Page 1

Installation Guide

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices.

See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and the installation, and has received safety

training to recognize and avoid the hazards involved. NEC2009 Article 100

No responsibility is assumed by Veris Industries for any consequences arising out of the

use of this material.

DANGER

Current Sensors

RoHS

Compliant

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

TM

TM

H221/H221SP

Split-Core Current Transducer,

High Current, 4-20mA Output

Product Overview

The H221 and the H221SP are current transducers that sense current (amperage) in the monitored conductor. The

H221 amperage range is eld-adjustable, with ranges of 0-100A thru 0-300A possible. The H221SP is factory-set at

a range with an upper limit specied by the customer upon ordering (100A, 150A, 200A, 250A, and 300A options

available for the upper limit). Both devices transform the monitored current into 4-20 mA DC output, suitable for

connection to building controllers or other appropriate data acquisition equipment. The H221 and H221SP require

12-30 VDC external power supply to generate their output.

Specifications

Sensor Power

Amperage Range

Sensor Output

Response Time

Insulation Class

Frequency

Temperature Range

Humidity Range

Accuracy

Zero Adjustment

Terminal Block Wire Size

Terminal Block Torque

Approvals

Installation Category

30mA (max.) @12-30VDC

H221: 0 -100A thru 0-300A ( scalable)

H221SP: Factory -set at a customer- specified upper limit (100, 150, 200,

250, and 300A available)

4-20mA

2 sec.

600VAC RMS, insulated conductors only

50 /60 Hz

-15° to 60°C ( 5° to 140°F)

10-9 0% RH non-condensing

±2% F.S. from 10% to 10 0% of selected current range

nominal output@0A: 4mA ± 0.5

12 to 22 AWG (3.3 to 0. 3 mm2)

3.5 to 4.4 in-lb (0.4 to 0.5 N- m)

AGENCY APPROVALS

UL508, CE

Cat. III, pollution degree 2

Z201198-0F Page 1 of 4 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

This product provides basic insulation only.

Listed for use on 75°C insulated conductors.

Product Identification

Part Number Description

H221 High current monitoring, 4-20 mA analog output, scalable amperage range (100 to 300 A upper limit)

H221SP High current monitoring, 4-20 mA analog output, amperage range set at factory (100, 150, 200, 250,

or 300 A upper limit, specied by customer at ordering)

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 2

Installation Guide

Current Sensors

H221/H221SP

TM

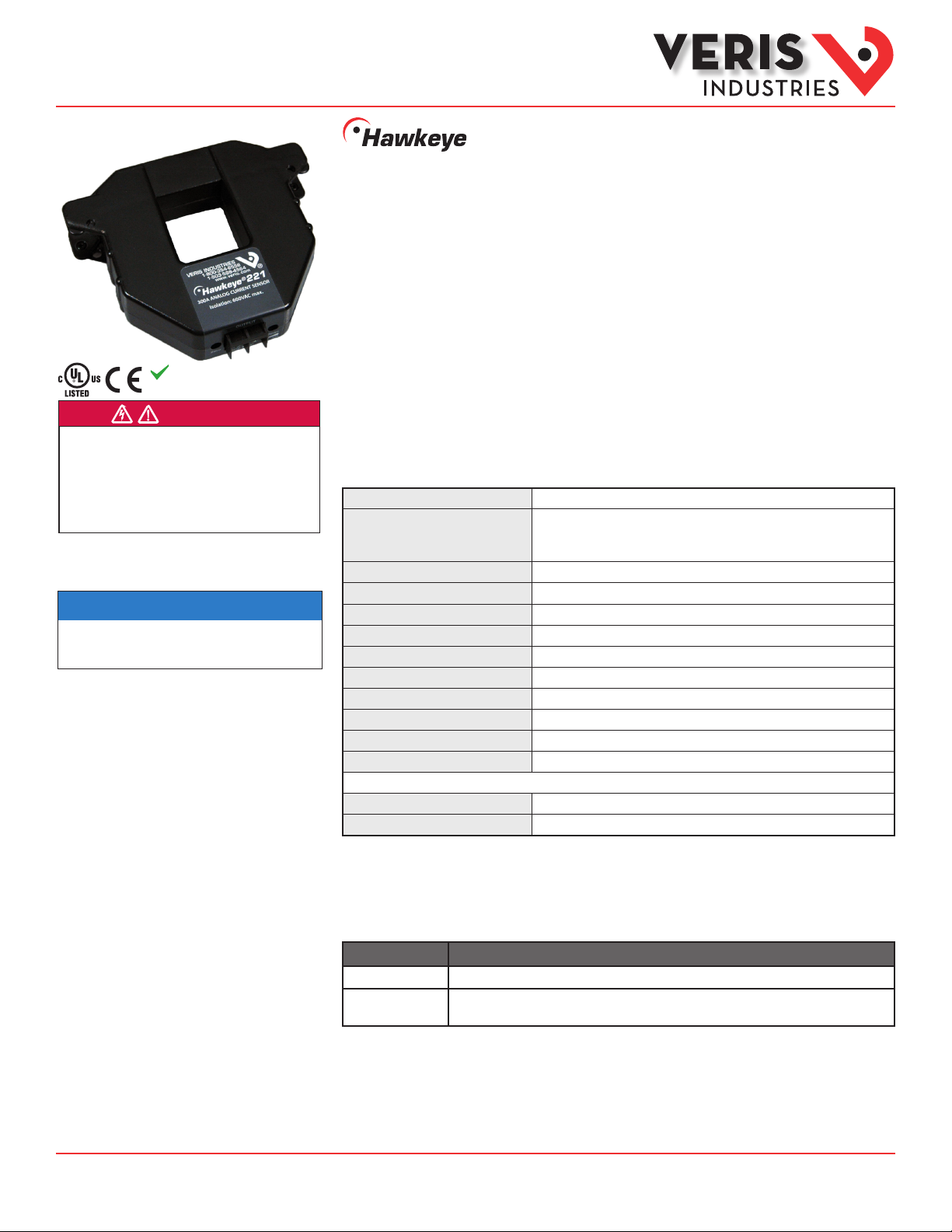

Dimensions

Installation

4.75”

(121 mm)

1.51”

(38 mm)

1.25”

(32 mm)

1.13”

(29 mm)

3.75”

(96 mm)

4.20”

(107 mm)

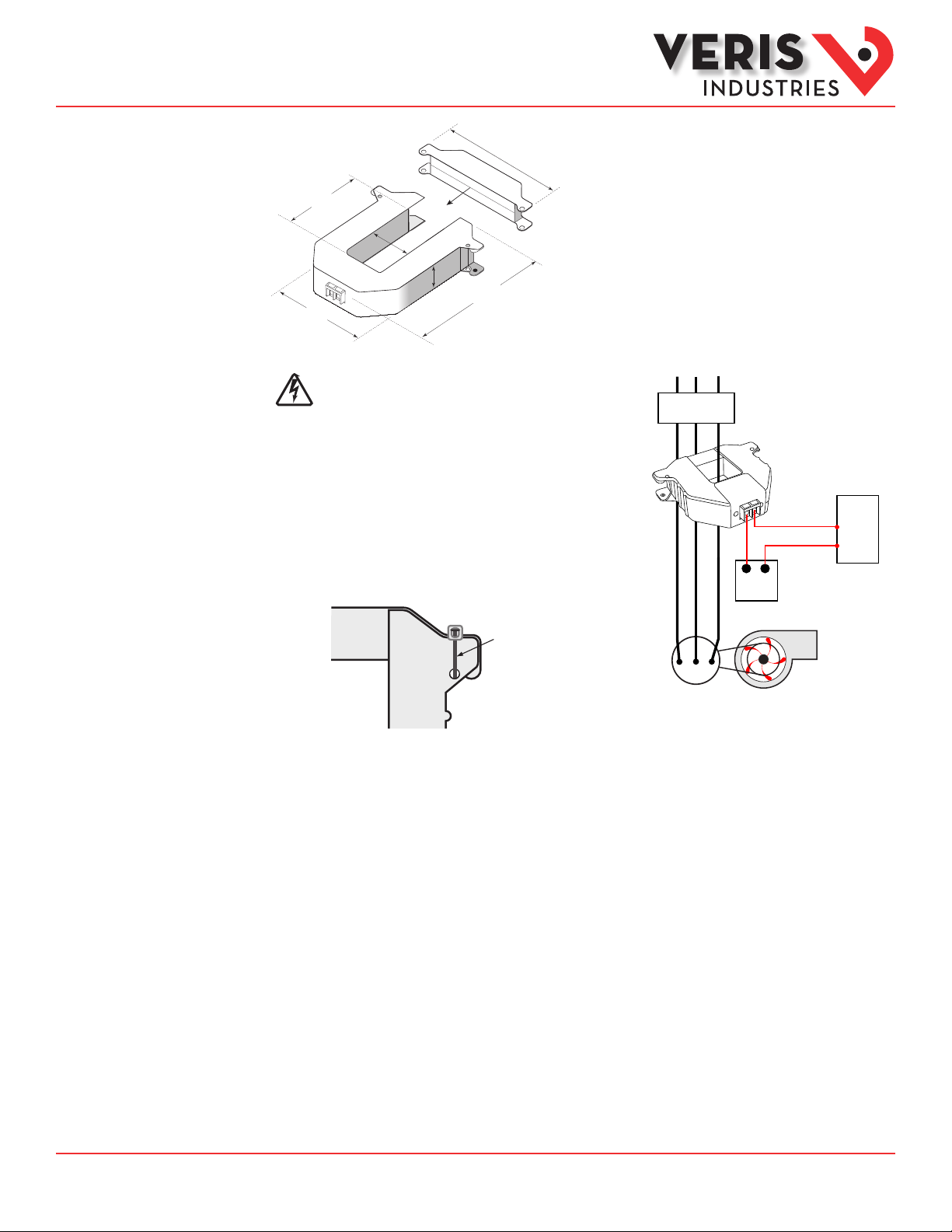

Disconnect and lock out power to the enclosure

containing the conductor to be monitored.

1. Choose a location for the sensor. The monitored conductor must pass

through the center window, and the sensor must be at least ½” (13 mm)

from any uninsulated conductors. Determine cable routing for the controller

connection, allowing the sensor to reach the conductor.

2. Wire the output connections between the sensor and the controller

(4-20 mA).

3. Snap the sensor over the conduc tor to be monitored.

4. Secure I-bar to main body of sensor with wire ties or other securing method.

CONTACTOR

DIGITAL CONTROL

+

AI

–

+

–

12-30VDC

Power Supply

Wire tie

Motor

Fan or Pump

5. Secure the enclosure and reconnect power.

6. Scale the sensor range, then scale the controller software to match the sensor’s output (see Scaling section).

Z201198-0F Page 2 of 4 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 3

Installation Guide

Zero

Out

Span

100 300

DDC

CONTROLLER

AI

V(COM)

4-20mA

Current Sensors

H221/H221SP

TM

Wiring

Output is not polarity sensitive. 12-30 VDC external power needed.

Example 1: External Power

DDC

CONTROLLER

AI

Zero

Power Supply

100 300

Out

Example 2: Powered by the controller

Span

Scaling

SENSOR

OUTPUT

20mA

4mA

0 10 20 30 40 50 60 70 80 90 100%

LOAD CURRENT

% of Set Span

Z201198-0F Page 3 of 4 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 4

Installation Guide

Current Sensors

H221/H221SP

TM

Calibration

(H221 Only)

The following calculation is given as an example and uses

sample current values. In an actual application, any values

appropriate to the application (within the range of the device)

can be substituted.

The H221SP is factory-calibrated.

1. Set Zero.

Apply power to the sensor with no load in the

monitored conductor. Turn the zero setpoint

screw until the controller reads 4 mA output.

Zero

Zero

Span

100 300

Out

2. Calculate the maximum and target readings.

A. Determine the maximum current likely to occur in the application.

B. Establish normal load conditions on the conduc tor. Measure this current using

an external measurement device, such as a portable amp clamp.

C. Calculate target output:

OK!

A

0A

Controller:

4mA Output =

0A Load

200 A

0A

150 A

Troubleshooting

If A = the max. current, and B = the reading from the amp clamp, then:

target output =

16 mA x — + 4 mA

e.g. target output = = 16 mA

B

A

16 mA x — + 4 mA

150

200

3. Set Span.

Turn the span setpoint screw until the controller reading equals the target output.

150A

Span

Zero

100 300

Out

100

300

Problem Solution

No Reading at Controller • Conrm that a 12-30 VDC power supply is in series with the sensor output terminals and the control

panel analog input terminals.

• Assure that sensor core mating surfaces are clean and that the core clamp is completely closed.

150A

Controller:

16 mA Output

= 150 A Load

Z201198-0F Page 4 of 4 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Loading...

Loading...