No. Description Quantity

08-514-274

1

08-514-281

08-514-282

2 08-514-272 Weldment, inner tube/boom: 1

3 08-025-004 X-handle, locking bolt 1

4 08-145-041

5 99-145-084 Lap link 1

6 99-145-037

7 99-145-019

8 08-145-002 Swivel hook, 3-ton 1

9 08-145-006

10 08-145-005 Swivel hook, 5-ton 1

Weldment, frame, base:

LM-EBT-8-24

LM-EBT-8-30

LM-EBT-8-36

5

/16” snap hook

5

/16” chain 36” long

5

/8” 31/4-ton shackle

7

/8” 61/2-ton shackle

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Copyright 2016 Vestil Manufacturing Co. Page 15 of 28

Page 16

01/11 rev. 10/26/2017 LM, MANUAL

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

”

FIG. 4D: LM-EBT – 4k, 6k & 8k Centers of Gravity and Maximum Load Ratings

for Varying Load Attachment Point and Boom Extension Combinations

J I H G F E D C B A

Hook position A B C D E F G H I J

Distance from end

of boom in inches

(cm)

Maximum rated load of a load suspended from a single hook located at the corresponding “Hook position”.

LM-EBT-4k

LM-EBT-6k

LM-EBT-8k

The center of gravity of the boom changes as boom length changes. As shown in the diagram below, the

horizontal center of gravity may be located at any point from RHCG to EHCG:

Retracted horizontal center of gravity (RHCG): boom fully retracted and unloaded. RHCG is measured from the

“origin point” of the above diagram (edges of the fork pockets);

Extended horizontal center of gravity (EHCG): boom fully extended and unloaded. EHCG is also measured from the

“origin point” of the above diagram (edges of the fork pockets);

All other combinations of boom extension and load position produce a horizontal center of gravity located

somewhere between RHCG and EHCG.

36”

91 cm

4000 lb.

1820 kg

6000 lb.

2727 kg

8000 lb.

3636 kg

48”

122 cm

3750 lb.

1705 kg

5000 lb.

2273 kg

6650 lb.

3022 kg

60”

152 cm

3500 lb.

1590 kg

4500 lb.

2046 kg

6000 lb.

2727 kg

72”

183 cm

3250 lb.

1477 kg

4000 lb.

1818 kg

5300 lb.

2409 kg

84”

213 cm

3000 lb.

1363 kg

3500 lb.

1591 kg

4650 lb.

2113 kg

96”

244 cm

2750 lb.

1250 kg

3000 lb.

1363 kg

4000 lb.

1820 kg

108”

274 cm

2500 lb.

1136 kg

2600 lb.

1182 kg

3500 lb.

1590 kg

120”

305 cm

2250 lb.

1022 kg

2300 lb.

1046 kg

3000 lb.

1363 kg

132”

335 cm

2000 lb.

909 kg

2000 lb.

909 kg

2600 lb.

1181 kg

144”

366 cm

1750 lb.

796 kg

1800 lb.

818 kg

2200 lb.

1000 kg

FIG. 4E: LM-EBT centers of gravity and dimensions

Model

LM-EBT-4-11 581/16” (147.5 cm) 371/2” (95.2 cm) 51/16” (12.9 cm) 861/4-1533/4” 13” 19” 11” 71/

LM-EBT-4-24 553/16” (140.2 cm) 365/16” (92.2 cm) 47/16” (11.3 cm) 861/4-1533/4” 13” 32” 24” 71/

LM-EBT-4-30 541/8” (137.5 cm) 355/16” (89.7 cm) 41/2” (11.4 cm) 861/4-1533/4” 13” 38” 30” 71/

LM-EBT-4-36 527/8” (134.3 cm) 349/16” (87.8 cm) 41/2” (11.4 cm) 861/4-1533/4” 13” 44” 36” 71/

LM-EBT-6-11 543/16” (137.6 cm) 3511/16” (90.6 cm) 413/16” (12.2 cm) 861/4-1533/4” 13” 19” 11” 71/

LM-EBT-6-24 525/16” (132.9 cm) 347/16” (87.5 cm) 41/8” (10.5 cm) 861/4-1533/4” 13” 32” 24” 71/

LM-EBT-6-30 5015/16” (129.4 cm) 3313/16” (85.9 cm) 41/4” (10.8 cm) 861/4-1533/4” 13” 38” 30” 71/

LM-EBT-6-36 497/8” (126.7 cm) 331/4” (84.5 cm) 43/16” (10.6 cm) 861/4-1533/4” 13” 44” 36” 71/

LM-EBT-8-24 571/8” (145.1 cm) 38” (96.5 cm) 413/16” (12.2 cm) 847/8-1493/8” 111/2” 32” 24” 71/

LM-EBT-8-30 571/8” (145.1 cm) 38” (96.5 cm) 413/16” (12.2 cm) 847/8-1493/8” 111/2” 38” 30” 71/

LM-EBT-8-36 571/8” (145.1 cm) 38” (96.5 cm) 413/16” (12.2 cm) 847/8-1493/8” 111/2” 44” 36” 71/

Extended horizontal

center of gravity

Retracted horizontal

center of gravity

Vertical center of

gravity

A B C D E F

Net

weight

21/

21/

21/

21/

21/

21/

21/

21/

21/

21/

21/

2

2

2

2

4

4

4

4

4

4

4

335.9 lb.

354.0 lb.

367.0 lb.

377.9 lb.

368.7 lb.

386.8 lb.

403.6 lb.

414.6 lb.

606.3 lb.

621.2 lb.

635.8 lb.

2

2

2

2

4

4

4

4

4

4

4

Copyright 2016 Vestil Manufacturing Co. Page 16 of 28

Page 17

01/11 rev. 10/26/2017 LM, MANUAL

FIG. 4F: LM-EBNT-4k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

Weldment, frame, boom/base:

08-514-287

1

08-514-003

08-514-288

08-514-289

2 08-145-041

3 99-145-084 Lap link 1

4 99-145-037

5 08-145-001 Swivel hook, 2-ton 1

6 08-145-010

7 99-645-019 2-ton hook and shackle 1

LM-EBNT-4-11

LM-EBNT-4-24

LM-EBNT-4-30

LM-EBNT-4-36

5

/16” snap hook 1

5

/16” x 36” chain 1

1

/2” 2-ton shackle 1

FIG. 4G: LM-EBNT-6k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

1 08-145-041

2 99-145-084 Lap link 1

3 99-145-037

4 08-145-001 Swivel hook, 2-ton 1

5 08-145-010

08-514-290

6

08-514-004

08-514-291

08-514-292

7 99-145-019

8 08-145-002 Swivel hook, 3-ton 1

5

/16” snap hook 1

5

/16” x 36” chain 1

1

/2” 2-ton shackle 1

Weldment, frame, boom/base:

LM-EBNT-6-11

LM-EBNT-6-24

LM-EBNT-6-30

LM-EBNT-6-36

5

/8” 31/4-ton shackle

FIG. 4H: LM-EBNT-8k Exploded Parts Diagram & Bill of Materials

Item Part No. Description Quantity

08-514-191

1

08-514-283

08-514-284

2 08-145-041

3 99-145-084 Lap link 1

4 99-145-037

5 99-145-019

6 08-145-002 Swivel hook, 3-ton 1

7 08-145-006

8 08-145-005 Swivel hook, 5-ton 1

Weldment, frame, boom/base:

LM-EBNT-8-24

LM-EBNT-8-30

LM-EBNT-8-36

5

/16” snap hook 1

5

/16” x 36” chain 1

5

/8” 31/4-ton shackle

7

/8” 61/2-ton shackle 1

1

1

1

1

1

1

1

1

1

1

1

1

1

Copyright 2016 Vestil Manufacturing Co. Page 17 of 28

Page 18

01/11 rev. 10/26/2017 LM, MANUAL

FIG. 4J: LM-EBNT- 4k, 6k & 8k Centers of Gravity and Maximum Load

Ratings for Varying Load Attachment Points

E D C B A

Hook position A B C D E

Distance from end of boom in

inches (cm)

Maximum rated load of a load suspended from a single hook located at the

corresponding “Hook position”.

LM-EBNT-4k

LM-EBNT-6k

LM-EBNT-8k

36”

91 cm

4000 lb.

1820 kg

6000 lb.

2727 kg

8000 lb.

3636 kg

48”

122 cm

3750 lb.

1705 kg

5000 lb.

2045 kg

6650 lb.

3023 kg

60”

152 cm

3500 lb.

1590 kg

4500 lb.

1727 kg

6000 lb.

2727 kg

72”

183 cm

3250 lb.

1477 kg

4000 lb.

1363 kg

5300 lb.

2409 kg

84”

213 cm

3000 lb.

1364 kg

3500 lb.

1591 kg

4850 lb.

2205 kg

Center of gravity has both a horizontal component and a vertical component. The vertical center of gravity

(VCG) lies along a line 15 inches (~38 cm) from the bottom edges of the fork pockets. Similarly, the horizontal

center of gravity (HCG) is located 35-7/8 inches (~91 cm) from the outer edges of the fork pockets.

FIG. 4K: LM-EBNT centers of gravity and dimensions

Model

LM-EBNT-4-11 321/16” (81.4 cm) 315/16” (10.0 cm) 813/4” 135/16” 19” 11” 71/2” 21/2” 239.6 lb.

LM-EBNT-4-24 2811/16” (72.9 cm) 315/16” (10.0 cm) 815/8” 135/16” 32” 24” 71/2” 21/2” 257.7 lb.

LM-EBNT-4-30 321/16” (81.4 cm) 315/16” (10.0 cm) 813/4” 135/16” 38” 30” 71/2” 21/2” 270.7 lb.

LM-EBNT-4-36 321/16” (81.4 cm) 315/16” (10.0 cm) 813/4” 135/16” 44” 36” 71/2” 21/2” 281.7 lb.

LM-EBNT-6-11 301/8” (76.5 cm) 35/8” (9.2 cm) 813/4” 135/16” 19” 11” 71/4” 21/4” 276.1 lb.

LM-EBNT-6-24 301/8” (76.5 cm) 35/8” (9.2 cm) 815/8” 135/16” 32” 24” 71/4” 21/4” 294.1 lb.

LM-EBNT-6-30 301/8” (76.5 cm) 35/8” (9.2 cm) 813/4” 135/16” 38” 30” 71/4” 21/4” 307.1 lb.

LM-EBNT-6-36 301/8” (76.5 cm) 35/8” (9.2 cm) 813/4” 135/16” 44” 36” 71/4” 21/4” 318.1 lb.

LM-EBNT-8-24 325/16” (82.1 cm) 41/16” (10.3 cm) 803/8” 111/2” 32” 24” 71/4” 21/4” 429.4 lb.

LM-EBNT-8-30 325/16” (82.1 cm) 41/16” (10.3 cm) 803/8” 111/2” 38” 30” 71/4” 21/4” 444.3 lb.

LM-EBNT-8-36 325/16” (82.1 cm) 41/16” (10.3 cm) 803/8” 111/2” 44” 36” 71/4” 21/4” 458.9 lb.

Copyright 2016 Vestil Manufacturing Co. Page 18 of 28

Horizontal center of

gravity

Vertical center of

gravity

A B C D E F Net weight

Page 19

01/11 rev. 10/26/2017 LM, MANUAL

1

5

5

5

5

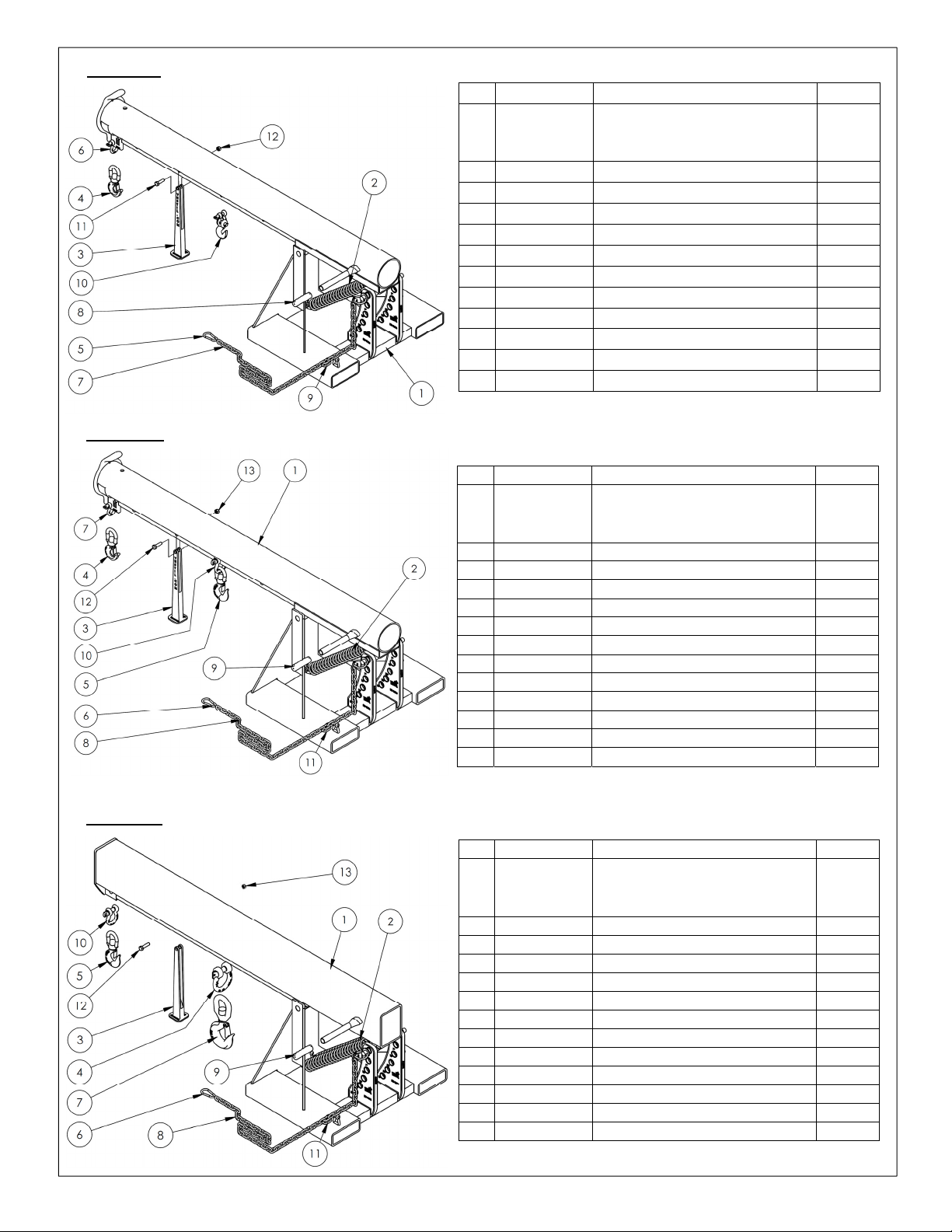

FIG. 5A: LMS-EBT-46-4 Exploded Parts Diagram & Bill of Materials

Item Part no. Description Quantity

1 08-514-268 Weldment, frame, boom/base 1

2 08-514-278 Weldment, inner tube, shorty 1

3 08-025-004 X-handle, locking bolt 1

4 08-145-001 Swivel hook, 2-ton 1

5 08-145-010

6 08-145-041

/2” 2-ton shackle 1

/16” snap hook 1

7 99-145-084 Lap link 1

8 99-145-037

/16” chain 36” long 1

9 99-645-019 2-ton hook and shackle 1

FIG. 5B: LMS-EBT-46-6 Exploded Parts Diagram & Bill of Materials

Item Part no. Description Quantity

1 08-514-270 Weldment, frame, boom/base 1

2 08-514-266 Weldment, inner tube, shorty 1

3 08-025-004 X-handle, locking bolt 1

4 08-145-002 Swivel hook, 3-ton 2

5 08-145-041

/16” snap hook 1

6 99-145-019 31/4-ton shackle, 5/8” 2

7 99-145-037

/16” chain 36” long 1

8 99-145-084 Lap link 1

FIG. 5C: LMS-EBT-46-8 Exploded Parts Diagram & Bill of Materials

Item Part no. Description Quantity

1 08-514-277 Weldment, frame, boom/base 1

2 08-514-275 Weldment, inner tube, shorty 1

3 08-025-004 X-handle, locking bolt 1

4 08-145-041

5 99-145-084 Lap link 1

6 99-145-037

7 99-145-019

8 08-145-002 Swivel hook, 3-ton 1

9 08-145-006

10 08-145-005 Swivel hook, 5-ton 1

5

/16” snap hook 1

5

/16” chain 36” long 1

5

/8” 31/4-ton shackle 1

7

/8” 61/2-ton shackle 1

Copyright 2016 Vestil Manufacturing Co. Page 19 of 28

Page 20

01/11 rev. 10/26/2017 LM, MANUAL

3

3

”

”

”

”

”

”

”

FIG. 5D: LMS-EBT-4k, 6k & 8k Centers of Gravity and Maximum Load

Ratings for Varying Load Attachment Points

G F E D C B A

Hook position

Distance from end of boom

A B C D E F G

/4”

31”

79 cm

37”

94 cm

43”

109 cm

52

/4”

134 cm

66”

168 cm

791/4”

201 cm

92

236 cm

Maximum rated load of a load suspended from a single hook located at the corresponding “Hook

position”.

LMS-EBT-46-4

LMS-EBT-46-4

Distance from end of boom

LMS-EBT-46-8

The center of gravity of the boom changes as boom length changes. As shown in the diagram below, the

horizontal center of gravity may be located at any point from RHCG to EHCG:

Retracted horizontal center of gravity (RHCG): boom fully retracted and unloaded. RHCG is measured from the

“origin point” of the above diagram (edges of the fork pockets);

4000 lb.

1820 kg

6000 lb.

2727 kg

31”

79 cm

8000 lb.

3636 kg

3880 lb.

1763 kg

5710 lb.

2595 kg

37”

94 cm

7600 lb.

3454 kg

3760 lb.

1709 kg

5420 lb.

2463 kg

43”

109 cm

7200 lb.

3272 kg

3560 lb.

1618 kg

4945 lb.

2247 kg

52”

134 cm

6610 lb.

3004 kg

3290 lb.

1495 kg

4300 lb.

1954 kg

64”

168 cm

5825 lb.

2647 kg

3020 lb.

1372 kg

3650 lb.

1659 kg

761/2”

201 cm

5010 lb.

2277 kg

2750 lb.

1250 kg

3000 lb.

1364 kg

89”

236 cm

4200 lb.

1909 kg

Extended horizontal center of gravity (EHCG): boom fully extended and unloaded. EHCG is also measured from

the “origin point” of the above diagram (edges of the fork pockets);

All other combinations of boom extension and load position produce a horizontal center of gravity located

somewhere between RHCG and EHCG.

FIG. 5E: LMS-46 centers of gravity and dimensions

Model

LMS-EBT-46-4 335/16” (84.6 cm) 2215/16” (58.3 cm) 41/8” (10.5 cm) 551/4-951/4” 13” 32” 24” 71/

LMS-EBT-46-6 315/16” (79.5 cm) 221/16” (56 cm) 33/4” (9.5 cm) 551/4-951/4” 13” 32” 24” 71/

LMS-EBT-46-8 341/16” (86.5 cm) 223/4” (57.8 cm) 43/8” (11.1 cm) 537/8-907/8” 111/

Extended horizontal

center of gravity

Copyright 2016 Vestil Manufacturing Co. Page 20 of 28

Retracted horizontal

center of gravity

Vertical center of

gravity

A B C D E F

32” 24” 71/

2

Net

weight

21/

21/

21/

2

4

4

267.2 lb.

302.5 lb.

442.3 lb.

2

4

4

Page 21

01/11 rev. 10/26/2017 LM, MANUAL

1

5

5

5

5

1

5

5

5

7

FIG. 5F: LMS-EBNT-40-4 Exploded Parts Diagram & Bill of Materials

Item Part no. Description Quantity

1 08-514-196 Weldment, frame, boom/base

2 08-145-001 Swivel hook, 2-ton 1

3 08-145-010

4 08-145-041

/2” 2-ton shackle 1

/16” snap hook 1

5 99-645-019 2-ton hook and shackle 1

6 99-145-037

/16” chain 36” long 1

7 99-145-084 Lap link 1

FIG. 5G: LMS-EBNT-40-6 Exploded Parts Diagram & Bill of Materials

1

Item Part no. Description Quantity

1 08-514-197 Weldment, frame, boom/base

2 08-145-002 Swivel hook, 3-ton 1

3 08-145-041

/16” snap hook 1

4 99-145-019 31/4-ton shackle, 5/8” 2

5 99-145-037

/16” chain 36” long 1

6 99-145-084 Lap link 1

7 08-145-001 Swivel hook, 2-ton 1

8 08-145-010

/2” 2-ton shackle 2

FIG. 5H: LMS-EBNT-40-8 Exploded Parts Diagram & Bill of Materials

Item Part no. Description Quantity

1 08-514-203 Weldment, frame, boom/base

2 08-145-041

3 99-145-084 Lap link 1

4 99-145-037

5 99-645-019

6 08-145-002 Swivel hook, 3-ton 1

7 08-145-006

8 08-145-005 Swivel hook, 5-ton 1

/16” snap hook 1

/16” chain 36” long 1

/8” 31/4-ton hook and shackle 1

/8” 61/2-ton shackle 1

1

1

Copyright 2016 Vestil Manufacturing Co. Page 21 of 28

Page 22

01/11 rev. 10/26/2017 LM, MANUAL

FIG. 5J: LMS-EBNT-40-4k, 6k & 8k Centers of Gravity and Maximum Load

Ratings for Varying Load Attachment Points

D C B A

Hook position A B C D

Distance from end of boom

Maximum rated load of a load suspended from a single hook located at the corresponding “Hook position”.

LMS-EBNT-46-4

LMS-EBNT-46-4

Distance from end of boom

LMS-EBNT-46-8

31”

79 cm

4000 lb.

1820 kg

6000 lb.

2727 kg

31”

79 cm

8000 lb.

3636 kg

37”

94 cm

3915 lb.

1779 kg

5650 lb.

2568 kg

37”

94 cm

7275 lb.

3306 kg

43”

109 cm

3830 lb.

1740 kg

5300 lb.

2409 kg

43”

109 cm

6550 lb.

2977 kg

481/8”

122 cm

3750 lb.

1705 kg

5000 lb.

(2045 kg

471/2”

122 cm

6000 lb.

3023 kg

Center of gravity has both a horizontal component and a vertical component. The vertical center of gravity (VCG)

lies along a line parallel to the bottom edges of the fork pockets. Similarly, the horizontal center of gravity (HCG) lies

along a vertical line from the outer edges of the fork pockets.

FIG. 5K: LMS-EBNT centers of gravity and dimensions

Model

LMS-EBNT-40-4 207/16” (20.4 cm) 39/16” (9.0 cm) 503/4” 135/16” 32” 24” 71/2” 21/2” 204 lb.

LMS-EBNT-40-6 191/2” (49.5 cm) 31/4” (8.3 cm) 505/8” 135/16” 32” 24” 71/4” 21/4” 239 lb.

LMS-EBNT-40-8 205/8” (52.4 cm) 35/8” (9.2 cm) 493/8” 111/2” 32” 24” 71/4” 21/4” 329 lb.

Horizontal center of

gravity

Vertical center of

gravity

A B C D E F Net weight

Copyright 2016 Vestil Manufacturing Co. Page 22 of 28

Page 23

01/11 rev. 10/26/2017 LM, MANUAL

Boom sleeve

Fork

pocket

Loading and Use Instructions:

Periodically review the “Safe use recommendations” on p. 2.

1. Drive the forklift forward and insert the tines into the fork pockets. Drive as far forward as possible. Lower the

forks completely. The drawings below demonstrate this step:

Fork

truck

Snap hook

Safety chain wrapped

around fork carriage &

snap hook fastened to

chain

Lower the

forks against

the bottoms

of the fork

pockets

2. Securely connect the boom to the carriage of the forklift with the safety chain.

Wrap the safety chain around the fork carriage and fasten the snap hook to the chain/strap. There should be

no slack in the chain/strap. The sole purpose of the safety chain is to prevent the boom from sliding off of the

forks. It is NOT intended or designed to bear the full load rating.

3. [Telescoping models only] Adjust the boom length:

a. Loosen the X-handle locking bolt (“locking bolt”), by turning it counterclockwise.

b. Grasp the adjustment handle at the end of the boom and pull the boom to the desired length.

c. Tighten the locking bolt by turning it clockwise.

Turn locking bolt counterclockwise

Boom extension

adjustment handle

Boom

to loosen

Turn locking bolt clockwise

to tighten against boom

Boom sleeve

4. [

Copyright 2016 Vestil Manufacturing Co. Page 23 of 28

Page 24

01/11 rev. 10/26/2017 LM, MANUAL

4. [OBT models only] Adjust the boom angle, if necessary, to accommodate the load. To safely perform the

adjustment process requires at least 2 people:

a. Person 1 grasps the (red) angle adjustment handle with one hand

b. While Person 2 pulls out the locking pin; then

c. Both 1 & 2 press down on the adjustment handle until the desired angle is achieved.

d. One of the participants reinserts the locking pin.

Material handling is dangerous. Improper use of this product might result in serious personal injuries.

Confirm that the load weighs less than the maximum rated load of your boom AND that your fork lift is rated to lift the

combined weight of the boom and the load.

Contact the manufacturer of your fork lift BEFORE using the boom. Request that the lift manufacturer provide:

1. Written approval to use the boom with your lift truck; AND

2. Markings (labels) for the lift truck that:

– Identify your LM-boom; AND

– Provide the approximate net weight of the forklift truck and boom at the maximum fork elevation with a

laterally-centered load. [29 CFR 1910.178(a)(5)].

DO NOT use the boom until the forklift manufacturer provides adjusted maximum rated load tags for your fork lift.

DO NOT attempt to lift loads weighing more than the rated load of either the boom or lift truck, whichever is smaller

Maximum rated load information appears in the tables on pages 4, 6, 8, 10, 12, 14, 16, 18, 20, and 22.

Strictly adhere to all rules applied at your worksite regarding forklift operation, fork attachment usage, and load rigging.

ONLY use rigging having maximum load ratings that exceed the load weight.

DO NOT connect a load to only 1 hook, which will cause the load to rotate during lifting and transport operations. Loads

should connect to both hooks simultaneously.

Load attached to only one hook (circled): load likely to rotate

Load attached to both hooks: load rotation minimized

.

Load

Copyright 2016 Vestil Manufacturing Co. Page 24 of 28

Load

Page 25

01/11 rev. 10/26/2017 LM, MANUAL

Test the stability of the load in the rigging. Raise the forks slowly to minimize load movement. Raise the forks until

the load is entirely suspended from the boom. Watch the load and boom closely for either of the following issues: 1)

Load sliding in rigging; or 2) Boom sliding towards tips of forks. If you notice either issue, immediately lower the forks

and adjust the rigging. Retest the stability of the load in the rigging

While transporting a load with the boom, the load should only be 6-8 inches above the ground. Adjust load height

to avoid obstacles along the travel path.

DO NOT exceed approximately 1.5mph (2.4kph) while transporting a load with the boom.

Travel ONLY on smooth, level surfaces. Turn slowly and smoothly.

If the load is unstable while suspended, DO NOT use the boom.

5. Attach the load to the boom by connecting the load to appropriate rigging. Attach the rigging to the end hook or to

both the end hook and the stabilizing hook (see diagram below).

a. Verify that the load attachment is stable;

b. Raise the load until it is elevated no more than 6-8 inches above the ground (entirely suspended from the

boom).

c. Slowly transport the load to the desired unloading location;

d. Slowly lower the load until it is entirely supported by the ground and there is slack in all rigging.

e. Disconnect the rigging from the hooks;

f. Adjust the fork position until no more than 6-8 inches above the ground;

g. Return the boom to its storage location.

NOTE: Return OBT and OBNT model booms to the fully lowered (horizontal) position by reversing Step 4 on

p. 24 BEFORE backing out of the fork pockets.

Shackle

End hook

Support

leg

Shackle

Stabilizing

hook

Inspections:

Immobilize the boom before conducting inspections and performing maintenance. If an inspection

reveals problems, restore the boom to normal operating condition BEFORE using it again. DO NOT use a

boom that is structurally damaged in any way. Structural damage includes, but is not limited to, cracked welds,

warping or deformation of the fork pockets, support leg, frame members, boom, or boom sleeve.

Inspect the boom regularly. An example of an inspection procedure appears in

1. Regular inspection — before using the boom (including its first use) inspect the following components for

conditions that might interfere with normal operation:

Frame and fork pockets: fork pockets should be square and solid. Each pocket should be rigidly welded to the

frame. Excessive wear or damage (or indications of metal fatigue) to any portion of the fork pockets, support

frame, boom or boom sleeve.

Boom: check all welds. The boom should be straight and undamaged, i.e. no cracks, punctures, warps, etc.

Telescoping models should slide without binding inside the receiver/sleeve.

Safety chain: all links of the chain should be intact and of equal dimensions. The chains should be securely

attached to the frame by means of a lap link. The snap hook at the end of the chain should close completely

and automatically.

Hooks and shackles: examine both the end hook and the stabilizing hook. Record the measurement of the

throat opening of each hook and compare the measurements with those taken during the very first inspection.

Replace a hook if its throat opening is more than 15 percent wider than the original throat opening

measurement, or if the hook is twisted more than 10° from the plane of the unbent hook. Discard the damaged

hook. The latch of the end hook should close automatically. Shackles should be securely attached to the

underside of the boom. Examine all pins that attach shackles to the boom for cracks and warps.

Locking bolt (telescoping models only): confirm that the locking bolt securely engages the top of the boom.

Support leg: inspect the support leg. It should be straight, undamaged (no cracks or deformations), and

securely attached to the underside of the boom.

Copyright 2016 Vestil Manufacturing Co. Page 25 of 28

Page 26

01/11 rev. 10/26/2017 LM, MANUAL

Labels: the product should always be labeled as shown in the labeling diagram on p. 27. Replace any label

that is damaged, significantly faded, or not easily readable from a reasonable distance.

2. Annual performance evaluation: At least once per year, authorized personnel should lift a maximum rated load with

the boom. Afterwards, conduct a “Prior-to-use inspection”. Confirm that the product is in normal operating condition

before returning it to service.

Maintenance:

Implement a maintenance program to ensure that the boom remains in normal operating condition. The following

steps should be utilized in conjunction with maintenance procedures applicable to fork truck attachments provided in

the most recent edition of ANSI B56.1.

Step 1: Tag the boom, “Out of Service.”

Step 2: Remove dirt and other matter from all surfaces.

Step 3: Conduct a “Prior-to-use” inspection (see p. 25). If severe deformities, corrosion, rusting, or excessive wear of

structural members is found, DO NOT use the product.

Step 4: Perform all necessary adjustments, replacements and/or repairs but DO NOT modify the boom.

DO NOT return the boom to service until all necessary adjustments and repairs are complete! There is

a significant difference between necessary adjustments and repairs, and modifications. An “adjustment” is a simple

correction that restores the boom to normal operating condition, such as tightening loose fasteners or removing dirt or

other debris from surfaces. Repair means removal of worn parts and installing replacement parts.

A “modification” is a change that alters the boom from original operating condition, like bending the structural

members or removing parts. NEVER modify the boom without the express, written approval of Vestil. Modifications

might make the boom unsafe to use and automatically void the Limited Warranty.

Step 5: Make a dated record of all repairs, adjustments, and replacements performed.

Copyright 2016 Vestil Manufacturing Co. Page 26 of 28

Page 27

01/11 rev. 10/26/2017 LM, MANUAL

Labeling diagram:

Each boom should be labeled as shown below. Replace any label that is damaged or not easily readable.

One of labels 928-935 as indicated in the table

(on either fork pocket)

Label Model

928 LM-OBT

929 LM-OBNT

930 LM-1T

931 LM-EBT

932 LM-HRT

933 LM-EBNT

934 LM-HRNT

935 LM-1NT

962 LMS-EBT

963 LMS-EBNT

Label 287 (on either fork pocket)

Label 218 (on either fork pocket)

Copyright 2016 Vestil Manufacturing Co. Page 27 of 28

Page 28

01/11 rev. 10/26/2017 LM, MANUAL

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and workmanship

during the warranty period. Our warranty obligation is to provide a replacement for a defective original part if the part

is covered by the warranty, after we receive a proper request from the warrantee (you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or from an

authorized distributor AND Vestil has been fully paid.

What is an “original part”?

An original part is a part used to make the product as shipped to the warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that displays the

shipping date; AND 2) a written request for warranty service including your name and phone number. Send requests

by any of the following methods:

Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 info@vestil.com

2999 North Wayne Street, PO Box 507 Phone

Angola, IN 46703 (260) 665-7586

In the written request, list the parts believed to be defective and include the address where replacements should be

delivered.

What is covered under the warranty?

After Vestil receives your request for warranty service, an authorized representative will contact you to determine

whether your claim is covered by the warranty. Before providing warranty service, Vestil may require you to send the

entire product, or just the defective part or parts, to its facility in Angola, IN. The warranty covers defects in the

following original dynamic components: motors, hydraulic pumps, electronic controllers, switches and cylinders. It

also covers defects in original parts that wear under normal usage conditions (“wearing parts”), such as bearings,

hoses, wheels, seals, brushes, and batteries.

How long is the warranty period?

The warranty period for original dynamic components is 1 year. For wearing parts, the warranty period is 90 days. The

warranty periods begin on the date when Vestil ships the product to the warrantee. If the product was purchased from

an authorized distributor, the periods begin when the distributor ships the product. Vestil may, at its sole discretion,

extend the warranty periods for products shipped from authorized distributors by up to 30 days to account for shipping

time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of Vestil will contact

you to discuss your claim.

What is not covered by the warranty?

1. Labor;

2. Freight;

3. Occurrence of any of the following, which automatically voids the warranty:

Product misuse;

Negligent operation or repair;

Corrosion or use in corrosive environments;

Inadequate or improper maintenance;

Damage sustained during shipping;

Collisions or other incidental contacts causing damage to the product;

Unauthorized modifications: DO NOT modify the product IN ANY WAY without first receiving written

authorization from Vestil. Modification(s) might make the product unsafe to use or might cause excessive

and/or abnormal wear.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to the extent

allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this Limited Warranty.

Copyright 2016 Vestil Manufacturing Co. Page 28 of 28

Loading...

Loading...