Page 1

Liebert CRV+

Precision Air Conditioner

User Manual

Page 2

Page 3

Copyright by Vertiv Co. Ltd.

The content in this document is subject to change without notice. All rights, including rights of

translation, reproduced by printing, copying or similar methods, and even of parts, are reserved. Violators

will be liable for damages. All rights, including rights deriving from patent license or registration of a

utility model or design, are reserved. No part of this document may be reproduced or transmitted in any

form or by any means without the prior written consent of Vertiv Co. Ltd.

Notice

The purchased products, services, and features are stipulated by the contract made between Vertiv Co.,

and the customer. All or part of the products, services, and features described in this document may not

be within the purchasing scope or the usage scope. Unless otherwise specified in the contract, all

statements, information, and recommendations in this document are provided "AS IS" without warranties,

guarantees or representations of any kind, either express or implied. The information in this document is

subject to change without notice. Every effort has been made in the preparation of this document to

ensure the accuracy of the contents, but all statements, information, and recommendations in this

document do not constitute a warranty of any kind, express or implied.

Vertiv Co., Ltd.

• China

Website: www.vertivco.com

E-mail: support@Vertivco.com

mer service hotline: 4008876510

Custo

• Asia Pacific

Homepage: www.vertivco.com.

E-mail: overseas.support@Vertivco.com

For Technical Support, users may contact the nearest Vertiv Co. local sales office or service center.

Page 4

Purpose of the Document

Warning/Danger/Caution

potentially harmful situation that can result in death or injury. It

which may result in danger and safety issues thereby having an

The Note section indicates additional and useful information,

help make maximum utilization of the resources at hand. Helpful

information related to the mainstream stuff also comes under

This doc

ument applies to the Liebert CRV+ series of precision air conditioners and cooling solutions

which maintain an optimal environmental control mainly for testing laboratories, data center rooms and

similar technological ecosystems at minimal operating costs. This document explains the product

description, installation measures, operational workflow, maintenance, and detailed aspects from the user

perspective. The figures used in this document are for reference only.

Please read this manual carefully before installing, maintaining, and troubleshooting, especially the

warning information in the manual

Styling used in this Guide

The styles used in the manual will be defined as mentioned in the following table:

Situation Description

Warning/Danger/Caution

The

also indicates instructions that need to be adhered to, failing

adverse effect on the reliability of the device and security. Even

for practices not related to physical injury, the content under

the Warning heading is used for precautions which need to be

taken which, otherwise, could result in equipment damage,

performance degradation, or interruption in service.

note indicates a hazardous or

Note

Version History

Issue

1 V1.0 ---

including tips and tweaks. It also calls attention to best

practices and industry-best protocols that are standardized and

the Note heading helping the users get to grips with the

definitions, concepts, and terminologies used in the manual.

Revision

Changes

Page 5

Safety Precautions & Measures

The important safety precautions and measures that should be followed during the installation and

maintenance of the Liebert CRV+ models are described in the following sections.

Read the manual prior to installation and operation of the unit. Only qualified personnel should move,

install, or service this equipment.

The user reads and takes into account all the precautions, compliance, and safety measures before

working on the equipment. The unit control must be used exclusively for the purpose which it is

intended for; the manufacturer takes no liability for incorrect use or a modification to the unit control.

Adhere to all the Warnings and Cautionary measures included in the manual.

Please read this manual carefully before installing, maintaining and troubleshooting; especially

the Warni

pay attention to the warning labels on the unit and its components.

This manual is retained for the entire service life of the machine. The user must read all the precautions,

danger, warnings, and cautionary measures mentioned in the manual prior to carrying out any operations

on the machine. Each machine is equipped with an electrical insulation, which allows the users to work in

safe conditions. The main switch is positioned on the electrical panel cover; Open the right door to access

it. Before any maintenance operation, switch off the machine with this electronic insulation device in order

to eliminate risks such as electrical shocks, burns, automatic restarting, moving parts, and remote

control. The panel key, supplied along with the unit, must be kept by the personnel responsible for the

maintenance. The protective covers can be removed after the electric power has been cut off by opening

the main switch.

ng/ Danger/ Caution information in the User Guide. Apart from the User Guide, also

In the following section, take a look at the various cautionary measures and warnings that need to be read

carefully prior to installing or operating the system.

Disconnect the local and remote power supplies prior to working with the unit.

Prior to the installation process, read all the instructions, verify if all the parts are in place, and check the

nameplate to ensure that the voltage matches the utility power that is available for that unit.

The controller doesn’t isolate power from the unit even in the Off mode. Moreover, some internal

components require and receive power even during the Off mode.

If the unit door is open while the fans are operating, the airflow may result in abrupt slamming of the door

resulting in injury. Another aspect is the presence of small objects in the fans bay which may result in

object ejection during the fan start-up and there is a probable risk of being hit by these objects leading to

grievous injury as well as causing equipment damage.

Page 6

The CRV+ unit isolation switch is inside the unit. The line side of this switch contains live high voltage.

In order to ensure there is no voltage inside the unit, install and open a remote isolation switch.

The unit contains fluids and gases under high pressure. Therefore, the pressure should be relieved

before working with the piping.

Various components such as compressors, refrigerant discharge lines, and humidifiers are extremely hot

during the unit operation. Therefore, allow sufficient time for the unit to cool down before working with

the unit cabinet. Handle the unit with extreme caution and wear safety equipment such as protective

gloves, safety shoes, and arm protection while working with the hot compressors, discharge lines, and

reheats.

There is a risk of leaking water that can cause damage to the equipment as well as the building. There

should be an effective water drain connection and facilities. Installation should be precise.

Implementation of the application and service practices should be suitable and fault-free. Not complying

with these norms will result in water leakage from the unit. Water leakage can result in massive damage

and loss of critical equipment in the hosting ecosystem. Therefore, care should be taken to ensure that

the unit must not be located directly above any equipment that could sustain damage due to water and

excessive moisture. Using a leak detection system for unit and system supply lines are recommended by

Vertiv Co.

Page 7

TABLE OF CONTENTS

Chapter 1 Introduction ........................................................................................................... 1

1.1 Model Nomenclature .................................................................................................................... 2

1.2 Basic Performance Parameters................................................................................................. 2

1.3 Product Description .................................................................................................................... 3

1.3.1 DC Brushless Compressor................................................................................................................. 4

1.3.2 Fan ....................................................................................................................................................... 5

1.3.3 Evaporator .......................................................................................................................................... 5

1.3.4 Electronic Expansion Valve (EEV) ................................................................................................... 6

1.3.5 Electrode Humidifier ......................................................................................................................... 6

1.3.6 Electric Heater ................................................................................................................................... 7

1.3.7 Sight Glass .......................................................................................................................................... 7

1.3.8 Filter Drier........................................................................................................................................... 7

1.3.9 Micro-Controller ................................................................................................................................ 7

1.3.10 Condenser ......................................................................................................................................... 8

1.4 Optional Equipment .....................................................................................................................8

1.5 Working Conditions .....................................................................................................................9

1.5.1 Operating Environment ..................................................................................................................... 9

1.5.2 Storage Environment ........................................................................................................................ 9

1.5.3 Refrigerant Charging Requirement ............................................................................................... 10

Chapter 2 Installation ........................................................................................................... 12

2.1 Pre-installation ........................................................................................................................... 12

2.1.1 Transportation & Movement........................................................................................................... 12

2.1.2 Unpacking ......................................................................................................................................... 13

2.1.3 Inspection ......................................................................................................................................... 14

2.2 Installation Preparation (Site Preparation) ......................................................................... 14

2.2.1 Equipment Room Requirement ...................................................................................................... 14

2.2.2 Installation Space requirements ................................................................................................... 15

2.2.3 Installation Tools ............................................................................................................................. 16

2.3 Mechanical Installation ............................................................................................................ 17

2.3.1 System arrangement during installation ...................................................................................... 18

2.3.2 System Installation Mode ............................................................................................................... 19

2.3.3 Product Dimensions ........................................................................................................................ 20

2.3.4 Installation Procedures .................................................................................................................. 23

2.3.5 Piping ................................................................................................................................................ 26

2.3.6 Removing Transportation Fastener and Vibration Absorber ................................................... 34

2.3.7 Checklist for completed mechanical installation ........................................................................ 36

Page 8

2.4 Electrical Installation................................................................................................................37

2.4.1 On-site Wire connections ............................................................................................................... 37

2.4.2 Installation Notes ............................................................................................................................ 37

2.4.3 Connecting cables of the Indoor unit ........................................................................................... 38

2.5 Commissioning Overview ....................................................................................................... 43

2.5.1 Self Check ......................................................................................................................................... 43

2.5.2 Preparations for Startup ................................................................................................................ 44

2.5.3 Startup Inspection .......................................................................................................................... 46

Chapter 3 System Operation & General Maintenance .................................... 50

3

.1

System Operation

3.1.1 Micro-Controller ............................................................................................................................... 50

3.1.2 Control buttons ................................................................................................................................ 50

3.1.3 Common Operational function examples ..................................................................................... 51

3.1.4 Main Screen ...................................................................................................................................... 52

3.1.5 Password interface .......................................................................................................................... 53

3.1.6 Menu Structure ................................................................................................................................ 53

3.2 General Maintenance ............................................................................................................... 69

3.2.1 Routine Maintenance & Inspection (Monthly) ............................................................................. 69

3.2.2 Routine Maintenance and Inspection (Half -Yearly) .................................................................. 70

3.2.3 Self-Diagnosing Functions ............................................................................................................. 71

3.2.4 Maintenance of Electrical Control utilities .................................................................................. 71

3.2.5 Air Filter Maintenance .................................................................................................................... 73

3.2.6 Fan Kit Maintenance ....................................................................................................................... 74

3.2.7 Electrical Heater Maintenance ...................................................................................................... 74

3.2.8 Refrigerating System Maintenance .............................................................................................. 74

3.2.9 Drainage system maintenance ...................................................................................................... 74

3.2.10 Troubleshooting ............................................................................................................................ 75

....................................................................................................................

..

50

APPENDIX 1 - Circuit Diagrams ............................................................................................................ 79

APPENDIX 2 - Micro-processing Controller Menu Structure................................................................ 82

APPENDIX 3 - Alarm Control Menu Table ............................................................................................ 84

APPENDIX 4 - Hazardous Substances or Elements Declaration .......................................................... 85

APPENDIX 5 - Troubleshooting of Common Startup Faults ................................................................. 86

Page 9

PART I

GENERAL INFORMATION

Page 10

Page 11

Chapter 1 Introduction

The Liebert CRV+ series is the next generation series of air conditioners that provide precise

environmental control. The Liebert CRV+ models are the latest in the long line of modern enterprisegrade products from the Liebert family. Incorporating the high standards associated with the Liebert

name, the CRV+ series utilizes the latest technology, system components, and streamlined

manufacturing process.

Liebert CRV+ air conditioners are products that are specifically created and designed for the small-andmedium data centers, computer rooms, and similar ecosystems which call for a high degree of accuracy

and precision. It addresses the needs and challenges associated with such applications and setups. It

caters to sensitive applications which need a suitable environment for optimal performance. Therefore,

care should be taken while testing these sensitive products or maintaining a favorable environment for

mission critical equipment, as even a slight deviation may lead to inaccurate results. Precision Air

Conditioning must not only keep room conditions within a specific range but also must have the

precision to react quickly to a drastic change in heat load and prevent wide temperature fluctuations.

The CRV+ air cooled AC unit is packed with features such as high reliability, high sensible heat ratio, and

large airflow. The unit is an air-cooled single cooling system and configured with DC Speed Regulation

back- inclined centrifugal fan.

Packed with a host of features, it lowers the sound emissions significantly and thereby reduces the noise

pollution. It is a top-notch system that adheres to the standard in Precision Air Cooling in terms of

energy-efficiency, space requirements, and reliability.

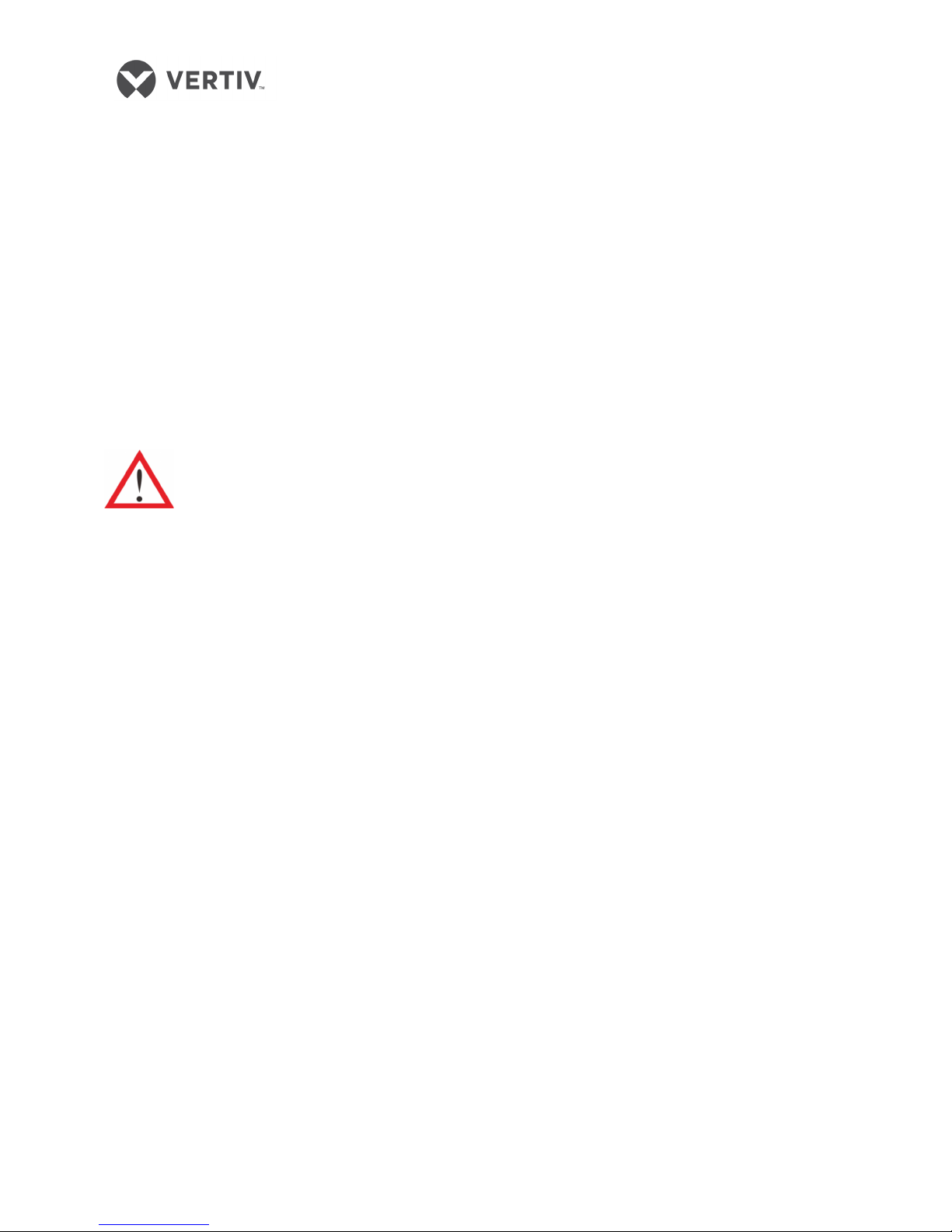

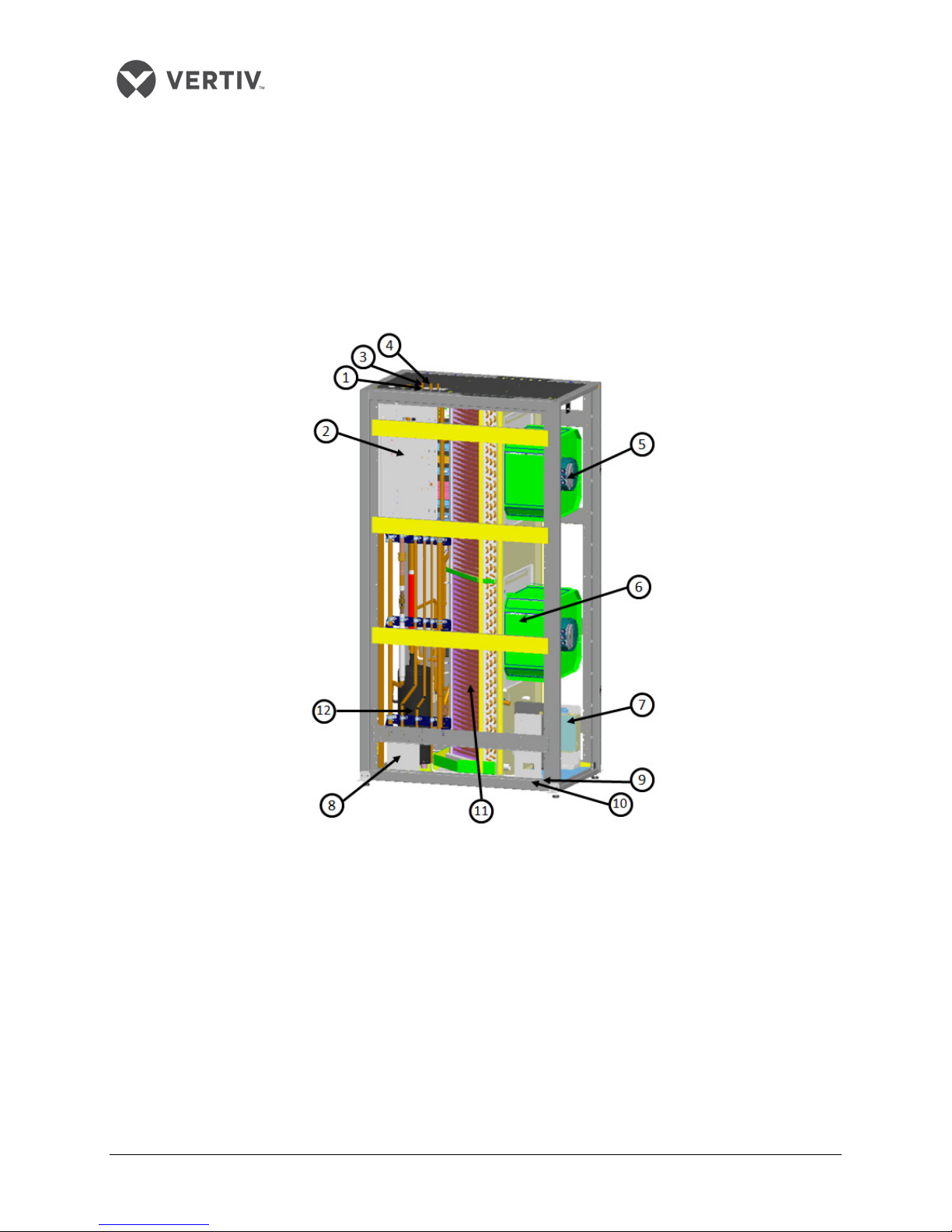

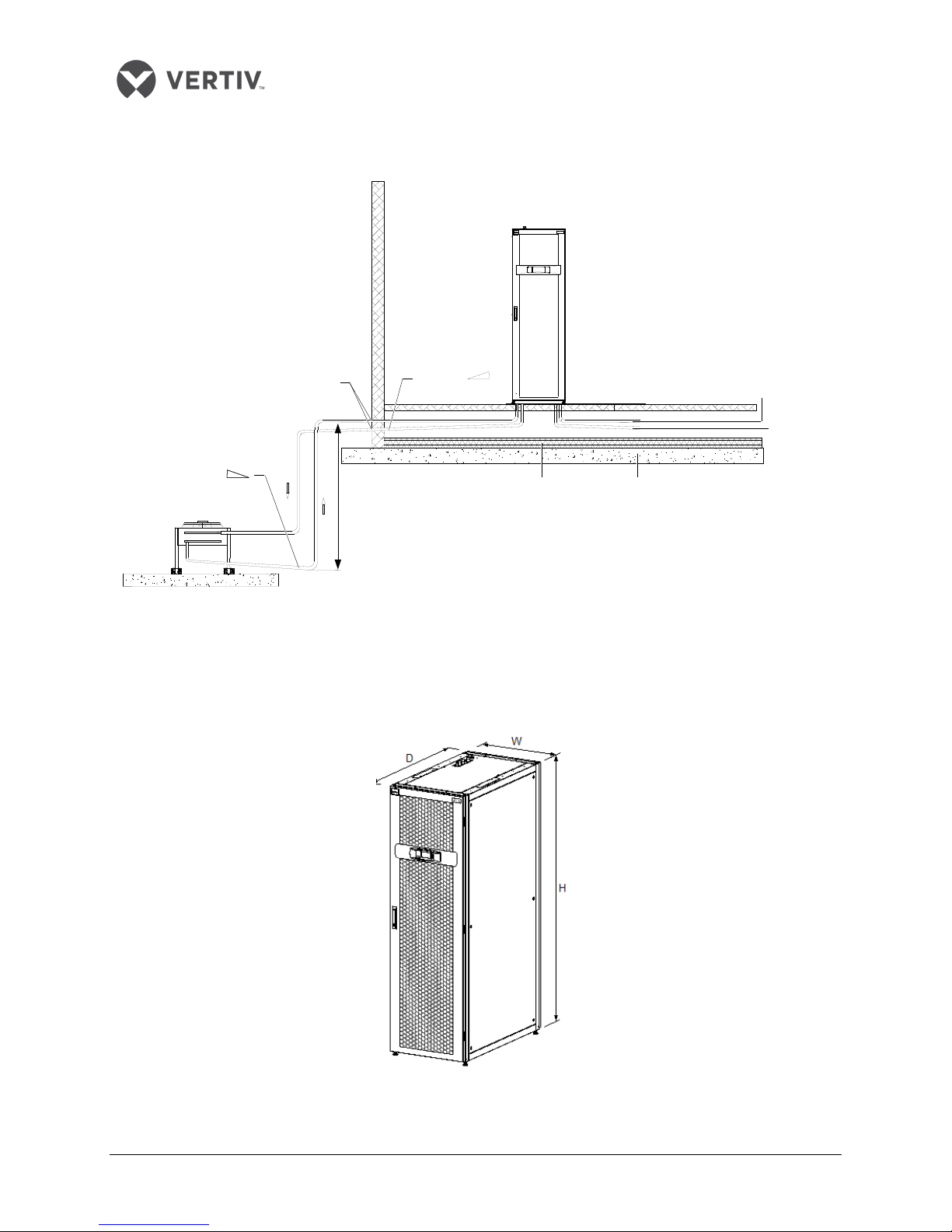

Figure 1-1 shows the appearance of various models in the Liebert CRV+ series:

Vertiv | Liebert CRV+ | User Manual 1

1-1 Models in the CRV+ series

Figure

Page 12

1.1 Model Nomenclature

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

C R 0 2 5 H A 1 3 8 O S 0

2 E 1 0 0 0 0 C V 0 0

0

CR Liebert CRV+

Bit 3 ~ Bit 5 Series Name Description

Bit 6 Air Discharge

R Horizontal supply with guide grill

Horizontal supply without guide grill

Bit 7 System Type

A

Bit 8Airflow

1 EC Fan

Bit 9 Power Supply

3 380-415V/3 ph/50Hz +N

T 380/3 ph/60Hz +N

CR025

20.8

6.1 3 1.5

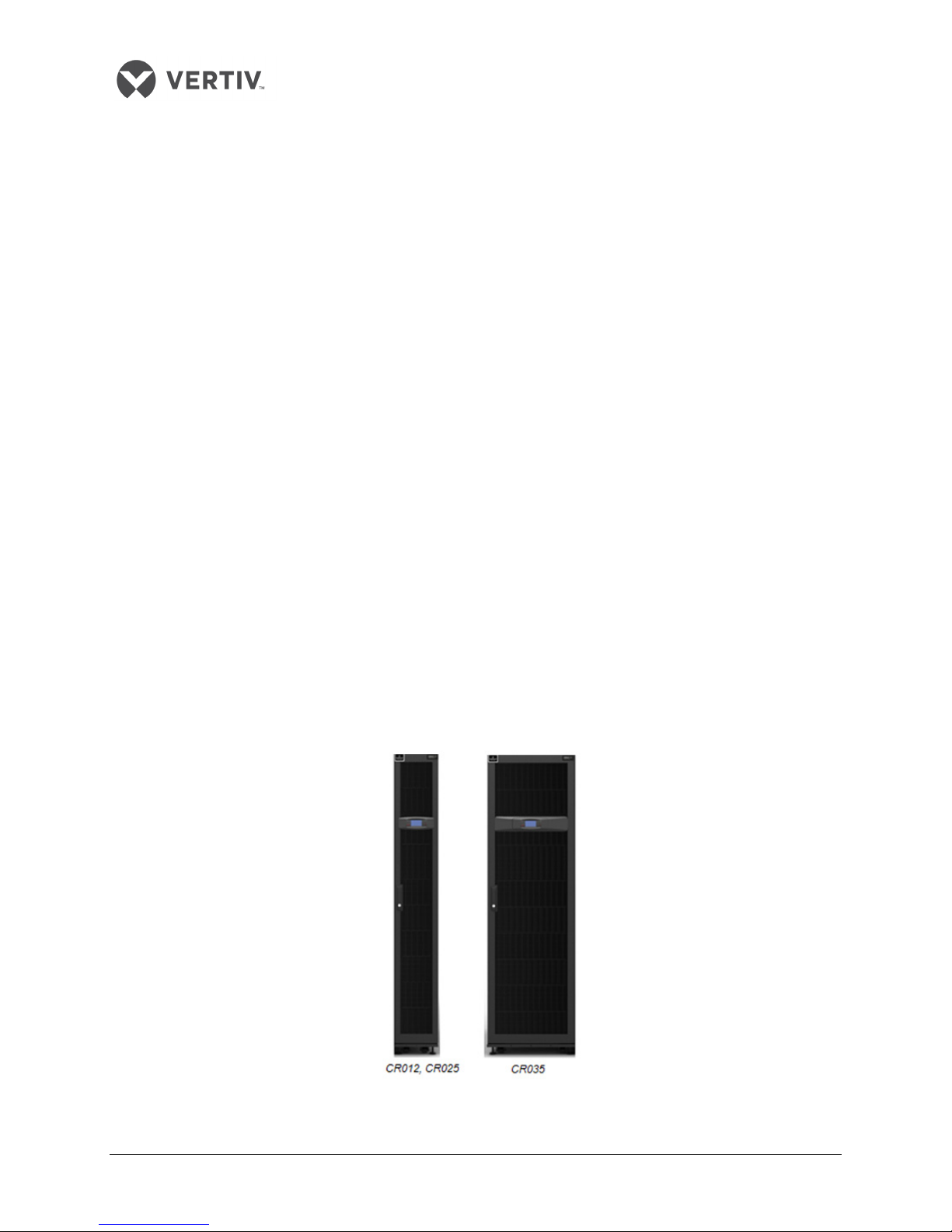

The model nomenclature of the CRV+ air cooled unit is shown in Figure 1-2:

Bit 1 and Bit 2 Product Model Bit 14 Filter

G4 with filter clogged switch

G4

Standard DX Air Cooled Coiled &

Electronic Expansion Valve (EEV)

With condensate drain pump

None

025 Nominal Capacity

H

Air cooled

Bit 10 System Configuration

8 R-410A brushless scroll compressor

Bit 11 Humidifier

0 None

S Electrode humidifier

Bit 12 Display

L Large Display

S Standard display panel

Bit 13 Heating

0

1

None

Electrical heater

0

2

Bit 15 Coil and value

E

Bit 16 Cabinet Color

1 Standard color ( Z-7021 black-grey)

Bit 17 High Pressure Option

0 None

Bit 18 Low Voltage Locking Option

0 None

Bit 19 Monitor

0 None

S SIC Card

Bit 20 Detector

0 None

Bit 21 Package

P Domestic

C Overseas (sea worthy)

Bit 22 Special Function

A None

V

Bit 23~25 Special Identifier for order

0

Figure 1-2 Model Nomenclature

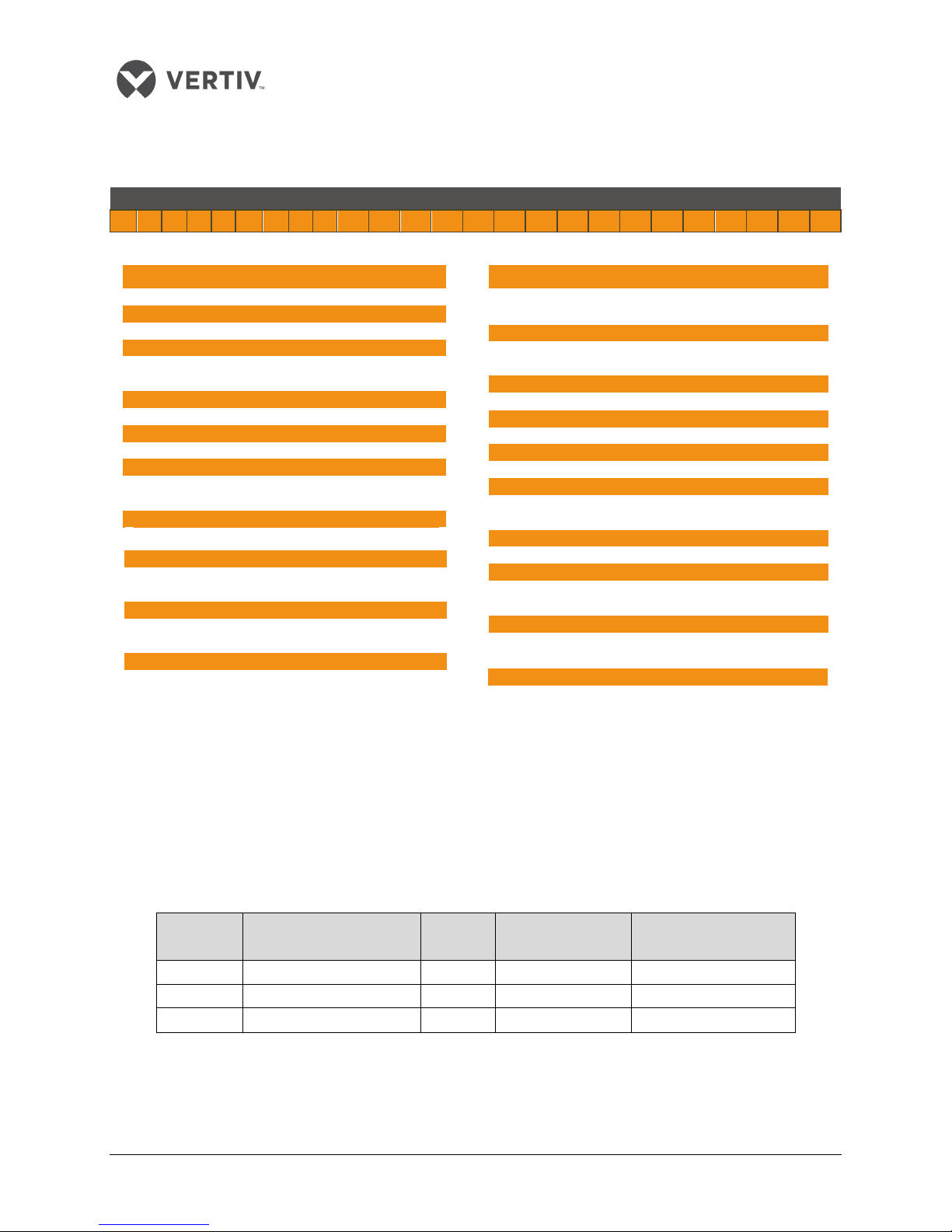

1.2 Basic Performance Parameters

The basic performance parameters of the Liebert CRV+ AC series are given in Table within Listing 1.1.

Listing 1.1

Model

Nominal cooling

capacity (kW)

CR012 13.6 3.3 2 /

CR035 38.1 10.1 5.5 1.5

Condition: Return air 37˚C, 24%RH & 45˚C condensing temperature

Vertiv | Liebert CRV+ | User Manual 2

Power

(kW)

Heating capacity

(kW)

Humidification

capacity (kg/h)

Page 13

1.3 Product Description

The Liebert CRV+ cooling unit is a comprehensive system that includes all the main functions

fundamental to precision cooling units such as cooling, humidification, dehumidification, re-heating, air

filtration, condensation management, temperature and humidity control, alarm functions and

compatibility with data communications. Liebert CRV+ is designed to comply with mission-critical

requirements and ensure that servers are maintained at the correct temperature and humidity levels.

Figure 1-3 shows the various components and their respective locations:

Vertiv | Liebert CRV+ | User Manual 3

Figure 1-3 Components and their locations

Page 14

Listing 1.2

2

Electric box

Top humidifier water supply

5

EC plug fans

Item Description Item Description

1 Top electrical entrance 7

8

3

condesate-pump drain

4 Supply and Return 10

6 Electric heaters

Model Dimensions (W x D x H)(mm)

CR012HA1380S02E10000PV000

CR012RA1380S12E10000PV000

CR025HA1380S02E10000PV000

CR025RA138SS12E10000PV000

CR035HA1380S02E10000PV000

CR035RA138SS12E10000PV000

9 Bottom electrical entrance

11

12

Humidifier

Condensate pump

Bottom condensate-pump drain

Evaporator Coil

Compressor

300 x 1100 x 2000

300 x 1100 x 2000

600 x 1100 x 2000

In the following sections, take a look at the list of components used in the Liebert CRV+ Precision Air

conditioning series.

1.3.1 DC Brushless Compressor

The Liebert CRV+ series models comprise of a DC Brushless compressor which has a host of

promising features as mentioned in the following list:

Low operational noise

Rapid Cooling

Less Vibration

Moreover, there are no brushes compared to typical DC motors. Its compactness, reliability, longer life

time, and better capacity control combined with streamlined energy-efficiency make it an ideal

compressor to bank on for the CRV+ series.

Figure 1-4 shows the image of a DC brushless compressor:

Vertiv | Liebert CRV+ | User Manual

Figure 1-4 DC Brushless compressor

4

Page 15

1.3.2 Fan

The EC Fans used in the Liebert CRV+ models are energy-efficient and innovative with integrated

electronics and a maintenance-free design.

Ability to regulate the airflow and reduce the fan input power leading to high energy-efficiency

Easy-to-connect facility with minimum wiring leading to high performance with a great variety of

possible air flow rates

Figure 1-5 shows the EC Fans used in the models belonging to the CRV+ series:

Figure 1-5 EC Fans

1.3.3 Evaporator

The sophisticated design of the distributor ensures that the refrigerant is distributed evenly in each loop,

thereby improving the effectiveness of the heat exchanger.

Streamlined Heat exchanger design and air distribution for optimum performance

Fin-tube heat exchanger for higher efficiency

Figure 1-6 shows the image of an Evaporator:

Figure 1-6 Evaporator

Vertiv | Liebert CRV+ | User Manual 5

Page 16

1.3.4 Electronic Expansion Valve (EEV)

The EEV is designed for modulating control of the refrigerant mass flow with precision. The EEV collects

temperature and pressure signals at the same time to accurately regulate the refrigerant flow. The EEV's

wide operating envelope also lowers down the condensing pressure, thereby resulting in significant

energy savings.

Designed for modulating control of the refrigerant mass flow with precision

Ensures effective control on super-heating at t

Better low load capacity

Designed for easy Installation-and-Service

Figure 1-7 depicts the image for the EEV used in the CRV+ Series:

he end of the evaporator

Figure 1-7 EEV

.3.5 Electrode Humidifier

1

The Electrode humidifier helps to maintain constant humidity in test chambers and is quite efficient

in small-and medium-load applications.

Figure 1-8 depicts the image of an Electrode Humidifier:

Figure 1-8 Electrode Humidifier

Vertiv | Liebert CRV+ | User Manual 6

Page 17

1.3.6 Electric Heater

In the CRV+ models, the PTC heaters are used as they have lower running temperatures, thereby

ensuring operational safety.

Less susceptible to overheating and long lasting due to less wear

Lower Maintenance and Smooth operation

Figure 1-9 shows an image of the Electric Heater:

Figure 1-9 PTC heater

1.3.7 Sight Glass

The sight glass is a utility for observing the refrigerant state; specifically the moisture content of the

system. If the moisture content exceeds the levels of defined standards, the color changes, thereby,

indicating irregularity in the moisture content.

1.3.8 Filter Drier

Moisture can adversely affect the operations and service life of a system in the refrigeration lifecycle. In

order to rectify that condition, filter driers are used to filter out particles, remove, and hold moisture to

prevent it from circulating through the system.

1.3.9 Micro-Controller

The Micro-Controller used in CRV+ provides a simple operational user-interface and is developed using

the latest and highly advanced PID regulation technology.

Multilevel Password protection

Self-recovery upon power failure, high-voltage & low-voltage protection

Phase loss protection

Automatic phase-sequence switching upon the anti - phase and rotate speed control of the

outdoor fan

High-end Fault diagnostic system to facilitate easy equipment maintenance

Vertiv | Liebert CRV+ | User Manual 7

Page 18

Figure 1-10 shows the image of the micro-controller:

Figure 1-10 Display panel of the Controller

1.3.10 C

The Liebert range of air condensers offers many advantages, some of which are listed below:

Figure 1-11 shows the image of the condenser used in the CRV+ series:

ondenser

arp and Powerful design

Sh

Antirust aluminum cabinets

Low sound levels

High reliability over a wide range of ambient conditions

Figure 1-11 Condenser

For more information on the condenser, refer to the separate condenser manual which explains the

entire condenser ecosystem in detail.

1.4 Optional Equipment

The Liebert CRV+ series is compatible with multiple temperature/humidity sensors based on the

requirement.

An interesting development is the compatibility with the Liebert CRV+ series models with the Modbus

protocol. Through the configured RS 485 port or TCP/IP port, the CRV+ systems can communicate with

the host computer in addition to remotely taking charge of the host software.

Vertiv | Liebert CRV+ | User Manual 8

Page 19

1.5 Working Conditions

Item

Requirement

Item

Requirement

Storage environment

Indoor, clean (without dust)

Ambient temperature

-33°C ~ +70°C

In this section, take a look at the environmental conditions including the Operating and Storage

environment.

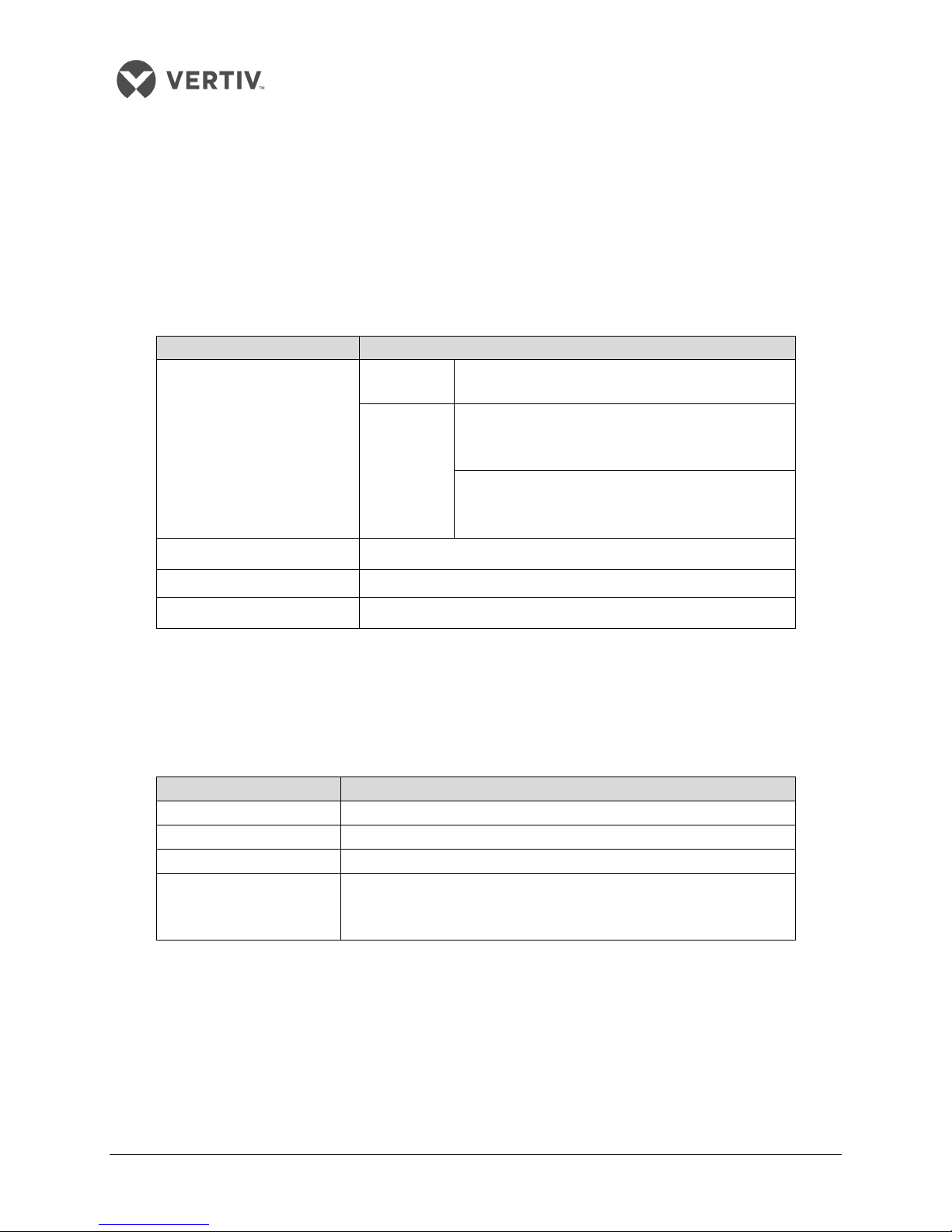

1.5.1 Operating Environment

The table in Listing 1.3 defines the Operating environment parameters including the Ambient

Temperature, Protection level, Altitude, and Voltage range.

Listing 1.3

Indoor 18°C ~ 40°C

CR012: -15°C ~ +45°C, if a low temperature kit is

Ambient temperature

Outdoor

Protection level (indoor unit) IP20

Altitude < 1000m. Above that, please contact Vertiv Co.

configured, the lowest outdoor operation

temperature is -34°C

CR025 and CR035: -20°C ~ +45°C, if a low

temperature kit is configured, the lowest outdoor

operation temperature is -34°C

Operation voltage range (380 ~ 415)V ± 10%, 3N ~ 50Hz / 60Hz

1.5.2 Storage Environment

The following table in Listing 1.4 defines the Storage Environment parameters including the ambient

humidity, ambient temperature, and storage time conditions.

Listing 1.4

Ambient humidity < 95%RH

Storage time

Total transportation and storage time should not exceed six months.

Otherwise, the performance needs to be re-calibrated

Vertiv | Liebert CRV+ | User Manual 9

Page 20

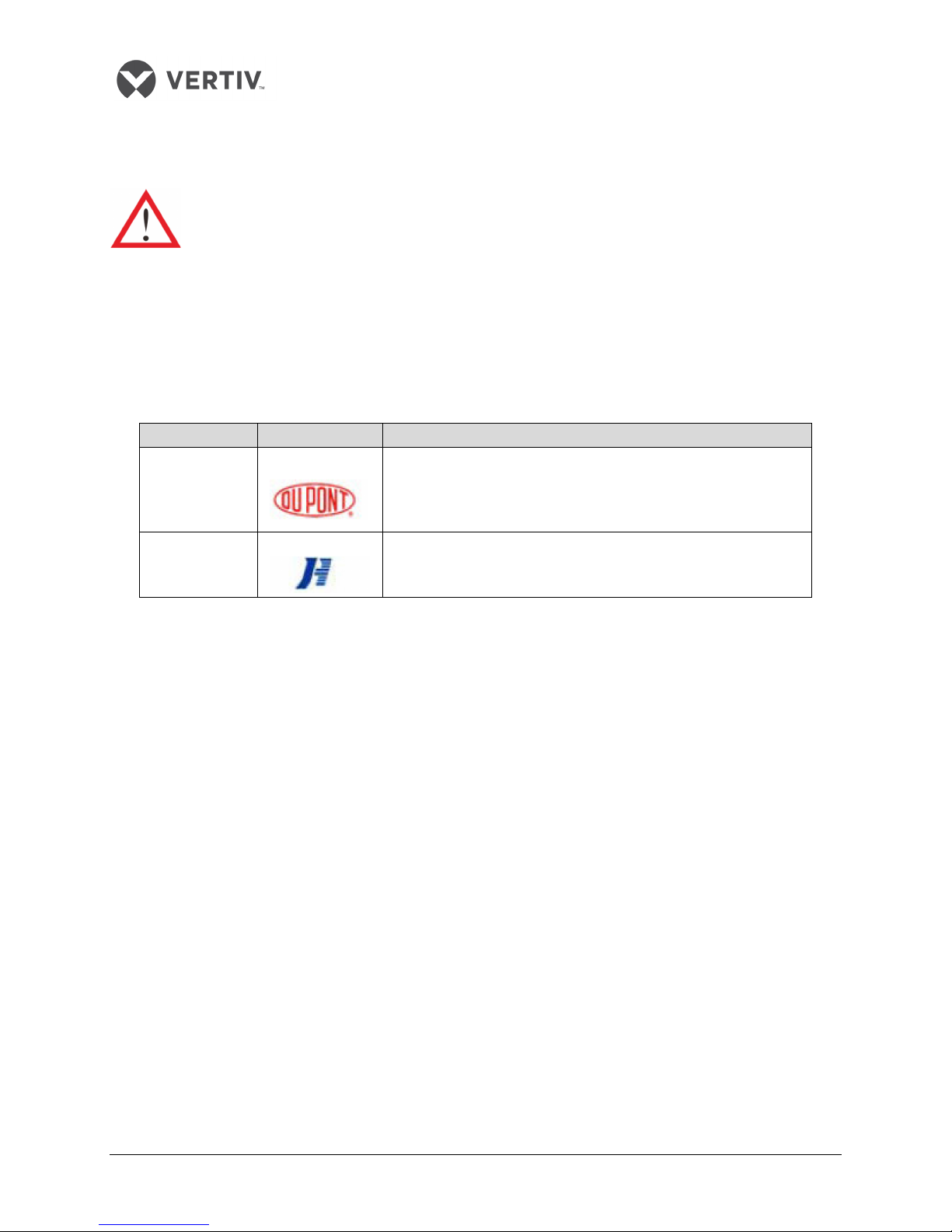

1.5.3 Refrigerant Charging Requirement

Brand

Logo

Note

Another essential aspect is the quality and make of the refrigerant oil. Adding poor quality oil,

counterfeit oil, or oil for a different model will damage the system. The quality issue due to

the wrong refrigerant oil will result in voiding of the warranty.

Low quality or counterfeit refr

igerant will damage the system drastically. Use the refrigerant approved by

Vertiv Co., Ltd. to avoid the system abnormality or damage caused by using other brands of refrigerant.

Listing 1.5 depicts the refrigerant brands, which are approved by Vertiv Co. Ltd.

Listing 1.5

DU PONT The DU PONT refrigerant adapts a custom made package

JUHUA

Vertiv | Liebert CRV+ | User Manual 10

Page 21

Part II

INSTALLATION

Vertiv | Liebert CRV+ | User Manual 11

Page 22

Chapter 2 Installation

The Installation process consists of the following procedures, namely-

Pre-installation

Installation Preparation

Mechanical Installation

Electrical Installation

2.1 Pre-installation

Pre-installation contains the following 3 sub sections, namely-

Transportation & Movement

Unpacking

Inspection

2.1.1 Transportation & Movement

When it comes to transporting the system, Railroad is the most preferable choice. However, if railroad

transportation is not possible, then the truck transport option is an optimal choice. One precaution is to

choose roads that do not have too many bumps and if any, avoid it as much as possible.

Liebert CRV+ systems are on the heavier side and therefore, it is recommended that equipment

like an electric forklift is utilized for these heavy duty systems.

Move the equipment to a location which is in the vicinity of the installation site.

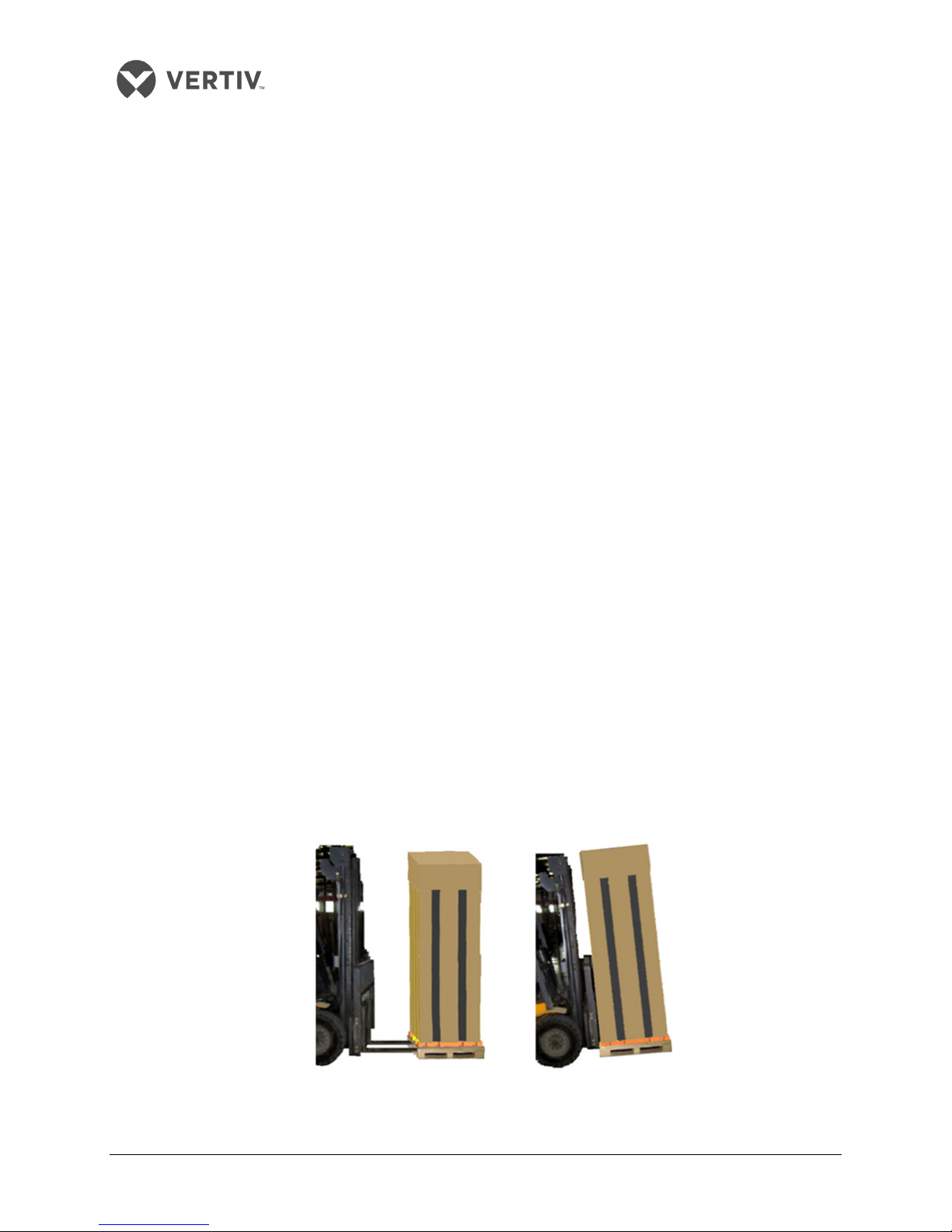

If an electric forklift is used, insert the tines of the forklift below the pallet as displayed in

Figure 2-1. Align the tines with the center of gravity to prevent the equipment from falling over.

Figure 2-1 depicts the way the tines of the forklift are inserted below the pallet and in the same

image, the graphic to the right indicates that the tines are aligned with the center of gravity to

prevent the equipment from falling over:

Figure 2-1 Moving the equipment using a Forklift truck

Vertiv | Liebert CRV+ | User Manual 12

Page 23

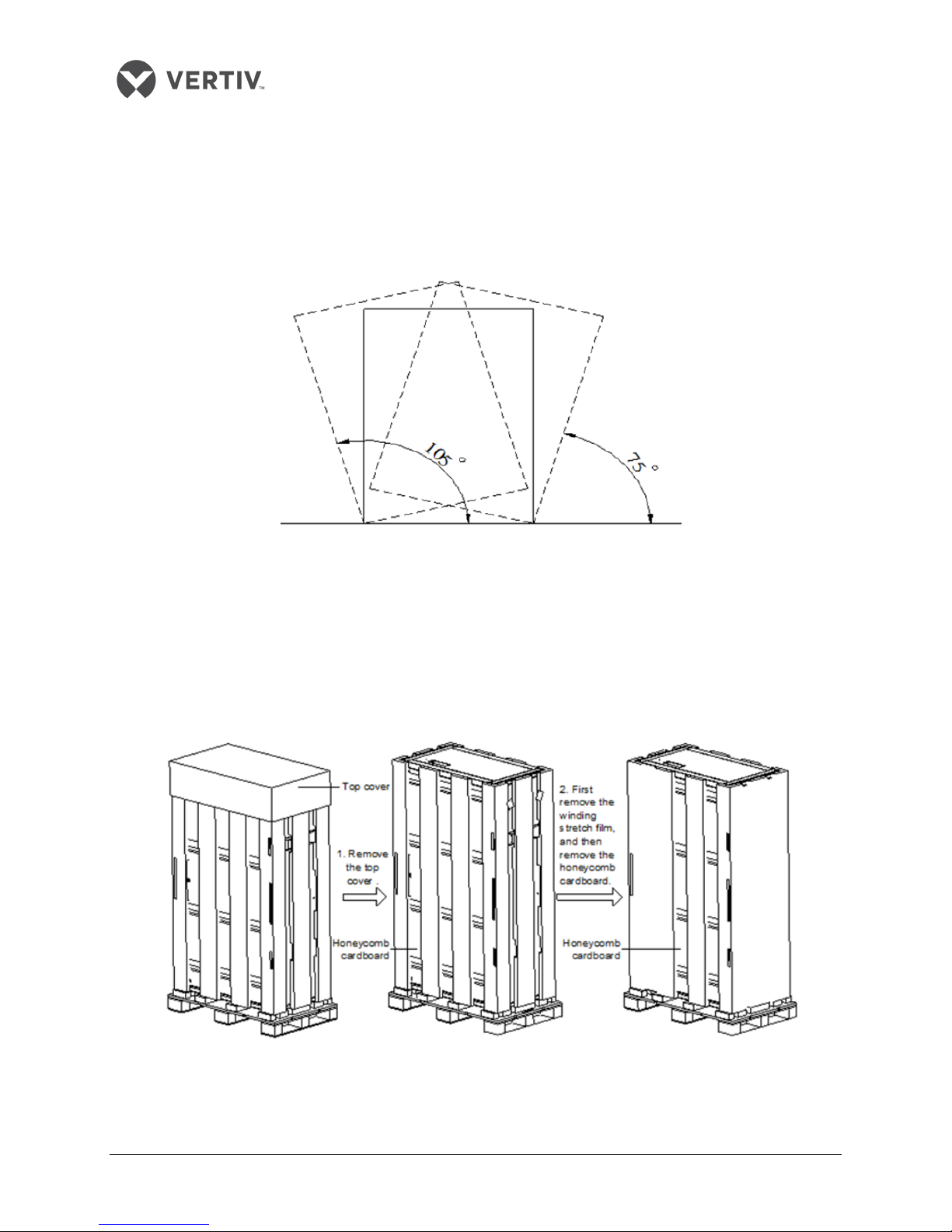

In the previous figure (Figure 2-1), the air conditioner is lifted using the forklift truck and is aligned with

the center of gravity. While moving the indoor unit, the obliquity has to be maintained with an angle of 75°

to 105°.

Figure 2-2 depicts the 75° to 105° obliquity that is suitable to move the air conditioning package to the

vicinity of the desired location:

Figure 2-2 Obliquity of the system

2.1.2 Unpacking

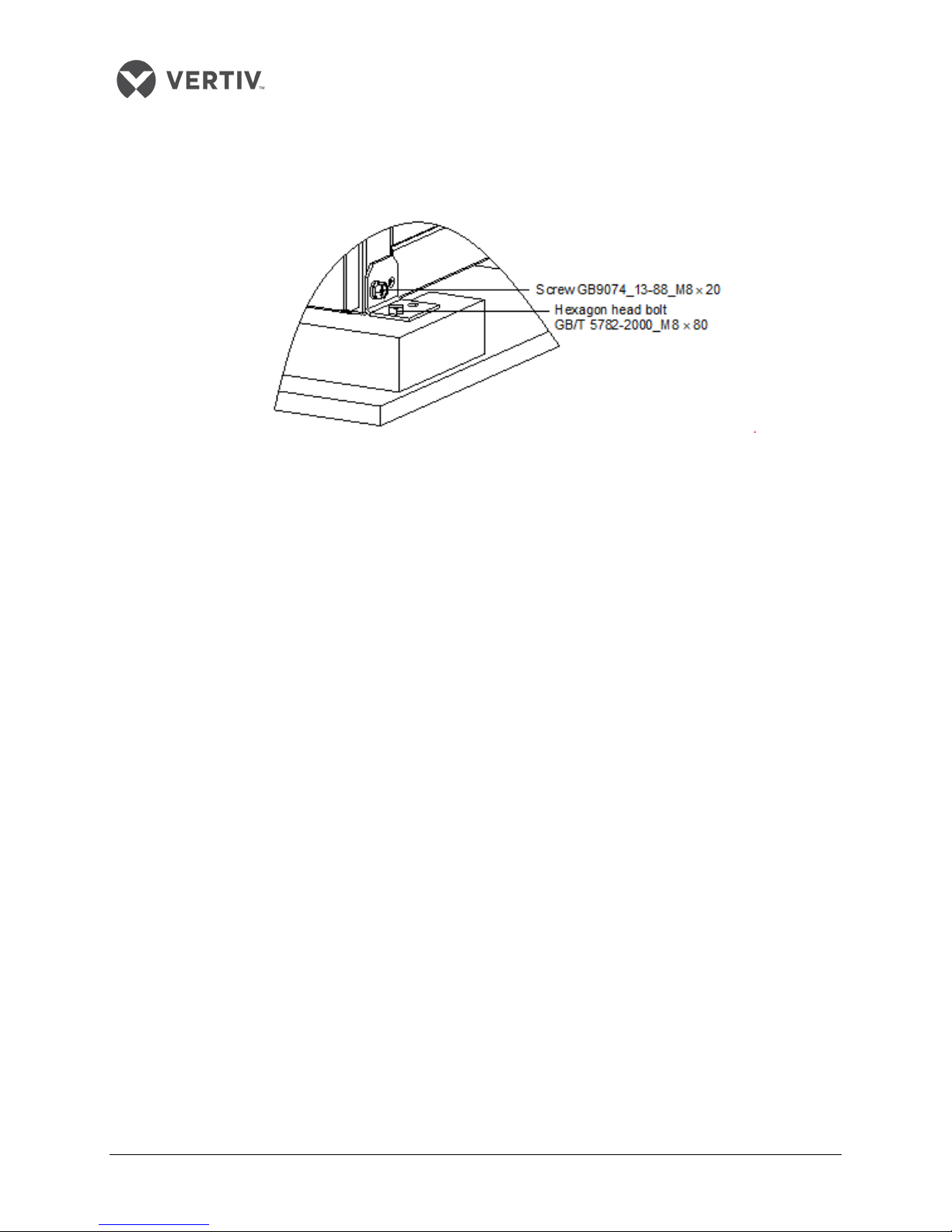

The cabinet uses a honeycomb cardboard and winding stretch film for packaging purposes. Shift the

product to a location closer to the final installation site prior to unpacking the unit.

Initially, remove the top cover and winding stretch film. Next, remove the honeycomb cardboard as

depicted in Figure 2-3.

Figure 2-3 Unpacking the outer package

Vertiv | Liebert CRV+ | User Manual 13

Page 24

The unit is fixed on the packing pallet with M8*20 and M8*80 screws. Use a 17mm open-end spanner,

ratchet spanner, or sleeve to remove the screws.

Refer to Figure 2-4 to see the schematic diagram for the same.

Figure 2-4 Screws on the pallet

2.1.3 Inspection

Moving forward, check the system fittings and its components against the packing list to ensure that

everything is in place and the assembly is intact.

If any parts or components are missing or damaged, immediately report to the carrier about the same. If

hidden damages are observed, then contact the local offices of that carrier as well as Vertiv Co. at the

earliest.

2.2 Installation Preparation (Site Preparation)

The CRV+ series of air conditioners is streamlined for maintaining a favorable environment for data

centers, computer rooms, and similar ecosystems. Strict adherence to the installation procedures is

mandatory in order to ascertain proper installation of the air conditioner.

2.2.1 Equipment Room Requirement

The equipment room must be prepared to ensure a smooth operation flow and obtain accurate results.

The equipment room must meet the standards for appropriate ventilation and heating. The design

specifications for the air conditioners must be ideal and should match the energy-efficient design

standards.

Following are the requirements for maintaining a favorable room environment prior to installation:

The equi

The outdoor air entering in should be kept at a minimum. The outside air will add the loads of

heating, cooling, humidifying, and dehumidifying of the system. It is recommended that the

inhalation of outside air be kept below 5% of the total indoor airflow.

All the doors and windows should be properly sealed to minimize the leakage. The seams should

be as narrow as possible.

pment room should be well insulated and have a sealed damp-proof layer.

Vertiv | Liebert CRV+ | User Manual 14

Page 25

Vertiv Co.

However, if these requirements are not met, rectifications must be made on the site so that

it complies with the specified requirements and conditions. However, if the recommended

rectifications or modifications are not implemented, then

accuracy and precision of the temperature and humidity provided by the

models. One important aspect to be considered is that the indoor unit must not be used for

the outdoor environment.

recommends that the site preparation is defined as per the requirements.

Vertiv Co.

does not guarantee the

Liebert CRV+

2.2.2 Installation Space requirements

Air conditioners in the Liebert CRV+ series are advanced precision air cooling units and therefore, these

air conditioners must be installed, preferably in a row of cabinets with high heat density and in a hot aisle

and cold aisle arrangement.

Allocate space so that it is accessible for the qualified service personnel for repairs, servicing, and

maintenance. For the CRV+ range, maintenance space must be allocated at the front and rear of the

equipment.

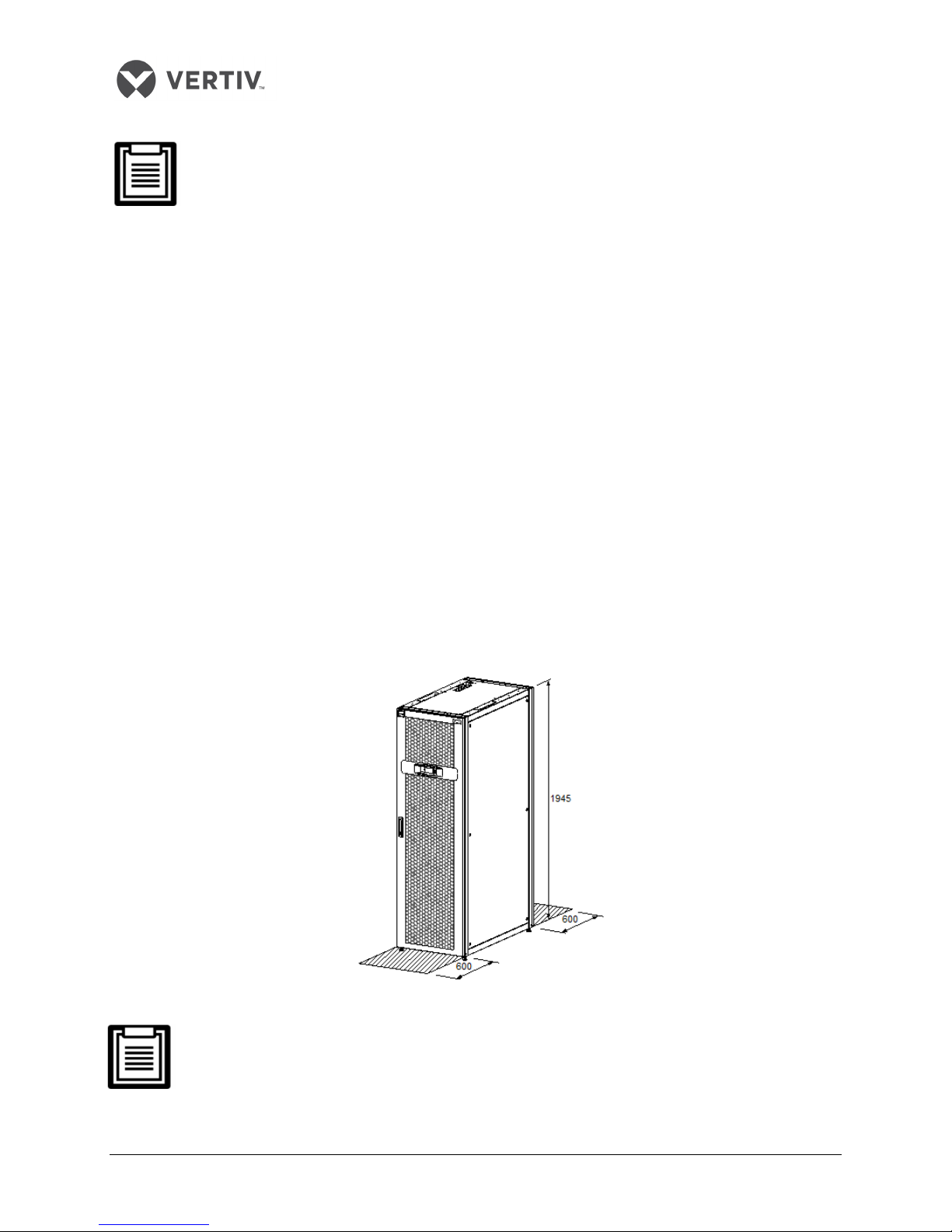

At the least, a space of 600 mm must be assigned for maintenance purposes in front of the system. A

minimum space of 600mm must be assigned for maintenance on the rear of the system.

The allocated space is to facilitate regular maintenance tasks such as replacement of the filter, blower,

and humidifier among others.

Figure 2-5 depicts the space allocated for servicing and maintenance.

Figure 2-5 CRV+ maintenance space

Contact the

work at an optimal level.

Vertiv Co

. team for special applications, which would need some modifications to

Vertiv | Liebert CRV+ | User Manual 15

Page 26

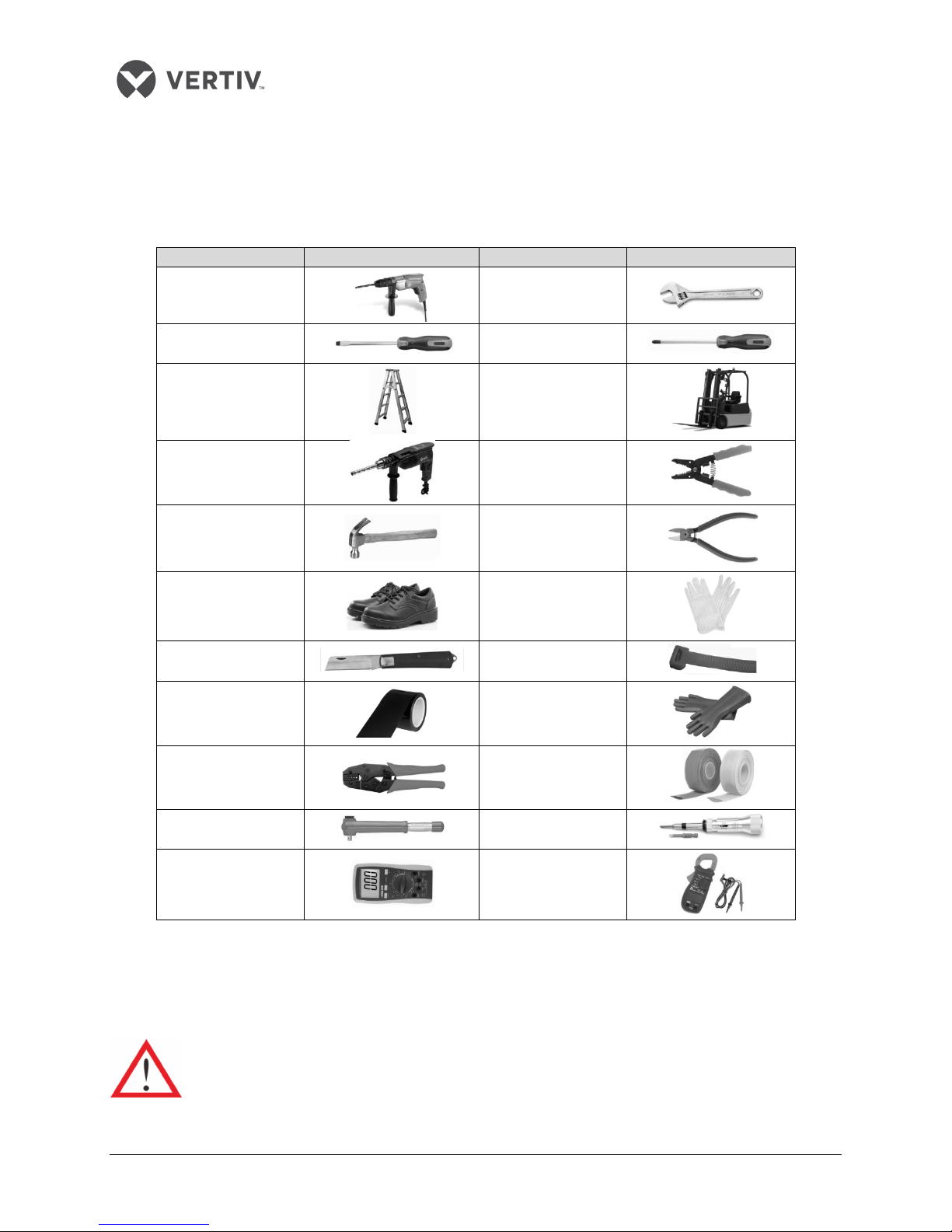

2.2.3 Installation Tools

Name

Drawing

Name

Drawing

Cross head

Insulated torque

Listing 2.1 shows the generic toolsets and utilities used in the installation and maintenance process:

Listing 2.1

Electric hand drill Adjustable wrench

Slotted screwdriver

Stepladder Forklift

Drill Wire cutting pliers

Claw hammer

Insulating shoes Antistatic gloves

Electrician knife Cable ties

Insulating tape Insulating gloves

Crimping pliers Heat shrinkable tube

screwdriver

Diagonal cutting

pliers

wrench

Multimeter Clip-on ammeter

The tools mentioned in Listing 2.1 are generic and commonplace; however, depending on various factors

such as site environment, cables, installation equipment, and on-site electrical connections these tools

may vary in a real-time scenario.

Ensure that the tools used in the installation, operation, and maintenance processes are

insulated. This safety measure is important for professionals and service personnel who

work with this CRV+ range air conditioner.

Vertiv | Liebert CRV+ | User Manual 16

rque screwdriver

To

Page 27

2.3 Mechanical Installation

Proper installation is important to achieve optimal performance and prolong the product life. In

this section, the mechanical installation will be discussed in detail to help the personnel get to

grips with the installation process.

fore proceeding with the mechanical installation, the following safety precautions need to be

Be

taken into account.

Prior to installation, ensure that the installation procedures have been read and implemented as

per the requirement. (Refer to section 2.2 on Installation Preparation for the details). Check if any

modifications are made to the plumbing, wiring, or ventilation facility before mounting the

equipment. Once the installation preparations are taken into consideration, move on to the next

step in the installation process, and eventually set up the system.

The CRV+ cooling units are designed for split-floor installation. The indoor unit must be installed

on the floor of the equipment room or computer room. The outdoor unit must be installed

outdoors or on the floor of the other rooms as per the building architecture.

Industry-wide standards are followed for the selection, layout, and fixing of pipes.

Several factors such as pressure drop, compressor oil return, noise reduction, and vibration are

considered during the design and installation process.

Follow the design drawings strictly when installing the equipment. Reserve space as per the

maintenance and serviceability instructions in the previous chapter on Installation Preparation.

The manufacturer’s engineering dimension drawings must be taken as a reference while installing

the equipment.

Vertiv | Liebert CRV+ | User Manual 17

Page 28

2.3.1 System arrangement during installation

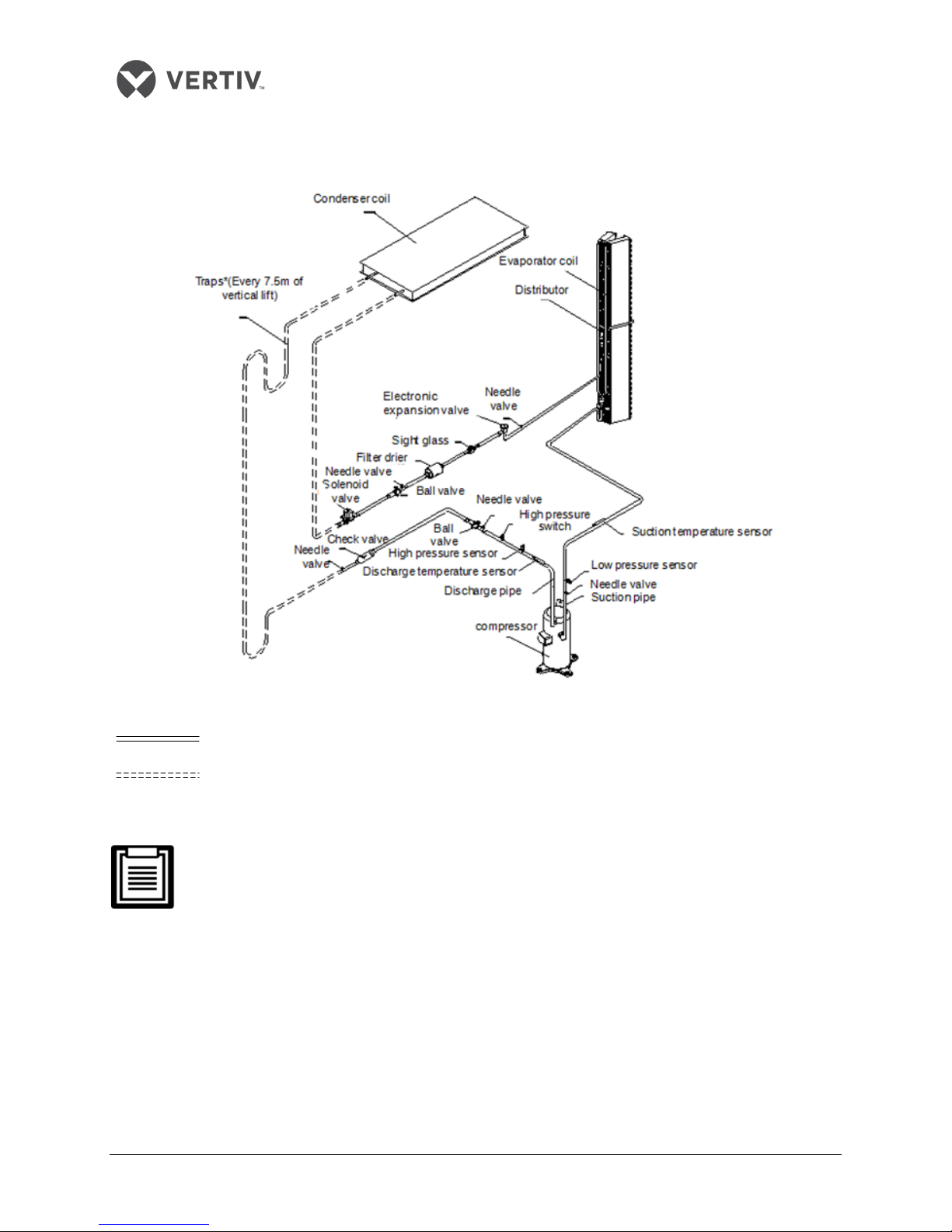

The general arrangement of the CRV+ air cooled AC unit is depicted in Figure 2-6.

Figure 2-6 System Arrangement

: Factory piping.

: Field piping (by technical personnel).

The following points should be considered before checking out the overall layout diagram:

single system is used as an example to describe the entire system.

The

Vertiv staff and qualified professionals lay out the piping in the laboratory.

Piping is done by technicians.

Components (marked with *) are not supplied by Vertiv Co. but are recommended for

proper circuit operation and maintenance.

Additional components (marked with +) are required when the equivalent length exceeds

30m.

Vertiv | Liebert CRV+ | User Manual 18

Page 29

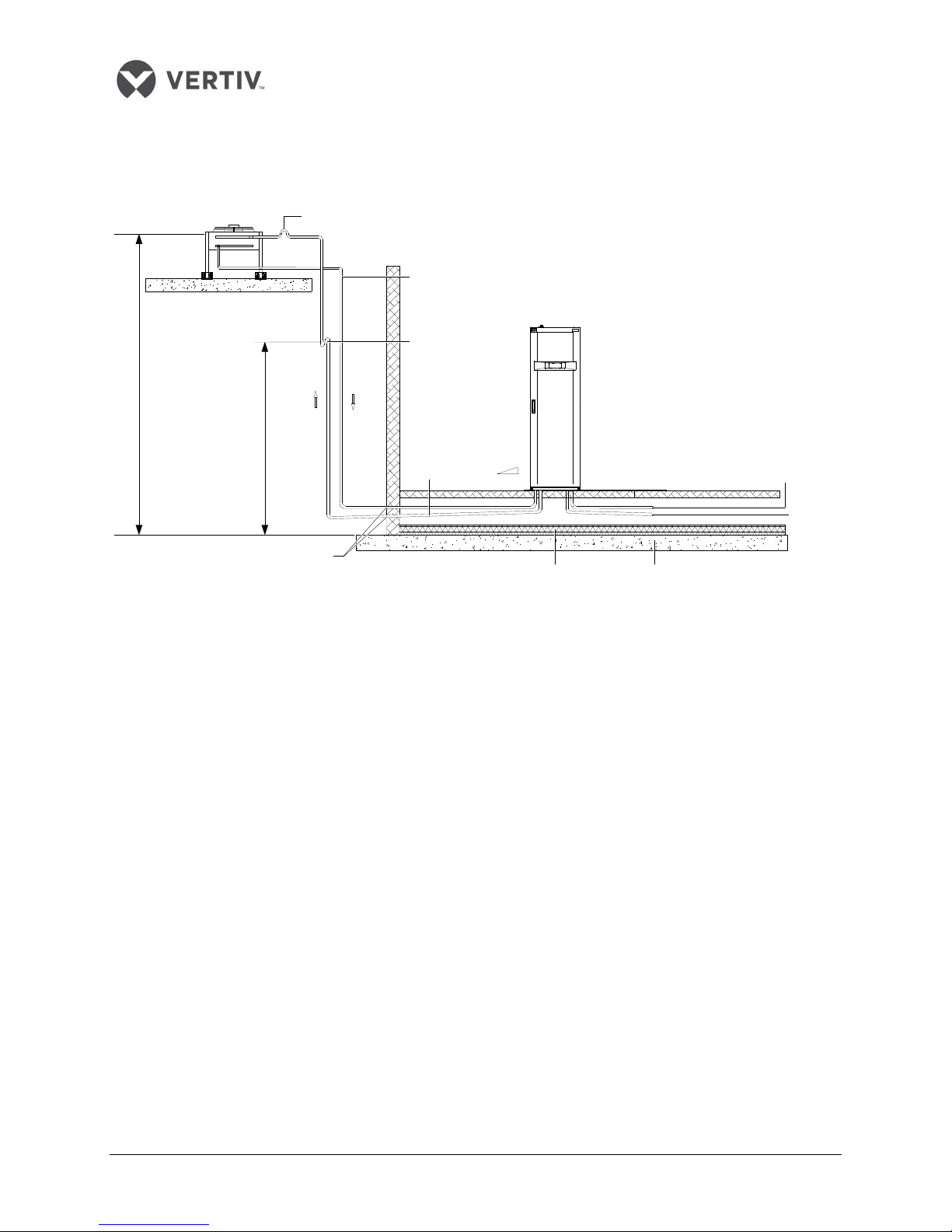

2.3.2 System Installation Mode

Back bend (must be higher than the

highest copper pipe of the condenser)

Heat insulation floor Floor

Sealed

Raised floor

Humidifier

water in

The system installation schematic diagram explains the process of installation for the Condenser:

Outdoor unit

Liquid line (avoid exposure to direct sunlight)

Indoor unit

Trap

Max. 30m

Max. 7.5m

Slope discharge

Condensed

water

Figure 2-7 Condenser is placed higher than the Compressors during installation

In Figure 2-7, the condenser is installed higher than the compressor. Therefore, an inverted back bend is

fitted to the discharge line and the liquid line of the condenser. The modification is essential as it helps

prevent the liquid refrigerant from flowing back once the condenser stops. The top end of the inverted

backbend must be installed higher than the ultimate level of the copper pipe of the condenser.

However, if the condenser is installed lower than the compressor, then there is no modification required

as it fits the bill perfectly.

Vertiv | Liebert CRV+ | User Manual 19

Page 30

Figure 2-8 depicts the schematic diagram of system installation when the condenser is installed at a

Heat insulation floor

Floor

Sealed

Raised floor

Humidifier

water in

water out

Indoor unit

Slope liquid

Min. 8m

Slope

discharge

Outdoor unit

lower level than the compressor.

Condensed

Figure 2-8 The Condenser is lower than the Compressor during installation

2.3.3 Product Dimensions

The dimensions and weight of the indoor unit are displayed in Figure 2-9 and in the table within Listing

2.2.

Vertiv | Liebert CRV+ | User Manual 20

Figure 2-9 Dimensions of an indoor unit

Page 31

Listing 2.2

Model

Dimensions (W × D × H) (mm)

Net weight (kg)

CR012HA1380S02E10000PV000

210

CR012RA1380S12E10000PV000

215

CR025HA1380S02E10000PV000

250

CR025RA138SS12E10000PV000

260

CR035RA138SS12E10000PV000

335

Model a b c d e f g h

I

CR012

/

43

44

130

44 / /

130

205

CR025

72

88

64

131

45

161

135

131

205

CR035

48

62

45

127

49

267

360

171

120

300×1100×2000

300 × 1100 × 2000

CR035HA1380S02E10000PV000

600 × 1100 × 2000

Base Plate pipe outlet Location & Dimensions

The locations of the pipe inlets and outlets on the unit base plate are shown in Figure 2-10:

315

The following table in Listing 2.3 depicts the dimensions of the base plate pipe outlet:

Vertiv | Liebert CRV+ | User Manual 21

Figure 2-10 Base Plate Location for pipe outlets

Listing 2.3

Page 32

Top plate pipe outlet Locations & Dimensions

CR012

/

80

39

125

100

40

106

110

CR035

47

38

71

233

137

50

155

118

The locations of the pipe inlets and outlets on the unit top plate are shown in Figure 2-11:

Figure 2-11 Top plate locations for pipe outlets

The following table in Listing 2.4 depicts the dimensions of the top plate pipe outlet:

Listing 2.4

Model a b c d e f g h

CR025 55 80 39 125 100 40 106 110

Front air outlet Locations and Dimensions

The location and dimensions of the air outlet at the front are shown in Figure 2-12:

Figure 2-12 Front air outlet locations & dimensions (unit: mm)

To prevent damage of the power cable, the cable entry hole is fitted with brushing for protection.

Vertiv | Liebert CRV+ | User Manual 22

Page 33

2.3.4 Installation Procedures

Closkwise

Hexagon bolt

Fixing nut

Counter closewise

or clockwise

The feet rise or drop

The CRV+ series of air conditioners is used between racks and one side of it is adjacent to the server

cabinet. The CRV+ series of Air Conditioners is especially used in small-and medium-range data centers,

computer rooms, and similar ecosystems.

Leveling the cabinet

Once all the components of the cabinet have been installed, level the cabinet. The following section is a

step-by-step illustration of the process of leveling the cabinet:

Place the cabinet in the desired location (preferably an open ground). Use a movable wrench to

loosen the fixing nuts on the four foot bolts in a clockwise sequence.

Rotate the hexagon bolts on the bottom of the feet clockwise or counter-clockwise till the feet

rises or drops to an appropriate position. Use a gradienter to ensure that the cabinet is in a

uniform level state.

Refer to the Figure 2-13

to understand the process better:

Figure 2-13 Leveling the cabinet

Screw down the fixing nuts on the feet bolts counter-clockwise and the leveling gets completed. If

the machine room has a mounting bracket, and its width does not exceed 30mm, remove the feet

and fix the cabinet onto the mounting bracket.

Vertiv | Liebert CRV+ | User Manual 23

Page 34

Removing the Feet and Fixing cabinet

Top fixing hole

Top fixing hole

Bottom fixing hole

Bottom fixing hole

Before explaining the task of removing the feet and eventually fixing the cabinet, it is vital that

2 persons will be required for this operation to avoid personal injury and cabinet damage.

Following are the instructions to be followed for removing the feet and fixing the cabinet:

Removing the feet

Use a moveable wrench to loosen the fixing nuts on the four fleet bolts in a clockwise sequence.

Rotate the hexagon bolts on the bottom of the feet clockwise till the feet drops from the cabinet

frames.

Fixing the cabinet

The cabinet provides two holes (diameter: 13.5 mm) respectively on its top, bottom, front, and rear as

depicted in Figure 2-14.

Install bolts in the four holes at the bottom to fix the cabinet onto the floor bracket of the machine

room.

Install bolts in the four holes at the top to fix the cabinet to connect the cabinet with the top

bracket of the machine room.

Vertiv | Liebert CRV+ | User Manual 24

Figure 2-14 Fixing holes of the cabinet

Page 35

Cabinet Connection

Cabinet

connector

Cabinet

connector

A

A amplified

Mounting screw

GB819_1_2000_M5x12

Cabinet connector

416 1100

The cabinet connectors come along with the accessories. Connect the unit with adjacent cabinets using

the cabinet connectors. The following section depicts the procedures for connecting the cabinet:

Before connecting the cabinet, level the cabinet as mentioned in the earlier section (Refer to

section Leveling the cabinet for in-depth information).

Loosen the fixing screw of the cabinet connector on the frame of the cabinet.

Rotate the cabinet connector 90 ° to the horizontal position. Use M5 countersunk head screws to

fix it on the cabinet frame. (Side of the door lock) as depicted in Figure 2-15.

Figure 2-15 Rotating the Cabinet connector

Use the M5 countersunk head screws to fix the cabinet connector (L-shaped) in the installation

holes of the cabinet frame (side of the hinge) and rack frame adjacent to the cabinet as depicted

in Figure 2-16.

Figure 2-16 Schematic diagram for connecting the cabinet

Install the other 6 cabinet connectors based on the same method.

Vertiv | Liebert CRV+ | User Manual 25

Page 36

2.3.5 Piping

A

A amplified

Fixing flake of the filter

Mounting screw

GB9074_4_88_M4x12

The pipes to be included in the Piping process of the AC are listed below:

Condensed water drainage pipe of the indoor unit;

Water inlet pipe of the electrode humidifier;

Connection of the copper pipe (discharge pipe and liquid pipe) between the indoor unit and

outdoor unit;

Pipe extension kit (optional).

The following points need to be taken into consideration during the Piping process:

All the joints of the refrigerating pipes must be silver-brazed.

The selection, layout, and fixing of the pipes will conform to the industry standards and

norms.

Vacuum pumping and refrigerant charging operations, and procedures must conform to the

industry standards.

Pressure drop, compressor oil return, noise return, and vibration must be considered during

the designing and installation process.

Removing Filters

Before the connection of the pipes in the indoor unit, the filters need to be removed.

Open the rear door of the cabinet to reveal the 2 filters, namely- the top and bottom filters.

Next, proceed to remove the fixing flake of the top filter. Prior to the removal of the fixing flake,

the screws of the flake need to be loosened. Then, the fixing flak will be removed, followed by

removing the top filter.

Use the same method to remove the bottom filter.

Figure 2-17 depicts the process of removing the filters:

Vertiv | Liebert CRV+ | User Manual 26

Figure 2-17 Removing the Filters

Page 37

Connecting the condenser water drainage pipe of the indoor unit

The Condensed water of the electrode humidifier and the evaporator converge to a common water tray

following which it is drained through the drainage pipe of the drain pump.

The unit is configured to adopt the top drain mode by default; therefore, connect the drainage

pipe of the pump upwards to the top drainage copper pipe.

Fix the drainage pipe to the drainage pipe connector with the hose clamps available in the

shipped accessories. The torque of the hose clamp is 15 kg cm.

Connect the drainage pipe to the drainage hole on the top of the cabinet.

To drain water from the bottom, direct the soft drainage pipe through the drainage hole of the

pump.

Fix the pipe to the copper pipe connector with the hose clamp. Moving forward, connect it to the

outer drainage pipe.

The outer diameter of the copper pipe is 12.7 mm and internal diameter of the soft pipe is 9 mm.

However, if the unit is not configured with a pump, the drainage pipe of the water tray should go through

the drainage hole of the tray and connect to the outer drainage pipe. The Trap is essential to drain the

condensate water.

The following points are to be taken into consideration about the trap:

Adopt a galvanized steel, PVC, or polyethylene pipe with a fair amount of flexibility

Allow a tilt of 2% towards the direction of the drainage flow.

The trap is mandatory and should be located 30 cm below the water tray. The tray must be kept under

the

movable floor.

Figure 2-18 Process of draining the Condensate water

Vertiv | Liebert CRV+ | User Manual 27

Page 38

Don’t cut off the brackets of the trap lest the smooth draining gets destroyed

Filling water to the trap before the unit is powered on

Use a Teflon belt between the flexible pipes and connector to avoid water leakage

The electrode humidifier contains flowing hot water, thus the plastic pipe must be resistant

to heat higher than 90° C

Figure 2-19 Connection of drainage pipes

Connecting the Water Inlet Pipe of an Electrode Humidifier

Water pipes should be connected for the electrode humidifier.

By default, the unit adheres to a top water inlet mode. If the water has to be filled from the top,

there is no need to change the water inlet pipe in the unit. In this case, connect a water inlet pipe

to the water inlet hole on the top of the cabinet.

However, if the water has to be filled from the bottom, unscrew the connector of the water inlet

soft pipe of the humidifier. The water inlet soft pipe needs to be routed through the rubber plug

hole close to the humidifier and connected to the outer water inlet pipe. Screw down a threaded

connector onto the water inlet pipe to complete the fixing process. Other connecting modes can

also be selected by the engineering methodologies, but the connections must be sealed to avoid

water leakage. The pressure range of the main pipe should be in the range of 100kPa – 700kPa.

In some cases, the process needs to be in compliance with the local laws and regulations

resulting in the introduction of some other components.

Vertiv | Liebert CRV+ | User Manual 28

Page 39

Figure 2-20 depicts the connection of the bottom water inlet pipe of the electrode humidifier:

Model

CR012

CR025

CR035

10m

16

12.7

16

12.7

19

16

30m

19

12.7

22

16

25

19

50m*

19

16

22

19

25

22

Water inlet

soft pipe

Water inlet

hole

Top water inlet

copper pipe

Figure 2-20 Connection of bottom water inlet pipe of electrode humidifier

Connecting the Copper pipes between the Indoor and Outdoor unit

The indoor and outdoor units are connected through welded copper pipes. Considering the effect of the

pipe diameter on the system pressure drop, the pipe diameter of the indoor unit and outdoor unit should

be determined by the specifications mentioned in the table under Listing 2.5. Alternatively, contact the

Vertiv support office to seek the help of the technician for gauging the length and diameter.

Listing 2.5

Pipe length D L D L D L

20m 16 12.7 19 16 22 19

40m* 19 16 22 16 25 19

A pipe extension kit is required for Equivalent Length marked with *.

D: Discharge line; L: Liquid Line

Consult Vertiv Co.If the pipe length exceeds 50m or 30m.

If the outdoor environment is lower than -20 °C, a low temperature kit is required. Therefore,

consult Vertiv Co. for the same.

Vertiv | Liebert CRV+ | User Manual 29

Page 40

The unit has refrigerating pipe connectors and labels on its top and bottom as shown in Figure 2-21 and

进水孔

排水孔

液管孔

排气管孔

进线孔

进线孔

Cable entry hole

Discharge pipe hole

Cable entry hole

Liquid pipe hole

Drainage hole

Water inlet hole

Drain hole

Cable entry hole

Liquid pipe hole

Discharge pipe hole

Figure 2-22.

During welding, do not burn the labels. The labels assist and point out the connections to the discharge

pipe and liquid pipe of the indoor unit. The horizontal sections of the discharge pipes must be tilted

downwards from the compressor with a slope of at least 1:200 (5mm down for every 1m run). The

discharge pipes must be insulated from heat at the location they are routed in the conditioned space

(including the raised floor).

Figure 2-21 Top pipe connectors

For bottom piping, before welding the compressor discharge pipe and liquid pipe, follow the

requirement labeled on the copper pipe; Cut the copper pipe using a cutter (a little bit of

the compressor lubricating oil may leak); however, do not weld the copper cap on the seal

directly as it may result in heating of the oil following which it may catch fire.

The exposure time of the system pipes should not exceed 15 minutes. If exposed for too

long, it will lead to the POE refrigeration oil being affected with damp. It may result in an

adverse effect on the life of the key components and the stability of the system operation.

Vertiv | Liebert CRV+ | User Manual 30

Figure 2-22 Bottom Pipe connectors

Page 41

Installing Pipe Extension Kit (for site installation)

There are instances where the one-way equivalent length of the pipe exceeds 30m. Or suppose the

vertical distance between the condenser and the indoor unit exceeds the value in the first table in the

following Listing 2.6.

Listing 2.6

Vertical distance between the Indoor and Outdoor unit

Positioning of the Outdoor Unit Height

Outdoor unit is higher than the Indoor unit Maximum : + 30m

Outdoor unit is lower than the indoor unit Minimum : - 8m

Equivalent length of the partial components

Outer diameter (OD) of the liquid pipe

(inches)

3/8 0.21 0.10 0.76

1/2 0.24 0.12 0.76

5/8 0.27 0.15 0.76

3/4 0.3 0.18 0.76

7/8 0.44 0.24 1.1

1-1/8 0.56 0.3 1.4

90° bend 45° bend T Type 3-way

Equivalent length (meters)

A trap must be installed every 7.5m of the vertical distance. Please consult Vertiv for such

specific inquiry and installation.

There is no necessity of cutting the indoor unit pipes while installing the solenoid valve.

After t

he entire system is installed, open the ball valve to keep the pressure and carry out the vacuum

operation, thereby avoiding the moisture absorption of the compressor refrigeration oil, Thus, it accounts

for operational safety and also extends the service life of the compressor (For electrical connections

related to the pipe extension kit, refer to the Electrical Installation section).

Take a look at the procedure for installing the Solenoid valve in the liquid pipe:

The solenoid valve must be as close to the indoor unit as possible. The valve body and coil of the

solenoid valve are separated when the valve is shipped out.

1) Mount the valve body horizontally in the refrigerant pipe as shown in Figure 2-23. Pay attention to

the arrow on the valve body as the arrow indicates the flow direction of the refrigerant in the valve.

Ensure that the arrow points towards the indoor unit.

Vertiv | Liebert CRV+ | User Manual 31

Page 42

Figure 2-23 Installing the Solenoid valve horizontally

2) After welding, install the coil and remove the cover of the wiring terminals. Direct the cable through

the cable hole in the cover and plug the two terminals and reinstall the cover.

Figure 2-24 shows the process of connecting the cables of the solenoid valve in a liquid pipe:

Figure 2-24 Connecting the cables of the Solenoid valve

3) Finally, clip the coil of the valve body, press the coil tightly to ensure complete contact between the

coil and valve body as displayed in Figure 2-25.

Charging Refrigerant and Adding Refrigeration Oil

The Liebert CRV+ air conditioners come pre-charged in the factory with 2Bar Nitrogen. The table in

Listing 2.7 indicates the standard charged amount. The users can determine the charging amount of the

Vertiv | Liebert CRV+ | User Manual 32

Figure 2-25 Fixing the coil

Page 43

refrigerant according to the system configuration and the length of the connection pipes between the

Outdoor unit model

LSF 12

LSF32

LSF38

LSF42

LSF52

LSF76

Recommended charging amount

2.44

3.24

3.93

4.4

5.73

6.39

Indoor unit model

CR012

CR025

CR035

Standard charging amount

2.41

4.52

5.24

16

0.174

22

0.321

25

0.431

28

/

indoor and outdoor unit.

The tables in Listing 2.7 depict the recommended charging amount of the outdoor unit and the

recommended charging amount for the indoor unit.

Listing 2.7

Recommended refrigerant charging amount of the outdoor unit

Recommended refrigerant charging amount of the indoor unit

The refilling amount of the refrigerant is calculated using the following formula:

Refrigerant refilling amount (kg) = Recommended refrigerant charging amount of outdoor unit+

recommended refrigerant charging amount of indoor unit+ refrigerant refilling amount of per meter

liquid pipe (kg/m) × total length of liquid pipe (m)

Refer to the table in Listing 2.8 for the refrigerant refilling amount of per meter liquid pipe for different

ODs:

Listing 2.8

Liquid pipe OD (mm) Refrigerant refilling amount of per meter liquid pipe (kg/m)

12.7 0.107

19 0.245

The refilled refrigerant will dilute the POE oil in the system and plays a major role in the lubrication and

cooling effects of the POE oil. Thus, it is for this purpose that the refrigerant oil must be added.

Vertiv | Liebert CRV+ | User Manual 33

Page 44

The refrigeration oil used in the Liebert CRV+ air conditioner is depicted in the table in Listing 2.9:

Unit model

Types of refrigeration oil

CR035

PVE (FVC68D)

Refrigeration oil adding amount with different pipe length

Liquid

CR012

Refrigeration oil

16

15

30

45

60

Liquid

CR025

Refrigeration oil charging is not

16

11

19

28

37

19

35

48

60

72

Liquid

CR035

Refrigeration oil charging is not

19

12

24

37

49

Listing 2.9

CR 012 PVE (FV505)

CR025 POE (RL32H)

Table depicting the amount of refrigeration oil to be added

(length unit: mm, refrigeration oil unit: ml)

pipe OD

(mm)

12.7

pipe OD

(mm)

12.7

pipe OD

(mm)

16

22 39 55 71 87

10 20 30 35 40 45 50

Refrigeration oil charging is not

needed

10 20 30 35 40 45 50

Refrigeration oil charging is not

needed

10 20 30 35 40 45 50

Refrigeration oil charging is not

needed

charging is not needed

needed

needed

15 30

Consult Vertiv Co. for adding the refrigeration oil

32

13

Do not use poor quality refrigeration oil as it can damage the system

Select the right make and type of refrigeration oil depending on the model.

If any error or damage occurs due to adding the incorrect make and type of oil, the warranty

will be void.

2.3.6 Removing Transportation Fastener and Vibration Absorber

Certain fasteners and vibration absorbers are mounted on the equipment to protect partial components

from getting damaged and distorted due to bumping, impact, and resonance.

Vertiv | Liebert CRV+ | User Manual 34

Page 45

Removal of these fasteners and absorbers is necessary before installation and commissioning.

M4 screw

(6 pcs)

Removing Pipe fixity

If the copper pipe gets close to the metal plate, it may result in wear and tear of the copper pipe. To

prevent this from occurring, vibration absorbers are fitted between them. However, these objects need

to be removed and then the area must be cleaned prior to installing and commissioning.

Removing limiting piece of the electrical control box

The electric control box may move during transportation. To prevent this abrupt movement, a limiting

piece of the electric control box is installed before delivery. The limiting piece has to be removed before

operating the unit so that the maintenance personnel can slide out the electrical control box during

maintenance.

Adjusting the wind-leading grill

Adjust the installation direction of the wind-leading grill to lead wind to the left or right depending on the

installation location of the Liebert CRV+ series air conditioners. The wind-leading grill is composed of

several pieces. Remove the screws on both sides of the single piece of the wind-leading grill, rotate it by

180°. Install it back to change the wind direction.

Figure 2-26 shows the mounting screws of a single piece of the wind-leading grill:

Sealing the holes of the top plate of the cabinet

Holes are reserved at the top of the cabinet to facilitate smooth on-site installation as well as the

connection of the rack on the top of the machine room. After the cabinet is installed on the site, seal the

remaining holes using rubber plugs and bolts. Use M13.5 rubber plugs to seal four holes at the top of the

cabinet and M12*30 bolts to seal 8 holes at the top plate of the cabinet. This prevents water from

entering the cabinet.

Vertiv | Liebert CRV+ | User Manual 35

Figure 2-26 Fixed mode of the wind leading grill

Page 46

Figure 2-27 depicts the schematic diagram of sealing the holes on the top plate of the cabinet.

Use the provided four M13.5 rubber plugs to seal the holes

Use the provided eight M12 × 30 bolts to seal the holes

Item

Result

Drainage pipe is connected

All pipe connectors are tight

F

igure 2-27 Sealing the top holes of the cabinet

2.3.7 Checklist for completed mechanical installation

Following are the points in the checklist (Refer Listing 2.10) that need to be verified and confirmed to

ensure that the mechanical installation was implemented successfully:

Sufficient space is kept for maintenance, according to the user manual.

The equipment is placed vertically and mounting fasteners are fastened

The pipes between the indoor unit and outdoor unit are completed. The ball valves

of the indoor unit and outdoor unit are fully opened

The wind direction of the wind-leading grill has been adjusted (if required)

Water supply pipe is connected to the electrode humidifier

The fasteners used for transportation have been removed

After installation, foreign materials in and around the equipment are removed

(such as shipping materials, construction materials, tools, and so on)

Listing 2.10

Vertiv | Liebert CRV+ | User Manual 36

Page 47

As soon as the mechanical installation has been implemented and completed accurately, then

the electrical installation of the product and its components can be carried out.

2.4 Electrical Installation

In this chapter, the electrical installation of the CRV+ air cooled units is explained in-depth to

help users get to grips with the various tasks which include the task introduction, notes, and

cable connections of the indoor unit apart from the checklist.

The air conditioners in the Liebert CRV+ series are professional devices used in industrial,

commercial, or other professional occasions. It is not tailored for the general public. The total

rating power is larger than 1 kW and is in with the IEC61000-3-12 standard. A port of less

than a 350 short circuit requires is required between the user power and the grid.

Permission is required from the power supply department to ensure that the air conditioner

is connected to a power no less than 350 circuit ratio.

2.4.1 On-site Wire connections

Following are the wires to have to be connected in/on the site:

Power cable and control cabinet of the indoor unit

Solenoid valve cable of the pipe extension kit (an optional requirement)

Outdoor unit (air-cooled), control Signal and Power cable

Input and Output control the cable of the unit

2.4.2 Installation Notes

The connections of all the power cables, control cab

compliance with the local and national electrical regulations.

Observe the unit nameplate for the full load current. The cables sizes must meet the conditions as

specified in the local wiring protocols and rules.

Mains supply requirement: (380 to 415) V ± 10%; 50 Hz/60-Hz, 3N-

The power soft cable is a Y-type connection. If damaged, it has to be replaced immediately to

eliminate the dangers. The replacement procedure must be carried out by an authorized

professional or experienced service personnel.

The electrical installation and maintenance must be carried out by an authorized personnel or a

trained engineer well-versed with the inner workings of the electrical connection (For example,

service engineer from the manufacturer’s side).

Prior to the wiring, a voltmeter must be used to measure the power supply voltage and ensure that

the power supply has been switched off.

Use screws, guide rails, or other modes to fix the device firmly during the installation process to avoid

movement or shaking during the start-up or operation mode.

For the air conditioner configured with EC fans, the unit power grid adheres to the TN or TT star

connection power distribution system. However, if there is a need to configure another type of

power grid, contact the Vertivsupport team for the same.

les, and ground cables should be in

Vertiv | Liebert CRV+ | User Manual 37

Page 48

An appropriate all –pole disconnection device must be supplied.

SCCR of the CRV+ air cooled unit - 5 kA

The power soft cable should not be lighter than an ordinary PVC-sheathed according to the 53

line according to GB5023.1(idt IEC60277)

For appliance of outdoor, the power cable should be not lighter than Chloroprene rubber

sheathed flexible cord which is 57 line according to IEC 60245.

2.4.3 Connecting cables of the Indoor unit

This section deals with the different types of connections related to the indoor unit, namely–

Electrical port location of the indoor unit

Connecting the Power cables of the indoor unit

Connecting the Control cables

Connecting the Solenoid valve of the Pipe extension kit (Optional)

Electrical Port location of the indoor unit

For any model in the CRV+ series, open the back door of the indoor unit following which the

specific layout and locations of the low voltage components can be viewed as depicted in Figure

2-28. For detailed layout information on low voltage components, refer to the labels pasted on

the cabinets and units.

Figure 2-28 Unit electrical control box and cable connection (open the back door 120°)

MCB current

Model MCB Current(A)

CR012 NDM1-63C32/3 32

CR025 NDM1-63C40/3 40

CR035 NDM1-63C50/3 50

Vertiv | Liebert CRV+ | User Manual 38

Listing 2.11

Page 49

Connecting the Power cable of the Indoor unit

Standard

The specific location of the power port of the indoor unit is depicted in Figure 2-28. Connect the

supply terminals L1-L3,N and PE to their respective counterparts of the external power supply

res

pectively.

Fix the input cables to the cable clamp, located on the inner side panel of the unit. The top cable

entry hole and bottom cable entry hole as depicted in Figure 2-29.

For the cable specifications, refer to the full-load current (FLA) described in the table within

Listing 2.12.

The cable sizes must strictly meet and adhere to the local wiring regulations and protocols as

it supersedes every type of connection.

Full Load current (unit A)

Model

CR012HA1380S02E10000PV000 19.1 19.1 / /

CR012RA1380S12E10000PV000 19.1 / / /

CR025HA1380S02E10000PV000 24.9 24.9 26 26

CR025RA138SS12E10000PV000 26 / / /

CR035HA1380S02E10000PV000 31.6 46.6 42.3 46.6

CR035RA138SS12E10000PV000 46.6 / / /

Figure 2-29 Top and bottom cable entry holes

Listing 2.12

Standard

model

Standard

model with

electric

heater

Standard

model with

humidifier

model with

electric

heater &

humidifier

Vertiv | Liebert CRV+ | User Manual 39

Page 50

The location of the terminal block for cable connections in the site is depicted in Figure 2-28. The

amplified view of the terminals is shown in Figure 2-30.

Figure 2-30 Terminal Block for cable connection in the site

The connection personnel must take anti-static measures before connecting the control

cables

Water-under-floor sensor

If a water-under-floor sensor is equipped, connect one end of the sensor to terminal 51# and the other

end to common terminal 24#.

Each unit can be connected with multiple sensors in parallel, but there would be only one water-underfloor alarm.

SIC card

If a SIC card is equipped, connect A#, B#, GND#, and 12# on the SIC card to the respective counterparts

on the terminal block. Refer to Appendix 1 Circuit Diagram fo

r in-depth information.

Vertiv | Liebert CRV+ | User Manual 40

Page 51

Rack sensor

Sensor

1 2 3 4 5 6 ID

传感器

Sensor

1.5m

1.5m

Each unit can be connected with a maximum of 10 temperature sensors. It is recommended that the

sensors be located in front of the heat loads to achieve the most precise temperature. If the sensors are

connected in series (see Figure 2-31), each temperature sensor monitors the temperature of air entering

each rack, and the read temperature value is used to control unit operation. The standard location of the

sensor is 1.5m height. Therefore, the sensors should be placed in positions as depicted in Figure 2-31, or

the devices cannot operate appropriately.

Figure 2-31 Layout figure of rack sensors

Following is the procedure to connect sensors for Liebert CRV+ models:

Insert the connector of the rack temperature sensor in the TB3 point. On connecting the cable,

route the cable through the top or bottom of the unit following which it should be connected to

the first sensor. Connect the first sensor to the second sensor. Thus, the sensors are connected in

a chain.

Fix the temperature in front of the hottest source inside the rack. Do not fix it in front of the

empty sub-rack. Affix the sensor on the rack surface using the magnets provided in the kit. Th

ensor must be fixed in a position that is mostly short of cool air.

s

Rack temperature sensor IRM-S0

Rack temperature 1 0 0 0 0 0 1 1

Rack temperature 2 0 0 0 0 1 0 2

Rack temperature 3 0 0 0 0 1 1 3

1 address settings are depicted in the table in Listing 2.13.

Listing 2.13

ON — “1”;

OFF — “0”

e

Rack temperature 4 0 0 0 1 0 0 10

Vertiv | Liebert CRV+ | User Manual 41

Page 52

Sensor

1 2 3 4 5 6 ID

Rack temperature 5 0 0 0 1 0 1 11

Rack temperature 6 0 0 0 1 1 0 12

Rack temperature 7 0 0 0 1 1 1 13

Rack temperature 8 0 0 1 0 0 0 20

Rack temperature 9 0 0 1 0 0 1 21

Rack temperature 10 0 0 1 0 1 0 22

ON — “1”;

OFF — “0”

Remote Shutdown

As depicted in Figure 2-30, terminals 37# and 38# can be connected to the remote shutdown switch.

The terminals must be shorted before delivery. If a remote shutdown signal is to be connected, remove

the short-connect cable.

Closing the terminals 37# and 38# will shut down the unit.

Control signals of the outdoor unit

Terminals 70# & 71# are the control signal input terminals of the outdoor unit. Their On and Off state is

the same as that of the compressor 2#. They can be connected to the compression rotation speedcontrol terminals on the control board of the outdoor unit. However, connecting them is an option

depending on the requirement.

External Common Alarm

Terminals 75# and 76# can be connected to the external common alarms. They generate signals to

external alarm devices such as an alarm indicator. When the critical alarm occurs, the contact will be

closed to trigger remote alarms, send signals to the building management system, or dial the paging

system automatically.

The users have to obtain the power supply of external common alarm system. For an in-depth definition

of the other terminals, refer to the Circuit Diagram

the Appendix-1.

in