Page 1

Liebert®

DCD™

Installer/User Guide

Page 2

The information contained in this document is subject to change

without notice and may not be suitable for all applications. While

every precaution has been taken to ensure the accuracy and

completeness of this document, Vertiv assumes no responsibility

and disclaims all liability for damages resulting from use of this

information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods,

tools, and materials to be used in performing procedures not

specifically described in this document.

The products covered by this instruction manual are manufactured

and/or sold by Vertiv. This document is the property of Vertiv and

contains confidential and proprietary information owned by Vertiv.

Any copying, use or disclosure of it without the written permission

of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered

trademarks of the respective companies. Any questions regarding

usage of trademark names should be directed to the original

manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent

section of this manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.VertivCo.com/en-us/support/ for additional assistance.

Vertiv | Liebert® DCD™Installer/UserGuide

Page 3

TABLE OF CONTENTS

1 Important Safety Instructions 5

2 Nomenclature and Components 9

2.1 Model Number Nomenclature 9

2.2 Component Locations 10

3 General Product Information 13

3.1 Product/System Description 13

3.1.1 Cooling Principle 14

3.2 DCD Active with Fan Module 16

4 Pre-installation Preparation and Guidelines 19

4.1 Planning Dimensions 19

4.2 UnitWeights 19

4.3 Room Preparation 19

4.4 Air-flow Considerations 20

4.5 Water-supply Considerations 20

4.5.1 Water Quality Requirements 21

4.5.2 Water Temperature Requirements 22

5 Equipment Inspection and Handling 23

5.1 Storing the Unit 24

5.2 Packaging Material 24

5.3 Handling the Unit while Packaged 24

5.4 Unpacking the Module 25

6 Installation 29

6.1 DCD Frame Preparation 29

6.2 Installing the DCD Frame on a DCM Rack 30

6.2.1 Required Tools 30

6.3 Installing the DCD Door 34

6.4 Installing the DCD Swivel-joint Covers 40

6.5 Reversing the Door Handle 44

6.6 Installing the Active Fan Module 44

6.6.1 Mounting the Active Fan Module on DCD 45

6.6.2 Connecting Supply Power and Sensors 47

7 Piping Considerations and Connections 49

7.1 System Connection Configuration 49

7.1.1 Using Chilled-water Distribution Units 51

7.1.2 Using Open-loop Chilled-water Systems 51

7.2 Connection Methods and Points 51

7.3 Floor Cut-out Dimensions for Units with Bottom Connections 52

7.4 Insulate Piping 52

7.5 Recommended Pipe Sizes 52

7.6 Chilled-water Connection Components 53

Vertiv | Liebert® DCD™Installer/User Guide | 3

Page 4

7.6.1 Strainer 53

7.6.2 Service Valves 53

7.6.3 Balancing Valves 53

7.6.4 Flexible Pipes 54

7.7 Leak Checking 55

7.8 Filling the Unit 55

7.8.1 Bleeding Air from the DCD 56

8 Installation Checklist andSystemFillforStart-up 57

9 Using the DCD Active TFT Display 61

9.1 Main Screen 61

9.1.1 Viewing Fan Status Detail 62

9.1.2 Viewing Exhaust-air Sensor Status 63

9.1.3 Viewing Cabinet Temperature-sensor Status 64

9.2 Settings Menu 65

9.2.1 Temperature Sensors Menu 66

9.2.2 Differential-pressure Regulation 66

9.2.3 Set-up Menu 67

10 Maintenance 69

10.1 General Maintenance 69

Appendices 71

Appendix A: Technical Support and Contacts 71

Appendix B: Specifications 73

Appendix C: Submittal Drawings 83

Vertiv | Liebert® DCD™Installer/User Guide | 4

Page 5

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and

maintenance of the Liebert®DCD. Read this manual thoroughly before attempting to install or operate

this unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit

and in this manual. Follow all installation, operation and maintenance instructions and all applicable

national and local building, electrical and plumbing codes.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power

disconnect switches, verify with a voltmeter that power is Off and wear personal protective

equipment (PPE) per NFPA 70E before working with the module. Failure to comply can cause

serious injury or death. Follow all local codes.

WARNING! Risk of heavy module falling. Can cause equipment damage, injury and death. Two

properly-trained and qualified people are required to move and install the module. The DCD™

weighs in excess of 210lb(95kg). Do not leave a DCD™ standing unattended on its side or its

end without adequate support to prevent it from falling over. The module must be supported at

all times or laid flat on protective material until it is installed. Read all instructions before

attempting to move, lift, remove packaging from, or prepare the module for installation. See

Table 4.2 on page19, for unit weights based on model.

WARNING! Risk of improper operation and overpressurization. Can cause equipment or other

property damage, injury and death. Only personnel properly trained and qualified in HVAC

installation or service should installor service this equipment

WARNING! Risk of contact with high-speed, rotating fan impeller blades. Can cause injury or

death. Open all local and remote electric power-supply disconnect switches, verify with a

voltmeter that power is off, and verify that all fan impellers have stopped rotating before

working in the unit cabinet.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

1 Important Safety Instructions

5

Page 6

NOTICE

NOTICE

NOTICE

CAUTION: Risk of improper repair and maintenance. Can cause reduced unit performance,

equipment damage and injury.

All maintenance and repair jobs must be performed by properly trained and qualified personnel.

All actions must be in accordance with regulations and the manufacturer’s instructions. Use

only Vertiv-approved tools and parts for maintenance and repair.

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty

coverage.

Prior to connecting any equipment to a main or alternate power source (for example: back-up

generator systems) for start-up, commissioning, testing, or normal operation, ensure that these

sources are correctly adjusted to the nameplate voltage and frequency of all equipment to be

connected. In general, power-source voltages should be stabilized and regulated to within

±10% of the load nameplate nominal voltage. Also, ensure that no three-phase sources are

single-phased at any time.

Risk of passageway interference. Can cause unit and/or structure damage. The unit may be

too large to fit through a passageway while on or off the skid. Measure the unit and passageway

dimensions, and refer to the installation plans prior to moving the unit to verify clearances.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a

height suitable to fit below the skid and/or unit to prevent exterior and/or underside damage.

Risk of improper storage. Keep the unit upright, indoors and protected from dampness,

freezing temperatures and contact damage.

6

Vertiv | Liebert® D CD™Installer/User G uide

Page 7

NOTICE

Risk of piping-system corrosion and freezing fluids. Can cause leaks resulting in equipment

and very expensive building damage. Cooling coils and piping systems are at high risk of

freezing and premature corrosion. Fluids in these systems must contain the proper antifreeze

and inhibitors to prevent freezing and premature coil and piping corrosion. The water or

water/glycol solution must be analyzed by a competent local water treatment specialist before

start up to establish the inhibitor and antifreeze solution requirement and at regularly

scheduled intervals throughout the life of the system to determine the pattern of inhibitor

depletion.

The complexity of water/glycol solution condition problems and the variations of required

treatment programs make it extremely important to obtain the advice of a competent and

experienced water treatment specialist and follow a regularly scheduled coolant fluid system

maintenance program.

Water chemistry varies greatly by location, as do the required additives, called inhibitors, that

reduce the corrosive effect of the fluids on the piping systems and components. The chemistry

of the water used must be considered, because water from some sources may contain corrosive

elements that reduce the effectiveness of the inhibited formulation. Sediment deposits prevent

the formation of a protective oxide layer on the inside of the coolant system components and

piping. The water/coolant fluid must be treated and circulating through the system

continuously to prevent the buildup of sediment deposits and or growth of sulfate reducing

bacteria.

Proper inhibitor maintenance must be performed in order to prevent corrosion of the system.

Consult glycol manufacturer for testing and maintenance of inhibitors.

Commercial ethylene glycol, when pure, is generally less corrosive to the common metals of

construction than water itself. It will, however, assume the corrosivity of the water from which it

is prepared and may become increasingly corrosive with use if not properly inhibited.

We recommend installing a monitored fluid-detection system that is wired to activate the

automatic-closure of field-installed coolant-fluid supply and return shut-off valves to reduce

the amount of coolant-fluid leakage and consequential equipment and building damage. The

shut-off valves must be sized to close-off against the maximum coolant-fluid system pressure

in case of a catastrophic fluid leak.

1 Important Safety Instructions

7

Page 8

NOTICE

NOTICE

Risk of clogged or leaking drain lines and leaking water-supply lines. Can cause equipment and

building damage.

This unit requires a water drain connection. Drain lines must be inspected at start-up and

periodically, and maintenance must be performed to ensure that drain water runs freely

through the drain system and that lines are clear and free of obstructions and in good

condition with no visible sign of damage or leaks. This unit may also require an external water

supply to operate.

Improper installation, application and service practices can result in water leakage from the

unit. Water leakage can result in catastrophic and expensive building and equipment damage

and loss of critical data center equipment.

Do not locate unit directly above any equipment that could sustain water damage.

We recommend installing a monitored fluid-detection system to immediately discover and

report coolant-fluid system and condensate drain-line leaks.

Risk coil and piping rupture. Can cause equipment damage and major fluid leaks resulting in

serious building damage, expensive repair costs and costly system down time.

Thermal expansion of the cooling fluid without means of expansion can cause the coil and

piping to rupture, spilling cooling fluid in the conditioned space. This can be caused, among

other ways, by closing the ball valves on both the supply and the return pipes. Always allow for

thermal expansion either by leaving at least one of the valves open or by opening the DCD™

bleed valve.

NOTE: This document is intended to be used together with site-specific documentation and

documentation for other parts of the system.

8

Vertiv | Liebert® D CD™Installer/User G uide

Page 9

2 NOMENCLATURE AND COMPONENTS

This section describes the model number for Liebert® DCD units and components.

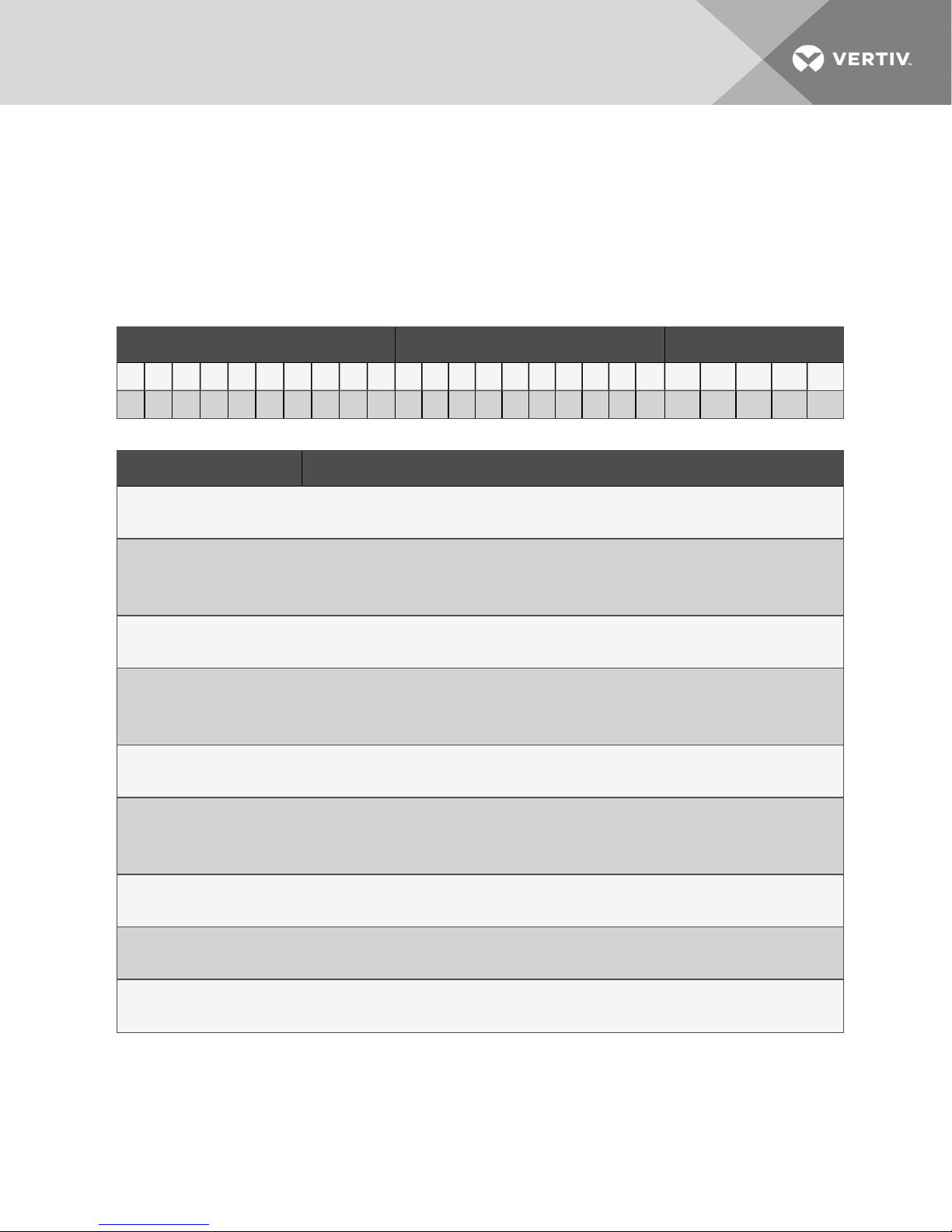

2.1 Model Number Nomenclature

Table 2.2 on the next page describes each digit of the model number.

Table 2.1 Liebert DCD Model-number Example

Model Number Digits 1 to 10 Model Det ails Model Number Digits 11 to 14

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

D C D 3 5 A 6 0 3 0 0 0 0 0 0 G 0 0 0 0 S A 0 0 2

Table 2.2 Model-number Digit Definitions for Liebert DCD

Digit Description

Digits 1, 2, 3 = the base unit

DCD = Data Center Door

Digit 4, 5 = Nominal Capacity

35 = 35kW

50 = 50kW

Digit 6 = Rack Height

A = 42U, 78-6/8 in. (2000mm)

Digit 7 = Rack Width

6 = 23-5/8 in. (600mm), onlyavailable on 35 models.

8 - 32-1/2 in. (800mm)

Digit 8 = Cabinet Type

0 = No aluminum frame

Digit 9 = Chilled-water Connection/Hinge Position

1 = Top connection/Hinges left

3 = Bottom connection/Hinges left

Digit 10 = Options

0 = None

Digits 11 to 15 = Not Used

0 = No options

Digit 16 = Color

G = RAL 7021 (dark gray)

2 Nomenclature and Components

9

Page 10

Table 2.2 Model-number Digit Definitions for Liebert DCD (continued)

Digit Description

Digits 17 to 20 = Not Used

0 = No options

Digit 21 = Packaging Type

S = Seaworthy (air freight), Long distance (wooden crate)

Digit 22 = SFA (SpecialFeatures)

A = Standard, no SFA

X = SFA(s) included

Digits 23 to 25 = Revision Identifier

2.2 Component Locations

Figure 2.1 Liebert DCD Component locations

Item Description

1 Upper and Lower swivel joints

2 Door handle

3 Door

4 Upper piping

5 DCD frame

6 Lower Piping

7 Aluminum profile

10

Vertiv | Liebert® D CD™Installer/User G uide

Page 11

Item Description

8 Condensate tray

9 Condensate drain plug

10 Chilled-water outlet

11 Chilled-water inlet

12 Condensate-hose adapter (on the bottom of the unit)

2 Nomenclature and Components

11

Page 12

This page intentionally left blank

12

Vertiv | Liebert® D CD™Installer/User G uide

Page 13

3 GENERAL PRODUCT INFORMATION

3.1 Product/System Description

The Liebert® DCD™ is an air-water heat exchanger that is integrated into the rear door of a server rack.

The DCD™ meets the requirements of the EN 60950 standard. The design allows installation on the back

of a server cabinet and maintains access to the back of the servers while the chilled water connections

remain stationary. The DCD35 is suitable for absorbing up to 35-kW heat loads from server racks 24in.

(600mm) x 42U. The DCD50 is suitable for absorbing up to 50-kW heat loads from server racks 31.5in.

(800mm) x 42U. It can be configured so that no heat is released in the installation area with proper

cabinet sealing.

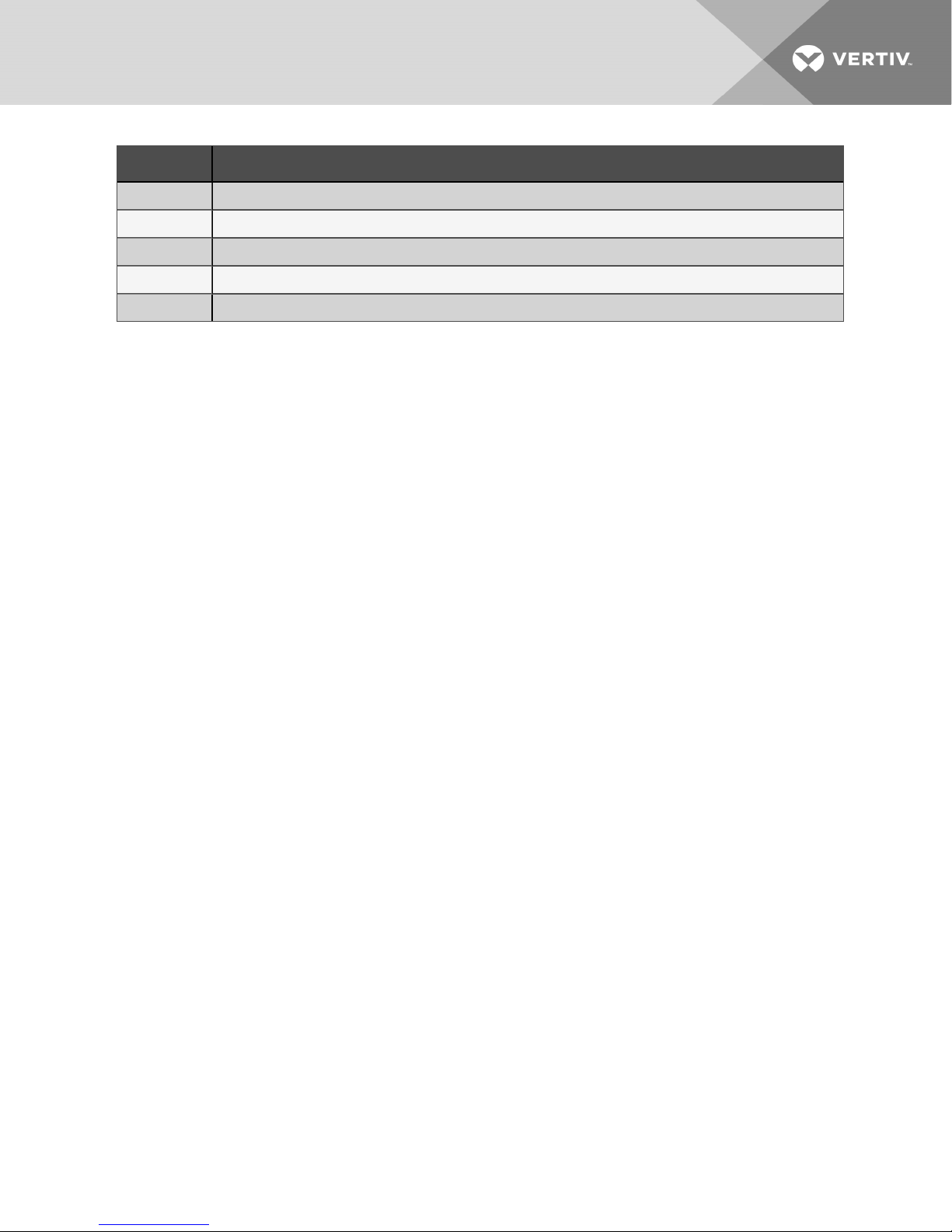

Heat produced by internal components (for example, servers), is reliably removed by the door with a builtin chilled water system or a chilled-water distribution unit, such as the Liebert® DCP™ (see Figure 3.1

below). A chilled-water distribution unit provides these benefits:

• Isolates the building’s chilled-water circuit from the chilled-water circuit in the data center. The

DCP circulates chilled water to DCD while preventing condensation by maintaining the water

temperature above the room dew point.

• Ensures the proper flow rate to the DCD. This is critical to achieve and maintaining the needed

capacity.

• Minimizes the possibility of a leak within the data center by separating the data center from

the building chilled-water circuit. Should a leak occur within the data center, the volume of

water is limited to the amount in the secondary piping system instead of the amount in the

entire-building chilled-water system.

Figure 3.1 Generic piping layout

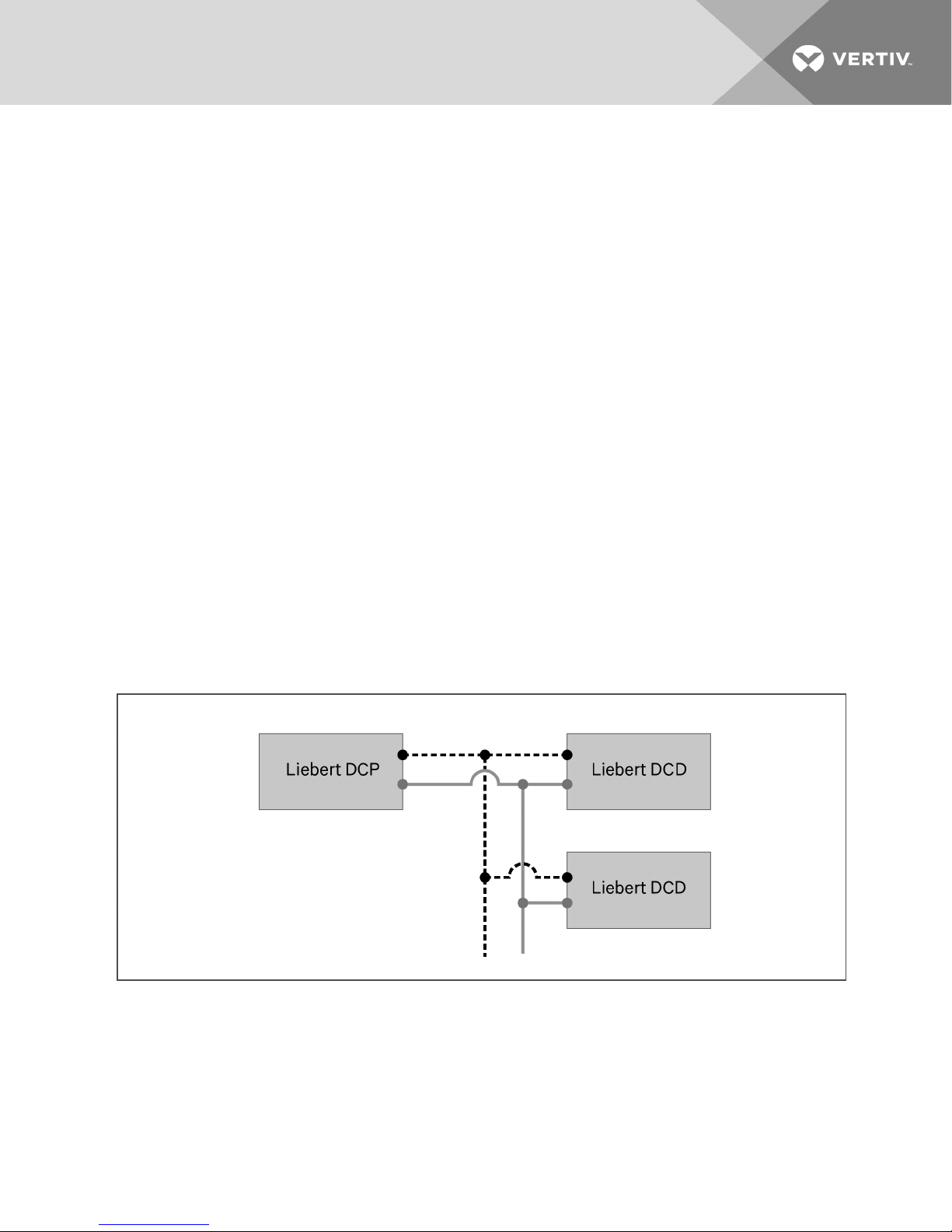

Room air is drawn in through the front of the rack and picks up heat from the servers. Cooling occurs

when the server exhaust air passes through the DCD™ heat exchanger (see Figure 3.2 on the next

page). The air is moved through the heat exchanger by the server fans.

3 General Product Information

13

Page 14

The DCD™ is not expected to produce any condensation because of its location within the conditioned

space and connected to a Liebert® DCP or if the chilled-water temperature is maintained above the dew

point, A condensate pan is provided as a precaution. It has a drain fitting to allow any condensate to be

emptied.

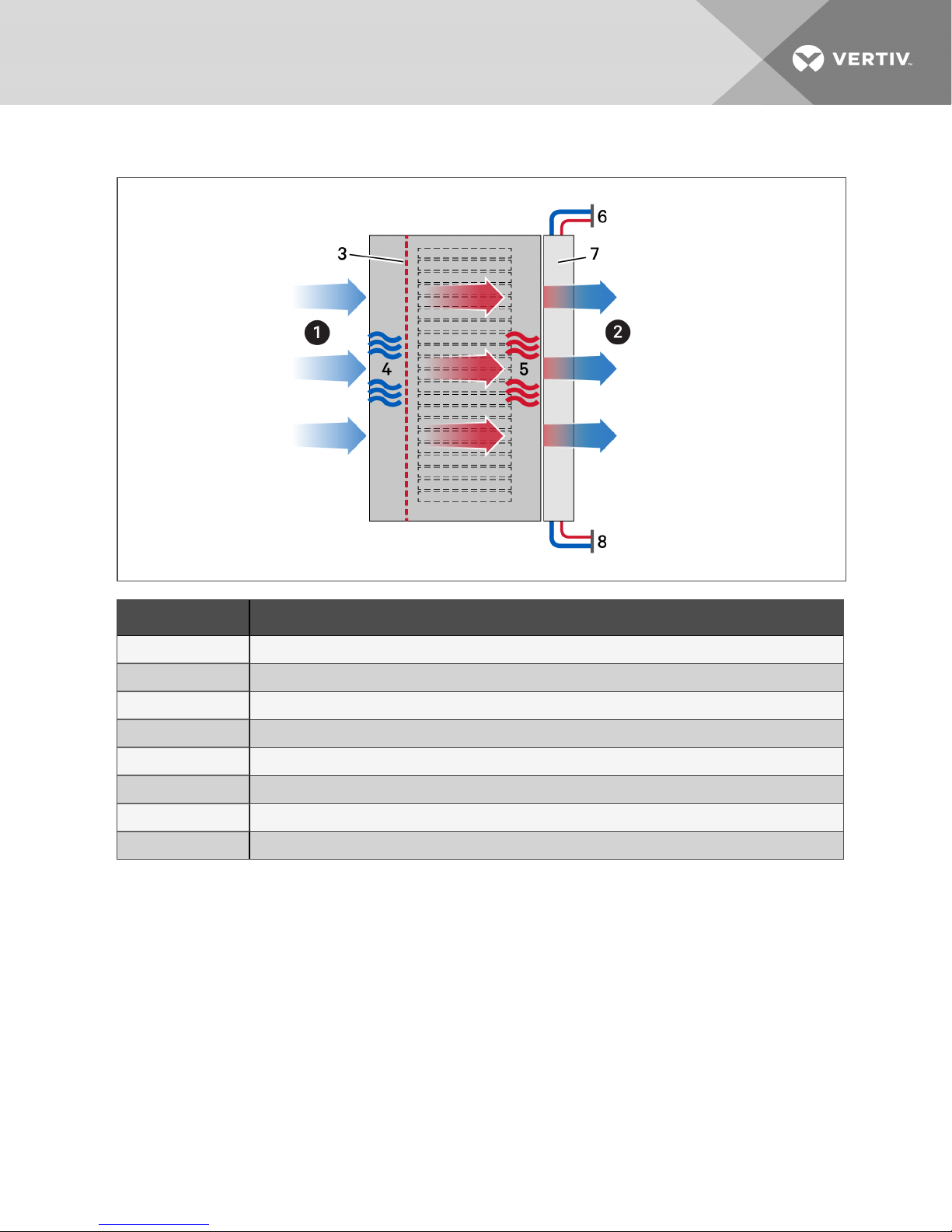

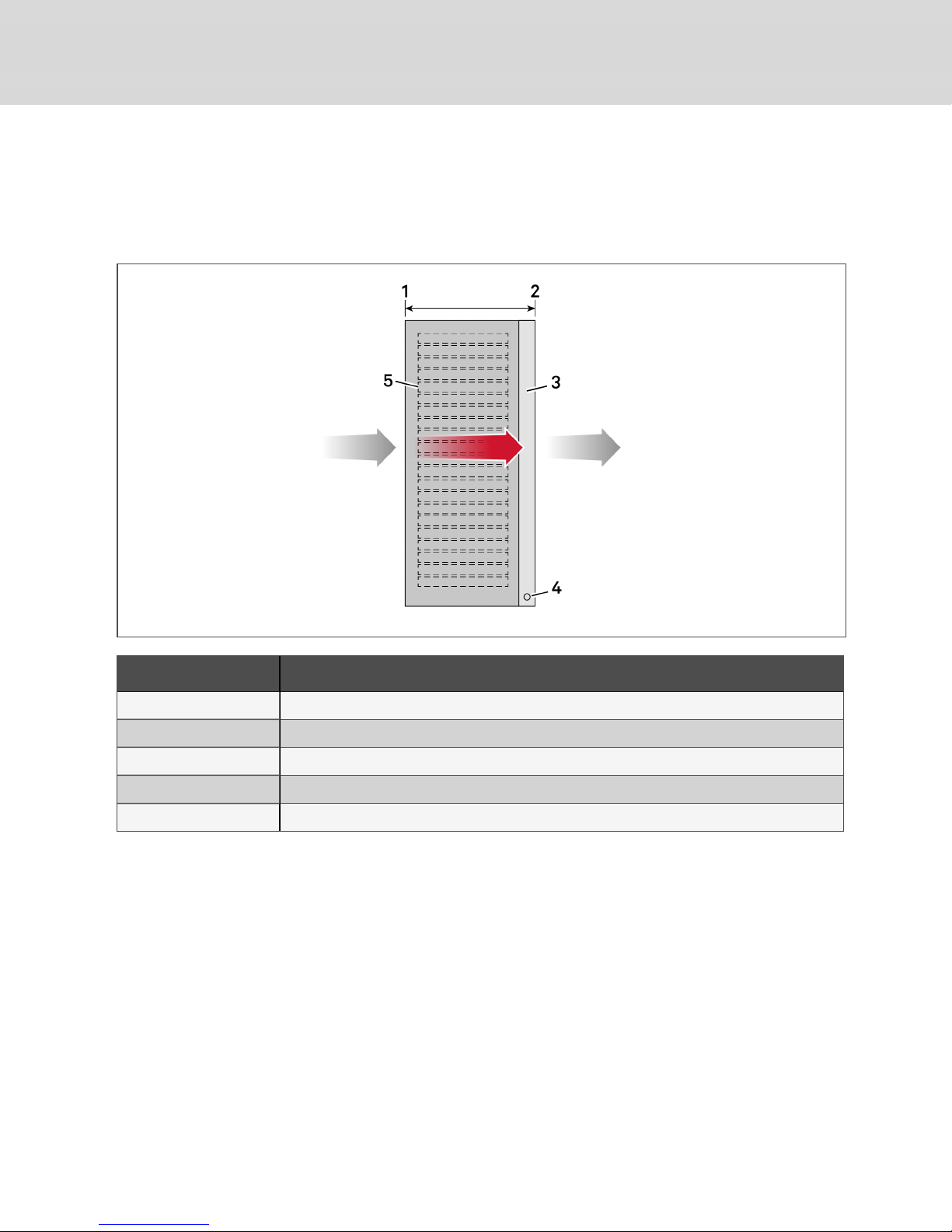

Figure 3.2 Top view of air flow and cooling of rack with Liebert DCD

Item Description

1 DCD unit

2 Server

3 Warm air

4 Air barrier

5 Coldair

6 Recirculation prevented

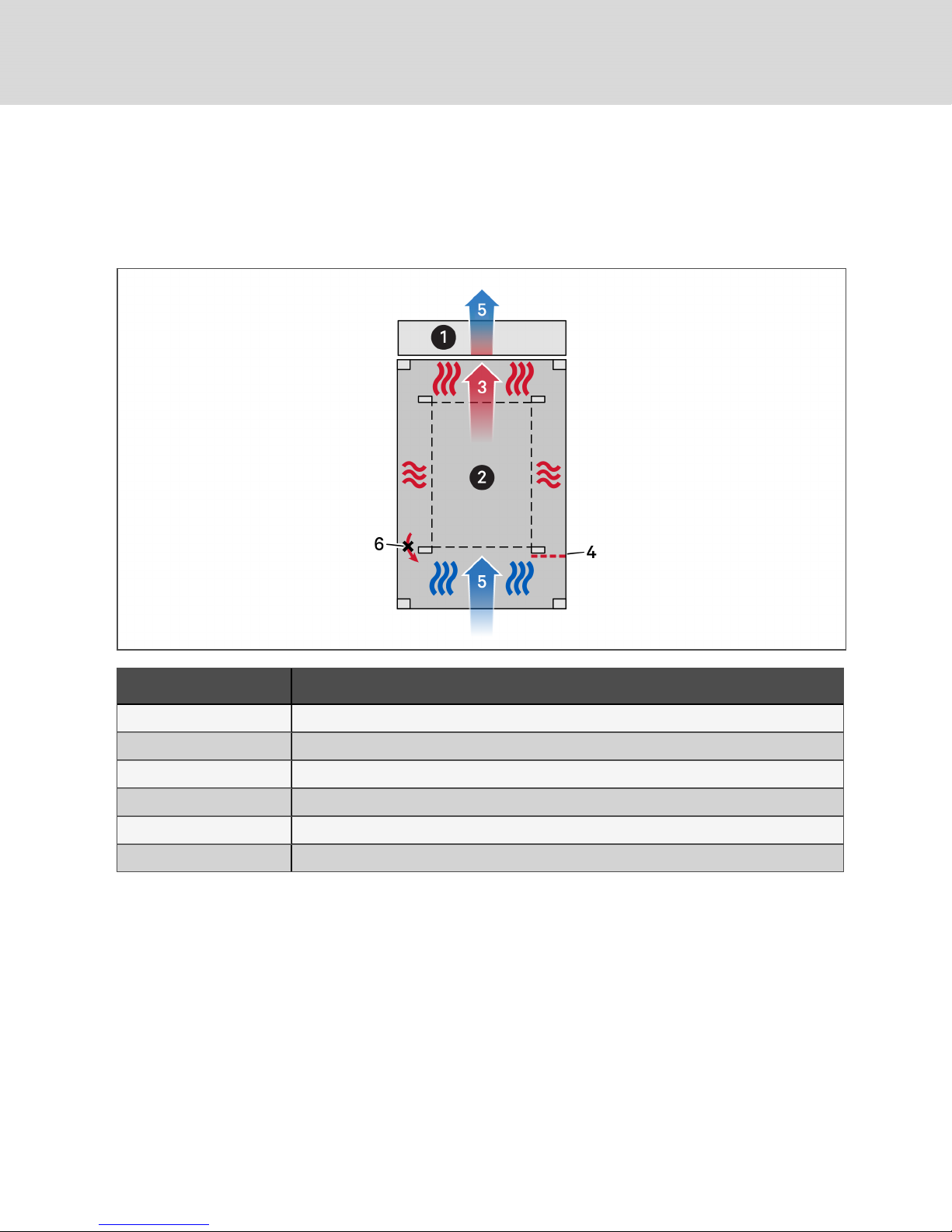

3.1.1 Cooling Principle

The server fans force air heated by the rack equipment through the unit’s air-water heat exchanger

where it is cooled. The air-side pressure-drop flow-rate dependency curve is shown in Figure B.7 on

page77.

14

Vertiv | Liebert® D CD™Installer/User G uide

Page 15

Figure 3.3 Cooling principle shown in side-view diagram of rack/DCD

Item Description

1 Air intake

2 Air outlet

3 Air barrier

4 Cold air

5 Warm air

6 Top cooling-water connections

7 DCD unit

8 Bottom cooling-water connections

NOTE: Before using the DCD™, check the system and rack equipment and make sure that they match

hydraulically. In particular, the server fans must be able to generate sufficient pressure to drive the air

through the DCD™.

NOTE: Cooling-water supply and return connections are supplied at each end of the DCD™, but

connections must be made at only one end, either the top or the bottom of the DCD™.

NOTE: In case of chilled-water supply-system failure, the cooling is provided either by adjacent DCD™

modules and/or the room cooling system. In this example, the equipment waste heat is released into

the room.

3 General Product Information

15

Page 16

3.2 DCD Active with Fan Module

The DCD Active is an option which includes a fan module to be attached to the DCD cooling coil. See

Table 3.1 on the facing page, for the physical and environmental data and requirements of the module.

The active-fan module operates by measuring pressure differential between ambient pressure and the

pressure inside the cabinet and modulating fan speed to reach a predefined pressure setpoint. The

default setpoint is 0-Pa pressure differential. There are two versions of active-fan module:

• Standard—actively maintains a 0-Pa pressure differential by modulating fan speed, and

indicates operating status via a green "operating"LED and a red "disturbance" LED.

• TFT—includes a touch-screen display and temperature sensors for precise control of the

pressure differential and fan speed based on pressure and temperature readings. See Using

the DCD Active TFT Display on page61, for details.

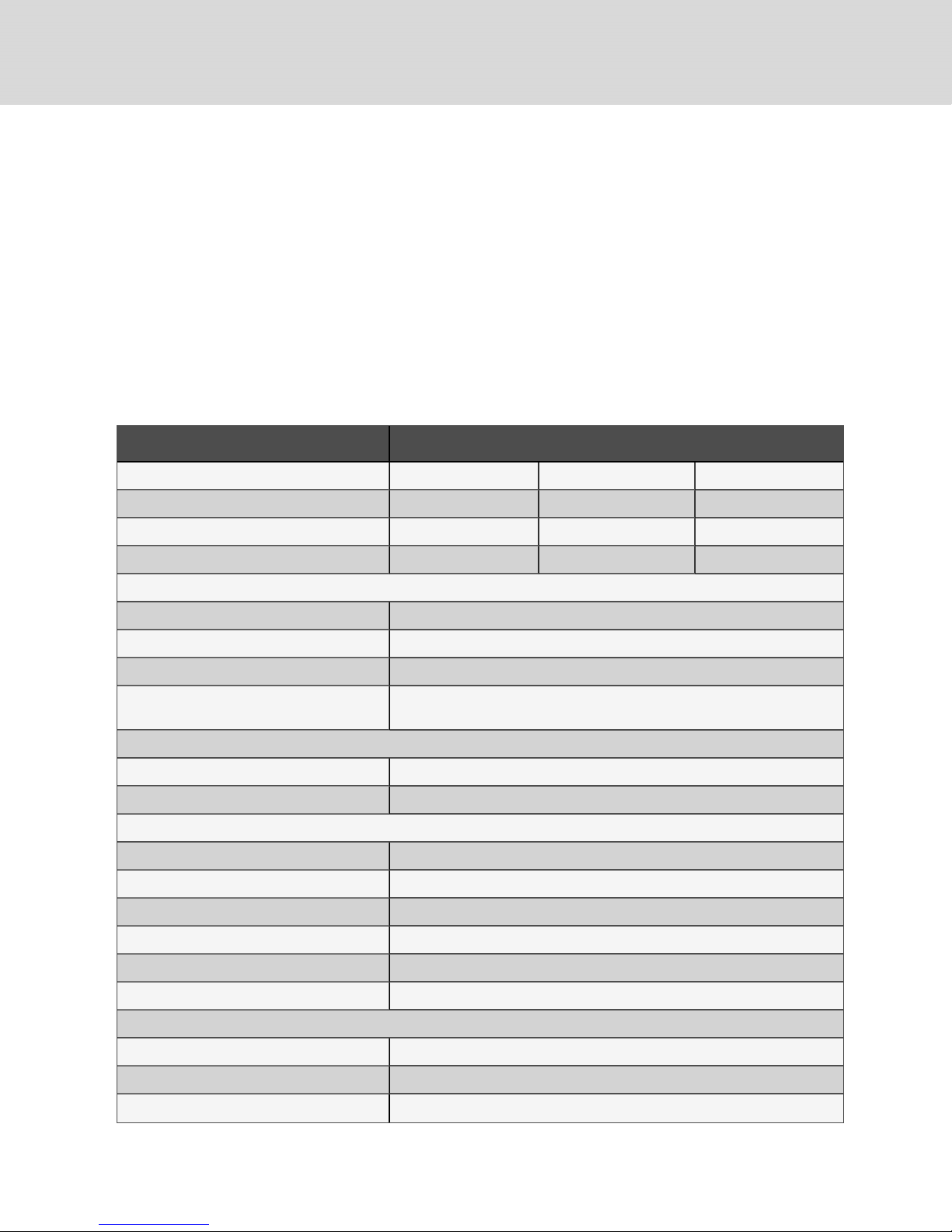

Table 3.1 DCD Active Specifications

Item Specification

Power Supply Single 110/230V A/B 230V A/B 110V

Operating voltage 95 - 264 V, 47 - 63 Hz 190 - 264 V, 47 - 63 Hz 95 - 264 V, 47 - 63 Hz

Rated current 5/11 A (110/230 V) 5A 11A

Fuses 10/12A T 10AT 12AT

ExternalTemperature Sensors

Output voltage 5 V

Output current maximum 5mA

Communication type OneWire

Usable types

IP Interface

Communication type RS-485, 3.3V

Data rate 9600 baud

PhysicalData

Dimensions (LxWxH)DCD35, in. (mm) 76.9 x16.5x4.9 (1954 x 420 x 125)

Dimensions (LxWxH)DCD50, in. (mm) 76.9x 22 .8X4.9 (1954 x 579 x 125)

Weight DCD35, lb(kg) 77(35)

Weight DCD50, lb(kg) 88.2 (40)

Degree of protection IP2 0

Degree of containment 2

Ambient Conditions

Operating temperature 50 to 104°F (10 to 40°C)

Liebert® SN-T

Maxim DS28EA00, DS18B20

Storage temperature –13 to 176°F (–25 to 80°C)

Relative humidity 0 to 95% non-c ondensing

16

Vertiv | Liebert® D CD™Installer/User G uide

Page 17

Table 3.1 DCD Active Specifications (continued)

Item Specification

Altitude above sea level, ft (m) maximum 6,562 (2000)

Pressure Connection

Operating pressure, –1.005 to 1.005 inAq(–250 to 250Pa)

Maximum pressure permitted ± 14.5psi (1bar)

Tolerance 3% of the measured value ± 0.0008 inAq (0.2Pa)

Working gases Air, Nitrogen

Hose—outer diameter, in. (mm) 0.24 (6)

3 General Product Information

17

Page 18

This page intentionally left blank

18

Vertiv | Liebert® D CD™Installer/User G uide

Page 19

4 PRE-INSTALLATION PREPARATION AND GUIDELINES

The Liebert DCD attaches to the rear of a computer cabinet with side panels. See the dimensional-data

drawings in the Submittal Drawings on page83.

NOTE: The cooling with Liebert DCD works only if a strict air separation exists between server cold air

intake and server warm air outlet. Unused rack spaces must be blocked with blanking plates. All

bushings (network cables, piping, etc.) must be sealed to prevent air leakage. Racks must have side

panels. The tops and bottoms of the racks must be sealed.

4.1 Planning Dimensions

Refer to site-specific drawings for exact placement. Efficient cooling depends on proper equipment

placement, proper use of plates in any voids in the rack and good cable management.

Ensure that there is 25.6-in.(649mm) clearance in the rear to allow the door to open fully.

The unit dimensions are described in the submittal documents included in the Submittal Drawings on

page83.

The following table lists the relevant documents by number and title.

Table 4.1 Dimension Planning Drawings

Document Number Title

DPN004112 Dimensional Data, DCD35

DPN004113 DimensionalData, DCD50

4.2 UnitWeights

Table 4.2 Liebert DCD unit weights

Model Number Weight, lb (kg)

DCD35 210 (95)

DCD50 230 (104)

4.3 Room Preparation

The room should be well-insulated and must have a sealed vapor barrier. The vapor barrier in the ceiling

and walls can be a polyethylene film. Paint on concrete walls and floors should contain either rubber or

plastic.

NOTE: The vapor barrier is the most important factor in maintaining environmental control in the

conditioned space.

Outside or fresh air should be kept to a minimum when temperature and humidity must be tightly

controlled. Outside air adds to the site’s cooling, heating, dehumidifying and humidifying loads. Doors

must be properly sealed to minimize leaks and must not contain ventilation grilles.

4 Pre-installation Preparation and Guidelines

19

Page 20

4.4 Air-flow Considerations

The server fans draw air into the rack where the equipment heats it. The server fans force the heated air

across the DCD™ coil. The DCD™ has a low air-side pressure drop, similar to a rack with perforated doors.

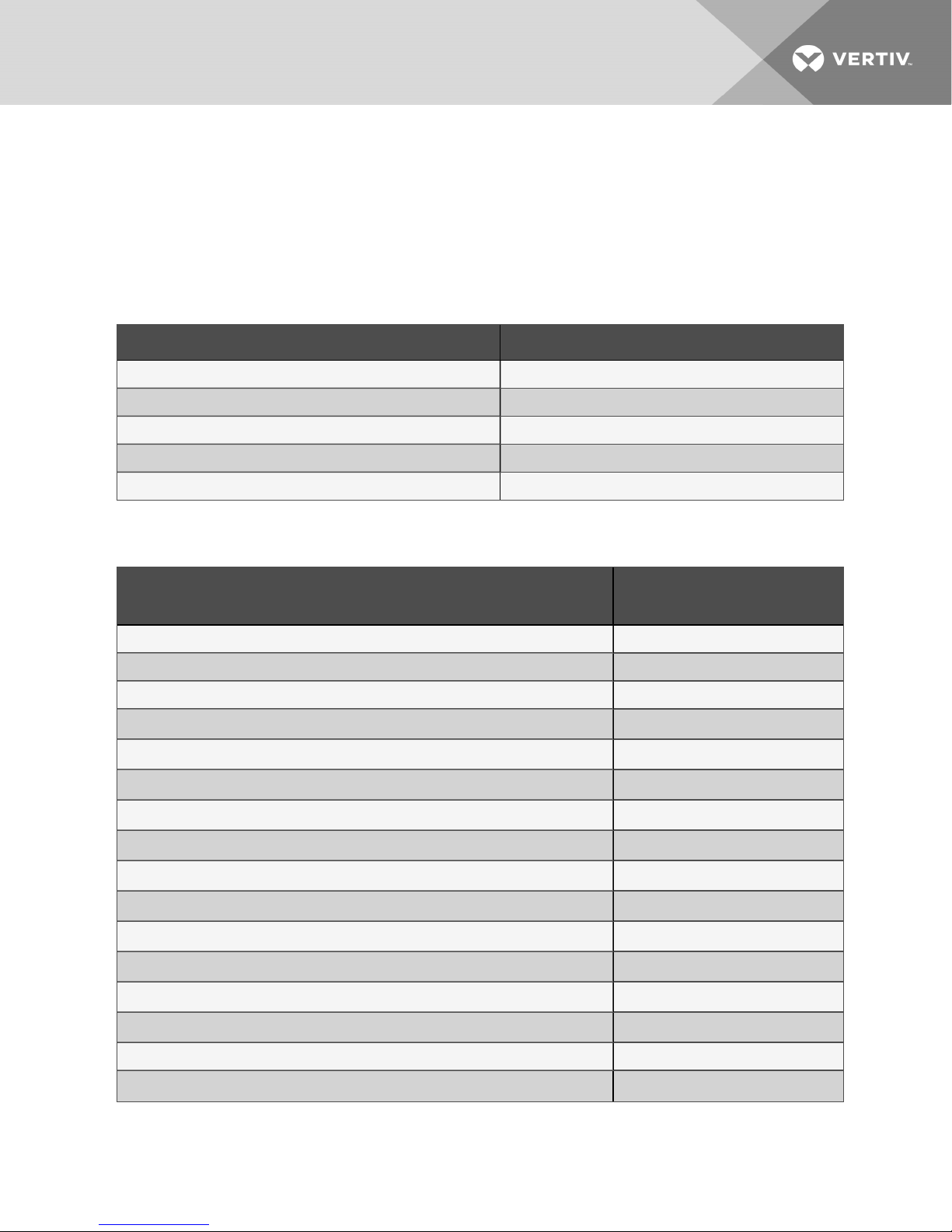

Figure 4.1 Generic airflow diagram—enclosure/rack shown from side

Item Description

1 Front of rack

2 Rear of rack

3 DCD

4 Cooling water connections

5 Criticalequipment

NOTE: To provide optimal cooling, strict separation between the hot and cold air must exist within the

rack and all the bushings (network cables, piping, etc.) must be sealed to prevent air leakage. Air

bypass and recirculation can severely reduce the cooling effectiveness of the DCD™. Install blanking

plates in any voids in the rack to prevent air bypass and air recirculation. Keep the coils clear of any

obstructions that may block the airflow. Contact the factory for further information. Refer to the user

manual supplied with the rack on which the DCD™ is mounted.

4.5 Water-supply Considerations

For reliable function of the DCD™, chilled water must be available in an appropriate amount, of the

required quality, and at the appropriate temperature and pressure.

20

Vertiv | Liebert® D CD™Installer/User G uide

Page 21

4.5.1 Water Quality Requirements

To safeguard the maximum lifetime of air/water heat exchangers, the water used for chilling purposes

must meet the VGB Chilled Water Guidelines (VGB-R 455 P). The chilled water used must be soft enough

to prevent deposits, but it must not be too soft because that would lead to corrosion of the heat

exchanger.

Table 4.3 below, lists the most important impurities and measures for their removal.

Table 4.3 Water Impurity

Water Impurity or Condition Corrective Method

Particles (dp < 0.3 mm) Filter the water

Excessive hardness Soften the water by ion exchange

Moderate level of particles and hardeners Add dispersion or stabilization agents

Moderate level of chemicalimpurities Add deadening agents and inhibitors

Biologicalimpurities (bacteria and algae) Add biocides

We recommend treating water to it get as closest as possible to the values in Table 4.4 on the next page.

Table 4.4 Hydrological data

HydrologicalData

Recommended

Purity Levels

pH values (7 - 10,5)

Carbonate hardness (3 - 8) °dH

Free carbon dioxide (8 - 15) mg/dm3

Combined carbon dioxide

Aggressive carbon dioxide

Sulfides

Oxygen

Chloride ions

Sulphate ions

Nitrates and nitrites

COB

Ammonia

Iron

Manganese

8 - 15mg/dm

0mg/dm

< 10mg/dm

< 50mg/dm

< 250mg/dm

< 10mg/dm

< 7mg/dm

< 5mg/dm

< 5mg/dm

< 0.2mg/dm

< 0.2mg/dm

3

3

3

3

3

3

3

3

3

3

3

Conductivity < 30S/cm

Solid residue from evaporation

4 Pre-installation Preparation and Guidelines

< 500mg/dm

3

21

Page 22

Table 4.4 Hydrological data (continued)

HydrologicalData

Potassium manganese consumption

Suspended matter

PartialFlow Cleaning Recommended

FullFlow Cleaning

Recommended

Purity Levels

< 25mg/dm

< 3mg/dm

3 -15 mg/dm

> 15mg/dm

3

3

3

3

4.5.2 Water Temperature Requirements

The cold water supply temperature must be higher than the dew point temperature of the cold space.

Failure to maintain the cold water supply temperature above the room dew point will result in

condensation. The DCD™ provides only for sensible cooling. You must avoid dehumidification of the room

by the DCD™. The built-in condensate tray with condensate drain is designed only for a short-term

condensation.

Table 4.5 Application conditions

Operating Ambient Temperature 50°F - 95°F (10°C - 35°C) (Other Temperatures on Request)

Maximum Absolute Air Humidity on Site 8g/kg

Chilled Water Temperature Intake 53.6°F (12°C) Other Temperatures on Request

Chilled Water Temperature Outlet 64.4°F (18°C) Other Temperatures on Request)

Water Temperature Difference 10.8°F (6°K)

Use of Glycol On Request (Not Rec ommended)

Chilled Water Connection Rack - Rear Side (Top or Bottom Connection)

Condensate TrayDrain Connection Rack - Rear Side; 5/8"

Maximum Operating Pressure 145psi (10bar)

22

Vertiv | Liebert® D CD™Installer/User G uide

Page 23

5 EQUIPMENT INSPECTION AND HANDLING

SAFETY INFORMATION

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment

damage, injury or death. Read all of the following instructions and verify that all lifting and

moving equipment is rated for the weight of the unit before attempting to move, lift, remove

packaging from or prepare the unit for installation. Unit weights are specified in Table 4.2 on

page19.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

NOTICE

Risk of passageway interference. Can cause unit and/or structure damage. The unit may be

too large to fit through a passageway while on or off the skid. Measure the unit and passageway

dimensions, and refer to the installation plans prior to moving the unit to verify clearances.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a

height suitable to fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Keep the unit upright, indoors and protected from dampness,

freezing temperatures and contact damage.

NOTICE

Risk of a leaking coil due to freezing during improper storage. Can cause equipment and

serious building damage.

The heat exchanger and the supply pipes must be cleared of any water before the unit is

stored, either before storage or after removal from a cabinet. Compressed air can be used to

remove the water. Remove all the vents and the screws before storing.

Upon arrival of the unit and before unpacking:

• Verify that the labeled equipment matches the bill of lading.

• Carefully inspect all items for visible or concealed damage.

• Report damage immediately to the carrier and file a damage claim with a copy sent to Vertiv or

to your sales representative.

Equipment Recommended for Handling the Unit:

• Forklift

• Pallet jack

5 Equipment Inspection and Handling

23

Page 24

5.1 Storing the Unit

• Keep the unit in its original packaging, protected from the weather and in dry conditions.

• Protect the unit’s working parts from sand, rain, dust and other particles and contaminants.

• Store at temperatures between -22°F and +122°F (-30°C and +50°C). The chilled-water circuit

must be empty during storage.

• After storage for a year or longer, the water-bearing hinges must be inspected for functionality.

• Remove all packaging before starting the unit.

• Chilled-water connections are not load-bearing. Do not use the connections as handles.

• When transporting the unit, always make sure the device is properly fastened and secured

against slipping.

NOTICE

Risk of a leaking coil due to freezing during improper storage. Can cause equipment and

serious building damage.

The heat exchanger and the supply pipes must be cleared of any water before the unit is

stored, either before storage or after removal from a cabinet. Compressed air can be used to

remove the water. Remove all the vents and the screws before storing.

5.2 Packaging Material

All material used to package this unit is recyclable. Please save for future use or dispose of the

material appropriately.

5.3 Handling the Unit while Packaged

Transport the unit with a forklift or pallet jack.

When using a forklift or pallet jack:

• If multiple units are delivered, they ship on a pallet with up to 4 modules, and a pallet jack is

required to move these to the installation location.

• Make sure that the fork tine length is suitable to move the packaged module.

• When moving the packaged unit, do not lift the unit any higher than 6in.(152mm). All

personnel except those moving the unit must be kept 20ft(5m) or more from the unit while it

is being moved.

• If the unit must be lifted higher than 6in.(152mm), all personnel not directly involved in

moving the unit must be 20ft (5m) or farther from the unit.

• Do not use piping on the module to lift or move the unit.

24

Vertiv | Liebert® D CD™Installer/User G uide

Page 25

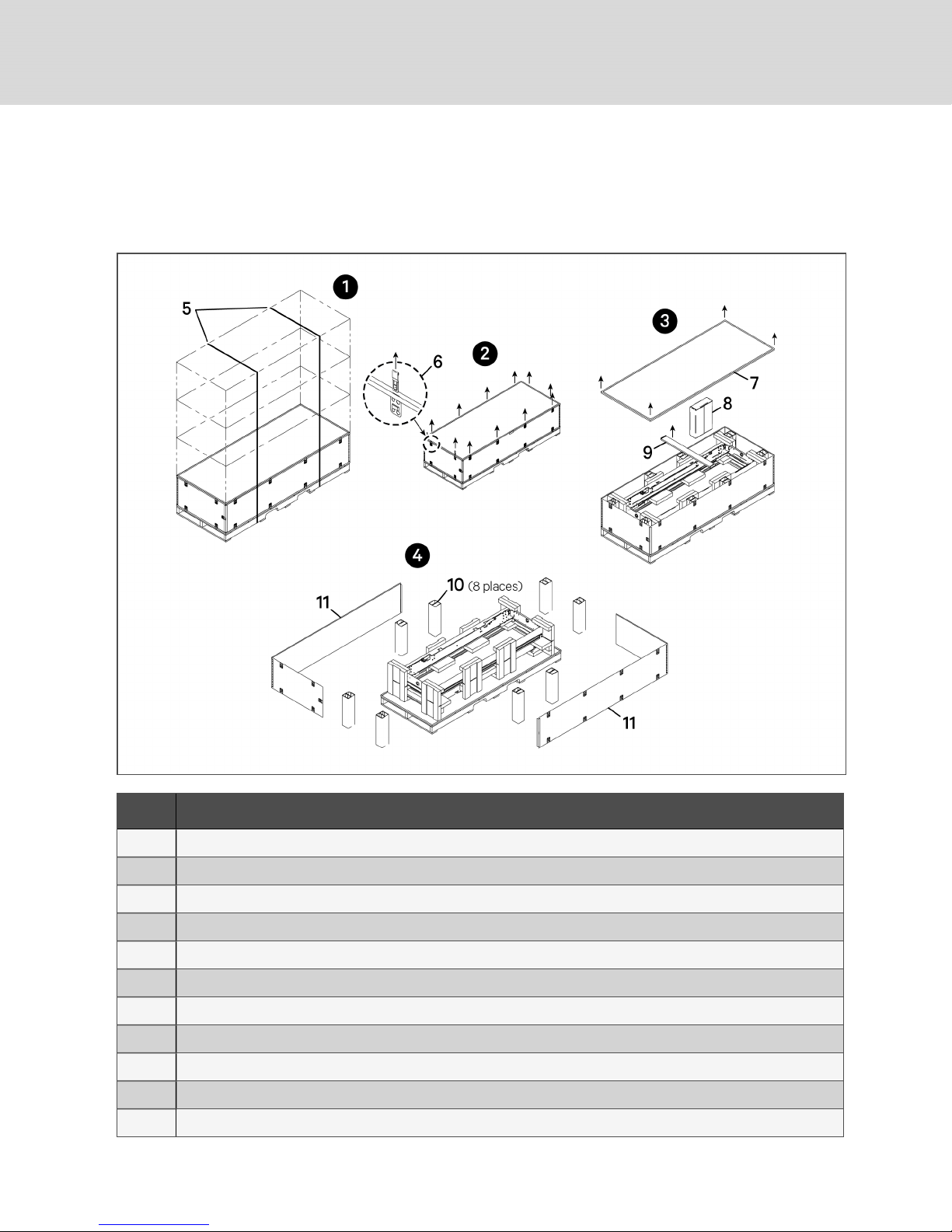

5.4 Unpacking the Module

The following equipment is required to unpack the module:

• Utility knife

• Flat-blade screwdriver, claw hammer, pliers or crowbar

• Forklift, pallet jack or similar device

Do not unpack the unit before moving it to the installation location. Once at the installation point, refer to

Figure 5.1 on the next page, and the following steps:

NOTE: Two properly-trained and qualified personnel must lift the unit.

1. For multiple-unit shipments, cut the bands and place all packaged modules on the floor for

unpacking.

2. On each module, slide the upper row of spring clips upward and remove them.

5 Equipment Inspection and Handling

25

Page 26

3. Remove the top cover and cross brace from the package, then remove and set aside the

hardware and key package.

4. Remove the remaining spring clips, side panels and any spacers from the package.

Figure 5.1 Removing packaging

Item Description

1 Cut and remove shipping bands if necessary, andlayeach module on the floor for unpacking.

2 Remove the top row of springclips from the packaging.

3 Remove the cover and cross brace, then remove the hardware/key kit package and set aside.

4 Remove the remainingspring clips, side panels, andanyspacers.

5 Shipping bands

6 Top spring clip

7 Top cover

8 Hardware/key kit

9 Cross brace

10 Spacer (8 places)

11 Side panel

26

Vertiv | Liebert® D CD™Installer/User G uide

Page 27

5. Lay two pieces of protective material, each longer and wider than the module frame, on the

floor.

6. Remove foam packaging from both sides of the unit.

7. Using two people, lift the module frame off the pallet and lay it on one piece of protective

material.

8. Compare the serial tag information on the module to the bill of lading. If the information does

not match the product specified, contact your Vertiv sales representative.

9. Using two people, lift the module and lay it on the second piece of protective material with the

door handle facing up.

5 Equipment Inspection and Handling

27

Page 28

This page intentionally left blank

28

Vertiv | Liebert® D CD™Installer/User G uide

Page 29

6 INSTALLATION

These instructions apply only to installing the Liebert® DCD™ on a DCM™ rack by Knurr®. For racks built

by other makers, refer to the instruction sheet shipped with the adapter kit to install the adapter and

DCD™ frame. The rack-adapter kit is described in the drawing DPN004114 included in the Submittal

Drawings on page83.

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment

damage, injury or death. Read all of the following instructions and verify that all lifting and

moving equipment is rated for the weight of the unit before attempting to move, lift, remove

packaging from or prepare the unit for installation. Unit weights are specified in Table 4.2 on

page19.

NOTICE

Risk of improper installation and commissioning. Can cause equipment damage.

Installation and commissioning of the unit must be performed only by properly trained and

qualified personnel. All actions must be in accordance with regulations and the manufacturer’s

instructions.

NOTICE

Risk of improper assembly. Can cause unit to malfunction.

The unit must be properly aligned and plumb with the rack to for the unit to function properly

and without water leaks. Use a carpenter’s level to make sure this requirement is met when

commencing the installation.

The hot and cold air within the cabinet must be separated.

NOTICE

Risk of airflow obstructions. Can cause improper air circulation.

To ensure sufficient air circulation make sure there are no obstructions (for example:

packaging materials, tools etc.) left in the unit or cabinet. In particular, check the DCD™’s grids,

heat exchanger, air intake, and the air outlet.

6.1 DCD Frame Preparation

The DCD™ mounts on the rear of the rack.

• Before attaching the frame: remove the rear door from the rack. Refer to the rack’s installation

manual for details.

NOTE: If installing the DCD™ on any type of rack other than the DCM, an adapter kit is necessary.

Follow the installation instructions included with the rack adapter kit for the specific rack. Once the

adapter kit and frame are installed, continue the installation, following the steps in Installing the DCD

Door on page34.

6 Installation

29

Page 30

6.2 Installing the DCD Frame on a DCM Rack

6.2.1 Required Tools

• Phillips screwdriver, PH3

• Adhesive-backed foam (factory-supplied)

• Utility knife

• 8 mm socket and driver

• Scratch awl

• Marker

• Adjustable wrench with a maximum adjustment size of 2 inches (51 mm)

• Torque wrenches, 1-1/2 in. (38 mm) and 1-7/16 (36 mm)

Table 6.1 Required factory-supplied parts

Part Name Vertiv Part # Quantity

Spring Nuts 000782699 16

Diamond Nuts 000770869 7

Self-Adhesive Foam 309894P3 1

Bolts N/A N/A

Condensate Drain Kit N/A N/A

1. After removing the packaging, lift the DCD™ from the pallet or from the protective material.

2. Align the frame of the DCD™ with the rear of the equipment rack.

• Bottom Chilled Water Connections: ensure that the chilled-water connections are

pointing down (see Figure 2.1 on page10).

• Top Chilled Water Connections: ensure that the chilled-water connections are pointing

up.

3. Use a marker or scratch awl to mark the positions for the 17 bolts that will attach the frame to

the DCM. Bolts will be inserted in:

• Five frame holes on the aluminum frame member on the door handle side of the rack.

• Three spring nuts near the top of the hinge side of the rack

• Three spring nuts near the bottom of the rack

• Three diamond nuts in the face of the rack’s top frame member

• Three diamond nuts in the face of the rack’s bottom frame member

4. Lay the DCD™ frame on the protective material.

5. Insert the spring nuts into the groove of the vertical aluminum profile.

6. Move spring nuts to the marked positions using a scratch awl or similar tool.

30

Vertiv | Liebert® D CD™Installer/User G uide

Page 31

7. Install the condensate drain assembly (refer to Figure 6.1 below).

a. Get the condensate drain parts from the parts bag.

b. Press the condensate-hose adapter into the top half of the drain assembly until it snaps

into place. The top of the condensate-hose adapter will extend above the top half of the

drain assembly.

c. Put the O-ring seal on the insert.

d. Insert the assembly in the top of the condensate drain hole.

e. Screw the nut onto the top half of the assembly, tightening it firmly by hand.

Figure 6.1 Condensate drain assembly

Item Description

1 Condensate-hose adapter

2 Bottom nut

3 O-ring

4 Tophalfof assembly

5 The condensate-hose adapter extends above the top half of the assembly.

6 The o-ring fits against the bottom of the DCD.

6 Installation

31

Page 32

8. Connect the condensate-hose Adapter to the condensate tray.

9. Lift the DCD™ frame and align it with the server rack again.

Figure 6.2 Align the DCD frame with the rack

32

Vertiv | Liebert® D CD™Installer/User G uide

Page 33

10. Insert and partly tighten bolts to hold it in place.

NOTE: Performing this step may be easier if a board or similar object is placed under the DCD™ frame to

hold it in place.

11. Insert and lightly tighten the bolts, working all around the perimeter to prevent the frame from

twisting and to ensure the parts fit properly (see Figure 6.3 below).

12. Torque the screws all around the perimeter to 2 ft-lb (3 Nm).

13. Verify that the frame is not twisting.

Figure 6.3 Tighten screws on frame

6 Installation

33

Page 34

14. Thread the brass swivel fitting to the frame by hand to ensure the threads mate properly.

15. Hold the brass body so that it does not rotate and use a torque wrench to tighten to 64 ft-lb

(85 Nm).

Figure 6.4 Brass swivel fitting threaded onto Liebert DCD pipe

Item Description

1 Tighten with a torque wrench

2 Hold stationary (brass body)

6.3 Installing the DCD Door

Required Tools

• Socket hexagonal screw driver - (Allen) 8 mm for M5 screws (5/16")

• Torque wrench

• Phillips screw driver PH3

• Utility knife

WARNING! Risk of heavy module falling. Can cause equipment damage, injury and death. Two

properly-trained and qualified people are required to move and install the module. The DCD™

weighs in excess of 210lb(95kg). Do not leave a DCD™ standing unattended on its side or its

end without adequate support to prevent it from falling over. The module must be supported at

all times or laid flat on protective material until it is installed. Read all instructions before

attempting to move, lift, remove packaging from, or prepare the module for installation. See

Table 4.2 on page19, for unit weights based on model.

1. Attach the three door hinges to the DCD™ door with the supplied screws.

2. Turn the DCD™ face down (handle side down) and lay it on the protective material.

34

Vertiv | Liebert® D CD™Installer/User G uide

Page 35

3. Vent the low-pressure holding charge in the DCD™ by removing the cap on the Schrader valve

and depressing the valve pin.

4. Replace and secure the cap on the Schrader valve.

Figure 6.5 Schrader valve at the top of the door

6 Installation

35

Page 36

5. Loosen the coil plug. This requires two adjustable wrenches in the wrench arrangement shown

in Figure 6.6 below.

One wrench holds the Coil Inlet Fitting stationary and the other turns the plug to remove it.

NOTICE

Risk of improper coil plug removal. Can cause damage to the coil.

It imperative that the coil inlet fitting held stationary and the coil plug is is turned. Turning the

coil inlet fitting can damage the coil.

Figure 6.6 Loosen the coil plug

Item Description

1 Coil inlet plug

2 Coil inlet fitting. Hold fitting stationary while removing plug.

3 Wrench removes plug.

4 Wrench holds fitting stationary.

36

Vertiv | Liebert® D CD™Installer/User G uide

Page 37

6. Remove any debris and wipe the threaded surfaces clean.

7. Align the door to the frame (see Figure 6.7 below).

8. Set the door in the frame—Angle the bottom of the door toward the frame and insert the door

(see Figure 6.7 below).

NOTE: Performing this step may be easier if a board or similar object is placed under the DCD™ frame to

hold it in place.

Figure 6.7 Frame and door alignment

6 Installation

37

Page 38

9. Fasten the door hinges to the frame, starting with the top hinge and finishing with the bottom

hinge (see Figure 6.8 below).

NOTE: Tilting the door may ease installing the hinge bolts.

Figure 6.8 DCD door hinge location

Item Description

1 Hinges, 4 screws in each hinge.

2 Tilt the door to make installingbolts easier.

10. Check that the door moves freely.

If there are any irregularities or roughness in the movement of the door:

• Check for obstructions or loosen screws of the hinges and adjust alignment.

• Tighten any loose screws.

11. Apply pipe wrap or plumber’s dope to the coil connection.

12. Thread one of the short, flexible pipes onto the coil connection by hand to ensure that the

threads properly mate (see Figure 6.9 on the facing page).

13. Tighten to 350 in-lb (39.5 Nm).

NOTICE

Risk of improper tightening. Can cause equipment damage.

Turn only the nut on the flexible pipe when tightening this connection. Moving the coil

connection may damage the coil.

38

Vertiv | Liebert® D CD™Installer/User G uide

Page 39

14. Pull the flexible piping slightly to elongate it enough to connect the union nuts.

NOTICE

Risk of overextending the flexible pipe. Can cause equipment damage.

Pull the flexible piping slightly to elongate it. This makes the piping long enough to connect

the union nuts. Only a slight elongation is necessary. Pulling too hard will overextend the pipe,

making it hard to fit and possibly causing leaks.

15. Insert the sealing ring in the door’s lower piping (see Figure 6.9 below).

Figure 6.9 Aligning pipes and Inserting the sealing ring

6 Installation

Item Description

1 Flexible pipe threaded onto coil connection.

2 Flexible pipe connected to union nuts.

3 Upper pipe connection.

4 Insert sealing ringinto lower pipe connection.

5 Sealing ring

6 Pullslightly on the flexible pipe to elongate it, but do not over-extend the pipe.

39

Page 40

16. With the door fully open, use a torque wrench tighten the union nuts to 64 ft-lb (85 Nm). If a

torque wrench is not available, use two wrenches to reduce the stress on the pipes (see Figure

6.10 below).

• Open-end wrench 1-5/8-in.(41-mm) or an adjustable wrench with maximum size of 2-in.

(51-mm)

• Open-end wrench 1-7/16-in.(36-mm) or an adjustable wrench with maximum size of 2-in.

(51-mm)

17. Check to make sure the door swings freely.

Figure 6.10 Tightening piping

6.4 Installing the DCD Swivel-joint Covers

Tool Required

• Socket hexagonal screw driver - 5/16" Allen (8 mm) for M5 screws

The swivel-joint covers can be identified by the number of identification holes on each cover.

NOTE: The DCD™ is set up for left-side hinges. You can flip the door for right-side hinges.

40

Vertiv | Liebert® D CD™Installer/User G uide

Page 41

Figure 6.11 Swivel-joint cover identification and location bottom connections

Item Description

1 Swivel-joint cover 1

2 Swivel-joint cover 2

3 Swivel-joint cover 3

4 Swivel-joint cover 4

5 Identification holes

6 Left-side hinges

7 Right-side hinges

6 Installation

41

Page 42

To install the covers:

1. Open the DCD™ door. The door must be open to install the covers.

2. Install the outer, then inner swivel-joint covers on the door (see Figure 6.12 below)

Figure 6.12 Swivel-joint cover locations

Item Description

1 Inside cover location

2 Outside cover locations

3 Joint cover

4 Upper cover

5 Lower cover

42

Vertiv | Liebert® D CD™Installer/User G uide

Page 43

3. Fasten screws using the hexagonal screwdriver or socket wrench.

4. Connect the earth (ground) wire of the door to the frame of the Liebert DCD (see Figure 6.13

below).

Figure 6.13 Securing ground wire

Item Descr iption

1 Ground wire connected to bottom corner of DCD

5. Use a “diode” or multimeter to determine that the connection is properly grounded.

6. Check the function of the door lock. The DCD is equipped with a half-inch cylinder lock and

keys.

6 Installation

43

Page 44

6.5 Reversing the Door Handle

If you are modifying a bottom-connection DCD™ to top connections, the handle can be reversed so that it

will not be upside down.

To reverse the handle:

1. Open the door and remove all the bolts holding the door-handle and lock assembly, including

the four brackets. Studs and nuts secure the brackets to the door frame.

2. Flip the door-handle and lock assembly 180 degrees and reattach it with the bolts and nuts.

3. Check the handle and lock to ensure they operate properly.

Figure 6.14 Reverse door handle

Item Description

1 Bolt that secures door-lock assembly, 4 total:2 above the lock and 2 below.

2 Door lock, secured with 3 bolts.

6.6 Installing the Active Fan Module

These instructions apply only to installing DCD Active fan module on a Liebert® DCD™. All materials

required for installation come with the module.

Power-supply Connection Requirements

Standard DCDActive fan modules include a single, wide-range voltage-input port (110/230V). An optional

A/B power-supply transfer switch (110V or 230V) is available to provide back-up if one or the other

supply fails.

44

Vertiv | Liebert® D CD™Installer/User G uide

Page 45

NOTICE

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power

disconnect switches, verify with a voltmeter that power is Off and wear personal protective

equipment (PPE) per NFPA 70E before working with the module. Failure to comply can cause

serious injury or death. Follow all local codes.

WARNING! Risk of contact with high-speed, rotating fan impeller blades. Can cause injury or

death. Open all local and remote electric power-supply disconnect switches, verify with a

voltmeter that power is off, and verify that all fan impellers have stopped rotating before

working in the unit cabinet.

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty

coverage.

Prior to connecting any equipment to a main or alternate power source (for example: back-up

generator systems) for start-up, commissioning, testing, or normal operation, ensure that these

sources are correctly adjusted to the nameplate voltage and frequency of all equipment to be

connected. In general, power-source voltages should be stabilized and regulated to within

±10% of the load nameplate nominal voltage. Also, ensure that no three-phase sources are

single-phased at any time.

6.6.1 Mounting the Active Fan Module on DCD

1. Remove the module cover by lifting up then out, see Figure 6.15 on the next page.

2. Disconnect the Protective-earthing (PE) ground wire from the cover, see Figure 6.15 on the

next page.

6 Installation

45

Page 46

Figure 6.15 Removing cover and disconnecting PE wire

Item Description

1 Key-hole mounting locations.

2 PE connector locations

46

Vertiv | Liebert® D CD™Installer/User G uide

Page 47

3. On the fan module, locate and loosen the screws, but do not remove the screws, see Figure 6.16

below. Then, pull the lower mount downward until it stops.

4. Hang the upper mount of the module on the DCD, then secure the module but pushing the

lower mount upward and tightening the screws.

Figure 6.16 Upper and Lower mounts on the fan module

Item Des cription

1 DCD35 Active fan module

2 DCD50 Active fan module

6.6.2 Connecting Supply Power and Sensors

NOTE: Before connecting the power supply, verify the supply and wiring per local electrical codes.

1. On the top of the module, route the wires/pressure hose through the wiring bridges to the

connectors, see Figure 6.17 on the next page.

2. For modules with the optional TFT, route the temperature-sensor wires from inside the cabinet

through the wire bridges and connect to the RJ-45 port, see Figure 6.17 on the next page.

6 Installation

47

Page 48

The module begins operating immediately and begins controlling the pressure differential in a short time

on both standard and TFT models. The green "operating" LEDis lit on standard models during normal

operation. On TFT models, the display shows the main screen after a brief start-up screen. If you have a

TFT module, see Using the DCD Active TFT Display on page61, to adjust setpoints and configure sensors.

Figure 6.17 Connectors on the Active fan module

Item Description

1 DCD35 Active fan module, top view

2 DCD50 Active fan module, top view

3 Wire bridge

4 IP-interface bushing

5 RJ-45 connector

6 Pressure-hose connector

7 Power-supply A connectors

8 Power-supplyB connec tors

48

Vertiv | Liebert® D CD™Installer/User G uide

Page 49

7 PIPING CONSIDERATIONS AND CONNECTIONS

Refer to site-specific drawings for general locations of the piping connections. The drawings should

specify where the piping connects to the DCD™.

NOTICE

Risk of coil and piping rupture. Can cause equipment damage and major fluid leaks resulting in

serious building damage, expensive repair costs and costly system down time.

Thermal expansion of the cooling fluid without means of expansion can cause the coil and

piping to rupture, spilling cooling fluid in the conditioned space. This can be caused, among

other ways, by closing the ball valves on both the supply and the return pipes. Always allow for

thermal expansion either by leaving at least one of the valves open or by opening the DCD

bleed valve (see Figure 7.8 on page56).

7.1 System Connection Configuration

If possible, when using a chilled-water-distribution unit such as the Liebert® DCP™, connect the DCD™ in

an interlaced configuration (see Figure 7.1 below). In an interlaced configuration, half the cooling

modules in an aisle are connected to one chilled-water-distribution unit and the other half are connected

to another chilled-water-distribution unit. Interlacing the connection piping will keep half the DCD™ units

operating and maintain cooling in the conditioned space should one unit fail.

Figure 7.1 Typical DCD interlaced piping

When using a chilled-water-distribution unit such as the Liebert® DCP, you may employ a ring design (see

Figure 7.2 below) or Tichelmann ring (see Figure 7.3 below) design. In these designs, the pressure drop

for each of the units is approximately the same, which results in even cooling performance.

7 PipingConsiderations and Connections

49

Page 50

Figure 7.2 Ring piping

Figure 7.3 Tichelmann ring piping

50

Vertiv | Liebert® D CD™Installer/User G uide

Page 51

However, if a ring configuration is not possible, connect the DCD™ units in a non-interlaced configuration

as shown in Figure 7.4 below.

Figure 7.4 Typical DCD non-interlaced piping

7.1.1 Using Chilled-water Distribution Units

Using a chilled-water-distribution unit provides these benefits:

• Isolates of the building’s chilled-water circuit from the chilled-water circuit within the data

center. The Liebert® DCP™ circulates the chilled water to DCD while preventing condensation

by maintaining the water temperature above the room dew point.

• Ensures that the proper flow rate to the DCD, a critical factor in achieving and maintaining the

needed capacity.

• Separating the data center from the building chilled-water circuit also minimizes the impact of

a leak within the data center. If a leak occurs, the volume of water is limited to the amount

within secondary piping system instead of the entire building chilled-water system.

7.1.2 Using Open-loop Chilled-water Systems

Maintaining the proper chilled-water flow rate is critical in achieving the design capacity of the DCD. If you

are not using a chilled-water-distribution unit, you must take steps to ensure the proper flow at the unit is

maintained. You should incorporate an expansion tank or another method into the design to account for

fluid expansion.

7.2 Connection Methods and Points

Refer to site-specific drawings for general locations of the piping connections. For connection locations,

refer also to Figure 7.5 on the next page, and 7.3 on the next page.

The assembly and connection means used for piping the DCD system are the same as those used in

conventional chilled-water systems. Observe all standard practices during installation and start-up to

prevent damage and contamination. All piping must be ASTM Type L copper.

The DCD supply- and return-piping connections are described in the Submittal Drawings on page83.

7 PipingConsiderations and Connections

51

Page 52

7.3 Floor Cut-out Dimensions for Units with Bottom Connections

Figure 7.5 Floor cut-out dimensions

7.4 Insulate Piping

Insulate all piping for the DCD to minimize the possibility of condensation.

7.5 Recommended Pipe Sizes

Elbows and restrictions should be minimized to establish sufficient fluid flow.

Table 7.1 Recommended pipe sizes

Piping Run Nominal Pipe Size, in.

2-5/8

Supply or Return Mains

Supply or Return Branches >10 ft 1-3/8

Supply or Return Branches <10 ft 1-1/8

NOTE: When using the DCD with a Liebert® DCP,

refer to the pipe sizes in the Liebert® DCP™ Installer/User Guide.

52

Vertiv | Liebert® D CD™Installer/User G uide

Page 53

7.6 Chilled-water Connection Components

NOTICE

Risk of improper storage. Can cause frozen or damaged coil and piping, resulting in fluid leaks,

equipment damage and serious building damage.

The heat exchanger and the piping must be cleared of any water before the unit is stored.

Compressed air can be used to remove the water. Remove all the vents and the screws before

storing. We recommend storing of the module indoors protected from freezing, dampness, and

contact damage.

NOTE: Chilled-water connections are 1-in. Female BPT. A BPT to NPT adapter is required for

installation in the United States.

Figure 7.6 Chilled water connections

Item Description

1 Chilled-water outlet

2 Chilled-water inlet

3 Condensate drain

7.6.1 Strainer

Install a 20-40 mesh strainer on the chilled-water supply to the Liebert® DCP. The strainer is required to

prevent particles in the chilled water from entering the DCP’s heat exchanger. The strainer must be no

more than 10ft (3m) from the DCP.

7.6.2 Service Valves

Install 1-in. ball valves (field-supplied/field-installed) on the supply and return lines to the DCD to allow

service on the unit without shutting down the entire system.

7.6.3 Balancing Valves

Install balancing valves (circuit setters) in the supply line to the unit. Refer to Capacity Performance for

DCD35 Models on page74, and Capacity Performance for DCD50 Models on page78, for the proper flow

rate required to achieve the site-specific capacity

7 PipingConsiderations and Connections

53

Page 54

7.6.4 Flexible Pipes

DCD™ Flex Pipe kits are available in 59-ft(1500-mm) nominal lengths. The kit consists of two hoses,

manual commissioning valve, and shut off valve. The connections are described in DPN004233 included

in the Submittal Drawings on page83.

Figure 7.7 Acceptable and Unacceptable pipe-bend radius

Item Description

1 Acceptable radii

2 Unacceptable radii

54

Vertiv | Liebert® D CD™Installer/User G uide

Page 55

7.7 Leak Checking

NOTICE

Risk of leaking water. Can cause equipment damage and serious building damage.

Check the chilled water system for leaks before commissioning. Check the chilled water pipe

connection to the heat exchanger regularly. Tighten this connection if necessary.

When setting up the heat exchanger for the first time, inspect the mechanical condition of the

chilled water supply and connection thoroughly.

• Confirm that the flow directions of field-installed components are correct.

• Confirm that all isolating valves are open.

• Test the water quality when filling the system, see Water Quality Requirements on page21.

• Set the pressure at 145 psig (10 bars) maximum for at least 30 minutes or according to local

codes.

• Repair any leaks.

7.8 Filling the Unit

If using a chilled-water-distribution unit, such as the Liebert® DCP™, refer to its user manual for

instructions on filling the DCD and starting the system.

7 PipingConsiderations and Connections

55

Page 56

7.8.1 Bleeding Air from the DCD

The DCD has two Schrader valves, one at the top and one at the bottom. The two valves provide flexibility

for bottom or top chilled-water connections. Air trapped in the unit or piping must be bled from the valve

at the top. Opening the lower valve releases water.

NOTICE

Risk of water release. Can cause equipment and building damage.

The Schrader valve at the top of the DCD must be used when bleeding air from the unit.

Opening the lower Schrader valve will release water.

1. Find the Schrader valve at the top of the DCD, see Figure 7.8 below.

2. Depress the pin to open the valve.

3. Keep the Schrader valve open until the water coming out has no bubbles.

NOTE: When using a top connection, the commissioning valve in the hose kit is an additional bleed

point. Use a bleeding apparatus to prevent water from spilling (available as a ship-loose item).

Figure 7.8 Schrader valve to bleed air from unit

56

Vertiv | Liebert® D CD™Installer/User G uide

Page 57

8 INSTALLATION CHECKLIST

ANDSYSTEMFILLFORSTART-UP

Checks to be Performed

Check device for damage upon receipt

Install and alignto server cabinet

Flexible hoses connected (optional)

properly

Packaging removed from the Liebert

DCD

Allassemblytools removed

Bushings installed properly

Chilled water connections leak-proof /

pressure-tested

Air bled from coil

Chilled water flow adjusted to proper

flow rate

Condensate line connected (if

applicable) androuted to a suitable drain

Unused server space is blocked with

blanking panels

Done (to be signed upon

completion)

Remarks

Top and bottom of server cabinet are

blocked and any cable entries are sealed

to minimize air leakage.

Location Date Installer Signature

8 InstallationChecklistandSystemFillforStart-up

57

Page 58

Customer Site Name

Customer Site Address

Site Contact

Phone Number

Installer Name

Installer Address

Ambient Room

Temperature

Room Humidity at Site

of Commissioning

°F (°C)

% Relative Humidity

Liebert DCD Serial#

Comments

Check ofalignment Yes No

Shipping damage Yes No

If yes, has the shipper been notified Yes No

Residualpackagingremoved Yes No

Assemblytools removed Yes No

58

Vertiv | Liebert® D CD™Installer/User G uide

Page 59

Building chilled water system

Chilled Water

Liebert DCD

Connected to Building Chilled Water? Liebert DCP™

Chilled Water Temperature

(primary)

Chilled Water Pressure

Connection

With Glycol Glycol Type

Without Glycol

Supply °C °F

Return °C °F

Supply bar Supply psi

Return bar Return psi

Liebert DCD Flexible Hose

ExternalFlow Regulator

ExternalIsolation Valves

Mechanical Functions

Damage to Heat Exchanger/

Connections/ Fins/Tubes/Surface

Remarks

None Existing

Thermodynamic Checks

Pipe Duct Inlets/Cable Sealed Yes No

Remarks

Condensed Drain Connected Yes No

Remarks:

Thermodynamic Checks

Condensate on Coil Surface Yes No

Remarks

Chilled Water Entering Heat Exchanger °F °C

Chilled water leaving heat exchanger °F °C

Cabinet Temperature inFront of Heat Exchanger °F °C

Cabinet Temperature Behind of Heat Exchanger °F °C

Chilled Water System Bled Yes No

8 InstallationChecklistandSystemFillforStart-up

59

Page 60

Chilled Water System Pressure Tested Yes No

Proper Chilled Water Flow Rate Set to Liebert DCD Yes No

Volume Flow

GPM External

l/m External

Correctness of values above is hereby affirmed

Start-up Performed By Date Signature

Customer Date Signature

60

Vertiv | Liebert® D CD™Installer/User G uide

Page 61

9 USING THE DCD ACTIVE TFT DISPLAY

If the TFT model of the DCD Active fan module is installed on your DCD unit, the touch-screen provides

real-time operating status details and lets you adjust and configure operational settings.

NOTE: The Standard model DCD Active offers no operating adjustments. When supplied with power,

the Standard DCD Active automatically monitors differential pressure and adjusts fan speed to

maintain a 0-Pa pressure differential.

9.1 Main Screen

When the DCD Active is powered, the TFT touch-screen displays the main screen, which provides a highlevel status summary. Touch an area of the screen to display details of the summarized data.

Touch on any screen to return to the previous screen.

Figure 9.1 Main screen

Item Descript ion

Fan-operation summary. Current fan-speed percentage and color-coded operating status. See Viewing Fan Status Detailon

1

the next page.

Cabinet sensors summary. Average of temperature readingsfrom all sensors on the hot side. See Viewing Cabinet

2

Temperature-sensor Status on page64.

3 Opens the settings menu. See Settings Menu on page65

Exhaust-air sensors summary. Average of temperature readings from all sensors on the cold side. See Viewing Exhaust-air

4

Sensor Status on page63.

9 Usingthe DCD Active TFT Display

61

Page 62

9.1.1 Viewing Fan Status Detail

Touch the fan-summary area on the main screen to view the fan details.

Figure 9.2 Fan Detail

Item Description

1 Current fan-speed operating percentage. All fans operate at the same speed.

Color-coded icon represents the operating status of each fan:

2

Also lists the current rotations-per-minute (rpm) for each fan.

• Green = OK

• Red = Disturbance

62

Vertiv | Liebert® D CD™Installer/User G uide

Page 63

9.1.2 Viewing Exhaust-air Sensor Status

Touch the exhaust-air-sensor summary area on the main screen to view the temperature-sensor details.

Figure 9.3 Exhaust Air Sensors detail

Item Description

1 Average of allexhaust-air (cold side) temperature-sensor readings.

2 Current reading of each temperature sensor.

9 Usingthe DCD Active TFT Display

63

Page 64

9.1.3 Viewing Cabinet Temperature-sensor Status

Touch the cabinet-sensor summary area on the main screen to view the temperature-sensor details.

Figure 9.4 Cabinet Sensors detail

Item Description

1 Average of allcabinet (hot side) temperature-sensor readings.

2 Current reading of each temperature sensor.

64

Vertiv | Liebert® D CD™Installer/User G uide

Page 65

9.2 Settings Menu

The settings menu offers unit and system information and lets you configure operating parameters.

Touch an icon to open the screen or sub-menu.

Figure 9.5 Settings menu

Item Descript ion

1 Info displays read-onlysystem information.

2 Messages displays read-onlysystem messages.

3 Opens the Temperature Sensors menu, see Temperature Sensors Menu on the next page

Opens the Regulation screen, which adjusts the differential-pressure setpoint, see Differential-pressure Regulation on the

4

next page.

5 Opens the Set-up menu, see Set-up Menu on page67.

9 Usingthe DCD Active TFT Display

65

Page 66

9.2.1 Temperature Sensors Menu

The temperature-sensors menu lets you choose the units used for readings, and it lets you "teach" the

DCD Active up to 4 cabinet temperature sensors to monitor and average, see Teaching Sensors to the

DCD Active on the facing page.

NOTE: Exhaust-air temperature sensors in the DCD Active can also be "taught," but are accessed via

the set-up menu. The teaching procedure is identical.

Figure 9.6 Temperature Sensors menu

Item Description

1 Opens the Choose Units screen, see Choosing Temperature Units below.

2 Opens the Teach Cabinets Sensors screen, Teaching Sensors to the DCD Active on the facing page.

Choosing Temperature Units

To choose Celsius or Fahrenheit for the temperatures readings, open the Choose Units screen, and touch

to check the box of the temperature unit to use.

9.2.2 Differential-pressure Regulation

Regulation lets you choose the way DCD Active manages the differential pressure by selecting a

differential-pressure setpoint.

Touch the –/+ buttons to select one of the following pressure setpoints:

• Slight excess pressure

• Neutral

• Slight under pressure

66

Vertiv | Liebert® D CD™Installer/User G uide

Page 67

9.2.3 Set-up Menu

The password-protected set-up menu lets you set the pressure level maintained by the selection for

differential-pressure setpoint, see Differential-pressure Regulation on the previous page, and it lets you

"teach" the DCD Active up to 4 exhaust-air temperature sensors to monitor and average, see Teaching

Sensors to the DCD Active below.

Default password = 94424

Figure 9.7 Set-up menu

Item Description

1 Opens Pressure Levels screen, see Setting Levels for the DifferentialPressure Setpoint below.

2 Opens Teach Exhaust Air Sensors screen, see Teaching Sensors to the DCD Active below.

Setting Levels for the Differential Pressure Setpoint

Touch the –/+ buttons to select the pressure (Pa) that DCD Active maintains for the differential-pressure

setpoint chosen in the Regulation screen, see Differential-pressure Regulation on the previous page:

• Low positive = Slight excess pressure

• Neutral = Neutral

• Low negative = Slight under pressure

Teaching Sensors to the DCD Active

The DCD Active can communicate with up-to 4(optional) temperature sensors in the cabinet and up-to 4

(optional) exhaust-air temperature sensors inside the DCD Active. When taught, each sensor is assigned

a number, 1to4, and DCD Active "learns" or "remembers" that sensor and uses it for averages and status

readings.

Though accessed through separate menus, the teaching procedure is identical.

9 Usingthe DCD Active TFT Display

67

Page 68

NOTE: Only the sensor being configured may be connected during the teaching procedure. Once

taught, the may be disconnected, and will be recognized.

Figure 9.8 Teach-sensor screens

teach_sensor_screens

To teach a sensor to the DCDActive:

1. Disconnect all sensors, except the sensor to configure.

2. For a cabinet sensor, open the teach-sensor screen via the Settings > Temperature Sensors

menu.

– or –

For an exhaust-air sensor, open the teach-sensor screen via the Settings > Set-up menu.

3. Use –/+ to assign a number, 1to4, to the sensor, the touch the magnifying-glass to begin

teaching.

4. Touch OK after confirming that a single sensor is connected.

The DCD Active takes a few seconds to locate the sensor, and the temperature reading from

the sensor displays when the connection is complete.

• To delete a learned sensor, disconnect the sensor, select its number, and complete the

teaching procedure. The number is no longer associated with the sensor.

• To re-assign a number, connect a new/different sensor, select the number, and complete

the teaching procedure. The number is assigned to the connected sensor.

5. Reconnect all the configured sensors, which begin communicating temperature data because

the DCDactive "remembers" them.

68

Vertiv | Liebert® D CD™Installer/User G uide

Page 69

10 MAINTENANCE

CAUTION: Risk of improper repair and maintenance. Can cause reduced unit performance,

equipment damage and injury.

All maintenance and repair jobs must be performed by properly trained and qualified personnel.

All actions must be in accordance with regulations and the manufacturer’s instructions. Use

only Vertiv-approved tools and parts for maintenance and repair.

NOTICE

Risk of dirty heat exchanger. Can cause reduced unit performance (increased pressure drop or

poor heat transfer).

Clean the heat exchanger fins with a vacuum cleaner, soft brush or compressed air.

10.1 General Maintenance

1. Check the heat exchanger for dirt and debris.

2. Check function of the isolation valves.

3. Check the chilled-water system for leaks.

10 Maintenance

69

Page 70

This page intentionally left blank

70

Vertiv | Liebert® D CD™Installer/User G uide

Page 71

APPENDICES

Appendix A: Technical Support and Contacts

A.1 Technical Support/Service in the United States

Vertiv™ Corporation

24x7 dispatch of technicians for all products.

1-800-543-2378

Liebert® Thermal Management Products

1-800-543-2778

Liebert® Channel Products

1-800-222-5877

Liebert® AC and DC Power Products

1-800-543-2378

A.2 Locations

United States

Vertiv Headquarters

1050 Dearborn Drive

Columbus, OH, 43085, USA

Europe

Via Leonardo Da Vinci 8 Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

Asia

7/F, Dah Sing Financial Centre

3108 Gloucester Road

Wanchai, Hong Kong

71

Page 72

This page intentionally left blank

72

Vertiv | Liebert® D CD™Installer/User G uide

Page 73

Appendix B: Specifications

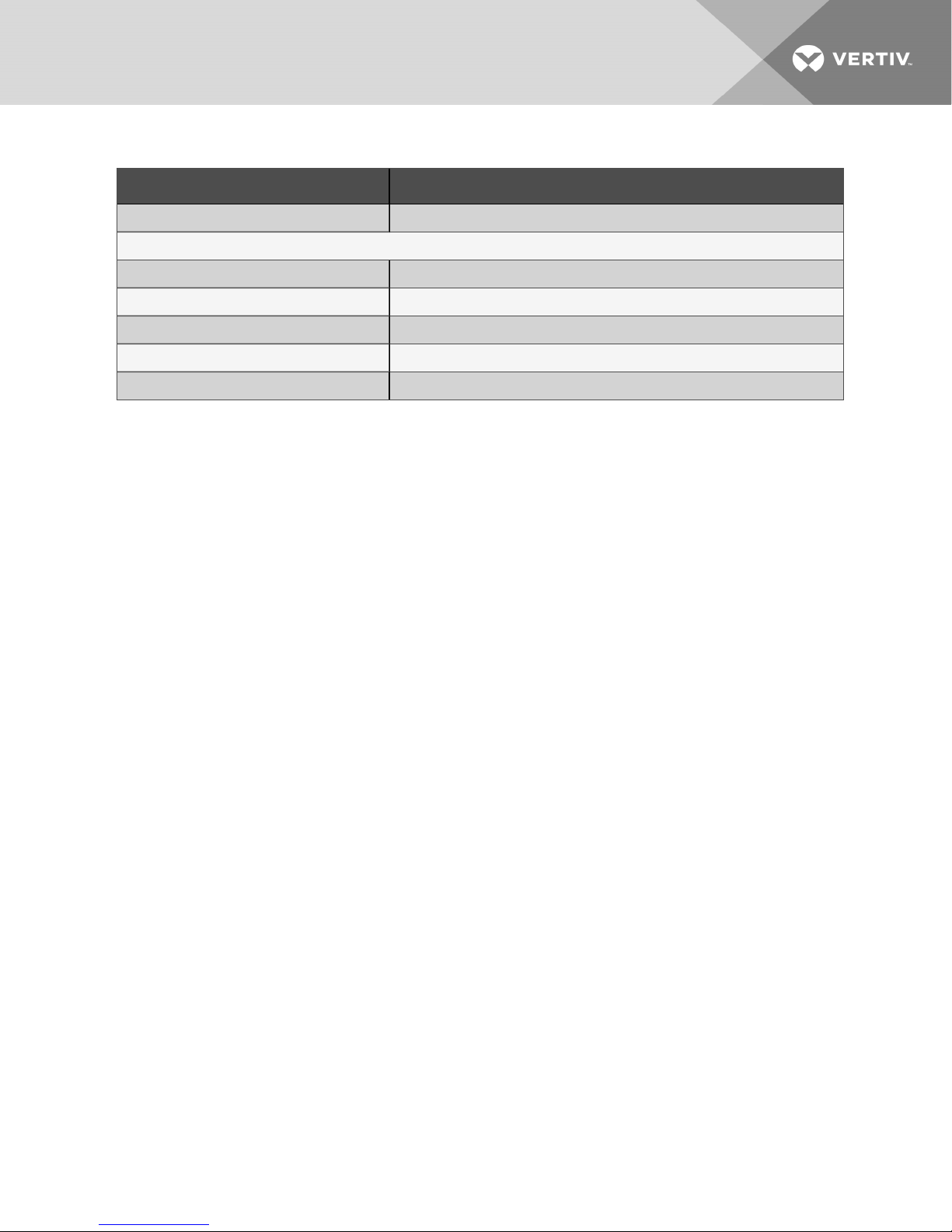

Table B.1 Liebert DCD Specifications

Model: 35 50

Housing Material Steel Plate

CoilMaterial Copper Tubes and Aluminum Fins

Ambient Operating

Temperature °F (°C)

Maximum Capacity 35kw 50kw

Maximum Absolute Humidity 8 g/kg

Dimensions, Door Only

Height, in. (mm) 78-3/4 (2000)

Width, in. (mm) 23-5/8 (600) 31.5 (800)

Depth, in. (mm) 6 (151)

Shipping Dimensions

Height, in. (mm) 24" (610)

Width, in. (mm) 36" (914)

Depth, in. (mm) 91 (2311)

Weight, lb (kg)

Unit Only 210 (95.2) 230 (104.3)

Shipping 325 (147.4) 355 (161.0)

Chilled Water Connections

Chilled Water Supply

*Connections at the door are 1" BPT. Connections to field-installed header are 1" NPTwith

50 - 95 (10 - 35)

1” NPT

required BPT/NPT adapter.

Chilled Water Return 1” NPT

Maximum Operating Pressure

bar (psi)

Exterior Finish Black Matte, Heat-Fused Powder Coat

Safety CSA Approved

145 (10)

73

Page 74

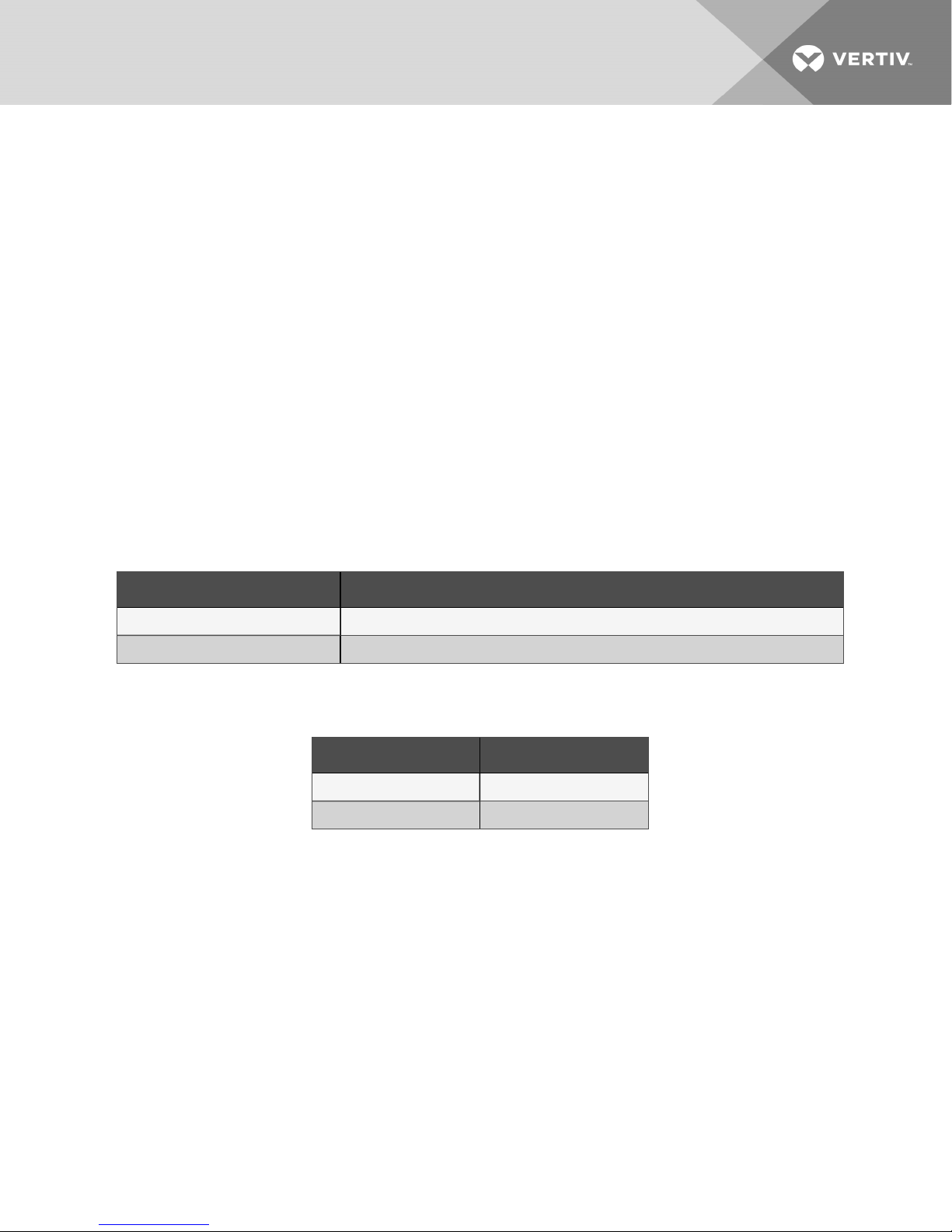

Table B.2 Replacement parts

Quantity

Part Name Part #

Replacement Parts

Swivel cover with slotted hole labeled "1" 080142908000001 1

Swivel cover with slotted hole labeled "2" 08042908000001 1

Swivel cover with slotted hole labeled "3" 080142928000001 1

Swivel cover with slotted hole labeled "4" 08014292800002 1

Self-Adhesive Foam 080144909 1

Condensate Hose Adapter 080090620 1

Spring Nuts 000782699 16

Diamond Nuts 000770869 7

Required

per Unit

GroundingWire

B.1 Capacity Performance for DCD35 Models

Figure B.1 DCD35 Performance @ 5.2 m3/h

000797999 1

000798169 1

74

Vertiv | Liebert® D CD™Installer/User G uide

Page 75

Figure B.2 DCD35 Performance @ 22.9 US GPM

Figure B.3 DCD35 Performance @ 3.5 m3/h

75

Page 76

Figure B.4 DCD35 Performance @ 15.4 US GPM

Figure B.5 DCD35 Performance @ 1.8 m3/h

76

Vertiv | Liebert® D CD™Installer/User G uide

Page 77

Figure B.6 DCD35 Performance @ 7.9 US GPM

Figure B.7 DCD35 Air-side pressure drop

77

Page 78

Figure B.8 DCD35 Water-side pressure drop

B.2 Capacity Performance for DCD50 Models

Figure B.9 DCD50 Performance @ 31.7 US GPM

78

Vertiv | Liebert® D CD™Installer/User G uide

Page 79

Figure B.10 DCD50 Performance @ 22.0 US GPM

Figure B.11 DCD50 Performance @ 12.9 US GPM

79

Page 80

Figure B.12 DCD50 Air-side pressure drop (H2O)

Figure B.13 DCD50 Air-side pressure drop (Pa)

80

Vertiv | Liebert® D CD™Installer/User G uide

Page 81

Figure B.14 DCD50 Water-side pressure drop (psi)

Figure B.15 DCD50 Water-side pressure drop (kPa)

81

Page 82

This page intentionally left blank

82

Vertiv | Liebert® D CD™Installer/User G uide

Page 83

Appendix C: Submittal Drawings