Page 1

Liebert®

DataMate™

Installer/User Guide

1.5-ton to 3-ton Capacity, 50Hz and 60Hz

Page 2

The information contained in this document is subject to change without notice

and may not be suitable for all applications. While every precaution has been

taken to ensure the accuracy and completeness of this document, Vertiv

assumes no responsibility and disclaims all liability for damages resulting from

use of this information or for any errors or omissions. Refer to other local

practices or building codes as applicable for the correct methods, tools, and

materials to be used in performing procedures not specifically described in this

document.

The products covered by this instruction manual are manufactured and/or sold

by Vertiv. This document is the property of Vertiv and contains confidential

and proprietary information owned by Vertiv. Any copying, use or disclosure of

it without the written permission of Vertiv is strictly prohibited.

Names of companies and products are trademarks or registered trademarks of

the respective companies. Any questions regarding usage of trademark names

should be directed to the original manufacturer.

Technical Support Site

If you encounter any installation or operational issues with your product, check the pertinent section of this

manual to see if the issue can be resolved by following outlined procedures.

Visit https://www.Vertiv.com/en-us/support/ for additional assistance.

Vertiv | Liebert® DataMate™ Installer/User Guide

Page 3

TABLE OF CONTENTS

1 Important Safety Instructions 1

1.1 AHRICertified 6

1.2 Agency Listed 7

2 Nomenclature 9

2.1 Nomenclature for Evaporator and Chilled Water Units 9

2.2 Nomenclature for Condensing Units 10

2.2.1 Outdoor Prop Fan Condensing Units for Air Cooled Systems 10

2.2.2 Indoor Condensing Units for Air Cooled Systems 11

2.2.3 Close Coupled Condensing Unit for Water/Glycol CooledSystems 12

2.2.4 Remote, Indoor Water/Glycol Cooled Condensing Units 13

2.3 System Configurations 14

3 Site Preparation and Equipment Handling 17

3.1 Planning Dimensions 17

3.2 Room Preparation 17

3.3 Application Limits 17

3.4 Location Considerations 18

3.4.1 Location Considerations for Evaporator, Indoor CondensingandChilled WaterUnits 19

3.4.2 Location Considerations for an Outdoor Condensing Unit 20

3.5 Unit Weights 21

3.6 Equipment Inspection and Handling 21

4 Installation 23

4.1 Installing Wall Mounted EvaporatorsandChilled Water Units 23

4.1.1 Changing Air Flow Direction 23

4.2 Installing Outdoor Condensing Unit forAir CooledSplit Systems 23

4.3 Installing Ceiling Mounted Condensing Units 23

4.3.1 Installing Suspension Rods andMounting Ceiling Units 24

4.3.2 Guidelines for Ducted Systems 26

4.4 Close Coupled Installations forIntegralWater/Glycol CondensingUnits 27

4.4.1 Connecting the Close Coupled Refrigerant Circuit 33

4.4.2 Connecting the Close Coupled Electrical Wiring 35

4.4.3 Final Installation Steps for Close Coupled Units 36

5 Piping and Refrigerant Requirements 37

5.1 Fluid Piping Required 38

5.1.1 Evaporator Drain Line Installation Requirements 38

5.1.2 Humidifier Drain Line Installation Requirements 38

5.1.3 Condensate Drain Pump Kit 38

5.1.4 Water Supply Line to the Humidifier 39

5.1.5 Chilled Water Loop Piping 39

i

Page 4

5.1.6 Water/Glycol Loop Piping 40

5.2 Refrigerant Piping 42

5.2.1 Piping when Condensing Unit is Above or Below Evaporator 43

5.2.2 Refrigerant Line Sizes and Equivalent Lengths 44

5.3 Refrigerant Charge Requirements 45

5.3.1 Field Fabricated Refrigeration Piping 46

5.3.2 Evacuation and Leak Testing Air Cooled Systems 46

5.3.3 Charging Air Cooled Systems 49

5.3.4 Field Charge Verification forAir Cooled Systems 49

5.3.5 Documenting Refrigerant Charge on Air Cooled Units 50

5.3.6 Evacuation and Leak Testing Water/Glycol Cooled Systems 50

5.3.7 Charging Water/Glycol Cooled Systems 52

5.3.8 Optimizing Refrigerant Charge on Water/Glycol Units 53

5.3.9 Documenting Refrigerant Charge on Water/Glycol-cooled Units 53

6 Electrical Connection Requirements 55

6.1 Input Power Connection Requirements 56

6.2 Control Wiring Connection Requirements 57

6.2.1 Wall Box Controller Control Connections 57

6.2.2 Split System Condensing Unit Control Connections 57

6.2.3 Water/Glycol Cooled Unit Control Connections 57

6.2.4 Additional Control Connections 57

7 Checklist for Completed Installation 59

8 Initial Start-up Checks andCommissioningProcedure forWarrantyInspection 61

9 Microprocessor Control 63

9.1 Controller Operation 63

9.1.1 Powering On/Off with Wall Mounted Display 64

9.1.2 Silencing an Audible Alarm 64

9.2 Main Menu <MENU> 64

9.2.1 Editing Setpoints 67

9.2.2 Viewing Unit Status 67

9.2.3 Viewing Active Alarms 68

9.2.4 Setting Controller Time 68

9.2.5 Setting Controller Date 68

9.2.6 Programming Setback 68

9.2.7 Editing Setup Operation 69

9.2.8 Changing Setpoint and Setup Passwords 71

9.2.9 Calibrating Sensors and Setting Sensor Response Delay 71

9.2.10 Enabling/Disabling Alarms 72

9.2.11 Setting Alarm Delays 72

9.2.12 Activating the Common Alarm Relay 73

ii

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 5

9.2.13 Configuring Custom Alarms 74

9.2.14 Customizing Alarm Message Text 74

9.2.15 LCD Display Contrast 74

9.2.16 Non-volatile Memory 74

9.2.17 Equipment Options DIP Switches 75

9.3 Running Diagnostics 76

9.3.1 Showing Test Inputs 76

9.3.2 Testing Outputs 76

9.3.3 Testing the Microcontroller 77

9.4 System Control and Performance 80

9.4.1 Temperature Control 80

9.4.2 Cooling/Heating Required 80

9.4.3 Electric Reheat 80

9.4.4 Humidity Control 80

9.4.5 Load Control 81

9.4.6 Monitoring 81

9.5 Alarm Notification, Acknowledgment, and Descriptions 81

9.5.1 Custom Alarms 81

9.5.2 High Head Pressure Alarm 82

9.5.3 Humidity Level Alarms 82

9.5.4 Temperature Level Alarms 83

9.5.5 Humidifier Problem Alarm 83

9.5.6 Loss of Power Alarm 83

9.5.7 Short Cycle Alarm 83

10 Maintenance 85

10.1 System Testing 86

10.1.1 Environmental Control Function Tests 86

10.1.2 Cooling Test 86

10.1.3 Heating Test 86

10.1.4 Humidification Test 86

10.1.5 Dehumidification Test 86

10.1.6 Remote Shutdown Test 86

10.2 Filter Maintenance 87

10.3 Electric Panel Maintenance 87

10.4 Direct Drive Blower Package Maintenance 87

10.4.1 Fan Impeller and Motor Bearing Maintenance 87

10.4.2 Air Distribution Inspection 87

10.5 Electric Reheat Maintenance 87

10.6 Refrigeration System Maintenance 87

10.6.1 Refrigeration Suction Pressure 87

iii

Page 6

10.6.2 Refrigeration Discharge Pressure 87

10.6.3 Thermostatic Expansion Valve (TXV) Maintenance 88

10.6.4 Air Cooled Condensing Unit Maintenance 88

10.6.5 Hot Gas Bypass Operation and Maintenance 88

10.6.6 Water/Glycol Condenser Maintenance 90

10.6.7 Regulating Valve Maintenance (Water/Glycol Cooled Condensers Only) 90

10.6.8 Glycol Solution Maintenance 90

10.7 Compressor Maintenance 91

10.7.1 Mechanical Failure of the Compressor 91

10.7.2 Electrical Failure of the Compressor 91

10.7.3 Replacement Compressors 92

10.7.4 Replacing a Failed Compressor 92

10.8 Steam Generating Humidifier Maintenance 92

10.8.1 Operating the Humidifier 93

10.8.2 Replacing the Canister 94

10.8.3 Circuit Board Adjustments 95

11 Preventive Maintenance Checklist 97

12 Troubleshooting 101

Appendices 105

Appendix A: Technical Support and Contacts 105

Appendix B: Submittal Drawings 107

iv

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 7

1 IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation and maintenance of the

Liebert®DataMate. Read this manual thoroughly before attempting to install or operate this unit.

Only qualified personnel should move, install or service this equipment.

Adhere to all warnings, cautions, notices and installation, operating and safety instructions on the unit and in this manual.

Follow all installation, operation and maintenance instructions and all applicable national and local building, electrical and

plumbing codes.

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC, and local codes,

as applicable. Before proceeding with installation, read all instructions, verify that all the parts are included

and check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the Unit Off mode. Some internal components require and receive

power even during the Unit Off mode of the controller. The only way to ensure that there is NO voltage inside

the unit is to install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all local

codes.

WARNING! Risk of electric shock. Can cause equipment damage, injury, or death. Open all local and remote

electric power supply disconnect switches and verify with a voltmeter that power is off before working within

any electric connection enclosures. Service and maintenance work must be performed only by properly

trained and qualified personnel and in accordance with applicable regulations and manufacturers’

specifications. Opening or removing the covers to any equipment may expose personnel to lethal voltages

within the unit even when it is apparently not operating and the input wiring is disconnected from the

electrical source.

WARNING! Risk of over-pressurization of the refrigeration system. Can cause piping rupture, explosive

discharge of high pressure refrigerant, loss of refrigerant, environmental pollution, equipment damage,

injury, or death. This unit contains fluids and gases under high pressure. Use extreme caution when

charging the refrigerant system. Do not pressurize the system higher than the design pressure marked on

the unit's nameplate. Relieve pressure before cutting into or making connections/disconnections to the

piping system. Local building or plumbing codes may require installing a pressure relief device in the

system.

Consult local building and plumbing codes for installation requirements of additional pressure relief devices

when isolation valves are field installed. Do not isolate any refrigerant circuits from over-pressurization

protection. The PFH and MCD condensing units include a factory installed pressure relief valve mounted on

top of the receiver. The valve is rated for a maximum working pressure of 475 psig.

1 Im portant Safety Instructions

1

Page 8

WARNING! Risk of contact with high speed, rotating fan blades. Can cause injury or death. Open all local and

remote electric power supply disconnect switches, verify with a voltmeter that power is off, and verify that all

fan blades have stopped rotating before working in the unit cabinet.

WARNING! Risk of electric shock. Can cause serious injury or death. The microprocessor does not isolate

power from the unit, even in the Unit Off mode. Some internal components require and receive power even

during the Unit Off mode of the control. Open all local and remote electric power disconnect switches and

verify with a voltmeter that power is Off before working on any component of the system.

WARNING! Risk of improper wiring, piping, moving, lifting and handling. Can cause equipment damage,

serious injury or death. Installation and service of this equipment should be done only by qualified personnel,

wearing appropriate, OSHA approved PPE, who have been specially trained in the installation of air

conditioning equipment.

WARNING! Risk of improper wire and loose electrical connections. Can cause overheated wire and electrical

connection terminals resulting in smoke, fire, equipment and building damage, injury or death. Use correctly

sized copper wire only and verify that all electrical connections are tight before turning power On. Check all

electrical connections periodically and tighten as necessary.

WARNING! Risk of unit falling off of the wall. Can cause building and equipment damage and serious injury. A

licensed professional structural engineer should evaluate the wall to determine if the unit may be safely

mounted on the wall and determine the type and size of fasteners required to support the weight of the unit

during all phases of operation because some vibration may occur during start, stop, and operation cycles.

The wall may need to be reinforced to support the maximum load of the unit. See Table 3.5 on page21, for

unit weights.

WARNING! Risk of ceiling collapse and heavy unit falling. Can cause building and equipment damage, serious

injury or death. If using a ceiling mounted condensing unit, verify that the supporting roof structure is

capable of supporting the weight of the unit(s) and the accessories. See the appropriate condensing unit

installer/user guide for the unit weights. Securely anchor the top ends of the suspension rods and verify that

all nuts are tight.

WARNING! Risk of smoke and fire. Can cause activation of fire suppression systems, building evacuation,

dispatching of fire/rescue equipment and personnel and catastrophic canister failure resulting in water

leaks, equipment damage, injury or death. Using a humidifier canister that has reached the end of it’s service

life can be extremely hazardous. If the canister cannot be replaced immediately at the end of life condition,

turn Off the power and water supply to the humidifier and remove the canister until a replacement canister

can be installed. Do not ignore humidifier problem alarms. Resetting humidifier without addressing cause

may result in fire or damage due to leaking water.

2

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 9

CAUTION: Risk of excessive refrigerant line pressure. Can cause tubing and component rupture resulting in

equipment damage and personal injury. Do not close off any field installed refrigerant line isolation valve for

repairs unless a pressure relief valve is field installed in the line between the isolation valve and the check

valve. The pressure relief valve must be rated 5% to 10% higher than the system design pressure. An

increase in ambient temperature can cause the pressure of the isolated refrigerant to rise and exceed the

system design pressure rating (marked on the unit nameplate).

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA approved PPE should attempt to move,

lift, remove packaging from or prepare the unit for installation.

CAUTION: Risk of contact with hot surfaces. Can cause injury. The compressor, refrigerant discharge lines,

fan motor, and some electrical components are extremely hot during unit operation. Allow sufficient time for

them to cool to a touch-safe temperature before working within the unit cabinet. Use extreme caution and

wear appropriate, OSHA approved PPE when working on or near hot components.

CAUTION: Risk of contact with hot surfaces. Can cause burn injury. The humidifier canister and steam

discharge lines are extremely hot during operation. Allow sufficient time for them to cool to a touch-safe

temperature before handling. Use extreme caution and wear appropriate, OSHA approved PPE when

performing maintenance on the humidifier.

NOTICE

CAUTION: Risk of contacting caustic substances. Can cause injury. Avoid touching or contacting the gas and

oils with exposed skin. Severe burns will result. Wear appropriate, OSHA approved PPE when handling

contaminated parts.

Risk of oil contamination with water. Can cause equipment damage.

Liebert®DataMateDX systems require the use of POE (polyolester) oil. POE oil absorbs water at a much faster

rate when exposed to air than previously used oils. Because water is the enemy of a reliable refrigeration

system, extreme care must be used when opening systems during installation or service. If water is absorbed

into the POE oil, it will not be easily removed and will not be removed through the normal evacuation process. If

the oil is too wet, it may require an oil change. POE oils also have a property that makes them act as a solvent

in a refrigeration system. Maintaining system cleanliness is extremely important because the oil will tend to

bring any foreign matter back to the compressor.

1 Im portant Safety Instructions

3

Page 10

NOTICE

NOTICE

Risk of clogged or leaking drain lines and leaking water supply lines. Can cause equipment and building

damage.

This unit requires a water drain connection. Drain lines must be inspected at start-up and periodically, and

maintenance must be performed to ensure that drain water runs freely through the drain system and that lines

are clear and free of obstructions and in good condition with no visible sign of damage or leaks. This unit may

also require an external water supply to operate.

Improper installation, application and service practices can result in water leakage from the unit. Water

leakage can result in catastrophic and expensive building and equipment damage and loss of critical data

center equipment.

Do not locate unit directly above any equipment that could sustain water damage.

We recommend installing a monitored fluid detection system to immediately discover and report coolant fluid

system and condensate drain line leaks.

Risk of leaking water/glycol. Can cause equipment and building damage.

Improper installation, application, and service practices can result in water leakage from the unit. Do not mount

this unit over equipment and furniture that can be damaged by leaking water. Install a water-tight drain pan

with a drain connection under the cooling unit and the ceiling mounted water/glycol condensing unit. Route the

drain line to a frequently used maintenance sink so that running water can be observed and reported in a

timely manner. Post a sign to alert people to report water flowing from the secondary drain pan. We

recommend installing monitored leak detection equipment for the unit and supply lines and in the secondary

drain pan. Check drain lines periodically for leaks, sediment buildup, obstructions, kinks and/or damage and

verify that they are free running.

4

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 11

NOTICE

Risk of piping system corrosion and freezing fluids. Can cause leaks resulting in equipment and very expensive

building damage. Cooling coils and piping systems are at high risk of freezing and premature corrosion. Fluids

in these systems must contain the proper antifreeze and inhibitors to prevent freezing and premature coil and

piping corrosion. The water or water/glycol solution must be analyzed by a competent local water treatment

specialist before start-up to establish the inhibitor and antifreeze solution requirement and at regularly

scheduled intervals throughout the life of the system to determine the pattern of inhibitor depletion.

The complexity of water/glycol solution condition problems and the variations of required treatment programs

make it extremely important to obtain the advice of a competent and experienced water treatment specialist

and follow a regularly scheduled coolant fluid system maintenance program.

Water chemistry varies greatly by location, as do the required additives, called inhibitors, that reduce the

corrosive effect of the fluids on the piping systems and components. The chemistry of the water used must be

considered, because water from some sources may contain corrosive elements that reduce the effectiveness of

the inhibited formulation. Sediment deposits prevent the formation of a protective oxide layer on the inside of

the coolant system components and piping. The water/coolant fluid must be treated and circulating through

the system continuously to prevent the buildup of sediment deposits and or growth of sulfate reducing

bacteria.

Proper inhibitor maintenance must be performed in order to prevent corrosion of the system. Consult glycol

manufacturer for testing and maintenance of inhibitors.

Commercial ethylene glycol, when pure, is generally less corrosive to the common metals of construction than

water itself. It will, however, assume the corrosivity of the water from which it is prepared and may become

increasingly corrosive with use if not properly inhibited.

NOTICE

NOTICE

We recommend installing a monitored fluid detection system that is wired to activate the automatic closure of

field installed coolant fluid supply and return shut-off valves to reduce the amount of coolant fluid leakage and

consequential equipment and building damage. The shut-off valves must be sized to close off against the

maximum coolant fluid system pressure in case of a catastrophic fluid leak.

Risk of frozen pipes and corrosion from improper coolant mixture. Can cause water leaks resulting in

equipment and building damage.

When piping or the cooling unit may be exposed to freezing temperatures, charge the system with the proper

percentage of glycol and water for the coldest design ambient temperature. Automotive antifreeze is

unacceptable and must NOT be used in any glycol fluid system. Use only HVAC glycol solution that meets the

requirements of recommended industry practices.

Risk of no flow condition. Can cause equipment damage. Do not leave the water/coolant fluid supply circuit in a

no flow condition. Idle fluid allows the collection of sediment that prevents the formation of a protective oxide

layer on the inside of tubes. Keep unit switched On and water/coolant fluid supply circuit system operating

continuously.

1 Im portant Safety Instructions

5

Page 12

NOTICE

NOTICE

NOTICE

NOTICE

Risk of improper water supply. Can reduce humidifier efficiency or obstruct humidifier plumbing.

Do not use completely demineralized water with this unit. The water must contain minerals for the electrode

principle to work.

Do not use a hot water source. It will cause deposits that will eventually block the fill valve opening.

Risk of water backing up in the drain line. Leaking and overflowing water can cause equipment and building

damage.

Do not install an external trap in the drain line. This line already has a factory installed trap inside the cabinet.

Installation of a second trap will prevent drain water flow and will cause the water to overflow the drain pan.

This line may contain boiling water. Use copper or other material that is rated for handling boiling water for the

drain line. Sagging condensate drain lines may inadvertently create an external trap.

Risk of doorway/hallway interference. Can cause unit and/or structure damage. The unit may be too large to fit

through a doorway or hallway while on the skid. Measure the unit and passageway dimensions, and refer to the

installation plans prior to moving the unit to verify clearances.

Risk of damage from forklift. Can cause unit damage. Keep tines of the forklift level and at a height suitable to

fit below the skid and/or unit to prevent exterior and/or underside damage.

NOTICE

Risk of improper storage. Can cause unit damage.

Keep the unit upright, indoors and protected from dampness, freezing temperatures and contact damage.

1.1 AHRICertified

The Liebert® DataMate™ 60-Hz system is AHRI Certified™, the trusted mark of performance assurance for heating,

ventilation, air conditioning, and commercial refrigeration equipment, using AHRI Standard 1360.

6

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 13

1.2 Agency Listed

Standard 60-Hz units are CSA Certified to the harmonized U.S. and Canadian product safety standard CSA C22.2 No

236/UL 1995 for “Heating and Cooling Equipment” and are marked with the CSA c-us logo.

1 Im portant Safety Instructions

7

Page 14

This page intentionally left blank

8

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 15

2 NOMENCLATURE

This section describes the model number configuration for Liebert® DataMate units and components.

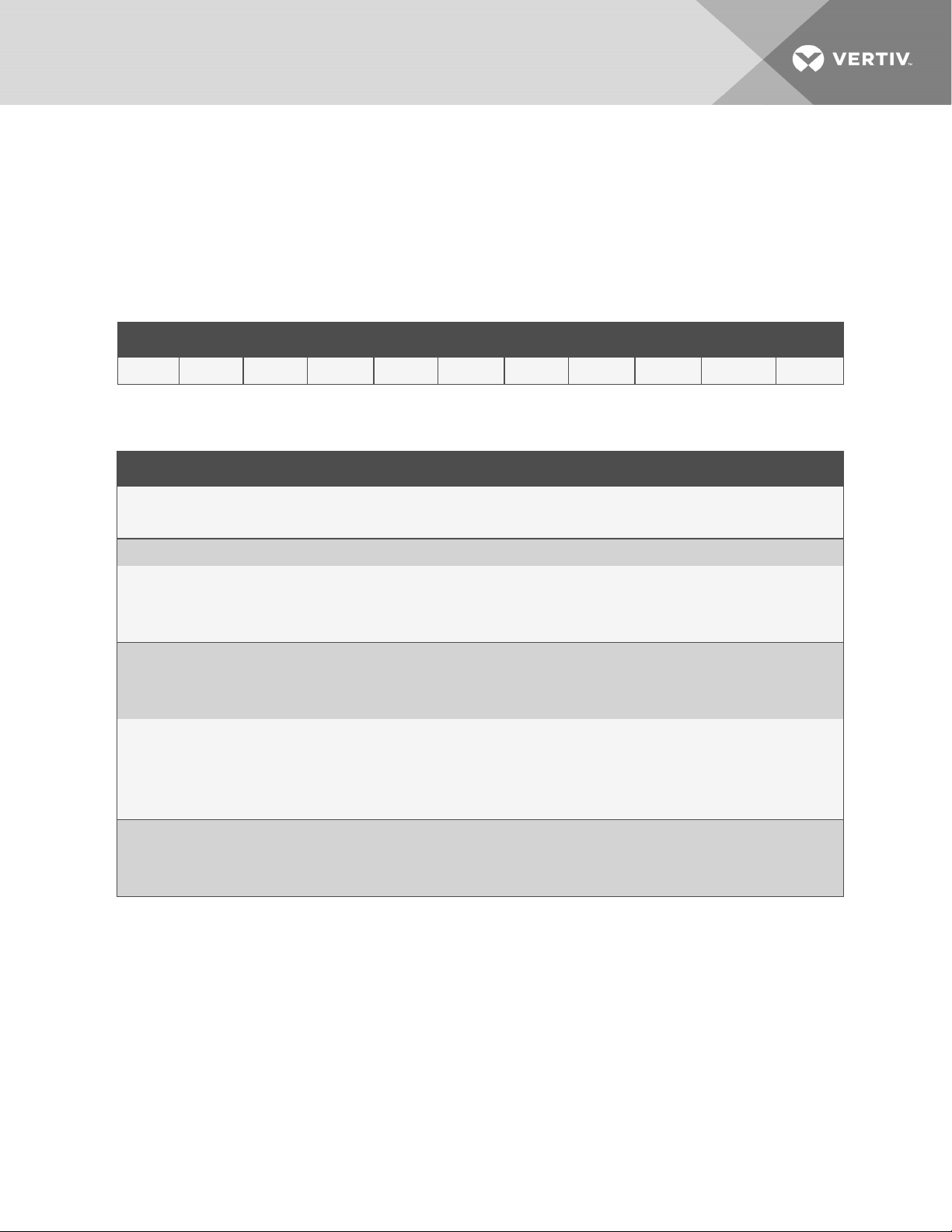

2.1 Nomenclature for Evaporator and Chilled Water Units

Table 2.2 below describes each digit of the model number.

Table 2.1 Nomenclature Example

1 2 3 4 5 6 7 8 9 10 11

D M E 0 3 7 E — P H N

Table 2.2 Nomenclature Digit Definitions for Evaporator and Chilled Water Units

Digit Description

Digits 1 , 2, 3 = The Base zunit

DME = DataMate evaporator/chilled water cooling unit

Digits 4, 5, 6 = Nominal Capacity, kB tuh

Digit7, 8 = Cooling Type

C – = Chilled water cooled

E – = Evaporator

Digit9 = Supply Power

P = 208/230V / 1 ph / 60Hz

W = 2 00/220 V / 1ph / 50Hz

Digit10 = Reheat and Humidifica tion

0 = Reheat only

C = Cooling only

H = Reheat and humidifier

Digit11 = Refrigerant/Revision

N = R-407C, field-supplied, field-charged (evaporator)

7 = Revision (chilled water)

2 N omenclature

9

Page 16

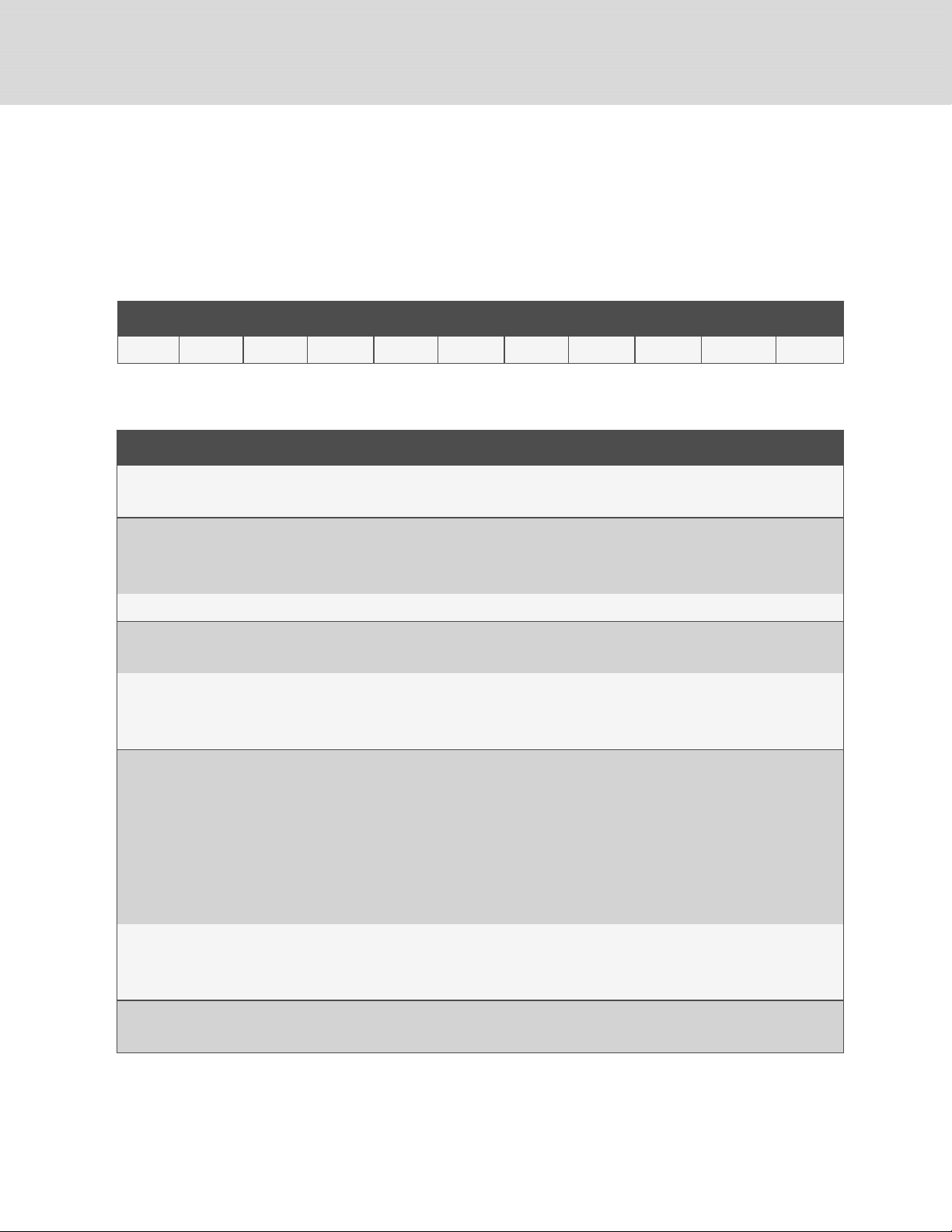

2.2 Nomenclature for Condensing Units

This section describes the model number configuration for DataMate condensing units.

2.2.1 Outdoor Prop Fan Condensing Units for Air Cooled Systems

Table 2.4 below describes each digit of the model number.

Table 2.3 Prop Fan Condensing Unit Nomenclature Example

1 2 3 4 5 6 7 8 9 10 11

P F H 0 3 7 A — P L N

Table 2.4 Nomenclature Digit Definitions for Outdoor, Prop Fan Condensing Units

Digit Description

Digits 1 to 3 = The Base Unit

PFH = Prop fan condensingunit with hot gas bypass

Digit4 = Sound Level

0 = Standard

Z = Quiet-Line

Digit5 and 6 = Nominal Capacity, kBtuh

Digit7 = Cooling Type

A = Air cooled

Digit8 = Coil Type

— = Standardcoil

C = Coated coil (epoxy with UVtopcoat)

Digit9 = Supply Power

A = 460V / 3ph / 60Hz

B = 575V / 3ph / 60Hz

M = 380/415V / 3ph / 50Hz

P = 208/230V / 1 ph / 60Hz

S = 220V / 1ph / 50Hz

Y = 208/230V / 3ph / 60Hz

Digit10 = Ambient Rating/Control

L = 95°F Ambient, Liebert® Lee-Temp™

H = 105°F Ambient, Liebert® Lee-Temp™

Digit11 = Refrigerant

N = R-407C field-supplied, field-charged

10

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 17

2.2.2 Indoor Condensing Units for Air Cooled Systems

Table 2.6 below describes each digit of the model number.

Table 2.5 Indoor, Air Cooled Condensing Unit Nomenclature Example

1 2 3 4 5 6 7 8 9 10

M C D 3 6 A L A H N

Table 2.6 Nomenclature Digit Definitions for Indoor, Air Cooled Condensing Units

Digit Description

Digits 1 to 2 = the Base Unit

MC = Mini-Mate2-style condensing unit

Digit3 = Disconnect

D = Disconnect switch

Digit4 and 5 = Nominal Capacity

24 = 24 kB tuh, 2-ton, 60Hz

35 = 35 kBtuh, 3-ton, 50Hz

36 = 36 kB tuh, 3-ton, 60Hz

Digit6 = Cooling Type

A = Air cooled

Digit7 = Head Pressure Control

L = Liebert® Lee-Temp™ Receiver

Digit8 = Supply Power

A = 460V / 3ph / 60Hz

M = 380/415V / 3ph / 50Hz

P = 208/230V / 1 ph / 60Hz

S = 220V / 1ph / 50Hz

X = 277V / 1ph / 50 Hz

Y = 208/230V / 3ph / 60Hz

Digit9 = Hot Gas B ypass

H = Hot gas bypass

Digit10 = Refrigerant

N = R-407C field-supplied, field-charged

2 N omenclature

11

Page 18

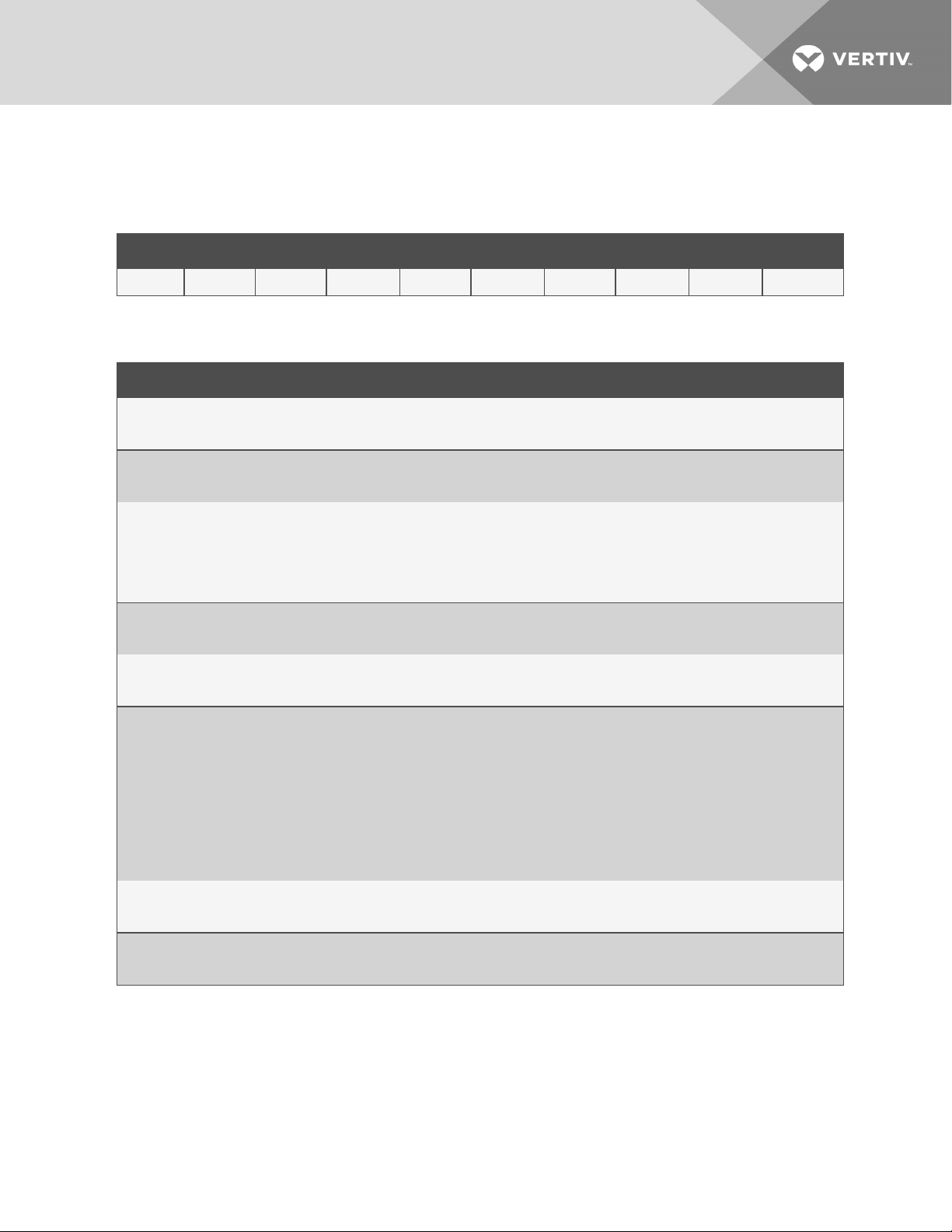

2.2.3 Close Coupled Condensing Unit for Water/Glycol CooledSystems

Table 2.8 below describes each digit of the model number.

Table 2.7 Close Coupled Water/Glycol Condensing Unit Nomenclature Example

1 2 3 4 5 6 7 8 9 10 11

D M C 0 4 0 W G P 0 N

Table 2.8 Nomenclature Digit Definitions for Close Coupled Water/Glycol Units

Digit Description

Digits 1 , 2, 3 = The Base Unit

DMC = DataMate condensingunit

Digits 4, 5, 6 = Nominal Capacity, kB tuh

Digit7, 8 = Cooling Type

WG = Water/Glycol cooled

Digit9 = Supply Power

P = 208/230V / 1 ph / 60Hz

Digits 1 0, 11 = Refrigerant

0N = R-407C, field-supplied, field-charged

12

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 19

2.2.4 Remote, Indoor Water/Glycol Cooled Condensing Units

Table 2.10 below describes each digit of the model number.

Table 2.9 Remote, Indoor Water/Glycol Condensing Unit Nomenclature Example

1 2 3 4 5 6 7 8 9 10

M C D 3 8 W 2 A H N

Table 2.10 Nomenclature Digit Definitions for Indoor, Water/Glycol Cooled Condensing Units

Digit Description

Digits 1 to 2 = The Base Unit

MC = Mini-Mate2-style condensing unit

Digit3 = Disconnect

D = Disconnect switch

Digit4 and 5 = Nominal Capacity, kBtuh

Digit6 = Cooling Type

W = Water/Glycol cooled

Digit7 = Head Pressure Control

2 = 2-way standardpressure fluid regulating valve

3 = 3-way standard pressure fluid regulating valve

D = 2-way high pressure fluid regulating valv e

T = 3-way high pressure fluid regulating valv e

Digit8 = Supply Power

A = 460V / 3ph / 60Hz

M = 380/415V / 3ph / 50Hz

P = 208/230V / 1 ph / 60Hz

S = 220V / 1ph / 50Hz

X = 277V / 1ph / 50 Hz

Y = 208/230V / 3ph / 60Hz

Digit9 = Hot Gas B ypass

H = Hot gas bypass

Digit10 = Refrigerant

N = R-407C field-supplied, field-charged

2 N omenclature

13

Page 20

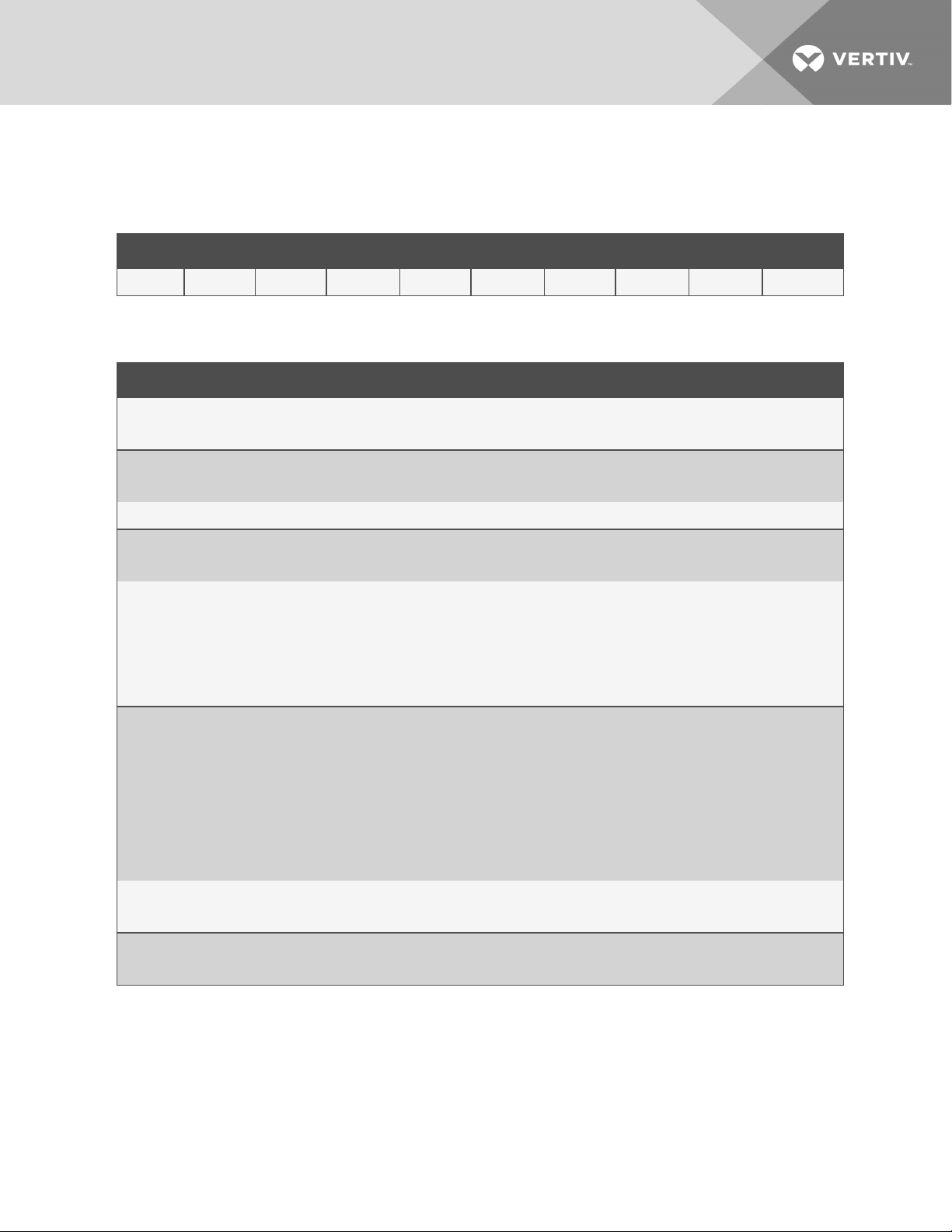

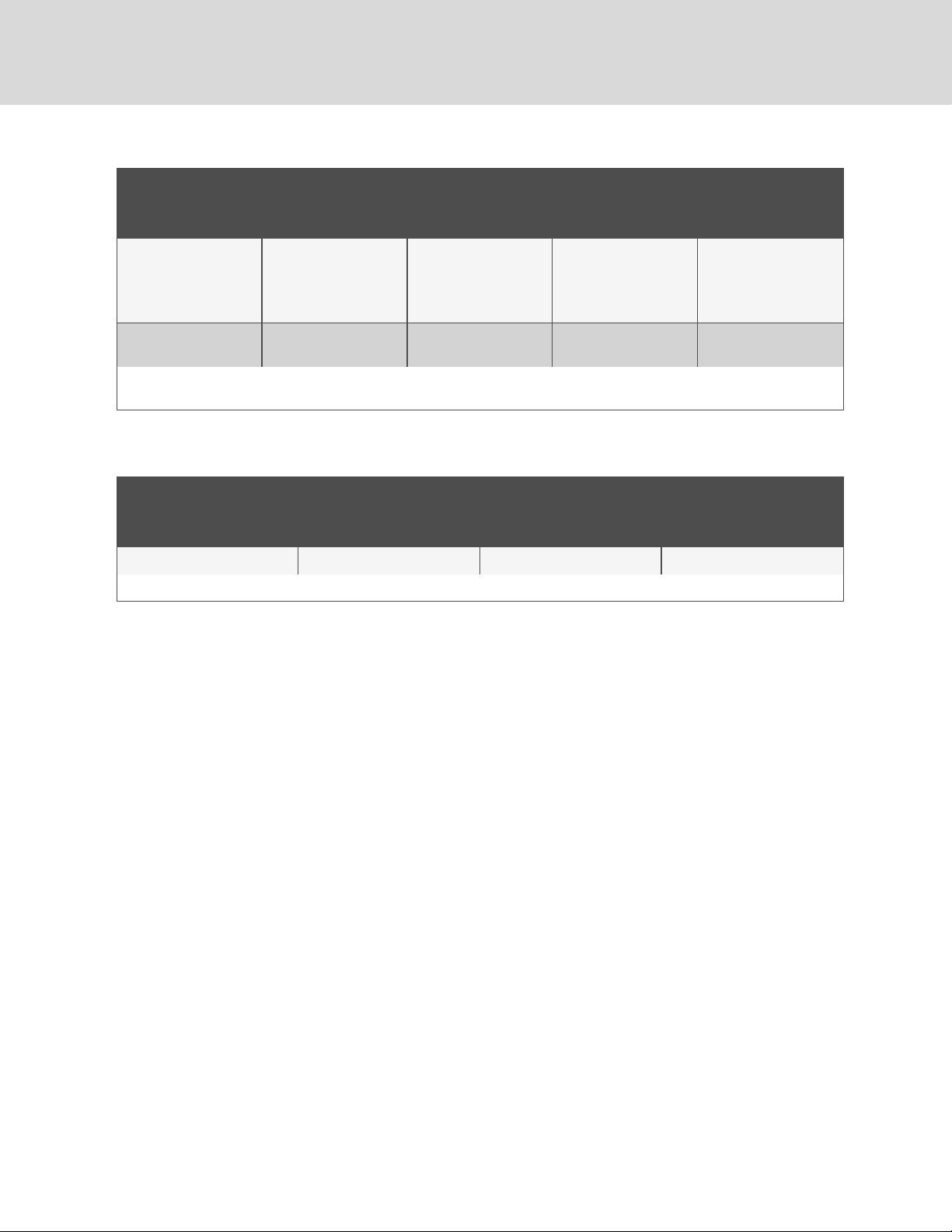

2.3 System Configurations

The following figures show the available capacity and cooling options for the Liebert® DataMate.

Figure 2.1 Air Cooled Units

Item Description

1 Air cooled with outdoor condensing unit suitable for installation on a roof or at ground level.

2 Air cooled with indoor condensing unit for applications where roof or other outdoorlocations are impractical.

14

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 21

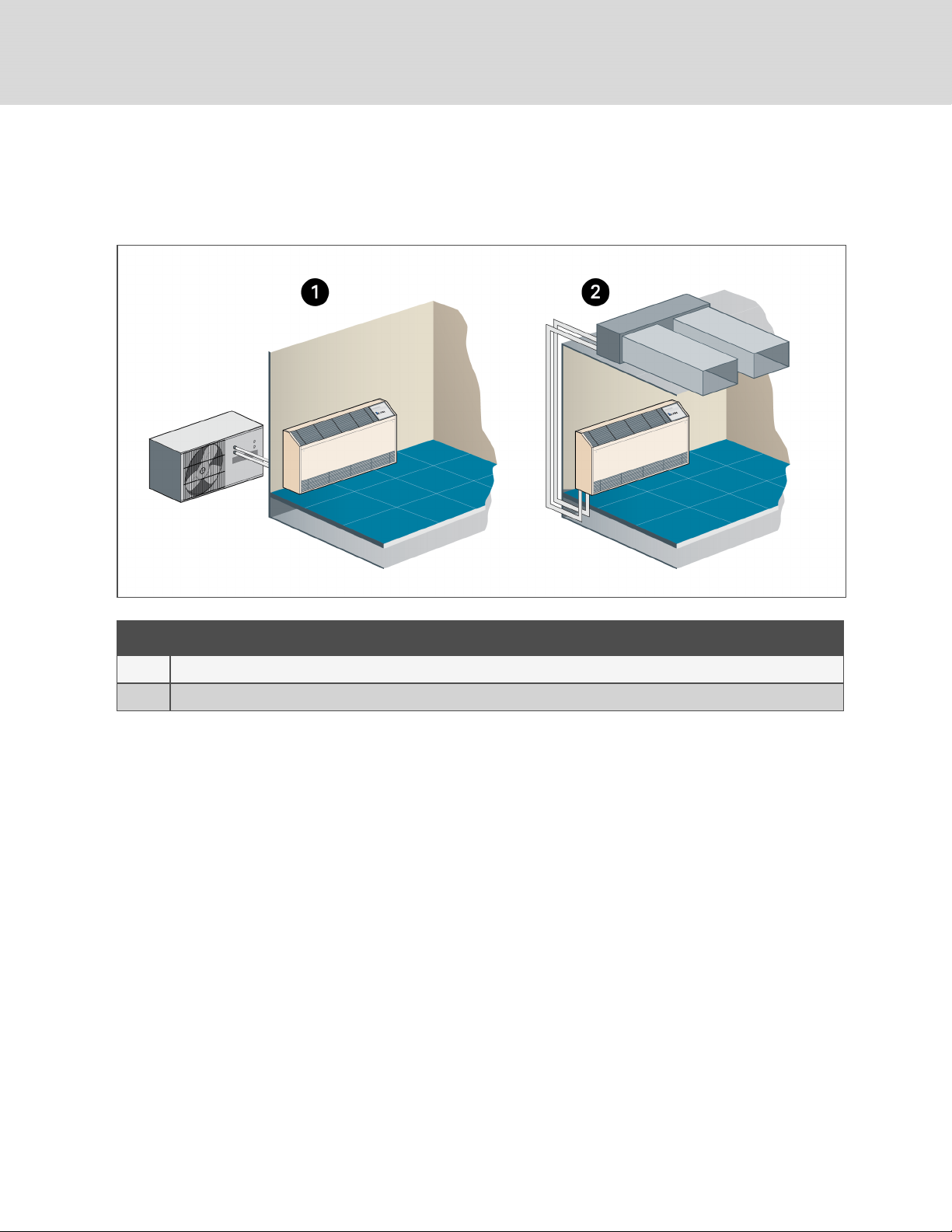

Figure 2.2 Water/Glycol Cooled Units

Item Description

1 Water/Glycol cooled with close coupled condensing unit conveniently needs only a single power supply and water supply connection installed.

2 Water/Glycol cooled with remote, indoor condensing unit that installs under the raised floor or above the dropped ceiling.

2 N omenclature

15

Page 22

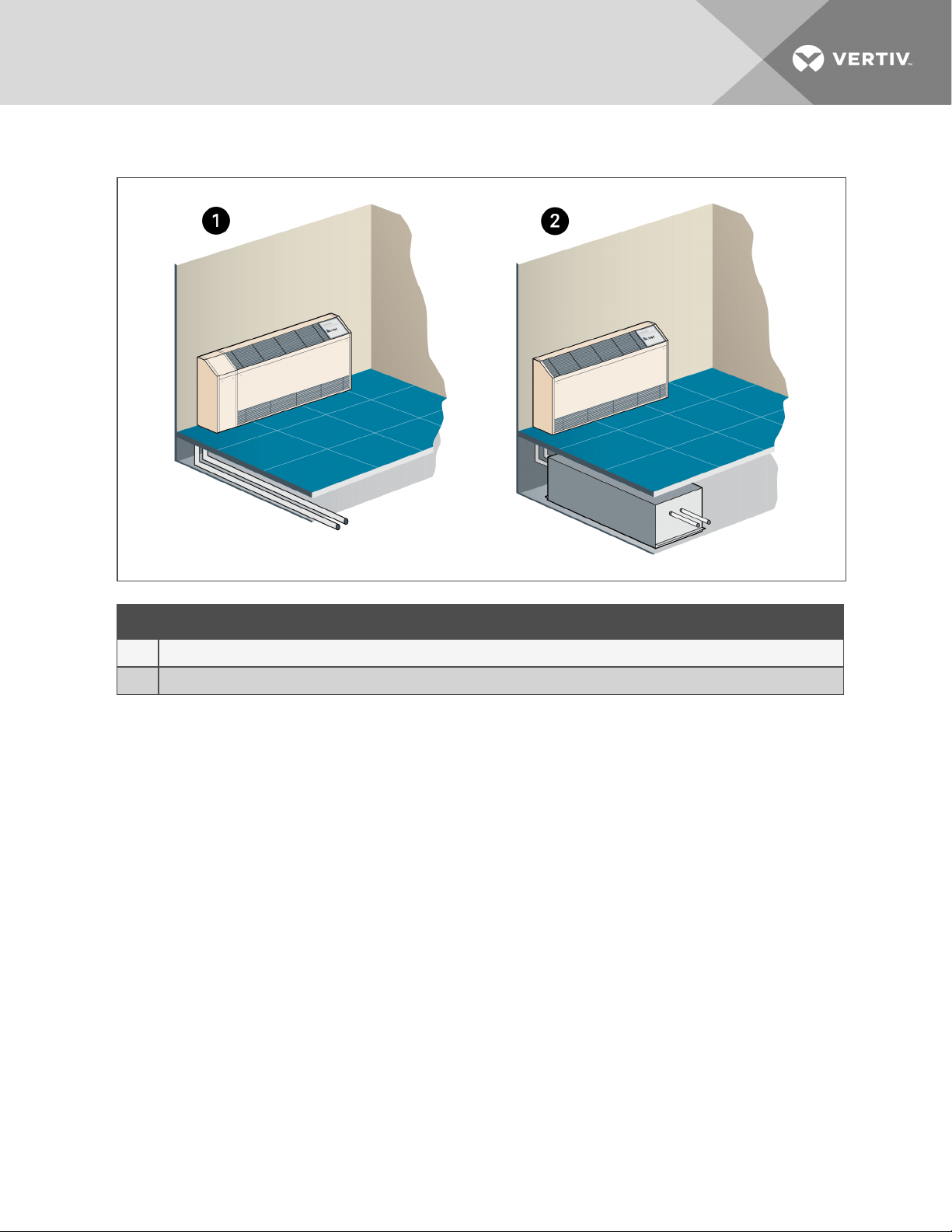

Figure 2.3 Chilled Water Units

Item Description

1 Chilled water cooled c onnects quickly and easily to a chilled water loop for ease of installation.

16

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 23

3 SITE PREPARATION AND EQUIPMENT HANDLING

NOTE: Before installing unit, determine whether any building alterations are required to run piping, wiring and

ductwork. Follow all unit dimensional drawings and refer to the submittal engineering dimensional drawings of

individual units for proper clearances.

3.1 Planning Dimensions

The unit dimensions are described in the submittal documents included in the Submittal Drawings on page107.

The following table lists the relevant documents by number and title.

Table 3.1 Dimension Planning Drawings

Docu ment Number Title

Evaporators/Chilled Water Units

DPN000262 Cabinet Dimensions, Evaporator/Chilled Water Unit

IndoorCondensing Units

DPN004420 Cabinet Dimensions, Air Cooled units

DPN004421 Cabinet Dimensions, Water/Glycol Cooled units

DPN000269 Cabinet Dimensions, Close Coupled Water/Glycol Condensing Unit

3.2 Room Preparation

The room should be well insulated and must have a sealed vapor barrier. The vapor barrier in the ceiling and walls can be a

polyethylene film. Paint on concrete walls and floors should be vapor resistant.

NOTE: The vapor barrier is the single most important requirement for maintaining environmental control in the

conditioned area.

Outside or fresh air should be kept to a minimum when tight temperature and humidity control is required. Outside air adds

to the site’s cooling, heating, dehumidifying and humidifying loads. We recommend keeping the outside air below 5% of the

total air circulated in the computer room. Doors should be properly sealed to minimize leaks and should not contain

ventilation grilles.

3.3 Application Limits

Table 3.2 Application Limits for Evaporator and Chilled Water Units

Input Vo ltage Range o f Return Air Co nditio ns to the U nit*

Minimum Maximum Dry Bulb Temperature Relative Humidity

–5% +10% 65 to 85°F (18 to 29°C) 20 to 80%

*The unit willoperate a t these conditions, but it will not control to these conditionextremes.

3 S ite Preparation and Equipment Hand ling

17

Page 24

Table 3.3 Application Limits for Indoor and Outdoor Air Cooled Condensing Unit

Input Vo ltage

Condensing Unit Type

Minimum Maximum Minimum Maximum

–5% +10%

–5% +10%

*Unit capacity ratings are stated for 95°F (35°C) for standard units and 105°F (41°C)for P FH highambient units. Exceeding these rating points by 20°F (11°C)

will result in lower cooling capacities, but will not dama ge the equipment.

Outdoor prop fa n

condensing unit

Indoorair cooled condensing

unit

Entering Dry Bu lb Air Temperature

115°F (48°C) standard

–30°F (–34°C)

–30°F (–34°C) 115°F (48°C)

ambient unit*

125°F (52°C)high ambient

unit*

Table 3.4 Application Limits for Indoor Water/Glycol Cooled Condensing Unit

Input Vo ltage Entering Fluid Temperature

Minimum Maximum Minimu m Maximum

–5% +10% 65°F (18°C)* 115°F (46°C)

*Operation below 65°F (18°C)m ay result in fluid noise and reduced valve life.

3.4 Location Considerations

When determining installation locations, consider that these units contain water and that water leaks from ceiling mounted

condensing units can cause damage to sensitive equipment and furniture below.

NOTICE

Risk of leaking water/glycol. Can cause equipment and building damage.

Improper installation, application, and service practices can result in water leakage from the unit. Do not mount

this unit over equipment and furniture that can be damaged by leaking water. Install a water-tight drain pan

with a drain connection under the cooling unit and the ceiling mounted water/glycol condensing unit. Route the

drain line to a frequently used maintenance sink so that running water can be observed and reported in a

timely manner. Post a sign to alert people to report water flowing from the secondary drain pan. We

recommend installing monitored leak detection equipment for the unit and supply lines and in the secondary

drain pan. Check drain lines periodically for leaks, sediment buildup, obstructions, kinks and/or damage and

verify that they are free running.

18

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 25

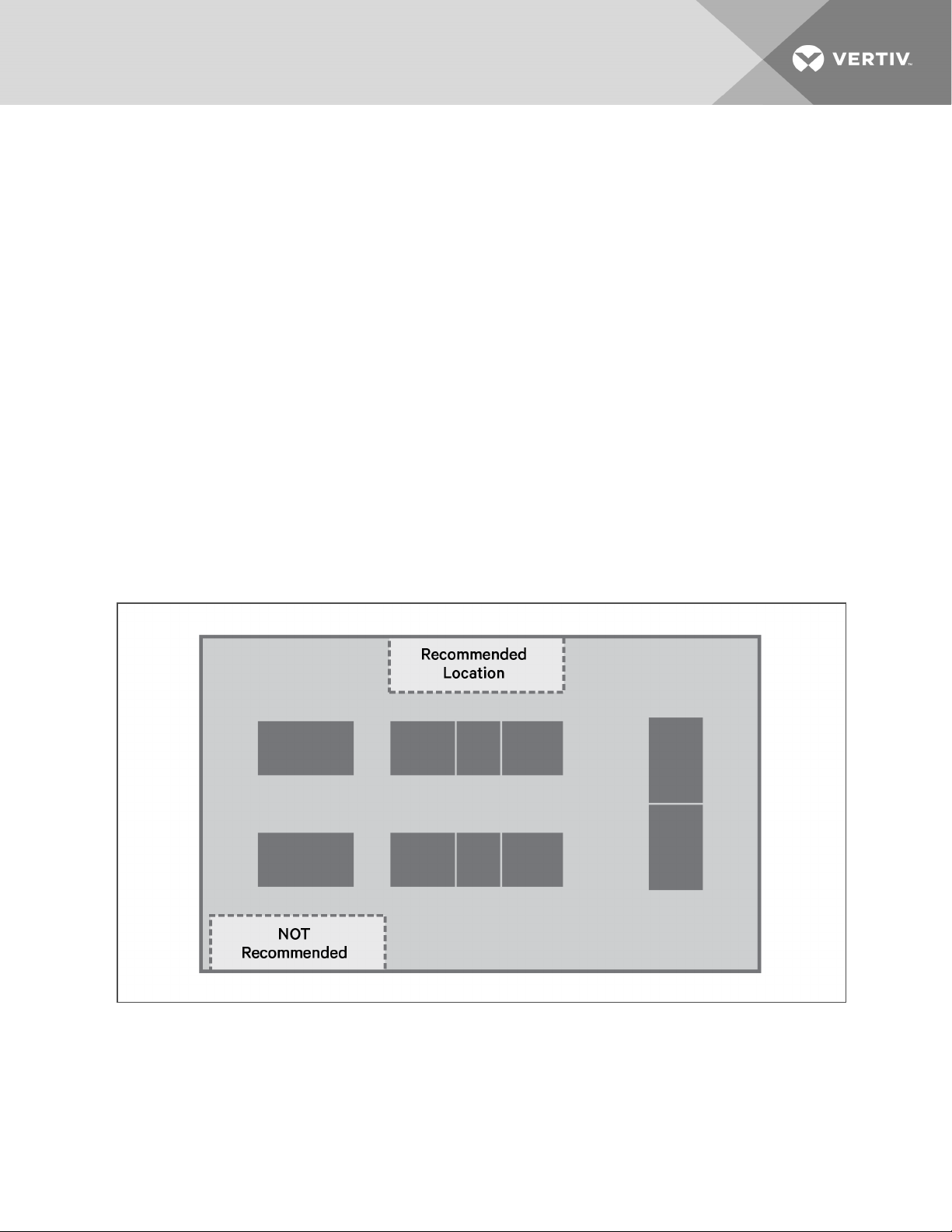

3.4.1 Location Considerations for Evaporator, Indoor CondensingandChilled WaterUnits

The system can be installed in several ways. However, you should always mount the evaporator on a wall in the equipment

room.

• For an air cooled system with an indoor condensing unit, the condensing unit may be installed near the

evaporator to minimize piping, or near the outside wall to minimize air duct work.

• For water/glycol cooled systems, a DMC condensing unit may be close coupled with the evaporator or a

remote MCD indoor condensing unit may be installed above the ceiling or below a raised floor.

Refer to Refrigerant Line Sizes and Equivalent Lengths on page44 for maximum refrigerant line lengths.

Do not install units in areas where normal unit operating sound may disturb the working environment.

When installing an air cooled or water/glycol cooled unit inside a space, ensure that national and local codes are met for

refrigerant concentration limits that might vary with building type and use.

Try to locate the evaporator in an unobstructed floor space to facilitate service. Avoid locations in confined areas that affect

the air flow pattern and result in short cooling cycles, downdrafts and air noise. Figure 3.1 below, shows location

recommendations. Avoid locating the unit in an alcove or at the extreme end of a long, narrow room. Avoid installing

multiple units close to each other, which can result in crossing air patterns, uneven loads and competing operating modes.

Do not attach additional devices (such as smoke detectors, etc.) to the cabinet. Doing so interferes with routine maintenance

and service.

Figure 3.1 Proper Location in the Room

3 S ite Preparation and Equipment Hand ling

19

Page 26

3.4.2 Location Considerations for an Outdoor Condensing Unit

For an air cooled system using an outdoor condensing unit, the condensing unit may be mounted on the roof or remotely in

any outdoor area.

Observe the following when planning the installation of the outdoor unit:

• To ensure a satisfactory air supply, locate air cooled condensing units in an environment with clear air, away

from loose dirt and foreign matter that may clog the coil.

• Condensing units must not be located in the vicinity of steam, hot air, or fume exhausts or closer than 18 inches

from a wall, obstruction, or adjacent unit.

• Avoid areas where heavy snow will accumulate at air inlet and discharge locations.

• The condensing unit should be located for maximum security and maintenance accessibility. Avoid ground

level sites with public access. Install a solid base, capable of supporting the weight of the condensing unit.

• The base should be at least 2in. (51mm) higher than the surrounding grade and 2 in. (51mm) larger than the

dimensions of the condensing unit base. For snowy areas, a base of sufficient height to clear snow accumulation

must be installed.

• Securely attach the unit to the base using the holes provided in the unit mounting rails to prevent unit

movement that might stress refrigerant piping and electrical wiring.

Before beginning, refer to Piping and Refrigerant Requirements on page37 for unit placement, piping guidelines, and

refrigerant charge requirements for your system.

The condensing unit must be located within the maximum distance from the evaporator using the evaporator guidelines

listed in Piping when Condensing Unit is Above or Below Evaporator on page43.

20

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 27

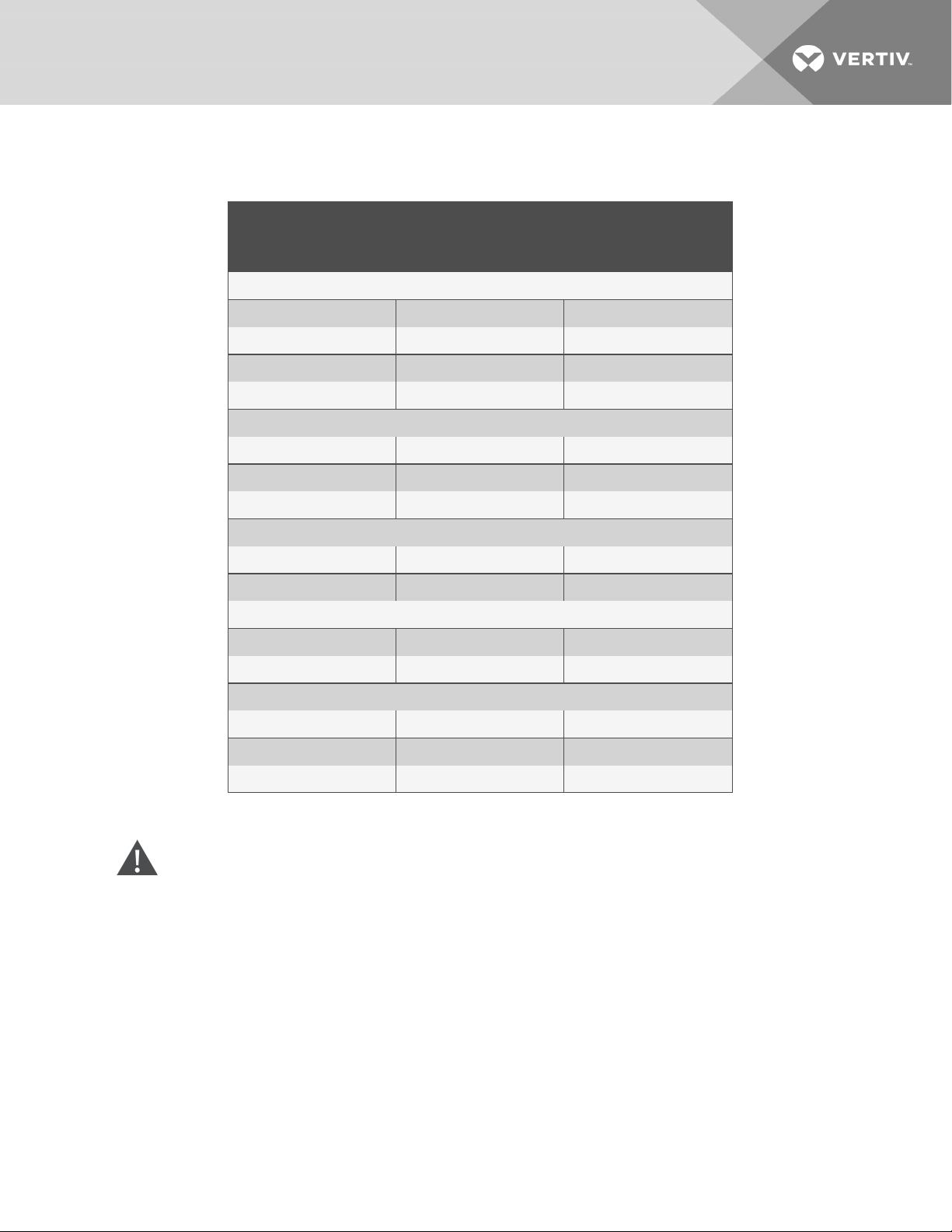

3.5 Unit Weights

Table 3.5 Evaporator and Condensing Unit weights

Evaporator Section

Outdoor, Propeller Fan CondensingUnit

Indoor, Centrifugal Fan Condensing Unit

Model Numb er

lb. (kg)

60Hz 50Hz

DME020E — 230 (104)

DME027E — 330 (150)

DME037E DME037E 365 (166)

DME044C DME044C 365 (166)

PFH020A — 200 (91)

PFH027A — 200 (91)

PFH037 A PFH036A 2 41 (109)

MCD24A — 230 (104)

MCD36A MCD35A 240 (109)

Water/Glycol Cooled CondensingUnit

MCD26W — 175 (79)

MCD38W MCD37W 220 (100)

Close Coupled Water/Glycol CondensingUnit

DMC022WG — 170 (77)

DMC029WG — 17 0 (77)

DMC040WG — 170 (77)

3.6 Equipment Inspection and Handling

CAUTION: Risk of contact with sharp edges, splinters, and exposed fasteners. Can cause injury. Only

properly trained and qualified personnel wearing appropriate, OSHA approved PPE should attempt to move,

lift, remove packaging from or prepare the unit for installation.

Do not un-crate the equipment until it is close to its final location. All required assemblies are banded and shipped in

corrugated containers. If any damage is discovered when the unit is un-crated, report it to the shipper immediately. If any

concealed damage is later discovered, report it to the shipper and to your Vertiv representative.

3 S ite Preparation and Equipment Hand ling

21

Page 28

This page intentionally left blank

22

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 29

4 INSTALLATION

Refer to the appropriate installation procedures depending the configuration and options of your Liebert® DataMate

Thermal Management System.

4.1 Installing Wall Mounted EvaporatorsandChilled Water Units

WARNING! Risk of unit falling off of the wall. Can cause building and equipment damage and serious injury. A

licensed professional structural engineer should evaluate the wall to determine if the unit may be safely

mounted on the wall and determine the type and size of fasteners required to support the weight of the unit

during all phases of operation because some vibration may occur during start, stop, and operation cycles.

The wall may need to be reinforced to support the maximum load of the unit. See Table 3.5 on page21, for

unit weights.

Unlatch the front cabinet door and remove the screws that secure the cabinet to the chassis. Lift off the cabinet. Eight

keyholes (0.50 in. head, 0.22 in. slot) are provided on the back of the unit for mounting on the wall. The unit must be level.

4.1.1 Changing Air Flow Direction

The air discharge grille on the evaporator can be placed in one of three different positions: vertical, horizontal, or 45°.

To change the air flow direction:

1. Remove the front panel using quarter-turn fasteners.

2. Remove the cabinet by removing the four retaining screws, then lift off the cabinet.

3. Remove the left end panel.

4. Remove the grille by sliding it to the left end of the unit.

5. Rotate or invert the grille to change the air discharge direction.

6. Reverse steps 1 through 4, to re-assemble the unit.

4 Inst allation

4.2 Installing Outdoor Condensing Unit forAir CooledSplit Systems

Refer to the appropriate guidelines and drawings when installing an outdoor, condensing unit for an air cooled split system.

See Location Considerations for an Outdoor Condensing Unit on page20. Follow all applicable national and local building,

electrical and plumbing codes.

4.3 Installing Ceiling Mounted Condensing Units

WARNING! Risk of ceiling collapse and heavy unit falling. Can cause building and equipment damage, serious

injury or death. If using a ceiling mounted condensing unit, verify that the supporting roof structure is

capable of supporting the weight of the unit(s) and the accessories. See Table 3.5 on page21, for the unit

weights. Securely anchor the top ends of the suspension rods and verify that all nuts are tight.

23

Page 30

NOTICE

Risk of leaking water/glycol. Can cause equipment and building damage.

Improper installation, application, and service practices can result in water leakage from the unit. Do not mount

this unit over equipment and furniture that can be damaged by leaking water. Install a water-tight drain pan

with a drain connection under the cooling unit and the ceiling mounted water/glycol condensing unit. Route the

drain line to a frequently used maintenance sink so that running water can be observed and reported in a

timely manner. Post a sign to alert people to report water flowing from the secondary drain pan. We

recommend installing monitored leak detection equipment for the unit and supply lines and in the secondary

drain pan. Check drain lines periodically for leaks, sediment buildup, obstructions, kinks and/or damage and

verify that they are free running.

4.3.1 Installing Suspension Rods andMounting Ceiling Units

Refer to the Location Considerations on page18 before beginning installation. These instructions apply to indoor air cooled

and remote indoor water/glycol condensing units.

NOTE: Follow all national and local building, electrical, and plumbing codes.

• The ceiling and ceiling supports of existing buildings may require reinforcements.

• Four 3/8-in.-16 TPI threaded suspension rods are required and field supplied.

• The factory supplied 3/8-in. 16 TPI hardware kit includes the remaining installation hardware.

• Recommended clearance between ceiling grids and building structural members is the unit’s height plus 3in.

(76mm).

To install the suspension rods:

1. Install the four field supplied 3/8-in. 16 TPI threaded rods by suspending them from suitable building structural

members so that they will align with the four mounting locations on the unit base.

2. Securely anchor the top ends of the suspension rods with field supplied nuts.

3. Make sure all nuts are tight and locked.

To lift and install the unit on the rods:

1. Using a suitable lifting device that is rated for the weight of the unit (see Unit Weights on page21), raise the

unit and pass the threaded rods through the four mounting locations in the unit base.

2. Attach the threaded rods to the flanges using the plain nuts to hold the unit in place as shown in Figure 4.1 on

the facing page.

3. Slowly lower the lifting device, making sure that the rods securely hold the weight of the unit.

4. Adjust the plain nuts to distribute the weight of the unit evenly by the rods, making sure that the unit does not

rest on the ceiling grid and that the unit is level.

5. Use the Nylock nuts to jam the plain nuts in place as shown in Figure 4.1 on the facing page.

24

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 31

Figure 4.1 Installing Threaded Rods and Hardware of Ceiling Mounted Units

Item Description Item D escription

1 3/8-in. threaded rod, field-supplied 7 3/8-in. fender washer

2 3/8-in. hex nut 8 3/8-in. hex nut

3 3/8-in. washer 9 3/8-in. N ylock locking nut

4 Sleeve 10 Unit base pan (reference)

5 Bracket on unit

6 Isolator

4 Inst allation

25

Page 32

4.3.2 Guidelines for Ducted Systems

Observe the following for all ductwork:

• Ductwork should be fabricated and installed in accordance with local and national codes.

• Use flexible ductwork or nonflammable cloth collars to attach ductwork to the unit and to control vibration

transmission to the building.

• Attach the ductwork to the unit using the flanges provided.

• Locate the unit and ductwork so that the discharge air does not short circuit to the return air inlet.

• Avoid directing the hot exhaust air toward adjacent doors or windows.

• Ductwork that runs through a conditioned space or is exposed to areas where condensation may occur must be

insulated. Insulation of ductwork is vital to prevent condensation during the cooling cycle.

• The use of a vapor barrier is required to prevent absorption of moisture from the surrounding air into the

insulation.

• If the return air duct is short or if noise is likely to be a problem, sound absorbing insulation should be used

inside the duct.

• Ductwork should be suspended using flexible hangers. Ductwork should not be fastened directly to the building

structure.

• For multiple unit installations, space the units so that the hot condensing unit exhaust air is not directed toward

the air inlet of an adjacent unit.

Consider the following in specific applications of ductwork to condensing units:

• In applications where the ceiling plenum is used as the heat rejection domain, the discharge air must be

directed away from the condensing unit air inlet and a screen must be added to the end of the discharge duct

to protect service personnel. Locate the air discharge a minimum of 4 ft. from an adjacent wall. Failure to do so

may result in reduced air flow and poor system performance.

• If the condensing unit draws air from the outside of the building, rain hoods must be installed. Hood intake and

ductwork cross-sectional area dimensions should be equal to or greater than the area of the condensing unit

intake flange. In addition, install a triple layer bird screen over rain hood openings to eliminate the possibility of

insects, birds, water, or debris entering the unit. Avoid directing the hot exhaust air toward adjacent doors or

windows.

Table 4.1 Indoor Condensing Unit Airflow, CFM at0.5iwg(124PA) esp

2 Ton 3 Ton

1000 1430

26

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 33

4.4 Close Coupled Installations forIntegralWater/Glycol CondensingUnits

You can mount the evaporator and indoor, DMC water/glycol cooled condensing unit directly next to each other, close

coupled.

The DMC condensing unit attaches to the left side of the evaporator chassis. For connection sizes, see Table 5.2 on

page37, for the appropriate submittal drawing for your unit. For condensing unit fluid requirements, see Water/Glycol Loop

Piping on page40.

To install the close coupled condensing unit:

1. You will need access to the rear of the unit, so make sure that the evaporator and condensing unit are moved

away from the wall for the installation.

2. On the evaporator, open the quarter-turn fasteners and remove the front access panel, then remove the four

screws from the front of the evaporator, see Figure 4.2 below.

Figure 4.2 Remove Front Access Cover and Evaporator Screws

4 Inst allation

Item Description

1 Remove front access panel.

2 Remove 4 screws.

3. Remove the evaporator's panel assembly by lifting up and away from the unit, see Figure 4.3 on the next

page.

27

Page 34

Figure 4.3 Remove Evaporator Panel Assembly

4. On the left end of the evaporator, remove the six screws that fasten the chassis extension to the evaporator:

• Two screws from the inside, bottom as shown in Figure 4.4 below.

• Four screws from the back side.

• Save the six screws to use when attaching the condensing unit.

NOTE: This piece is not used with the close coupled units and may be recycled.

Figure 4.4 Remove the Chassis Extension

28

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 35

Item Description

1 2 screws at bottom (4 more on back of unit)

2 Chassis extension (not used in close coupling, recycle)

5. On the evaporator panel assembly:

• Remove the cutout from the bottom-left side, see Figure 4.5 below.

• Remove the support bracket inside the bottom-left side, see Figure 4.6 below.

Figure 4.5 Cutout to Remove from Panel Assembly

Figure 4.6 Support Bracket to Remove from Panel Assembly

4 Inst allation

29

Page 36

6. On the condensing unit, open the quarter-turn fasteners and remove the front access panel, see Figure 4.7

below.

Figure 4.7 Remove Front Access Panel from Condensing Unit

30

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 37

7. Prepare to cut the refrigerant piping:

• Carefully remove the insulation from the suction line, see Figure 4.8 below.

• Slide the units together, and mark the connection point.

CAUTION: Risk of explosion from high pressure inert gases. Cutting pressurized lines can cause serious

injury. Do not cut the liquid and suction lines until nitrogen has been purged.

Figure 4.8 Mark the Pipes to Cut for Connection

Item Description

1 Insulation ca refully removed.

2 Unitstogether to m ark pipes.

4 Inst allation

31

Page 38

8. Slide the units apart.

9. Purge the nitrogen in both evaporator and condensing unit sections.

NOTE: Make sure that you plan enough time to complete steps 10 to 13, and all the steps in Connecting the Close

Coupled Refrigerant Circuit on the facing page, on the same day. This is critical to keep moisture out of the system.

10. Use a tube cutter to cut the pipes, then install tubing sleeves on the suction and liquid lines, see Figure 4.9

below.

Figure 4.9 Pipe Cut with Tubing Sleeve Installed

11. Slide the units together, and install the four screws removed in step 4 into the rear of the units to join the

chassis, see Figure 4.10 on the facing page.

12. From the front in the blower section, install the two screws removed in step 4 into the clearance holes in the

evaporator section and make sure they grab the bite holes in the condensing unit, see Figure 4.10 on the

facing page.

13. Proceed to Connecting the Close Coupled Refrigerant Circuit on the facing page.

32

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 39

Figure 4.10 Fastening the Evaporator and Condensing Unit Chassis Together

Item Description

1 Screw locations on rear of unit.

2 Screwsfrom blowersection to condenser section.

4.4.1 Connecting the Close Coupled Refrigerant Circuit

1. Access the liquid line from the front and suction line through front and rear of unit, see Figure 4.11 on the next

page. Loosen or remove the piping brackets/clamps as necessary to connect the lines.

2. Remove the clamps, and slide the tubing sleeve into place making sure that the connection point is in the

middle of the sleeve for both the liquid line and suction line connections

3. Use a brazing blanket to protect the expansion valve capillary tube and the equalizer line, and move wiring

away from the brazing area.

IMPORTANT! Use good brazing practices and flowing nitrogen during brazing. See Field Fabricated Refrigeration

Piping on page46, for detailed steps.

4. Braze the liquid line from the front of the unit.

5. Braze the suction line from the front and rear of the unit.

6. Replace the clamps and replace the suction line insulation.

4 Inst allation

33

Page 40

Figure 4.11 Liquid Line and Suction Line Connections

Item Description

1 Liquidconnection with sleev e in place (front panel access)

2 Suctionconnection (rear panel access)

3 Sleeve in place on suction connection

34

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 41

4.4.2 Connecting the Close Coupled Electrical Wiring

WARNING! Arc flash and electric shock hazard. Open all local and remote electric power supply disconnect

switches, verify with a voltmeter that power is Off and wear appropriate, OSHA approved personal protective

equipment (PPE) per NFPA 70E before working within the electric control enclosure. Failure to comply can

cause serious injury or death. Customer must provide earth ground to unit, per NEC, CEC, and local codes,

as applicable. Before proceeding with installation, read all instructions, verify that all the parts are included

and check the nameplate to be sure the voltage matches available utility power. The Liebert® controller does

not isolate power from the unit, even in the Unit Off mode. Some internal components require and receive

power even during the Unit Off mode of the controller. The only way to ensure that there is NO voltage inside

the unit is to install and open a remote disconnect switch. Refer to unit electrical schematic. Follow all local

codes.

When close coupling the DataMate evaporator with the integral, water/glycol condensing unit, a single power feed

connection is made at the condensing unit. The condensing unit ships with a power/control wire harness to internally

connect the two units.

1. Refer to Electrical Connection Requirements on page55, and Water/Glycol Cooled Unit Control Connections on

page57, for input power and control wiring requirements before making the electrical connections.

2. Route the wiring harness from the condensing unit along the top of the evaporator as shown in Figure 4.12

below.

3. Refer to the unit electrical schematic and to DPN000271 included in the Submittal Drawings on page107 to

make the appropriate connections.

4. If the integral condensing unit is used in a glycol loop, it must be connected to the drycooler. There are

terminals on the condensing unit electric box for Class1 wiring to the heat rejection equipment.

Figure 4.12 Power/Control Wire Harness Routing

4 Inst allation

35

Page 42

4.4.3 Final Installation Steps for Close Coupled Units

1. Refer to Installing Wall Mounted EvaporatorsandChilled Water Units on page23, to install the close coupled

unit on the wall, if necessary.

2. Refer to Fluid Piping Required on page38, and the appropriate piping connection drawings included in the

Submittal Drawings on page107, to connect the heat rejection equipment and other fluid piping connections,

as necessary.

3. Refer to Evacuation and Leak Testing Water/Glycol Cooled Systems on page50, and Charging Water/Glycol

Cooled Systems on page52, to charge the system with refrigerant.

4. Replace the evaporator panel assembly and secure it with the four screws on the front of the evaporator.

5. Replace the front access panels on the evaporator and condensing unit, and secure the panels with the quarterturn fasteners.

36

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 43

5 PIPING AND REFRIGERANT REQUIREMENTS

All field supplied refrigeration piping to the unit must be sweat copper. Use prevailing good piping practices for all

connections which include brazing copper pipes using a brazing alloy of minimum temperature of 1350 °F (732 °C) and

adhering to all local codes. All other fluid connections to units, with the exception of the condensate drain, are sweat copper.

Factory installed piping brackets must not be removed. Field installed piping must be installed in accordance with local

codes and must be properly assembled, supported, isolated, and insulated. Avoid piping runs through noise sensitive areas,

such as office walls and conference rooms.

The following pipe connections are required:

• A drain line from the evaporator coil drain pan.

• A drain line from the optional humidifier (if applicable).

• A drain line from the optional condensate pump (if applicable).

• A water supply line to the optional humidifier (if applicable).

• On air cooled and water/glycol cooled systems: refrigerant piping connections between the evaporator unit and

the condensing unit.

• On chilled water systems: connections to the building chilled water source. See Chilled Water Loop Piping on

page39, for additional requirements.

• On water/glycol systems: connections to a water or glycol loop. See Water/Glycol Loop Piping on page40, for

additional requirements.

Refer to specific text and detailed diagrams in this manual for other unit specific piping requirements.

The pipe connection locations, piping general arrangement, and schematics are described in the submittal documents

included in the Submittal Drawings on page107.

The following tables list the relevant documents by number and title.

Table 5.1 Piping General Arrangement Drawings

Docu ment Number Title

DPN004406 Piping, Air Cooled Models

DPN004405 Piping, Split System Water/Glycol Models

DPN004403 Piping, Close Coupled Water/Glycol and Chilled Water Models

Table 5.2 Piping Connection Drawings

Docu ment Number Title

Evaporator and Chilled Water Units

DPN004306 Piping Connections, Chilled Water Units

Split System IndoorCondensing Units

DPN004420 PipingConnections, Air Cooled Condensing Unit

DPN004421 Piping Connections, Remote Water/Glycol Cooled Condensing Unit

DPN004309 Piping Connections, Close Coupled Water/Glycol Cooled Units

5 Pip ing and Refrigeran t Requirements

37

Page 44

5.1 Fluid Piping Required

5.1.1 Evaporator Drain Line Installation Requirements

A 3/4 in. (19mm) OD hose barb connection is provided for the evaporator coil condensate drain.

Observe the following requirements when installing and routing the drain line:

• The drain line must be located so it will not be exposed to freezing temperatures.

• The drain should be the full size of the drain connection.

• Pitch the drain line per local and national codes.

NOTE: The drain line must be trapped outside the unit.

5.1.2 Humidifier Drain Line Installation Requirements

On units with an optional humidifier, a 1/2 in. (13mm) OD hose barb connection is provided for the steam generating

humidifier canister.

Observe the following requirements when installing and routing the drain line:

• The drain should be the full size of the drain connection.

• Pitch the drain line per local and national codes.

NOTE: The drain line must be trapped outside the unit. This line may contain boiling water. User copper or other

suitable material for the drain line.

5.1.3 Condensate Drain Pump Kit

WARNING! Risk of electric shock. Can cause equipment damage, injury, or death. Open all local and remote

electric power supply disconnect switches and verify with a voltmeter that power is off before working within

any electric connection enclosures. Service and maintenance work must be performed only by properly

trained and qualified personnel and in accordance with applicable regulations and manufacturers’

specifications. Opening or removing the covers to any equipment may expose personnel to lethal voltages

within the unit even when it is apparently not operating and the input wiring is disconnected from the

electrical source.

The optional condensate pump kit is required when the evaporator is installed below the level of the gravity fed drain line.

The condensate pump is field installed inside the evaporator unit. The pump kit includes a check valve, sump, sump level

sensor, controls, fittings, and complete instructions.

Table 5.3 Condensate Drain Pump Drawings

Docu ment Number Title

DPN004306 Field Installed Pump Connection

To install the condensate drain pump:

1. Refer to the instructions and drawings supplied with the pump.

2. Disconnect all power to the unit, and remove the evaporator housing.

3. Make the following piping connections, see Table 5.3 above:

• Unit drain pan

• Unit's humidifier drain (if applicable)

38

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 45

• Output to field provided/field installed drain line

4. With the wiring harness, make the following electrical connections to :

• Connect yellow electric leads L1 and L2 to the line voltage terminal block in the cooling unit.

• Connect the green ground lead to the lug near the terminal block.

• Connect red wires from the auxiliary pump contacts to terminals TB6-4 and TB6-5 to shut down unit at

the occurrence of a high water condition in the pump.

5. Tighten all connections and, before installing the housing, run the unit to make sure the pump works properly.

Operate the pump and check the drain line and discharge line for leaks. Correct as needed.

NOTE: Schedule periodic inspection of the piping connections. Clean the pump's sump at the same time you wash the

evaporator air filter. We recommend at least monthly cleaning.

5.1.4 Water Supply Line to the Humidifier

Units supplied with the optional humidifier package have a 1/4-in. (6.2-mm) tube compression at the water supply inlet.

• The supply pressure range is 10psig to 150psig (69kPag to1034kPag).

• The required flow rate is 1 gpm (3.8 lpm).

• Install a shut-off valve in the supply line to isolate the humidifier for maintenance.

5.1.5 Chilled Water Loop Piping

NOTICE

Risk of piping system corrosion and freezing fluids. Can cause leaks resulting in equipment and very expensive

building damage. Cooling coils and piping systems are at high risk of freezing and premature corrosion. Fluids

in these systems must contain the proper antifreeze and inhibitors to prevent freezing and premature coil and

piping corrosion. The water or water/glycol solution must be analyzed by a competent local water treatment

specialist before start-up to establish the inhibitor and antifreeze solution requirement and at regularly

scheduled intervals throughout the life of the system to determine the pattern of inhibitor depletion.

The complexity of water/glycol solution condition problems and the variations of required treatment programs

make it extremely important to obtain the advice of a competent and experienced water treatment specialist

and follow a regularly scheduled coolant fluid system maintenance program.

Water chemistry varies greatly by location, as do the required additives, called inhibitors, that reduce the

corrosive effect of the fluids on the piping systems and components. The chemistry of the water used must be

considered, because water from some sources may contain corrosive elements that reduce the effectiveness of

the inhibited formulation. Sediment deposits prevent the formation of a protective oxide layer on the inside of

the coolant system components and piping. The water/coolant fluid must be treated and circulating through

the system continuously to prevent the buildup of sediment deposits and or growth of sulfate reducing

bacteria.

5 Pip ing and Refrigeran t Requirements

39

Page 46

Proper inhibitor maintenance must be performed in order to prevent corrosion of the system. Consult glycol

manufacturer for testing and maintenance of inhibitors.

Commercial ethylene glycol, when pure, is generally less corrosive to the common metals of construction than

water itself. It will, however, assume the corrosivity of the water from which it is prepared and may become

increasingly corrosive with use if not properly inhibited.

We recommend installing a monitored fluid detection system that is wired to activate the automatic closure of

field installed coolant fluid supply and return shut-off valves to reduce the amount of coolant fluid leakage and

consequential equipment and building damage. The shut-off valves must be sized to close off against the

maximum coolant fluid system pressure in case of a catastrophic fluid leak.

NOTICE

Risk of no flow condition. Can cause equipment damage.

Do not leave the water/coolant fluid supply circuit in a no flow condition. Idle fluid allows the collection of

sediment that prevents the formation of a protective oxide layer on the inside of tubes. Keep unit switched On

and water/coolant fluid supply circuit system operating continuously.

See Table 5.4 below, for the chilled water loop requirements.

Install manual service shut-off valves at the supply and return lines of each unit. These shut-off valves are used for routine

service and for emergency isolation of the unit.

Refer to the appropriate piping general arrangement schematics for your system for the recommended, field installed

hardware such as shut-off valves and hose bibs. See Table 5.1 on page37.

NOTE: Ambient conditions and the minimum supplied water temperature determines whether or not you should

insulate the chilled water supply and return lines to prevent condensation on the lines.

Table 5.4 Requirements for Chilled Water Loop Installation

Minimum Recomm ended

Water Temperature, °F(°C)

42 (5.5) 300 (2,0 68) with a max imum close off pressure of 60psig(414kPa) 7/8 O. D. Cu

Standard Pressure Valve

Design Pressure, Psig(Kpag)

Supp ly/Return

Connection Sizes,

in.

5.1.6 Water/Glycol Loop Piping

NOTICE

Risk of frozen pipes and corrosion from improper coolant mixture. Can cause water leaks resulting in

equipment and building damage.

When piping or the cooling unit may be exposed to freezing temperatures, charge the system with the proper

percentage of glycol and water for the coldest design ambient temperature. Automotive antifreeze is

unacceptable and must NOT be used in any glycol fluid system. Use only HVAC glycol solution that meets the

requirements of recommended industry practices.

Do not use galvanized pipe.

Install manual service shut-off valves at the supply and return line to each unit. This permits routine service and emergency

isolation of the unit. Refer to the appropriate submittal drawing for the piping connection sizes of your unit, see Table 5.2

on page37.

40

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 47

Refer to the appropriate piping general arrangement schematics for your system for the recommended, field installed

hardware such as shut-off valves. See Table 5.1 on page37.

When the fluid quality is poor, we recommend installing a 16-20# mesh Y strainer filter in the supply line to extend the

service life of the coaxial condensers. These filters must be easily replaced or cleaned.

The standard maximum fluid pressure is 150 psig (1034 kPa). For applications above this pressure, contact a Vertiv

representative.

The water cooled system will operate in conjunction with a cooling tower or city water. The water/glycol cooled system will

operate in conjunction with a cooling tower, city water, or drycooler.

NOTE: HVAC grade ethylene or propylene glycol should be used on glycol systems. Automotive antifreeze must not

be used.

Water/Glycol Coolant Regulating Valve

Water/glycol cooled units include a coolant flow regulating valve that may require adjustment.

To adjust the valve:

1. Attach refrigeration gauges to the compressor discharge and suction lines.

2. Raise the head pressure by turning the adjusting screw clockwise.

3. Allow enough time between adjustments for the system to stabilize. Refer to recommended operating

pressures in Water/Glycol Loop Piping on the previous page.

4. The coolant flow should stop when the refrigeration system is off for approximately 10 to 15 minutes. If the

coolant continues to flow, the valve is improperly adjusted (head pressure is too low).

5. Flush the valve by inserting a screwdriver or similar tool under the two sides of the main spring and lifting. This

opens the valve seat and flushes out any dirt particles,

5 Pip ing and Refrigeran t Requirements

41

Page 48

5.2 Refrigerant Piping

WARNING! Risk of over-pressurization of the refrigeration system. Can cause piping rupture, explosive

discharge of high pressure refrigerant, loss of refrigerant, environmental pollution, equipment damage,

injury, or death. This unit contains fluids and gases under high pressure. Use extreme caution when

charging the refrigerant system. Do not pressurize the system higher than the design pressure marked on

the unit's nameplate. Relieve pressure before cutting into or making connections/disconnections to the

piping system. Local building or plumbing codes may require installing a pressure relief device in the

system.

Consult local building and plumbing codes for installation requirements of additional pressure relief devices

when isolation valves are field installed. Do not isolate any refrigerant circuits from over-pressurization

protection. The PFH and MCD condensing units include a factory installed pressure relief valve mounted on

top of the receiver. The valve is rated for a maximum working pressure of 475 psig.

NOTICE

Risk of oil contamination with water. Can cause equipment damage.

Liebert®DataMateDX systems require the use of POE (polyolester) oil. POE oil absorbs water at a much faster

rate when exposed to air than previously used oils. Because water is the enemy of a reliable refrigeration

system, extreme care must be used when opening systems during installation or service. If water is absorbed

into the POE oil, it will not be easily removed and will not be removed through the normal evacuation process. If

the oil is too wet, it may require an oil change. POE oils also have a property that makes them act as a solvent

in a refrigeration system. Maintaining system cleanliness is extremely important because the oil will tend to

bring any foreign matter back to the compressor.

NOTICE

Risk of improper refrigerant charging. Can cause equipment damage.

Refrigerant charge must be weighed into compressorized systems before they are started.

Split systems require two refrigerant lines between the evaporator and the condensing unit:

• One insulated copper suction line

• One copper liquid line

42

Vertiv | Liebert® DataMate™ Installer/User G uide

Page 49

Observe the following requirements for all field supplied refrigeration piping:

• All piping must be ACR type copper.

• For all piping connections, use prevailing good piping practices, which includes brazing copper pipes using a

brazing alloy of a minimum temperature of 1350°F(732°C) and adhere to local codes.

• Factory installed piping brackets must not be removed.

• Piping must be installed in accordance with local codes and must be properly assembled, supported, isolated,

and insulated.

• Use prevailing good refrigeration practices such as piping supports, leak testing, evacuation, dehydration, and

charging of the refrigeration circuits.

• Isolate the refrigeration piping from the building with vibration isolating supports.

• Avoid piping runs through noise sensitive areas such as office walls and conference rooms.

• When sealing openings in walls and to reduce vibration transmission, use a soft, flexible material to pack

around the tubes to prevent tube damage.

• When installing remote condensing units above the evaporator, the suction gas lines should be trapped at the

evaporator. These traps will retain refrigerant oil in the off cycle. When the unit starts, oil in the traps is carried

up the vertical risers and returns to the compressors.

5.2.1 Piping when Condensing Unit is Above or Below Evaporator

Refer to Pipe Length and Condensing Unit Elevation Relative to Evaporator below, for the maximum vertical rise/fall

between condensing unit and evaporator.

When installing remote condensing units above the evaporator, trap the suction gas line at the evaporator as shown in

Figure 5.1 on the next page. This trap will retain refrigerant oil during the Off cycle. When the unit starts, oil in the trap is

carried up the vertical riser and returns to the compressor. For rises over 25ft.(7.6m), trap every 20ft.(6m) or evenly

divided.

When installing remote condensing units below the evaporator, trap the suction gas line with an inverted trap the height of

the evaporator as shown in Figure 5.1 on the next page. This prevents refrigerant migration to the compressor during Off

cycles. The maximum recommended vertical level drop to condensing unit is15ft.(4.6m).

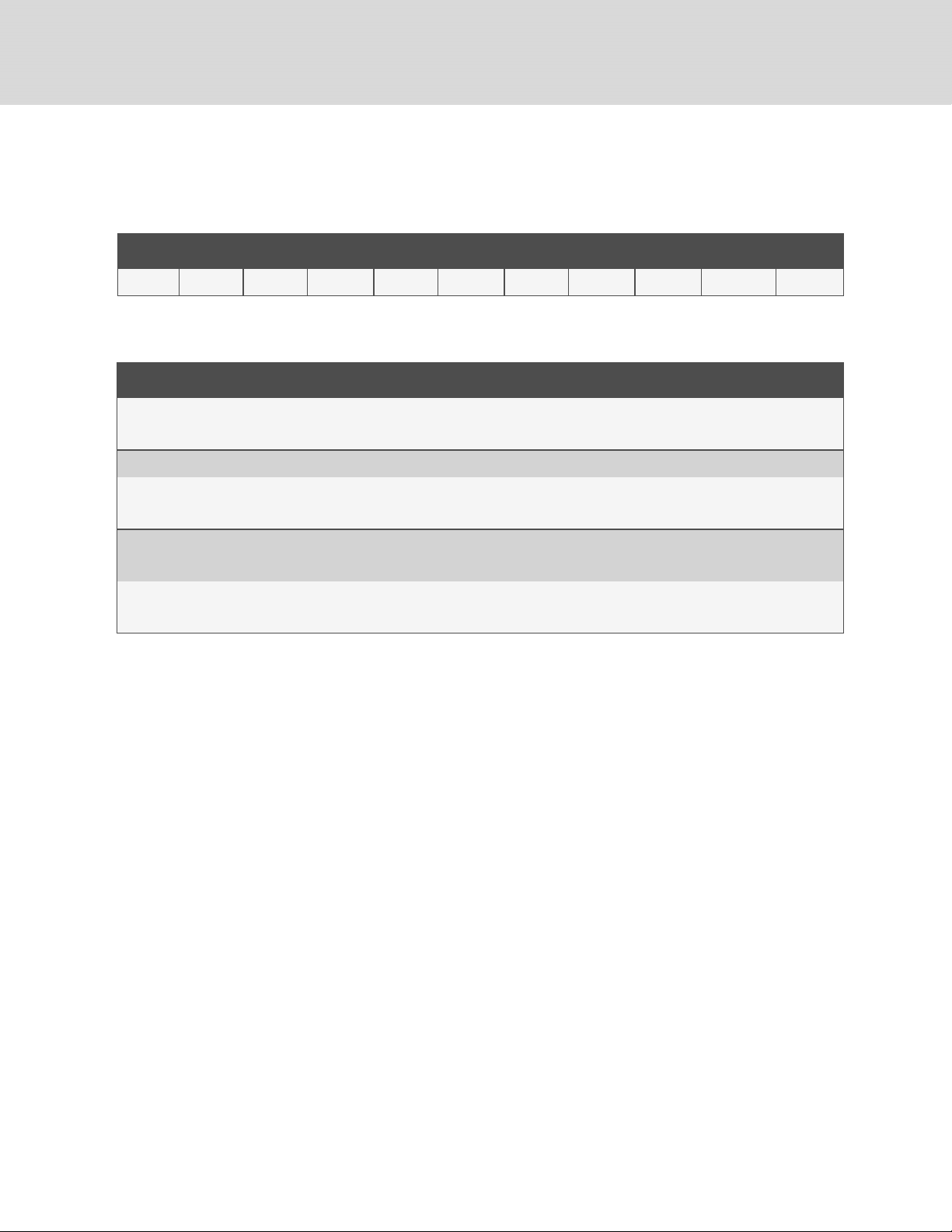

Table 5.5 Pipe Length and Condensing Unit Elevation Relative to Evaporator

Nomin al

SystemSize, Ton

1.5 a nd 2 150 (45) 40 (12) 15 (4.6)

3 1 50 (45) 50 (15) 15 (4.6)

Maximum recommended total equivalent pipe length is 150 ft. (46m). Suction and liquid lines may require

additional specialty items when vertical lines exceed 20 ft. (6m) and/or condensing unit installation

is more than 15 ft. (4.6m) below the evaporator. Contact Vertiv Technical Supportfor a ssistance.

Maximum Equivalent

PipeLength, ft. (m)

Maximum

Condensing Unit Level

Abo veEvaporator, ft.(m)

Maximum

Condensing Unit Level

BelowEvaporator, ft.(m )

5 Pip ing and Refrigeran t Requirements

43

Page 50

Figure 5.1 Refrigerant Piping Diagram when Condenser is Above or Below Evaporator

NOTE: Any horizontal pipe must be pitched down toward the condensing unit at a minimum rate of 1/2in. (13mm) per

10ft.(3m) to assure oil return to compressor.

Item Description

1 Condensingunit above evaporator

2 Condensing unit below evaporator

3 Evaporator

4 Condensing unit

5.2.2 Refrigerant Line Sizes and Equivalent Lengths