Vertiv Liebert LDMF User Manual

Liebert®

LDMF™ Distribution Monitoring

User Manual

The information contained in this document is subject to change

without notice and may not be suitable for all applications. While

every precaution has been taken to ensure the accuracy and

completeness of this document, Vertiv assumes no responsibility

and disclaims all liability for damages resulting from use of this

information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods,

tools, and materials to be used in performing procedures not

specifically described in this document.

The products covered by this instruction manual are manufactured

and/or sold by Vertiv This document is the property of Vertiv and

contains confidential and proprietary information owned by Vertiv.

Any copying, use or disclosure of it without the written permission of

Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered

trademarks of the respective companies. Any questions regarding

usage of trademark names should be directed to the original

manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent

section of this manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.VertivCo.com/en-us/support/ for additional assistance.

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.0 GLOSSARY OF ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.0 MAJOR COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 PM4 Monitor Board (PMB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 PM4 Interface Board (PIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.3 PM4 Large Interface Board (PLIB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Branch Circuit Monitoring Sensor Module (BSM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.5 Power Supply With EMI Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.6 Human-Machine Interface/Display Assembly (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.7 PM4 Adapter Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.1 Installing a BSM (CT Module Assembly) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.1 Connecting Panelboards A and B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Installing a Solid-Core Current Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Installing a Current Transformer on the PIB Interface Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Connecting a Current Transformer to the PM4 Large Interface Board (PLIB) . . . . . . . . . . 14

5.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.1 LDMF Setup Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.2 Modbus Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Downloading the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.4 Using the Monitor Tool (Used Only for Startup and Diagnostics). . . . . . . . . . . . . . . . . . . . . . .20

5.4.1 Starting the Monitor Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.4.2 Monitor Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.3 Panel Status and Real-Time Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4.4 Main Breaker Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4.5 Breaker Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4.6 Mode Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Vertiv | Liebert® LDMF™ Distribution Monitoring User Manual | i

5.5 Using the Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.5.1 Starting the Configuration Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.5.2 Main Configuration Window Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.3 Load a Configuration File from Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.5.4 Install Configuration Changes in the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5.5 Save the Configuration File to Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.6 Select Panel to View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.7 Select Breakers to View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.8 Edit the Liebert LDMF Unit Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5.9 Edit the Panel Properties or Set a Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.5.10 Edit the Breaker Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5.11 Add a Circuit Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

5.5.12 Adding a Subfeed Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.5.13 Delete a Circuit Breaker/Subfeed Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.6 Upgrading the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.7 Display Controls (HMI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5.7.1 Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.7.2 Liebert LDMF Parameter Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

5.7.3 Liebert LDMF Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

5.7.4 Liebert LDMF Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.0 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.0 TROUBLESHOOTING / FREQUENTLY ASKED QUESTIONS . . . . . . . . . . . 43

FIGURES

Figure 1 RS-232 port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2 Main panelboard screens—examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Figure 3 Subfeed screens—examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 4 Branch breaker screens—examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

TAB LES

Table 1 CT matrix for the Liebert LDMF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2 Large branch breaker CT wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3 CT Table for Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4 CT Table for PM4 Large Interface Board #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 5 CT Table for PM4 Large Interface Board #2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Table 6 Parameters monitored for breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 7 Alarm conditions and factory setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 8 Monitor Menu Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 9 Monitor mode buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Table 10 Overview of main Configuration window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Table 11 Edit breaker properties and description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Vertiv | Liebert® LDMF™ Distribution Monitoring User Manual | ii

IMPORTANT SAFETY INSTRUCTIONS

WARNING

As with all types of electrical equipment, dangerous voltages exist within the equipment

where the Liebert LDMF Distribution Monitor components are installed. For maximum

safety, ensure power is removed and circuit breakers/disconnects are tagged/locked out

per all applicable national, state and local electrical codes prior to working inside

equipment.

The area around the equipment must be free of any debris or standing water.

All power and control wiring must be installed by a qualified electrician in accordance with

the NEC and all applicable national, state and local codes.

ONLY qualified service personnel should perform maintenance and/or service on the

Liebert LDMF system. When performing maintenance and/or service on any component,

verify test equipment is insulated and has been inspected prior to use.

To avoid damage to the circuit boards, personnel handling these components should be

wearing an electrostatic discharge strap or other approved protective device.

When replacing or installing a solid core Current Transformer (CT), power must be

removed from equipment to prevent damage to the CT and/or circuit board. If the CT is a

split-core design, follow proper electrical safety procedures and ensure the CT wires are

connected to the applicable burdening circuit before attaching the CT around the

conductor.

These safety precautions are to be used in conjunction with NEC and local/state electrical

code.

ELECTROMAGNETIC COMPATIBILITY—The Liebert LDMF as a functional component of a

power distribution and supply product complies with the limits for a Class A Digital Device,

pursuant to Part 15 of FCC rules. Operation is subject to the following two conditions:

• This device must not cause harmful interference, and

• This device must accept any interference received, including interference that may cause undesired

operation.

Operating this device in a residential area is likely to cause harmful interference that users must

correct at their own expense.

Liebert LDMF as a functional component of a power distribution and supply product complies

with the requirements of EMC Directive 2004/108/EC and the published technical standards.

Continued compliance requires installation in accordance with these instructions and use of

accessories approved by Vertiv.

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 1

1.0 GLOSSARY OF ABBREVIATIONS

The following abbreviations are used in this manual.

BCMS Branch Circuit Monitoring System

BMS Building Management System

BSM Branch Sensor Module

DSP Digital Signal Processor

GUI Graphic User Interface

HMI Human-Machine Interface

IGM Information Gathering Module

LDMF Liebert Distribution Monitor Front Access

LDMFS Liebert Distribution Monitor Front (Square-D Panelboards)

LDMFG Liebert Distribution Monitor Front (GE Panelboards)

LDMFI Liebert Distribution Monitor Front (I-Line Panelboards)

LDMF4

PAB PM4 Adapter Board

PCD Power Conditioning and Distribution

PDU Power Distribution Unit

PM4 Power Monitoring 4th Generation

Liebert Distribution Monitor Front (480V Distribution

Cabinets)

PIB PM4 Interface Board

PLIB PM4 Large Interface Board

PMB PM4 Monitoring Board

STP Service Terminal Port

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 2

2.0 PRODUCT OVERVIEW

The Liebert LDMF monitors the main panelboard circuit breaker and individual panelboard

branch circuit breakers. The measurements are used to report the voltage, current and alarm

conditions for each breaker. The Liebert LDMF utilizes branch circuit sensor modules and

individual current transformers (CT) to monitor current. In addition, the Liebert LDMF monitors

options like subfeed and output circuit breakers and provides a full array of power parameters

and alarms.

The Liebert LDMF is available as an option for the Liebert PPC™, Liebert FDC™, Liebert FPC™,

Liebert RX™and Liebert RDC™.

The Liebert LDMF system can communicate with a Building Management System (BMS) and

Liebert SiteScan® Web via optional Liebert IntelliSlot™ cards or Liebert SiteLink® interface.

The Liebert LDMF consists of a monitor board, interface board, optional local display and Branch

Sensor Modules (BSM).

The Liebert LDMF is capable of receiving input from current branch sensor modules. The sensor

module (BSM) contains 100A current transformers (CTs) encapsulated in an epoxy-filled plastic

enclosure designed to be mounted next to the panelboard. Sensor modules are designed to work

3/4" or 1"-spaced panelboards. If a sensor module CT fails, connections are provided for up to six

replacement CTs. The optional CTs can be attached directly to the load cable feeding the failed

CT.

Higher-rated CTs may be used for monitoring optional subfeed circuit breakers. For subfeed

breakers, such as main panelboard breakers, the Liebert LDMF monitors not only the three-phase

current but also the ground and neutral current. These subfeed circuit breakers are in addition to

the panelboard circuit breakers that can be monitored through the BSM. The Liebert LDMF can

accommodate 18 individual large current transformers.

If your Liebert power center is supplied with a Square D® I-Line™ panelboard, the Liebert LDMF

can monitor it as well as its output breakers. A PM4 Large Interface Board (PLIB) replaces the

panelboard PM4 Interface Board (PIB) and can monitor up to 42 CTs. Each PLIB can monitor

eight four-wire or five-wire I-Line and/or subfeed breakers including ground and neutral current.

There are two (2) PLIBs per monitor board that can monitor up to 16 five-wire I-Line and/or

subfeed breakers.

The Liebert LDMF system includes three Liebert IntelliSlot ports for remote communication.

Optional Liebert IntelliSlot cards can provide the following remote communications:

• IS-WEBS card for SNMP/WEB with RJ-45 connection to Ethernet LAN

• IS-485S card for Modbus 485, 2-wire connection

• IS-IPBMS card for Modbus IP, with RJ-45 connection to Ethernet LAN

• IS-UNITY-DP card for HTTP/HTTPS, Vertiv Protocol, e-mail, SMS, SNMP v1/v2c/v3, BACnet IP/MSTP and

Modbus TCP/RTU output using a serial RS-485 two-wire connection

In addition to Liebert LDMF remote communications, an optional local display offers easy-to-use

viewing of electrical data for various branch breakers as well as alarm details such as the type and

source of each alarm.

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 3

3.0 MAJOR COMPONENTS

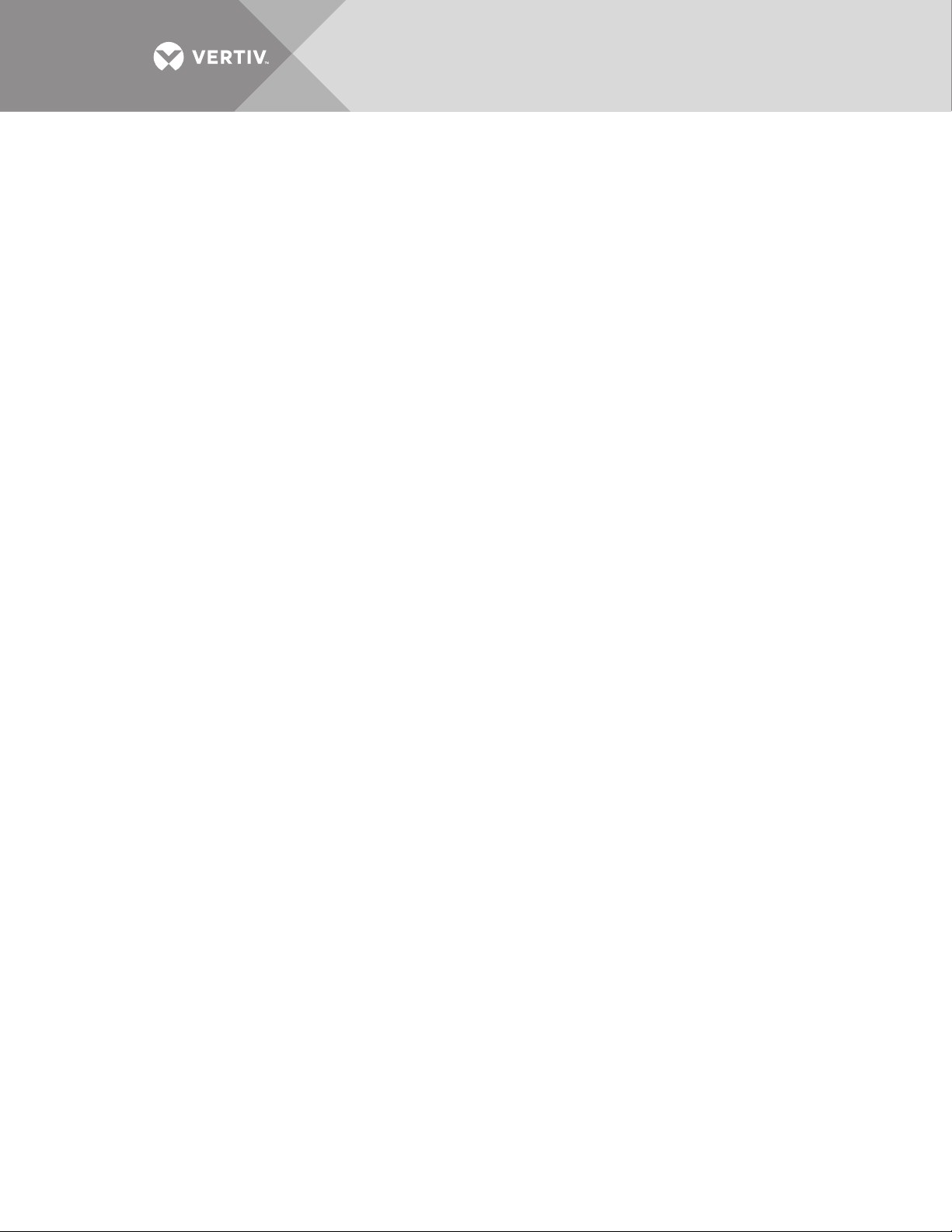

3.1 PM4 Monitor Board (PMB)

The PM4 Monitor Board (PMB) is the main processing and storage circuit board. The PMB

contains the non-volatile memory where the configuration file is stored. The CT Module

Assemblies will connect directly to the PMB via the 4 ribbon cables connectors. The PMB is a

DSP-based logic controller with internal flash memory to store breaker configuration, alarms and

energy data. The on-board battery supplies power to the real-time clock.

All the electrical parameters are accumulated on the PMB for processing to Liebert Velocity

protocol for remote monitoring and the HMI interface for the local display. Kilowatt-hours (kWh)

data is accumulated on this board for the panelboard mains, subfeeds and each branch circuit

breaker. A remote command can be used to reset the accumulated energy data.

Additional PMB Capabilities

• Six (6) auxiliary CT connectors, which allow for replacing a failed CT.

• A DB9 serial port on the outside panel is available for local configuration.

3.2 PM4 Interface Board (PIB)

The Liebert LDMF PM4 Interface Board (PIB) provides connections for the voltage and currents

of the panelboard main circuit breaker as well as the CT current for any installed large branches

or subfeed breakers (maximum of 18 CTs).

For the large branches or subfeed breakers, the nine CTs on the A side of the board are normally

associated with the A-side voltages for power calculations. The B-side CTs are normally

associated with the B-side voltages. A cross-configuration tool allows changing that association

for subfeeds.

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 4

The 18 large branch CT inputs can also be used to monitor up to three subfeed circuit breakers.

This is configured using the configuration tool (see 5.5 - Using the Configuration Tool). The CTs

from the B side of the PIB are cross-configured to the A side so that the three subfeeds appear

within the A-side panelboard register space. The 18 large branch breakers require CT’s with 1A

secondary.

WARNING

Before connecting a large CT to the PIB, note the CT MUST have a 1A secondary.

Connecting

anything other than a 1A secondary CT will damage the PIB and the CT.

To ensure the proper current ratio and accuracy, the CTs should be purchased through

Vertiv. See Ta bl e 1 for details. Contact your local Vertiv representative or call Vertiv

Support at 800-543-2378.

Table 1 CT matrix for the Liebert LDMF

Part Number Description Phase CT Ground CT Neutral CT

539217G1-L 3-pole 0-100A Subfeed Breaker 5W CT Kit 200:1 100:1 200:1

539217G2-L 3-pole 125-225A Subfeed Breaker 5W CT Kit 500:1 100:1 500:1

539217G3-L 3-pole 250-400A Subfeed Breaker 5W CT Kit 1000:1 100:1 1000:1

539217G12-L 3-pole 125-225A Subfeed Breaker 4W CT Kit 500:1 — 500:1

539217G13-L 3-pole 250-400A Subfeed Breaker 4W CT Kit 1000:1 — 1000:1

539217G4-L 3-pole 0-100A I-Line Breaker 3W CT Kit 47" Frame 200:1 — —

539217G5-L 3-pole 125-225A I-Line Breaker 3W CT Kit 47" Frame 500:1 — —

539217G6-L 3-pole 250-400A I-Line Breaker 3W CT Kit 47" Frame 1000:1 — —

539217G7-L 1-pole 0-100A Branch Breaker CT Kit 200:1 — —

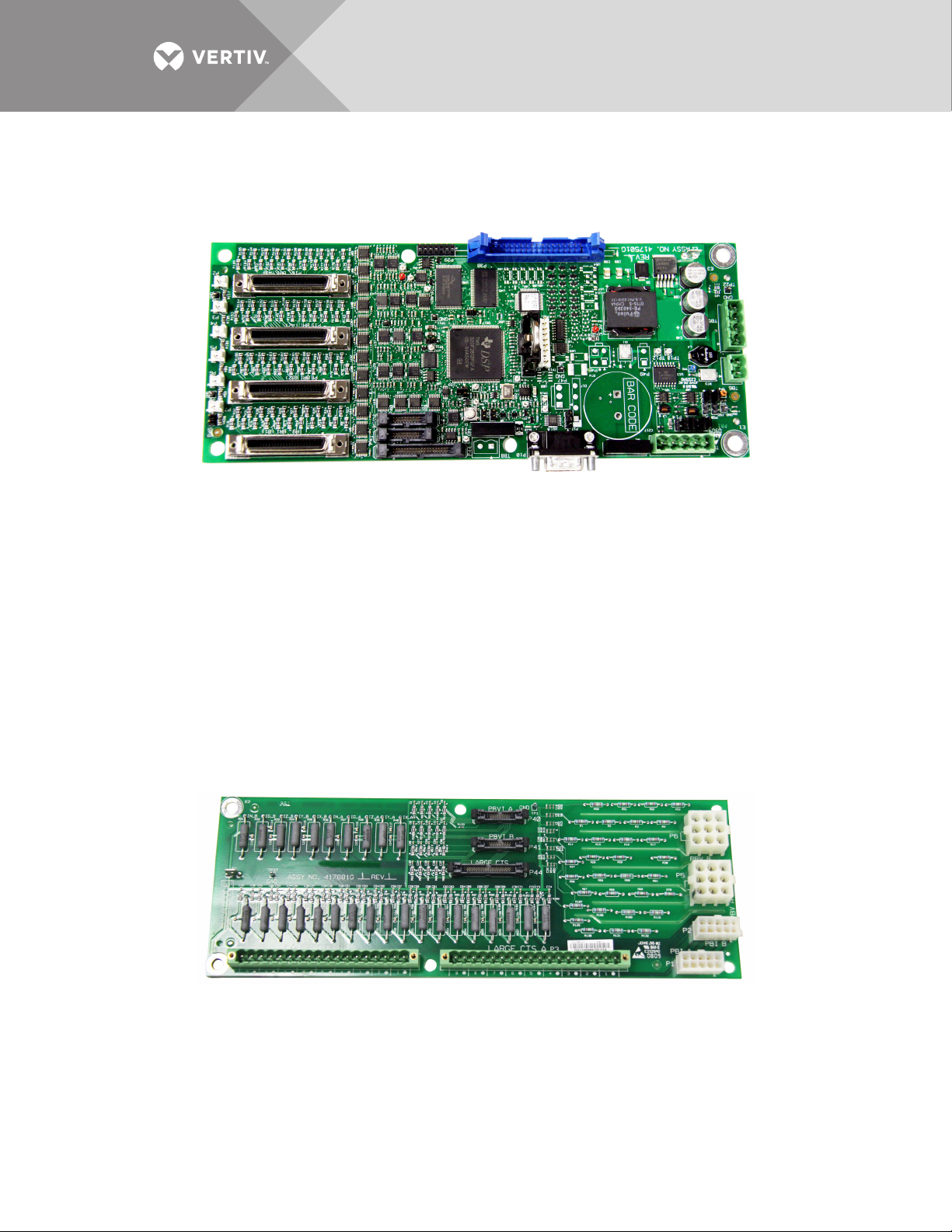

3.3 PM4 Large Interface Board (PLIB)

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 5

The PM4 Large Interface Board (PLIB) provides voltage and current attenuation for Square-D ILine panelboards. There are 42 CT locations on each LIB for a total capacity of eight 4-wire (3

phases and neutral) or 5-wire (3 phases, neutral and ground) breakers.

WARNING

Before connecting a large CT to the PLIB, note the CT MUST have a 1A secondary.

Connecting anything other than a 1A secondary CT will damage the PLIB and the CT.

To ensure the proper current ratio and accuracy, the CTs should be purchased through

Vertiv. See Ta bl e 1 for details. Contact your local Vertiv representative or call Vertiv

Support at 800-543-2378.

Two PLIBs are supplied for a total maximum monitoring capacity of sixteen 5-wire I-Line

and/or subfeed breakers.

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 6

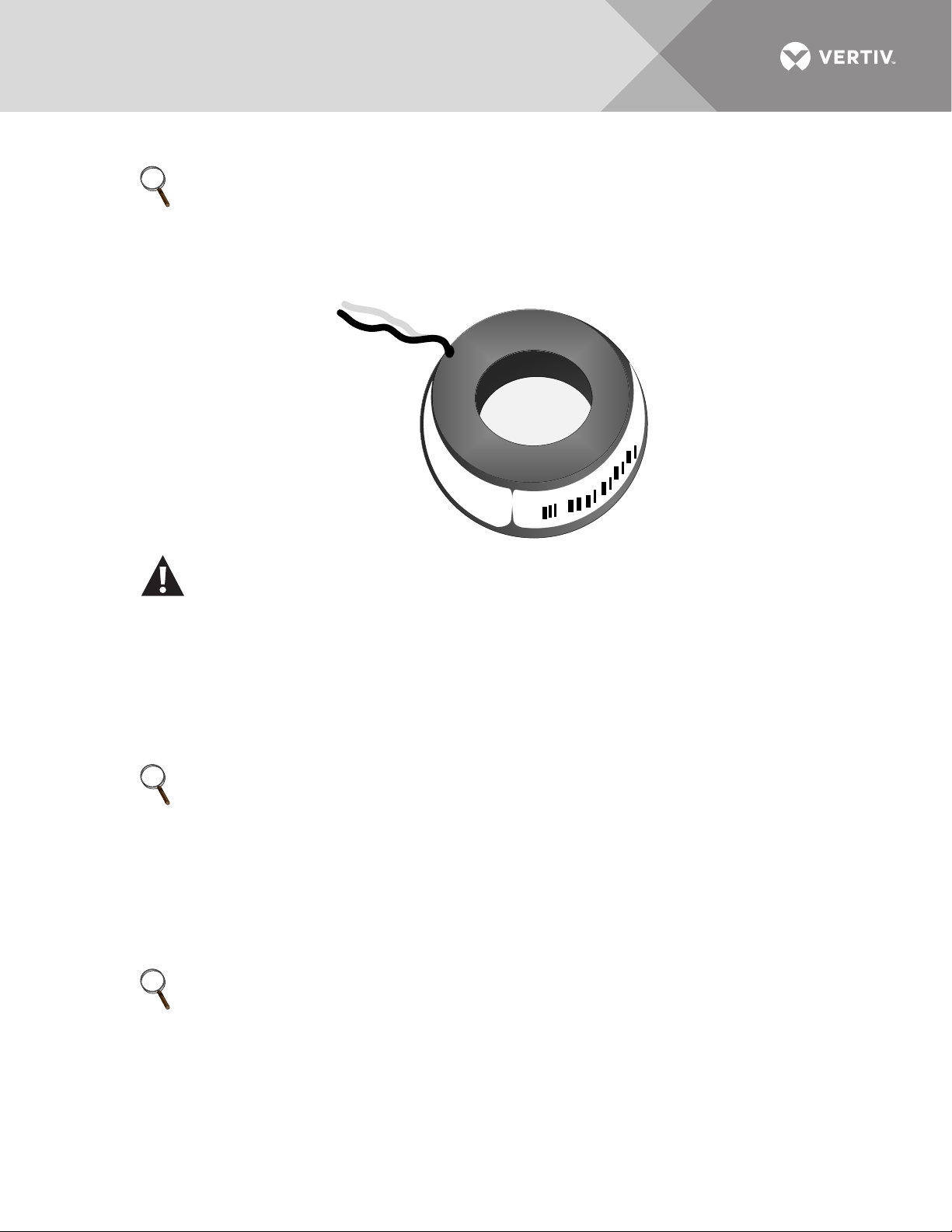

3.4 Branch Circuit Monitoring Sensor Module (BSM)

The Branch Circuit Monitoring Sensor Module (BSM)—more commonly referred to as the CT

Module—contain 21, 27 or 36 individual Current Transformers filled inside an epoxy enclosure.

Each load circuit is passed through one of the openings for branch circuit current monitoring. The

signals leave the CT module via a ribbon cable which is connected directly to the PM4 Monitor

Board (PMB) for attenuation and processing.

There are two BSM designs depending on the manufacturer of the panelboard installed:

• Utilize 1" spacing between circuits.

• Utilize 3/4" spacing between circuits.

NOTE

The diameter of each CT hole is 0.433" (11mm). Wire diameter and thickness of insulation must be

taken into account before wiring each branch circuit. Using wire that is too large may prevent the

conductor from fitting through the CT hole. Do not attempt to alter the diameter of the CT

opening.

For larger panelboards, the CT Module is designed to interlock to maintain alignment between

the breaker poles and the CT Modules.

3.5 Power Supply With EMI Filter

The power supply assembly converts 100-240VAC (+10%/-13% range) 50/60Hz into 12VDC to

provide logic level power for the PMB.

The Power Supply is fed from the line side of the panelboard main breaker. If during normal

operation the panelboard main breaker trips or is turned off, the PMB will still have power to

communicate alarms via the local display or remotely via Liebert IntelliSlot® cards.

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 7

3.6 Human-Machine Interface/Display Assembly (Optional)

The LDMF allows users to view the panelboard circuit data locally through the optional display.

The user interface has function keys to scroll through and view each panelboard's data as well as

the associated branch circuits and/or subfeeds.

Along with the branch circuit data the LDMF Display also has an alarm annunciation window that

lists all active alarms. The display has an LED status indicator that changes to red in the event of

an alarm. The Silence/Reset button will silence the audible alarm when pressed once and held

until alarm is silenced. When pressed a second time, the button clears the alarm and turns off the

red LED.

Alarm thresholds cannot be added, deleted or adjusted on the local display. These functions may

be performed only by using the LDMF Configuration software, which is available for download at

the Liebert Web site. Refer to 5.3 - Downloading the Software for downloading instructions and

see 5.5 - Using the Configuration Tool for details on using the software.

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 8

3.7 PM4 Adapter Board

• The PM4 Adapter Board (PAB) is provided with each Liebert LDMF. The PAB is typically mounted on the

back of the display, which is located on the front door of the unit. The PAB provides a customer interface to

the LDMF summary alarm contacts.

• If two Liebert LDMF systems are provided, the two PABs are connected to each other at the factory. It is

only necessary to connect to one PAB to monitor the Customer Summary Alarm; the two Liebert LDMF

units share summary alarm contacts.

• On the Liebert FPC and Liebert PPC the PAB has additional connections on TB1 that include Remote

Emergency Power Off (EPO). The field-selectable switch S1 on the PAB allows the selection for either

Manual or Auto restart. The factory default setting is Manual.

• Manual restart allows for an orderly supervised startup after power failure. The control circuit

automatically energizes the shunt trip mechanism of the main input breaker upon sensing output voltage

failure.

• Setting the switch to Auto deactivates the manual restart. In Auto restart mode, the main input breaker

does not trip due to power failure and the unit will restart when power is restored.

NOTE

The TB1 connections for customer alarms 1 - 5 are used only with the VPMP product.

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 9

4.0 INSTALLATION

WARNING

Dangerous voltages exist in power distribution units and power conditioning units. To

ensure maximum safety, all circuits breakers in the panelboard should be removed of power

and the input feeder breaker should be turned Off and locked-out in accordance with NEC

and local/state code.

NOTE

Liebert LDMF components and any other monitoring devices should be installed only by properly

trained and qualified personnel.

This section provides instructions for installing and connecting Liebert LDMF current

transformers. If any Liebert LDMF component requires service, contact Vertiv Support at

800-543-2378 for assistance.

4.1 Installing a BSM (CT Module Assembly)

In most cases the BSM—the CT Module—is factory-installed and no further work is required. If a

CT Module must be added, it attaches easily to the side of a panelboard to monitor any

combination of 1-, 2- and 3-pole circuit breakers.

• For side-by-side panelboards (21 circuits on each side), attach one CT Module

to each side of the panelboard, ensuring that the center of the CT hole lines up

to the branch circuit breaker connection.

• For Square-D Inline panelboards (42 circuits in a row), the two CT second, lower

CT Module so that the two cutout sections line up, then attach the screws to

secure the CT Modules to the panelboard.

• For GE Inline type panelboards, the two CT Modules fit end to end. Flip the

second, lower CT Module so that the 50-pin ribbon cable connector, mounted

on the bottom of the CT Module, lines up with the hole in the panelboard

mounting bracket.

Install the circuit breakers according to the manufacturer's

documentation. Route the circuit wire through the center of the CT and

attach securely to the circuit breaker.

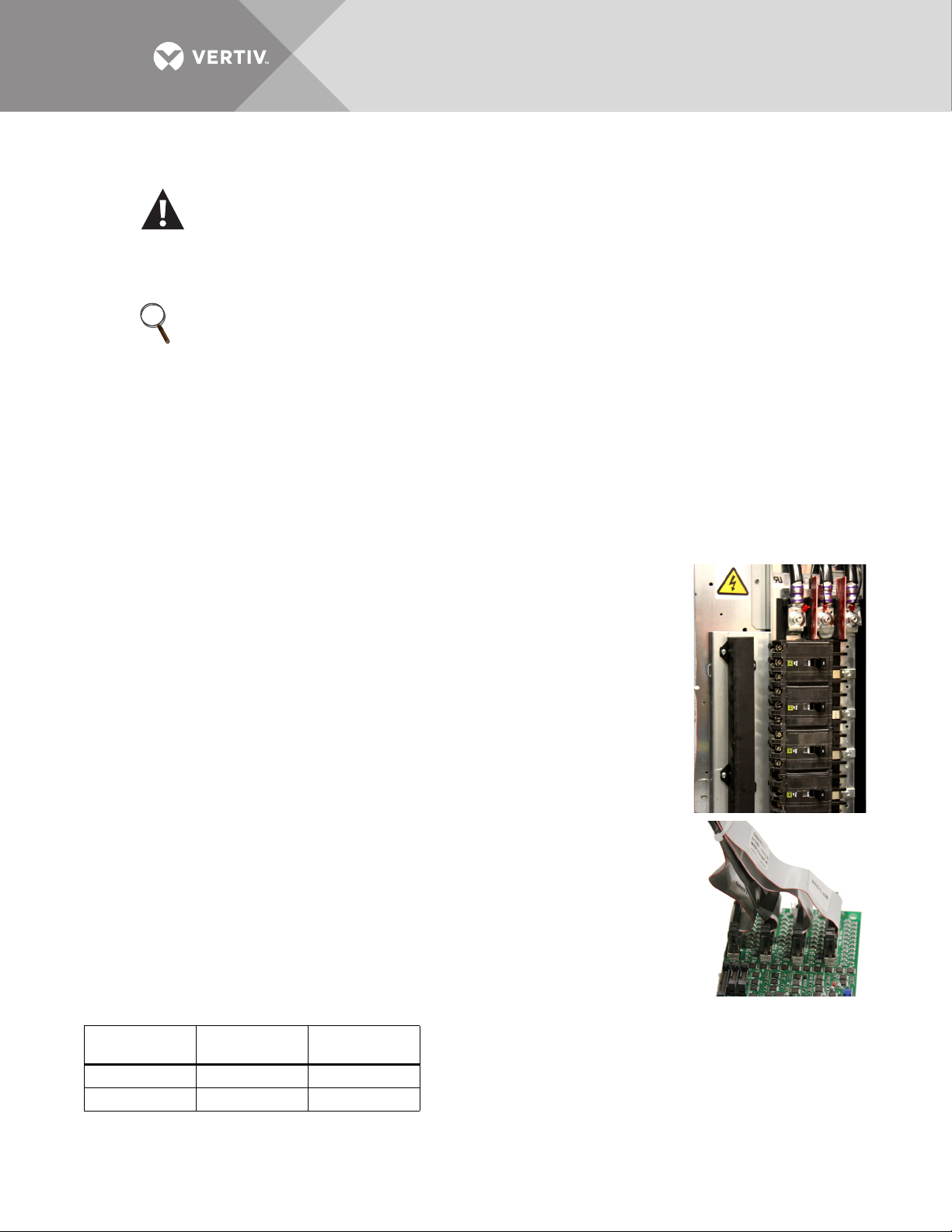

4.1.1 Connecting Panelboards A and B

The CT Module connects to the PMB via a 50-pin ribbon cable attached

to the back of the CT Module. Route the ribbon cable and attach to the

appropriate connector (see figure at right).

There are four connectors that are labeled for easy identification: two for

Panelboard A (A1 and A2) and two for Panelboard B (B1 and B2).

• Connect the CT module that will monitor Circuits 1-21 to the A1 or B1

connector, depending on whether the CT Module is monitoring Panelboard A

or B.

• Connect the CT module that will monitor Circuits 22-42 to the corresponding A2 or B2 connector.

Circuits

Monitored

1-21 A1 B1

22-42 A2 B2

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 10

Panelboard A

Connector

Panelboard B

Connector

To configure the branch circuits, refer to 5.5.11 - Add a Circuit Breaker.

L

O

T

N

U

M

B

E

R

I

N

S

T

R

U

M

E

N

T

S

NOTE

• Panelboard A is either Panelboard 1 or Panelboard 3.

• Panelboard B is either Panelboard 2 or Panelboard 4 depending on which Liebert LDMF

Control Board is being configured.

4.2 Installing a Solid-Core Current Transformer

WARNING

A solid-core CT cannot be installed on a wire while current is flowing through the wire.

Damage to the burden resistor and CT will occur. Power must be removed before installing

and/or removing any CT. CT’s should be installed only by properly trained qualified

electricians.

The CT for the panelboard main input circuit breaker is hard-wired to the connectors. Removing

CT wires from the connector requires a pin extraction tool.

Contact Vertiv Support at 800-543-2378 for assistance.

NOTE

When replacing or installing a CT, ensure that the replacement CT has a secondary rating of 1A—

for example, 100:1, 200:1, 500:1 or 1000:1. Using a higher-rated CT—for example, 100:5 or 500:5will damage the burden resistors on the PIB board.

Typically the three-phase and neutral wires utilize a CT rating of 100:1, 200:1 500:1 or 1000:1, while

the ground wire utilizes a CT rating of 100:1.

Route the circuit wire through the core of the CT and wire-tie the CT to the cable. Refer to the

manufacturer's documentation for proper orientation to ensure accurate readings.

NOTE

When installing CT’s for a large branch circuit breaker or subfeed, verify which monitoring board

is installed.

• A PIB can support up to three subfeeds,.

• One LIB can support up to eight output and/or subfeed breakers.

• Two LIB boards are provided to support up to 16 output and/or subfeed breakers.

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 11

4.3 Installing a Current Transformer on the PIB Interface Board

If subfeed breakers are ordered with the unit, the phase,

neutral and ground CTs are wired to the Interface

Board.The CTs will be zip-tied inside the equipment for the

electrician to install on each conductor when the

conductors are wired to the subfeed/large branch breaker.

The ground and neutral CTs for each factory-supplied

subfeed or large breaker are factory-installed and wired.

CTs have a white or H1 that depicts how to position the CT

on the cable to ensure accurate readings. The white dot or

H1 must face toward the source when installing the CT on

the phase cables. The neutral conductor CTs are placed in

the opposite direction, with the marking faced toward the load. Route the conductors through the

core of the CTs and wire-tie the CT to the cable to ensure the CT stays in place.

If subfeed breakers are installed in the field, up to five CTs may be installed (three phases, neutral

and ground). The neutral and ground CTs may be omitted if monitoring of neutral and ground is

not required. The 5-wire CT kits will be shipped separately and grouped together with each CT

with a label indicating whether it is a phase CT, neutral CT or ground CT.

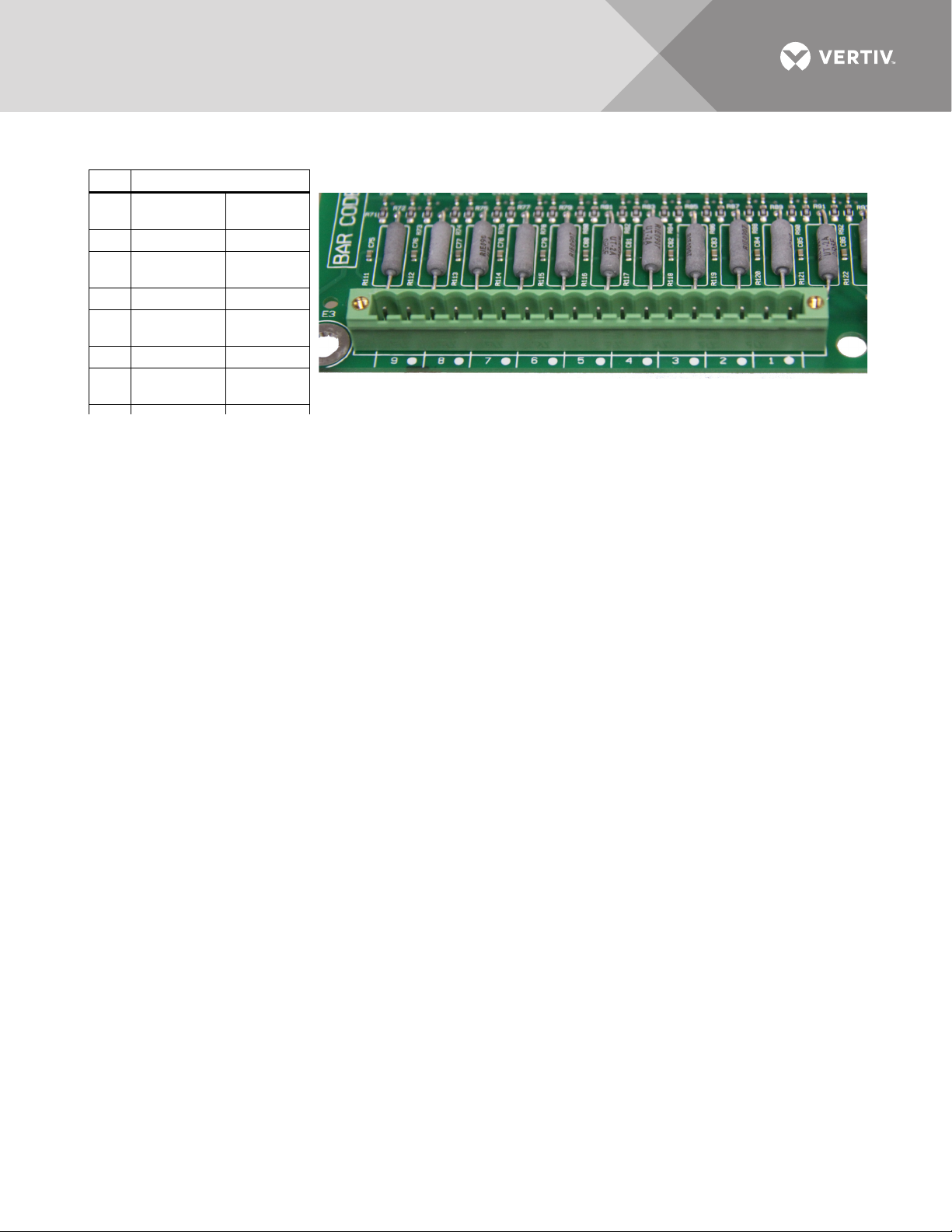

There are two 18-pin terminal blocks on the Interface Board for large branch circuit breakers

and/or subfeeds-one for Panelboard A and one for Panelboard B.

The circuit board is marked with a triangle to indicate Pin 1. Pin 1 should be used for the white wire

of CT1 (Phase A). The black wire should be connected to Pin 2. The same pattern will follow for

the remaining CTs.

After all CTs are installed, use the Configuration tool to label and set alarm parameters. To

configure the Liebert LDMF, see 5.5.11 - Add a Circuit Breaker.

If the Power Distribution Center is supplied with optional isolated ground, the isolated ground

circuit can be monitored by the Liebert LDMF. Usually the CT is already installed and wired to the

Large Branch Terminal Block at the factory. If not, perform the following steps:

(For Isolated Ground CT Installation only)

• Connect the isolated ground CT to Pins 17 and 18 on the two 18-pin terminal blocks on the Interface

Board.

• Connect the isolated ground CT white wire to Pin 17 and the CT black wire to Pin 18.

Refer to the following example and Tab le 2 for wiring configuration details.

Example: When installing a subfeed breaker where the three phases, neutral and ground will be

monitored, the CTs should be wired as follows:

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 12

If a second subfeed or large branch breaker will be installed, the same pattern will continue. Pins

Table 2 Large branch breaker CT wiring

Pin Wiring

1Phase A CT

White

wire

2 Phase A CT Black wire

3Phase B CT

White

wire

4 Phase B CT Black wire

5Phase C CT

White

wire

6 Phase C CT Black wire

7Neutral CT

White

wire

11 and 12 will be Phase A CT for the second breaker, Pins 13 and 14 will be Phase B CT and so on.

Vertiv™ | Liebert® LDMF™ Distribution Monitoring User Manual | 13

Loading...

Loading...