Page 1

TM

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices.

See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

DANGER

CURRENT MONITORING

INSTALLATION GUIDE

H540/548

VERIS INDUSTRIES, INC.

POR TLAN D, OREG ON USA

TOLL FREE USA 1.800.354.8556

TEL USA 1.503.598.4564

FAX USA 1.503.598.4664

CAUTION: Consult instructions

prior to installation

!

STATUS OUTPUT: 1A@30VAC/DC

RELAY COIL: 24VAC/DC; 16mA nom.

RELAY OUTPUT: 16(8)A@250VA C; 3/4 HP

548

RS

HAND

OC

OFF

AUTO

SO

SP

SC

CAUTION: Consult instructions

prior to installation

!

STATUS OUTPUT: 1A@30VAC/DC

RELAY COIL: 24VAC/DC; 16mA nom.

RELAY OUTPUT: 16(8)A@250VAC ; 3/4 HP

VERIS INDUSTRIES, INC.

POR TLAN D, OREG ON USA

TOLL FREE USA 1.800.354.8556

TEL USA 1.503.598.4564

FAX USA 1.503.598.4664

540

HAND

OFF

AUTO

TM

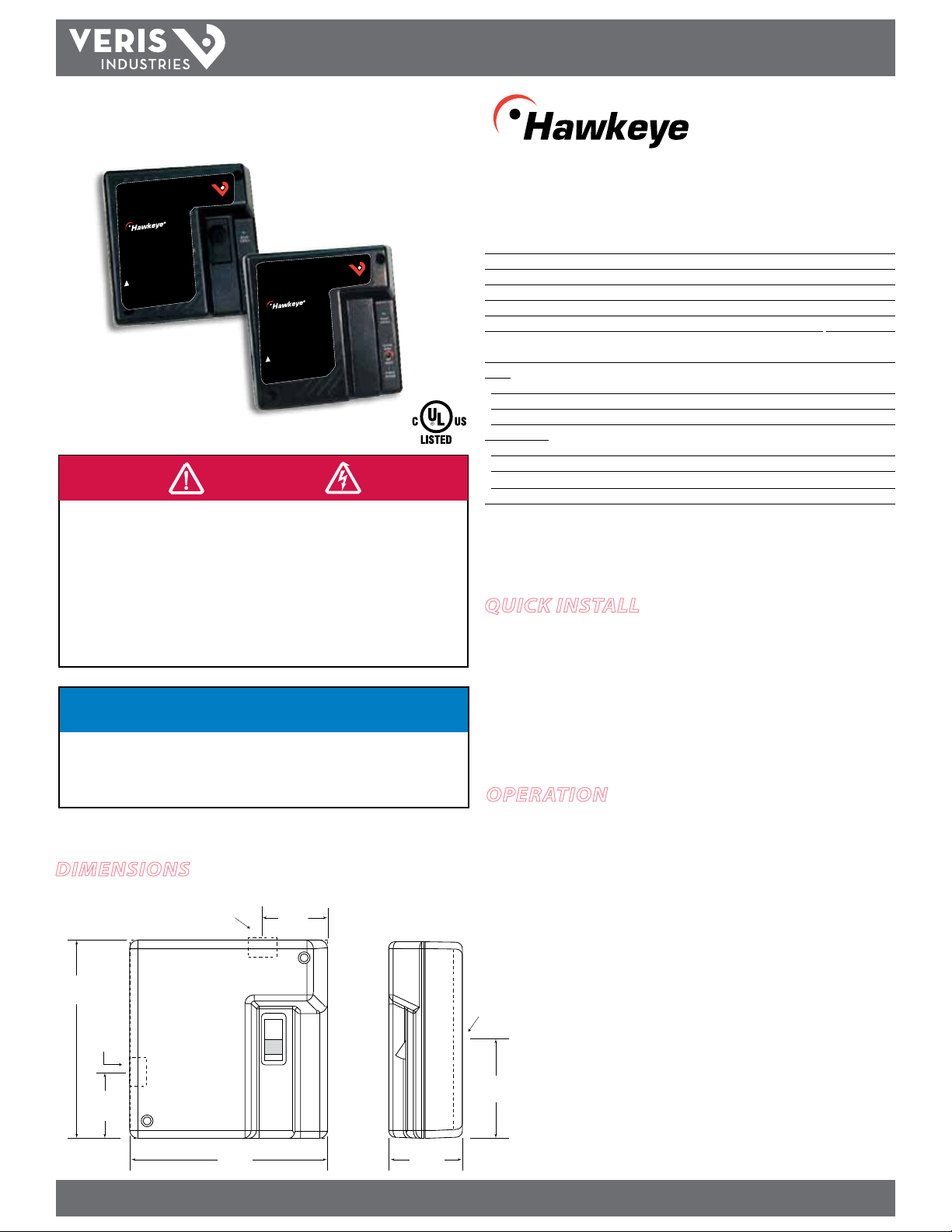

540/548

Fractional HP Motor Status Sensor/

Command Relay

Installer’s Specifications

Sensor Power Induced from the monitore d conductor

Amperage Range H540: 0.25 to 15 A; H548: 0.5 to 15 A

Frequency Range 50-60 Hz

RS

OC

SO

SP

SC

Operating Temperature Range -15°C to 50°C (5° to 122°F)

Operating Humidity Range 0-95% non-condensing

Wire to Relay Contact s Use 12 AWG (3.3 mm

2

) or larger wire*

Terminal Block Torque Relay control ter minals: 3.5 in-lb (0.4 N-m)

All other terminals: 12 in-lb (1.35 N-m)

Relay:

Switching Capacity at 120 VAC 1 HP

Relay Outpu t SPST F.S. N.O. or N.C.

Relay Coil 24 VAC/DC; 36 mA nom

Current Sensor:

Sensor Supply Voltage Induced

Status Output Rating N.O. 1.0 A at 30 VAC/DC

Tri p Point H540: Fixed (on/o status); H548: Adjustable (belt loss detection)

Agency Approvals UL508, Installation Category III

* For current loads up to 10A, use 75°C rated wire insulation. For loads greater than 10A, use 90°C

rated wire insulation.

Specication Note: For CE compliance, insulate conductor a ccording to IEC 61010‑1:2001.

The product design provi des for basic insulation only.

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

Dimensions

C

Wire

Opening

4.25"

(108 mm)

Wire

Opening

C

L

1.16"

(30 mm)

Z202762-0E PAGE 1 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countri es.

(108 mm)

L

1.16"

(30 mm)

4.25"

1.53"

(39 mm)

quick install

1. Disconnect power sources prior to installation.

2. Remove the sensor lid and wire the command relay connections and relay controls

to the base.

3. Set the relay contact jumper.

4. This device has four wiring options, detailed on page 2-3 of this installation guide.

Choose the option appropriate to the application and follow instructions.

operation

The H540 and H548 devices combine a switching relay, a current status sensor, and a

Hand-O-Auto (HOA) switch into a single housing. The device is connected in series

between the power source and the motor device, and the relay and HOA switch

control the on/o functioning of the motor. The current switch trip point is xed at

0.25 A on the H540 and adjustable from 0.5 to 15 A in the H548. The maximum load

is 15 A for both devices. The H540 and H548 require no additional power source for

operation.

Wire

Opening

C

L

2.13"

(55 mm)

Page 2

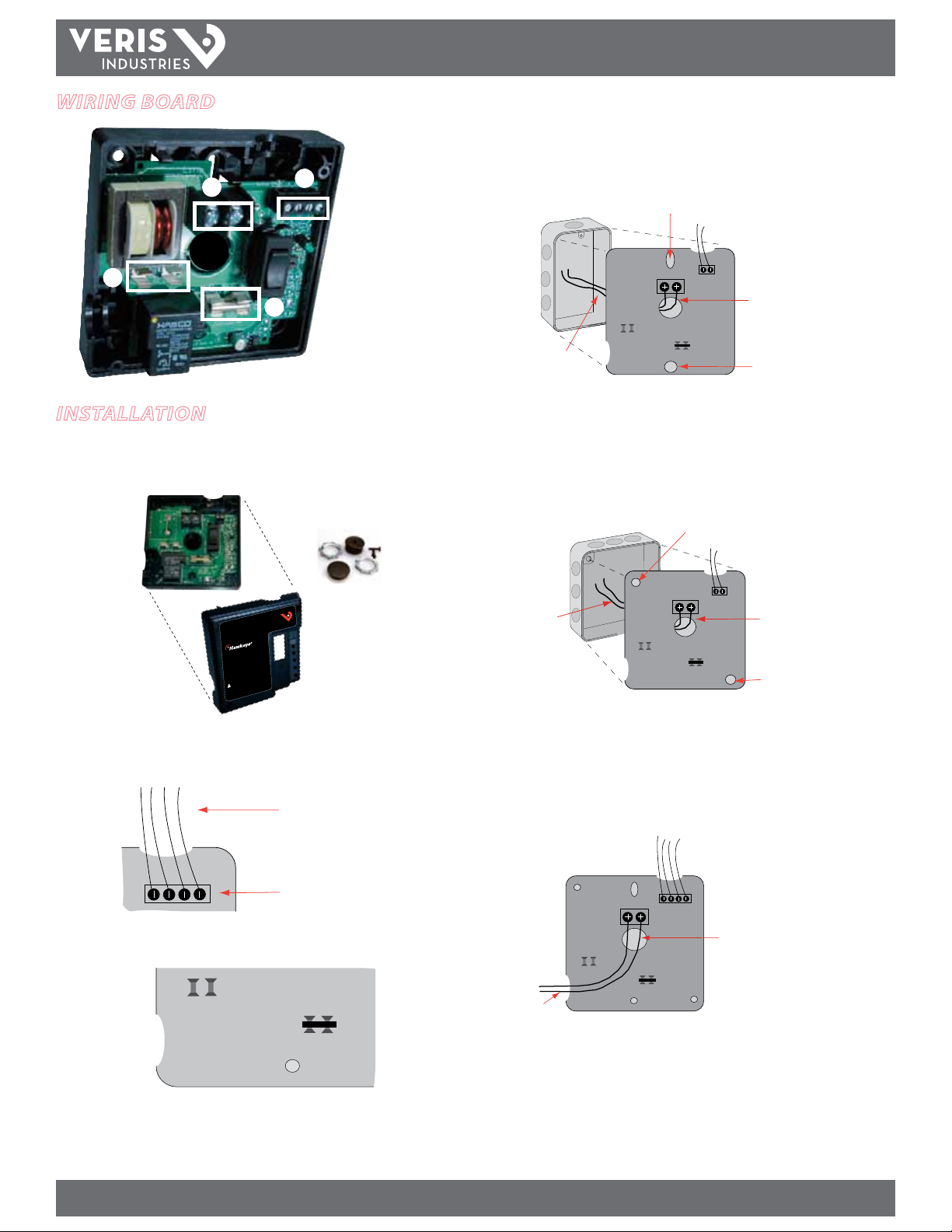

Wiring boarD

TM

H540/548

INSTALLATION GUIDE

4. Select one of the following mounting congurations (a, b, c, or d) to match your

installation.

1

3

2

1. Line Current Terminals

4

2. 24VAC/DC Relay Control

3. N.C. Block

4. N.O. Block

installation

Prior to installation, disconnect and lock out all power sources.

1. Open the device. Set aside the lid and the bag of hardware enclosed.

VERIS INDUSTRIES, INC.

P ORTL AND, OR EGON U SA

TOLL FREE USA 1.800.354.8556

TEL USA 1.503.598.4564

FAX USA 1.503.598.4664

RS

535

HAND

OC

OFF

SO

AUTO

SP

CAUTION: Consult instructions

prior to installation

!

STATUS OUTPUT: 1A@30VAC/DC

RELAY COIL: 24VAC/DC; 16mA nom.

RELAY OUTPUT: 16(8)A@250VAC; 3/4 HP

SC

a.) duplex box:

Mounting slot

Connect line voltage wires

to line current terminals

Mounting hole

Line Voltage

Wires

N.C. Block

N.O. Block

Wire the 12 AWG lines from the controller through the back of the device, to

the line current terminals. Tighten line current terminal blocks to 12 in-lb.

(1.35 N-m) torque. Use the base as a template for mounting to the wall using

the mounting hole and slot shown.

b.) 4S junction box:

Mounting hole

Line Voltage

Wires

Connect line voltage wires

to line current terminals

Mounting hole

2. Wire the 24 AC/DC relay control through the top hole of the device. Use only copper

conductors for command relay inputs. Tighten terminal blocks to 3.5 in-lb (0.4

N-m) torque. Keep wires away from the N. O. and N. C. jumper blocks.

Status Output & Relay Coil

(Low Voltage Wires Only)

24VAC/DC Relay Control /

Status Control

3. Set the relay contact jumper for N.O. or N. C. operation (the device is shipped with

the jumper set in the N.O. position).

N.C. Block

N.O. Block

Wire the 12 AWG lines from the controller through the side of the device, onto

the line current terminals. Tighten line current terminal blocks to 12 in-lb.

(1.35 N-m) torque. Use the base as a template for mounting to the wall using

any of the mounting holes shown.

c.) surface mounting:

Connect line voltage wires

to line current terminals

Line Voltage

Wires

Wire the 12 AWG lines from the controller through the side of the device, onto

the line current terminals. Tighten line current terminal blocks to 12 in-lb.

(1.35 N-m) torque. Use the base as a template for mounting to the wall using

any of the mounting holes shown.

Z202762-0E PAGE 2 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countri es.

Page 3

TM

Connect line voltage wires

to line current terminals

H540/548

d.) nipple mount to another enclosure:

Insert the conduit nuts (provided) into the slots in the side hole of the device

for additional weight support.

INSTALLATION GUIDE

calibration (H548 only)

Note: Testing the solid-state status output of this sensor with a digital ohmmeter

may yield inaccurate, but relative readings of switching (e.g. 6 MΩ) Use an analog

V-O-M for readings similar to loop values. Calibration to be done while motor is

running normally.

1. For under-current status indication: (Belt loss, fan & pump status)

• Turn the set point screw clockwise until the status closed LED goes out

and the status open LED comes on.

• Turn the set point screw counter-clockwise until the status open LED goes

out and the status closed LED comes on.

• Turn the set point screw 1/2 turn counter-clockwise.

• The sensor is now calibrated to provide indication of current ow below

normal full load amps.

Output Status:

Normal: Output closed

ENCLOSURE

Line voltage wires

Nipple to existing enclosure

(conduit nipple fitting not provided)

Wire the 12 AWG lines from the controller through the side of the device,

from the enclosure to the line current terminals. Tighten line current terminal

blocks to 12 in-lb. (1.35 N-m) torque.

5. Use the knockout seal to cover any unused holes in the housing. Attach the cover,

securing with the screws provided.

NOTE: If a conduit is used, connect the conduit to the mounti ng hub before connecting it to the

device. Be sure to support the H540/548 housing when nipple‑m ounted to another enclosure, or

the unit may shift o n opening, potentially causing undue stress on the wiring a nd the terminals.

Alarm: Output open

2. For over-current status indication: (Locked rotor)

• Turn the set point screw counter-clockwise until the status open LED goes

out and the status closed LED comes on.

• Turn the set point screw clockwise until the status closed LED goes out

and the status open LED comes on.

• Turn the set point screw clockwise 1/2 turn

• The sensor is now calibrated to provide indication of current ows above

normal full load amps

Output Status:

Normal: Output open

Alarm: Output closed

Z202762-0E PAGE 3 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countri es.

Page 4

TM

H540/548

INSTALLATION GUIDE

Wiring example

1

5

8

1. Current Sensor: In-series current sensor for motor status.

2. Power Terminal Block: Wire the H540/548 in series with the motor using these

terminals.

3

4

2

7

6

9

10

11

12

Keep all wires

away from

the jumper

block areas.

setting contact jumper

The H540/548 has a jumper for N.O. or N.C. relay function. The jumper aects the

relay contacts only when the HOA switch is in AUTO. The product is shipped with the

jumper in the N.O. position. To select N.C. function, move to the N.C. jumper block.

Always disconnect power to the device before before touching the jumper.

3. Relay Coil Terminal Blocks: Wire the output signal from the control panel to

actuate the relay. 24 VAC/DC; 36mA nominal.

4. Status Terminal Blocks: Wire the status input back to the control panel.

5. N.C. Relay Jumper Block: Insert a jumper here to ensure normally closed relay

operation when the switch is in auto. Disconnect power to the device before

before touching the jumper.

6. H.O.A . Switch: Control the motor locally.

HAND – When the switch is in this position, the motor is always on.

OFF – When the switch is in this position, the motor is always o.

AUTO – When the switch is in this position, the control system commands the

motor.

7. Relay Status LED: For positive indication of energized coil.

8. Relay: Enables actuation of circuit by a control system.

9. N.O. Relay Jumper Block: Inser t a jumper here to ensure normally open relay

operation when the switch is in auto. Disconnect power to the device before

before touching the jumper.

10. Status Open LED: Indicates that the current is below the trip point and the

status contact is open (used to calibrate the current switch in H548 models only).

11. Current Switch Set-Point Screw: Used to adjust the point in the current range

at which the current switch will change states (used to calibrate the current

switch in H548 models only).

CAUTION!

Do not rely on status indicators to de termine whether or n ot the relay contacts are

connected to a power source. Doing so may result in i njury or death from electrical

shock.

If the connections to the unit a re made through more than one metallic conduit, bond

the conduits to prevent the hazard of elec tric shock. A bonding plate is available (Veris

pa rt AH10 ).

12. Status Closed LED: Indicates that the current is above the trip point and the

status contact is closed (used to calibrate the current switch in H548 models only).

Z202762-0E PAGE 4 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countri es.

Loading...

Loading...