Page 1

6%2)3).$5342)%3

POWER MONITORING

NOTICE

DANGER

INSTALLATION GUIDE

H704-42(H)(E), H704-42/1(H)(E)

Branch Current Monitor

Installer's Specifications

General:

Operating Temp. Range 0° to 60°C (32° to 140°F) (<95% RH, non-condensing)

Storage Temp. Range -40° to 70°C (-4 0° to 158°F)

Control (Mains) Power Source 120 VAC L-N, 50/60 Hz (208/230 VAC for H704-42/1(E))

(+10/-25%) Input current < 75 mA

Primary Fusing 250 VAC/100 mA, (T) 5 x 20 mm, (if equipped) Littelfuse 218 series

or equivalent

Altitude of Operation 3 km max.

Measured Current Inputs:

Number of Channels 42

Frequency 50/60 Hz

Sample Frequency 1280 Hz

Update Rate 1.2 sec

Accuracy ±2% from 5 A to 50 A *

Overload Capability Tested to 10,000 A single-cycle

Connection to Conductor Solid-core toroid

Measured Currents Current range 0-50 A (max. conductor si ze is AWG#6 THHN)

Measured Currents, H version Current range 0-100 A (max. conduc tor size is AWG#2 THHN)

Network Communications:

Typ e Modbus RTU

Connection DIP switch-selectable 2-wire or 4-wire

Address DIP switch-selectable address 1 to 247

Baud Rate DIP switch-selectable 2400, 4800, 9600, 19200

Parity DIP switch-selectable NONE, ODD, EVEN

Communication Format 8-data-bits, 1-start-bi t, 1-stop-bit

Termination 5-position depluggable connector

(TX+ TX- SHIELD TX+/RX+ TX-/RX-)

Defaults:

Warning Register 60% of current sensor max. (configurable)

Alarm Register 70% of current sensor max. (configurable)

Breaker Size Register 20 A

MODEL # CT SPACING

H704-42(H)(E) ¾" on center

H704-42/1(H)(E) 1" on center

For a 400A Panel, order the H704-42Y55

* In case of a current fault above 60A (120 for the H version), all adjacent channels will re port

higher than actua l readings. To prevent this from causing over-current warnings and alarms,

configure the warning an d alarm delays for a longer time period than the resp onse time of the

br eak er.

quick install

1. Disconnect and lock out power.

2. Mount current sensor strips adjacent to breaker terminations.

3. Verify that serial numbers on CT and board match.

4. Mount board onto electrical/fire enclosure.

5. Connect CTs and wire the board.

6. Reconnect power.

7. Configure communication and addressing parameters.

Note: Data acquisition board and CT strips are calibrated as a set. Match the serial

numbered parts together.

Z202366-0M page 1 ©2008 Veris Industries USA 800.354.8556 or 503.598.4564 / support@veris.com 02081

Page 2

6%2)3).$5342)%3

H704

6 4 2

12

10 8 18

16

14

24

22

20

30

28

26

36

34

32

42

40

38

10

11

INSTALLATION GUIDE

operation

The H704-42 Branch Current Monitor is a current sensing device designed to monitor

all 42 poles of a panel board. Designed for critical load monitoring such as Co-location

Data Centers and lighting panels, the H704-42 provides important branch circuit

amperage and capacit y information. By reporting current levels and initiating

capacity warnings and alarms, the H704-42 allows the management of power and

eliminates open circuits caused by overloaded breakers.

The H704-42 consists of a Data Acquisition Board and two 21-unit current sensor

strips. The strips are mounted on each side of the panel board along the termination

points of each breaker. The conductor passes through the appropriate current sensor

before terminating at the breaker. Each strip transmits the current data to the Data

Acquisition Board through snap on ribbon cable. An optional hardware kit is available

for mounting the H704-42.

Data is transmitted using an RS485 Modbus protocol. Each Data Acquisition Board is

addressed on the modbus daisy chain network.

Setup is made easy with a PC based configuration tool which allows for global or

individual selection of breaker size, warning levels, and alarm levels.

*For 208/230VAC Power Connection versio n, order H704-42(H)(E)/H704-42/1(H)(E)

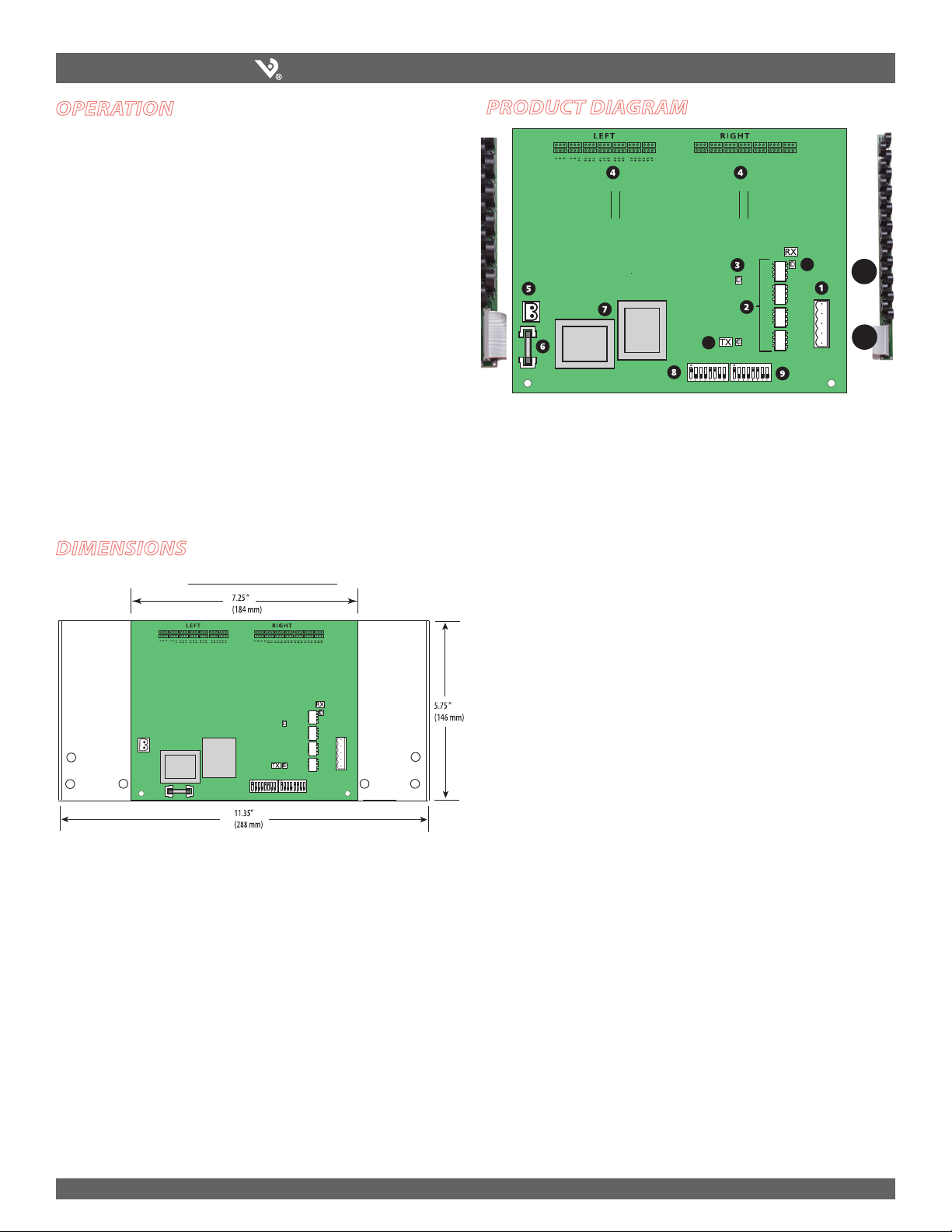

dimensions

Circuit Board and Mounti ng Bracket

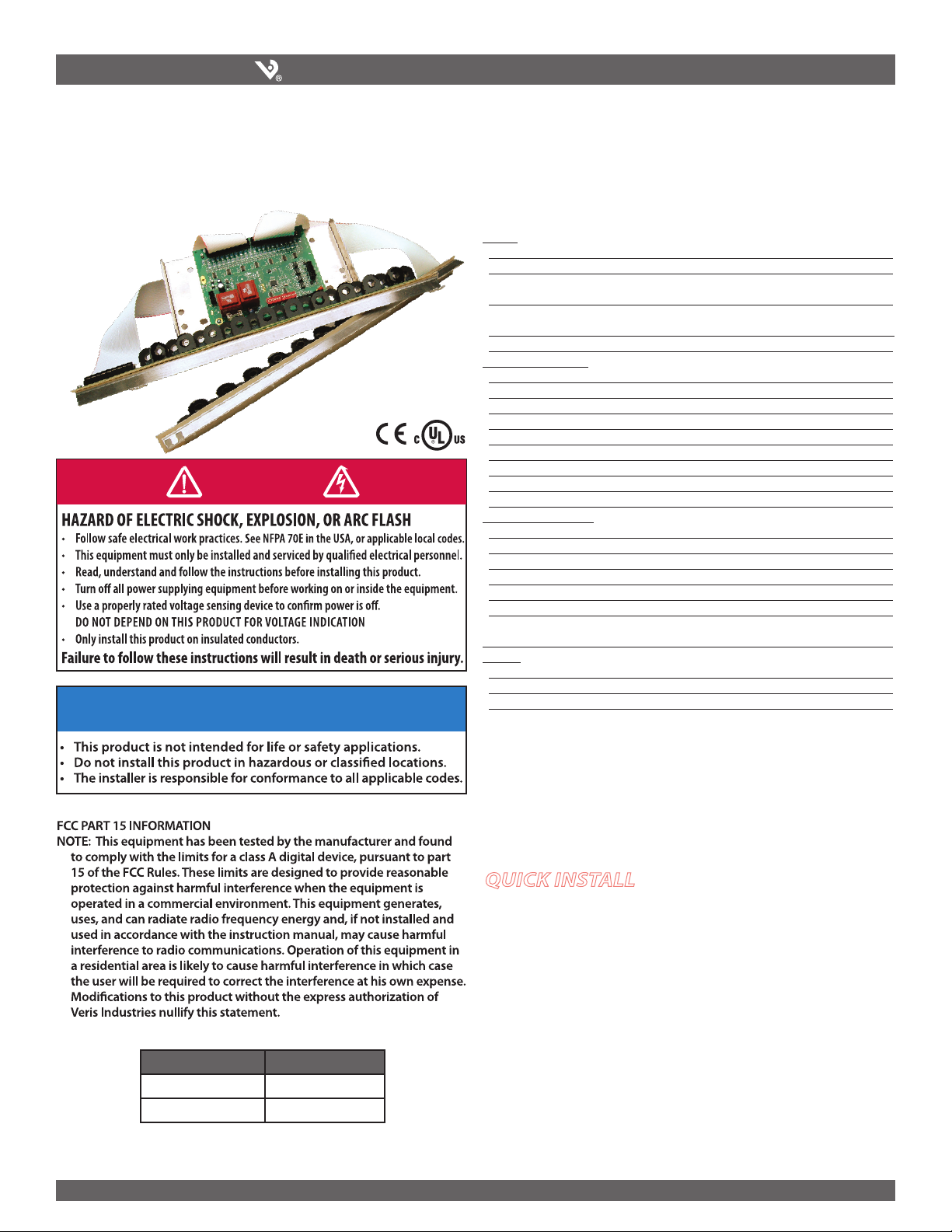

product diagram

12

13

1. RS 485 2 or 4-Wire Connection: Daisy chain multiple H704-42's using a 2-wire

or 4-wire modbus network.

2. Optical Communications Isolation: Optical isolators are used to separate 120

VAC portions of the circuit from the RS485 network.

3. Alive LED: Flashes once per second to indicate correct operation. If steadily lit or

out, indicates internal failure.

4. 50-Pin Ribbon Cable Connec tors (Data Acquisition Board): 18-inch (457 mm)

ribbon cables are provided standard** for easy snap connection of current sensor

strips to this point of the Data Acquisition Board.

5. Control (Mains) Power Connection*: Easy 2-wire 120 VAC line to neutral 50/60

Hz.

6. 250VAC 100mA Time Delay Fuse: Fused power connection for circuit protec tion.

7. Power Transformers: Linear power supply for reliability and low noise

8. Baud Rate & Parity Selection Switches: Field selectable RS-485 serial interface

control.

9. Modbus Address Dip Switches: Each Modbus device must have a unique

address. These switches must be set to assign an individual address before the

device is connected to the network.

10. TX LED: Indicates successful transmission of information over the Modbus

network.

11. RX LED: Indicates data received on the Modbus network

12. Current Sensors: Each current sensor is capable of monitoring conductors

carrying up to a maximum of 50 amps. Maximum wire size capacity is #6 AWG

THHN. H version can monitor up to 100 amps with a maximum wire size capacity

of #2 AWG THHN

13. 50 Pin Ribbon Cable Connectors (CT Strips): 18" ribbon cables are provided

standard** for easy snap connection of Data Acquisition Board strips to this point

of the current sensor strips

Z202366-0M page 2 ©2008 Veris Industries USA 800.354.8556 or 503.598.4564 / support@veris.com 02081

*For 208/230VAC Power Connection versio n, order catalog number H704-42/H704-42/1E.

**Additional sizes are available for sa le.

Page 3

6%2)3).$5342)%3

H704

11.375"

(289 mm)

1.12"

(28 mm)

5.75"

(146 mm)

Data Acquisition Board

Mounting Bracket

Data Acquisition Board

19.5

495

1.0

25

0.75

19

Side View

1.3

33

0.4 opening

10.16

0.75 on center

19

1.2

31

20.31

515

“Right” strip shown

19.5"

(241 mm)

0.75 " o n ce nter

(19 mm)

0.35" open ing

(9 mm )

1.0"

(26 mm)

24.0"

1.0"

INSTALLATION GUIDE

safety

UL listed under standard 508 as an "open type device."

Installation categor y: CAT II or CAT III

Critical components evaluated to UL 1950.

The H704 Series must be installed in as appropriate electrical and fire enclosure per

local regulations.

For use in a Pollution Degree 2 or better environment only.

A Pollution Degree 2 environment must control conductive pollution and the

possibility of condensation or high humidity. Consideration must be given to the

enclosure, the correct use of ventilation, thermal properties of the equipment and

the relationship with the environment.

This symbol indicates an electrical shock hazard exists.

Documentation must be consulted where this symbol is used

on the product.

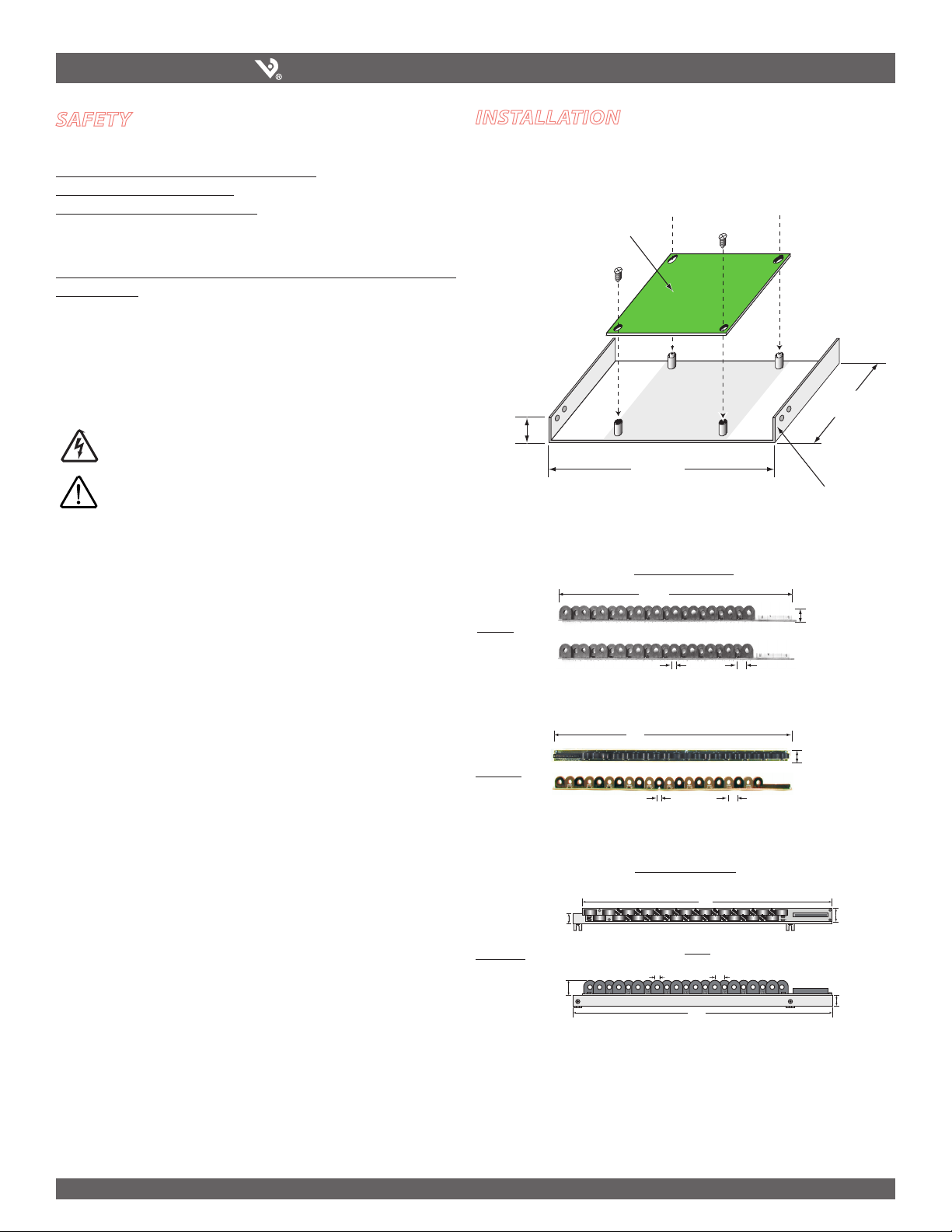

installation

1. Inspect the Mounting Bracket Kit. The acquisition and interconnection boards are

mounted to the bracket at the factory.

50A Solid-Core CT Strips

H704 -42

H704 -42/1

100A Solid-Core CT Strip

H704 -42(H)

Z202366-0M page 3 ©2008 Veris Industries USA 800.354.8556 or 503.598.4564 / support@veris.com 02081

Page 4

6%2)3).$5342)%3

installation, cont.

(#522%.43%.3/2342)0

(#522%.43%.3/2342)0

(#522%.43%.3/2342)0

(#522%.43%.3/2342)0

(

$ATA

!CQUISIT ION

"OARD

-ODBUS

5PTO

(g S

2IBBON

#ABLE

4O#ONTROLLER

OR0#

0ANEL"O ARD 0ANEL"O ARD

64212108181614242220302826363432424038

4

LEFT RIGHT

RX

20

20202 020202020202020202020202020202 020

H704

INSTALLATION GUIDE

2. Disconnect power to the electrical panel and lock it out. Connect 2-wire

120 VAC* power to power terminals. (see Product Diagram for location) Observe

polarity.

3. Current Sensor Strip Installation: Locate panel board screws which are 16.50”

(420 mm) apart and allow the current sensors to line up directly with breaker

terminations. Loosen these two screws sufficiently for the brackets (1 & 2) to slip

under screws. Do not remove screws completely. Slide the current sensor strip

mounting bracket under these loosened screws. Be sure to face the inside of the

bracket toward the breakers. Tighten screws. Repeat for the other side of the panel

board.

4. Check that CT serial numbers and meter serial numbers match. Meter and CT sold

as set with accuracy calibrated as a set.

5. Acquisition Board Installation: Find screw holes under panel board in side

of PDU chassis or panel. Attach Data Acquisition Board bracket using screws and

bolts provided.

6. Pass power wiring through appropriate CT's observing local code for bending

radius. Current sensors accommodate for #6 THNN sized conductor. (max.

diameter 0.35”/9 mm). Use insulated wire only.

* For 208/230VAC Power Connection version, order H704-42E/H704-42/IE

16.5 0”

distan ce

between

bracket

screws

Mounted

Data Acquisition Board

Z202366-0M page 4 ©2008 Veris Industries USA 800.354.8556 or 503.598.4564 / support@veris.com 02081

Page 5

6%2)3).$5342)%3

H704

Master (Network Display)

Slave (H663 series)

TX+

SHLD

TX+

RX+

TX–

RX –

TX–

TX+

SHLD

TX+

RX+

TX–

RX –

TX–

SHIELD

SHIELD

Master or Slave

TX+

SHLD

TX+

RX+

TX–

RX –

TX–

SHIELD

SHIELD

wiring

Power must be disconnec ted and locked out before making any wiring connections.

1. Connect 2-wire or 4-wire Modbus RS485 daisy chain network.

2-Wi re

INSTALLATION GUIDE

4-Wire

NOTES

A. The Modbus cable should be mechanically secured where it enters the

electrical panel.

B. All Modbus devices should be connected together in a daisy-chain fashion,

and properly terminated.

C. The Modbus cable should be shielded twisted pair wire such as Belden

1120A. The cable must be voltage rated for the installation.

WARNING: After wiring the Modbus cable, remove all scraps

of wire or foil shield from the electrical panel. This could be

DANGEROUS if wire scraps come into contact with high voltage

conductors!

2. Use the Software Configuration Tool to set up breaker size, warning levels, and

alarm levels. This tool is available online at http://www.veris.com/modbus.asp

3. Reconnect power.

Disconnect and lock out power source before making any connec tions.

Connect 2-wire 120 VAC power to power terminals. See Product Diagram

section for location. Observe polarity.

Z202366-0M page 5 ©2008 Veris Industries USA 800.354.8556 or 503.598.4564 / support@veris.com 02081

Page 6

6%2)3).$5342)%3

configuration

1

1248163264 128

O

N

1

1

X

X

X

X

X

X

2

On

Off

3

Off

On

Off

On

4

Off

Off

On

On

567

X

X

X

X

X

X

8

X

X

X

X

X

X

2400 Baud

4800 Baud

9600 Baud

19200 Baud

2 wire

4 wire

Wiring, Baud Rate, Parity

Wiring

None

Even

Odd

Off

Off

On

Off

On

Off

ParityBaud Rate

DESIRED RESULT

Switch #

Baud Rate and Parity Switch Setttings

40

1. Communications Configuration: Communications parameters for the H704

series are field selectable for your convenience. Please see Produc t Diagram

section for selector location. The following parameters are configurable:

Parity On or Off•

Parity: Odd or even•

Wiring: Two or four•

Baud Rate: 2400, 4800, 9600 or 19200•

H704

The values of each dip switch are as follows:

INSTALLATION GUIDE

Example: 2-wire 9600 Baud No Parit y (Default Only)

2. Address Configuration: Each Modbus device on a single network must have a

unique address. The switch block must be set to assign a unique address before the

device is connected to the Modbus RS485 network. If an address is selected which

conflicts with another device, neither device will be able to communicate.

H704 series can be addressed as any whole number between and including 1-247.

Each unit is equipped with a set of 8 dip switches for addressing. See below.

=

LSB MSB

or

=

1=1

2=2

3=4

4=8

5=1 6

6=32

7=6 4

8 =128

To determine an address you simply add the values of any switch that is on.

For example:

Switch number 4 has an ON Value of 8 and switch number 6 has an ON Value of 32.

(8+32 = 40)

See the Communications Setup section for a pictorial listing of the first 63 switch

positions.

Z202366-0M page 6 ©2008 Veris Industries USA 800.354.8556 or 503.598.4564 / support@veris.com 02081

VALUE

Page 7

6%2)3).$5342)%3

communications setup

DO NOT

USE ZERO

12345678 910

11 12 13 14 15 16 17 18 19 20 21

22 23 24 25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40 41 42 43

44 45 46 47 48 49 50 51 52 53 54

55 56 57 58 59 60 61 62 63

H704

INSTALLATION GUIDE

Z202366-0M page 7 ©2008 Veris Industries USA 800.354.8556 or 503.598.4564 / support@veris.com 02081

Page 8

6%2)3).$5342)%3

service

Changing the Fuse

1. Disconnect and lock out power to panel.

2. Disconnect and lock out 120V Control (Mains) Power Source to Data Acquisition

Board.

3. Remove old fuse.

4. Replace with new fuse, Littelfuse 218 series or equivalent.

5. Reconnect 120V to Data Acquisition Board.

6. Reconnect power to panel.

7. Check “Alive” LED for proper function (See Product Diagram section for location).

accessories

CBL008 — Cable, Ribbon, 18 in (457 mm), BCM

CBL016 — Cable, Ribbon, 48 in (1219 mm), BCM

CBL017 — Cable, Ribbon, 60 in (1524 mm), BCM

CBL018 — Cable, Ribbon, 72 in (1829 mm), BCM

CBL019 — Cable, Ribbon, 97 in (2464 mm), BCM

CBL020 — Cable, Ribbon, 120 in (3048 mm), BCM

CBL021 — Cable, Ribbon, 240 in (6096 mm), BCM

H704

INSTALLATION GUIDE

Z202366-0M page 8 ©2008 Veris Industries USA 800.354.8556 or 503.598.4564 / support@veris.com 02081

Loading...

Loading...