Vertiv Liebert DSE Packaged Series, Liebert DSE Packaged 400, Liebert DSE Packaged 500 Installer/user Manual

Liebert®

DSE™ Packaged Solution

Installer/User Guide

400 kW to 500 kW

The information contained in this document is subject to change without notice

and may not be suitable for all applications. While every precaution has been

taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages resulting from

use of this information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods, tools, and

materials to be used in performing procedures not specifically described in this

document.

The products covered by this instruction manual are manufactured and/or sold

by Vertiv. This document is the property of Vertiv and contains confidential

and proprietary information owned by Vertiv. Any copying, use or disclosure of

it without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark names

should be directed to the original manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.Vertiv.com/en-us/support/ for additional assistance.

Vertiv | DSE Packaged Solution Installer/User Guide

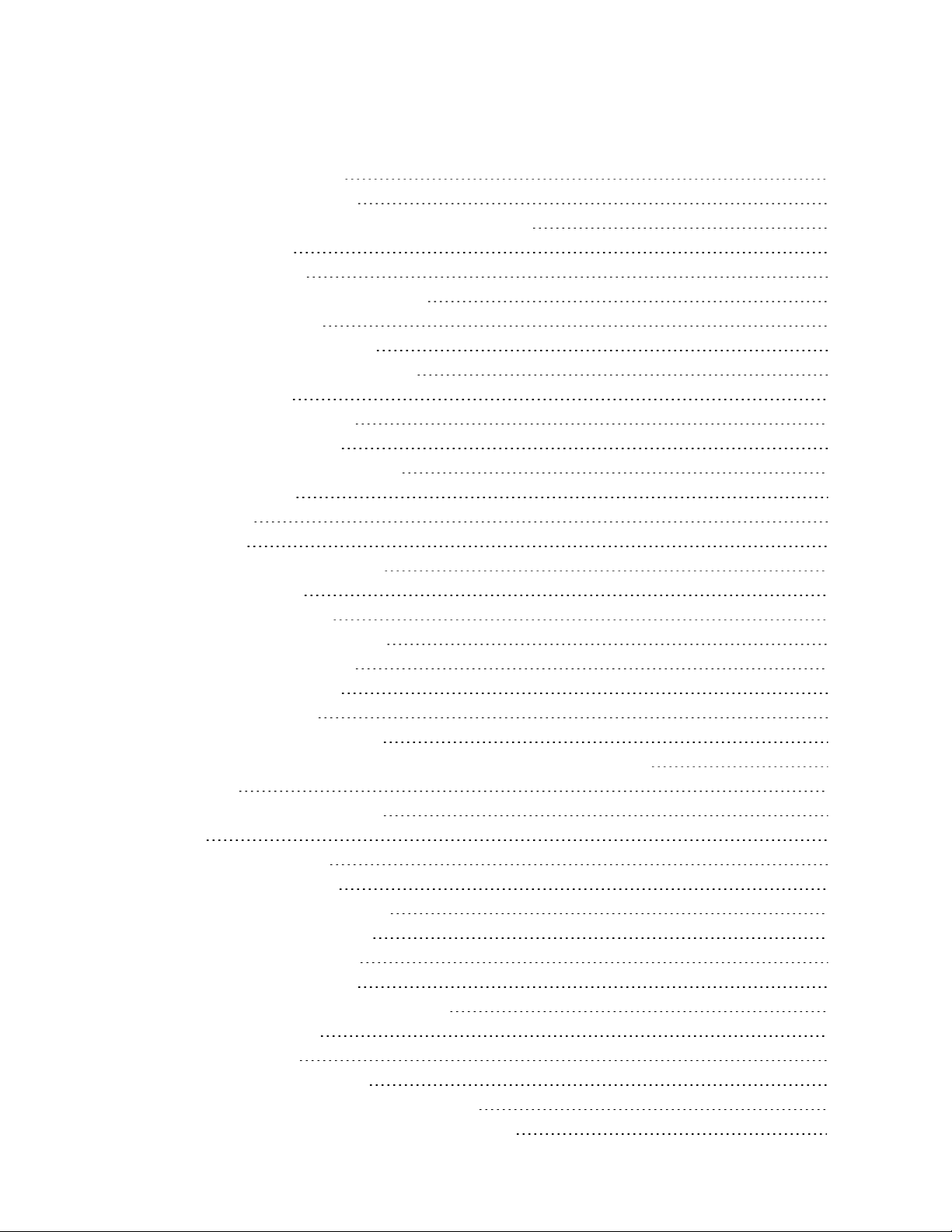

TABLE OF CONTENTS

1 Important Safety Instructions 1

2 Nomenclature and Components 5

2.1 Liebert DSE Packaged Solution Model Number Nomenclature 5

2.2 Component Location 7

2.3 Air Flow Configurations 8

3 Pre-installation PreparationandGuidelines 11

3.1 Storage before Installation 11

3.2 Rooftop Unit Installation Guidelines 12

3.2.1 Service Clearance for Rooftop Units 12

3.3 Planning Dimensions 13

3.4 Connections and System Setup 13

3.4.1 Electrical Connections 13

3.4.2 Evaporator Drip Pan Connection 13

3.5 Operating Conditions 15

3.5.1 Cooling 16

3.6 Unit Weights 16

4 Equipment Inspection and Handling 17

4.1 Rigging to Lift the Unit 17

5 Electrical Field Connections 21

6 Checklist for Completed Installation 29

6.1 Moving and Placing Equipment 29

6.2 Electrical Installation Checks 29

6.3 Other Installation Checks 29

6.4 BMS and Sensor Installation Checks 29

7 Initial Start-up Checks andCommissioningProcedure forWarrantyInspection 31

8 Maintenance 33

8.1 Service Access for Unit Maintenance 34

8.2 Filters 35

8.2.1 Replacing the Filters 36

8.3 Evaporator Fan Maintenance 37

8.3.1 Fan Assembly Troubleshooting 37

8.3.2 Fan Assembly Maintenance 38

8.3.3 Blower Motor Lubrication 38

8.3.4 Removing Fan Assembly 38

8.4 Electronic Expansion Valve (EEV) Maintenance 38

8.5 Compressor Maintenance 38

8.5.1 Compressor Oil 39

8.5.2 Replacement Compressors 39

8.5.3 Rotalock Valve on Digital-Scroll Compressors 39

8.5.4 Unloading Solenoids on a Digital Scroll Compressor 40

Vertiv | DSE Packaged Solution Installer/User Guide | i

8.5.5 Compressor Electrical Failure (Motor Burnout) 40

8.5.6 Replacing a Compressor with Electrical Failure (MotorBurnout) 40

8.5.7 Compressor Mechanical Failure 41

8.5.8 Replacing a Compressor with Mechanical Failure 41

8.5.9 Refrigerant Piping and Charging 42

8.5.10 Refrigerant Charge Requirements for Air Cooled Systems 42

8.5.11 Additional Oil Requirements for Scroll and Digital Scroll Compressors 43

8.5.12 Evacuation, Leak Testing, and Charging 44

8.6 General Condenser Maintenance 46

8.7 Condenser Cleaning 46

8.7.1 When to Clean the Condenser Coil 46

8.7.2 What to Use to Clean the Condenser Coil 46

8.7.3 Cleaning the Condenser Coil 46

8.7.4 Cleaning the Condenser Fan 47

8.8 Replacing the Condenser Fan 47

8.8.1 Verifing the Fan Address 54

8.9 Replacing the Premium Efficiency Control Board 55

8.9.1 Preparing to Replace the Board 55

8.9.2 Installing the Replacement Board 57

8.10 Pumped Refrigerant Economizer (PRE) 58

9 Preventive Maintenance Checklist 59

Appendices 63

Appendix A: Technical Support and Contacts 63

Appendix B: Submittal Drawings 65

Vertiv | DSE Packaged Solution Installer/User Guide | ii

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and maintenance of the

Liebert®DSE™ Packaged Solution. Read this manual thoroughly before attempting to install or operate this unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit and in this manual.

Follow all installation, operation and maintenance instructions and all applicable national and local building, electrical and

plumbing codes.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA-approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC and local codes, as

applicable. Before proceeding with installation, read all instructions, verify that all the parts are included and

check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require and receive

power even during the “Unit Off” mode of the controller. The factory-supplied disconnect switch is on the

exterior of the enclosure. The factory-supplied, optional disconnect switch is inside the unit. The line side of

this switch contains live high-voltage. The only way to ensure that there is NO voltage inside the unit is to

install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all local codes.

WARNING! Risk of electric shock. Can cause equipment damage, injury or death. Open all local and remote

electric power supply disconnect switches and verify with a voltmeter that power is off before working within

any electric connection enclosures. Service and maintenance work must be performed only by properly

trained and qualified personnel and in accordance with applicable regulations and manufacturers’

specifications. Opening or removing the covers to any equipment may expose personnel to lethal voltages

within the unit even when it is apparently not operating and the input wiring is disconnected from the

electrical source.

WARNING! Risk of electric shock. Can cause serious injury or death. The Liebert® iCOM microprocessor does

not isolate power from the unit, even in the "Unit Off" mode. Some internal components require and receive

power even during the "unit off" mode of the Liebert® iCOM control. Open all local and remote electric power

disconnect switches and verify with a voltmeter that power is Off before working on any component of the

system.

WARNING! Risk of over-pressurization of the refrigeration system. Can cause explosive discharge of highpressure refrigerant, loss of refrigerant, environmental pollution, equipment damage, injury, or death. This

unit contains fluids and gases under high pressure. Use extreme caution when charging the refrigerant

system. Do not pressurize the system higher than the design pressure marked on the unit's nameplate.

1 Im portant Safety In structions

1

WARNING! Risk of pressurized doors flying open or slamming closed suddenly. Can cause serious injury. Do

not attempt to open doors while fans are running. Do not turn on fans with doors open. Before opening the

door, open all local and remote electric power supply disconnect switches, verify with a voltmeter that power

is off, and verify that all fans have stopped rotating. Do not leave unsecured objects in the fan's bay after any

maintenance operation.

WARNING! Risk of contact with flying objects. Can cause serious injury or death. Do not leave unsecured

objects or tools in the fan's bay after performing maintenance operations. Re-install all panels before starting

up this unit after maintenance is performed.

WARNING! Risk of very heavy, 250-lb (113.4-kg) fan modules dropping downward suddenly. Can cause injury

or death. Support fan modules before removing mounting hardware. Use caution to keep body parts out of

the fan modules pathway during repositioning. Only properly trained and qualified personnel should work on

this equipment.

WARNING! Risk of improper moving. Can cause equipment damage, injury or death. Use only lifting

equipment that is rated for the unit weight by an OSHA-certified rating organization. The center of gravity

varies depending on the unit size and selected options. The slings must be equally spaced on either side of

the center of gravity indicator.Use the center of gravity indicators on the unit to determine the position of the

slings. Unit weights are listed in Table 3.3 on page16, and Table 3.4 on page16

WARNING! Risk of contact with high-speed rotating fan blades. Can cause serious injury or death. Open all

local and remote electric power-supply disconnect switches, verify with a voltmeter that power is off, and

verify that all fan blades have stopped rotating before working in the unit cabinet or on the fan assembly. If

control voltage is applied, the fan motor can restart without warning after a power failure. Do not operate the

unit with any or all cabinet panels removed.

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause overheated wire

and electrical connection terminals resulting in smoke, fire, equipment and building damage, injury or death.

Use correctly sized copper wire only and verify that all electrical connections are tight before turning power

On. Check all electrical connections periodically and tighten as necessary.

WARNING! Risk of wiring damage, short circuits and electric shock. Can cause overheated wiring, smoke, fire,

activation of fire suppression systems and EMS personnel and equipment, building and equipment damage,

injury or death. Insert CSA certified or UL listed bushings into holes and or knockouts used to route wiring

through metal panels to protect the wire insulation from contact with sheet metal edges.

2

Vertiv | D SE Packaged Solution Inst aller/User G uide

WARNING! Risk of explosive discharge of high-pressure refrigerant. Can cause serious injury. Neutral and

service ports on the rotalock valve do not have a valve core. Front-seat the service valves and relieve

pressure from the compressor before loosening a part or a component attached to the service valve. Follow

local codes to properly reclaim refrigerant.

CAUTION: Risk of improper moving, lifting and handling. Can cause equipment damage or injury. Only

properly trained and qualified personnel should work on this equipment. Condenser fan modules weigh in

excess of 125 lbs. (56.7 kg). Use proper lifting techniques and wear appropriate, OSHA-approved PPE to avoid

injury and dropping the fan module during removal. Equipment used in handling/lifting, and/or installing the

fan assembly must meet OSHA requirements. Use handling/lifting equipment rated for the weight of the fan

assembly. Use ladders rated for the weight of the fan assembly and technicians if used during installation.

Refer to handling/lifting, and/or installation equipment operating manual for manufacturer's safety

requirements and operating procedures.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA-approved PPE should attempt to move,

lift, remove packaging from or prepare the unit for installation.

CAUTION: Risk of low-hanging panels. Can cause injury or equipment damage. Wear appropriate, OSHAapproved PPE when entering and working within the enclosure.

CAUTION: Risk of exposure to harmful noise levels. Can cause hearing injury or loss. Depending on the

installation and operating conditions, a sound pressure level greater than 70dB(A) may arise. Take

appropriate technical safety measures. Operating personnel must wear appropriate, OSHA-approved PPE

and observe all appropriate hearing-protection safety requirements.

1 Im portant Safety In structions

3

NOTICE

NOTICE

NOTICE

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty coverage.

Prior to connecting any equipment to a main or alternate power source (for example: back-up generator

systems) for start-up, commissioning, testing, or normal operation, ensure that these sources are correctly

adjusted to the nameplate voltage and frequency of all equipment to be connected. In general, power-source

voltages should be stabilized and regulated to within ±10% of the load nameplate nominal voltage. Also, ensure

that no three-phase sources are single-phased at any time.

Risk of oil contamination with water. Can cause equipment damage.

Liebert®DSE Packaged Solution systems require the use of POE (polyolester) oil. POE oil absorbs water at a

much faster rate when exposed to air than previously used oils. Because water is the enemy of a reliable

refrigeration system, extreme care must be used when opening systems during service. If water is absorbed

into the POE oil, it will not be easily removed and will not be removed through the normal evacuation process. If

the oil is too wet, it may require an oil change. POE oils also have a property that makes them act as a solvent

in a refrigeration system. Maintaining system cleanliness is extremely important because the oil will tend to

bring any foreign matter back to the compressor.

Risk of improper operation in high-humidity conditions. Can cause unit damage and water carryover.

The Liebert®DSE Packaged Solution operations only as a sensible cooling unit and does not provide

dehumidification.

NOTE: The Liebert®cooling unit has a factory installed high pressure safety switch in the high side refrigerant

circuit.

Agency Listed

Standard 60-Hz units are CSA Certified to the harmonized U.S. and Canadian product safety standard CSA C22.2 No

236/UL 1995 for “Heating and Cooling Equipment” and are marked with the CSA c-us logo.

4

Vertiv | D SE Packaged Solution Inst aller/User G uide

2 NOMENCLATURE AND COMPONENTS

This section describes the configuration number for Liebert® DSE Packaged Solution 400 kW/500 kW unit and components.

2.1 Liebert DSE Packaged Solution Model Number Nomenclature

The following tables describe each digit of the 40-digit Liebert® DSE™ Packaged Solution.

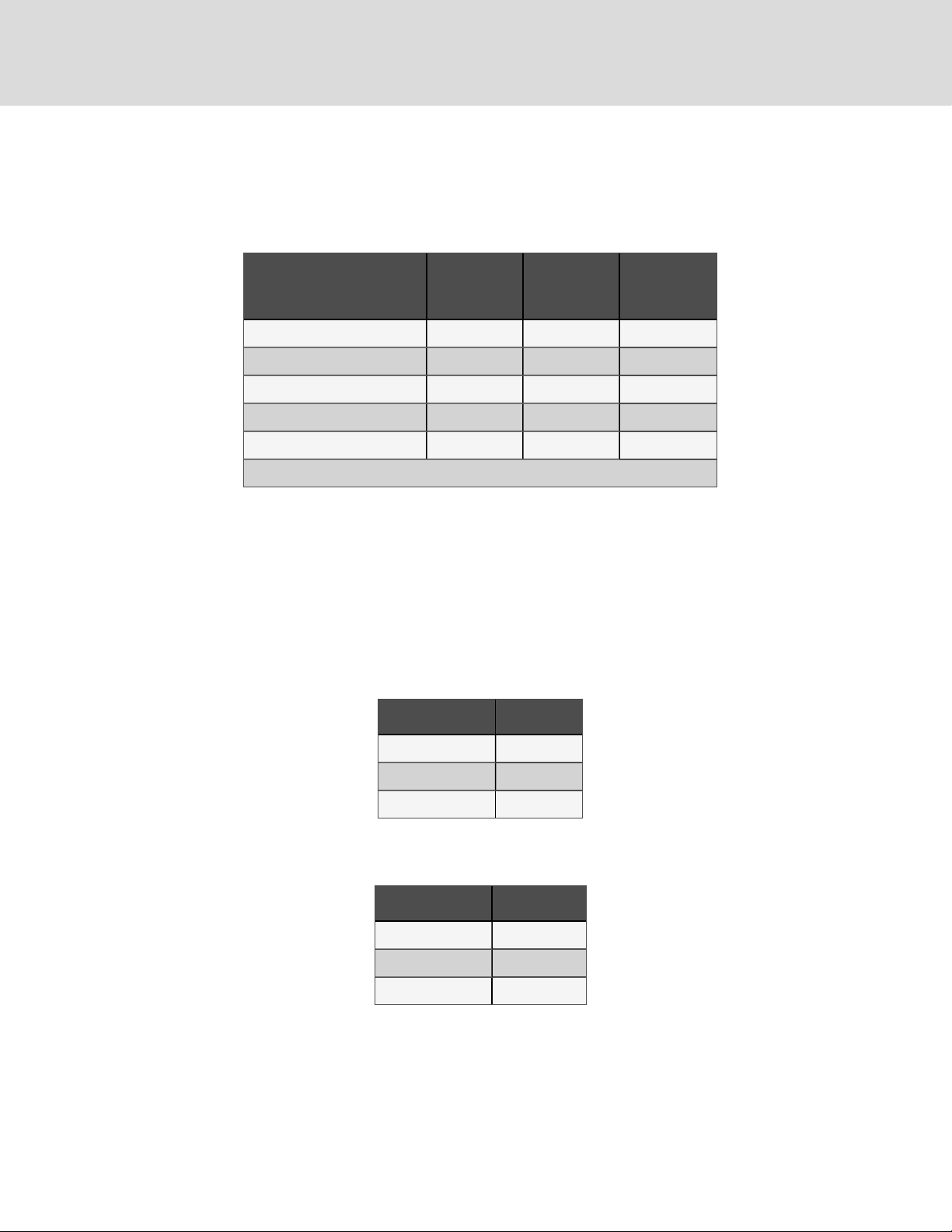

Table 2.1 DSE 400 kW/500 kW Packaged Solution Configuration Number Digits 1 to 10 Example

DSE 400 kW/500 kW Packaged S olutionConfiguration Number Digits 1 to 10 Example

1 2 3 4 5 6 7 8 9 10

D P 4 0 0 T P 2 A T

Table 2.2 DSE 400 kW/500 kW Packaged Solution Configuration Number Digits 11 to 36 Example

DSE 400 kW/500 kW Packaged S olutionConfiguration Number Digits 11 to 36 Example

11 12 13 14 15 16 17 18 19 20 21 22 23 24 25–36

0 H 0 8 1 6 L 0 U 0 P A A P —

DSE 400 kW/500 kW Packaged Solution Configu ration Numb er 37 to 40 Example

37 38 39 40

— — — —

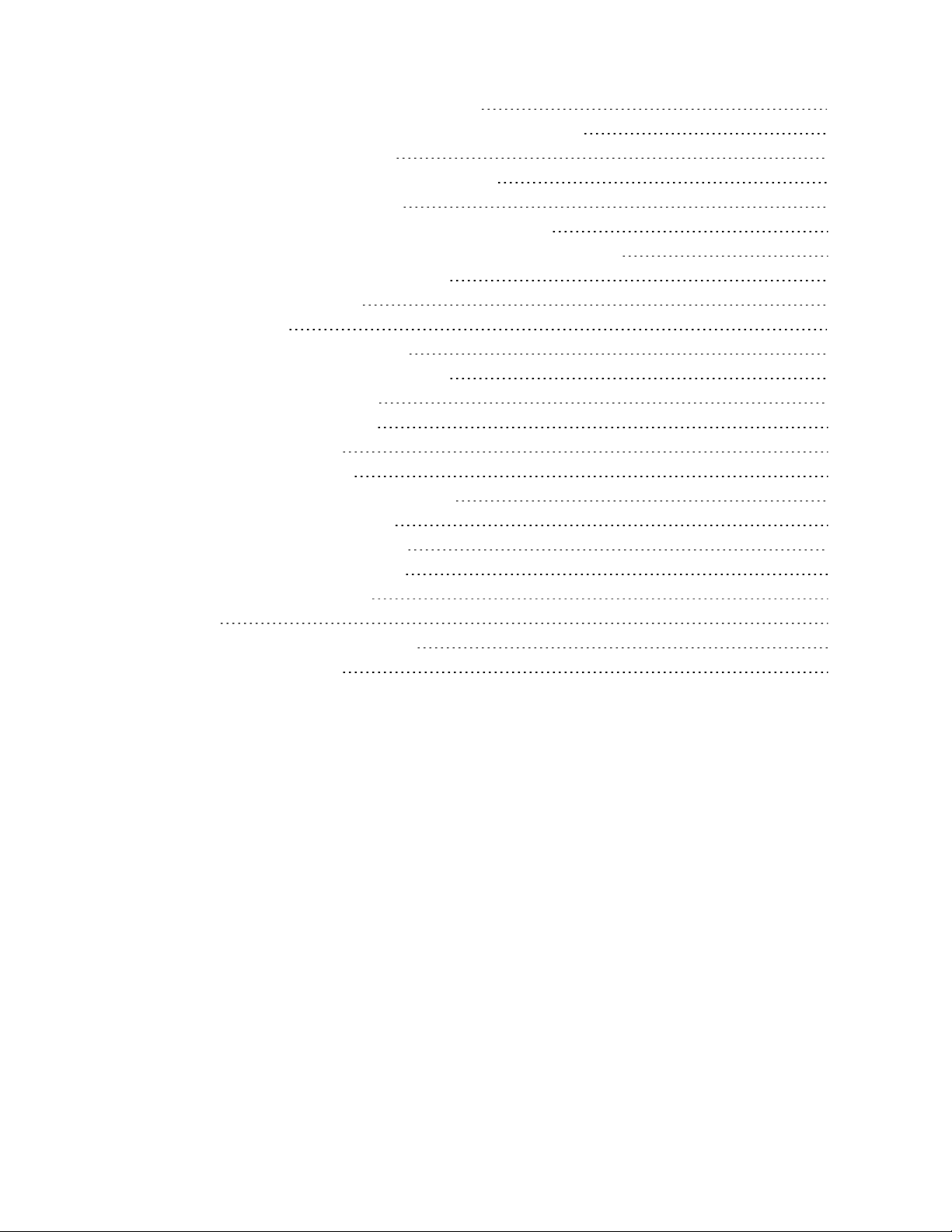

Table 2.3 DSE Packaged Solution Model Number Digit Definitions

Digit Description

Digits 1 a nd 2 = Product Family

DP = Liebert® DSE Packaged Solution

Digit3to5 = Cooling Capacity, kW

400 = Nominal sensible c apacity, 400-kW

500 = Nominal sensible capacity, 500-kW

Digit6 = Air Discharge

F = Perimeter, front inlet/frontsupply

R = Roof-top, bottom inlet/bottom supply

B = Roof-top draw-thru, bottom inlet/bottom supply

Digit7 = System Type

P = Air-cooled, Econ-O-Phase

2 N omenclature an d Components

5

Table 2.3 DSE Packaged Solution Model Number Digit Definitions (continued)

Digit Description

Digit8 = Air-flow (Fan Type)

2 = Direct-drive plenumfans and VFD (standard air flow)

Digit9 = Power Supply

A = 460V - 3ph - 60Hz

Digit10 = Cooling System

T = Tandem with digital scroll, R-410A

Digit11 = Humidifier

0 = None

Digit12 = Display

2 = iCOM (High Definition)

Digit13 = Options

0 = None

A = Supply-air isolating gravity damper

Digit14 = Air Filter

8 = MERV 8, 4-in.

9 = MERV 11 , 4-in.

1

Digit15 = Coil Option

1 = Non-coated evaporator coil, non-coated condenser coil

Digit16 = Enclosure Option

6 = Liebert® standard pebble-gray color

Digit17 = High-voltage option

L = Locking disconnect

6 = Locking disconnect + ATS

Digit18 = Option pac kages

0 = None

L = Low-voltage terminal package

Digit19 = Monitoring Cards

B = Base Comms and Connectivity

Digit20 = Sensors

0 = None

A = Compressorhigh-temp

Digit21 = Packaging

P = Domestic

6

Vertiv | D SE Packaged Solution Inst aller/User G uide

Table 2.3 DSE Packaged Solution Model Number Digit Definitions (continued)

Digit Description

Digit22 = Controls Power

0 = Controlspower from main input feed

A = Separate, 120-V feed from UPS

S = Quick Start and Capacitive Buffer

Digit23 = EconoPhase

A = Standard capacity

Digit24 = Packa ging

P = Domestic

Digit25 to 36 = Placeholder

Digit37 to 40 = Factory configuration number

1. For damper:If Digit 6 = F, the damper is on front supply. Damper is not available if Digit 6 = R or B .

2. For controls power: if Digit 22 = 0, there is no power buffer.

2

2.2 Component Location

The unit component locations are described in the submittal documents included in the Submittal Drawings on page65.

The following table lists the relevant documents by number and title.

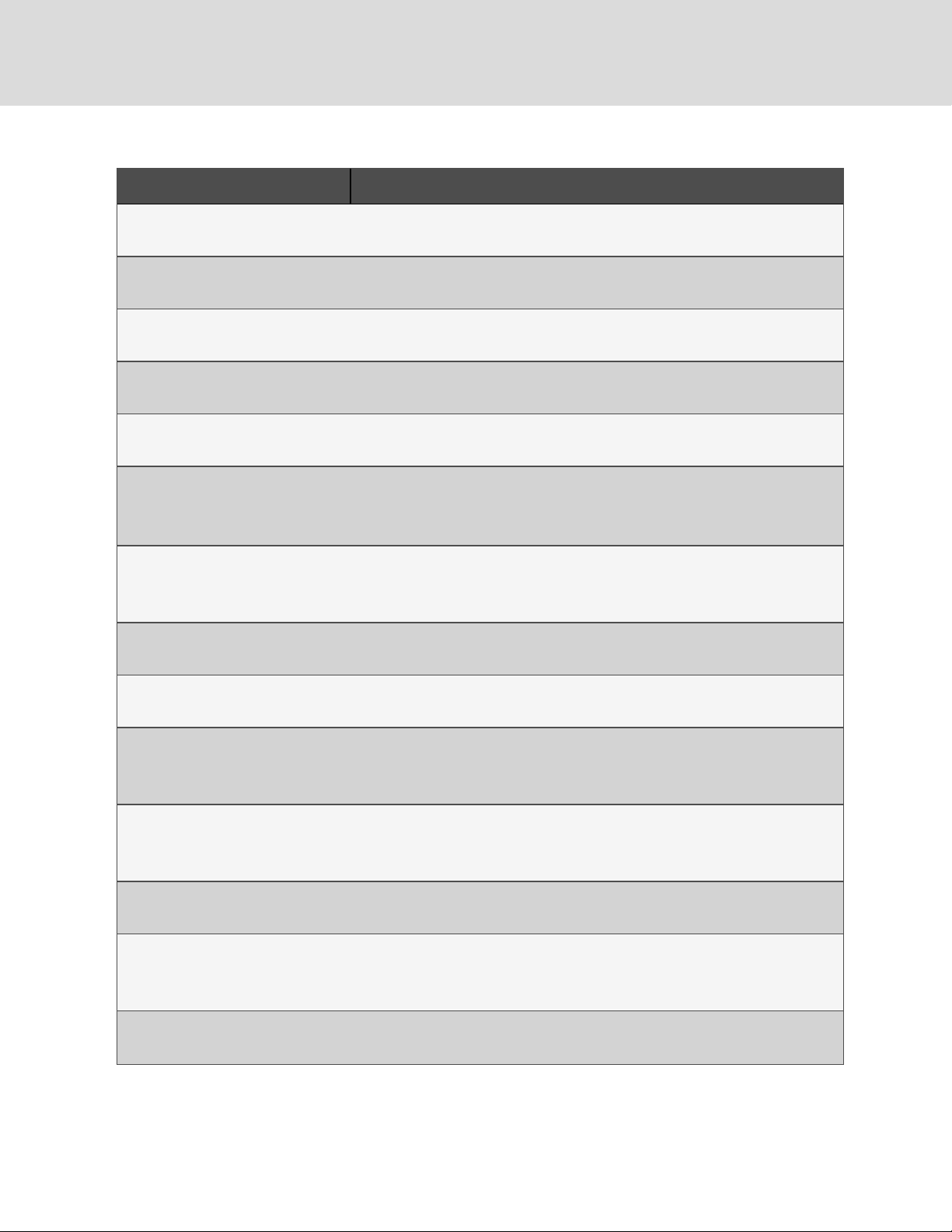

Table 2.4 Component Location Drawings

Docu ment Number Title

DPN004155 Component Location, Perimeter Unit

DPN004190 Component Location, Roof-top Unit

DPN004592 Component Location, Roof-top Draw-through Unit

2 N omenclature an d Components

7

2.3 Air Flow Configurations

Figure 2.1 Perimeter Unit Air Flow Configuration

Item Description

1 Return air from data c enter

2 Supply air to data center

8

Vertiv | D SE Packaged Solution Inst aller/User G uide

Figure 2.2 Rooftop Unit Air Flow Configuration

Item Description

1 Return air from data c enter

2 Supply air to data center

2 N omenclature an d Components

9

Figure 2.3 Rooftop Unit Draw Through Air Flow Configuration

Item Description

1 Return air from data c enter

2 Supply air to data center

Table 2.5 Air Flow Configuration Drawings

Document N umber Title

DPN004598 Airflow Schematic, Perimeter Unit

DPN004190 Component Location, Rooftop Unit

DPN004592 Component Location, Rooftop Draw Through Unit

10

Vertiv | D SE Packaged Solution Inst aller/User G uide

3 PRE-INSTALLATION PREPARATIONANDGUIDELINES

3.1 Storage before Installation

If storing the unit for long periods before installation:

• Remove the packaging from the unit, and allow proper clearance around the unit to perform periodic

inspections and maintenance.

• Inspect the unit periodically for condensation inside the unit or other signs of other effects of the storage

environment.

• Rotate the fans and motor shaft by hand periodically for several revolutions. Look for signs of lubrication

problem or obstructions.

• If storing at low temperatures trapped moisture can collect on walls and electrical components. We

recommend routine inspections and, if needed, install electric heaters to prevent condensation.

NOTE: Before installing unit, determine whether any building alterations are required to run wiring and duct work.

Follow all unit dimensional drawings and refer to the submittal engineering dimensional drawings of individual units

for proper clearances.

Refer to Table 2.3 on page5, and submittal drawings to determine the type of system being installed and anticipate

building alterations and duct work needed.

The unit and anchor dimensions are described in the submittal documents included in the Submittal Drawings on page65.

• Verify that mounting surface/roof top is level, solid and sufficient to support the unit. See Table 3.3 on

page16, and Table 3.4 on page16, for unit weights.

• Verify that the support structure for the unit (concrete or other type) has a flat, regular surface and is adequate

to support the unit operating weight.

• Verify that adequate water-control/drain system is in place. If connecting the drip-pan clean-out line, refer to

the appropriate submittal document in Table 3.1 on page13, for the clean-out line location and port size.

• Verify that the high-voltage electric-supply lines are adequately sized based on the electrical specification on

the unit's name plate and meet local code.

• Verify that the utility electric-supply lines (lights and outlet) are adequately sized and meet local code.

• Verify that all control and communication wiring are properly routed to the unit control panel and meet local

code.

• Confirm that the conditioned space has a proper envelope and vapor barrier.

• Handle outside air and humidity control externally to the Liebert® DSE™ Packaged Solution unit. The DSE™

Packaged Solution does not control humidity and is not intended to handle outside air.

• Allow at least the minimum recommended clearances for maintenance and service. See the appropriate

submittal documents for dimensions in Submittal Drawings on page65

• Ensure that there is no obstruction when installing duct work connections and transitions to minimize friction

losses and turbulence.

• Verify that all duct joints are sealed to prevent air leakage or water penetration.

• If unit is installed but will not be commissioned for a long period, operate the fans or install electric heaters to

prevent internal condensation. Refer to Storage before Installation above, and follow the guidelines until

commissioned.

3 Pre-install ation PreparationandG uidelines

11

3.2 Rooftop Unit Installation Guidelines

The rooftop units must be supported by an appropriately designed curb. A curb is the interface between the building and

the rooftop unit. It supports the weight of the roof-top unit by transferring the load onto the roof's structural members,

streamlines duct-work connections, and provides the weatherproof seal to the roof.

• A structural engineer must verify that the roof has adequate strength and ability to support loads from the

weight of the unit, curb, snow, wind and seismic events.

• The curb and any cribbing must be designed and certified by a qualified engineer to support the anchoring

loads of the unit and provide for a leak free design. Sealing of the curb to the roof is the responsibility of the

qualified engineer or architect to design and qualified contractor to execute.

• The roof curb should be installed by qualified personnel. Improper installation or faulty construction can result

in water or air leaks ori in structural failure and collapse.

• The roof curb mounting surface must be square and level prior to setting equipment.

• The installer must ensure that any appropriate sealing material is applied between the unit and the curb to

provide water- and air-tight connections in accordance with the design of the curb.

• Sealing materials cannot interfere with the anchoring connection surface of the roof-top unit, or the unit may not

be able to withstand its rated seismic or wind capacities. Vibration isolators should not be used without the

express consent of Vertiv engineering.

• Any flashing from the rooftop unit to the curb is the responsibility of the installing contractors.

• Any water ingress through any penetrations from flashing or other connections to the roof-top unit are the

responsibility of the installing contractor to remedy.

3.2.1 Service Clearance for Rooftop Units

Allow for recommended service clearances around the unit per appropriate submittal drawing for your unit, listed in Table

3.1 on the facing page. Provide a roof walkway along the sides of the unit for service and access to controls and

components. Contact your Vertiv sales representative for service requirements that are less than those recommended .

Applications in geographic areas subjected to seismic or hurricane conditions must meet code requirements for fastening

the unit to the curb and the curb to the building structure.

12

Vertiv | D SE Packaged Solution Inst aller/User G uide

3.3 Planning Dimensions

The unit and anchor dimensions are described in the submittal documents included in the Submittal Drawings on page65

The following table lists the relevant documents by number and title.

Table 3.1 Dimension Planning Drawings

Docu ment Number Title

DPN004465 Equipment Floor Plan Layout for Perimeter and Rooftop Units

DPN004653 Equipment Floor-Plan Layout for Rooftop Draw Through Units

Perimeter Units

DPN004148 Cabinet and Anchor Dimensional Data

DPN004326 Drip Pan Clean Out Access and Location

Rooftop Units

DPN004188 Cabinet and Anchor Dimensional Data

DPN004593 Cabinet and Anchor Dimensional Data, Draw Through Units

DPN004651 Condensate Drain Access and Location

3.4 Connections and System Setup

3.4.1 Electrical Connections

• Three-phase electrical service is required for all models. Electrical service must conform to national and local

electrical codes. See Electrical Field Connections on page21, for the details.

• Plan the routing of wiring and duct work to the unit. Refer to the appropriate electrical connection drawings for

your system in Submittal Drawings on page65.

3.4.2 Evaporator Drip Pan Connection

Connect the evaporator clean-out line to an adequate water-drain system. See Figure 3.1 on the next page, or Figure 3.2

on page15, for the connection on the unit. Observe the following requirements when installing and routing the clean out line:

• Insulate the line with heat trace so it will not freeze.

• The line must be the full size of the drain connection. The connection port is 1 in. pipe with CPVC 1 in. FPT

fitting.

• Slope the drain line continuously away from the unit, and pitch the drain line toward the drain.

• The line must be made of a material that is suitable for draining water and be rigid enough that it does not sag

between supports, which creates unintentional traps.

• The drain line must comply with all applicable codes.

3 Pre-install ation PreparationandG uidelines

13

Figure 3.1 Drip Pan Clean Out Line Location on Perimeter and Rooftop Units

Item Description

1 Water drain connection for evaporator drippan. Accessed by removing the floor panel a bove it. (Next to the compressor com partment).

2 Location of the drip-pan clean-out line in the perimeter unit.

14

Vertiv | D SE Packaged Solution Inst aller/User G uide

Figure 3.2 Drip Pan Clean Out Line Location on Draw-Through Rooftop Units

D

Item Description

1 Rear of unit

2 Left side view of unit

3 Location of the drip-pan clean-out line on rooftop unit.

3.5 Operating Conditions

The Liebert® DSE™ Packaged Solution must supply air to a conditioned space within the operating envelope that ASHRAE

recommends for data centers. Operating the DSE™ Packaged Solution outside of this envelope can decrease equipment

reliability. Refer to ASHRAE’s publication, “Thermal Guidelines for Data Processing Environments.”

3 Pre-install ation PreparationandG uidelines

15

3.5.1 Cooling

Table 3.2 below, provides the recommended maximum and minimum return-air temperature and dew-point conditions for

the DSE Packaged Solution Applications.

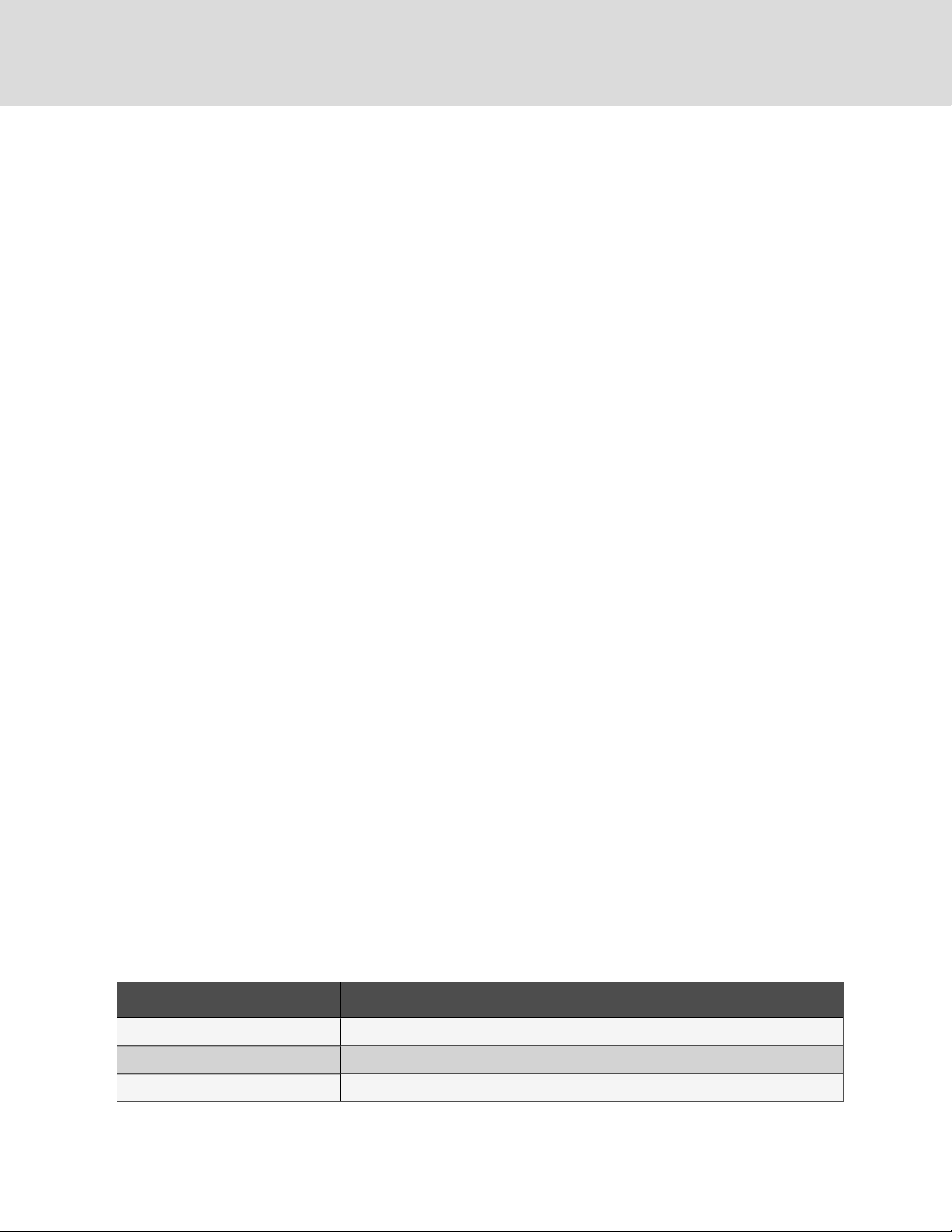

Table 3.2 Application Envelope for DP400/500

Control Settings

Maximum Return Air Temperature 105°F (40°C) 105°F (40°C) 105°F (40°C)

Minimum return-air temperature 85°F (29°C) 95°F (35°C) * 95°F (35°C)*

Maximum dew point 59°F (15°C) 52°F (11 °C) 52°F (11°C)

Maximum Supply-Air Setpoint 80°F (27°C) 80°F (27°C) * 80°F (27°C) *

Minimum Supply Air ControlSetpoint 68°F (20°C) 7 0°F (21°C) 75°F (24°C)

*Note: DP500 minimum air-side temperature differential at full load is 25°F (14°C)

DP400F

DP400R

DP400B

DP500F

DP500B

DP500R

Operating outside this envelope can decrease equipment reliability.

NOTE: When running above 77°F (25°C) supply-air temperature, the superheat readings on the refrigeration circuits

may be higher than 13°F(7.2°C). The EEVs will run out of stroke and limit mass flow, which will result in higher than

normal superheat.

3.6 Unit Weights

Table 3.3 DSE400 Unit Weights

Model Weight, lb (kg)

Perimeter 23,500 (10,659)

Rooftop 25, 500 (11, 567)

Rooftop Draw Through 25,500 (11, 567)

Table 3.4 DSE500 Unit Weights

Model Weight, lb (kg)

Perimeter 224,000 (10,886)

Rooftop 26,000 (11, 793)

Rooftop Draw Through 26,000 (11,793)

16

Vertiv | D SE Packaged Solution Inst aller/User G uide

4 EQUIPMENT INSPECTION AND HANDLING

SAFETY INFORMATION

WARNING! Risk of improper moving. Can cause equipment damage, injury or death. Use only lifting

equipment that is rated for the unit weight by an OSHA-certified rating organization. The center of gravity

varies depending on the unit size and selected options. The slings must be equally spaced on either side of

the center of gravity indicator. Use the center of gravity indicators on the unit to determine the position of the

slings. Unit weights are listed in Table 3.3 on page16 and Table 3.4 on page16.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA-approved PPE should attempt to move,

lift, remove packaging from or prepare the unit for installation.

• Carefully inspect all items for visible or concealed damage.

• Report damage immediately to the carrier and file a damage claim with a copy sent to Vertiv or to your sales

representative.

Equipment Recommended for Handling the Unit:

• Lift beam

• Slings

• Spreader bars

• Shims and blocks

4.1 Rigging to Lift the Unit

Depending on whether you have a perimeter or roof-top configuration, see Figure 4.1 on the next page, or Figure 4.2 on

page19, for the location of the lifting lugs on the unit and for the use of spreader bars and shimmed blocks to prevent

damage to the unit.

• Unit must remain level when lifted to prevent damage to internal equipment.

• Do not place unit directly on the ground. If the unit must be set down, use shims or blocks for leveling and to

keep unit off the ground.

Before lifting or moving, clear the area of all unnecessary personnel. Clear the area of any debris and unrelated tools or

foreign objects.

4 Equipm ent Ins pection and Han dlin g

17

Figure 4.1 Lugs to Attach Rigging to a Perimeter Unit Configuration

Item Description

1 Lugsto attach rigging. Typical both sides.

18

Vertiv | D SE Packaged Solution Inst aller/User G uide

Figure 4.2 Lugs to Attach Rigging to a Rooftop Unit Configuration

Item Description

1 Lugsto attach rigging. Typical both sides.

4 Equipm ent Ins pection and Han dlin g

19

This page intentionally left blank

20

Vertiv | D SE Packaged Solution Inst aller/User G uide

5 ELECTRICAL FIELD CONNECTIONS

Three-phase electrical service is required for all models. Electrical service must conform to national and local electrical

codes. Refer to equipment nameplate regarding wire size and circuit protection requirements. Refer to the appropriate

submittal drawing, listed in Table 5.1 on the next page, for electrical service entrances into unit

A manual electrical disconnect switch should be installed in accordance with local codes and distribution system. Consult

local codes for external disconnect requirements.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA-approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC and local codes, as

applicable. Before proceeding with installation, read all instructions, verify that all the parts are included and

check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does not

isolate power from the unit, even in the “Unit Off” mode. Some internal components require and receive

power even during the “Unit Off” mode of the controller. The factory-supplied disconnect switch is on the

exterior of the enclosure. The factory-supplied, optional disconnect switch is inside the unit. The line side of

this switch contains live high-voltage. The only way to ensure that there is NO voltage inside the unit is to

install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all local codes.

WARNING! Risk of electric shock. Can cause equipment damage, injury or death. Open all local and remote

electric power supply disconnect switches and verify with a voltmeter that power is off before working within

any electric connection enclosures. Service and maintenance work must be performed only by properly

trained and qualified personnel and in accordance with applicable regulations and manufacturers’

specifications. Opening or removing the covers to any equipment may expose personnel to lethal voltages

within the unit even when it is apparently not operating and the input wiring is disconnected from the

electrical source.

5 El ectrical Field Connections

WARNING! Risk of improper wire sizing/rating and loose electrical connections. Can cause overheated wire

and electrical connection terminals resulting in smoke, fire, equipment and building damage, injury or death.

Use correctly sized copper wire only and verify that all electrical connections are tight before turning power

On. Check all electrical connections periodically and tighten as necessary.

WARNING! Risk of wiring damage, short circuits and electric shock. Can cause overheated wiring, smoke, fire,

activation of fire suppression systems and EMS personnel and equipment, building and equipment damage,

injury or death. Insert CSA certified or UL listed bushings into holes and or knockouts used to route wiring

through metal panels to protect the wire insulation from contact with sheet metal edges.

21

NOTICE

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty coverage.

Prior to connecting any equipment to a main or alternate power source (for example: back-up generator

systems) for start-up, commissioning, testing, or normal operation, ensure that these sources are correctly

adjusted to the nameplate voltage and frequency of all equipment to be connected. In general, power-source

voltages should be stabilized and regulated to within ±10% of the load nameplate nominal voltage. Also, ensure

that no three-phase sources are single-phased at any time.

See transformer label for primary tap connections. Installer will need to change transformer primary taps if

applied unit voltage is other than pre-wired tap voltage.

NOTICE

Risk of improper electrical connection of three-phase input power. Can cause backward compressor rotation

and unit damage. Service technicians should use a gauge set on the system during the initial start up to verify

that the three-phase power is connected properly. Three-phase power must be connected to the unit line

voltage terminals in the proper sequence so that the compressors rotate in the proper direction. Incoming

power must be properly phased to prevent compressors from running backward. We recommend checking the

unit’s phasing with proper instrumentation to ensure that power connections were made correctly. We also

recommend verifying discharge and suction pressures during start up to ensure that the compressors are

running in the correct direction.

NOTE: Use water-tight fittings for all electrical connections. Failure to do so risks damage to the outdoor unit.

The unit requires two separate power-supply connections:

• A 3-phase, 460V power supply to the DSE™ Packaged Solution unit electrical enclosure or ATS.

• A separate 120V power feed to the utility box (for light switches and convenience outlet).

• An optional, separate 120V power feed from a field-supplied UPS to the DSE™ Packaged Solution-unit lowvoltage controls, which are located in the main electrical panel.

The electrical connections are described in the submittal documents included in the Submittal Drawings on page65.

Low voltage connections are detailed in

• Figure 5.1 on the facing page

• Figure 5.2 on page24

• Figure 5.3 on page25

• Figure 5.4 on page26

• Figure 5.5 on page27

The following table lists the relevant documents by number and title.

Table 5.1 Electrical Field Connection Drawings

Docu ment Number Title

DPN004960 Electrical Connections

DPN005099 Service Door Access 400/500 kW P erimeter Unit

DPN005051 Service Door Access 400/500 kW Draw Through Rooftop Unit

22

Vertiv | D SE Packaged Solution Inst aller/User G uide

Figure 5.1 Low Voltage BMS Wiring to Unit in Main Electrical Enclosure

Item Description

1 Low voltage BMS wiringto unit

5 El ectrical Field Connections

23

Figure 5.2 Location of iCOM Master Board and iCOM Slave Board

Item Description

1 iCOM master control board

2 iCOM slave control board

24

Vertiv | D SE Packaged Solution Inst aller/User G uide

Figure 5.3 Low Voltage iCOM/vNSA Switch Wiring to Unit in Main Electrical Enclosure

Item Description

1 Location of the connection for CAT5 cable from Liebert® VNSAICOM8 network switch.

5 El ectrical Field Connections

25

Figure 5.4 120V UPS Power Feed Connection for Low Voltage Controls in Main Electrical Enclosure

Item Description

1 Location of the connection for the power feed from the optional 120-V UPS

26

Vertiv | D SE Packaged Solution Inst aller/User G uide

Loading...

Loading...