Page 1

Liebert®

CW™ ThermalManagementSystem

Installer/User Guide

340kW to 440 kW Capacity, 60Hz

Page 2

The information contained in this document is subject to change

without notice and may not be suitable for all applications. While

every precaution has been taken to ensure the accuracy and

completeness of this document, Vertiv assumes no responsibility

and disclaims all liability for damages resulting from use of this

information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods,

tools, and materials to be used in performing procedures not

specifically described in this document.

The products covered by this instruction manual are manufactured

and/or sold by Vertiv This document is the property of Vertiv and

contains confidential and proprietary information owned by Vertiv.

Any copying, use or disclosure of it without the written permission

of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered

trademarks of the respective companies. Any questions regarding

usage of trademark names should be directed to the original

manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent

section of this manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.VertivCo.com/en-us/support/ for additional assistance.

Vertiv |Liebert® CW™ Installer/User Guide

Page 3

TABLE OF CONTENTS

1 Important Safety Instructions 5

2 Nomenclature and Components 9

2.1 Liebert CW Model-number Nomenclature 9

2.2 Component Location 10

3 Planning Guidelines 11

3.1 Capacity and Physical Data 11

3.2 Shipping Dimensions and Unit Weights 12

3.3 Planning Dimensions 13

4 Pre-installation PreparationandGuidelines 15

4.1 Site Preparation 15

4.1.1 Preparing a Concrete Slab 15

5 Equipment Inspection and Handling 17

5.1 Hardware Kit 17

5.2 Rigging 18

6 Installing the Unit 21

6.1 Connecting Unit Sections (Recommended) 23

6.2 Routing the Filter-clog Pick-up Tube in the Plenum 24

7 Electrical Connections in the Unit 25

7.1 Fan High-voltage connections 25

7.2 Fan-control Low-voltage connections 25

7.3 Condensate-pump High- and Low-voltage Connections 27

8 Piping Requirements 29

8.1 Installing Water Supply and Return Piping 29

8.2 Installing Drain Traps on a Unit without a Condensate Pump 29

8.3 Installing Condensate-discharge Tubing on Units with a Condensate Pump 31

8.4 Flushing the Entire Water System before Start-up 32

Appendices 33

Appendix A: Technical Support and Contacts 33

Appendix B: Optional Configuration forLiebert®CW440Seismic Application 35

Appendix C: Submittal Drawings 37

Vertiv | Liebert® CW™ Installer/User Guide | 3

Page 4

Vertiv | Liebert® CW™ Installer/User Guide | 4

Page 5

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and

maintenance of the Liebert®CW. Read this manual thoroughly before attempting to install or operate this

unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit

and in this manual. Follow all installation, operation and maintenance instructions and all applicable

national and local building, electrical and plumbing codes.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the controller. The only way to ensure

that there is NO voltage inside the unit is to install and open a remote disconnect switch. Refer

to unit electrical schematic. Follow all local codes.

WARNING! Risk of improper moving. Can cause equipment damage, injury or death. Use only

lifting equipment that is rated for the unit weight by an OSHA-certified rating organization. The

center of gravity varies depending on the unit size and selected options. The slings must be

equally spaced on either side of the center of gravity indicator.

Shipping weights and unit weights are listed in the tables in Shipping Dimensions and Unit

Weights on page12. Use the center of gravity indicators on the unit to determine the position of

the slings.

WARNING! Risk of improper lifting. Can cause equipment damage, injury, or death. A spreader

bar or equivalent must be used when rigging to ensure the lifting force is completely vertical at

these fasteners. Lift points are rated for lifting this section only. Do not lift assembled sections

from these lift points.

WARNING! Risk of contact with high-speed, rotating fan impeller blades. Can cause injury or

death. Open all local and remote electric power-supply disconnect switches, verify with a

voltmeter that power is off, and verify that all fan impellers have stopped rotating before

working in the unit cabinet.

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment

damage, injury or death. Read all of the following instructions and verify that all lifting and

moving equipment is rated for the weight of the unit before attempting to move, lift, remove

packaging from or prepare the unit for installation.

1 ImportantSafety Instructions 5

Page 6

NOTICE

NOTICE

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

Risk of improper power-supply connection. Can cause equipment damage and loss of warranty

coverage.

Prior to connecting any equipment to a main or alternate power source (for example: back-up

generator systems) for start-up, commissioning, testing, or normal operation, ensure that these

sources are correctly adjusted to the nameplate voltage and frequency of all equipment to be

connected. In general, power-source voltages should be stabilized and regulated to within

±10% of the load nameplate nominal voltage. Also, ensure that no three-phase sources are

single-phased at any time.

Risk of piping-system corrosion and freezing fluids. Can cause leaks resulting in equipment

and very expensive building damage. Cooling coils and piping systems are at high risk of

freezing and premature corrosion. Fluids in these systems must contain the proper antifreeze

and inhibitors to prevent freezing and premature coil and piping corrosion. The water or

water/glycol solution must be analyzed by a competent local water treatment specialist before

start up to establish the inhibitor and antifreeze solution requirement and at regularly

scheduled intervals throughout the life of the system to determine the pattern of inhibitor

depletion.

The complexity of water/glycol solution condition problems and the variations of required

treatment programs make it extremely important to obtain the advice of a competent and

experienced water treatment specialist and follow a regularly scheduled coolant fluid system

maintenance program.

Water chemistry varies greatly by location, as do the required additives, called inhibitors, that

reduce the corrosive effect of the fluids on the piping systems and components. The chemistry

of the water used must be considered, because water from some sources may contain corrosive

elements that reduce the effectiveness of the inhibited formulation. Sediment deposits prevent

the formation of a protective oxide layer on the inside of the coolant system components and

piping. The water/coolant fluid must be treated and circulating through the system

continuously to prevent the buildup of sediment deposits and or growth of sulfate reducing

bacteria.

Proper inhibitor maintenance must be performed in order to prevent corrosion of the system.

Consult glycol manufacturer for testing and maintenance of inhibitors.

Commercial ethylene glycol, when pure, is generally less corrosive to the common metals of

construction than water itself. It will, however, assume the corrosivity of the water from which it

is prepared and may become increasingly corrosive with use if not properly inhibited.

We recommend installing a monitored fluid-detection system that is wired to activate the

automatic-closure of field-installed coolant-fluid supply and return shut-off valves to reduce

the amount of coolant-fluid leakage and consequential equipment and building damage. The

shut-off valves must be sized to close-off against the maximum coolant-fluid system pressure

in case of a catastrophic fluid leak.

6

Vertiv | Liebert® CW™ Installer/UserGuide

Page 7

NOTICE

NOTICE

NOTICE

Risk of frozen pipes and corrosion from improper coolant mixture. Can cause water leaks

resulting in equipment and building damage.

When the cooling unit or piping may be exposed to freezing temperatures, charge the system

with the proper percentage of glycol and water for the coldest design ambient temperature.

Automotive antifreeze is unacceptable and must NOT be used in any glycol fluid system. Use

only HVAC glycol solution that meets the requirements of recommended industry practices.

Risk of no-flow condition. Can cause equipment damage. Do not leave the water/coolant fluidsupply circuit in a no-flow condition. Idle fluid allows the collection of sediment that prevents

the formation of a protective oxide layer on the inside of tubes. Keep unit switched On and

water/coolant fluid-supply circuit system operating continuously.

Risk of clogged or leaking drain lines and leaking water-supply lines. Can cause equipment and

building damage.

This unit requires a water drain connection. Drain lines must be inspected at start-up and

periodically, and maintenance must be performed to ensure that drain water runs freely

through the drain system and that lines are clear and free of obstructions and in good

condition with no visible sign of damage or leaks. This unit may also require an external water

supply to operate.

Improper installation, application and service practices can result in water leakage from the

unit. Water leakage can result in catastrophic and expensive building and equipment damage

and loss of critical data center equipment.

NOTICE

NOTICE

NOTICE

Do not locate unit directly above any equipment that could sustain water damage.

We recommend installing a monitored fluid-detection system to immediately discover and

report coolant-fluid system and condensate drain-line leaks.

Risk of doorway/hallway interference. Can cause unit and/or structure damage. The unit may

be too large to fit through a doorway or hallway while on the skid. Measure the unit and

passageway dimensions, and refer to the installation plans prior to moving the unit to verify

clearances.

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a

height suitable to fit below the skid and/or unit to prevent exterior and/or underside damage.

Risk of improper storage. Can cause unit damage.

Keep the unit upright, indoors and protected from dampness, freezing temperatures and

contact damage.

1 ImportantSafety Instructions 7

Page 8

This page intentionally left blank

8

Vertiv | Liebert® CW™ Installer/UserGuide

Page 9

2 NOMENCLATURE AND COMPONENTS

This section describes the model-number configuration for Liebert® CW units and components.

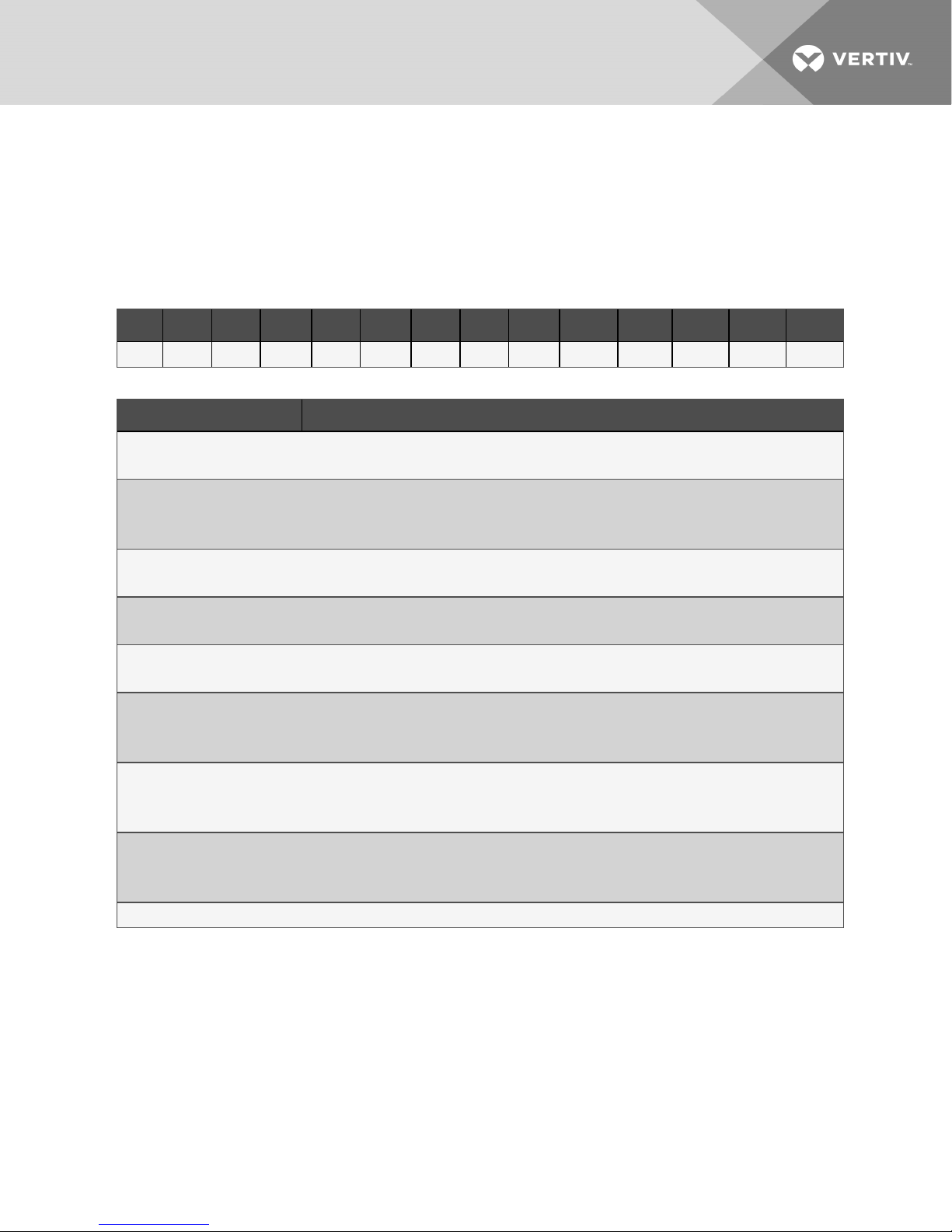

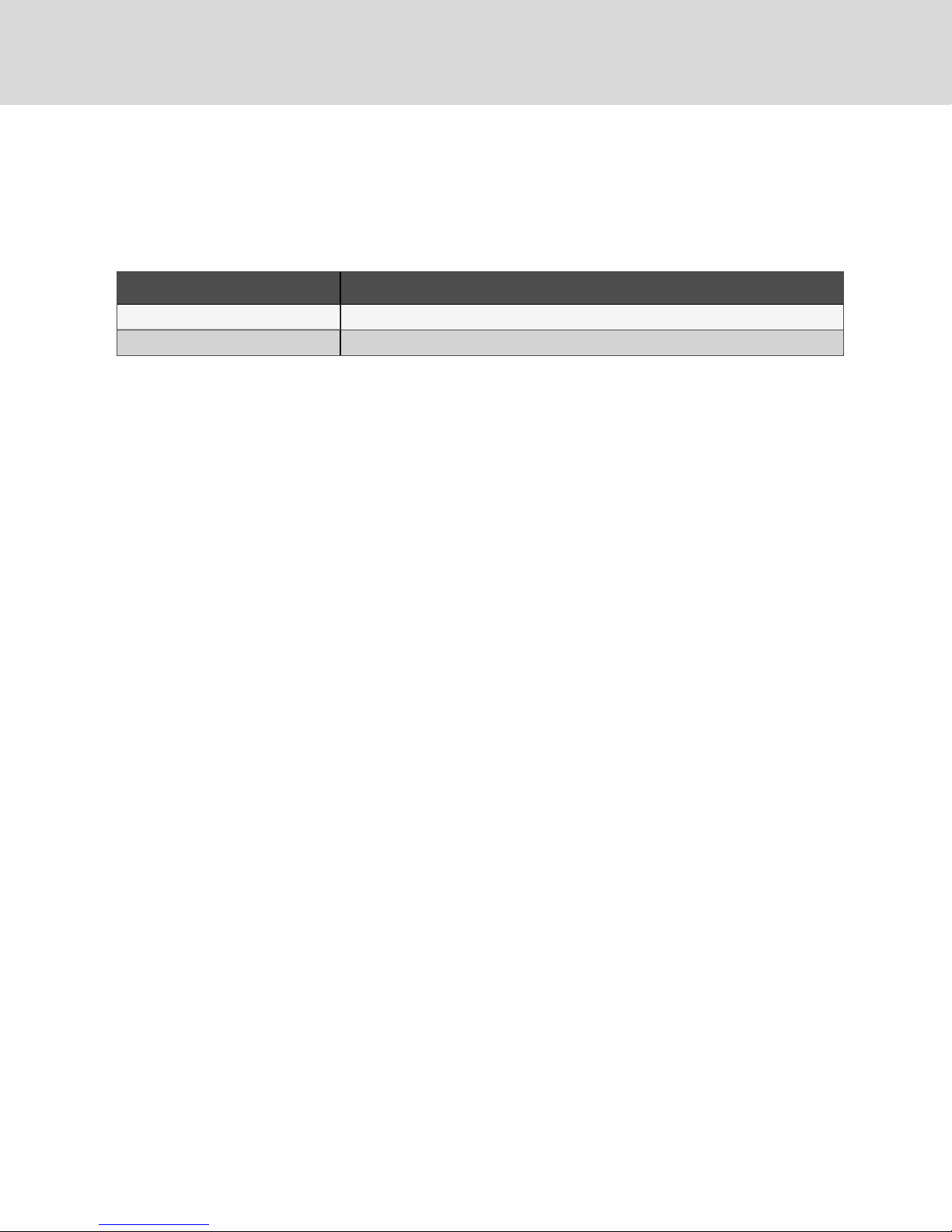

2.1 Liebert CW Model-number Nomenclature

Table 2.2 below describes each digit of the model number.

Table 2.1 CW Model Number

1 2 3 4 5 6 7 8 9 10 11 12 1 3 14

C W 0 2 6 D C S A 2 A X X X

Table 2.2 CW Model-number Digit Definitions

Digit Descript ion

Digits 1 and2 = Unit Family

CW = Liebert® CW floor-mounted, chilled-water unit

Digit 3, 4, 5 = Nominal Cooling Capacity, kW

340 = 340 kW

440 = 440kW

Digit 6 = Air Distribution

D = Downflow

Digit 7 = Cooling Type

C = Chilled water

Digit 8 = Fan Type

1 = EC fan

Digit 9 = Voltage

A = 460V - 3ph- 60Hz

B = 575V - 3ph - 60Hz

Digit 10 = Valve Type

2 = 2-way valve, standardpressure

1 = 2-way valve, high pressure

Digit 11 = Configuration Code

A-Z= Standard configuration

S = SFA

Digit 12, 13, 14= Factory configuration number

2 Nomenclature and Components 9

Page 10

2.2 Component Location

The unit component locations are described in the submittal documents included in the Submittal

Drawings on page37.

The following table lists the relevant documents by number and title.

Table 2.3 Component-location Drawings

Document Number Title

DPN003577 Component Location, CW340

DPN003574 Component Location, CW440

10

Vertiv | Liebert® CW™ Installer/UserGuide

Page 11

3 PLANNING GUIDELINES

3.1 Capacity and Physical Data

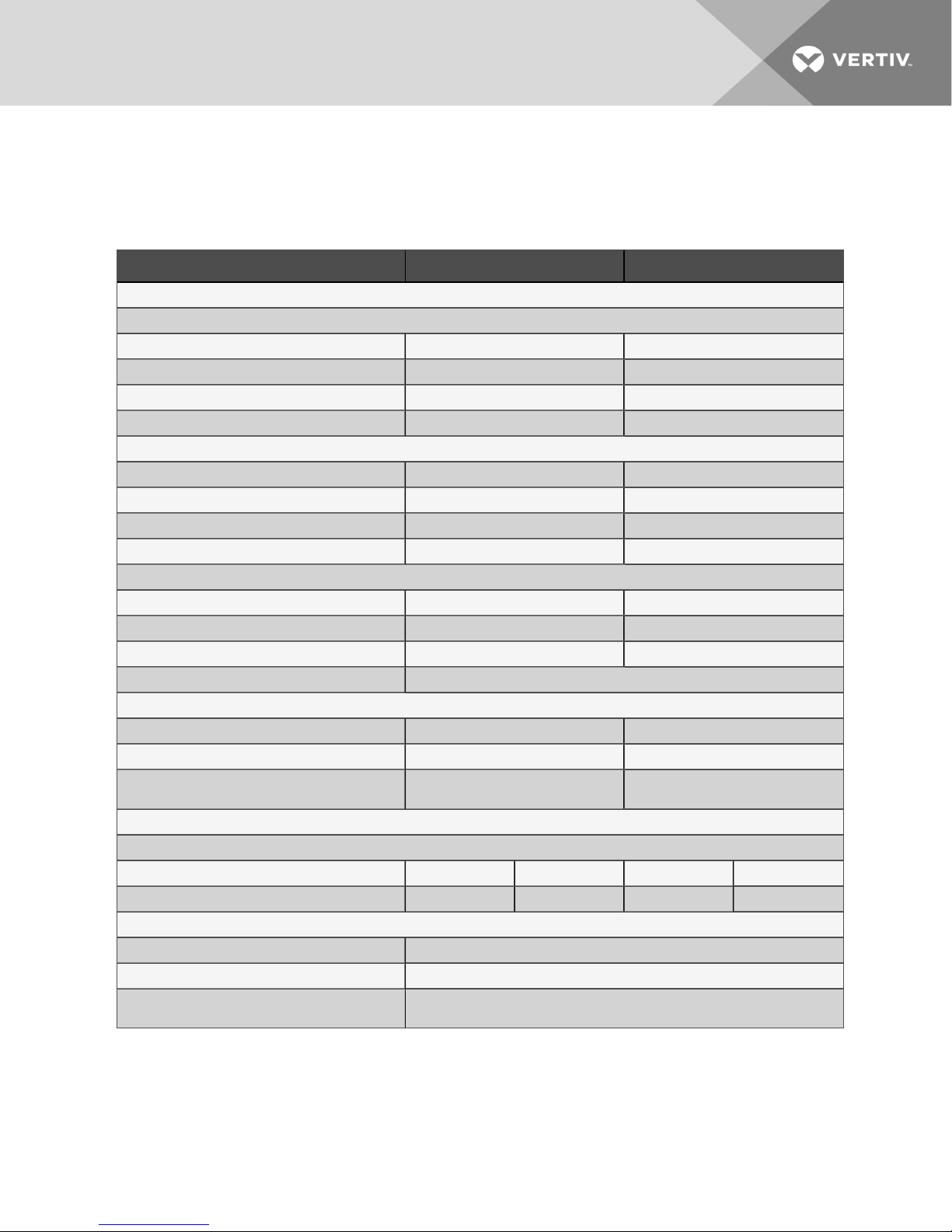

Table 3.1 Performance data, Standard Chilled-water Unit withECfans

Model No. 340 440

NET CAPACITY DATA kBTU/H (kW) BASED ON 45°F (7.2°C) ENTERING WATER, 10°F (5.5°C) WATER RISE

75°F DB, 61°F WB (23.9°C DB , 16.1°C WB) 45% RH

Total Capacity, kBTUH (kW) 1410 (431) 1758 (515)

Sensible Capacity, kBTUH (kW) 1184(346) 1525 (447)

Flow Rate, GPM (l/s) 300 (18.9) 385 (24.29)

Pressure Drop, ft (kPA) 44 (130.7) 29 (87.3)

Fan Data - EC Fans - Available in Downflow Orientations

NominalAir Volume, CFM (CMH) 45,000 (76,455) 60,000 (101,941)

Fan Motor, Maximum hp (kW), each 16.1 (12.0) 16.1(12.0)

Standard Ext. Static Pressure, inches of water (PA) 0.3 (74.7) 0.3 (74.7)

Number of fans 3 4

Chilled Water Coil

Face Area, ft2(m2) 96 (8.91) 130 (12.08)

Number of Rows 6 6

Face Velocity, FPM(m/s) 470 (2.39) 460 (2.34)

Chilled Water Valves Maximum design water pressure 400PSI (2757 kPa)

Valve Actuator, Sensors and Body

Valve CV 70 130

Valve Size, in. 3.0 3.0

2-wayValve (optional)Close-off Pressure, PSI

(kPA)

Filter Section

Disposable Type - MERV8 (standard) or MERV11 (option)

NominalSizes, in. 20 x 24 x 4 18 x 24 x 4 20 x24 x 4 18 x 24 x 4

Quantity of each 18 9 22 11

Connection Sizes

Chilled Water (grooved, black pipe) 4 in.

Condensate Drain 2 x 1-1/4 in.

Condensate Discharge (when supplied with pump),

O.D.

100 (689) 100 (689)

1/2-in. compression

3 Planning Guidelines 11

Page 12

Table 3.2 Electrical data—with EC fans, 460

V/60 Hz

Model Qty. fans Voltage No reheat/No humidifier

FLA 46.5

CW340 3

CW440 4

WSA 50.4

OPD 60

FLA 62.0

WSA 65.9

OPD 80.0

3.2 Shipping Dimensions and Unit Weights

Table 3.3 Shipping Dimensions and weights for CW340

Model/Skid* Dimensions L x W x H, in. (mm) Weight, lb (kg)

Coil 190 x 70 x 87 (4826 x 1778x 2210) 4034 (1829)

Fan and Filter box 150 x 70 x 87 (3810 x 1778x 2210) 3027 (1373)

*Each system ships on two skids. Skid 1 is the coil section. Skid 2 isthe fan/filter-box sections.

Table 3.4 Shipping Dimensions and weights for CW440

Sections* Dimensions L x W x H, in. (mm) Weight, lb (kg)

Coil 190 x 70 x 87 (4826 x 1778x 2210) 4528 (2053)

Fan and Filter box 190 x 70 x 87 (4826 x 1778x 2210) 3896 (1767)

*Each system ships on two skids. Skid 1 is the coil section. Skid 2 isthe fan/filter-box sections.

12

Vertiv | Liebert® CW™ Installer/UserGuide

Page 13

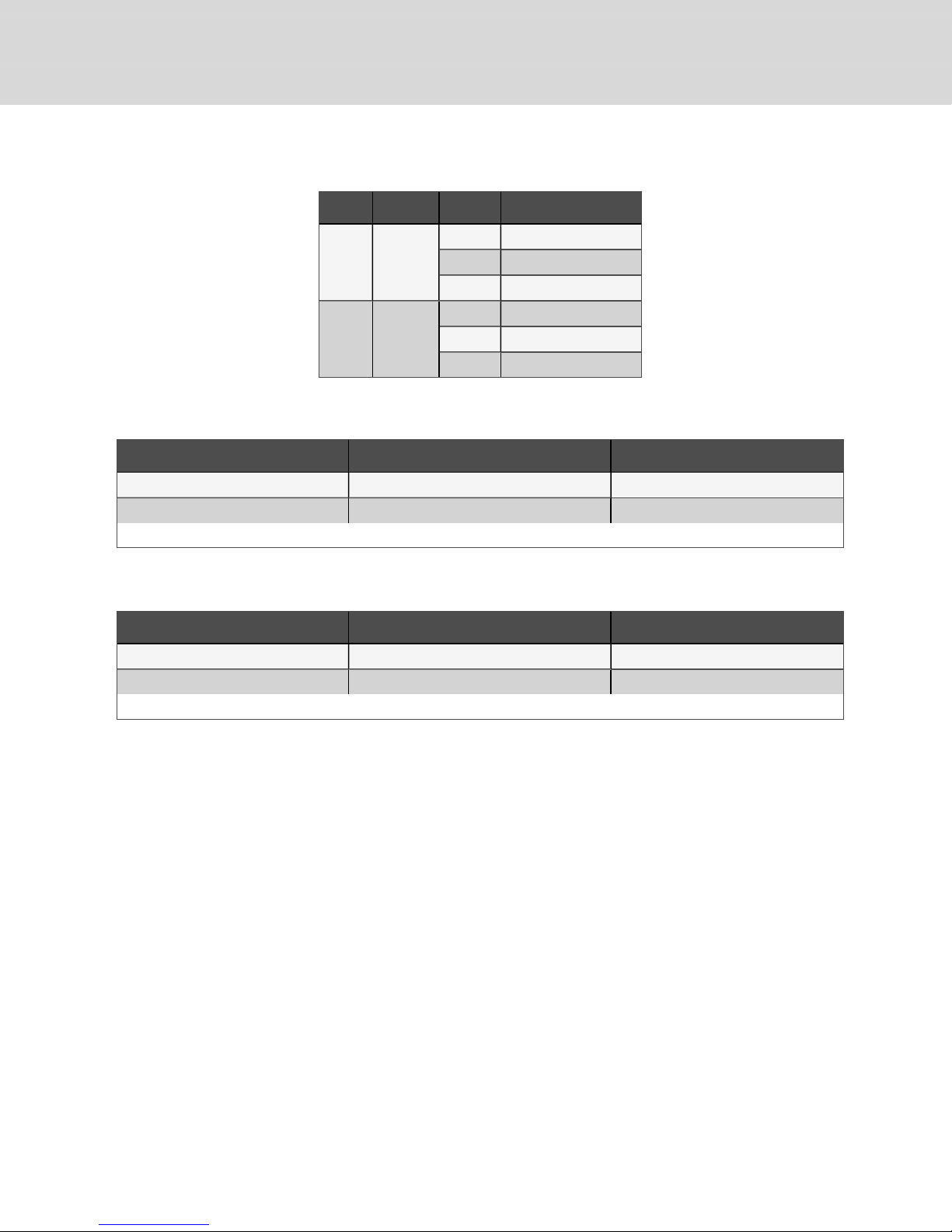

3.3 Planning Dimensions

The unit, floor stand, and plenum dimensions are described in the submittal documents included in the

Submittal Drawings on page37.

The following table lists the relevant documents by number and title.

Table 3.5 Dimension Planning Drawings

Document Number Title

Downflow Units with EC Fans

DPN003561 Cabinet DimensionalData, CW340 with filter plenum

DPN003569 Cabinet DimensionalData, CW440 with filter plenum

Floor Stands for Units with EC Fans

DPN003964 Floorstand DimensionalData, Downflow Models, CW340

DPN003570 Floorstand D imensionalData, Downflow Models, CW440

3 Planning Guidelines 13

Page 14

Table 3.5 Dimension Planning Drawings (continued)

Document Number Title

Plenums for Units with EC Fans

DPN003964 Optionalrear-ducted EC fan sec tion for CW340

DPN003676 Optionalrear-ducted EC fan section for CW440

14

Vertiv | Liebert® CW™ Installer/UserGuide

Page 15

4 PRE-INSTALLATION PREPARATIONANDGUIDELINES

NOTE: Before installing unit, determine whether any building alterations are required to run piping,

wiring and ductwork. Follow all unit dimensional drawings and refer to the submittal engineering

dimensional drawings of individual units for proper clearances.

Refer to Table 2.2 on page9, and submittal drawings to determine the type of system being installed

and anticipate building alterations, piping and ductwork needed.

The unit dimensions, pipe-connection locations, and piping schematics are described in the submittal

documents included in the Submittal Drawings on page37.

• Verify that the floor is level, solid and sufficient to support the unit. See Table 3.3 on page12

for unit weights.

• Confirm that the room is properly insulated and has a sealed vapor barrier.

• For proper humidity control, keep outside or fresh air to an absolute minimum (less than 5% of

total air circulated in the room).

• Do not install a Liebert® CW in an alcove or at the end of a long, narrow room.

• Install the units as close as possible to the largest heat load.

• Allow at least the minimum recommended clearances for maintenance and service. See the

appropriate submittal drawings for dimensions.

• We recommend installing an under-floor water detection system. Contact your Vertiv

representative for information.

4.1 Site Preparation

Prepare the site for installation prior to arrival and unloading of the unit.

• If installing the unit on a concrete slab or housekeeping pad, sweep the concrete clean and

mark the final position of the unit(s) on the slab.

• Verify that all required clearances as specified by Vertiv are met.

• Mark the direction of the final unit placement to avoid accidental reversal of the unit.

• Protect stub-outs for electric conduit and any other projections against damage and clearly

mark their locations.

• Locate and mark the high point on the slab. This step is critical for the placement of multiple,

joined units.

• If installing on a structural-steel support structure, verify suitability of the supports beneath

the unit(s).

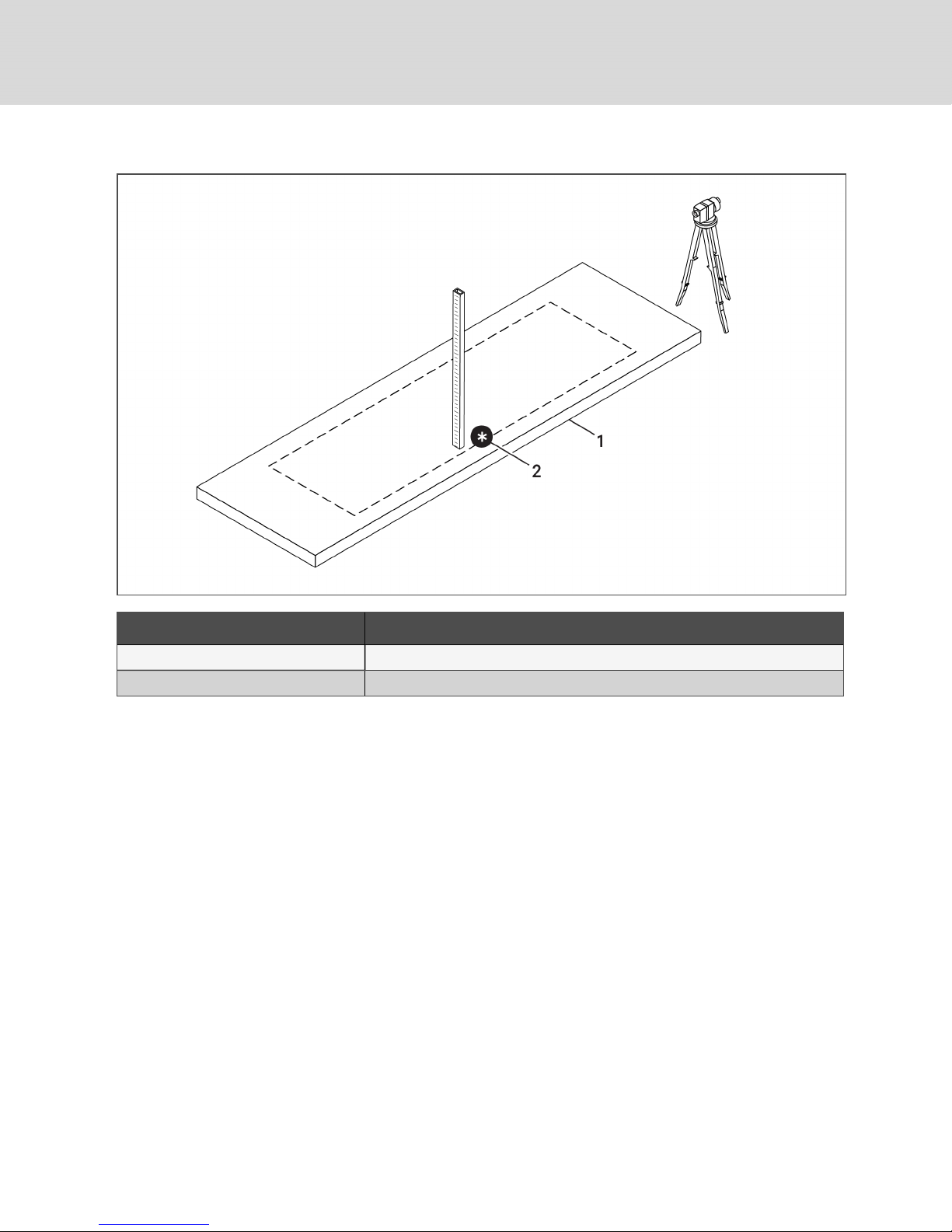

4.1.1 Preparing a Concrete Slab

1. Sweep the slab broom clean.

2. Lay out the final location of the unit on the slab, using either chalk line or tape, see Figure 4.1

on the next page.

3. Using a laser level or optical level, locate the high point on the slab and mark it, see Figure 4.1

on the next page.

4 Pre-installation PreparationandGuidelines 15

Page 16

Figure 4.1 Unit and high-point marking on concrete slab

Item Description

1 Concrete slab

2 High point

16

Vertiv | Liebert® CW™ Installer/UserGuide

Page 17

5 EQUIPMENT INSPECTION AND HANDLING

SAFETY INFORMATION

WARNING! Risk of top-heavy unit falling over. Improper handling can cause equipment

damage, injury or death. Read all of the following instructions and verify that all lifting and

moving equipment is rated for the weight of the unit before attempting to move, lift, remove

packaging from or prepare the unit for installation. Unit weights are specified in Table 3.3 on

page12.

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause

injury. Only properly trained and qualified personnel wearing appropriate, OSHA-approved PPE

should attempt to move, lift, remove packaging from or prepare the unit for installation.

NOTICE

Risk of passageway interference. Can cause unit and/or structure damage. The unit may be

too large to fit through a passageway while on or off the skid. Measure the unit and passageway

dimensions, and refer to the installation plans prior to moving the unit to verify clearances.

NOTICE

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a

height suitable to fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Keep the unit upright, indoors and protected from dampness,

freezing temperatures and contact damage.

Upon arrival of the unit and before unpacking:

• Verify that the labeled equipment matches the bill of lading.

• Carefully inspect all items for visible or concealed damage.

• Report damage immediately to the carrier and file a damage claim with a copy sent to Vertiv or

to your sales representative.

• For initial access use a 7/32-in. Allen wrench for panel removal.

Equipment Recommended for Handling the Unit:

• Forklift

• Slings

• Spreader bars

5.1 Hardware Kit

The coil section of the unit ships with a hardware kit containing materials for reassembly of the unit

sections.

• 1-in. wide adhesive-backed foam (1/2-in. wide for seismic) for gasketing between unit sections

• 1-in. wide adhesive-backed foam for panel gasketing at the field-weld locations of sections

(seismic only)

5 EquipmentInspection and Handling 17

Page 18

5.2 Rigging

WARNING! Risk of improper lifting. Can cause equipment damage, injury, or death. A spreader

bar or equivalent must be used when rigging to ensure the lifting force is completely vertical at

these fasteners. Lift points are rated for lifting this section only. Do not lift assembled sections

from these lift points.

Vertiv does not provide rigging. Refer to the following for recommended rigging process.

• Use proper rigging equipment to make sure attachment and lifting at the designated lift points

is in the vertical direction. See Figure 5.2 on the facing page, and Figure 5.3 on page20, for

lift-point locations on the sections.

• All sections have four lift points to use rigging fasteners supplied.

• One rigging-fastener kit provided with fan and filter-section skid. See Figure 5.1 below, for

installation.

• Rigging fasteners are pre-installed on coil section, Figure 5.2 on the facing page.

NOTE: The rigging fastener kit provided with the fan and filter sections include additional hardware

and instructions for installation and use. See instructions included with the rigging-fastener kit. Refer

to Figure 6.2 on the next page for fastener location and lift points on the coil section.

Figure 5.1 Rigging-fastener installation

Item Description

1 Eye nut, 1/2-13 thread

2 Lock washer, 1/2-in.

3 Flat washer, 1/2-in.

4 1-in. x 1-in. tube

5 Screw, 1/2-13 x4 in.

18

Vertiv | Liebert® CW™ Installer/UserGuide

Page 19

Figure 5.2 Lift points on the coil section

Item Description

1 Coilsection

5 EquipmentInspection and Handling 19

Page 20

Figure 5.3 Lift points on filter-plenum, plenum extension, and fan sections

Item Description

1 Plenum extension

2 Filter plenum

3 Fan section

20

Vertiv | Liebert® CW™ Installer/UserGuide

Page 21

6 INSTALLING THE UNIT

Referring to Figure 6.1 on the next page, perform the following steps:

1. Referencing the highest point, set the fan section on marked location and level it with steel

shims.

2. Install additional steel shims, spaced not more than 6 ft apart.

3. Apply 1-in. (25-mm) wide [1/2-in (13 mm) wide on CW440 seismic installations] adhesivebacked foam (factory-supplied) to the inner-most edge of the mating surface of the bottom

section.

4. Once the section is in place, remove rigging fasteners (shown in Rigging on page18) before

stacking next section on top of lower section.

5. Swing the upper, split-unit section within 2 to 3 inches of the first section.

6. Make final adjustments to align the sections, and lower the upper section onto the section(s)

below.

7. Repeat steps 3 to 5 to place the filter and the (optional) plenum sections, see Figure 6.2 on

page23, for plenum placement.

6 Installingthe Unit 21

Page 22

Figure 6.1 Placing the unit and upper sections

Item Description

1 Connection locations

2 Bolt, 1/2-13 x 7.5in.

3 Flat washer, 1/2-in.

4 Lock nut, 1/2-13 thread

5 Steel shims under allliftingpoints

6 Established high point

7 Concrete slab or Housekeeping pad

8 Installfactory-supplied foam gasketing

22

Vertiv | Liebert® CW™ Installer/UserGuide

Page 23

Figure 6.2 Placing the (optional) plenum

Item Description

1 Connection locations

2 Bolt, 1/2-13 x 7.5in.

3 Flat washer, 1/2-in.

4 Lock nut, 1/2-13 thread

5 Installfactory-supplied foam gasketing

6 Optional, 18-in. decorative plenum

6.1 Connecting Unit Sections (Recommended)

Secure the coil-section frame to the fan-base frame and the filter-section frame to the coil-section frame.

8 locations on the CW340 or 10 locations on the CW440 are provided to connect the 3unit sections. If a

plenum option is included, 12locations on the CW340 or 14locations on the CW440 are provided.

The following is the factory-supplied hardware required (per location):

• Bolts 1/2 in. x 7.5 in.

• Nut hex, 1/2 in.

• (2) Flat washers, American National Standard Series W, type A, plain washers

6 Installingthe Unit 23

Page 24

6.2 Routing the Filter-clog Pick-up Tube in the Plenum

The pressure pick-up tube must be routed and mounted for proper operation of the filter-clog alarm. The

tube is factory-connected to the filter-clog switch in the low-voltage control box of the coil sections.

1. Locate the pick-up tube, which is coiled outside the low-voltage control box in the coil section.

2. Uncoil and route the tube into the filter plenum through the hole labeled "Filter Clog Sample

Tube" on the filter slide rail, see Figure 6.3 below.

Figure 6.3 Pressure tube routed from filter-clog switch into the filter plenum

Item Description

1 Filter-clog-sample-tube hole

2 Pressure pick-up tube

24

Vertiv | Liebert® CW™ Installer/UserGuide

Page 25

7 ELECTRICAL CONNECTIONS IN THE UNIT

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power-supply

disconnect switches, verify with a voltmeter that power is Off and wear appropriate,

OSHA-approved personal protective equipment (PPE) per NFPA 70E before working within the

electric control enclosure. Failure to comply can cause serious injury or death. Customer must

provide earth ground to unit, per NEC, CEC and local codes, as applicable. Before proceeding

with installation, read all instructions, verify that all the parts are included and check the

nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the “Unit Off” mode. Some internal components require

and receive power even during the “Unit Off” mode of the controller. The only way to ensure

that there is NO voltage inside the unit is to install and open a remote disconnect switch. Refer

to unit electrical schematic. Follow all local codes.

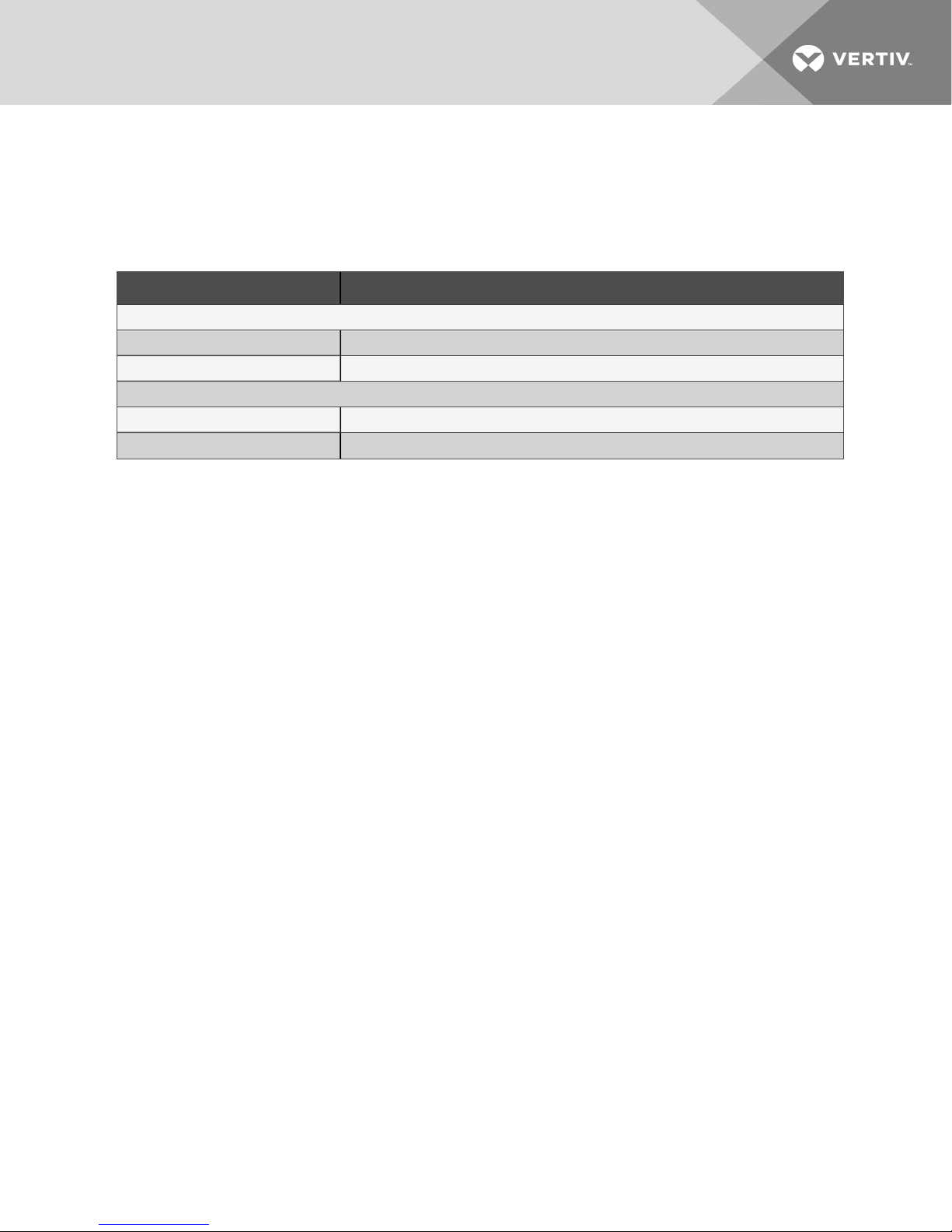

The electrical connections are described in the submittal documents included in the Submittal Drawings

on page37.

The following table lists the relevant documents by number and title.

Table 6.1 Electrical Field-connection Drawings

Document Number Title

DPN003601 ElectricalField Connections, D ownflow, CW340 and CW440

7.1 Fan High-voltage connections

Unshielded wiring is used for ON / OFF switching of the fans.

• Locate the high-voltage (AC power for fans) wires that are coiled and secured on top of the

lower section.

• Refer to the wire and fan numbers listed in the submittal drawing and 7.1 above, to connect

the wires from the lower section to the upper section of the unit.

• Use the quick-connect sockets located at the base of the coil section to connection to the

high-voltage panel.

7.2 Fan-control Low-voltage connections

Shielded wiring is used for analog-control of the fans.

• Locate the low-voltage (control wiring for fans) wires that are coiled and secured on top of the

lower section.

• Connect the wires from the lower section to the upper section of the unit, see Figure 6.4 on

the next page.

7 Electrical Connectionsin the Unit 25

Page 26

Figure 6.4 High- and Low-voltage connections in the fan section

Item Description

1 RS-485 connection

2 High-voltage connections. CW440 connec tions shown. CW340 has 3 quick-connect sockets.

26

Vertiv | Liebert® CW™ Installer/UserGuide

Page 27

7.3 Condensate-pump High- and Low-voltage Connections

The coil and fan sections are factory-wired with a quick-connect connector for the condensate pump.

After the coil section is lowered and secured to the fan section, connect the pump harness from the fan

section to the plug provided in the under-side of the coil section, see Figure 6.5 below.

Figure 6.5 Condensate-pump harness connection

Item Description

1 High-voltage power connection

2 Wire harness from EP

3 Low-voltage alarm connection

4 Condensate pump

5 Rear-side view

7 Electrical Connectionsin the Unit 27

Page 28

This page intentionally left blank

28

Vertiv | Liebert® CW™ Installer/UserGuide

Page 29

8 PIPING REQUIREMENTS

Factory-installed piping brackets must not be removed. Field-installed piping must be installed in

accordance with local codes and must be properly assembled, supported, isolated and insulated. Avoid

piping runs through noise-sensitive areas, such as office walls and conference rooms.

Refer to specific text and detailed diagrams in this manual for other unit-specific piping requirements.

All piping below the elevated floor must be located so that it offers the least resistance to air flow. Careful

planning of the piping layout under the raised floor is required to prevent the air flow from being blocked.

When installing piping on the subfloor, we recommend that the pipes be mounted in a horizontal plane

rather than stacked one above the other. Whenever possible, the pipes should be run parallel to the air

flow.

The pipe connection locations, piping general arrangement and schematics are described in the

submittal documents included in the Submittal Drawings on page37.

The following tables list the relevant documents by number and title.

Table 7.1 Piping Connection Drawings

Document Number Title

DPN003596 Piping Schematic, Downflow, CW340 and CW440

8.1 Installing Water Supply and Return Piping

We recommend installing an additional valve in a water-supply pipe to flush the system prior to start-up.

The additional valve may also provide water for periodic maintenance that includes cleaning the coils.

• Install all water-supply and water-return lines in accordance with industry best practices and

all local codes.

• The cooling water pipes are grooved to receive field-supplied, grooved pipe connectors.

• Follow the instructions provided by the manufacturer of the grooved pipe connectors for

correct installation and torque requirements of the assembly bolts.

8.2 Installing Drain Traps on a Unit without a Condensate Pump

Install field-fabricated drain traps at all trap locations on the unit. Drain traps are essential to allow water

to flow out of the drain pan(s). More importantly, when there is negative internal static within the unit, the

trap prevents outdoor air from being pulled into the unit and splashing water inside the unit. Drain-trap

design is dependent on the total static pressure (TSP). We recommend installing threaded plugs at

several locations to permit periodic cleaning and filling of the trap.

• See Figure 7.1 on the next page, for the location and number of traps.

• Drain-trap materials are installer-provided.

• Use industry best practices and follow all local codes when fabricating the traps.

• Figure 7.2 on the next page, shows a typical drain-trap design or, if a negative pressure trap is

needed, see Figure 7.3 on page31, and observe the following:

• Dimension “H” equals the Total Static Pressure in inches of water column plus a minimum

of one inch.

• The outlet side of the drain trap should have a water column equal to one-half of

dimension “H.”

• Use materials and fittings as local conditions dictate.

• Because the trap must be filled with water at all times, consider fabricating the trap from

metal so that an electric heat tape can be installed to prevent freezing.

8 PipingRequirements 29

Page 30

Figure 7.1 Drain-trap locations

Figure 7.2 Typical Drain-trap construction

Item Description

1 Condensate-discharge pipe from unit

2 Coupling (threaded socket)

3 Nipple

4 Cross

5 Threaded plugs (for clean-out)

6 Bend

7 Tee

8 Vacuum breaker

9 Sloped drain pipe

30

Vertiv | Liebert® CW™ Installer/UserGuide

Page 31

Figure 7.3 Negative-pressure drain-trap construction

Item Description

1 Condensate drain pan

2 Condensate-discharge pipe from unit/drain pan

3 One-half of dimension "H"

4 TotalStatic Pressure in inches of water column plus a minimum of one inch.

8.3 Installing Condensate-discharge Tubing on Units with a Condensate Pump

On units with a condensate pump, the factory-mounted pump requires field assembly to the two

condensate connections on the coil. After the unit is assembled, see Figure 7.4 on the next page, to

connect the piping to the pump. The pump-discharge connection is ½-in. copper compression. The

factory provides the compression a ring and nut for the discharge tube attached to the drain line into the

pump.

• Condensate pump (60 Hz): Condensate pump is rated for approximately 400 gph at 10 feet

total head.

• Condensate pump (50 Hz): Condensate pump is rated for approximately 315 gph at 10 feet

total head.

• Size the piping based on available condensate head.

• Condensate-pump discharge (drain) line must comply with all applicable codes.

8 PipingRequirements 31

Page 32

Figure 7.4 Field connections for the factory-piped condensate pump

Item Description

1 Connection locations

2 Condensate pump

8.4 Flushing the Entire Water System before Start-up

Both the pressurized water system and the drain system must be flushed before start-up:

• Flush all fresh-water lines before connecting to the cooling coils until the water runs clear and

all debris is flushed out.

• Flush again after the fresh-water lines are connected to the coils to clear any debris from the

cooling coils. Do not flush debris from the water lines into the coils.

• Thoroughly flush the drain system by running clean water through all drain pans and drain

lines, then visually inspect drain pans to verify that all debris is removed.

32

Vertiv | Liebert® CW™ Installer/UserGuide

Page 33

APPENDICES

Appendix A: Technical Support and Contacts

A.1 Technical Support/Service in the United States

Vertiv™ Corporation

24x7 dispatch of technicians for all products.

1-800-543-2378

Liebert® Thermal Management Products

1-800-543-2778

Liebert® Channel Products

1-800-222-5877

Liebert® AC and DC Power Products

1-800-543-2378

A.2 Locations

United States

Vertiv Headquarters

1050 Dearborn Drive

Columbus, OH, 43085, USA

Europe

Via Leonardo Da Vinci 8 Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

Asia

7/F, Dah Sing Financial Centre

3108 Gloucester Road

Wanchai, Hong Kong

33

Page 34

This page intentionally left blank

34

Vertiv | Liebert® CW™ Installer/UserGuide

Page 35

Appendix B: Optional Configuration forLiebert®CW440Seismic Application

Electrical wiring, conduit, and/or other connections to the equipment is the responsibility of others. Data

and recommendations are supplied in the Submittal Drawings on page37,.

The following table lists the relevant documents by number and title.

Table B.1 Seismic-application Drawings

Document Number Title

DPN003636 Seismic Data for CW440D

35

Page 36

This page intentionally left blank

36

Vertiv | Liebert® CW™ Installer/UserGuide

Page 37

Appendix C: Submittal Drawings

The submittal drawings are in the order of document part number (DPN). Table C.1 below, groups the

drawings by topic/application.

Table C.1 Submittal-drawings Contents

Document Number Title

Component Location

DPN003577 Component Location, CW340

DPN003574 Component Location, CW440

Planning Dimensions - Downflow Units with EC Fans

DPN003561 Cabinet DimensionalData, CW340 with filter plenum

DPN003569 Cabinet DimensionalData, CW440 with filter plenum

Planning Dimensions - Floor Stands for Units with EC Fans

DPN003964 Floorstand DimensionalData, Downflow Models, CW340

DPN003570 Floorstand D imensionalData, Downflow Models, CW440

37

Page 38

Table C.1 Submittal-drawings Contents (continued)

Document Number Title

Planning Dimensions - Plenums for Units with EC Fans

DPN003964 Optionalrear-ducted EC fan sec tion for CW340

DPN003676 Optionalrear-ducted EC fan section for CW440

Piping Connections - Downflow Units with EC Fans

DPN003596 Piping Schematic, Downflow, CW340 and CW440

Electrical Connections - Downflow Units

DPN003601 ElectricalField Connections, D ownflow, CW340 and CW440

Seismic Anchorage Data

DPN003636 Seismic Data for CW440D

38

Vertiv | Liebert® CW™ Installer/UserGuide

Page 39

56"

Approximate Dry Weight

1422mm

OPENING

LIEBERT CW

CABINET DIMENSIONAL DATA

CW340 & FILTER PLENUM (plenum shipped separately)

122"

3099mm

OPENING

60"

1524mm

Note:

1. Filters are accessible

through front and top of unit

only.

2. Electrical connections

can be made from top

or bottom of unit.

102"

2591mm

TOTAL

HEIGHT

31"

788mm

FILTER

PLENUM

71"

1803mm

BASE

UNIT

1 9/16"

39mm

TYP.

TOP VIEW

138 3/4"

3525mm

FRONT VIEW

Base Unit

60"

1524mm

CW340

1 3/8"

35mm

HANDLE

Filter Plenum

(shipped separately)

Section lb. (kg)

Base Unit 3480 (1578)

Filter Plenum 595 (270)

DPN003561

Page :1 /1

Form No.: DPN001040_REV4

Striated area indicates the recommended

minimum clearance to be provided for

component access.

36"

914mm

Shaded area indicates the required minimum clearance

below the unit for the floorstands/fans to be installed.

REV : 3

REV DATE : 2/18

36"

914mm

Page 40

LIEBERT CW

Approximate Dry Weight

CABINET DIMENSIONAL DATA

56"

1422mm

OPENING

105 1/2"

2679mm

TOTAL

HEIGHT

34 1/2"

877mm

FILTER

PLENUM

CW440 & FILTER PLENUM (plenum shipped separately)

163"

4140mm

OPENING

Note:

1. Filters are accessible

through front and top of unit

only.

2. Electrical connections

can be made from top

or bottom of unit.

2 11/16"

69mm

TYP.

TOP VIEW

180"

4572mm

5/16"

8mm

BEZEL

58"

1473mm

1 5/16"

34mm

HANDLE

60"

1524mm

71"

1803mm

BASE

UNIT

Section lb. (kg)

Base Unit 3828 (1736)

Filter Plenum 742 (336)

FRONT VIEW

Striated area indicates the recommended

minimum clearance to be provided for

component access.

Shaded area indicates the required minimum clearance

below the unit for the floorstand/fans to be installed.

Base Unit

60"

1524mm

CW440

Filter Plenum

shipped separately

36"

914mm

36"

914mm

DPN003569

Page :1 /1

Form No.: DPN001040_REV4

REV : 3

REV DATE : 2/18

Page 41

LIEBERT CW

FAN SECTION DIMENSIONAL DATA

CW440 MODEL

Piping access area

(See Note 5)

43"

1092mm

TOP VIEW

180"

4572mm

38 1/4"

972mm

38 1/4"

972mm

38 1/4"

972mm

FRONT VIEW PANELS REMOVED FOR CLARITY

Attachment

Point

Attachment

Point

1"X1"X3" long steel tube

38 1/4"

972mm

Typ. (6) places

10"

254mm

Attachment

Point

PANELS REMOVED FOR CLARITY

60"

1524mm

OVERALL

RIGHT SIDE

BOTTOM VIEW

FANS REMOVED FOR CLARITY

Attachment

Point

Typ.

Attachment

Point

86"

2184mm

Typ.

10 1/2"

267mm

Typ.

Attachment

Point

NOTE:

1. This fan section is designed for 36" (914mm) raised floor height and can accomodate floors between 34" - 43" (864mm - 1092mm) high.

3. The fan section is not symmetrical and its orientation to the Liebert CW is critical for proper installation.

3. The EC fans must be field wired into connectors inside of the unit.

4. The EC fans are removed out the front of the fan section, and there must be clearance in front of fan section to be able to service fans (See DPN003569).

5. The fan section may be ordered with the piping access area at the opposite end, and the fans oriented accordingly.

73"

1854mm

DPN003570

Page :1 /1

Form No.: DPN001040_REV4

REV : 2

REV DATE : 1/17

Page 42

LIEBERT CW

COMPONENT LOCATION DIAGRAM

CW440

3

4

1

2

1. iCom Control Display

2. Electric Box

3. Filters

4. Coil

5. Disconnect

6. EC Fans

5

Note:

1. Unit with Plenum (shipped separately) attached shown

in order to provide view of filters.

2. Some panels removed from views for clarity.

6

DPN003574

Page :1 /1

Form No.: DPN001040_REV4

REV : 2

REV DATE : 1/17

Page 43

LIEBERT CW

COMPONENT LOCATION DIAGRAM

CW340

3

4

1

2

5

1. iCom Control Display

2. Electric Box

3. Filters

4. Coil

5. Disconnect

6. EC Fans

Note:

1. Unit with Plenum (shipped separately) attached shown

in order to provide view of filters.

2. Some panels removed from views for clarity.

DPN003577

Page :1 /1

Form No.: DPN001040_REV4

6

REV : 2

REV DATE : 1/17

Page 44

LIEBERT CW

POINT

DESCRIPTION

X in. (mm)

Y in. (mm)

CONNECTION SIZE/OPENING

Condensate Drain

1-1/4" NPT Female

(w/ optional pump)

1/2" O.D. Cu Hose Barb

Condensate Drain

1-1/4" NPT Female

(w/ optional pump)

1/2" O.D. Cu Hose Barb

CWS1

2-way Chilled Water Supply

51-1/4 (1302)

CWS2

2-way Chilled Water Supply

16-1/2 (419)

CWR1

2-way Chilled Water Return

19-3/8 (492)

CWR2

2-way Chilled Water Return

24-1/2 (622)

HV1

Electrical Connection (High Voltage)

5-5/16 (135)

HV2

Electrical Connection (High Voltage)

10-1/16 (256)

HV3

Electrical Connection (High Voltage)

10-1/4 (260)

HV4

Electrical Connection (High Voltage)

6-1/2 (165)

LV1

Electrical Connection (Low Voltage)

11-15/16 (303)

LV2

Electrical Connection (Low Voltage)

9-11/16 (246)

LV3

Electrical Connection (Low Voltage)

7-7/16 (189)

LV4

Electrical Connection (Low Voltage)

11-1/4 (286)

LV5

Electrical Connection (Low Voltage)

9-3/8 (238)

LV6

Electrical Connection (Low Voltage)

7-3/8 (187)

LV7

Electrical Connection (Low Voltage)

5-1/2 (140)

1-1/4" (32mm) [1-5/8" (41mm) /

PRIMARY CONNECTION LOCATIONS

CW340 & CW440

SECTION A-A

X

Top Piping Option Connection Locations

CWS1

CWR1

HV1

HV2

DETAIL A

LV1

LV2

LV3

LV4

LV5

HV3

CWS2

CWR2

DETAIL B

A

B

Y

0

SECTION B-B

X

Bottom Piping Option Connection Locations

CD1

SECTION C-C

Notes:

1 All views shown in standard configuration. CW340 & CW440 can be ordered with piping and

electrical connection locations located on left end of unit with fan sections adjusted as required.

LV7

2. If unit is ordered with Piping & Electrical Connection locations on the left side, then the callouts &

LV6

dimensions shown in this drawing will be reversed.

3. All "X" & "Y" dimensions are from front right corner of unit as shown. If unit is ordered with Piping &

HV4

Electrical Connections on left side, then dimensions are from front left corner.

4. Knockout diameters are concentric (see Detail A & B).

5. Field pitch Condensate Drain line a minimum of 1/8" (3.2mm) per 12" (305mm). All units with a

gravity drain require an external condensate trap. Select appropriate drain system materials.

The drain line must comply with all local codes.

CD2

Y

0

A

CD1

C

A

CD2

B

C

B

DPN003596

Page :1 /1

Form No.: DPN001040_REV4

5

2-5/16 (59)

5

7-1/2 (191)

11-9/16 (294)

11 (279)

49 (1245)

4-7/16 (113)

6-1/2 (166)

9-1/2 (242)

4" Grooved Pipe

2-1/8" (54mm)]

1-1/4" (32mm)

1-3/8" (35mm)

4

REV : 4

REV DATE : 3/18

Page 45

LIEBERT CW

n terminals

ELECTRICAL FIELD CONNECTION

DEFINITIONS AND LOCATIONS

CW340 & CW440 DOWNFLOW MODELS

STANDARD ELECTRICAL CONNECTIONS

1) Primary high voltage entrance - 2.50” (64mm); 1.75” (44mm) @ EP Box; 1.375” (35mm) diameter concentric knockouts located in

bottom of box

2) Primary low voltage entrance - Quantity (3) 1.375” (35mm) diameter knockouts located in bottom of box

3) Three phase electrical service - Terminals are on top of disconnect switch. Three phase service not by Liebert.

4) Earth ground - Terminal for field supplied earth grounding wire.

5) Remote unit shutdown - Replace existing jumper between terminals 37 & 38 with field supplied normally closed switch having a

minimum 75VA, 24VAC rating. Use field supplied Class 1 wiring.

6) Customer alarm inputs - Terminals for field supplied, normally open contacts, having a minimum 75VA, 24VAC rating, betwee

24 & 50, 51, 55, 56. Use field supplied Class 1 wiring. Terminal availability varies by unit options.

7) Common alarm - On any alarm, normally open dry contact is closed across terminals 75 & 76 for remote indication. 1 AMP, 24VAC max

load. Use Class 1 field supplied wiring.

8) Fan section RS485 connections – Quick connect socket located at the base of the coil section, below the low voltage panel provides

RS485 control for the fans. Requires field connection of fan section low voltage harness.

9) Fan section high voltage connections – Quick connect sockets located at the base of the coil section, below the high voltage panel

provide three phase power to the fans. Requires field connection of fan section high voltage harness.

OPTIONAL ELECTRICAL CONNECTIONS

10) Unit factory installed fused disconnect switch– Access to the high voltage electric panel compartment can be obtained only with the

switch in the “off” position.

11) Secondary disconnect switch and earth ground – Fuses are included in the 65KAIC SCCR fused disconnect switch models.

12) Smoke sensor alarm - Factory wired dry contacts from smoke sensor are 91-common, 92-NO, and 93-NC. Supervised contacts, 80 &

81, open on sensor trouble indication. This smoke sensor is not intended to function as, or replace, any room smoke detection system that

may be required by local or national codes. 1 AMP, 24VAC max load. Use Class 1 field supplied wiring.

13) Condensate alarm (with condensate pump option) - On pump high water indication, normally open dry contact is closed across terminals

88 & 89 for remote indication. 1 AMP, 24VAC max load. Use Class 1 field supplied wiring.

14) Remote Humidifier - On any call for humidification, normally open dry contact is closed across terminals 11 & 12 to signal field supplied

remote humidifier. 1AMP, 24VAC max load. Use Class 1 field supplied wiring.

15) Reversing Starter Power Supply Notification – Normally open contact terminals 102 and 103 will close when Power Supply 1 is

engaged; 106 and 107 will close when Power Supply 2 is engaged.

OPTIONAL LOW VOLTAGE TERMINAL PACKAGE CONNECTIONS

16) Remote unit shutdown - Two additional contact pairs available for unit shutdown (labeled as 37B & 38B, 37C & 38C). Replace jumpers

with field supplied normally closed switch having a minimum 75VA, 24VAC rating. Use field supplied Class 1 wiring.

17) Common alarm - On any alarm, two additional normally open dry contacts are closed across terminals 94 & 95 and 96 & 97 for remote

indication. 1 AMP, 24VAC max load. Use Class 1 field supplied wiring.

18) Main fan auxiliary switch - On closure of main fan contactor, normally open dry contact is closed across terminals 84 & 85 for remote

indication. 1 AMP, 24VAC max load. Use Class 1 field supplied wiring.

19) Liqui-Tect™ shutdown and dry contact - On Liqui-Tect™ activation, normally open dry contact is closed across terminals 58 & 59 for

remote indication (Liqui-Tect sensor ordered separately). 1 AMP, 24VAC max load. Use Class 1 field supplied wiring.

DPN003601

Page :1 /4

Form No.: DPN001040_REV4

REV : 3

REV DATE : 9/17

Page 46

LIEBERT CW

ELECTRICAL FIELD CONNECTION

DEFINITIONS AND LOCATIONS

CW340 & CW440 DOWNFLOW MODELS

High Temp

Stat

Filter Clog Switch

Air Safety Switch

Note: Typical orientation of components shown. Component location varies by option and unit.

RS485 Interface Board

Large iCOM™ Board

T6 Transformer

Condensate Pump

Alarm Relay

Intellislots

Smoke Detector

Power Supply

Condensate Pump fuses

2

Control fuses

Terminals for

Field Low Voltage

wiring connections

iCOM™ Fuse Board

Main Fan

fuses

A

B

C

D

T1 Transformer

4

3

1

10 Disconnect

Fan Contactors

15

107106103102

19

58

Note: Refer to Page 1 of 4 for descriptions of numbered callouts.

DPN003601

Page :2 /4

Form No.: DPN001040_REV4

18

17

12

8180939291

7

767597969594858459

A

B

6

13

14

12115655515024

16

5

383738B37B38C37C8988

C

D

FIELD TERMINAL LAYOUT

REV : 3

REV DATE : 9/17

Page 47

RS485 Interface Board

Large iCOM™ Board

LIEBERT CW

ELECTRICAL FIELD CONNECTION

DEFINITIONS AND LOCATIONS

CW340 & CW440 DOWNFLOW MODELS

Main Fan

fuses

Intellislots

Condensate Pump fuses

2

Control fuses

4

10

3

1

High Temp

Stat

Filter Clog Switch

Air Safety Switch

T6 Transformer

Note: Typical orientation of components shown. Component location varies by option and unit.

Condensate Pump

Alarm Relay

15

Smoke Detector

Power Supply

Terminals for

Field Low Voltage

wiring connections

iCOM™ Fuse Board

12

T1 Transformer

Fan Contactors

6

11

14

107106103102

19

58

Note: Refer to Page 1 of 4 for descriptions of numbered callouts.

DPN003601

Page :3 /4

Form No.: DPN001040_REV4

18

17

8180939291

7

767597969594858459

A

B

FIELD TERMINAL LAYOUT

12115655515024

13

16

5

383738B37B38C37C8988

REV : 3

REV DATE : 9/17

C

D

Page 48

8

Fan Section

RS485 Connection

LIEBERT CW

ELECTRICAL FIELD CONNECTION

DEFINITIONS AND LOCATIONS

CW340 & CW440 DOWNFLOW MODELS

Field Fan Section Connections

DPN003601

Page :4 /4

Form No.: DPN001040_REV4

Fan Section High Voltage

9

Connections (CW440 shown.

CW340 will have 3 quick

connect sockets)

REV : 3

REV DATE : 9/17

Page 49

LIEBERT CW

N

otes:

puted as

SEISMIC DATA

ANCHORAGE FOR CW440D

IMPORTANT SEISMIC REQUIREMENTS COMPLIANCE NOTE:

Values presented in this document are provided for unit anchorage sizing and do not imply compliance to IBC,

ASCE, or OSHPD seismic requirements. The Liebert CW440 has not been tested and certified. The anchorage

loads are provided as guidelines for the sizing of anchors for the attachment of the unit to the building structure

or housekeeping pad. Approval of all anchorage is subject to approval by the engineer of record for the project

or building.

1. The seismic overturn resistance anchorage load calculations provided for the Liebert CW440D computer room air handler are com

defined in the International Building Code (IBC) 2009, IBC 2012, and American Society of Civil Engineers (ASCE) Minimum Design Loads

for Buildings and Other Structures, ASCE 7-10.

2. The computer room air handler must be installed and attached to the building structure without spring isolators per the manufacturer

supplied installation instructions. The calculations exclude all non-factory supplied accessories. The unit base shall be bolted to

building/structure.

3. Mounting requirement details such as anchor brand, type, embedment depth, edge spacing, anchor-to-anchor spacing, concrete strength,

special inspection and attachment to non-building structures must be outlined and approved by the engineer of record for the project or

building. Structural floors and housekeeping pads must also be designed and approved by the project or building structural engineer of

record to withstand the seismic overturn anchor loads defined in the anchor table. The installing contractor is responsible for the proper

installation of all anchors and mounting hardware, observing the mounting requirements detailed in the installation drawings and

additionally outlined by the engineer of record.

4. Use flat washer, lock washer and nut to connect the Liebert CW440D. A minimum of 1/2" diameter anchors with American National

Standard Series W, type A, plain washers (ANSI B18.22.1-1965, R1975) selected to match the nominal anchor diameter must be installed

at each anchor location between the anchor head and equipment for tension load distribution.

DPN003636

Page :1 /3

Form No.: DPN001040_REV4

REV : 1

REV DATE : 2/17

Page 50

1"

25mm

Typ.

LIEBERT CW

SEISMIC DATA

ANCHORAGE FOR CW440D

178"

4521mm

62"

1575mm

1"

25mm

Typ.

A

A

Floor Anchoring Dimensions

Front of Unit

1 7/8"

48mm

Typ.

Notes:

1. Anchor Bolt sized per Hilti Kwik Bolt TZ Carbon and Stainless in Concrete, ICC ESR-1917.

Alternates are subject to review by Vertiv or Engineer of Record.

87 1/8"

2213mm

MIN. PAD

THICKNESS

2

SECTION A-A

3/4"

O

21mm

Anchor Holes

Typ. (6) Plcs

MIN. EMBEDMENT

EC Fans Removed

For Clarity

87 1/8"

2213mm

ANSI B18.22.1-1965(R2003)

TYPE A, SERIES W PLAIN

WASHER REQUIRED AT

EACH ANCHOR LOCATION

2

MIN. HOLE

DEPTH

2

2. Specified by Engineer of Record.

3. Operating mass includes the operating refrigerant, water volume, floor stand and plenum.

Operating mass*

Model No.

CW440 1/2" 6500 2948 3616 1640 1910 866 991 450

Sds=1.70, Rp=6, ap=2.5, Ip=1.5

Anchor

Size

3

Lbs kg Lbs kg Lbs kg Lbs kg

DPN003636

Page :2 /3

Form No.: DPN001040_REV4

Maximum

Compresssive

Reaction

Maximum Load per Anchor

Tension Shear

REV : 1

REV DATE : 2/17

Page 51

LIEBERT CW

Anchor

SEISMIC DATA

ANCHORAGE FOR CW440D

SECTION WELDING DIMENSIONS

FRAME TUBE

(OUTSIDE FACE)

GASKET

B

WELD

B

A

TYPICAL

(5mm)3/16

E

E

A

E

E

Welded Connection (Typ.)

E

E

E

Section B-B Filter to Coil Welds

C

C

D

Notes:

1. Gasket material is added to the inner most top mating edge of each section prior to stacking.

2. Weld materail must be designated for use in welding 304L Stainless Steel (308SS or equivalent).

3. Desocrative extension plenums to be bolted in (4) places.

Model No.

CW440 1/2" 3-1/2 (89) 6 (152) 2 (51)

DPN003636

Page :3 /3

Form No.: DPN001040_REV4

DIMENSIONAL DATA in. (mm)

Size

C D E

C

C

D D

Section A-A Coil to Fan Welds

REV : 1

REV DATE : 2/17

Page 52

LIEBERT CW

OPTIONAL DUCTED REAR CONNECTION

CW440 MODEL

Rear View

1 7/8"

48mm

1Piping Section

Notes:

1. Because Piping Section may appear at either end of unit

dimensions shown may be reversed depending on configuration

ordered.

DPN003676

Page :1 /1

Form No.: DPN001040_REV4

Fans Removed For Clarity

176 1/4"

4477mm

Top View

Rear View

1 3/4"

44mm

2 9/16"

65mm

27 5/16"

694mm

REV : 2

REV DATE : 10/18

Page 53

LIEBERT CW

FAN SECTION DIMENSIONAL DATA

3 FAN CW340 MODEL

Piping access area

(See Note 5)

43"

1092mm

Attachment

Point

TOP VIEW

138 11/16"

3523mm

38 1/4"

972mm

38 1/4"

972mm

38 1/4"

972mm

FRONT VIEW PANELS REMOVED FOR CLARITY

Attachment

Point

1"X1"X3" long steel tube

Typ. (6) places

10"

254mm

Attachment

Point

Attachment

Point

60"

1524mm

OVERALL

RIGHT SIDE

PANELS REMOVED FOR CLARITY

Attachment

Point

Attachment

Point

58 7/8"

1495mm

Typ.

BOTTOM VIEW

FANS REMOVED FOR CLARITY

NOTE:

1. This fan section is designed for 36" (914mm) raised floor height and can accomodate floors between 34" - 43" (864mm - 1092mm) high..

3. The fan section is not symmetrical and its orientation to the Liebert CW is critical for proper installation.

3. The EC fans must be field wired into connectors inside of the unit.

4. The EC fans are removed out the front of the fan section, and there must be clearance in front of fan section to be able to service fans (See DPN003561).

5. The fan section may be ordered with the piping access area at the opposite end, and the fans oriented accordingly.

DPN003964

Page :1 /1

Form No.: DPN001040_REV4

58 7/8"

1495mm

Typ.

10 1/2"

267mm

Typ.

REV : 1

REV DATE : 1/17

Page 54

Vertiv | Liebert® CW™ Installer/UserGuide

Page 55

VertivCo.com | Vertiv Headquarters, 1050 Dearborn Drive, Columbus, OH, 43085, USA

© 2018 Vertiv Co. Allrights reserved. Vertiv andthe Vertiv logo are trademarks or registered trademarks of Vertiv Co. Allother names and logos referred to

are trade names, trademarks or registered trademarks of their respec tive owners. While every precaution has been taken to ensure accuracy and

completeness herein, Vertiv Co. assumes no responsibility, and disclaims allliability, for damages resulting from use of this informationor for any errors or

omissions. Spec ifications are subject to change without notice.

SL-18062_REV4_9-18/590-1783-501C

Loading...

Loading...