Page 1

H904 , H934 & H720

VERIS INDUSTRIES

VFD Switches and

Current Sensors

Variable Frequency Drive

Monitoring and Control

DESCRIPTION

Hawkeye 904, 934, and 720 current monitoring devices provide unique solutions

for accurately monitoring status of motors controlled by variable frequency drives.

The microprocessor-based H904 and H934 store the sensed amperage values

for normal operation at various frequency ranges in non-volatile memory. This

information allows the device to distinguish between a reduced amp draw due to

normal changes in the frequency and an abnormal amp drop due to belt loss or other

mechanical failures. The relay on the H934 is isolated from the current switch, and all

relay connections are externally accessible on the device.

The H720 analog output corresponds to current in the monitored conductor from 10

to 80 Hz.

APPLICATIONS

current monitoring

● Monitoring positive status on motors controlled by variable frequency drives

● Replacing pressure switches

● Measuring current and load trending

DETECTS BELT LOSS/COUPLING SHEAR!

DETECTS BELT LOSS/COUPLING SHEAR!

Fan/pump

Calibrated

Trip Point

O O

Now you can easily detect when drive belts slip, break, or pump couplings shear.

In fact, a typical HVAC motor that loses its load has a reduction of current draw

of up to 50%. That’s why our sensors are the industry standard for status.

Loss of Belt/Coupling Shear

On

Electrical

Failure

TM

H904

H934

H720

U.S. Patent No. 5,705,989

FEATURES (H720)

● Analog output

● Superior to Hall eec t and metal core sensors...frequency tolerant 10-80 Hz

● Accurate to 0.5% of full scale

● Suitable for load side monitoring of VFDs

● Adjustable zero and span for precise scaling

● Adjustable mounting bracket for easy placement

FEATURES (H904 and H934)

● Microprocessor-based...real labor saver...No need to calibrate to

detect belt loss on VFDs

● Self-adjusting trip point...factory programmed to detect belt loss

undercurrent conditions

● Provides accurate status for VFD loads...prevents costly long-term failures

● Automatically compensates for the eects of frequency and amperage

changes associated with VFDs

● Nuisance Reduction feature...provides a secondar y setpoint option of

50% of the originally measured current

● LED indicates normal and alarm conditions...rapid troubleshooting

● Huge labor savings...no need to calibrate in live starter enclosures...

install and go

● Available with a relay (H934)...status and control in one package,

saving time and space

● Bracket can be installed in three dierent congurations...added exibility

● Monitors both frequency and amperage...distinguishes normal drops in

amperage due to frequency changes from abnormal drops due to

mechanical failure

● Split-core design is ideal for retrots...no need to remove conductor

● 5-year warranty

Maximize Reliability

Minimize Installed Cost

Year

SPECIFICATIONS

Sensor Power H904/H934: Induced from monitored conductor; H720: 12-30VDC

Insulation Class 60 0VAC RM S

Frequency Range H720: 10 to 80 Hz; H904/H934: 20 to 34 Hz for on/o status, 34 to 75 Hz for belt loss indic ation

Temperature Range -15° to 60°C (5° to 140°F)

Humidity Range 10-90% RH non-condensing

O Delay (H90 4/H934) 0 sec to 2 min.

Accurac y (H720) 0.5% (combined linearity, hysteresis, and repeatability)

Terminal Block Wire Size 24-14 AWG (0.2 to 2.1 mm2)

Terminal Block Torque 3.5 to 4.4 in-lbs (0.4 to 0.5 N-m)

Agency Approvals UL 508 open device listing

Do not use the LED status indicators as evidence of applied voltage.

800.354.8556

5

Warranty

+1 503.598.4564

www.veris.com

HQ00 01758.B 01131

Page 2

800.354.8556

E150462

+1 503.598.4564

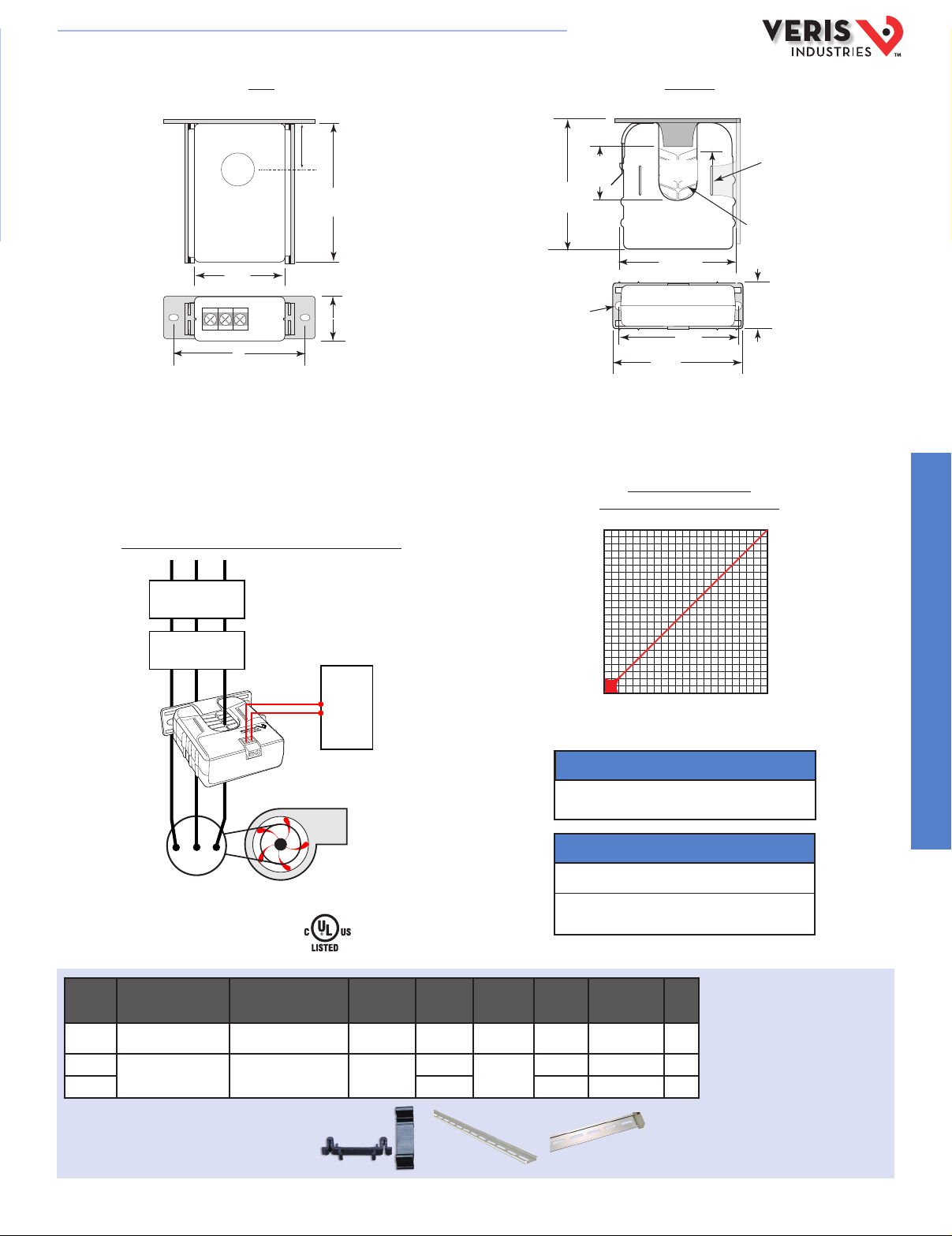

DIMENSIONAL DRAWINGS

H720

Removable/Adjustable Mounting Bracket

0.7"

(19 mm)

0.33"

(9 mm)

(80 mm)

3.13"

www.veris.com

**3.1”

(79 mm)

Removable Mounting Bracket

1.1”

(26 mm)

H904/934

0.8”

(21 mm)

1.0”

(25 mm)

Bracket can

be mounted

on three sides

for added

installation

exibility.

Self-gripping Iris

2.15"

(55 mm)

1.00"

(26 mm)

3.0"

(76 mm)

APPLICATION/WIRING DIAGRAM (H904)

Monitoring Fan /Pump Motors for Positive Proof of Flow

CONTACTOR

VFD

CONTROL

DI

2.8”

(70 mm)

Ø 0.3”

(8 mm)

2.5”

(64 mm)

3.0”

(76 mm)

* Terminal block may extend up to 1/8” over the height dimensions shown.

1.4”*

(36 mm)

EXAMPLE LINEAR OUTPUT (H720)

Scale software as shown

Requires 12-30VDC for sensor power

20mA

SENSOR OUTPUT

4mA

0A

SENSED AMPS

200A

Fan or Pump

Motor

NOTE: The H904 is not intended for use in staged pump or variable inlet vane applications.

ORDERING INFORMATION

MODEL AMPERAGE RANGE STATUS OUTPUT MIN. TRIP

POINT

H720

H904

H934 SP ST, N. O.

ACCESSORIES

DIN Rail Clip Set (AH01)

DIN Rail (AV01) and DIN Stop Clip (AV02)

HQ00 01758.B 01131

lower limit: 0A

Upper limit: 20 to 200A

3.5 - 135A, 20 - 75 Hz Max. N.O. 0.1A@30VAC/DC 3.5A or le ss

4-20mA n/a none Solid-core

AH01

RELAY

TYPE

none

HOUSING STATUS

Split-core

AV01

H934 RELAY CONTACT RATINGS

Resistive..................................5A@250VAC, 30VDC

TYPICAL COIL PERFORMANCE

Voltage AC DC

24V................................... 10mA 10mA

RELAY

LED

POWER LED

n n

n n n

AV02

UL

n

current monitoring

Loading...

Loading...