Page 1

GAS COOKER USAGE

AND INSTALLATION MANUAL

EN

FSHG 60

Page 2

Dear Customer,

We take offering quality products more than your expectation as goal, offers you

the products produced in modern facilities where each cooker was carefully and

particularly tested for quality.

This leaflet contains all the necessary information for installing and using

your new cooker.

Before you begin using your new cooker, we suggest you read this leaflet carefully

because it contains all the basic information for proper and reliable installation,

proper use and regular maintenance of your cooker. This cooker must be installed

only by a qualified professional in accordance with safety standards and laws.

Never attempt to repair your cooker on your own.

CE Declaration of conformity

This cooker is only for domestic use inside a house (excluding professional use).

Any other use (such as heating a room) is improper and dangerous.

This cooker has been designed, constructed, and marketed incompliance with:

Safety requirements of the "Gas" Directive 2009/142/EC ;

Requirements of the Directive 93/68/EC.

Page 3

2

CONTENTS

1.

2. WARNINGS

General safety warnings

Installation warnings

During usage

During cleaning and maintenance

3. INSTALLATION

Adjusting the feet

Gas connection

Changing gas

USE OF YOUR PRODUCT

Using gas burners

Using cooktop burners

Accessories used in oven

CLEANING AND MAINTENANCE

Cleaning

Maintenance

SERVICE AND TRANSPORT

Information on transport

TECHNICAL CHARACTERISTICS

Installation environment for your cooker

Installing your cooker

Using the gas oven burner

Requirements before contacting the customer service

3.1

3.2

3.3

3.4

3.5

4.

4.1

4.1.1

4.1.2

4.2

5.

5.1

5.2

6.

6.1

6.2

Page 4

3

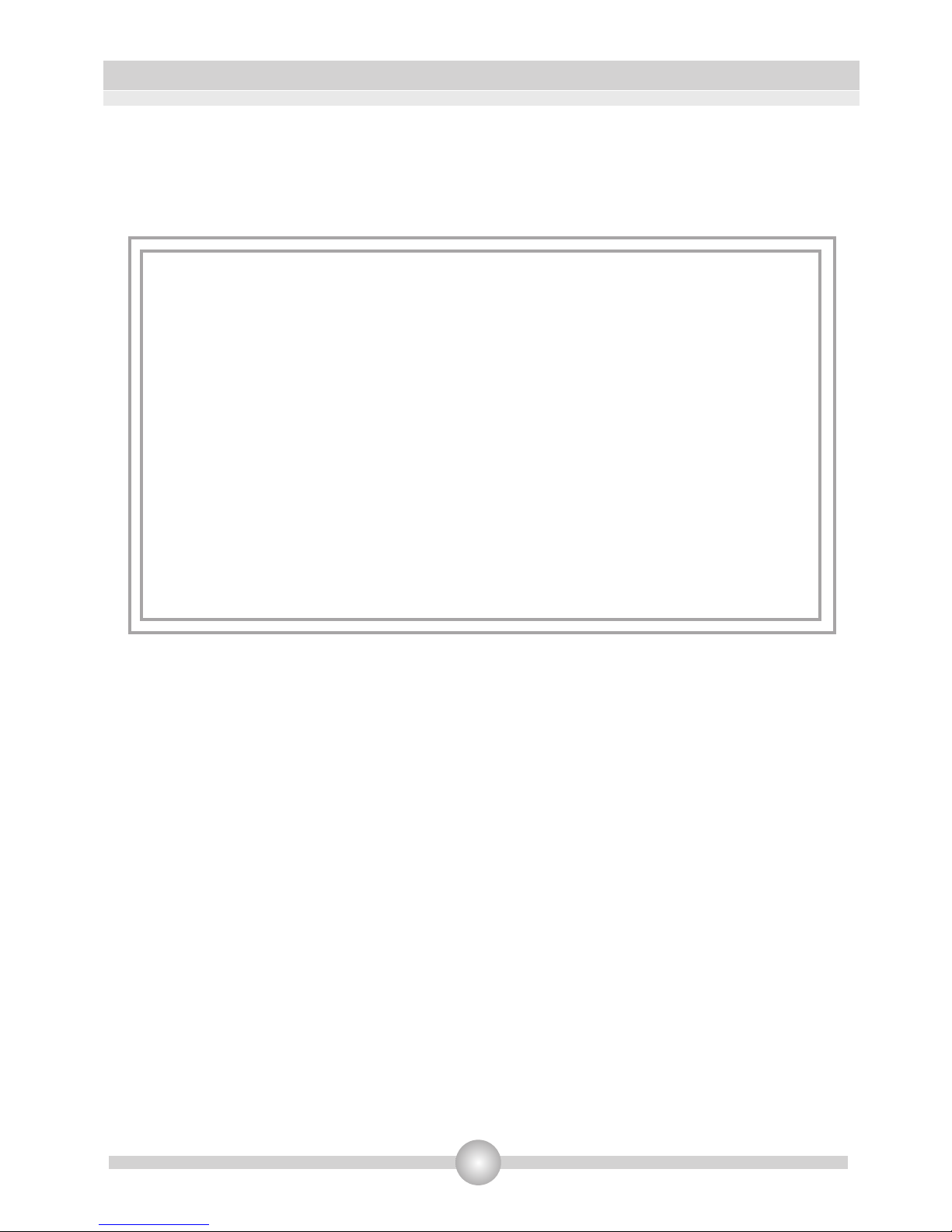

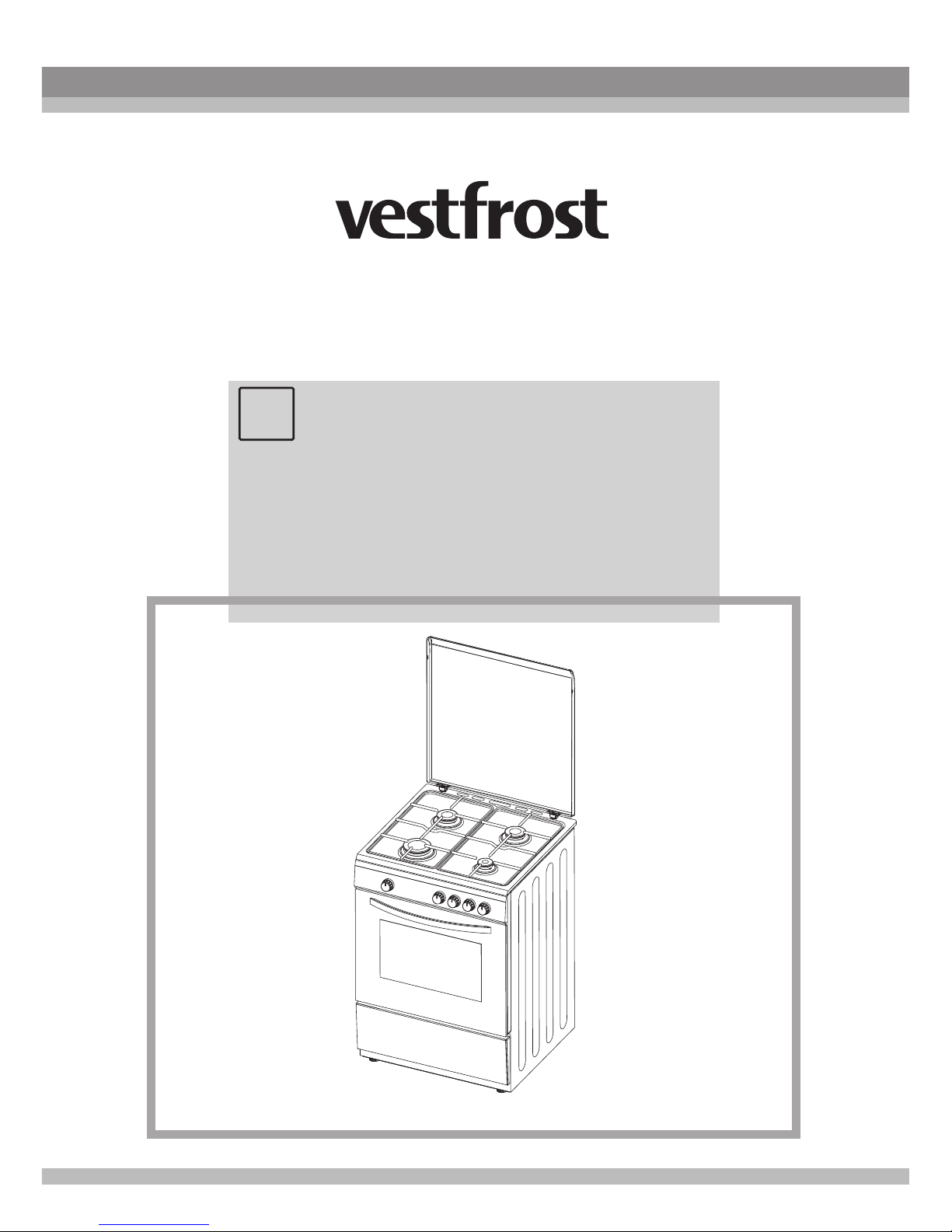

1. TECHNICAL CHARACTERISTICS

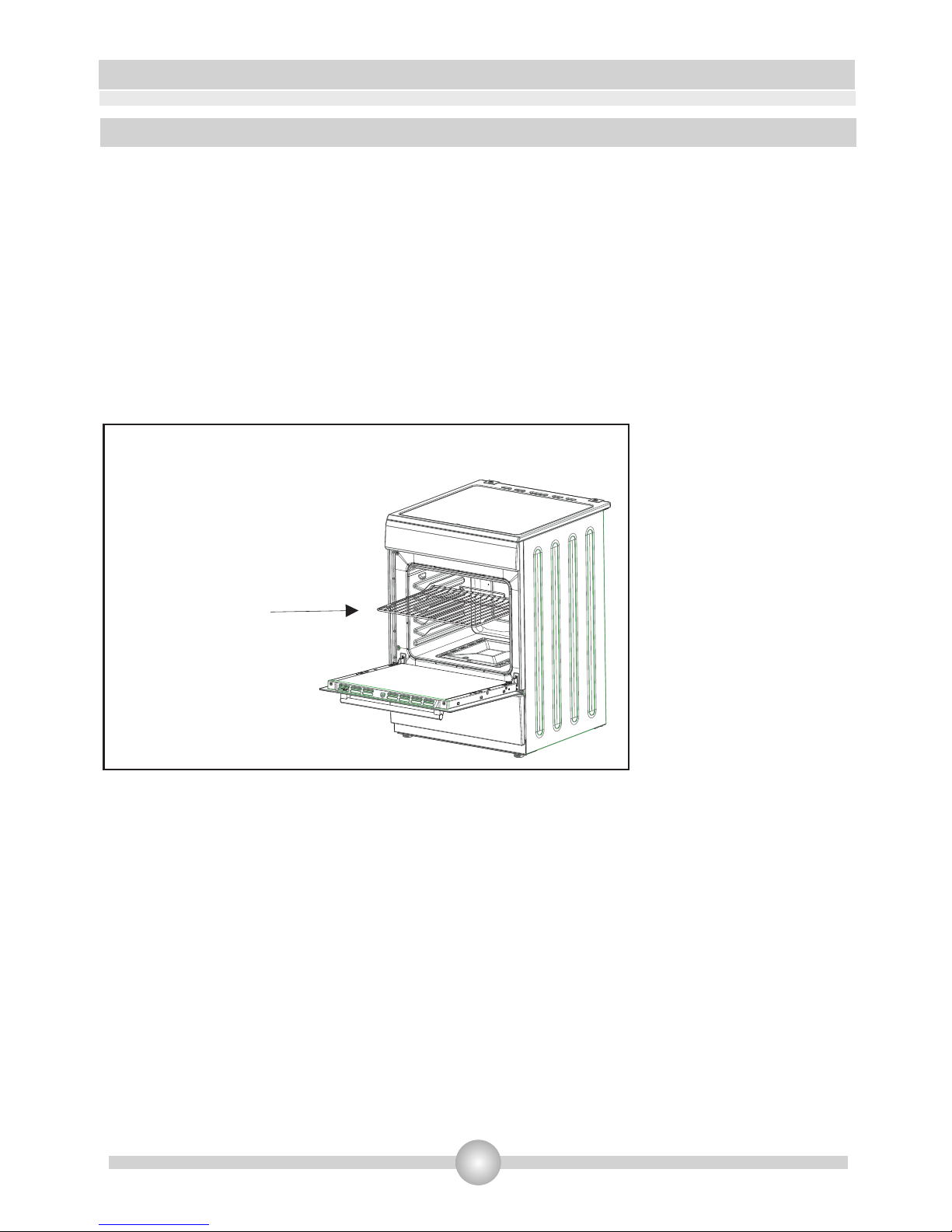

Cooker parts list:

1- Cooktop Cover

2- Cooktop

3- Control Panel

4- Oven Door Handle

5 - Storage compartment door

6- Adjustable feet

7- Oven Door

8- Oven Tray

9-Wire Shelf

MODEL

FSHG 60 60 60 85

DEPTHSIZE(cm)

LENGTH

(cm)

HEIGHT

(cm)

10- Semi-rapid burner

11- Rapid burner

12- Auxiliary burner

13- Pan support grid

14- Semi-rapid burner

10

11

12

13

14

1

2

3

4

5

6

7

8

9

Page 5

4

2. WARNINGS

READ THESE INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE USING YOUR

APPLIANCE, AND KEEP IT IN A CONVENIENT PLACE FOR REFERENCE WHEN NECESSARY.

THIS MANUAL IS PREPARED FOR MORE THAN ONE MODEL IN COMMON. YOUR APPLIANCE

MAY NOT HAVE SOME OF THE FEATURES THAT ARE EXPLAINED IN THIS MANUAL. PAY

ATTENTION TO THE EXPRESSIONS THAT HAVE FIGURES, WHILE YOU ARE READING THE

OPERATING MANUAL.

General Safety Warnings

- This appliance is intended for domestic household

use only and should not be used for any other purpose

or in any other application, such as for non-domestic

use or in a commercial environment.

- If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

- This appliance can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they

have been given supervision or instruction

concerning use of the appliance in a safe way

and understand the hazards involved. Children

shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

- WARNING: The appliance and its accessible

parts become hot during use. Care should be

taken to avoid touching heating elements.

Children less than 8 years of age shall be kept

away unless continuously supervised.

- WARNING: Unattended cooking on a hob with

Page 6

5

2. WARNINGS

fat or oil can be dangerous and may result in

fire. NEVER try to extinguish a fire with water,

but switch off the appliance and then cover

flame e.g. with a lid or a fire blanket.

- WARNING: Danger of fire: do not store items

on the cooking surfaces.

- Any spillage should be removed from the lid

before opening.

- The hob surface should be allowed to cool

before closing the lid.

- The appliance is not intended to be operated

by means of an external timer or separate

remote-control system.

- During use, the appliance becomes hot. Care

should be taken to avoid touching heating

elements inside the oven.

- Do not use harsh abrasive cleaners or sharp

metal scrapers to clean the oven door glass

since they can scratch the surface, which may

result in shattering of the glass.

- Do not use steam cleaners for cleaning the

appliance.

- CAUTION: Accessible parts may become hot

during use. Young children should be kept

away.

• Your appliance is produced in accordance with all applicable local and international

standards and regulations.

Page 7

6

2. . WARNINGS

• Maintenance and repair work must be made only by authorised service technicians.

Installation and repair work that is carried out by unauthorised technicians may endanger

you. It is dangerous to alter or modify the specifications of the appliance in any way.

• Prior to installation, ensure that the local distribution conditions (nature of the gas and

gas pressure) and the requirements of the appliance are compatible. The requirements for

this appliance are stated on the label.

• Do not try to lift or move the appliance by pulling the door handle.

• This appliance is not connected to a combustion products evacuation device. It shall be

installed and connected in accordance with current installation regulations. Particular

attention shall be given to the relevant requirements regarding ventilation.

• If after 15 s the burner has not lit, stop operating the device and open the kitchen door

or window and/or wait at least 1 min before attempting a further ignition of the burner.

• These instructions are only valid if the country symbol appears on the appliance. If the

symbol does not appear on the appliance, it is necessary to refer to the technical

instructions which will provide the necessary instructions concerning modification of the

appliance to the conditions of use of the country.

• All possible security measures have been taken to ensure your safety. Since the glass

may break, you should be careful while cleaning to avoid scratching. Avoid hitting or

knocking on the glass with accessories.

• While the oven door is open, do not let children climb on the door or sit on it.

Installation Warnings

• Do not operate the appliance before it is fully installed.

• The appliance must be installed by an authorised technician and put into use. The

producer is not responsible for any damage that might be caused by defective placement

and installation by unauthorised people.

• When you unpack the appliance, make sure that has not been damaged during

transportation. In case of any defect; do not use the appliance and contact a qualified

service agent immediately. As the materials used for packaging (nylon, staplers,

styrofoam...etc) may cause harmful effects to children, they should be collected and

removed immediately.

• Protect your appliance against atmospheric effects. Do not expose it to effects such as sun,

rain, snow etc.

• The surrounding materials of the appliance (cabinet) must be able to withstand a

temperature of min 100°C.

During usage

• When you first run your oven a certain smell will emanate from the insulation materials.

For this reason, before using your oven, run it empty at maximum temperature for 45

minutes. At the same time you need to properly ventilate the environment in which the

product is installed.

• During usage, the outer and inner surfaces of the oven get hot. While opening the oven

door, step back to avoid the hot steam coming out of the oven. There may be a risk of

burns.

• Do not put flammable or combustible materials, in or near the appliance when it is

operating.

• Always use oven gloves to remove and replace food in the oven.

Page 8

• Do not leave the cooker while cooking with solid or liquid oils. They may catch fire on

condition of extreme heating. Never pour water on to flames that are caused by oil. Cover

the saucepan or frypan with its cover in order to choke the flame that has occured in this case

and turn the cooker off.

• Always position pans over the centre of the cooking zone, and turn the handles to a safe

position so they cannot be knocked or grabbed.

• If you will not use the appliance for a long time, plug it off. Keep the main control switch off. Also when

you do not use the appliance, keep the gas valve off.

• Make sure the appliance control knobs are always in the "0" (stop) position when it is not used.

• The trays incline when pulled out. Be careful not to let hot liquid spill over.

• CAUTION: The use of a gas cooking appliance results in the production of heat, moisture and products

of combustion in the room in which it is installed. Ensure that the kitchen is well ventilated especially

when the appliance is in use, keep natural ventilation holes open or install a mechanical ventilation

device (mechanical extractor hood).

• Prolonged intensive use of the appliance may call for additional ventilation, for example opening of

a window, or more effective ventilation, for example increasing the level of mechanical ventilation

where present.

• CAUTION:

Turn off all the burners before shutting the lid.

The hob surface should be allowed to cool before closing the lid.

• When the door or drawer of the oven is open, do not leave anything on it. You may unbalance your

appliance or break the cover.

• Do not put heavy things or flammable or ignitable goods (nylon, plastic bag, paper, cloth...etc) into

the drawer. This includes cookware with plastic accessories (e.g. handles).

During cleaning and maintenance

• Always turn the appliance off before operations such as cleaning or maintenance. You can do it

after plugging the appliance off or turning the main switches off.

• Do not remove the control knobs to clean the control panel.

TO MAINTAIN THE EFFICIENCY AND SAFETY OF YOUR APPLIANCE, WE RECOMMEND YOU

ALWAYS USE ORIGINAL SPARE PARTS AND TO CALL ONLY OUR AUTHORISED

SERVICE AGENTS IN CASE OF NEED.

7

2. . WARNINGS

Page 9

8

3. INSTALLATION

This modern, functional and practical cooker that was manufactured with the parts and materials

of highest quality will meet your cooking needs in every aspect. Before using your cooker, please

read this leaflet carefully to find out all its functions and achieve the best possible results. For

proper installation, consider the following recommendations to avoid any problem or

dangerous situation. They must also be read by the technician who will install the cooker.

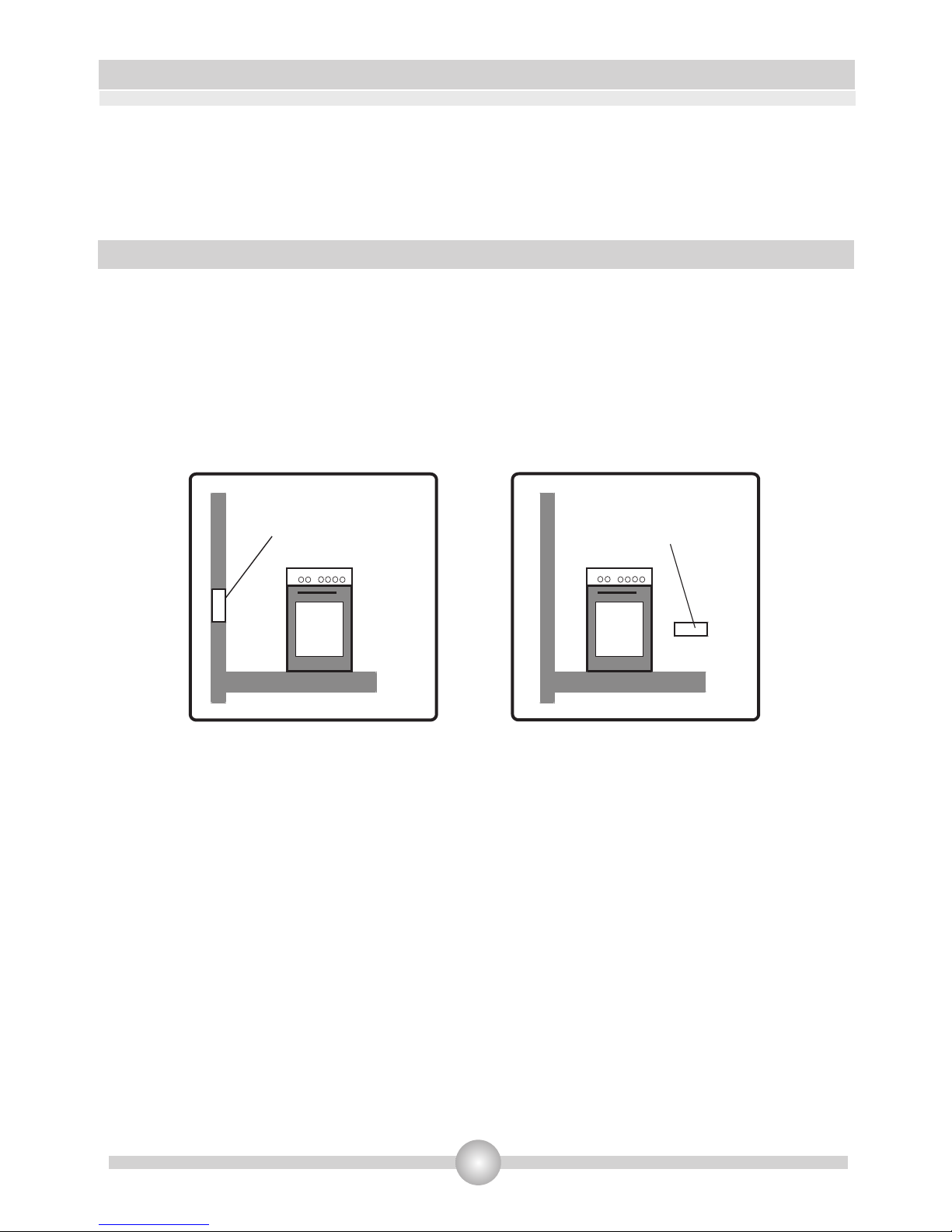

3.1 Installation environment for your cooker

Your cooker must be set up and used in a place where it will always have ventilation. Gas

combustion is made possible by the oxygen in the air. It is therefore necessary that the air be

renewed and that combustion products be discharged in accordance with the regulations. There

must be a natural ventilation enough to provide the gas to be used in the environment. The

airflow must enter via vents installed on walls in direct contact with the outside (see diagram

below).

While operating, this cooker needs 2m3 /h air per kw input.

•

•

• The airflow must enter through the bottom (minimum 100cm ²) and come out on top (minimum

100cm ²). These vents must therefore have a minimum area of 100 cm2 for the effective passage

of air. These vents should be open and never closed. They should preferably be located near the

rear of the cooker (for the air inlet Fig. 1 and 2) and opposite the burnt gases caused by cooking

(for evacuation) that is to say at least 1.80m above the ground. If you cannot open these vents

toto the outside, where the cooker is installed, the necessary air may also come from another

location provided it is properly ventilated and is neither a bedroom nor a dangerous place.

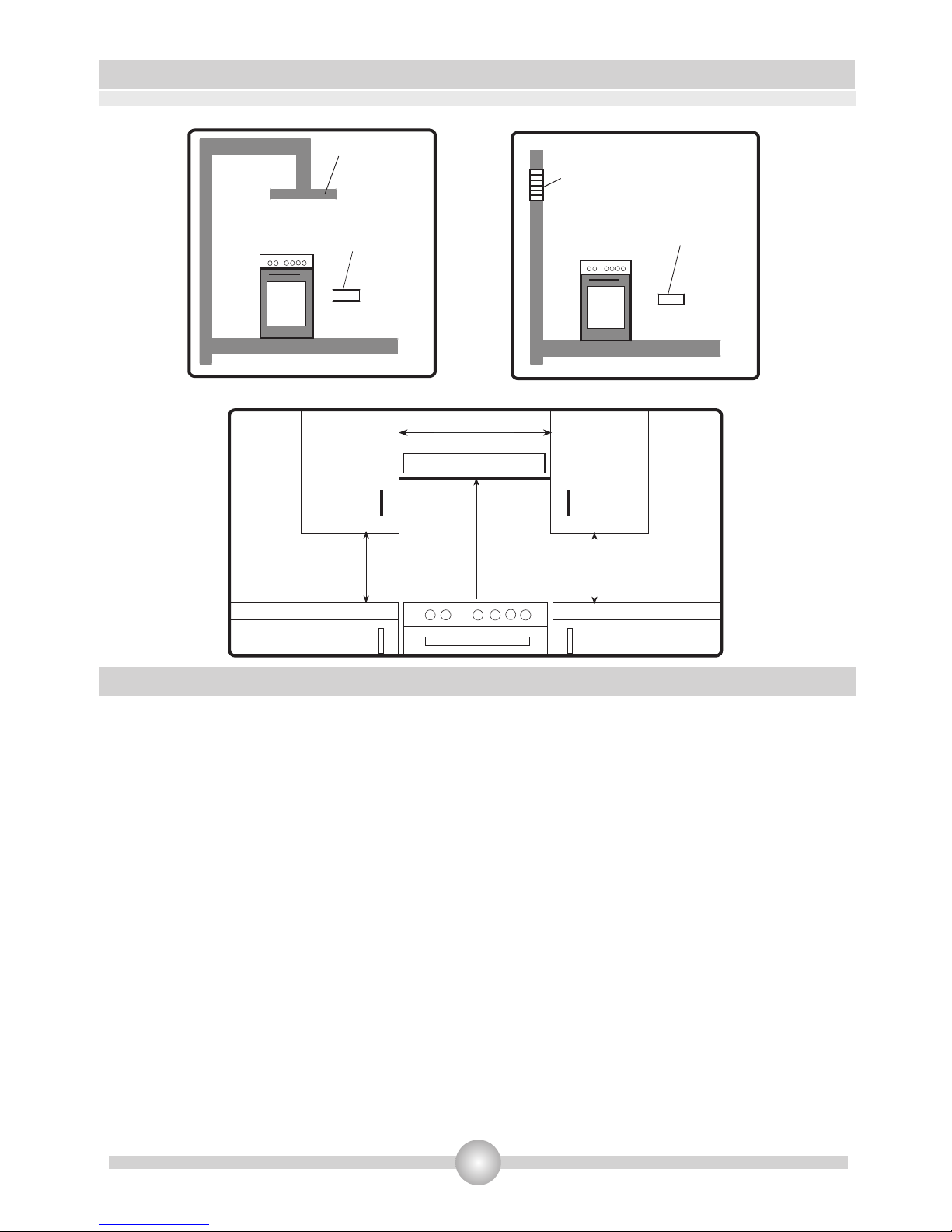

Evacuating burnt gases

It is advisable to install either an exhaust hood directly connected to a pipe leading directly to the

outside (Fig. 3), or an electrical ventilator installed on the window or outside wall (Fig. 4) to

evacuate flue gases directly outside. The electrical ventilator power supply must be calculated in

order to renew the air in the kitchen 4-5 times per hour.

Air inlet section

2

min. 100cm

Air inlet section

2

min. 100cm

Figure 1

Figure 2

Page 10

9

3. INSTALLATION

Extracting

hood

Electrical ventilator

Air inlet section

2

min. 100cm

Air inlet section

2

min. 100cm

Figure 3

Figure 4

•

•

•

•

•

•

3.2 Installing your cooker

The cooker may be placed near another piece of furniture, but make sure that the height of

surrounding furniture does not exceed the cooker height (see fig. 5).

If kitchen furniture are above the cooker, leave a space of at least 10cm between the sides of the

cooker and the furniture.

The minimum height between the cooktop and the hood (or wall units) is shown in Fig. 5. The

exhaust hood must be located at least 65cm from the cooktop. If there is no hood, the height of

.

the furniture located above the cooktop must not be less than 70cm

Leave a 2cm space between the rear of the cooker and the wall, and between the sides and

adjacent furniture.

Pay attention not to place the cooker near a refrigerator; there must be no flammable or

ignitable materials such as curtain, cloth, etc... that may easily get burnt.

Adjacent furniture must be manufactured resistant to temperatures up to 90°C.

Figure 5

Min. 60cm

COOKER HOOD

Min. 42cm

Min. 42cm

Min. 65cm (with hood)

Min. 70cm (without hood )

Page 11

3. INSTALLATION

Figure 6

9

3.3 Adjustment of feet

.

3.4 Gas connection

Your stands on 4 adjustable feet. When the is

placed where to be used, check if the product is balanced. If it

is not balanced, you can make the adjustment by turning the

feet clockwise if required. It is possible to raise the appliance

maximum 30mm by the feet. If the feet are adjusted

appropriately, it is required not to move the appliance by

dragging, it should be moved by lifting it up

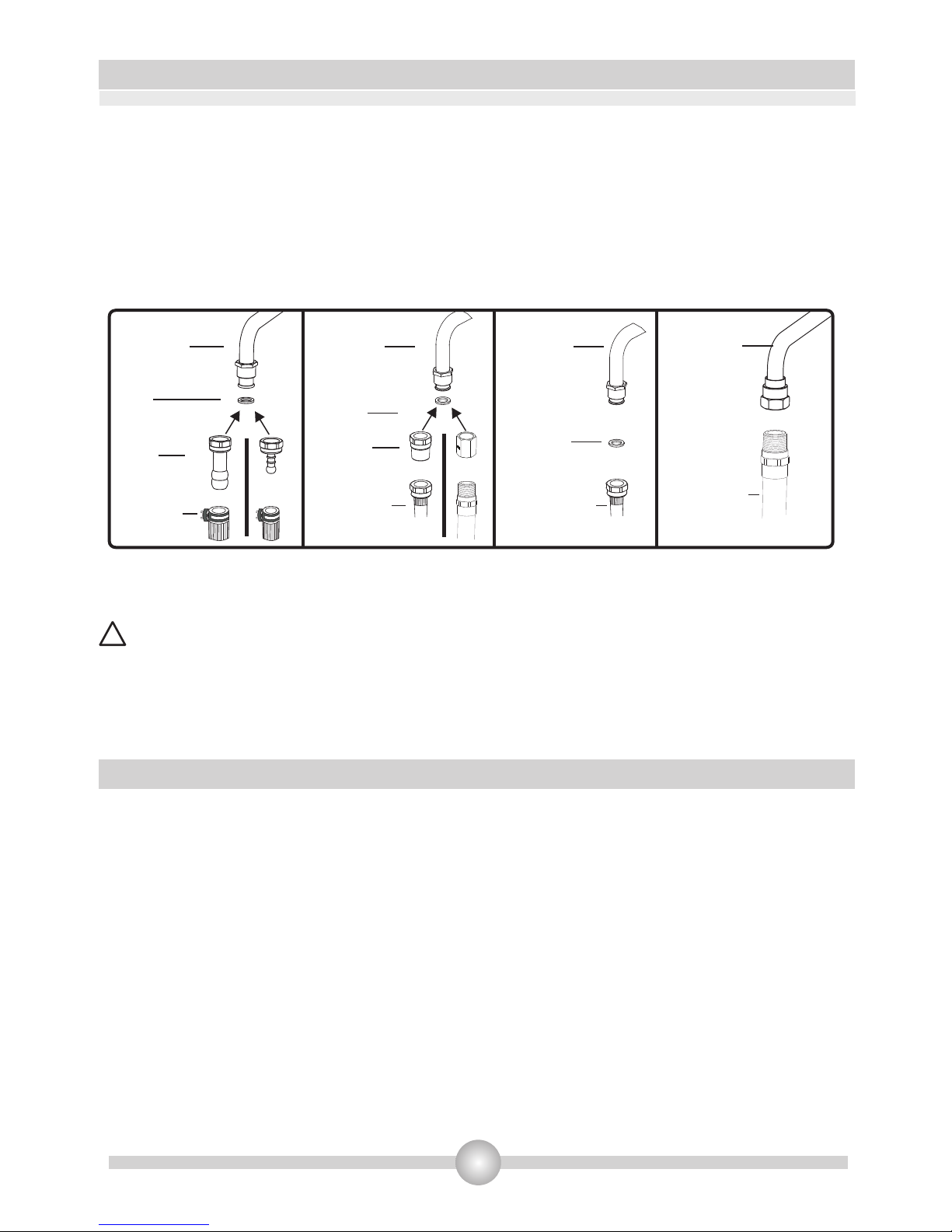

Assembly of gas supply and leakage check

The connection of the appliance should be performed in accordance with local and international

standards and regulations applicable. You can find the information related to appropriate gas types

and appropriate gas injectors on technical data table. If the pressure of used gas is different than

these values stated or not stable in your area, it may be required to assemble an available pressure

regulator on the gas inlet. It is certainly required to contact to the authorized service to make these

adjusments.

The points that must be checked during flexible hose assembly

If the gas connection is made by a flexible hose that is fixed on the gas inlet of appliance, it must be

fixed by a pipe collar as well. Connect your appliance with a short and durable hose that is as close

as possible to the gas source. The hose's permitted maximum lenght is 1.5m. The hose that brings

gas to the appliance must be changed once a year for your safety.

0

The hose must be kept clear from areas that may heat up to temperatures in excess of 90 C. The

hose must not be ruptured, bent or folded. It must be kept clear of sharp corners, moving things,

and should not be defective. Before assembly, it must be checked whether there is any production

defect.

As gas is turned on, all connection parts and hose must be checked with soapy water or leakage

fluids. Do not use naked flame to check gas leakage. All metal components used during gas

connection must be clear of rust. Also check the expiry dates of components to be used.

The points that must be checked during fixed gas connection assembly

To assemble a fixed gas connection (gas connection made by threads, e.g. a nut), there are different

methods used in different countries. The most common parts are already supplied with your appliance.

Any other part can be supplied as spare part.

During connections always keep the nut on the gas manifold fixed, while rotating the counter-part. Use

spanners of appropriate size for safe connection. For all surfaces between different components,

product product

Page 12

3. INSTALLATION

10

always use the seals provided in the gas conversion kit. The seals used during connection should

also be approved to be used in gas connections. Do not use plumbing seals for gas connections.

Remember that this appliance is ready to be connected to gas supply in the country for which it has

been produced. The main country of destination is marked on the rear cover of the appliance. If you

need to use it in another country, any of the connections in the figure below can be required. In

such a case, learn the appropriate connection parts and obtain those parts to perform a safe

connection.

It is required to call the authorized service to be able to make the gas connections appropriately

and in compliance with safety standards.

Surely do not use any match or lighter for control of gas leakage

The gas inlet of this product is on the right side of the appliance. If connection point needs to be

moved to the left side of the appliance, you can request an extension pipe from your authorized

service.

During the electric connection, follow the instructions stated in the user manual

The earthing cable must be connected to the earth terminal

You have to ensure the power cord with suitable insulation to be connected to the power source

during the connection If there is no appropriate earthed electric outlet in accordance with

regulations in the place where the appliance to be installed, contact to our authorized service.

The earthed electric outlet must be close to the appliance.

Do not use an extension cord

The power cord must not touch to the hot surface of the product.

In case the cord is damaged, contact Authorized Service to have it changed

Any wrong electric connection may damage your appliance, as well as endangering your safety,

rendering your guarantee invalid

ATTENTION! .

3.5 Electric connection and safety

.

• .

•

.

• .

•

• .

•

.

Adapter

Gas Pipe Gas Pipe Gas Pipe Gas Pipe

Seal

Seal

Seal

Hose

Fitting

Gas Hose

with Collar

Mechanical

Gas Hose

Mechanical

Gas Hose

Mechanical

Gas Hose

Page 13

12

•

•

•

•

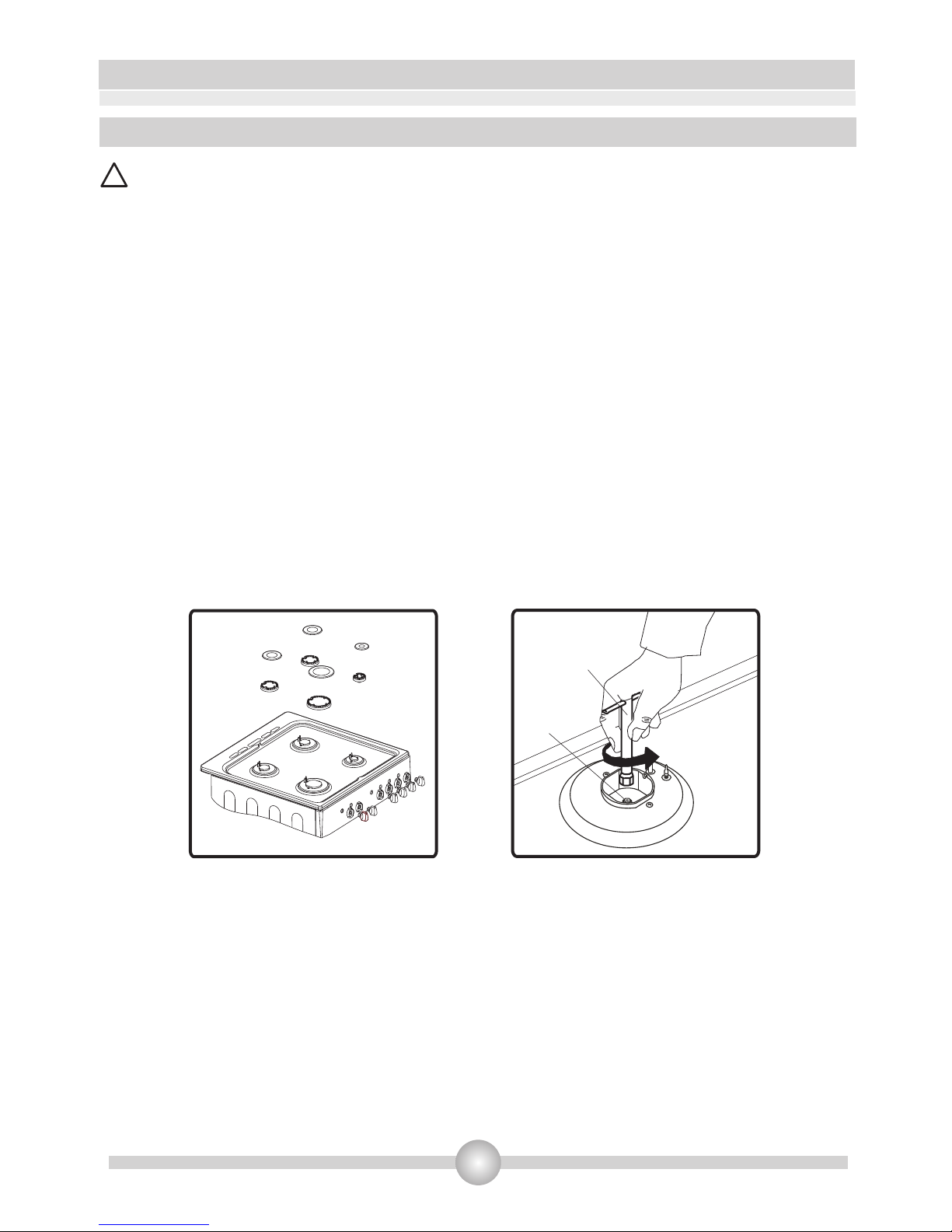

3.6 Changing gas

Warning : The following procedures must be undertaken by authorised service personnel.

Your cooker has been designed to use either liquefied petroleum gas (propane or butane), or

natural gas. The gas burners can be adapted to these different types of gas, by replacing the

corresponding injectors and adjusting the minimum flame length of each burner. The steps

below must be strictly carried out:

Changing Injectors:

Cooktop burners:

Shut off main gas.

Remove the burner cap and the upper burner (Figure 8).

Unscrew the injectors. For this, use a 7mm spanner (Figure 9).

Install the new injectors in accordance with the type of gas used, as shown on the technical data

table. Be careful to tighten straight the new injectors, because if you mount them sideways, you will

damage the thread of the rack and the rack will need to be changed (and it will not be in guarantee

extent).

Oven Injectors :

The oven burners are fitted by a single screw that is placed on the tip of the burner.

For the oven burner (below), open the oven door, remove the screws holding the lower sheet.

Open the compartment beneath the oven (pull-down door) to access the front screw located on

the burner (Figure 11). If the cooker has a sub-oven front , you must first dismantle the oven

door to gain access to the screws holding the sheet.

3. INSTALLATION

!

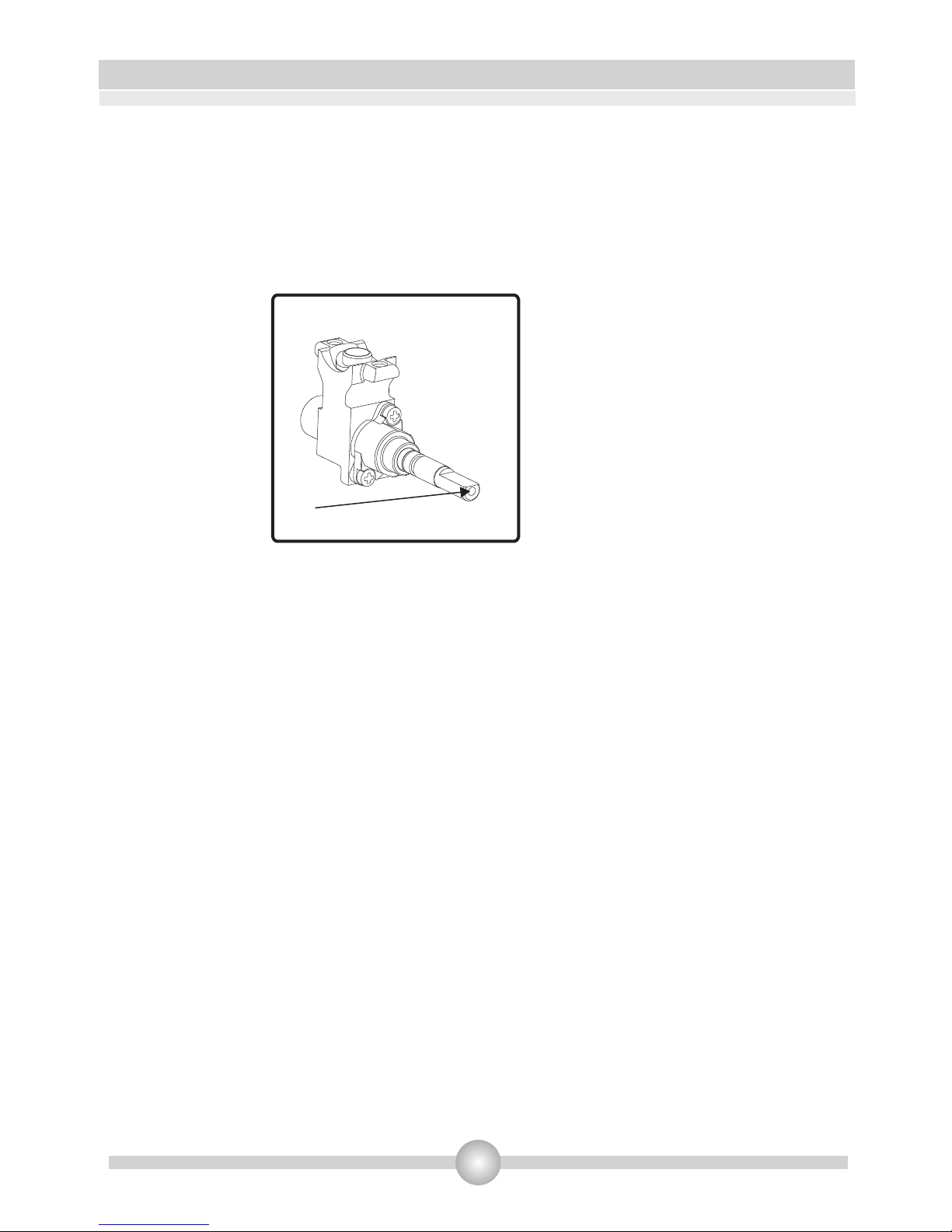

Figure 9

Injector

Spanner

Figure 8

Page 14

3. INSTALLATION

13

Remove the burner screw, and move the burner diagonally to access the injector at the rear

bottom of the muffle oven (Figure 11).

Unscrew the injectors. For this, use a 7mm spanner. Install the new injectors in accordance with

the type of gas used, as shown on the technical data table. Be careful to tighten straight the new

injectors, because if you mount them sideways, you will damage the thread of the rack and the

rack will need to be changed (and it will not be in guarantee extent).

Adjusting the flame to minimum on the valve

The flame length at minimum position is adjusted with a flat screw located on the valve. For valves

with thermocouple, the screw is located on the side of the valve spindle (Figure 12).

To determine the min. position, ignite the burners one after another and set them at minimum

position. With the help of a small screwdriver fasten or loosen the by pass screw around 90

degrees. When the flame has a length of at least 4mm, the adjustment is correct. For control, make

sure that the flame does not die out when passing from the maximum position to the minimum

position. Create an artificial wind with your hand toward the flame to see if the flames are stable.

Figure 10 Figure 11

Screw

Injector

Figure 12

Bypass screw

Valve with thermocouple

Page 15

3. INSTALLATION

14

For the oven burner, let it run at minimum position for 5 minutes. Open and close the oven

door 2-3 times to check the stability of the burner flame.

During the conversion from LPG to NG, the bypass screw must be unscrewed. When converting

from NG to LPG, the same screw must be tightened up. During this adjustment, make sure the

cooker is unplugged and the gas supply is open.

Changing the Gas Inlet:

Regularly check the expiry date of your cooker gas pipe. When the expiry date is reached, it is

necessary to change the hose.

These pipes are available on the market and must be consistent with current standards.

After changing the hose, you should check that there is no leakage by referring to the

information in the above paragraph: Connecting gas and checking leakage.

Figure 17

Figure 15

B

Screw(inside the hole)

Valve without flame failure device

Page 16

4. USE OF YOUR PRODUCT

15

•

4.1 Using gas burners

Igniting the burners

The symbols of the levers on the control panel indicate the position of the burner.

Manual Ignition of the Gas Burners

If your cooker is not fitted with electrical ignition or in case there is a failure in the grid, follow

the procedures listed below:

For cooktop burners: To turn one of the burners, press and turn the valve lever concerned

counterclockwise until maximum position and immediately ignite a match or gas lighter near

the crown burner holes. Move the ignition source away as soon as you see a stable flame.

For cooktop burners with thermocouple: Cooktops fitted with safety thermocouple provide

security when the flame goes out accidentally. For this reason, during the manual ignition, press

and hold the valve lever until you see stable flames. If the flames remain unstable after releasing

the button, repeat the procedure. If the flame goes out, the thermocouple system will close off

the said gas valve towards the burner and will prevent any accumulation of unburned gas. You

must wait at least 90 seconds before re-igniting a gas burner after an automatic cut.

For the oven burner (fitted with thermocouple): All oven burners are fitted with safety

thermocouple and provide security when the flame goes out accidentally. To ignite the oven

burner, press and turn the oven valve lever counterclockwise until it reaches maximum position.

While pressing the lever, immediately ignite a match or gas lighter near the ignition hole located

on the left front of the burner. Once the burner is lit with a steady flame, withdraw the ignition

source at once and hold pressed for about 3 seconds. If the flames remain cut out after

releasing the knob, repeat the procedure. If the flame goes out, the thermocouple system will

shut off the gas inlet of the oven valve towards the burner and will prevent any accumulation of

unburned gas. If the oven burner does not ignite after you keep the burner knob pressed for at

least 30 seconds, open the oven door and do not attempt re-ignition until at least 90 seconds.

When oven flames go out accidentally, repeat the same procedure.

Page 17

4. USE OF YOUR PRODUCT

16

MAX Position

Off Position

Intermediate

MIN Position

Figure 14

4.1.1

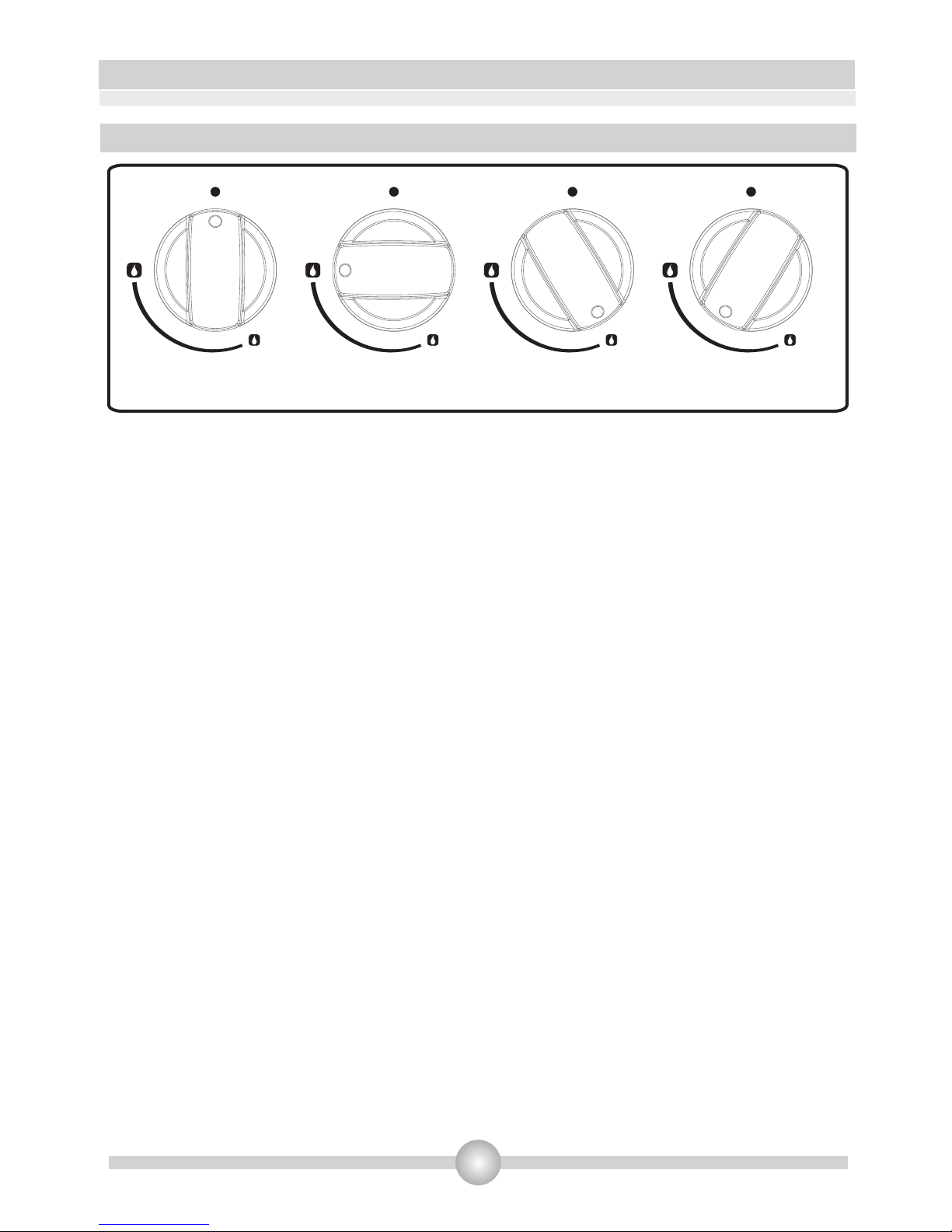

Cooktop valve levers have 3 positions: Off (0), max (big flame symbol) and min (small flame

symbol). After igniting the burner to "Max" position (as explained above), you can adjust the flame

length between "Max" and "Min" positions. Do not put the lever between the "Max” and “Off”

positions.

Using cooktop burners

Page 18

4. USE OF YOUR PRODUCT

17

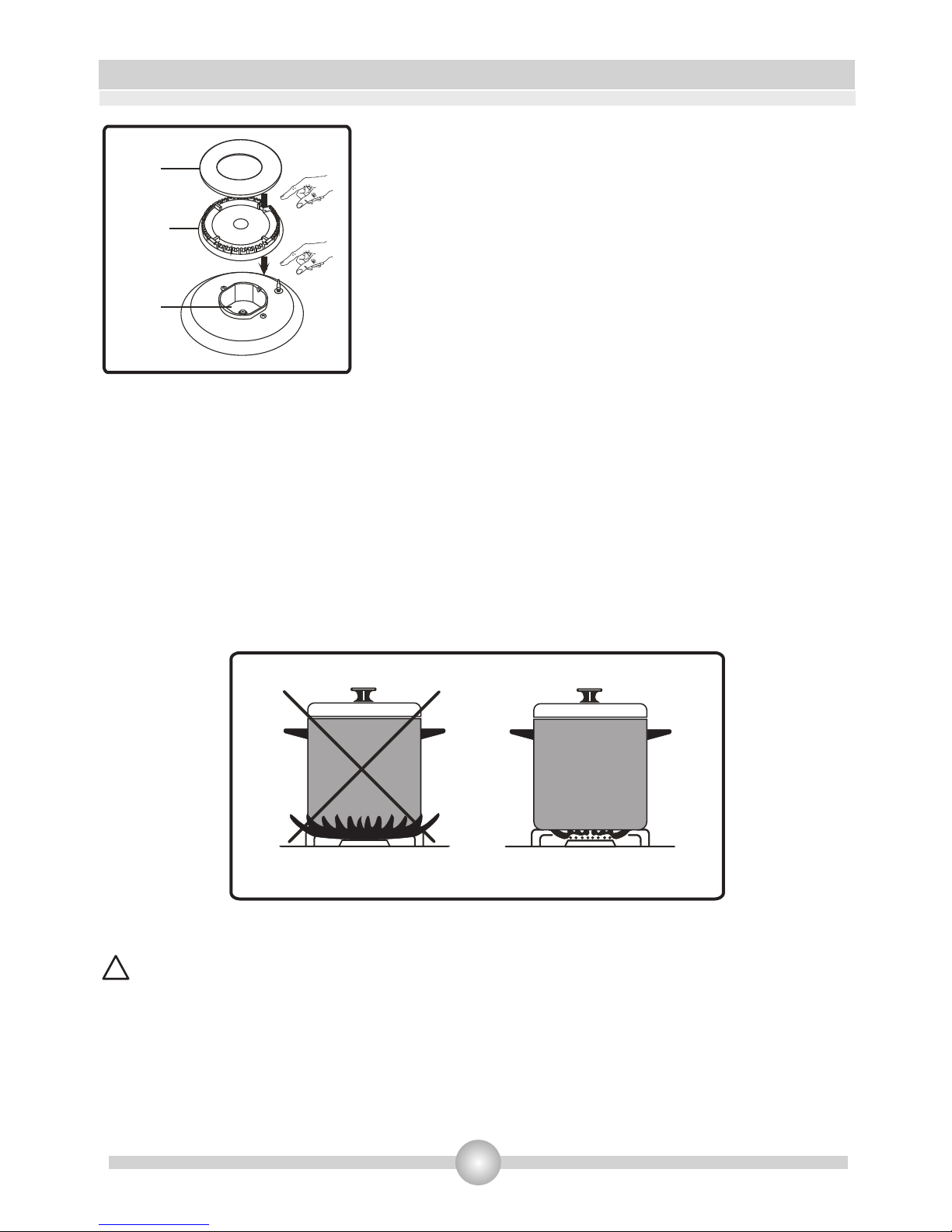

After the ignition, check the flames visually. If you see

yellow tip, lifted or unstable flames; turn the gas flow off,

and check the position of burner caps and crowns (fig.15).

Take note: these are very hot, let them cool to avoid burning

yourself. Be careful that no liquid flows inside the burners. If

the flames accidentally escape from the burner, close the

valves, ventilate the kitchen with fresh air, and wait at least 90

seconds before re-igniting.

To stop the cooking, turn the burner lever clockwise until the

mark on the lever is facing the point "0" (lever mark up).

Your cooktop is fitted with burners of different diameters.

The cheapest

way to use the gas is to reduce the flame to minimum position once you reach boiling point. It is

recommended to always cover your cooking pan.

Rapid Burner: 22-26cm

Semi-rapid burner 14-22cm

Auxiliary burner: 12-18cm

In order to obtain the most efficiency

from the cookers, pay attention to the sizes of saucepans that you put the on the cookers and

make sure that the saucepans have flat bases. Do not use saucepans with concave or convex

bottom to avoid wasting energy. Use proper-sized saucepans corresponding to the flame; if you

use containers smaller than those specified below, you will have wasted energy.

When not using your cooker for a long while, always close the gas inlet valve.

Use only flat pans.

Ensure that the base of the pan is dry before placing it on the burners.

WARNING:

•

•

Figure 16

!

Cap

Crown

Burner

Figure 15

Page 19

•

•

The temperature of parts exposed to the flame can be very high when in use. So, it is imperative

to keep children and animals out of the reach of the burners during and after cooking.

After use, the cooktop remains hot for a long time. Do not touch it and do not place objects on

it.

4.1.2 Using the gas oven burner

Preheating

When you need to preheat the oven, we recommend you do so 10 minutes before placing a dish.

For recipes needing high temperatures, e.g. bread, pastries, scones, souffles, etc..., best results

are achieved if the oven is preheated first. For best results when cooking frozen or chilled food

always preheat the oven first.

Cooking

Your cooker has been delivered with wire shelf and oven tray. You may also use glass dishes,

cake pans, oven plates specially adapted to oven baking, which you may find on the market.

Make sure you follow the instructions given by the manufacturer on the possible use of the

dishes. If small sized containers are used, place them on the shelf such that they are precisely in

the middle of the wire. The following instructions should also be followed for all glazed dishes.

If food for cooking does not cover the entire surface of the cooktop, if it is food from the freezer,

the tray may undergo changes in shape due to high temperatures caused by cooking. The tray

will take back its original shape only when it has completely cooled after cooking. This is a

perfectly normal phenomenon caused by heat transfer.

If you use dishes and other glassware for cooking, do not expose directly to cold after taking

them out of the oven. Do not place on cold or wet surfaces. Place them on a dry kitchen towel or

on a trivet, and make sure they cool slowly, so as to prevent them from breaking.

•

•

•

•

• Be careful not to put the oven tray on the bottom of the oven because it may overheat and

damage the oven enamel.

18

4. USE OF YOUR PRODUCT

Figure 18

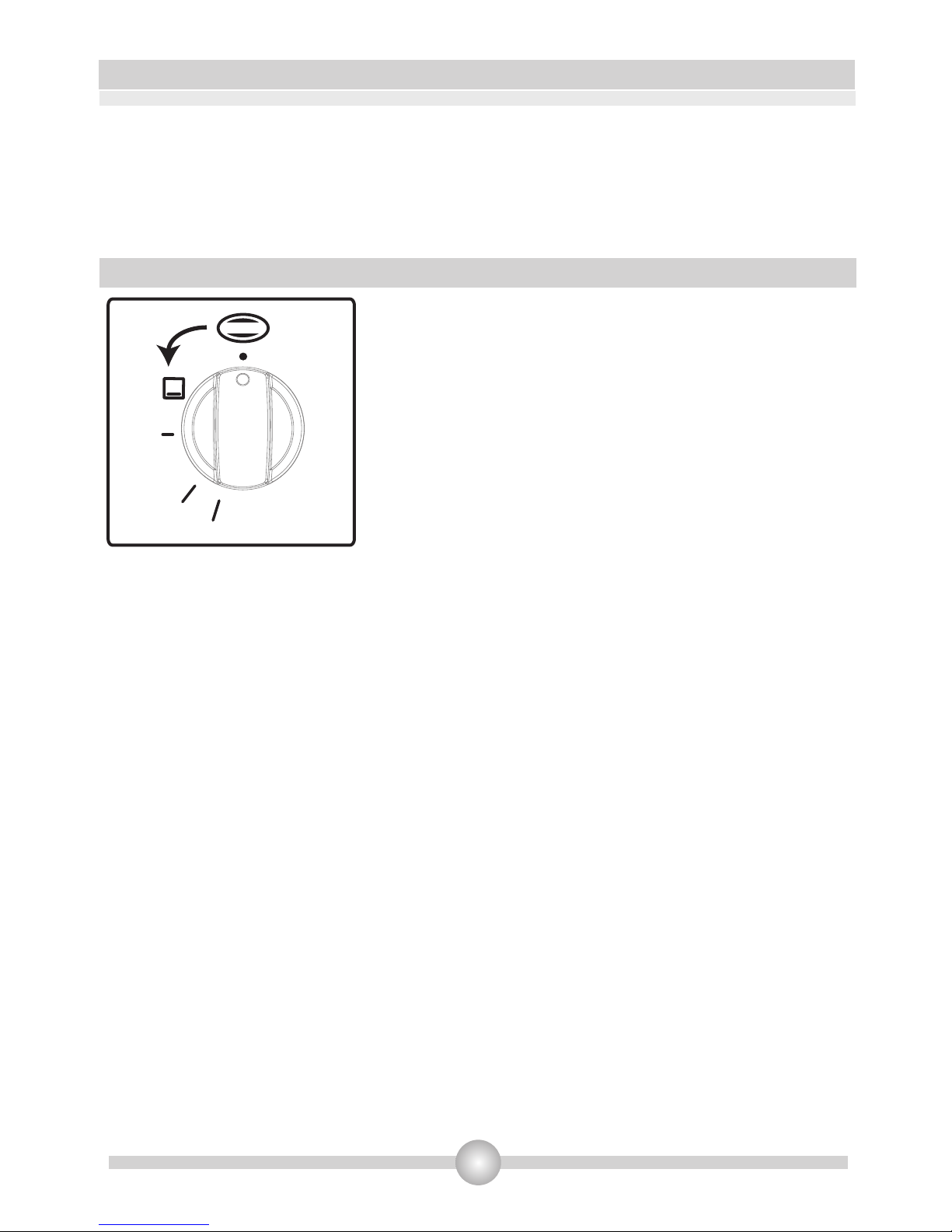

After igniting the oven burner as explained above, you may

adjust the temperature inside the oven, by positioning the

control in front of the signs on the control panel.

Do not operate the oven by placing the lever

between the "Off" position and the point indicating min

temperature (counterclockwise). Always use the oven

between the maximum and minimum positions. To stop the

cooking, turn the burner lever clockwise until the mark on the

lever is facing the point "0" (lever mark up).

If your oven

is fitted with an oven thermostat; refer to the temperature

table below to select temperature according to the food

cooked.

290

230

150

• It is important to ensure that the pan is centered correctly above the burners.

Page 20

19

4. USE OF YOUR PRODUCT

•

•

•

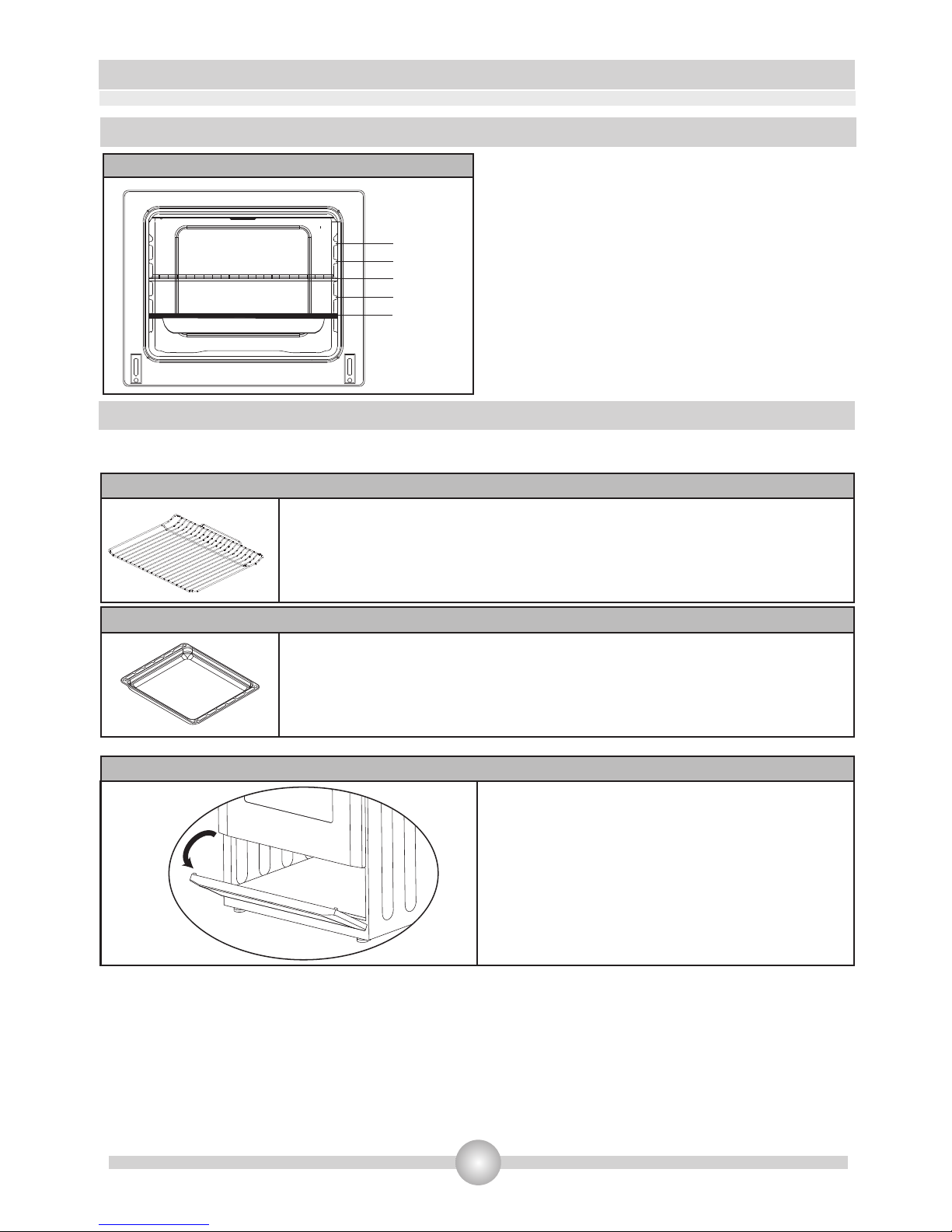

4.2 Accessories used in oven

The oven is supplied with accessories. You may also use accessories you purchase from the

market (but they must be heat and flame resistant). You can also use glass dishes, cake moulds,

special oven trays that are appropriate for use in oven. Pay attention to the manufacturer's user

instructions for accessories.

In case a small-sized dish is used, place the dish at the centre of the grid so that stands

correctly.

Do not place a glass baking pan in a cold environment immediately after cooking. Do not place

it on cold and wet surfaces either. Make sure it cools down gradually on a trivet or cloth,

otherwise it will break.

WARNING- Fit

the grid correctly

into any

correspondent

rack in the oven

cavity and push it

to the end.

Page 21

20

4. USE OF YOUR PRODUCT

The medium-sized tray is used for cooking stews.

To position this tray correctly in the cavity, put it to any rack and push

the tray fully home.

This compartment is used to store oven

accessories.

Do not put any flammable material in this

compartment.

Medium-sized tray

Oven accessories

The grid is used in supporting different cooking utensils.

To position grid correctly in the cavity, put it to any rack and push the

grid fully home.

Wire Grid

* Accessories for your oven may be different depending on the model.

Oven muffle

Positions on moulded slides

Position 5

Position 4

Position 3

Position 2

Position 1

Flapping door

Page 22

21

5. CLEANING AND MAINTENANCE

5.1

Make sure all burner control levers and controls are turned off and the cooker is cold before

cleaning the oven.

Check whether they are appropriate and recommended by the manufacturer, before using the

cleaning materials on your oven. Do not use caustic creams, abrasive cleaning powders, , scouring

pads, thick steel wool or hard tools to avoid damaging surfaces. In case liquids overflows around

your oven, the enamelled place may be damaged. Immediately clean up spilled liquids with a

suitable product.

Cleaning inside the oven

The inside of enamelled oven is cleaned in the best way when the oven is warm. After each use,

wipe the oven with a soft cloth that has been dampened with soap water. Later wipe it with a wet

cloth once more and then dry it. It may be required to use a liquid cleaning material from time to

time for thorough cleaning. Do not clean with dry/powder cleaners or steam cleaners.

Cleaning

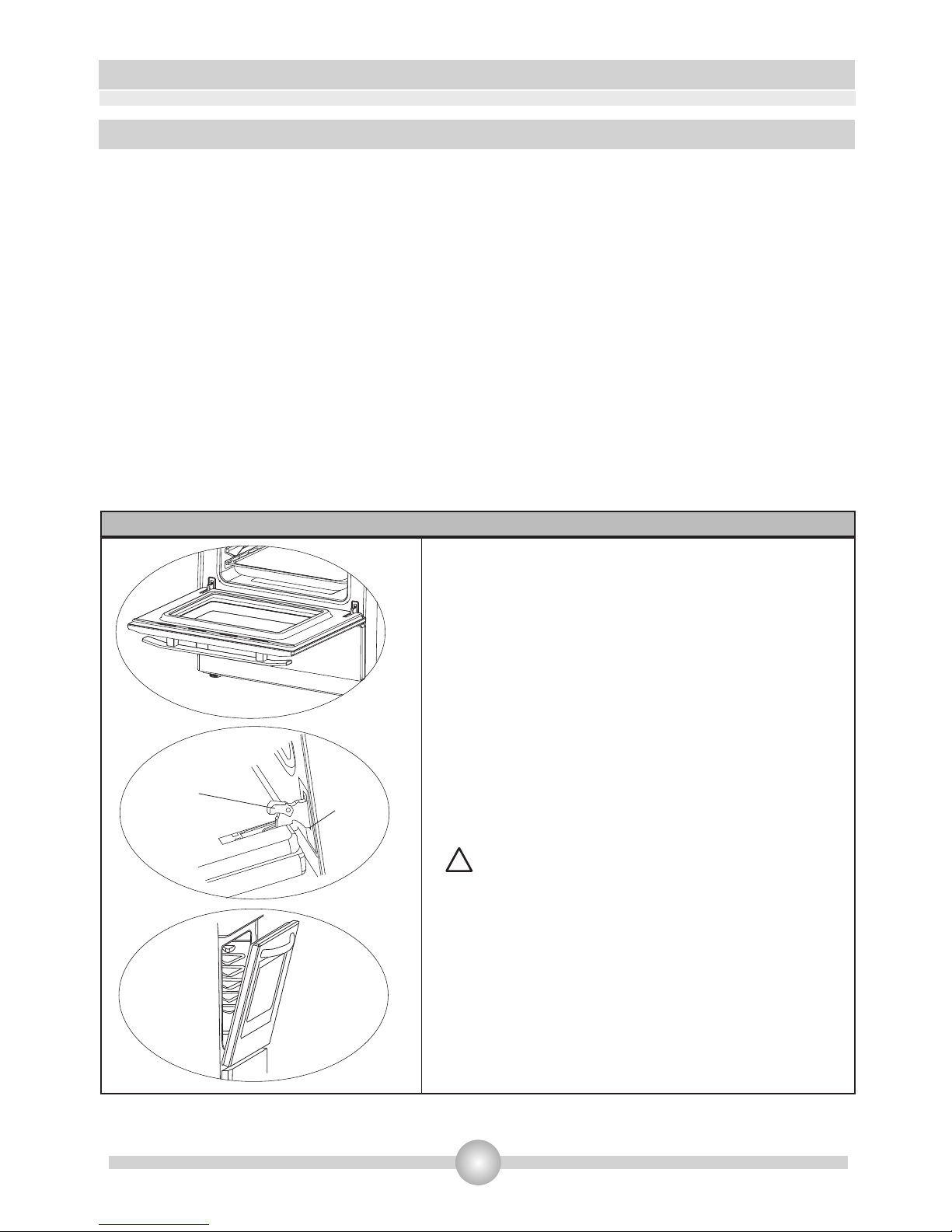

To dismantle the oven door

Tightening

latch

Recessed

support

1

2

3

To dismantle the oven door

Open the oven door (1).

Open the tightening latch up to the final

position (2).

Close the door until it is almost completely

closed as shown in the third diagram and

remove the door by pulling it.

Make sure that the embedded supports are

well positioned on the hinge support as shown in

the second diagram.

Reassembling the door is done by reversing the

procedure explained above. Make sure the

tightening latches are well refitted.

:

•

•

•

!

Page 23

22

5. CLEANING AND MAINTENANCE

Cleaning gas burners

Remove enamelled grilles, burner caps and crowns(Figure 15).

Clean them with soapy water

Rinse and dry with a soft cloth (do not leave them wet)

After cleaning, make sure that you re-assemble the parts correctly.

Do not clean any part of the cooktop with metal sponge. It causes the surface to be scratched.

The upper surfaces of enamel grills may deteriorate over time due to their use and the burner

flames. These parts will not get rusted and it is not a production fault.

When cleaning the cooktop plate, make sure that no water flows inside the burners to avoid

blocking the injectors.

Other Controls

Check the expiry date of the gas supply pipe regularly. If the date expires, please change it quickly.

In case of problems when using the control levers of the burners and oven (eg levers difficult to

turn), please contact the customer service.

•

•

•

•

•

•

•

Enamelled Parts:

In order to keep them as new, it is necessary to clean them frequently with mildly warm soapy

water and then dry with a soft tissue. Do not wash them while hot and never use abrasive

powders or abrasive cleaning materials. The following elements should not have prolonged

contact with the enamelled parts: vinegar, coffee, milk, salt, water, lemon, or tomato juice,

otherwise they will cause irreparable damage to the enamel surface.

Stainless Steel:

Stainless steel parts must be cleaned regularly with mildly warm soapy water and a soft sponge

and then dried with a soft cloth. Do not use abrasive powders or abrasive cleaning metarials. The

following elements should not have prolonged contact with the enamelled parts: vinegar, coffee,

milk, salt, water, lemon, or tomato juice, otherwise they will cause irreparable damage to the

stainless steel surface.

5.2 Maintenance

Page 24

•

•

•

•

•

6.1 Requirements before contacting the customer service

If the cooker does not operate:

Check that the cooker is properly connected to the gas supply and that the propane or butane

bottles are not empty.

If the oven does not heat:

Heat has perhaps not been settled with the control lever of the oven.

Cooking (if the lower and upper parts do not cook equally):

Check the location of grilles and trays, cooking time and thermostat temperature

recommended in this leaflet.

Cooktop burners do not operate correctly:

Check that burner parts have been properly repositioned (especially after cleaning or

installation).

The gas supply pressure may be too low or too high. For cookers which operate with LPG bottles

(Propane or Butane), check that the bottles are not empty.

If the problems of the cooker continue even after performing the above checks, contact the

customer service.

6.2 Information on transport

If you need to transport the cooker, keep the original case of the equipment and carry it along.

Follow the transport instructions on the case. Sellotape the burners so that nothing moves during

transportation (better still, put these items in a separate box). Place a paper between the upper

cover and the cooktop, recover the upper cover, and then sellotape it to the cooker side surfaces.

Open the oven door and put the carton or paper on the inside glass of the oven so that the trays

and the grille do not damage the oven door during transportation. Also sellotape the oven door

and the side walls.

If no original case, take measures to protect the cooker, especially its external surfaces (glass and

painted surfaces), against any moves.

23

6. SERVICE AND TRANSPORT

Page 25

24

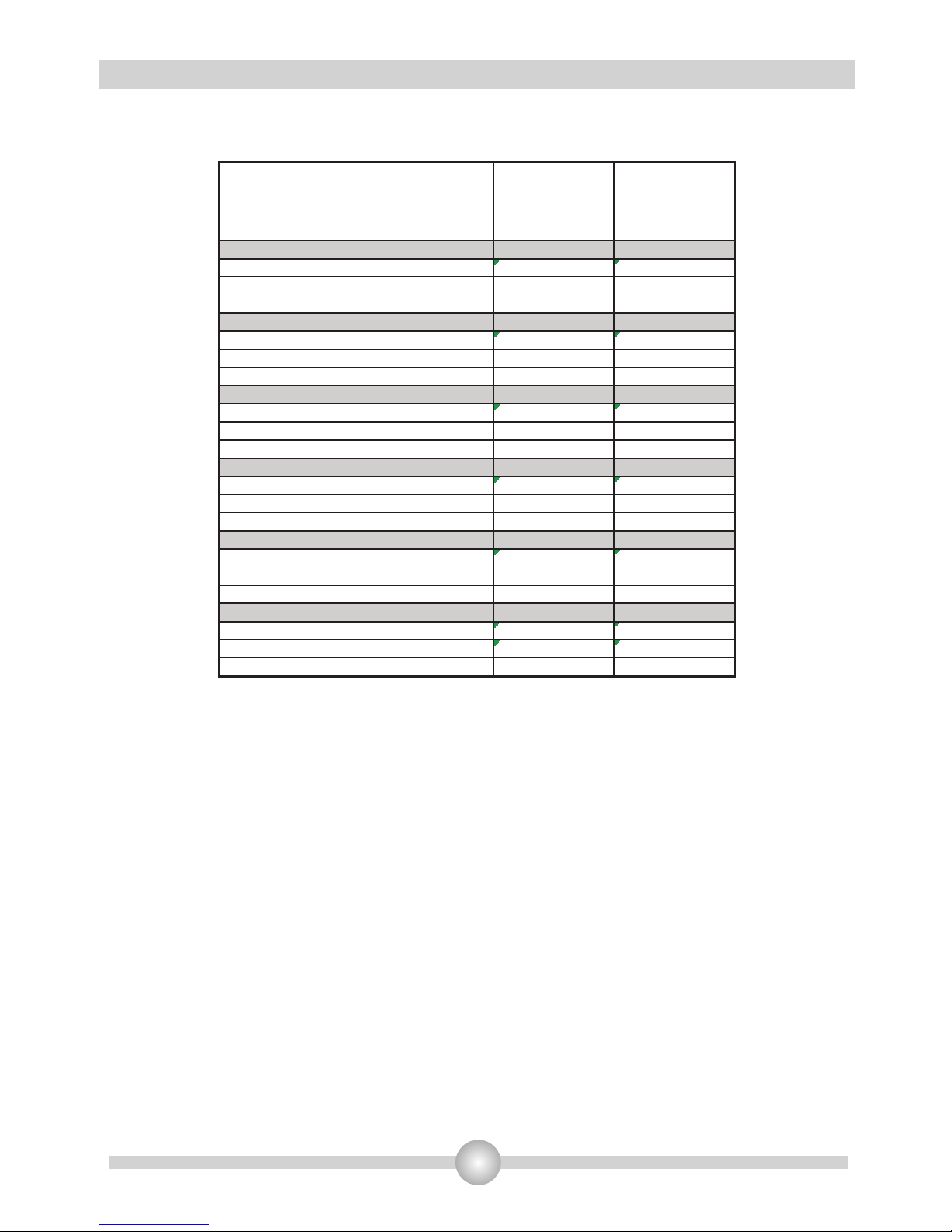

INJECTOR TABLE

G30 28-30mbar 10.3 kW 749 g/h

II2E3B/P DE Clase: 1

NG

G20 20 mbar

LPG

G30 50 mbar

LARGE BURNER

DIA. of INJECTOR (1/100mm) 115 75

NOMINAL RATING (KW) 2,75 3

CONSUMPTION 261,9 l/h 218,1 g/h

MEDIUM BURNER

DIA. of INJECTOR (1/100mm) 97 58

NOMINAL RATING (KW) 1,75 1,75

CONSUMPTION 166,7 l/h 127,2 g/h

MEDIUM BURNER

DIA. of INJECTOR (1/100mm) 97 58

NOMINAL RATING (KW) 1,75 1,75

CONSUMPTION 166,7 l/h 127,2 g/h

SMALL BURNER

DIA. of INJECTOR (1/100mm) 72 43

NOMINAL RATING (KW) 1 1

CONSUMPTION 95,2 l/h 72,7 g/h

OVEN BURNER

DIA. of INJECTOR (1/100mm) 120 68

NOMINAL RATING (KW) 2,8 2,8

CONSUMPTION 266,7 l/h 203,6 g/h

GRILL BURNER

DIA. of INJECTOR (1/100mm) 110 62

NOMINAL RATING (KW) 2,2 2,2

CONSUMPTION 209,5 l/h 160 g/h

Page 26

The symbol on the product or on its packaging indicates that this product

may not be treated as household waste. Instead it shall be handed over to

the applicable collection point for the recycling of electrical and electronic

equipment. By ensuring this product is disposed of correctly, you will help

prevent potential negative consequences for the environment and human

health, which could otherwise be caused by inappropriate waste handling of

this product. For more detailed information about recyling of this product,

please contact your local city office, your household waste disposal service or

the shop where you purchased the product.

Page 27

GASHERD BEDIENUNGS- UND

INSTALLATIONSANLEITUNG

DE

FSHG 60

Page 28

Werte Kunden,

Unser Ziel ist es, Ihnen hochwertige Produkte zu liefern, die Ihre Erwartungen

übertreffen und bieten Ihnen deshalb nur Produkte an, die mit größter Sorgfalt

und unter strengen Qualitätskontrollen in modernen Produktionsanlagen

hergestellt werden.

Diese Broschüre enthält alle erforderlichen Informationen zur Aufstellung und

Verwendung Ihres neuen Herds.

Wir empfehlen Ihnen, diese Bedienungsanleitung sorgfältig durchzulesen,

bevor Sie Ihren Herd in Betrieb nehmen, da sie alle grundlegenden

Informationen zur korrekten Aufstellung, richtigen Verwendung und

regelmäßigen Pflege und Wartung Ihres Herds enthält. Dieser Herd darf nur

von qualifiziertem Personal in Übereinstimmung mit den sicherheitsrelevanten

Normen und Gesetzen installiert werden. Versuchen Sie niemals, den Herd

selbst zu reparieren.

Dieser Herd ist nur für die Verwendung in privaten Haushalten vorgesehen

(gewerbliche Nutzung ist ausgeschlossen). Jegliche andere Verwendung des

Geräts (z. B. Beheizen eines Raums) ist unzulässig und daher gefährlich.

Dieser Herd wurde in Erfüllung der folgenden Richtlinien entwickelt, gebaut

und auf den Markt gebracht:

Sicherheitsanforderungen der "Gas"-Richtlinie 2009/142/EC;

Anforderungen der Richtlinie 93/68/EC.

Page 29

2

INHALT

1. TECHNISCHE EIGENSCHAFTEN

2. SICHERHEITSHINWEISE

Allgemeine Hinweise

Aufstellungshinweise

Während der Verwendung

Reinigung und Wartung

Sicherheit von Kindern

3. EINBAU

3.1 Aufstellungsort/-umgebung des Herds

3.2 Aufstellung des Herds

3.3 Einrichten der Stellfüße

3.4 Gasanschluss

3.5 Umstellung des Gastyps

4. VERWENDUNG

4.1 Verwendung der Gasbrenner

4.1.1 Verwendung der Kochfeld-Brenner

4.1.2 Verwendung der Brenner im Backraum

4.2 Im Herd verwendetes Zubehör

5. REINIGUNG UND WARTUNG

5.1 Reinigung

5.2 Wartung

6. KUNDENDIENST UND TRANSPORT

6.1 Bevor Sie sich an den Kundendienst wenden

6.2 Informationen zum Transport

Page 30

3

1. KURZÜBERSICHT ÜBER DAS GERÄT

Teileliste:

1- Abdeckung Kochfeld

2-Kochfeld

3-Bedienfeld

4-Klappengriff

5-Unterbau oder Auszug vorne

6-Stellfüße

7-Backraumtür

8-Backblech

9-Wire Grid

MODELl

TIEFE

(cm)

LÄNGE

(cm)

HÖHE

(cm)

10-Halb-Schnellkochplatte

11-Schnellkochplatte

12-Zusatzkochplatte

13-Topfhaltegitter

14-Halb-Schnellkochplatte

10

11

12

13

14

1

2

3

4

5

6

7

8

9

FSHG 60 60 60 85

Page 31

4

2. WARNHINWEISE

LESEN SIE DIESE ANLEITUNG VOLLSTÄNDIG UND SORGFÄLTIG DURCH, BEVOR

SIE IHR GERÄT IN BETRIEB NEHMEN, UND HALTEN SIE ES STETS ZUR

VERFÜGUNG WENN NÖTIG.

DIESES HANDBUCH WURDE FÜR VERSCHIEDENE MODELLE EINER REIHE

VERFASST. ES KANN SEIN, DASS IHR GERÄT ÜBER EINIGE EIGENSCHAFTEN, DIE

IN DIESEM HANDBUCH ERLÄUTERT WURDEN NICHT VERFÜGT. ACHTEN SIE AUF

DIE AUSDRÜCKE, DIE EINE ABBILDUNG HABEN, WÄHREND SIE DIESE

BETRIEBSANLEITUNG LESEN.

Allgemeine Sicherheitshinweise

Dieses Gerät kann von Kindern ab 8 Jahren

und älter und Personen mit eingeschränkten

physischen, sensorischen oder geistigen

Fähigkeiten oder mangelnder Erfahrung und

Wissen verwendet werden, wenn sie unter

Aufsicht sind oder ausführliche Anleitung zur

Benutzung des Gerätes in einer sicheren Weise

erhalten haben und die damit verbundenen

Gefahren verstehen. Kinder dürfen nicht mit

dem Gerät spielen. Reinigung und Wartung darf

nicht von Kindern ohne Aufsicht erfolgen.

WARNUNG: Das Gerät und die zugänglichen

Teile werden während des Gebrauchs heiß.

Achten Sie darauf, dass Sie nicht die

Heizelemente berühren. Kinder unter 8 Jahren

sollten ferngehalten werden, es sei denn sie

werden kontinuierlich überwacht.

Page 32

5

2. WARNHINWEISE

WARNUNG: Unbeaufsichtigtes Kochen auf

einem Herd mit Fett oder Öl kann gefährlich sein

und zu Bränden führen. NIEMALS versuchen, ein

Feuer mit Wasser zu löschen, aber schalten Sie

das Gerät aus und dann decken Sie die Flamme

z.B. mit einem Deckel oder einer Löschdecke ab.

WARNUNG: Brandgefahr: lagern Sie keine

Gegenstände auf den Kochflächen.

WARNUNG: Wenn die Oberfläche rissig ist,

schalten Sie das Gerät aus, um die Gefahr eines

elektrischen Schlages zu vermeiden.

Für Kochfelder mit Abdeckung: Entfernen Sie vor

d e m Ö f f n e n d e r A b d e c k u n g a l l e

Verunreinigungen darauf. Lassen Sie die

Kochfelder stets abkühlen, bevor Sie die

Abdeckung schließen.

Das Gerät ist nicht für die Steuerung durch

externe Zeitgeber oder ein separates

Fernbediensystem ausgelegt.

Page 33

6

2. WARNHINWEISE

Zur Vermeidung vom Kippen des Gerätes

müssen die stabilisierenden Halterungen

eingebaut sein.

Während der Verwendung wird das Gerät heiß. Achten

Sie darauf, dass Sie nicht die Heizelemente im Inneren

des Backraums berühren.

Griffe die während der Verwendung für kurze Zeit im

normalen Gebrauch gehalten wurden können heiß

werden

Verwenden Sie keine aggressiven oder scheuernden

Reinigungsmittel oder Metallschaber, um die Scheibe in

der Backraumtür zu reinigen.

Diese können die Oberfläche zerkratzen, was zum

Bersten der Glasscheibe führen kann.

Verwenden Sie keine Dampfreiniger zur Reinigung des

Gerätes.

WARNUNG: Stellen Sie sicher, dass das Gerät

ausgeschaltet ist, bevor Sie die Lampe austauschen,

um die Gefahr von elektrischen Schlägen zu vermeiden.

VORSICHT: Die außen zugänglichen Teile können sehr

heiß werden, wenn das Kochen oder Grillen in

Verwendung ist.

Page 34

7

2. WARNHINWEISE

Halten Sie kleine Kinder fern von dem Gerät.

hr Gerät wurde in Übereinstimmung mit den

einschlägigen lokalen und internationalen Normen und

Vorschriften hergestellt.

Wartungs-und Reparaturarbeiten dürfen nur von autorisierten Service-Technikern vorgenommen werden.

Installations-und Reparaturarbeiten, die durch nicht autorisierte Techniker durchgeführt wurden, können

Sie gefährden. Jegliche Modifikation der technischen Eigenschaften des Gerätes ist gefährlich und daher

verboten.

Stellen Sie vor der Installation sicher, dass die lokalen Netzbedingungen (Gastyp und

Gasdruck oder Strom-Spannung-und Frequenz) und die Anpassung des Gerätes kompatibel

sind. Die Anpassungsbedingungen dieses Gerätes sind auf dem Typenschild angegeben

VORSICHT: Dieses Gerät ist nur ist nur zum Kochen von Speisen und für den Gebrauch im

Haushalt bestimmt und sollte nicht für andere Zwecke oder auf einer anderen Anwendung, z.

B. für gewerbliche und industrielle Anwendung oder in einem kommerziellen Umfeld

verwendet werden.

Heben oder verschieben Sie das Gerät nicht durch Ziehen am Türgriff.

Dieses Gerät ist nicht an ein Abzugsgerät für Verbrennungsprodukte angeschlossen. Es muss in

Übereinstimmung mit den aktuell gültigen Installationsrichtlinien eingebaut und angeschlossen werden.

Besonderes Augenmerk ist dabei auf die relevanten Richtlinien bezüglich der Belüftung zu richten. (Nur für

Gasgeräte)

Wenn der Brenner nach 15 Sekunden noch immer nicht läuft, stoppen Sie ihn, öffnen Sie die Backraumtür

und/oder warten Sie mindestens 1 Minute, bevor Sie nochmals versuchen, ihn zu zünden. (Nur für

Gasgeräte)

Wenn der Brenner nach 15 Sekunden noch immer nicht läuft, stoppen Sie ihn, öffnen Sie die Backraumtür

und/oder warten Sie mindestens 1 Minute, bevor Sie nochmals versuchen, ihn zu zünden. (Nur für

Gasgeräte)

Diese Anleitungen sind nur gültig, wenn das Land-Symbol auf dem Gerät angezeigt wird. Wenn das

Symbol nicht auf dem Gerät angezeigt wird, ist es notwendig, die technischen Anweisungen, die die

erforderlichen Anweisungen zur Änderung des Gerätes an die Bedingungen der Nutzung des Landes

bieten, zu beziehen. (Nur für Gasgeräte)

Es wurden alle erdenklichen Sicherheitsvorkehrungen getroffen, um Ihre Sicherheit zu garantieren. Da

das Glas brechen könnte, sollten Sie bei der Reinigung stets vorsichtig sein, um Kratzer zu vermeiden.

Vermeiden Sie Schläge auf das Glas durch Zubehörgeräte.

Stellen Sie sicher, dass das Netzkabel während der Installation nicht eingeklemmt ist. Wird das Netzkabel

beschädigt, muss es vom Hersteller, dem Vertrieb oder einer ähnlich qualifizierten Person ersetzt werden,

um eine Gefährdung zu vermeiden.

Lassen Sie Kinder niemals auf die Backraumtür klettern oder darauf sitzen, wenn diese offen ist.

Page 35

8

2. WARNHINWEISE

Warnhinweise zur Installation:

Nehmen Sie das Gerät nicht in Betrieb, solange es nicht vollständig eingebaut ist.

Das Gerät muss von einem autorisierten Techniker aufgestellt und in Betrieb genommen werden. Der

Hersteller ist nicht verantwortlich für Schäden, die durch fehlerhafte Aufstellung und Montage durch

nicht autorisierte Personen verursacht werden könnten.

Wenn Sie das Gerät auspacken, stellen Sie sicher, dass es nicht während des Transports beschädigt

wurde. Wenn Sie irgendwelche Beschädigungen entdecken, nehmen Sie das Gerät keinesfalls in

Betrieb und kontaktieren Sie umgehend den autorisierten Wartungsdienst. Da die für die Verpackung

verwendeten Materialien (Nylon, Heftklammern, Styropor etc.) für Kinder gefährlich sein können,

sollten Sie diese einsammeln und sofort entsorgen.

Schützen Sie das Gerät vor Umwelteinflüssen. Setzen Sie es niemals Einflüssen wie Sonne, Regen,

Schnee oder Staub etc. Aus.

Die umgebenden Materialien des Gerätes (Schaltschrank) müssen einer Temperatur von mindestens

100 ° C standhalten.

Während der Verwendung

Wenn Sie Ihren Herd das erste Mal einschalten, kommt es zu einer gewissen Geruchsentwicklung,

die von den Isoliermaterialien und den Heizelementen herrührt. Deshalb sollten Sie den Herd vor der

ersten Verwendung bei maximaler Temperatur für 45 Minuten leer betreiben. Bitte lüften Sie während

dieser Zeit die Umgebung, in welcher das Produkt

Während der Verwendung können die äußeren und inneren Oberflächen des Ofens heiß werden.

Wenn Sie die Backraumtür öffnen, treten Sie etwas zurück, um dem aus dem Backraum

entweichenden heißen Dampf auszuweichen. Es kann die Gefahr von Verbrennungen bestehen.

Legen Sie keine entzündlichen oder brennbaren Materialien, in das Gerät oder in die Nähe des

Gerätes, wenn es in Betrieb ist.

Verwenden Sie stets hitzebeständige Handschuhe, wenn Sie Nahrungsmittel in den Herd geben oder

herausnehmen.

Lassen Sie den Herd beim Kochen mit festen oder flüssigen Fetten nicht unbeaufsichtigt. Diese

könnten bei sehr hohen Temperaturen zu brennen beginnen. Gießen Sie niemals Wasser in

brennendes Fett oder Öl. Decken Sie die Kasserolle oder Pfanne mit dem Deckel zu, um die

Flammen zu ersticken und schalten Sie den Herd ab.

Positionieren Sie Pfannen immer über der Mitte der Kochzone, und drehen Sie die Griffe in eine

sichere Position, damit sie nicht geschlagen oder angefasst werden können.

Wenn das Gerät längere Zeit nicht benutzt wird, ziehen Sie den Netzstecker aus der Steckdose.

Halten Sie den Netzhauptschalter ausgeschaltet. Drehen Sie auch den Gaszufuhrhahn ab, wenn Sie

das Gerät nicht verwenden.

Achten Sie stets darauf, dass die Regler in der Position "0" (Stop), wenn der Herd nicht in Betrieb ist.

Page 36

9

2. WARNHINWEISE

Stellen Sie niemals etwas auf die Backrohrtür oder den Auszug, wenn diese offen sind. Dadurch

könnte das Gerät kippen oder die Klappe beschädigt werden.

Geben Sie keine schweren Gegenstände oder entzündliche, brennbare Objekte (Nylon, Plastikbeutel,

Papier, Stoff etc.) in die untere Ausziehlade. Dazu gehören Kochgeschirr mit Zubehör aus Kunststoff

(z.B. Griffe).

Hängen Sie keine Handtücher, Geschirrtücher oder Kleidung auf das Gerät oder auf seine Griffe.

Reinigung und Wartung:

Schalten Sie das Gerät aus, bevor Sie irgendwelche Reinigungs- oder Wartungsarbeiten

durchführen. Das können Sie machen nachdem Sie das Gerät ausstecken oder den Hauptschalter

ausschalten.

FÜR EINE EINWANDFREIE FUNKTION UND DIE GRÖSSTMÖGLICHE SICHERHEIT SOLLTEN

SIE STETS ORIGINALERSATZTEILE VERWENDEN UND IM BEDARFSFALL NUR EINEN

AUTORISIERTEN WARTUNGSDIENST ANRUFEN.

VORSICHT: Glasabdeckungen können springen, wenn sie zu heiß

werden. Schalten Sie alle Brenner aus, bevor Sie die Abdeckung

schließen. Lassen Sie die Kochfelder stets abkühlen, bevor Sie die

Abdeckung schließen.

Page 37

10

3. INSTALLATION

Dieser moderne, zweckmäßige und praktische Herd wurde aus hochwertigen Teilen und Materialien

gefertigt und wird all Ihren Ansprüchen in jeder Hinsicht gerecht werden. Lesen Sie diese Broschüre

sorgfältig durch, bevor Sie den Herd in Betrieb nehmen, um alle notwendigen Informationen über seine

Funktionen kennenzulernen und die bestmöglichen Resultate zu erzielen. Beachten Sie die folgenden

Empfehlungen, um Probleme oder gefährliche Situationen zu vermeiden und das Gerät richtig

aufzustellen. Sie sind insbesondere für den Techniker, der die Aufstellung des Geräts vornimmt, von

Bedeutung.

3.1 Aufstellungsort/-umgebung des Herds

• Ihr Herd muss an einem Ort aufgestellt und verwendet werden, der gut belüftet ist. Eine

Gasverbrennung ist nur mit dem Sauerstoff in der Luft möglich. Daher muss ein ausreichender

Luftaustausch erfolgen und eine Abführung der Verbrennungsgase in Übereinstimmung mit den

Vorschriften sichergestellt sein. Es muss eine ausreichende Belüftung vorhanden sein, um die

Luftversorgung in der Verwendungsumgebung zu gewährleisten. Die Belüftung muss durch Öffnungen

an Wänden mit direktem Kontakt nach außen (siehe Diagramm unten).

• Im Betrieb benötigt dieses Gerät 2 m3/h Luft je kW Leistung.

• Der Luftstrom muss am Boden eintreten (mindestens 100 cm²) und oben austreten (mindestens

100 cm²). Diese Belüftungsöffnungen müssen also jeweils einen Mindestquerschnitt von 100 cm2 für

einen effektiven Luftdurchsatz aufweisen. Diese müssen stets offen bleiben und dürfen nicht

geschlossen werden. Sie sollten sich nach Möglichkeit in der Nähe der Herdrückseite befinden (für den

Lufteinlass Fig. 1 und 2) bzw. an der Entstehungsstelle der Verbrennungsgase (für den Abzug), alsoe

etwa 1,80 m über Bodenniveau. Können diese Öffnungen nicht dort, wo der Herd aufgestellt ist, von

außen hergestellt werden, kann die erforderliche Verbrennungsluft auch von anderer Stelle zugeführt

werden, sofern diese über ausreichende Belüftung verfügt und es sich nicht um ein Schlafzimmer oder

einen Raum mit besonderen Gefahren handelt.

Abzug der Verbrennungsgase

Es wird empfohlen, entweder eine Abzugshaube mit direkter Rohrverbindung nach außen (Fig. 3)

zu installieren, oder einen elektrischen Ventilator am Fenster oder an der Außenwand (Fig. 4), um

Rauchgase direkt nach außen zu leiten. Die Leistung des Ventilators muss so ausgelegt werden, dass

die Luft in der Küche 4-5 Mal pro Stunde erneuert wird.

Querschnitt des Lufteinlasses

mindestens 100 cm2.

Querschnitt des Lufteinlasses

mindestens 100 cm2.

Abb.1

Abb.2

Page 38

11

3. INSTALLATION

Abzugshaube

Elektrischer Ventilator

Lufteinlass mit

mindestens 100

cm2 Querschnitt

Lufteinlass mit

mindestens 100

cm2 Querschnitt

Abb.3

Abb.4

3.2 Aufstellung des Herds

• Der Herd darf neben weiteren Möbelstücken aufgestellt werden, solange diese nicht höher als der

Herd sind (siehe Abb. 5).

• Befinden sich über dem Herd weitere Möbelstücke, muss ein Abstand von mind. 10 cm zwischen

den Seiten des Herds und dem Möbelstück eingehalten werden.

• Die Mindesthöhe zwischen Kochfeld und Abzugshaube (oder Wandschrank) ist in Abb. 5 gezeigt.

Die Abzugshaube muss mindestens 65 cm Abstand zum Kochfeld haben. Ist keine Abzugshaube

vorhanden, darf der Abstand zwischen Kochfeld und Möbelstück darüber 70 cm nicht unterschreiten.

• Halten Sie einen Abstand von 2 cm zwischen der Rückseite des Herds und der Wand ein, sowie

zwischen den Seiten des Herds und angrenzenden Möbelstücken..

• Achten Sie darauf, den Herd nicht direkt neben einen Kühlschrank zu stellen. Auch dürfen keine

brennbaren oder entzündlichen Materialien wie Vorhänge, Stoffe etc. in der Nähe sein, die leicht

verbrennen.

• Angrenzende Möbelstücke müssen für Temperaturen von mindestens 90 °C ausgelegt sein.

Abb.5

Min. 60cm

DUNSTABZUG

Min. 42cm

Min. 42cm

Min. 65 cm. (mit Haube)

Mind. 70 cm. (mit Haube)

Page 39

Abb.6

3.3 Einrichten der Stellfüße

Der Herd steht auf 4 einstellbaren Standfüßen. Nach dem

Einstellen der gewünschten Position muss die Einrichtung

überprüft werden. Stellen Sie dazu die 4 Stellfüße durch

Anziehen oder Lockern ein (Abb. 6). Der Herd muss absolut

waagrecht aufgestellt werden.

Der max. Einstellspielraum beträgt 30 mm.

Zum Einstellen der Standfüße können Sie den Auszug des

Herds entfernen.

Nach dem Einstellen der Standfüße darf der Herd nicht mehr

durch Ziehen bewegt werden, sonder nur noch durch Heben

(aber nicht an den Türgriffen).

Page 40

2.3 Gasanschluss

Anschluss der Gasversorgung und Leckprüfung

Der Anschluss des Herds muss nach den inländischen und internationalen Standards sowie

einschlägigen Vorschriften vorgenommen werden. Überprüfen Sie zuerst, für welchen Gastyp

der Herd gerüstet ist. Diese Information nden Sie auf einem Aufkleber an der Herdrückseite. Sie

nden die Informationen zu den geeigneten Gastypen und den entsprechenden Gasbrennern

in der Tabelle mit den technischen Daten. Achten Sie darauf, dass der Gaszufuhrdruck für die

Ventile laut den technischen Daten geeignet ist, damit das Gerät möglichst efzient arbeiten kann

und möglichst wenig Gas verbraucht. Wenn der Druck des verwendeten Gases unterschiedlich

zu den genannten Werten oder in Ihrem Gebiet nicht stabil ist, kann es erforderlich werden einen

geeigneten Druckregler auf den Gaseinlass zu montieren. Um diese Einstellungen vornehmen zu

lassen, müssen Sie sich unbedingt an den autorisierten Kundendienst wenden.

Diese Punkte müssen bei der Installation des exiblen Schlauchs geprüft werden

Wenn die Gasverbindung aus einem exiblem Schlauch besteht, der an dem Gaseinlass

des Gerätes befestigt wird, dann muss zusätzlich eine Rohrmanschette angebracht werden.

Verbinden Sie das Gerät mit der Gasquelle mittels eines möglichst kurzen und dichten

Schlauchs. Die maximal erlaubte Schlauchlänge beträgt 1,5 m. Zu Ihrer Sicherheit muss der

Gasanschlussschlauch einmal (1) jährlich ausgewechselt werden.

Der Schlauch muss von Bereichen ferngehalten werden, die sich auf Temperaturen über 900 C

aufheizen können. Der Schlauch darf nicht gerissen sein oder gedehnt oder geknickt werden. Er

muss von scharfen Kanten, sich bewegenden Gegenständen entfernt gehalten werden und darf

nicht beschädigt sein. Vor der Installation muss er auf Produktionsschäden geprüft werden.

Wenn das aufgedreht ist, müssen alle Verbindungsteile und der Schlauch mit Seifenwasser

oder Lecküssigkeiten auf Dichtheit geprüft werden. Es sollten keine Luftblasen zu sehen sein.

Wenn sich solche Blasen zeigen, muss die Anschlussdichtung überprüft werden und dann die

Überprüfung erneut durchgeführt werden. Verwenden Sie zur Dichtheitsprüfung keine offenen

Flammen! Alle für den Gasanschluss verwendeten Metallteile müssen rostfrei sein. Überprüfen

Sie auch die Verfallsdaten der verwendeten Teile.

Diese Punkte müssen bei der Installation des festen Gasanschlusses geprüft werden

Um einen festen Gasanschluss (Gasanschluss mit Gewinde, z. B. einer Mutter) werden in allen

Ländern unterschiedliche Methoden verwendet. Die dafür üblichsten Teile werden schon mit Ihrem

Herd ausgeliefert. Weitere Teile können als Ersatzteile geliefert werden.

Während des Anschlusses müssen Sie die Mutter an der Gassammelleitung immer xieren,

wenn Sie die Kontermutter festdrehen. Verwenden Sie zum sicheren Anschluss Maulschlüssel

mit einer geeigneten Größe. Bei allen Oberächen zwischen den Teilen müssen Sie immer die

Dichtungen verwenden, die mit dem Gasumwandlungskit geliefert wurden. Die verwendeten

Dichtungen müssen auch zu Verwendung bei Gasanschlüssen genehmigt sein. Verwenden Sie

für Gasanschlüsse niemals Sanitärdichtungen!

3. INSTALLATION

Page 41

3. INSTALLATION

Denken Sie daran, dass dieser Herd für den Anschluss an eine Gasversorgung in dem Land

vorgesehen ist, für das er hergestellt wurde. Das Land, für das der Herd hergestellt ist, ist auf

der Rückabdeckung des Gerätes angegeben. Wenn Sie ihn in einem anderen Land verwenden

wollen, können die in der nachfolgenden Abbildung gezeigte Anschlüsse erforderlich werden. In

derartigen Fällen müssen Sie sich mit den örtlichen Behörden in Verbindung setzen, um etwas

über den korrekten Gasanschluss zu erfahren.

Zur Erstellung des geeigneten Gasanschlusses nach den Sicherheitsvorschriften müssen Sie den autorisierten

Kundendienst beauftragen.

ACHTUNG! Verwenden Sie für die Dichtheitskontrolle unter keinen Umständen ein Feuerzeug oder

Streichhölzer!

Ändern der Gaszufuhr:

In manchen Ländern können die Typen für die Gaszufuhr von NG/LPG Gase unterschiedlich sein. In diesem

Fall müssen Sie alle aktuellen Anschlussteile und Muttern (sofern vorhanden) entfernen und die neue Gaszufuhr

entsprechend verbinden. Unter allen Umständen müssen alle Teile, die für einen Gasanschluss verwendet

werden, von den inländischen und /oder ausländischen Behörden genehmigt sein. Für alle Gasanschlüsse

verweisen wir auf die „Anbringung der Gasversorgung und Leckprüfung“ Klausel, die vorstehend erklärt ist.

2.4 Gasversorgung

Vorsicht: Folgende Handlungen dürfen nur von autorisiertem Personal durchgeführt werden.

Ihr Herd ist dazu eingerichtet, mit LPG/Erdgas Gas betrieben zu werden. Die Gasbrenner können an diese

verschiedenen Gastypen angepasst werden, indem die Brennerdüsen entsprechen ausgetauscht und

die minimale Flammhöhe jedes Brenners eingestellt wird. Zu diesem Zweck sind die folgenden Schritte

auszuführen.

Austauschen der Brennerdüsen:

Kochfeldbrenner:

• Trennen Sie die Hauptgasversorgung und nehmen Sie den Herd von der Stromversorgung.

• Entfernen Sie die Abdeckung und den Adapter. (Abb. 7).

• Schrauben Sie die Düsen ab. Verwenden Sie dazu einen 7 mm-Schlüssel (Abb. 8).

• Ersetzen Sie die Düse mit der aus dem Gasumwandlungskit, die den entsprechenden Durchmesser hat,

der für das zu verwendende Gas gemäß der Informationsgrak (die ebenfalls dem Gasumstellungskit beiliegt)

geeignet ist.

Gasschlauch

Gasschlauch

mit Schelle

Mechanischer

Gasschlauch

Mechanischer

Gasschlauch

Mechanischer

Gasschlauch

Gasschlauch Gasschlauch Gasschlauch

Dichtung

Dichtung

Adapter

Dichtung

Schlauchbefestigung

Abbildung 6

Page 42

14

3,6 Umstellung des Gastyps

Warnung: Die folgenden Massnahmen dürfen nur vom autorisierten Kundendienst

durchgeführt werden.

Ihr Herd ist für die Verwendung von Flüssiggas (Propan oder Butan) oder Erdgas vorgesehen. Die

Gasbrenner können an diese verschiedenen Gastypen angepasst werden, indem die Brennerdüsen

entsprechen getauscht und die minimale Flammhöhe jedes Brenners eingestellt wird. Die folgenden

Schritte müssen dazu unbedingt ausgeführt werden:

Austauschen der Brennerdüsen:

Kochfeld-Brenner:

• Schließen Sie die Gaszufuhr und trennen Sie das Gerät vom Netz.

• Entfernen Sie die Brennerkappe und den oberen Brenner (Abb. 8).

• Schrauben Sie die Düsen ab. Verwenden Sie dazu einen 7 mm-Schlüssel (Abb. 9).

Installieren Sie die neuen Düsen je nach verwendetem Gastyp wie in der Tabelle mit den technischen

Daten angegeben. Ziehen Sie die neuen Düsen sorgfältig an; wenn Sie sie seitlich aufsetzen, könnten

Sie das Gewinde am Aufsatz zerstören. In diesem Fall müsste der Aufsatz ausgetauscht werden

Backraum-Düsen:

Der Brenner im Backraum ist mit einer einzelnen Schraube versehen, die sich an der Brennerspitze

befindet.

Für den Backraum-Brenner (unten) öffnen Sie die Backraumtür und entfernen Sie die Schrauben, die

die untere Verkleidung halten. Öffnen Sie das Fach unter dem Backraum (Auszug oder Klappe) um die

vordere Schraube auf dem Brenner zu erreichen (Abb. 12). Wenn der Herd eine Unterbaufront

aufweist, müssen Sie zuerst die Backraumtür ausbauen, um die Halteschrauben der Verkleidung zu

erreichen.

3. INSTALLATION

!

Abb.9

Düse

Schlüssel

Abb.8

Page 43

3. INSTALLATION

15

Entfernen Sie die Brennerschraube und bewegen Sie den Brenner diagonal, um die Düse hinten unten

zu erreichen (Abb. 11).

Schrauben Sie die Düsen ab. Verwenden Sie dazu einen 7 mm-Schlüssel. Installieren Sie die neuen

Düsen je nach verwendetem Gastyp wie in der Tabelle mit den technischen Daten angegeben. Ziehen

Sie die neuen Düsen sorgfältig an; wenn Sie sie seitlich aufsetzen, könnten Sie das Gewinde am

Aufsatz zerstören. In diesem Fall müsste der Aufsatz ausgetauscht werden (dies ist nicht von der

Garantie gedeckt).

Einstellen der Flammhöhe am Ventil auf minimal

Die Flammhöhe wird mit der Flachkopfschraube auf dem Ventil auf minimal gestellt. Bei Ventilen mit

Thermoelement befindet sich die Schraube auf der Seite der Ventilspindel (Abb. 12). Bei Ventilen ohne

Thermoelement befindet sich die Schraube im Ventilschaft. Für eine einfachere Einstellung der

Flammhöhe empfehlen wir, bei Herden mit Thermoelement und Mikroschalter (automatische Zündung)

zuerst das Bedienfeld zu entfernen.

Um die Minimalposition zu bestimmen, zünden Sie die Brenner der Reihe nach an und stellen Sie die

Minimalposition ein. Verändern Sie nun mit einem kleinen Schraubendreher die Bypassschraube um

etwa 90° (festziehen oder lockern). Wenn die Flamme mindestens 4 mm hoch ist, ist die Einstellung

korrekt. Stellen Sie zur Kontrolle sicher, dass die Flamme nicht ausgeht, wenn sie von der Maximal- in

die Minimalstellung geregelt wird. Erzeugen Sie mit der Hand eine Luftströmung zur Flamme, um zu

testen, ob diese stabil ist.

Abb.10 Abb.11

Schraube

Düse

Abb.12

Bypassschraube

Ventil mit Thermoelement

Page 44

3. INSTALLATION

16

Lassen Sie den Backraumbrenner 5 Minuten lang in der Minimalposition brennen. Öffnen und

schließen Sie die Backraumtür 2-3 Mal, um die Stabilität der Brennerflamme zu testen.

Für die Brenner des Grills ist eine Einstellung der Minimalflammhöhe nicht notwendig.

Bei der Umstellung von Flüssig- auf Erdgas muss die Bypassschraube herausgedreht werden. Beim

Umstellen von Erdgas auf Flüssiggas muss diese Schraube festgezogen werden. Bei dieser

Einstellung stellen Sie bitte sicher, dass der Herd vom Netz getrennt und die Gaszufuhr offen ist.

Ändern des Gaszufuhranschlusses:

Überprüfen Sie regelmäßig das Haltbarkeitsdatum des Gasrohrs. Ist das Haltbarkeitsdatum erreicht,

muss der Schlauch ausgetauscht werden.

Diese Rohre sind im Handel erhältlich, achten Sie darauf, dass die aktuell gültigen Normen erfüllt

werden. Nach dem Austauschen des Schlauchs müssen Sie die Dichtheit prüfen. Informationen dazu

finden Sie im obenstehenden Abschnitt: Gas anschließen und Dichtheit überprüfen

Abb.13

Bypassschrauben

Page 45

4. VERWENDUNG IHRES HERDS

17

4.1 Verwendung der Gasbrenner

Anzünden der Gasbrenner

Die Symbole auf den Reglern am Bedienfeld zeigen die Stellung des Brenners an.

• Manuelle Zündung der Gasbrenner

Ist Ihr Herd nicht mit elektrischer Zündung ausgestattet, oder bei einem Ausfall des Stromnetzes,

gehen Sie wie folgt vor:

Für Kochfeld-Brenner: Um den Brenner einzuschalten, drücken Sie den entsprechenden Regler und

drehen ihn gleichzeitig gegen den Uhrzeigersinn in die Maximalstellung. Zünden Sie gleichzeitig mit

einem Streichholz oder einem Gasfeuerzeug das Gas in der Nähe der Brennerdüsenöffnungen.

Sobald Sie eine stabile Flamme sehen, nehmen Sie die Zündquelle weg.

Für Kochfeld-Brenner mit Thermoelement: Kochfelder mit Thermoelement bieten zusätzliche

Sicherheit, wenn die Flamme ausgehen sollte. Halten Sie den Regler daher bei der manuellen

Zündung gedrückt, bis Sie eine stabile Flamme sehen. Wenn die Flamme nach dem Loslassen des

Reglers instabil wird, wiederholen Sie den Vorgang. Wenn die Flamme ausgeht, schließt das

Thermoelement das Gasventil zum Brenner und verhindert so eine Ansammlung von unverbranntem

Gas. Warten Sie daher 90 Sekunden, bevor Sie einen Gasbrenner nach der automatischen

Abregelung erneut zu zünden versuchen.

Für den Backraum-Brenner (mit Thermoelement): Alle Brenner im Backraum/Grill sind mit

Thermoelementen ausgestattet. Diese bieten zusätzliche Sicherheit, wenn die Flamme ausgehen

sollte. Um den Backraum-Brenner einzuschalten, drücken Sie den entsprechenden Regler und drehen

ihn gleichzeitig gegen den Uhrzeigersinn in die Maximalstellung. Zünden Sie gleichzeitig mit einem

Streichholz oder einem Gasfeuerzeug das Gas in der Nähe der Brennerdüsenöffnung links vorne am

Brenner. Sobald Sie eine stabile Flamme sehen, nehmen Sie die Zündquelle weg, halten den Regler

aber noch für etwa 3 Sekunden gedrückt. Wenn die Flamme nach dem Loslassen des Reglers instabil

wird, wiederholen Sie den Vorgang. Wenn die Flamme ausgeht, schließt das Thermoelement das

Gasventil zum Brenner und verhindert so eine Ansammlung von unverbranntem Gas. Wenn der

Backraumbrenner nicht zündet, nachdem Sie den Regler für mindestens 30 Sekunden gedrückt

gehalten haben, öffnen Sie zunächst die Backraumtür und warten Sie 90 Sekunden, ehe Sie erneut

eine Zündung versuchen. Auch wenn die Flamme im Backraum ausgeht, wiederholen Sie diesen

Vorgang.

Page 46

4. VERWENDUNG IHRES HERDS

18

MAX-Stellung

Aus-Stellung

Zwischenstellung

MIN-Stellung

Abb.14

4.1.1 Verwendung der Kochfeld-Brenner

Die Regler für die Brenner im Kochfeld haben 3 Stellungen: Aus (0), Max (großes Flammensymbol)

und Min (kleines Flammensymbol). Nach dem Zünden der Brenner in der Stellung "MAX" (wie oben

beschrieben), können Sie die Flammhöhe auf eine Stellung zwischen "MAX" und "MIN" regeln. Drehen

Sie den Regler nicht in die Stellung zwischen "MAX" und "AUS".

Page 47

4. VERWENDUNG IHRES HERDS

19

Überprüfen Sie die Flamme nach der Zündung visuell. Wenn Sie

eine gelbe Spitze, losgelöste oder instabile Flammen sehen,

drehen Sie die Gaszufuhr ab und prüfen Sie die Position der

Brennerabdeckungen und der Flammenkränze (Abb. 15).

Vorsicht: diese Elemente können sehr heiß werden, lassen Sie sie

daher abkühlen, damit Sie sich nicht verbrennen. Achten Sie

darauf, dass keine Flüssigkeiten in den Brenner eindringen. Wenn

die Flammen sich vom Brenner ablösen, schließen Sie die Ventile,

lüften Sie die Küche gut durch und warten Sie mindestens 90

Sekunden, bevor Sie ihn wieder zünden.

Um den Kochvorgang zu beenden, drehen Sie den Regler im

Uhrzeigersinn, bis die Markierung auf dem Regler auf "0" zeigt

(Reglermarkierung zeigt nach oben).

Ihr Kochfeld ist mit Brennern mit unterschiedlichen Durchmessern ausgestattet. Um eine möglichst

gute Wirksamkeit zu erzielen, sollten Sie darauf achten, dass die Größe des Kochgeschirrs mit der

Größe des Kochfelds gut übereinstimmt und das Kochgeschirr einen flachen Boden aufweist.

Verwenden Sie kein Geschirr mit gewölbtem Boden, da damit Energie verschwendet wird. Verwenden

Sie stets zur Brennergröße passendes Geschirr. Wenn Sie kleineres Geschirr verwenden, wird Energie

verschwendet. Am sparsamsten ist der Betrieb, wenn Sie die Flamme nach Erreichen des Siedepunkts

auf die Minimalstellung regeln. Es wird empfohlen, das Kochgeschirr stets mit dem Deckel zu

schließen.

Schnellkochbrenner: 22-26cm

Halb-Schnellkochbrenner 14-22 cm

Zusatzbrenner: 12-18cm

Wenn Sie den Herd längere Zeit nicht verwenden, sollten Sie stets das Gaszufuhrventil schließen.

WARNHINWEIS:

• Verwenden Sie nur flaches Geschirr mit einem ausreichend dicken Boden.

• Stellen Sie sicher, dass der Boden des Geschirrs trocken ist, bevor Sie es auf den Brenner stellen.

Abb.16

!

Abdeckung

Flammenkranz

Zündstift

Brenner

Abb.15

Niedrig

Page 48

• Im Betrieb können Teile, die mit der Flamme in Berührung kommen, sehr heiß werden. Halten

Sie daher während und nach dem Betrieb unbedingt Kinder und Tiere von dem Herd fern.

• Nach der Verwendung bleibt das Kochfeld noch längere Zeit heiß. Berühren Sie es nicht und

legen Sie keine Gegenstände darauf.

• Legen Sie niemals Besteckteile oder Deckel auf das Kochfeld. Diese können sehr heiß werden

und schwere Verbrennungen verursachen.

4.1.2 Verwendung der Brenner im Backraum

Vorheizen

Wenn Sie den Backraum vorheizen müssen, sollten Sie dies etwa 10 Minuten vor dem Einbringen des

Garguts tun. Für Rezepte, die höhere Temperaturen benötigen, etwa Brot, Gebäck, Brötchen, Soufflés

sollten Sie den Ofen zuerst vorheizen. Auch bei der Zubereitung von gefrorenen oder tiefgekühlten

Gerichten sollten Sie den Ofen vorheizen.

20

4. VERWENDUNG IHRES HERDS

Abb.17

Nach dem Zünden des Brenners wie oben beschrieben können

Sie die Temperatur im Backraum einstellen, indem Sie den Regler

vor den Symbolen auf dem Bedienfeld oder an der Reglerbasis

einstellen (min bis max). Ist Ihr Herd mit einem Thermostat

ausgestattet, entnehmen Sie bitte der Temperaturtabelle unten die

richtige Temperatur für das Gargut. Drehen Sie den Regler nicht

in die Stellung zwischen "MIN" und "AUS" (gegen den

Uhrzeigersinn). Stellen Sie den Regler stets zwischen die

Positionen Maximum und Minimum. Um den Kochvorgang zu

beenden, drehen Sie den Regler im Uhrzeigersinn, bis die

Markierung auf dem Regler auf "0" zeigt (Reglermarkierung zeigt

nach oben).

290

230

150

KORRIGIEREN

FALSCHE

kreisförmigen Topfboden

FALSCHE

Topf-Base noch nicht beigelegt

Figure 16

• Es ist wichtig, um sicherzustellen, dass die Pfanne richtig über den Brennern zentriert ist.

FALSCHE

kleinen Topf Durchmesser

Page 49

Kochvorgang

• Ihr Herd wird (je nach Modell) mit verschiedenen Backblechen, Einschüben, einem Grill und einem

Drehspieß für Brathühnchen ausgeliefert. Sie können auch handelsübliches Glasgeschirr,

Kuchenformen, Backbleche etc. verwenden.

• Beachten Sie dabei stets die Angaben und Hinweise des Herstellers zur richtigen Verwendung.

Wenn kleine Behälter verwendet werden, platzieren Sie diese zentral auf dem Grillrost. Die folgenden

Hinweise sollten bei der Verwendung von glasiertem Geschirr beachtet werden:

• Wenn das zubereitete Gericht nicht das ganze Kochfeld bedeckt, es sich um Gerichte direkt aus

dem Gefrierschrank handelt, oder wenn der Einschub verwendet wird, um heruntertropfende

Flüssigkeiten aufzufangen, könnte sich die Platte aufgrund der hohen Koch- oder Brattemperaturen

verformen. Nach dem vollständigen Abkühlen erhält die Platte wieder ihre ursprüngliche Form. Dieser

Vorgang wird durch den Wärmeaustausch verursacht und ist ganz normal.

• Wenn Sie Geschirr oder andere Glaswaren zum Kochen verwenden, dürfen Sie diese nach dem

Herausnehmen aus dem Ofen nicht direkt in eine kalte Umgebung bringen. Stellen Sie diese nicht auf

kalte oder nasse Oberflächen. Stellen Sie sie auf ein trockenes Küchentuch oder einen Untersetzer

und lassen Sie sie langsam abkühlen.

• Stellen Sie den Einschub oder das Backblech niemals direkt auf den Boden des Backraums. Die

Emaillierung könnte dadurch beschädigt werden.

21

4. VERWENDUNG IHRES HERDS

Page 50

22

4. VERWENDUNG IHRES HERDS

4.2 Im Backraum verwendetes Zubehör

• Es sind verschiedene Zubehörteile für den Backraum vorhanden. Sie können auch

handelsübliches Zubehör verwenden (dieses muss jedoch hitze- und feuerfest sein). Sie können auch