Page 1

TM

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices.

See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and the installation, and has received safety

training to recognize and avoid the hazards involved. NEC2009 Article 100

No responsibility is assumed by Veris Industries for any consequences arising out of the

use of this material.

DANGER

CURRENT MONITORING

INSTALLATION GUIDE

TM

H11 D

Split-Core Current Switch,

Auto Calibration With Display

RoHS

Compliant

SPECIFICATIONS

Sensor Power Induced from monitored c urrent

Amperage Range 60 Hz: 2.5 - 200A max.

50 Hz: 3.0 - 200A max.

Status Output N.O. when device is unpowered, 1.0A@30VAC/DC

not polarity sensitive

Response Time 1 sec.

Accuracy ±2% of full scale

Frequency Range 50/60 Hz

Temperature Range -15° to 60°C (5° t o 140°F)

Humidity Range 10-90% RH non-condensing

LCD Backlight O at low currents; illuminates when monito red current exceeds 4.5A;

ashes during an alarm s tate while current remains above 4.5A

On-State Resistance ≤1.0 Ω

O-S tate Resistance ≥1.0 MΩ

Setpoint Target Range, Switch Setting A* ±40% of learned nominal cur rent;

max. learned current of 142A to enable an upper tr ip limit at or below 200A

Setpoint Target Range, Switch Setting B* ±60% of learned nominal c urrent;

max. learned current of 125A to enable an upper trip limit at or below 20 0A

Switch Setting C* On/Off Status; contac ts are closed while amperage is above 2.5A

Alarm Reset Range ±5% of learned nominal current **

Setpoint Calibration Learn Period 30 sec.; self-learning, pushb utton reset

Normal-to-Alarm Output Delay 1 sec. maximum

Alarm-to-Normal Out put Delay 30 sec. nominal

Insulation Class 600VAC RMS (UL), 300VAC RMS (CE)

Terminal Block Wire Size 24 to 14 AWG (0.2 to 2.1 mm2)

Terminal Block Torque 3.5 to 4.4 in-lbs (0.4 to 0.5 N-m)

Agency Approvals CE EN 61010-1:2001, UL508, Installation Category III, pollution degree 2

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

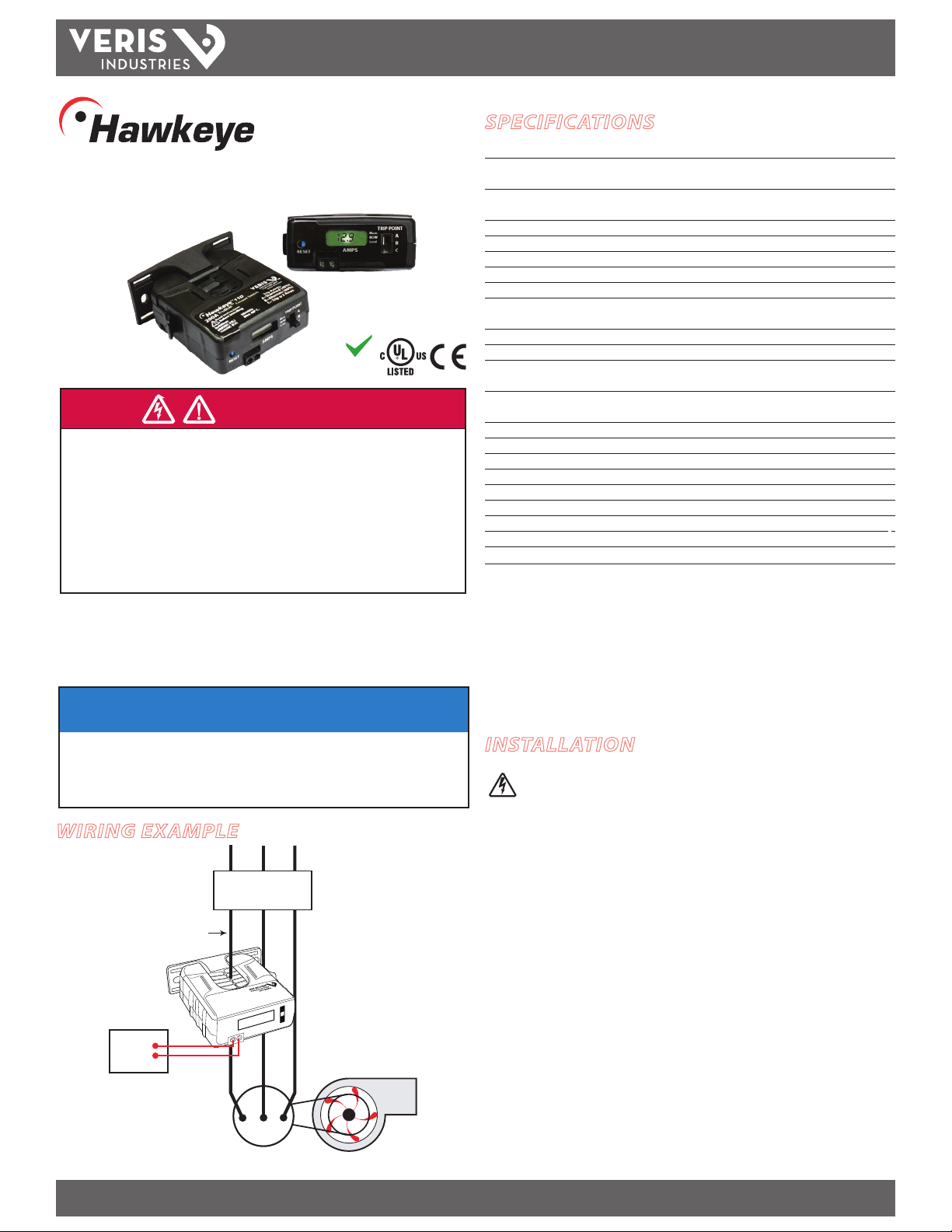

WIRING EXAMPLE

CONTACTOR

Insulated Conductor

CONTROLLER

Digital

Input

Z206073-0C PAGE 1 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 01131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat,Aerosp ond, Veris, and the Veris ‘ V’ logo are trad emarks or regis tered trademar ks of Veris Industrie s, L.L.C. in the USA an d/or other countries .

MOTOR

Fan or Pump

* Trip point switch positions A and B are not for use in ap plications where the current will uctuate

by more than 40% (A) or 60% (B) of the nominal current. If the current will u ctuate by more

than 60%, use the H11D for on/o status (position C) only.

** The upper trip limit a larm resets when the current drops by 5% of the learned nominal current.

The lower trip limit alarm rese ts when the current rises by 5% of learned nominal current.

Specication Note: For CE compliance, conductor sha ll be insulated according to IEC 61010‑1:2001.

Listed for use with 75°C insulated conductors.

The product design provi des for basic insulation only.

Do not use the LCD as evidence of applied voltage.

INSTALLATION

Disconnect power to the enclosure containing the

conductor to be monitored.

1. Determine normal operating conditions for the application, and move the slide

switch to the best setpoint range (A, B, or C) for these conditions (e.g., if normal

operation, including duct opening/closing and lter blockage is 50% of the

learned nominal current, then set the slide switch to the B range (±60%), or use

the C range (on/o status) to indicate when current falls below 2.5A at 60 Hz). For

most blower systems, the 40% (A) setting is appropriate.

2. Locate a mounting surface for the removable mounting bracket that allows the

monitored conductor to pass through the center window when it is installed and

that keeps the product at least ½” from any uninsulated conductors. Determine

cable routing for the controller connection, allowing wiring to reach the mounting

location.

3. Drill holes and mount the bracket to the chosen surface using the included screws.

4. Wire the output connections between the sensor and the controller (solid-state

contact).

5. Verify that the core mating surfaces are clean. Snap the sensor over the conductor

and clip the assembly to the mounting bracket.

6. Secure the enclosure and reconnect power.

Page 2

TM

H11D

INSTALLATION GUIDE

PRODUCT OVERVIEW

The H11D is an over-current and under-current monitor intended for use with HVAC

systems (fans, blowers). When the H11D is unpowered, the status output contacts

are open. When the device is powered, the contacts close and remain closed during

normal operation. The H11D learns the nominal amperage in the conductor, then

monitors for amperage changes outside the range chosen using the slide switch. If

the amperage goes out of the established range, the contacts open, raising an alarm

in the system controller. This alarm state persists until the amperage comes back to

within range (5% of learned nominal rate below the upper trip limit or 5% of learned

nominal rate above the lower trip limit of the learned nominal conditions) and

remains within range for 30 seconds to ensure that the system has truly returned to

normal operation. If load conditions change, use the reset button to send the H11D

back into learning mode.

The status output is suitable for connection to system controllers or other data

acquisition equipment operating at up to 1 A@30 VAC/DC. The H11D requires no

external power supply to generate its output.

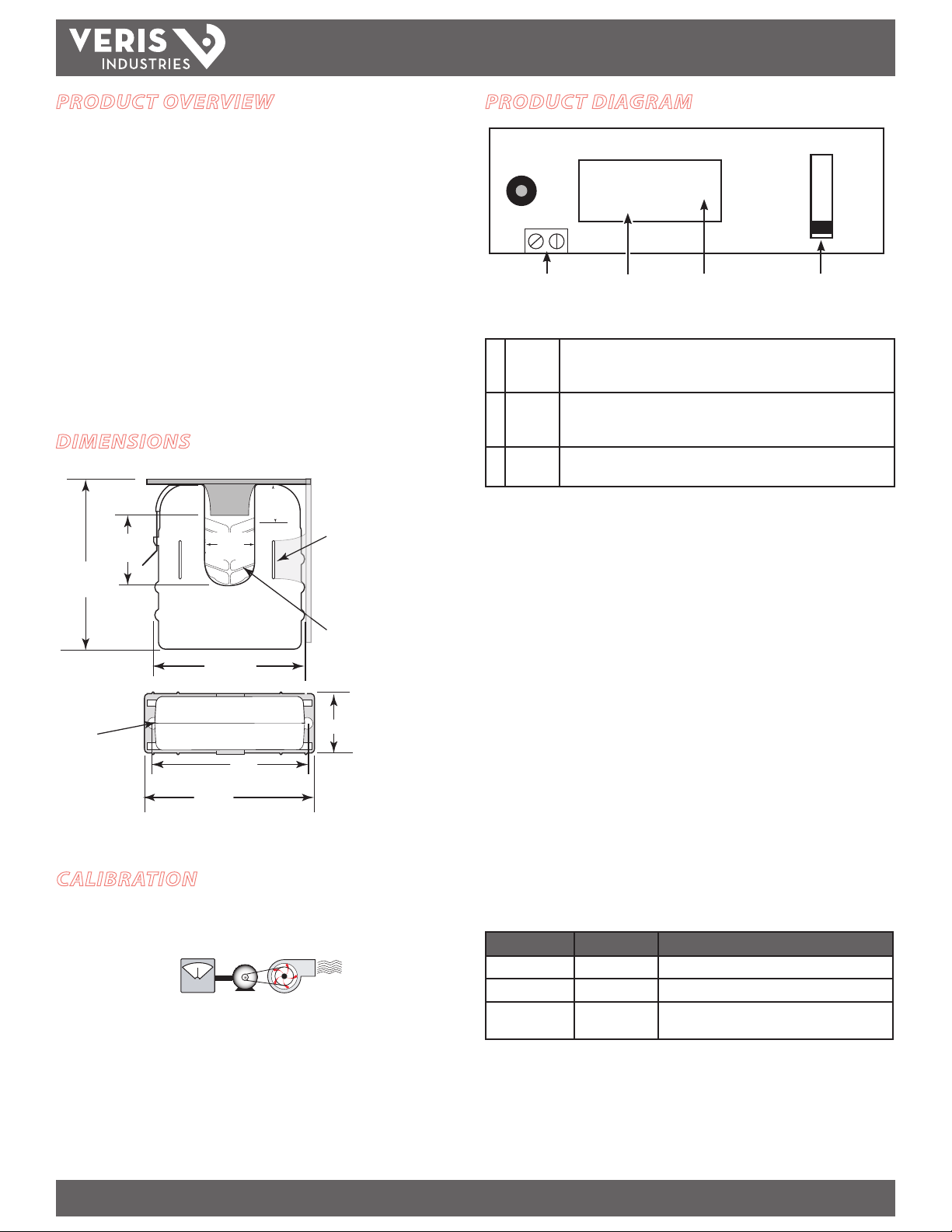

DIMENSIONS

Removable Mounting Bracket

3.1”

(79 mm)

Ø 0.3”

(8 mm)

1.1”

(26 mm)

1.0”

(25 mm)

0.8”

(21 mm)

2.8”

(70 mm)

2.5”

(64 mm)

3.0”

(76 mm)

Bracket can

be mounted

on three sides

for added

installation

exibility.

Self-gripping Iris

1.4”*

(36 mm)

PRODUCT DIAGRAM

TRIP POINT

Mem

NOW

RESET

N.O. Status Output Slide SwitchLCD Value Indicato r

AMPS

Lrnd

Slide Switch Options

A Standard ±40% of learned nominal amperage.

Max. learned nominal current is 142 A to enable an upper trip limit at or

below 200 A.

B Alternate ±60% of learned nominal amperage.

Max. learned nominal current is 125 A to enable an upper trip limit at or

below 200 A.

C On/O

Status

Trip limits above the 200 A maximum are not permitted.

Contacts remain closed while amerage is above 2.5 A at 60 Hz.

Contacts open when amperage drops below 2.5 A.

LCD Values

If the slide switch is in position A or B, the number shown in the LCD during normal

operation cycles among the values listed below. An indicator appears to the right of

the number, indicating which value is currently visible (Mem, NOW, or Lrnd)

Mem: the trip memory, or the amperage value above or below range that

tripped the switch into alarm mode. This value remains stored in nonvolatile

memory until the H11D is reset.*

NOW: the present amperage owing through the conductor

Lrnd: the nominal amperage conditions established when the H11D is

initially powered or reset.

* The LCD only shows the trip memory value (Mem) after a trip event has

occurred. If no trip event has occurred, the LCD only cycles between NOW and

Lrnd.

A

B

C

If the slide switch is in position C (on/o status only), the LCD does not cycle. The

value displayed is always the present amperage owing through the conductor, and

CALIBRATION

The H11D automatically calibrates when first powered and each time it is

reset. Before beginning calibration, establish normal load conditions.

OK!

A

1. When amperage ows through the conductor, the H11D automatically enters the

learning mode for approximately 30 seconds.

2. When in normal operation (after learning mode is complete), the LCD cycles

between the values for the present amperage in the conductor (designated by the

indicator adjacent to NOW) and the learned nominal amperage (designated by the

indicator adacent to Lrnd).

3. If the nominal load on the conductor changes, the H11D can re-learn the new

conditions. Press the reset button to return to the learning mode.

OK!

the indicator remains on NOW.

Operation Modes

Mode Output Status LCD

Learn (30 sec) Closed (≤ 1 Ω) NOW indicator ashes on/o

Normal Operation Closed (≤ 1 Ω) Display cycles between NOW and Lrnd

Alarm Open (≥ 1 MΩ) Display cycles among all three values: NOW, Lrnd,

and Mem *

*The LCD backlight remains o at low currents. It turns on wh en the current exceeds 4.5 A and

ashes during the alarm state while t he current remains above 4.5 A.

Note: In rare instances, status contacts may close momentarily whe n the unit initially recovers

from an extend ed power o state (typically longer than 10 seconds) to an alarm state.

Z206073-0C PAGE 2 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 01131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat,Aerosp ond, Veris, and the Veris ‘ V’ logo are trad emarks or regis tered trademar ks of Veris Industrie s, L.L.C. in the USA an d/or other countries .

Page 3

TM

H11D

INSTALLATION GUIDE

FUNCTIONAL ILLUSTRATION

ALARM RESET

5% Typical

NOMINAL

LEARNED

CURRENT

NORMAL

ØAAC ØAAC

POWER

ON

LEARN

(MODE)

30 SEC

(CURRENT

MONITOR

MODE)

ALARM

(MODE)

1 SEC. DELAY 30 SEC. DELAY

NORMAL

(CURRENT

MONITOR MODE)

POWER LOSS

ALARM

(MODE)

Amperage Over-Limit Mode

Regardless of the trip point slide switch position and for any learned nominal current,

if the amperage in the conductor exceeds 200 A, the H11D enters the over-limit mode.

In this mode, the LCD value for NOW always reads OL (over limit). The H11D returns to

normal operation mode when the amperage drops below 200 A. The status output

contacts do not change state when the H11D enters over-limit mode.

MEMORY RESET

During setup, the H11D automatically determines the alarm limits according to the

switch settings and stores them in nonvolatile memory. The H11D requires a memory

reset to clear the nonvolatile memory if any signicant system changes occur, such as:

• The sensor is reinstalled on a dierent motor.

• The motor is re-sheaved.

• The system is air balanced or air duc t restrictions change.

• The motor load changes signicantly.

NOTES

For load currents less than sensor minimum rating:

Wrap the monitored conductor through the center window and around the sensor

body to produce multiple turns. This increases the current measured by the

transducer.

Program the controller to account for the extra

turns, e.g., if four turns pass through the sensor

(as shown), divide the normal controller reading

by 4.

The LCD displays the sum current of all the

conductors passing through the center window.

The trip points and on/o status are established

by the total current passing through the center window during the learning mode.

Example: A conductor with a load of 2 A is wrapped through the center window

3 times, with the trip point slide switch in the A (40%) position. The total current

detected by the H11D is, therefore, 6 A (2A x 3). This is the value displayed in the LCD.

During calibration, the H11D learns the nominal amperage and calculates 40% of that

value: 6 A x 40%, or 2.4 A. The trip limit currents are then set at 6A ±2.4, or 8.4 A and

3.6 A.

< 2.5 A

(Sensor Min.)

1A

4x

CAUTION

RISK OF EQUIPMENT DAMAGE

• Derate the product’s maximum current for the number of turns

through the sensing window using the following formula.

Rated Max. Amps ÷ Number of Turns = Max. monitored Amps

e.g. : 100A ÷ 4 Turns = 25 Amps max. in monitored conductor

• Failure to follow these instructions can result in overheating

and permanent equipment damage.

To reset the H11D:

1. Establish normal operating conditions for the monitored conductor (e.g. clean air

lters, close duct access doors).

2. The reset button has two positions, in and out. Push the button until there is a

noticeable click to change the position of this switch. This causes a change of

state, which triggers the reset function. The nonvolatile memory is erased and the

H11D enters the learning mode.

Note: The reset function can be performed even if the H11D is not installed

on a conductor. Pushing the button (changing the state) will clear the

nonvolatile memory at the next power-up.

Note: In normal operation, this button can be in either the in or out position.

For load currents greater than sensor maximum rating:

Use a 5 Amp (H68xx series) current transformer (CT) as shown. This technique can be

combined with wrapping (see above) to add range for a low current load on a high

current source.

240A

> 200 A (Sensor max.)

5A

300A:

4A

H68xx‑5A CT

DANGER: 5A CTs can present hazardous voltages.

Install CTs in accordance with manufacturer's instructions.

Terminate the CT secondary before applying current.

TROUBLESHOOTING

Problem Solution

No Reading at Controller •Checksensorcalibration(seeCalibrationsection)

•Checkforamperageinmonitoredconductor(>2.5A)

•Verifythatsensorcorematingsurfacesarecleanand

that the core clamp is completely closed

Z206073-0C PAGE 3 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 01131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat,Aerosp ond, Veris, and the Veris ‘ V’ logo are trad emarks or regis tered trademar ks of Veris Industrie s, L.L.C. in the USA an d/or other countries .

Loading...

Loading...