Veris FSRxxxx Installation Instructions

TM

FLOW SENSORS

INSTALLATION GUIDE

FSRxxxx SERIES

Ultrasonic Flow Meter

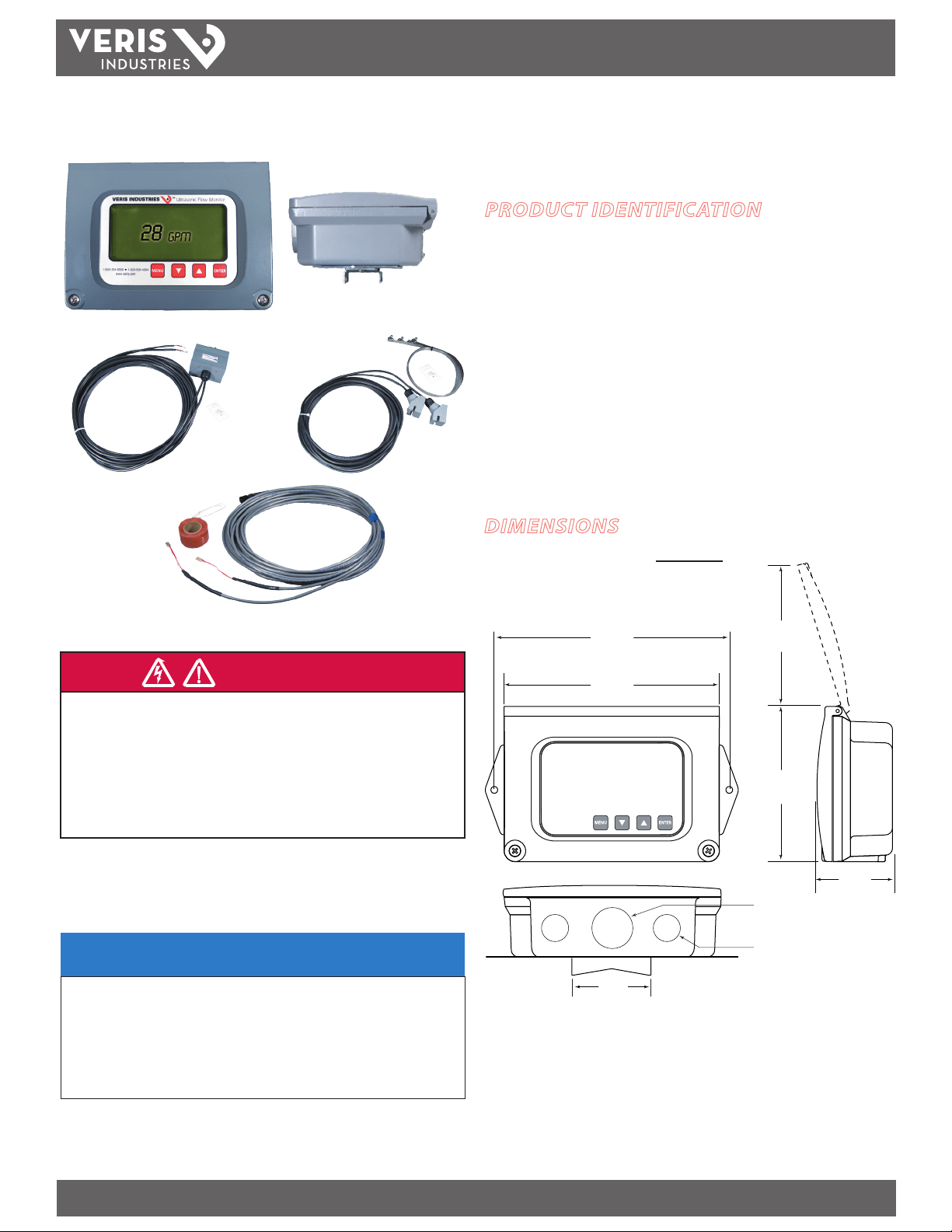

PRODUCT IDENTIFICATION

Monitor: FSR Series

Transducers: FST1, FST2, FST3, FST4, FST5

FSR

Note: Do not cut transducer cables to alter length. This will void the

factory warranty. Cables are available in several lengths. Assess the

installation location prior to ordering to determine the optimum length.

If the wrong length is ordered, contact the factory.

FST1, 2, 3

Temp Sensors

FST4, 5

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and the installation, and has received safety

training to recognize and avoid the hazards involved. NEC2009 Article 100

No responsibility is assumed by Veris Industries for any consequences arising out of the

use of this material.

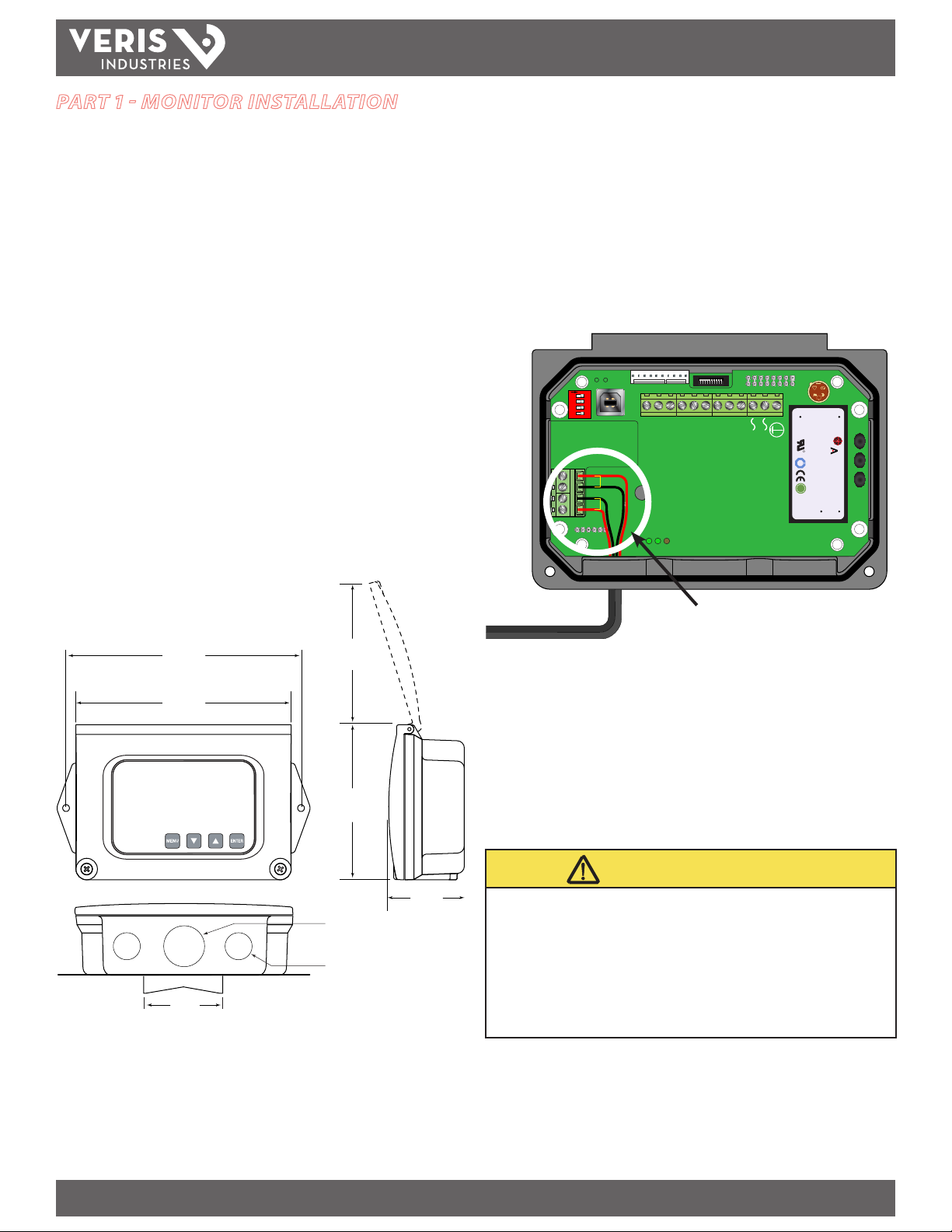

DIMENSIONS

(163 mm)

(153 mm)

6.4”

6.0”

FSR Monitor

4.1”

(105 mm)

4.3”

(110 mm)

0.75”

(19 mm)

2.1”

(53 mm)

2x 0.5”

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classied locations

other than those listed in Specications.

• Read and understand the instructions before installing

this product.

• Turn off all power supplying equipment before working on it.

• The installer is responsible for conformance to all applicable codes.

No responsibility is assumed by Veris Industries for any consequences arising out of the

use of this material.

1.4”

(35 mm)

(13 mm)

Z205739-0D PAGE 1 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

INSTALLATION GUIDE

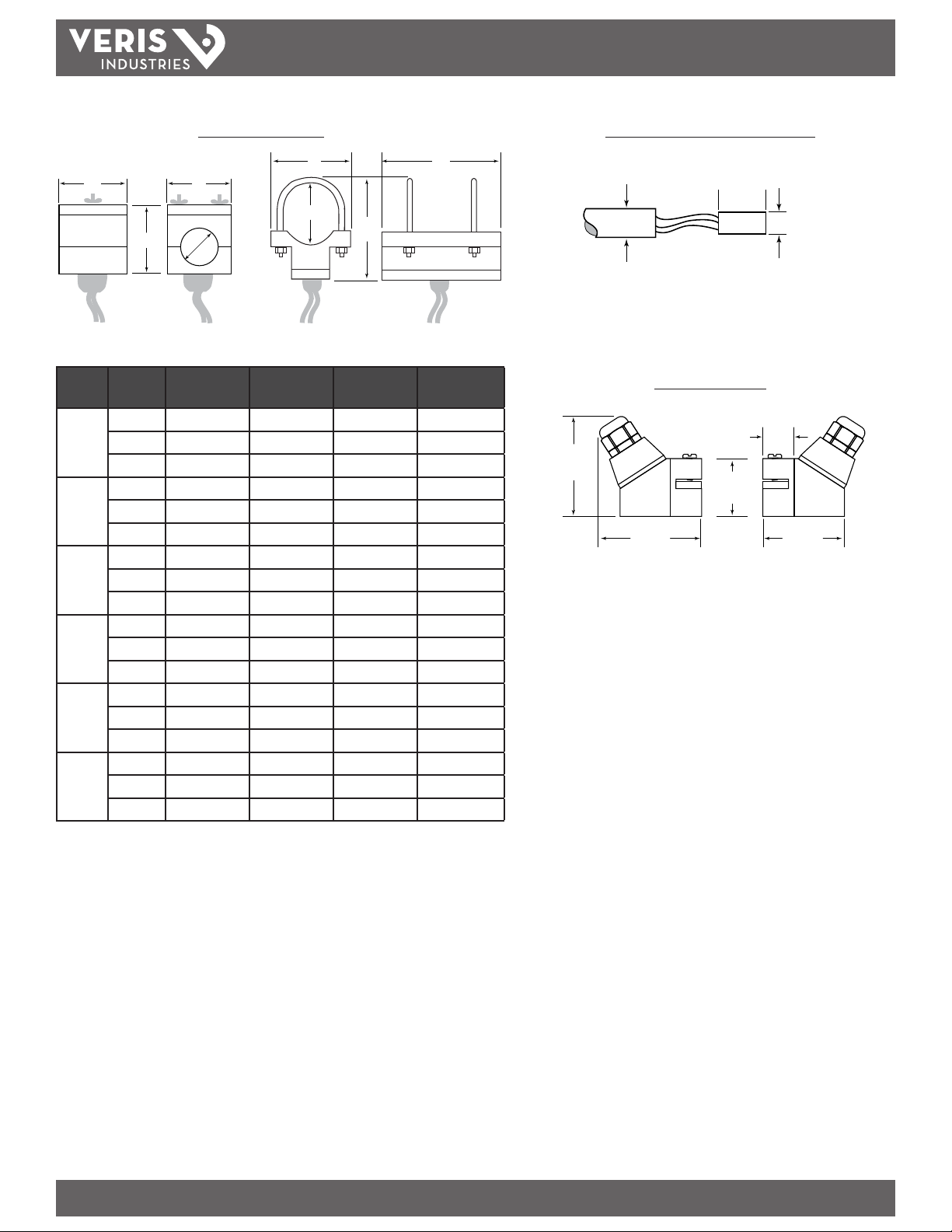

FST(1, 2, 3) Insert Temperature SensorFST(1, 2, 3) Transducer

A

C

A

C

D

B

B

D

U-Bolt Connection

(2” Pipe Only)

Cable Diameter

0.3 “ (7 mm)

0.5 “

(13 mm)

0.2 “

(5 mm)

Pipe

Size

½”

¾”

1”

1¼”

1½”

2”

(U-bolt

only)

Pipe

A B C D

Material

ANSI 2.46” (63 mm) 2.36” (60 mm) 2.66” (68 mm) 0.840 (22 mm)

Copper 2.46” (63 mm) 2.36” (60 mm) 3.33” (85 mm) 0.625” (16 mm)

Tubing 2.46” (63 mm) 2.28” (58 mm) 3.33” (85 mm) 0.500” (13 mm)

ANSI 2.46” (63 mm) 2.57” (66 mm) 2.66” (68 mm) 1.050” (27 mm)

Copper 2.46” (63 mm) 2.50” (64 mm) 3.56” (91 mm) 0.875” (23 mm)

Tubing 2.46” (63 mm) 2.50” (64 mm) 3.56” (91 mm) 0.750” (19 mm)

ANSI 2.46” (63 mm) 2.92” (75 mm) 2.86” (73 mm) 1.315” (34 mm)

Copper 2.46” (63 mm) 2.87” (73 mm) 3.80” (97 mm) 1.125” (29 mm)

Tubing 2.46” (63 mm) 2.75” (70 mm) 3.80” (97 mm) 1.000” (26 mm)

ANSI 2.79” (71 mm) 3.18” (81 mm) 3.14” (80 mm) 1.660” (43 mm)

Copper 2.46” (63 mm) 3.00” (77 mm) 4.04” (103 mm) 1.375” (35 mm)

Tubing 2.46” (63 mm) 3.00” (77 mm) 4.04” (103 mm) 1.250” (32 mm)

ANSI 3.02” (77 mm) 3.42” (87 mm) 3.33” (85 mm) 1.900” (49 mm)

Copper 2.71” (69 mm) 2.86” (73 mm) 4.28” (109 mm) 1.625” (42 mm)

Tubing 2.71” (69 mm) 3.31” (85 mm) 4.28” (109 mm) 1.500” (39 mm)

ANSI 3.71” (95 mm) 3.42” (87 mm) 5.50” (140 mm) 2.375” (61 mm) *

Copper 3.71” (95 mm) 3.38” (86 mm) 5.50” (140 mm) 2.125” (54 mm) *

Tubing 3.21” (82 mm) 3.85” (98 mm) 4.75” (121 mm) 2.000” (51 mm) *

2.7”

(67 mm)

FST(4, 5) Transducer

2.9”

(74 mm)

0.75”

(19 mm)

1.6”

(40 mm)

2.2”

(56 mm)

* Varies due to U-bolt feature

Z205739-0D PAGE 2 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

TABLE OF CONTENTS

Quick Install ................................................................................................................4

1 - Transducer Location .................................................................................................4

2 - Electrical Connections..............................................................................................4

3 - Pipe Preparation and Transducer Mounting ............................................................4

4 - Startup.....................................................................................................................5

Introduction ................................................................................................................6

General .........................................................................................................................6

Application Versatility ..................................................................................................6

User Safety....................................................................................................................6

Data Integrity ...............................................................................................................6

Product Identification ...................................................................................................6

Part 1 - Transmitter Installation ...............................................................................7

Transducer Connections ................................................................................................7

AC Power Connections ..................................................................................................8

DC Power Connections ..................................................................................................8

Part 2 – Transducer Installation ................................................................................9

General .........................................................................................................................9

Step 1 - Mounting Location ..........................................................................................9

Step 2 - Transducer Spacing ..........................................................................................9

Step 3 - Entering Pipe and Liquid Data .......................................................................10

Step 4 - Transducer Mounting ..................................................................................... 11

V-Mount and W-Mount Installation ........................................................................... 11

FSTxxxx Small Pipe Transducer Installation ................................................................12

Mounting Transducers in Z-Mount Configuration ....................................................... 12

Part 3 - Inputs/Outputs ............................................................................................ 14

General ....................................................................................................................... 14

4-20 mA Output ..........................................................................................................14

Control Outputs (non BTU only) ..................................................................................14

Frequency Output (non BTU only) ...............................................................................15

RS-485 ........................................................................................................................16

Heat Flow (BTU only) ..................................................................................................16

INSTALLATION GUIDE

Part 5 - Software Utility ...........................................................................................28

Introduction................................................................................................................28

System Requirements .................................................................................................28

Installation .................................................................................................................28

Initialization ...............................................................................................................28

Basic Tab .....................................................................................................................28

Flow Tab......................................................................................................................30

Filtering Tab ................................................................................................................30

Output Tab ..................................................................................................................31

Channel 1 - 4-20 mA Configuration ............................................................................ 31

Channel 2 - RTD Configuration (BTU only) ..................................................................32

Channel 2 - Control Output Configuration (non BTU only) ..........................................33

Setting Zero and Calibration .......................................................................................33

Target Dbg Data Screen - Definitions ..........................................................................34

Saving Meter Configuration on a PC ...........................................................................35

Printing a Flow Meter Configuration Report ............................................................... 35

Appendix ...................................................................................................................35

Specifications .............................................................................................................35

Menu Maps .................................................................................................................37

Communications Protocols .........................................................................................40

Heating and Cooling Measurement ............................................................................44

Meter Error Codes .......................................................................................................46

Control Drawings ........................................................................................................47

K-Factors Explained .................................................................................................... 51

Fluid Properties ..........................................................................................................52

Pipe Charts..................................................................................................................53

CE Compliance Drawings .............................................................................................58

PART 4 - Startup and Configuration ........................................................................ 18

Before Starting the Instrument .................................................................................. 18

Instrument Startup ..................................................................................................... 18

Keypad Programming .................................................................................................18

Menu Structure ........................................................................................................... 18

BSC Menu -- Basic Menu ............................................................................................. 19

CH1 Menu -- Channel 1 Menu .....................................................................................20

CH2 Menu -- Channel 2 Menu .....................................................................................23

SEN Menu -- Sensor Menu .......................................................................................... 24

SEC Menu -- Security Menu ........................................................................................24

SER Menu -- Service Menu ..........................................................................................25

DSP Menu -- Display Menu .........................................................................................27

Z205739-0D PAGE 3 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

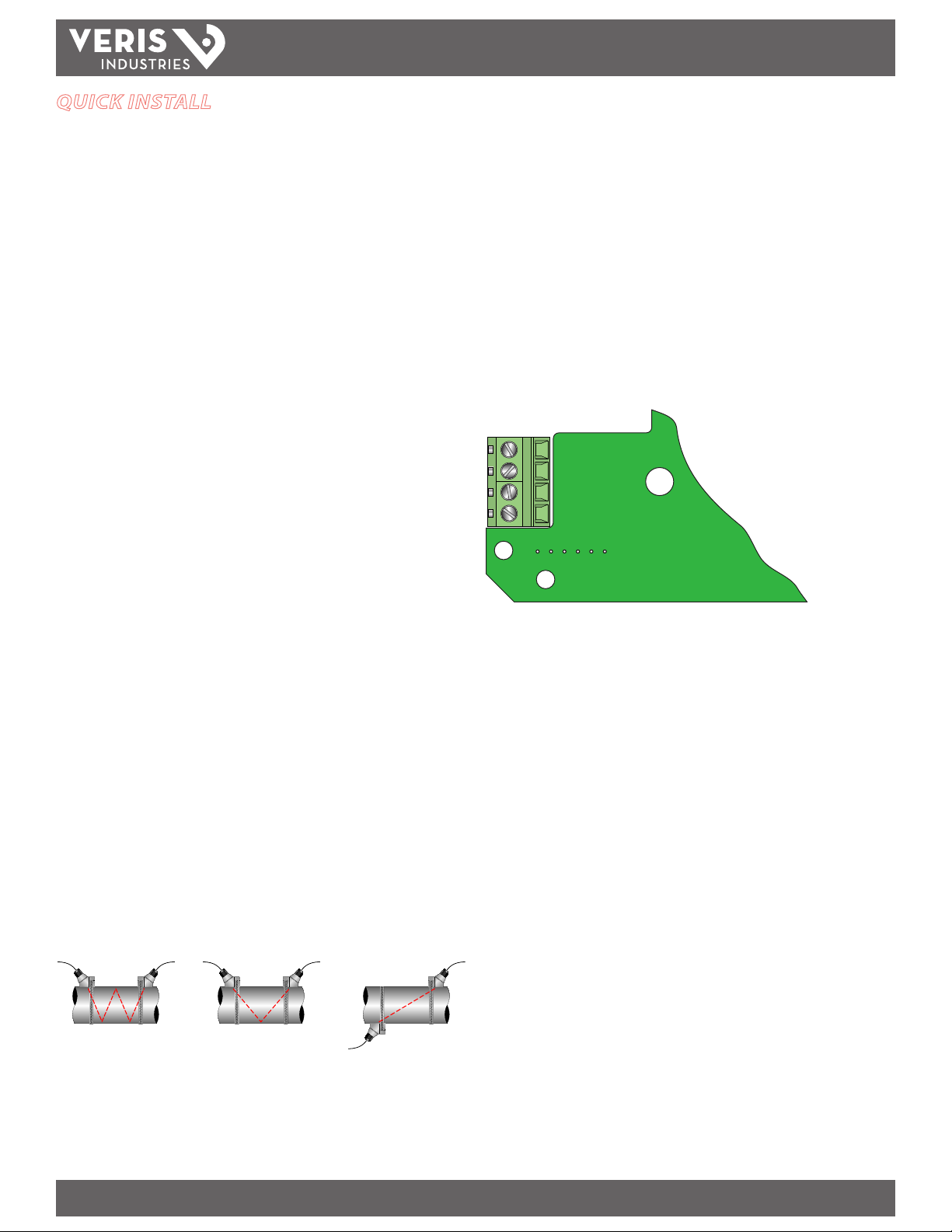

QUICK INSTALL

This manual contains detailed operating instructions for all aspects of the FSR Series.

The following condensed instructions are provided to assist the operator in getting

the instrument started up and running as quickly as possible. This pertains to basic

operation only. If specic instrument features are to be used or if the installer is

unfamiliar with this type of instrument, refer to the appropriate sec tion in the

manual for complete details.

Note: The following steps require informati on supplied by the meter itself, so it is necessary to

supply power to the unit, at least temp orarily, to obtain setup informatio n.

1 - Transducer Location

1. In general, selec t a mounting location on the piping system with a minimum of

10 pipe diameters (10x the pipe inside diameter) of straight pipe upstream and 5

straight diameters downstream. See Table 2.1 for additional congurations.

2. Select a mounting method for the transducers based on pipe size and liquid

characteristics. See Table 2.2. Transducer congurations are illustrated in Figure

Q.1 below. The V-mount conguration is usually the rst choice, with W-mount

and Z-mount used if needed to boost signal strength.

Note: All FST1xxxx, FST2xxx x, and FST3xxxx transducers use V-Mount congu ration.

3. Enter the following data into the meter via the integral keypad or the software

utility (if not entered by the factory)

INSTALLATION GUIDE

2 - Electrical Connections

Transducer/Power Connections

1. Route the transducer cables from the transducer mounting location back to the

enclosure. Connect the transducer wires to the terminal block in the enclosure.

Note: Do not cut transducer cables to alter length. This will void the

factory warranty. Cables are available in several lengths. Assess the

installation location prior to ordering to determine the optimum

length. If the wrong length is ordered, contact the factory.

2. Verify that power supply is correct for the meters power option.

AC units require 95 to 265 VAC, 47 to 63 Hz @ 17 VA maximum. DC units

require 10 to 28 VDC @ 5 Watts maximum.

3. Connect power to the ow meter.

Downstream+

DownstreamUpstreamUpstream+

1. Transducer mounting method

2. Pipe O.D. (Outside Diameter)

3. Pipe wall thickness

4. Pipe material

5. Pipe sound speed*

6. Pipe relative roughness*

7. Pipe liner thickness

8. Pipe liner material

9. Fluid type

10. Fluid sound speed*

11. Fluid viscosity*

12. Fluid specic gravity*

* Nominal values for these parameters are included within the operating system. Modify if the

exact system values a re known.

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

Figure Q.2 - Transducer Connections

3 - Pipe Preparation and Transducer Mounting

FST4xxxx, FST5xxxx Transducers

1. Place the ow meter in signal strength measuring mode. This value is available on

the display (Service Menu) or in the data display of the software utility.

2. The pipe surface, where the transducers are to be mounted, must be clean and dry.

Remove scale, rust or loose paint to ensure satisfactory acoustic conduction. Wire

brushing the rough surfaces of pipes to smooth bare metal may also be useful.

Plastic pipes do not require preparation other than cleaning.

3. Apply a single ½” (12 mm) bead of acoustic couplant grease to the upstream

transducer and secure it to the pipe with a mounting strap.

4. Apply acoustic couplant grease to the downstream transducer and press it onto

the pipe using hand pressure at the lineal distance calculated in Step 1.

5. Space the transducers according to the recommended values found on the product

conguration sheet or from the software utility. Secure the transducers with the

mounting straps at these locations.

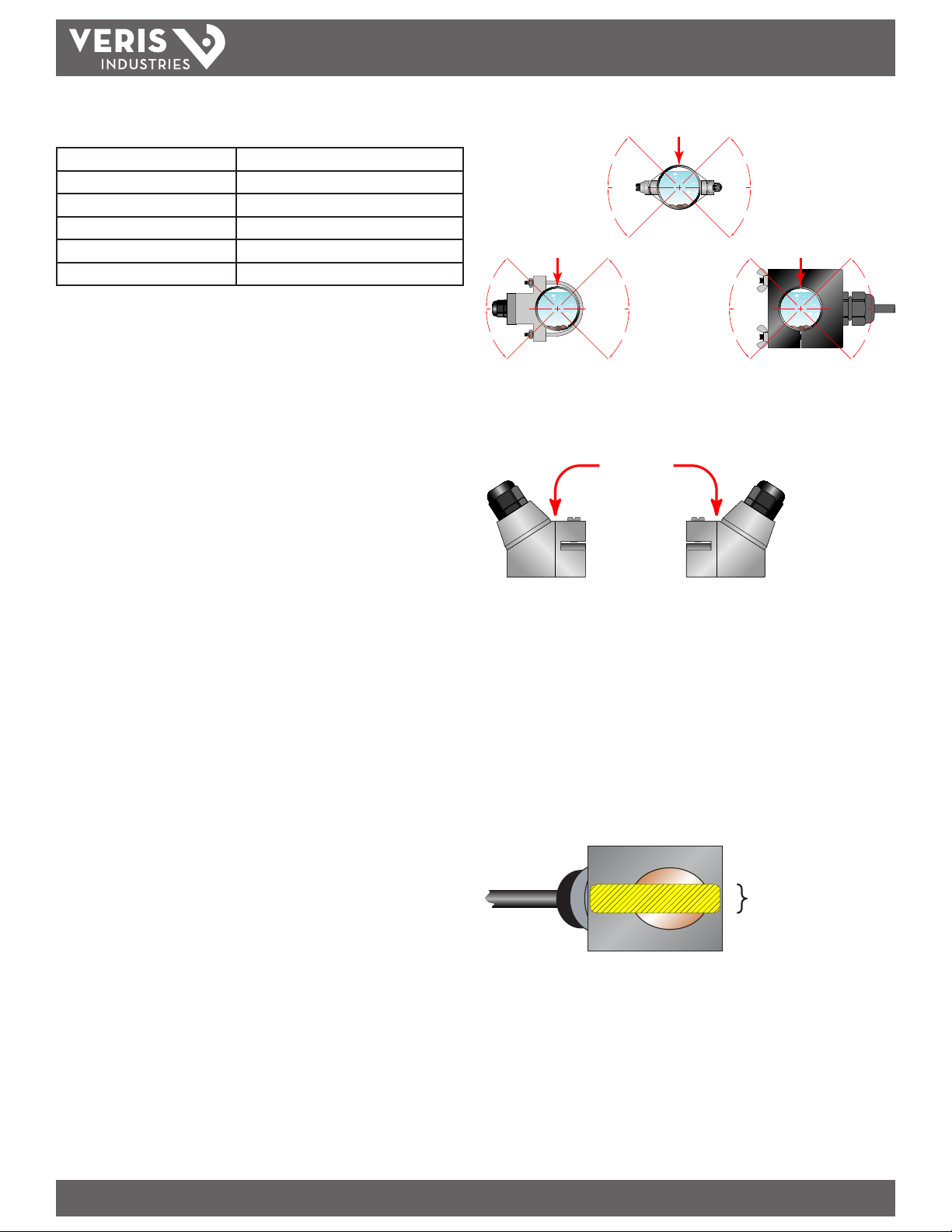

W-Mount V-Mount Z-Mount

Figure Q.1 - Transducer Mounting Congurations

4. Record the value calculated and displayed as Transducer Spacing (FST4, FST5 only).

Z205739-0D PAGE 4 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

FST1xxxx, FST2xxxx, and FST3xxxx Transducers

1. Place the ow meter in signal strength measuring mode. This value is available on

the display (Service Menu) or in the data display of the software utility.

2. The pipe surface, where the transducers are to be mounted, must be clean and dry.

Remove scale, rust or loose paint to ensure satisfactory acoustic conduction. Wire

brushing the rough surfaces of pipes to smooth bare metal may also be useful.

Plastic pipes do not require preparation other than cleaning.

3. Apply a single ½” (12 mm) bead of acoustic couplant grease to the top half of the

transducer and secure it to the pipe with bottom half or U-bolts.

4. Tighten the nuts so that the acoustic coupling grease begins to ow out from the

edges of the transducer and from the gap between the transducer and the pipe.

Do not over tighten.

4 - Startup

Initial Settings and Power Up

1. Apply power to the monitor.

2. Verify that SIG STR is greater than 5.0.

INSTALLATION GUIDE

3. Input proper units of measure and I/O data.

Z205739-0D PAGE 5 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

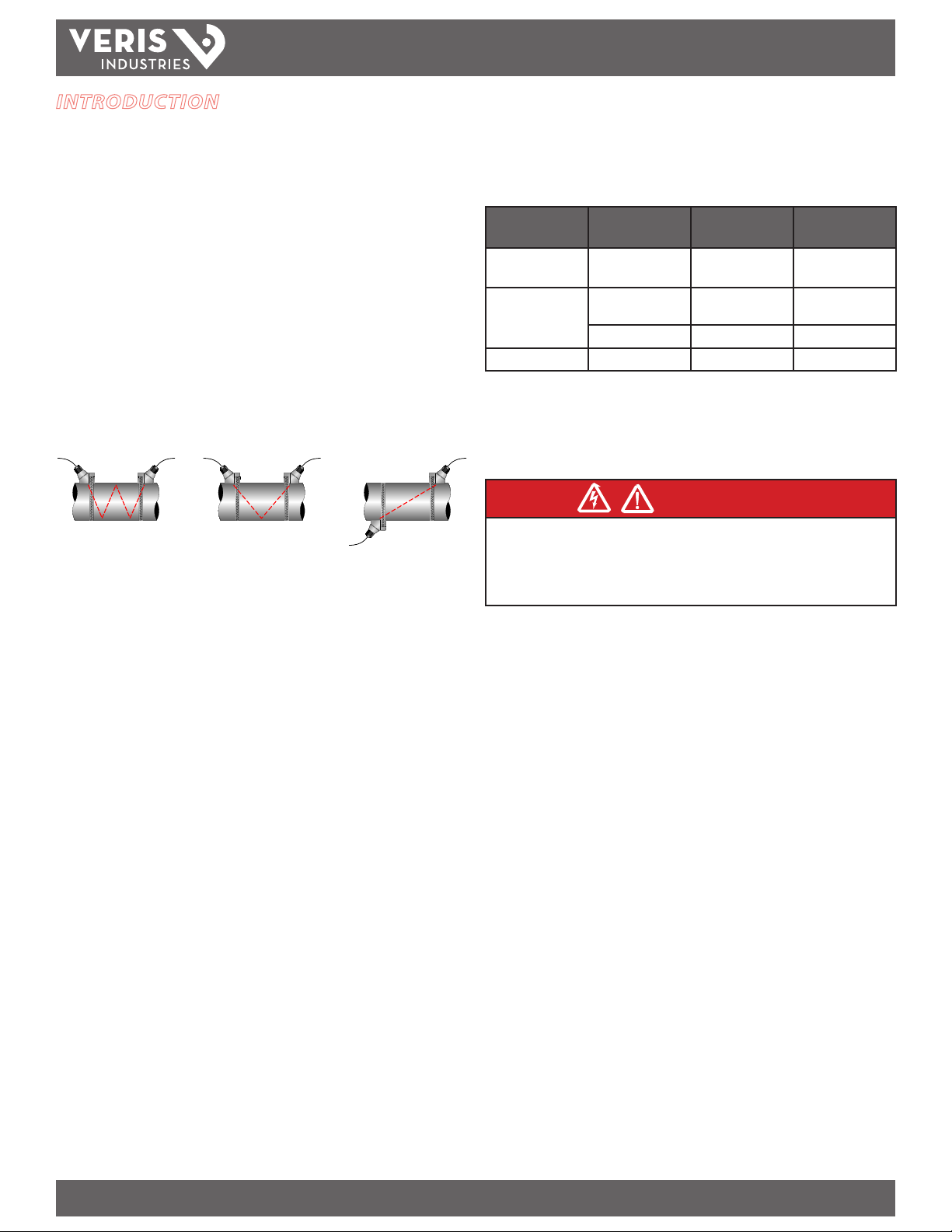

INTRODUCTION

General

The Veris ultrasonic ow meter is designed to measure the uid velocity of liquid

within a closed conduit. The transducers are a non-contacting clamp-on or clamparound type that does not foul and is easy to install.

The Veris family of transit time ow meters utilize two transducers that function

as both ultrasonic transmitters and receivers. The transducers are clamped on

the outside of a closed pipe at a specic distance from each other. The transducers

can be mounted in V-Mount where the sound transverses the pipe two times,

W-Mount where the sound transverses the pipe four times, or in Z-Mount where the

transducers are mounted on opposite sides of the pipe and the sound crosses the pipe

once. The selection of mounting method is based on pipe and liquid characteristics

that both have an eect on how much signal is generated. The ow meter operates

by alternately transmitting and receiving a frequency modulated burst of sound

energy between the two transducers and measuring the time interval that it takes

for sound to travel between the two transducers. The dierence in the time interval

measured is directly related to the velocity of the liquid in the pipe.

INSTALLATION GUIDE

Because the transducers are non-contacting and have no moving parts, the ow

meter is not aected by system pressure, fouling, or wear. FST4 and FST5 transducers

are rated to a pipe surface temperature of -40 to +250 °F (-40 to +121 °C). FST1, FST2,

and FST3 small pipe transducers are rated from -40 to +185 °F (-40 to +85 °C).

Frequency Transducers Transmission

Modes

2 MHz All ½” thru 1½”

2” Tubing

1 MHz

500 kHz larger than 24” W, V, and Z 24” and Greater

2” ANSI and Copper

all 2” to 24” W, V, and Z 2” to 24”

Selected by

Firmware

Selected by

Firmware

User Safety

The FSR Series employs modular construction and provides electrical safety for the

operator. The display face contains voltages no greater than 28 VDC. The display face

swings open to allow access to user connections.

Pipe Size and

Type

Specic to

Transducer

Specic to

Transducer

TOP VIEW

OF PIPE

W-Mount V-Mount Z-Mount

Figure 1.1 - Ultrasound Transmission

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

Application Versatility

The FSRxxxx ow meter can be successfully applied on a wide range of metering

applications. The simple-to-program monitor allows the standard product to be used

on pipe sizes ranging from ½ inch to 100 inches (12 mm to 2540 mm) pipe*. A variety

of liquid applications can be accommodated:

ultrapure liquids

potable water

chemicals

sewage

reclaimed water

cooling water

river water

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Disconnect electrical power before opening the instrument enclosure.

• Wiring mus t conform to applicable codes.

Failure to follow these instructions will result in death or serious injury.

Data Integrity

Non-volatile ash memory retains all user-entered conguration values in memory

for several years at 77°F (25°C), even if power is lost or turned o. Password

protection is provided as part of the Security menu (SEC MENU) and prevents

inadvertent conguration changes or totalizer resets.

Product Identification

The serial number and complete model number of the monitor are located on the top

outside surface of the housing. If technical assistance is required, please provide the

Customer Service Department with this information.

plant euent

others

Z205739-0D PAGE 6 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

PART 1 - MONITOR INSTALLATION

After unpacking, save the shipping carton and packing materials in case the

instrument is stored or re-shipped. Inspect the equipment and carton for damage. If

there is evidence of shipping damage, notify the carrier immediately.

Mount the enclosure in an area that is convenient for servicing, calibration, and

observation of the LCD readout.

1. Locate the monitor within the length of transducer cables supplied. If this is

not possible, it is recommended that the cable be exchanged for one that is of

proper length. If additional cable is added, utilize RG59 75 Ω coaxial cable and

BNC connections. Transducer cables that are up to 990 feet (300 meters) can be

accommodated.

2. Mount the monitor in a location:

• Where little vibration exists.

• That is protected from corrosive uids.

• That is within the monitor’s ambient temperature limits -40 to +185°F

(-40 to +85°C).

• That is out of direct sunlight. Direct sunlight may increase monitor

temperature to above the maximum limit.

3. Mounting - Refer to Figure 1.2 for enclosure and mounting dimension details.

Ensure that enough room is available to allow for door swing, maintenance and

conduit entrances. Secure the enclosure to a at surface with two appropriate

fasteners.

INSTALLATION GUIDE

Transducer Connections

To access terminal strips for wiring, loosen the two screws in the enclosure door and

open.

Guide the transducer terminations through the monitor conduit hole located in the

bottom-left of the enclosure. Secure the transducer cable with the supplied conduit

nut (if exible conduit was ordered with the transducer).

The terminals within the unit are of a screw-down barrier terminal type. Connec t

the appropriate wires at the corresponding screw terminals in the monitor. Observe

upstream and downstream (+/–) orientation. See Figure 1.3.

372

VE

D

ACL

C US

E167432

PRODUCT SERVICE

TUV

RoHS

R

AC IN : 100-240VAC,50/60Hz

DC OUT :

PWC-15E

R

+15V / 0.3A

$

0.15A

R2807

-Vo

1500mA250V

C US

W

www.astrodyne.com

strodyne

ACN

+Vo

O

N

1 2 3 4

+

+

-

-

-

-

+

+

Downstream

Downstream

Upstream

Upstream

Modbus B

Modbus A

TFX Rx

TFX Tx

Reset Total

Modbus Gnd

Modbus

Signal Gnd.

Control 1

Control 2

Frequency Out

4-20 mA Out

95 - 264 VAC

AC Neutral

Figure 1.2 - FSR Dimensions

6.4”

(163 mm)

6.0”

(153 mm)

1.4”

4.1”

(105 mm)

4.3”

(110 mm)

0.75”

(19 mm)

2x 0.5”

(13 mm)

2.1”

(53 mm)

To Transducers

Note: Wire colors may va ry!

(+) connectio n with be either red or blue;

(–) connection will be e ither black or clear.

Figure 1.3 - Transducer Connections.

Note: The transducer cable carries low level, high freque ncy signals. Do not add length to the cable

supplied with the transducers. If additional cable is required, contact the manufacturer to arrange

an exchange for a transducer with the a ppropriate length of cable. Cables to 990 feet (300 meters)

are available. If adding cabl e, ensure that it is RG59 75 Ω compatible and uses BNC terminations.

Connect power to the screw terminal block in the monitor. See Figure 1.4 and Figure

1.5. Utilize the conduit hole on the right side of the enclosure for this purpose. Use

wiring practices that conform to local and national codes (e.g., The National Electrical

Code® Handbook in the U.S.).

CAUTION

• HAZARD OF IMPROPER OR UNSAFE OPERATION

• This instrument requires clean electric al line power. Do not operate this unit on

circuit s with noisy compone nts (e.g., fluores cent lights, relays, compressors, or

variable frequency drives).

• Do not use with high current step-down transformers from high voltage sources.

• Do not run signal wires with line power in the s ame wiring tray or conduit.

Any other wiring method may be unsafe or cause improper operation of the

instrument.

4. Conduit Holes - Conduit holes should be used where cables enter the enclosure.

Holes not used for cable entry should be sealed with plugs.

Note: Use NEMA 4 [IP-65] rated ttings/plugs to maintain the watertight integrity o f the

enclosure. Generally, the right conduit hole (viewed from fro nt) is used for power, the left conduit

hole for transducer connectio ns, and the center hole is utilized fo r I/O wiring.

Z205739-0D PAGE 7 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

INSTALLATION GUIDE

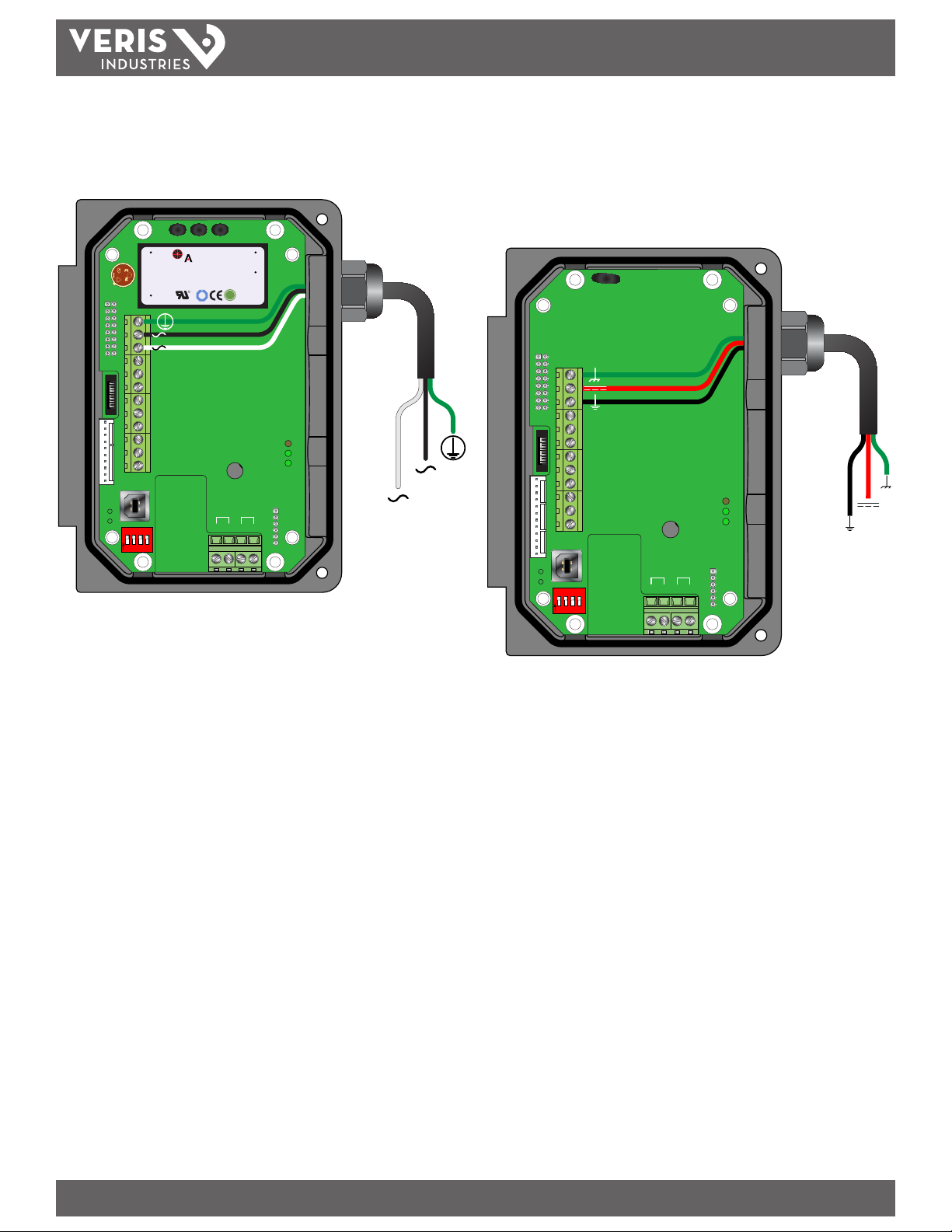

AC Power Connections

Connect 90 to 265 VAC, AC Neutral and Chassis Ground to the terminals referenced in

Figure 1.4. Do not operate without an earth (chassis) ground connection.

ACN

1500mA250V

372

W

C US

VE

D

R

AC IN : 100-240VAC,50/60Hz

DC OUT :

C US

ACL

95 - 264 VAC

95 - 264 VAC

AC Neutral

AC Neutral

www.astrodyne.com

PWC-15E

E167432

Signal Gnd.

Control 1

Control 2

Frequency Out

4-20 mA Out

Reset Total

Modbus Gnd

Modbus B

Modbus A

O

1 2 3 4

N

Figure 1.4 - AC Power Connections

strodyne

+15V / 0.3A

$

R

TUV

PRODUCT SERVICE

+Vo

-Vo

0.15A

R2807

RoHS

Modbus

TFX Rx

TFX Tx

Downstream

Upstream

-

-

+

+

DC Power Connections

The device can be operated from a 10 to 28 VDC source, as long as the source is

capable of supplying a minimum of 5 Watts of power.

Connect the DC power to 10 to 28 VDC In, Power Gnd., and Chassis Gnd., as in Figure

1.5.

10 - 28 VDC

10 - 28 VDC

Power Gnd.

Power Gnd.

Signal Gnd.

Control 1

Control 2

Frequency Out

4-20 mA Out

Reset Total

O

1 2 3 4

N

Modbus Gnd

Modbus B

Modbus A

Modbus

TFX Rx

TFX Tx

Downstream

Upstream

-

-

+

+

Power

Ground

10 -28 VDC

Note: In electrically noisy ap plications, ground the meter to the pipe where the transducers are

mounted to provide additio nal noise suppression. This approach is only eective with conduc tive

metal pipes. Remove the ear th (chassis) ground derived from the line voltage p ower supply at the

meter and connect a new ea rth ground between the meter and the pipe b eing measured.

Note: The terminal blocks accomodate wire ga uges up to 14 AWG.

Note: AC powered versions are protected by a eld replaceabl e fuse. This fuse is equivalent to

Littelfuse/Wick mann P.N. 3720500041 or 37405000410.

Figure 1.5 - DC Power Connections

Note: DC powered versions are protected by an au tomatically reset ting fuse. This fuse does not

require replacement.

Z205739-0D PAGE 8 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

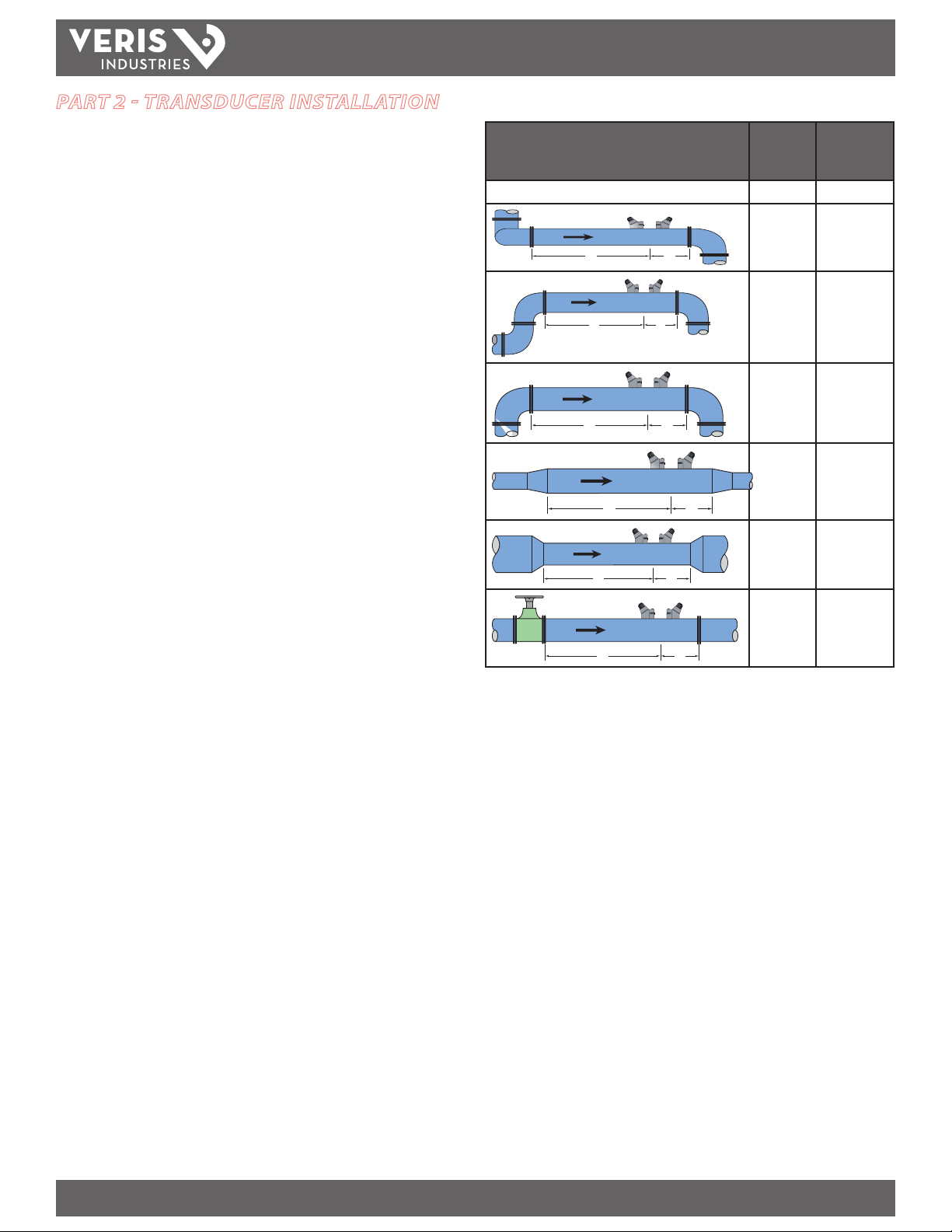

PART 2 - TRANSDUCER INSTALLATION

INSTALLATION GUIDE

General

The FST transducers contain piezoelectric crystals for transmitting and receiving

ultrasonic signals through walls of liquid piping systems. FST transducers are

relatively simple and straightforward to install, but spacing and alignment of the

transducers is critical to the system’s accuracy and performance. Take care to ensure

that these instructions are carefully executed. FST1, FST2, and FST3 small pipe

transducers have integrated transmitter and receiver elements that eliminate the

requirement for spacing measurement and alignment.

Mounting of the FST4 and FST5 clamp-on ultrasonic transit time transducers is a

three-step process:

1. Select the optimum location on a piping system.

2. Enter the pipe and liquid parameters into either the sof tware utility or key the

parameters into the transmitter using the keypad. The software utility or the

monitor’s rmware calculates proper transducer spacing based on these entries.

3. Pipe preparation and transducer mounting.

BTU meters require two RTDs to measure heat usage. The ow meter utilizes 1,000 Ω,

three-wire, platinum RTDs in two mounting styles. Surface mount RTDs are available

for use on well insulated pipes. Mounting the RTD in an uninsulated area causes

inconsistent temperature readings. Insertion (wetted) RTDs should be sued in these

areas instead.

Step 1 - Mounting Location

The rst step in the installation process is the selection of an optimum location for

the ow measurement to be made. This requires a basic knowledge of the piping

system and its plumbing.

Piping Configuration and Transducer Positioning Upstream

Pipe

Diameters

* **

25 5

Flow

*

Flow

*

**

14 5

**

10 5

Flow

*

**

10 5

Flow

*

Flow

*

Flow

*

**

10 5

**

24 5

**

Downstream

Pipe

Diameters

An optimum location is dened as:

• A piping system that is completely full of liquid when measurements are

being taken. The pipe may become completely empty during a process

cycle, which results in the error code 0010 (Low Signal Strength) being

displayed on the ow meter while the pipe is empty. This error code clears

automatically once the pipe rells with liquid. It is not recommended to

mount the transducers in an area where the pipe may become par tially

lled. Partially lled pipes cause erroneous and unpredictable operation

of the meter.

• A piping system that contains lengths of straight pipe such as

those described in Table 2.1. The optimum straight pipe diameter

recommendations apply to pipes in both horizontal and vertical

orientation. The straight runs in Table 2.1 apply to liquid velocities that

are nominally 7 FPS (2.2 MPS). As liquid velocity increases above this

nominal rate, the requirement for straight pipe increases proportionally.

• Mount the transducers in an area where they will not be inadvertently

bumped or disturbed during normal operation.

• Avoid installations on downward owing pipes unless adequate

downstream head pressure is present to overcome partial lling of or

cavitation in the pipe.

• Note: Do not cut transducer cables to alter length. This will

void the factory warranty. Cables are available in several

lengths. Assess the installation location prior to ordering to

determine the optimum length. If the wrong length is ordered,

contact the factory.

Table 2.1 - Piping Conguration and Transducer Positioning

The ow meter system provides repeatable measurements on piping systems that do

not meet these requirements, but accuracy of these readings may be inuenced to

various degrees.

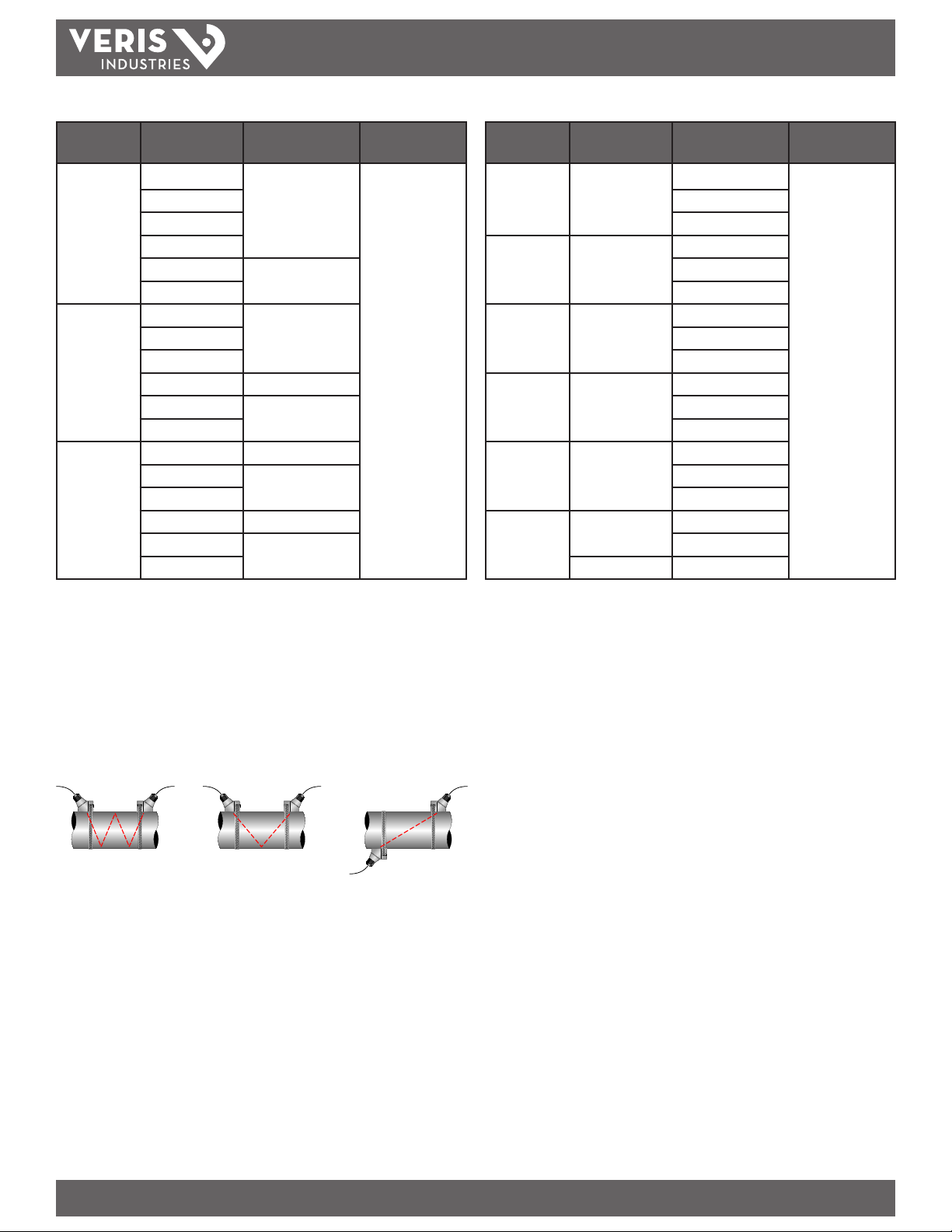

Step 2 - Transducer Spacing

Transit time ow meters can be used with two dierent transducer types. Meters

that utilize the FST4 and FST5 transducer sets consist of two separate sensors

that function as both ultrasonic transmitters and receivers. FST1, FST2, and FST3

transducers integrate both the transmitter and receiver into one assembly that xes

the separation of the piezoelectric crystals. These transducers are clamped on the

outside of a closed pipe at a specic distance from each other.

The FST4 and FST5 transducers can be mounted in:

W-Mount where the sound traverses the pipe four times. This mounting

method produces the best relative travel time values but the weakest signal

strength.

V-Mount where the sound traverses the pipe twice. V-Mount is a compromise

between travel time and signal strength.

Z-Mount where the transducers are mounted on opposite sides of the pipe

and the sound crosses the pipe once. Z-Mount will yield the best signal

strength but the smallest relative travel time.

Z205739-0D PAGE 9 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

INSTALLATION GUIDE

Mounting

Mode

W-Mount

V-Mount

Z-Mount

Pipe Material Pipe Size Liquid

Composition

Plastic (all types)

Carbon Steel

Stainless Steel

Copper

Ductile Iron

Cast Iron

Plastic (all types)

Stainless Steel

Copper 4-30 in. (100-750 mm)

Ductile Iron

Cast Iron

Plastic (all types) > 30 in. (>750 mm)

Carbon Steel

Stainless Steel

Copper > 30 in. (>750 mm)

Ductile Iron

Cast Iron

2-4 in. (50-100 mm)

Not Recommended

4-12 in. (100-300 mm)Carbon Steel

Low TSS; non-aerated

2-12 in. (50-300 mm)

>12 in. (>300 mm)

>12 in. (>300 mm)

Size Frequency

1/2 2 MHz

3/4 2 MHz

1 2 MHz

1 1/4 2 MHz

1 1/2 2 MHz

2

1 MHz

2 MHz FST3

Setting

Transducer Mounting Mode

FST1

FST2

FST3

FST1

FST2

FST3

FST1

FST2

FST3

FST1

FST2

FST3

FST1

FST2

FST3

FST1

FST2

V

Table 2.2 - Transducer Mounting Modes — FST4, FST5

For further details, reference Figure 2.1. The appropriate mounting conguration is

based on pipe and liquid characteristics. Selection of the proper transducer mounting

method is not entirely predictable and many times is an iterative process. Table 2.2

contains recommended mounting congurations for common applications. These

recommended congurations may need to be modied for specic applications

if such things as aeration, suspended solids, out of round piping or poor piping

conditions are present. Use of meter diagnostics in determining the optimum

transducer mounting is covered later in this section.

TOP VIEW

OF PIPE

W-Mount V-Mount Z-Mount

Figure 2.1- Transducer Mounting Modes — FST4, FST5

TOP VIEW

OF PIPE

TOP VIEW

OF PIPE

Table 2.3 - Transducer Mounting Mod es — FST1, FST2, FST3

Step 3 - Entering Pipe and Liquid Data

The system calculates proper transducer spacing by utilizing piping and liquid

information entered by the user. Enter this information via the keypad or via the

optional software utility.

The best accuracy is achieved when transducer spacing is exactly what the meter

calculates, so use the calculated spacing if signal strength is satisfactory. If the pipe is

not round, the wall thickness is not correct, or the actual liquid being measured has a

dierent sound speed than the liquid programmed into the transmitter, the spacing

can vary from the calculated value. If that is the case, place the transducers sat the

highest signal level obser ved by moving the transducers slowly around the mount

area.

Note: Transducer spacing is calculated on “ideal” pipe. Ideal p ipe is almost never found so the

transducer spacing distances may need to be altered. An eec tive way to maximize signal strength

is to congure the display to show signal strength, x o ne transducer on the pipe and then starting

at the calculated spacing, move the rema ining transducer small distances forward and back to

nd the maximum signal s trength point.

Important! Enter all of the data on this list, save the data, and reset the

meter before mounting transducers.

Z205739-0D PAGE 10 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

INSTALLATION GUIDE

The following information is required before programming the instrument:

Transducer mounting conguration Pipe O.D. (Outer Diameter)

Pipe wall thickness Pipe material

Pipe sound speed

1

Pipe relative roughness

1

Pipe liner thickness (if present) Pipe liner material (if present)

Fluid type Fluid sound speed

Fluid viscosity

1

Fluid specic gravity

1

1

Note: Much of the data relating to material sound spee d, viscosity, and specic gravity is

pre-programmed into the o w meter. This data only needs to be modied if it is kn own that a

particular ap plications data varies from the reference values. Refer to Part 4 of this man ual for

instructions on entering conguration data into the ow meter via the monitor’s keypad. Refer to

Part 5 for data entry via the sof tware.

1

Nominal values for these parameters are included within the operating system. The nominal

values may be used as they appear o r may be modied if exact system values are kno wn.

After entering the data listed above, the meter calculates proper transducer spacing

for the particular data set. This distance is in inches if it is congured in English units,

or millimeters if congured in metric units.

Step 4 - Transducer Mounting

Pipe Preparation

TOP OF PIPE

45°

YES

45°

45°

YES

45°

FLOW METER MOUNTING

ORIENTATION

FST4, FST5 TRANSDUCERS

TOP OF PIPE TOP OF PIPE

45°

YES

45°

FLOW METER

MOUNTING ORIENTATION

2” FST1, FST2, FST3 TRANSDUCERS

Figure 2.2 - Transducer Orientation — Horizontal Pipes

Alignment

Marks

45°

YES

45°

45°

YES

45°

FLOW METER

MOUNTING ORIENTATION

<2” FST1, FST2, FST3 TRANSDUCERS

45°

YES

45°

Before mounting the transducers onto the pipe surface, clean an area slightly larger

than the at surface of each transducer to eliminate all rust, scale and moisture.

For pipes with rough surfaces, such as ductile iron pipe, wire brush the surface to a

shiny nish. Paint and other coatings need not be removed unless aked or bubbled.

Plastic pipes typically do not require surface preparation other than soap and water

cleaning.

Properly orient the transducers and spaced them on the pipe to provide optimum

reliability and per formance. On horizontal pipes, when Z-Mount is required, mount

the transducers 180 radial degrees from one another and at least 45 degrees from

the top-dead-center and bottom-dead-center of the pipe. See Figure 2.2 Also see

Z-Mount Transducer Installation. On vertical pipes the orientation is not critical.

Measure the spacing between the transducers using the two spacing mark s on the

sides of the transducers. These marks are approximately 0.75” (19 mm) back from the

nose of the FST4/FST5 transducers. See Figure 2.3.

Mount FST1, FST2, and FST3 transducers with the cable exiting within ±45 degrees

of the side of a horizontal pipe. See Figure 2.2. On vertical pipes the orientation does

not apply.

Figure 2.3 - Transducer Alignment Marks

V-Mount and W-Mount Installation

Application of Couplant

For FST4 and FST5 transducers, place a single bead of couplant, approximately ½

inch (12 mm) thick, on the at face of the transducer. See Figure 2.4. Generally, a

silicone-based grease is used as an acoustic couplant, but any grease-like substance

that is rated not to “ow” at the temperature that the pipe may operate at will be

acceptable. For pipe surface temperature over 130°F (55°C) Sonotemp® (P.N. D0022011-010) is recommended.

½”

(12 mm)

Figure 2.4 - Application of Couplant

Z205739-0D PAG E 11 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

INSTALLATION GUIDE

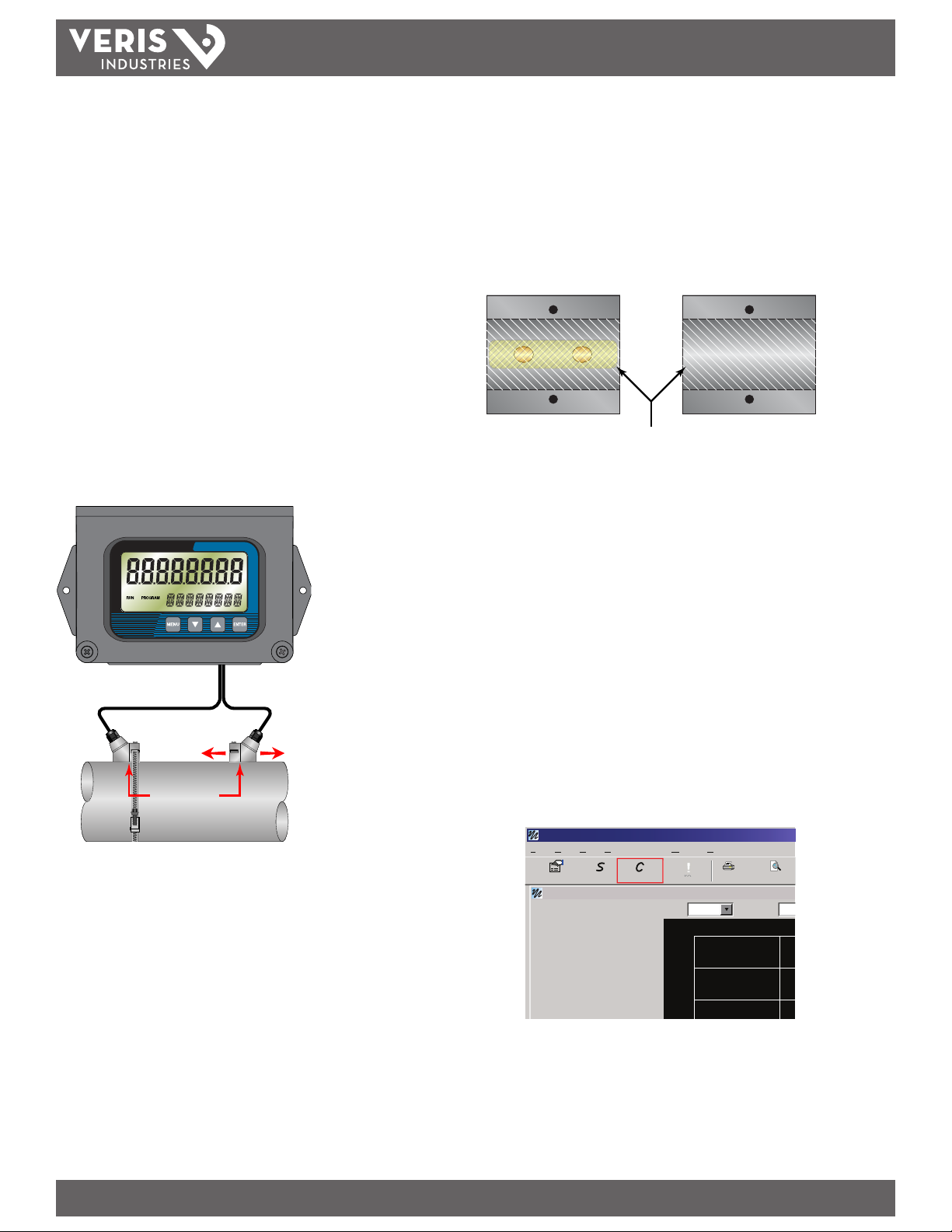

Transducer Positioning

1. Place the upstream transducer in position and secure with a mounting strap. Place

straps in the arched groove on the end of the transducer. A screw is provided to

help hold the transducer onto the strap. Tighten the transducer strap securely.

2. Place the downstream transducer on the pipe at the calculated transducer spacing.

See Figure 2.5. Apply rm hand pressure. If signal strength is greater than 5,

secure the transducer at this location. If the signal strength is not 5 or greater

then using rm hand pressure, slowly move the transducer both towards and

away from the upstream transducer while observing signal strength. Clamp

thetransducer where the highest signal strength is observed. Signal levels much

less than 5 may not yield acceptable data.

Note: Signal strength readings upd ate only every few seconds, so it is advisable to move

the transducer 1/8”, wait, see if signal is increasing or decreasing and then repeat unti l

the highest level is achieved.

3. If after adjustment of the transducers the signal strength does not rise to above 5,

then select an alternate transducer mounting method. If the mounting method

was W-Mount, then re-congure the monitor for V-Mount, move the downstream

transducer to the new spacing distance and repeat Step 4.

Small Pipe Transducer Installation

The small pipe transducers are designed for specic pipe outside diameters. Do not

attempt to mount a transducer onto a pipe that is either too large or too small for the

transducer.

FST1, FST2, and FST3 installation consists of the following steps:

1. Apply a thin coating of acoustic coupling grease to both halves of the transducer

housing where the housing will contact the pipe. See Figure 2.6.

1/16” (1.5 mm)

Acoustic Couplant Grease

Figure 2.6 - Application of Acoustic Couplant — FST1, FST2, FST3 Transducers

2. On horizontal pipes, mount the transducer in an orientation such that the cable

exits at ±45 degrees from the side of the pipe. Do not mount with the cable

exiting on either the top or bottom of the pipe. On vertical pipes the orientation

does not matter. See Figure 2.2.

Transducer

Spacing

Figure 2.5 - Transducer Positioning

3. Tighten the wing nuts or “U” bolts so that the acoustic coupling grease begins to

ow out from the edges of the transducer or from the gap between the transducer

halves. Do not over tighten.

4. If signal strength is less than 5, remount the transducer at another location on the

piping system.

5. Conguration Procedure:

a. Establish communications with the transit tme meter. See Part 5 Software Utility.

b. From the tool bar, select calibration.

USP - Device Addr 127

Configuration CalibrationStrategy

Device Addr 127

1350 Gal/Min

Flow:

Pos:

Neg:

Margin:

Delta T:

0 OB

0 OB

0 OB

15.6%

100%

-2.50 ns

09:53:39

Totalizer Net:

Sig. Strength:

Last Update:

Errors

2000

1600

1200

HelpWindowCommunicationsViewEditFile

!

Print PreviePrint

Scale:60 MinTime:

200

c. On the pop-up screen, click Next twice to get to page 3 of 3. Click Edit in this

screen.

Z205739-0D PAGE 12 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

INSTALLATION GUIDE

Calibration (Page 3 of 3) - Linearization

28.2

Gal/M

Delta Time

1) Please establish a

reference flow rate.

1FPS / 0.3MPS Minimum.

2) Enter the reference flow

rate below. (Do not enter 0)

3) Wait for flow to stabilize.

4) Press the Set button.

Flow:

Set

Edit

Export...

d. In the Calibration Points Editor screen, use the Add and Remove buttons as

needed. Click OK when complete.

e. The display returns to Calibration (Page 3 of 3). Click nish

f. Power cycle the unit to activate the new settings.

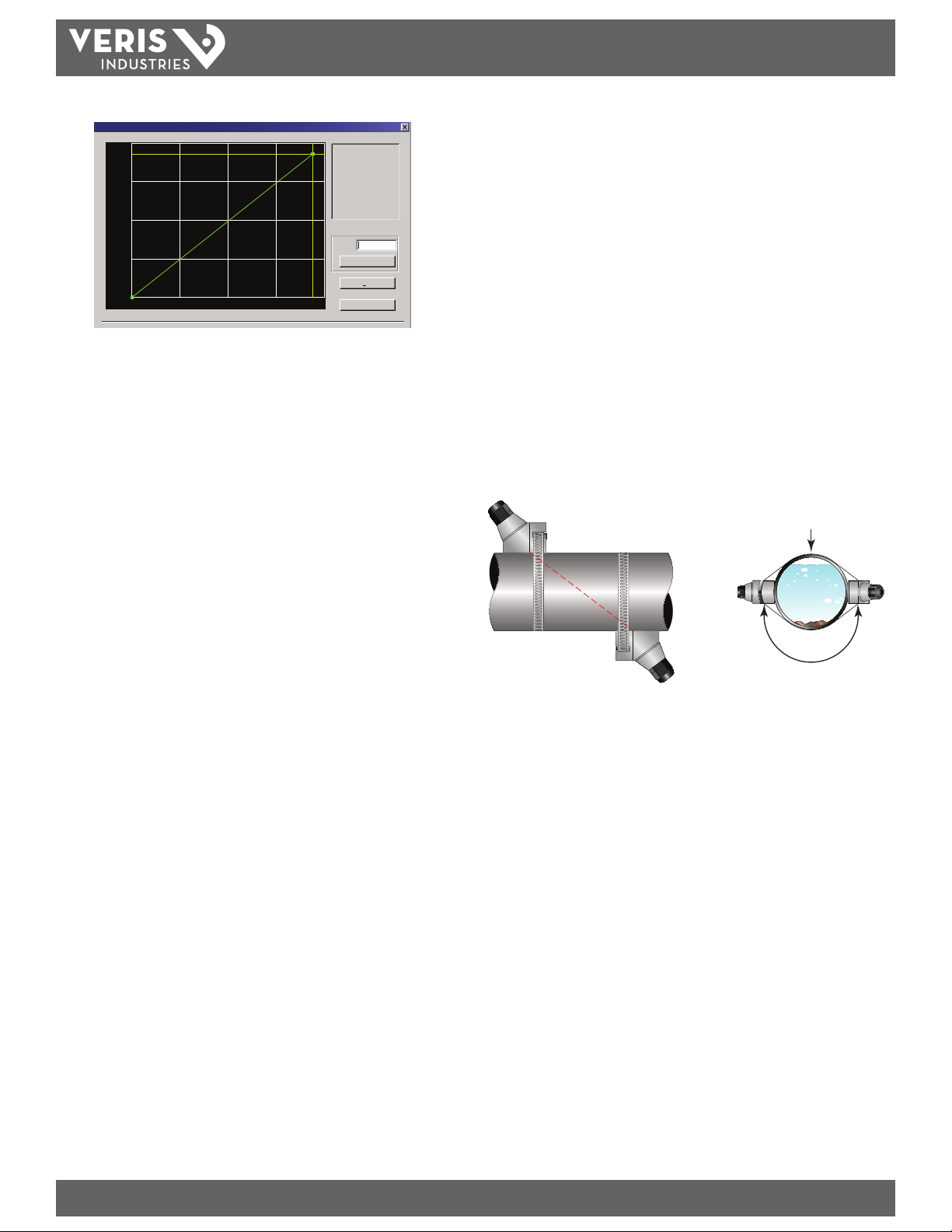

Mounting Transducers in Z-Mount Configuration

Installation on larger pipes requires careful measurements of the linear and radial

placement of the FST4 and FST5 transducers. Failure to properly orient and place the

transducers on the pipe may lead to weak signal strength and/or inaccurate readings.

1. Place the transducers on opposite sides of the pipe. This distance around the pipe

is calculated by multiplying the pipe diameter by 1.57. The transducer spacing

along the pipe is the same as found in the Transducer Positioning section.

2. For FST4 and FST5 transducers, place a single bead of couplant, approximately ½

inch (12 mm) thick, on the at face of the transducer. See Figure 2.4. Generally,

a silicone-based grease is used as an acoustic couplant, but any good quality

grease-like substance that is rated to not “ow” at the temperature that the pipe

may operate at is acceptable.

3. Place the upstream transducer in position and secure with a stainless steel strap

or other fastening device. Place straps in the arched groove on the end of the

transducer. A screw is provided to help hold the transducer onto the strap. Tighten

transducer strap securely. Larger pipes may require more than one strap to reach

the circumference of the pipe.

4. Place the downstream transducer on the pipe at the calculated transducer spacing.

See Figure 2.7. Using rm hand pressure, slowly move the transducer both towards

and away from the upstream transducer while observing signal strength. Clamp

the transducer at the position where the highest signal strength is observed.

Signal strength of between 5 and 98 is acceptable. The fac tory default signal

strength setting is 5, however there are many application specic conditions that

may prevent the signal strength from attaining this level.

A minimum signal strength of 5 is acceptable as long as this signal level is

maintained under all ow conditions. On certain pipes, a slight twist to the

transducer may cause signal strength to rise to acceptable levels.

5. Certain pipe and liquid characteristics may cause signal strength to rise to greater

than 98. At this level, the signals may saturate the input ampliers and cause

erratic readings. To lower the signal strength, change the transducer mounting

method to the next longest transmission path. For example, if there is excessive

signal strength and the transducers are mounted in a Z-Mount, try changing to

V-Mount or W-Mount. Finally you can also move one transducer slightly o line

with the other transducer to lower signal strength.

6. Secure the transducer with a stainless steel strap or other fastener.

TOP OF PIPE

TOP VIEW

OF PIPE

Distance = Pipe Outer Diameter * 1.57

Figure 2.7 - Z-Mount Transducer Placement

PIPE CROSS

SECTIONAL

VIEW

Z205739-0D PAGE 13 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

1 2 3 4

O

N

PART 3 - INPUTS/OUTPUTS

FSRxxxx SERIES

INSTALLATION GUIDE

General

The FSR1 is available in two congurations: the ow model and the energy model.

The ow model is equipped with a 4-20 mA output, two open collec tor outputs, a

rate frequency output, and RS-485 communications using the Modbus RTU command

set. The energy version has inputs for two 1,000 Ω RTD sensors in place of the rate

frequency and alarm outputs. This version allows the measurement of pipe input and

output temperatures for calculating energy usage calculations.

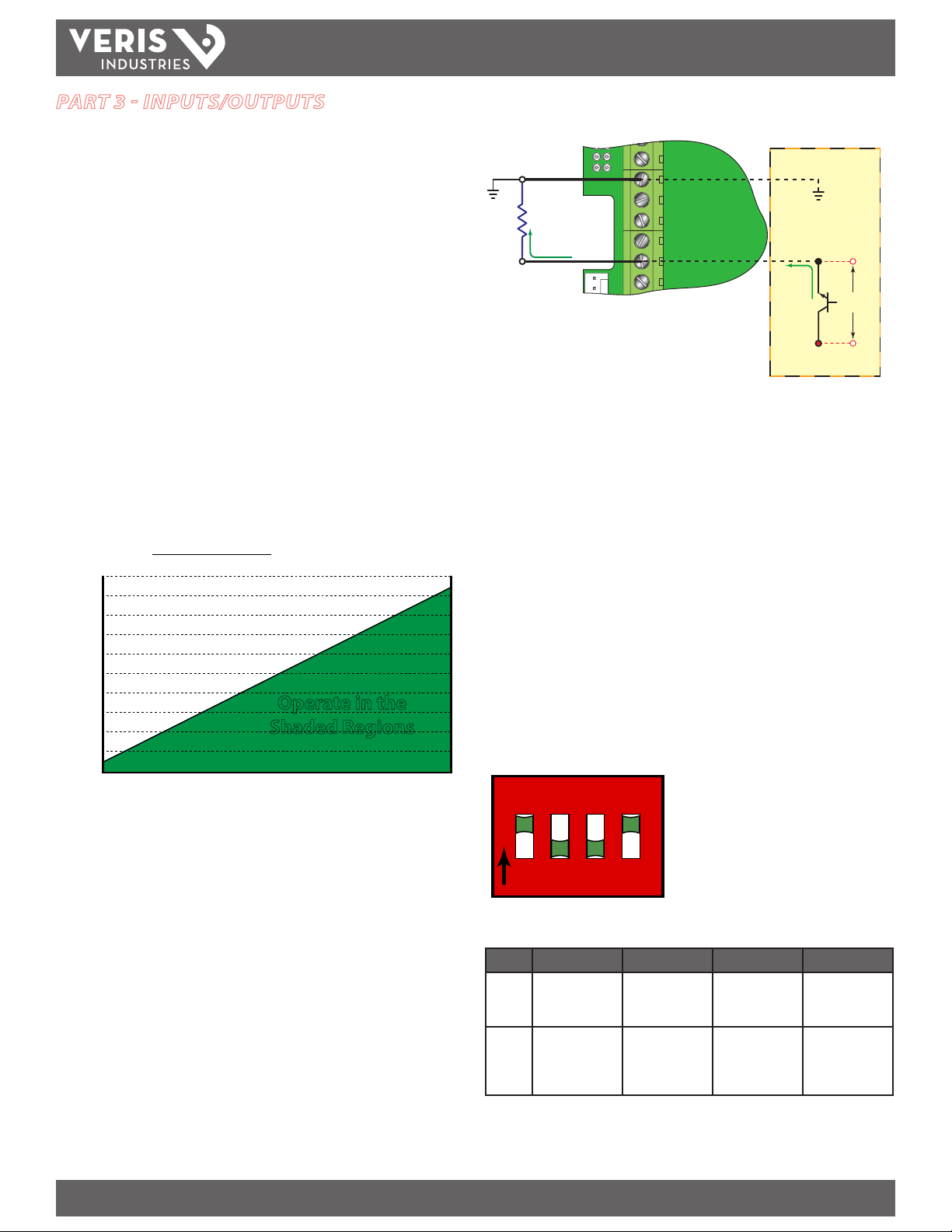

4-20 mA Output

The 4-20 mA output interfaces with most recording and logging systems by

transmitting an analog current signal that is propor tional to system ow rate. The

4-20 mA output is internally powered (current sourcing) and can span negative to

positive ow/energy rates.

For AC powered units, the 4-20 mA output is driven from a +15 VDC source located

within the meter, isolated from earth ground connections. The AC powered model

accommodates loop loads up to 400 Ω. DC powered meters utilize the DC power

supply voltage to drive the current loop. The current loop is not isolated from DC

ground or power. Figure 3.1 shows graphically the allowable loads for various input

voltages. The combination of input voltage and loop load must stay within the

shaded area of Figure 3.1.

Supply Voltage - 7 VDC

1100

1000

900

800

700

600

500

400

Loop Load (Ohms)

300

200

100

10 12 14 16 18 20 22 24 26 28

0.02

Supply Voltage (VDC)

= Maximum Loop Resistance

Operate in the

Shaded Regions

90-265 VAC

Loop

Resistance

Figure 3.2 - 4-20 mA Output

AC Neutral

Signal Gnd.

Control 1

Control 2

Frequency Out

4-20 mA Out

Reset Total

Signal Ground

Meter Power

7 VDC

Drop

The 4-20 mA output signal is available between the 4-20 mA Out and Signal Gnd.

terminals as shown in Figure 3.2.

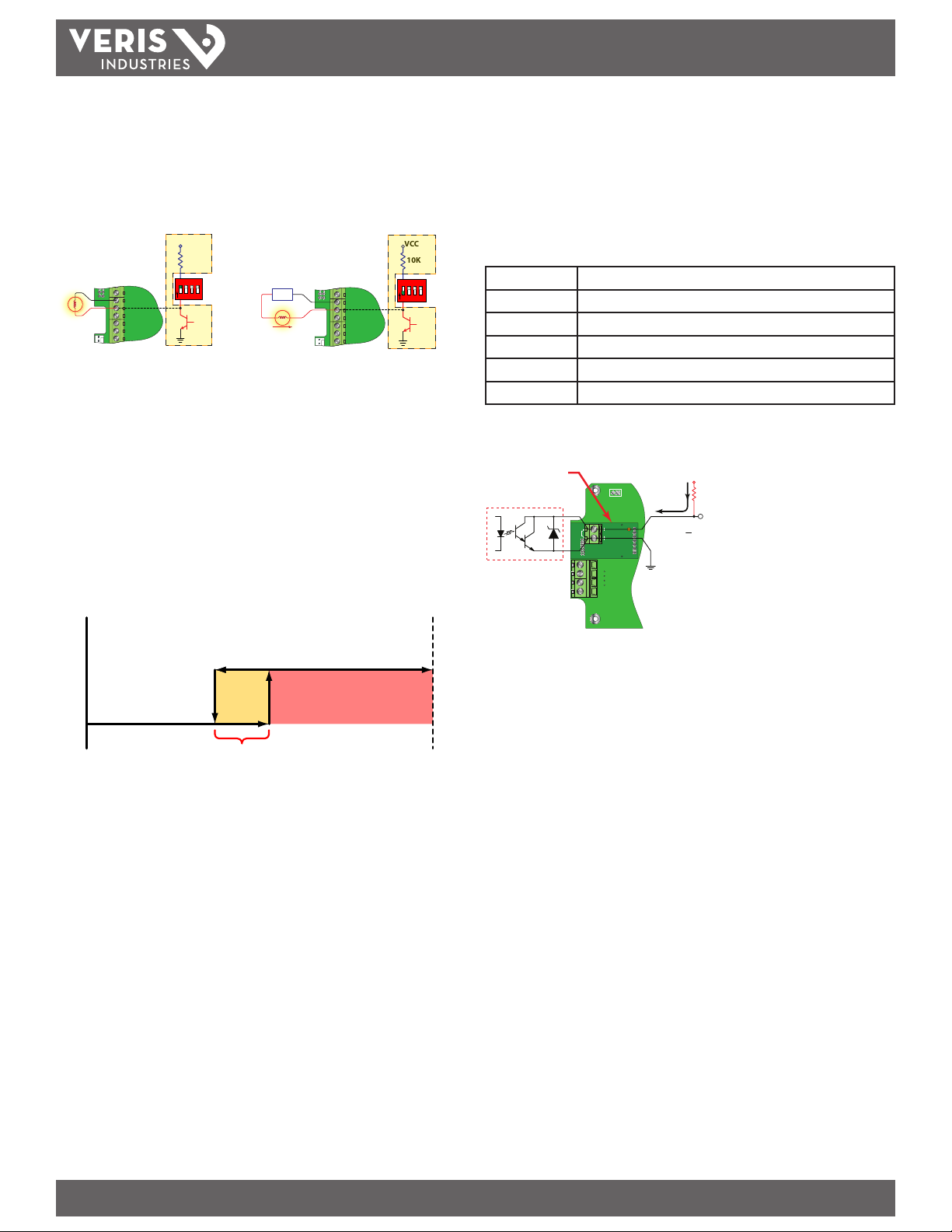

Control Outputs

Two independent open collector transistor outputs are included with the ow meter.

Each output can be congured for one of the following four functions:

Rate Alarm

Signal Strength Alarm

Totalizing/Totalizing Pulse

Errors

None

Both control outputs are rated for a maximum of 100 mA and 10 to 28 VDC. A pull-up

resistor can be added externally or an internal 10 kΩ pull-up resistor can be selected

using DIP switches on the power supply board.

Figure 3.1 - Allowable Loop Resistance (DC Powered Units)

Figure 3.3 - Switch Settings

Switch S1 S2 S3 S4

On Control 1 pull-up;

Resistor IN circuit

O Control 1 pull-up;

Resistor OUT OF

circuit

Table 3.1 - DIP Switch Functions

Control 2 pull-up;

Resistor IN circuit

Control 2 pull-up;

Resistor OUT OF

circuit

Frequency output

pull-up;

Resistor IN circuit

Frequency output

pull-up;

Resistor OUT OF

circuit

Z205739-0D PAGE 14 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Square wave

output

Simulated turbine

output

TM

FSRxxxx SERIES

INSTALLATION GUIDE

Set the on/o values for the Rate Alarm and Signal Strength Alarm using either the

keypad or the software utility.

Typical control connections are illustrated in Figure 3.4. Please note that only

the Control 1 output is shown. Control 2 is identical except the pull-up resistor is

governed by SW2.

VCC

10K

O

90-265 VAC

AC Neutral

Signal Gnd.

Control 1

Control 2

Frequency Out

4-20 mA Out

Reset Total

N

1 2 3 4

SW1/SW2

Figure 3.4 - Typical Control Connections

10 - 28

VDC

100 mA Maximum

90-265 VAC

AC Neutral

Signal Gnd.

Control 1

Control 2

Frequency Out

4-20 mA Out

Reset Total

O

N

VCC

10K

1 2 3 4

SW1/SW2

Alarm Output

The ow rate output permits output changeover at two separate ow rates allowing

operation with an adjustable switch deadband. Figure 3.5 illustrates how the setting

of the two set points inuences rate alarm operation.

A single-point ow rate alarm places the ON setting slightly higher than the OFF

setting, establishing a switch deadband. If a deadband is not established, switch

chatter (rapid switching) may result if the ow rate is very close to the switch point.

Minimum

Flow

Maximum

Flow

Totalizer Output for Energy Meter

Energy units can be ordered with a totalizer pulse output option. This option is

installed in the position where the Ethernet option would normally be; therefore,

the totalizer pulse output option and the Ethernet communications output cannot be

installed simultaneously.

Optional totalizing pulse specications:

Signal 1 pulse for each increment of the totalizer’s least signicant digit

Type Opto-isolated, open collector transistor

Pulse Width 30 msec, max. pulse rate 16 Hz

Voltage 28 VDC max.

Current 100 mA max. (current sink)

Pull-up Resistor 2.8 kΩ to 10 kΩ

Wiring and conguring this option is similar to the totalizing pulse output for the

ow only version. This option must use an external current limiting resistor.

Totalizing

Pulse Output

Option

Internal

RxD

TB1

Total Pulse

100 mA

Maximum

V

CC

2.8K to 10K

Isolated Output

Total Pulse

Pull-up

Resistor

Set OFF

Set ON

Output ON

Output OFF

Deadband

Figure 3.5 - Single Point Alarm Operation

Batch/Totalizer Output

Totalizer mode congures the output to send a 33 mSec pulse each time the display

totalizer increments divided by the TOT MULT. The TOT MULT value must be a whole,

positive, numerical value.

Fir example, If the totalizer exponent (TOTL E) is set to E2 (×100) and the totalizer

multiplier (TOT MULT) is set to 1, then the control output pulses each time the display

totalizer increments or once per 100 measurement units totalized.

Signal Strength Alarm

The SIG STR alarm provides an indication that the signal level reported by the

transducers has fallen to a point where ow measurements may not be possible.

It can also be used to indicated that the pipe has emptied. Like the rate alarm

described previously, the signal strength alarm requires that two points be entered,

establishing an alarm deadband. The ON value must be lower than the OFF value. If a

deadband is not established and the signal strength decreases to approximately the

value of the switch point, the output may “chatter.”

Error Alarm Outputs

When a control output is set to ERROR mode, the output activates when an error

causes the meter to stop measuring reliably. See the Appendix of this manual for a list

of potential error codes.

Z205739-0D PAGE 15 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

FSRxxxx SERIES

INSTALLATION GUIDE

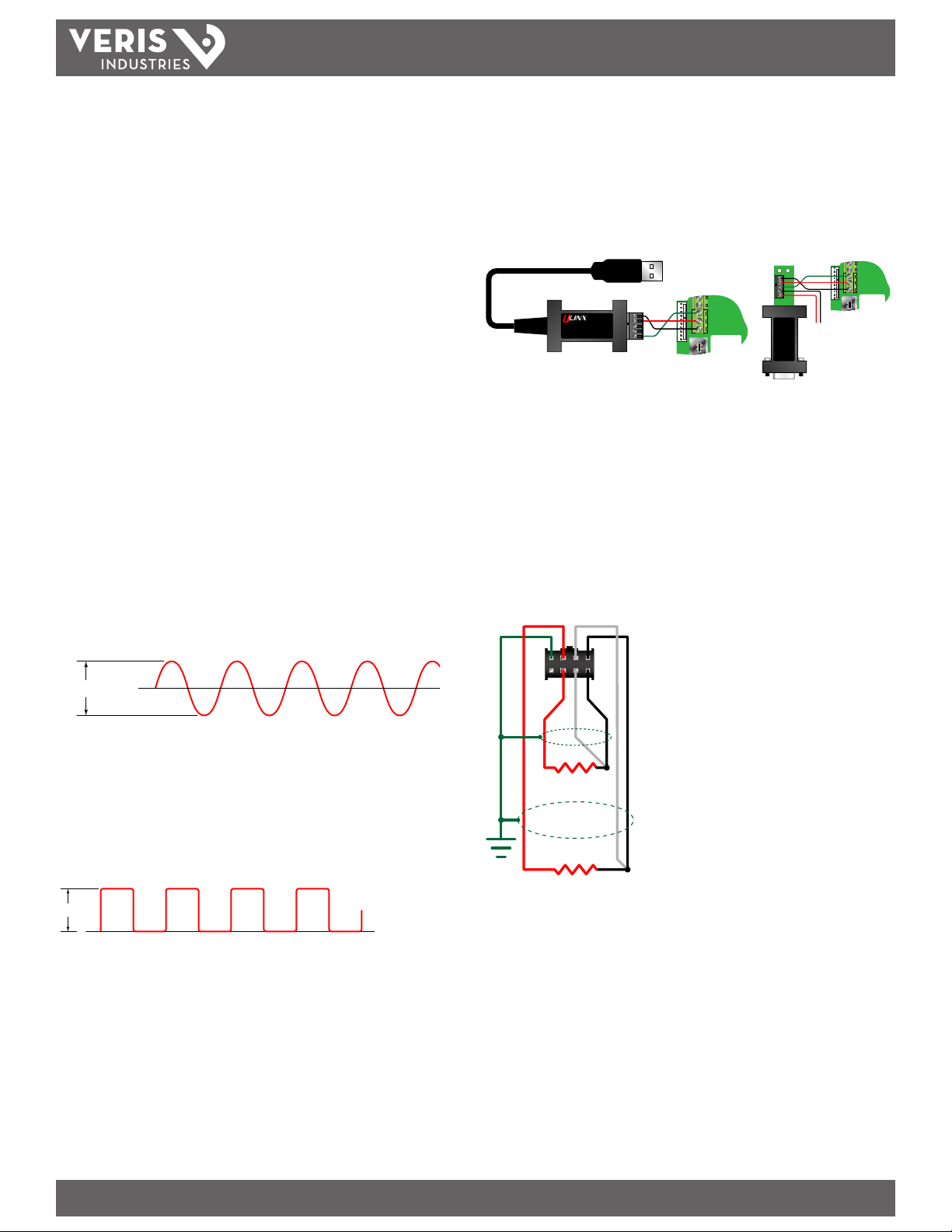

Frequency Output [FSRxxx1x only]

The frequency output is an open-collector transistor circuit that outputs a pulse

waveform that varies proportionally with ow rate. This type of frequency output is

also know as a “Rate Pulse” output. The frequency output is proportional to the max

ow rate entered into the meter. The maximum output frequency is 1000 Hz.

In addition to the control outputs, the frequency output can be used to provide total

information by use of a K-factor that relates the number of pulses from the frequenc y

output to the number of accumulated pulses that equates to a specic volume.

This relationship is described by the following equation: K-factor = 60,000 / full scale

units. The 60,000 relates to measurement units in volume/min. Measurement units in

seconds, hours or days would require a dierent numerator.

If the frequency output is to be used as a totalizing output, then the meter and the

receiving instrument must have identical K-factor values programmed into them

to ensure that accurate readings are recorded by the receiving instrument. Unlike

standard mechanical ow meters such as turbines, gear or nutating disk meters, the

K-factor can be changed by modifying the MAX RATE ow rate value.

Note: For a full treatment of K-factors p lease see the Appendix of this manual.

There are two frequency output types available:

1.) Turbine meter simulation - This option is utilized when a receiving

instrument is capable of interfacing directly with a turbine ow meter’s

magnetic pickup. The output is a relatively low voltage AC signal whose

amplitude swings above and below the signal ground reference. The

minimum AC amplitude is approximately 500 mV peak-to-peak. To activate

the turbine output circuit, turn SW4 OFF .

To interconnect meters, utilize three-wire shielded cable such as Belden® 9939 or

equal. In noisy environments, connect the shield on one end to earth ground. Use a

USB to RS-485 converter to communicate with a PC running Windows 98, Windows

ME, Windows 2000, Windows NT, Windows XP, Windows Vista, or Windows 7.

For computers with RS-232C serial ports, use an RS-232C to RS-485 converter to

interconnect the RS-485 network to a communication port on a PC. If monitoring

more than 126 meters, use an additional converter and communication port.

4-20 mA Out

Reset Total

Modbus Gnd

Modbus B

Modbus A

RS232 to RS485

Model 485USBTB-2W

USB to RS485

TD(A)-

TD(B)+

GND

GND

4-20 mA Out

Reset Total

A (-)

B (+)

A (-)

B (+)

GND

Modbus Gnd

Modbus B

Modbus A

+12V

RS-485

To 12 VDC

Supply

Model 485SD9TB

RS-232

RS-485 Converter

Figure 3.9 - RS-485 Network Connectio ns

Heat Flow [BTU meters only]

The BTU meter allows the integration of two 1000 Ω, 3-wire, platinum RTDs with the

ow meter, providing a means of measuring energy consumed in liquid heating and

cooling systems. The RTDs are attached at the factory to a simple plug-in connector

eliminating the possibility of mis-wiring. Simply install the RTDs on or in the pipe as

recommended, and then plug the RTDs into the meter. The surface mount versions

are available in standard lengths of 20 feet (6 meters), 50 feet (15 meters) and 100

feet (30 meters) of attached shielded cable.

BACK OF

CONNECTOR

500 mV

0

p-p

Figure 3.7 - Frequency Output Waveform (Simulated Turbine)

2.) Square-wave frequency - This option is utilized when a receiving

instrument requires that the pulse voltage level be either of a higher

potential and/or referenced to DC ground. The output is a square-wave with

a peak voltage equaling the instrument supply voltage when the SW3 is ON.

If desired, an external pull-up resistor and power source can be utilized by

leaving SW3 OFF. Set SW4 to ON for a square-wave output.

+V

0

Figure 3.8 - Frequency Output Waveform (Square Wave)

RS-485

The RS-485 feature allows up to 126 metering systems to be placed on a single threewire cable bus. Each meter is assigned a unique numeric address that allows all of the

meters on the cable network to be independently accessed. A Modbus RTU command

protocol is used to interrogate the meters. An explanation of the command structure

is detailed in the APPENDIX of this manual. Flow rate, total, signal strength and

temperature (if so equipped) can be monitored over the digital communications bus.

Baud rates up to 9600 and cable lengths to 5,000 feet (1,500 meters) are supported

without repeaters or “end of line” resistors.

1000 Ω

RETURN LINE

RTD #2

1000 Ω

SUPPLY LINE

RTD #1

Figure 3.10 - RTD Schematic

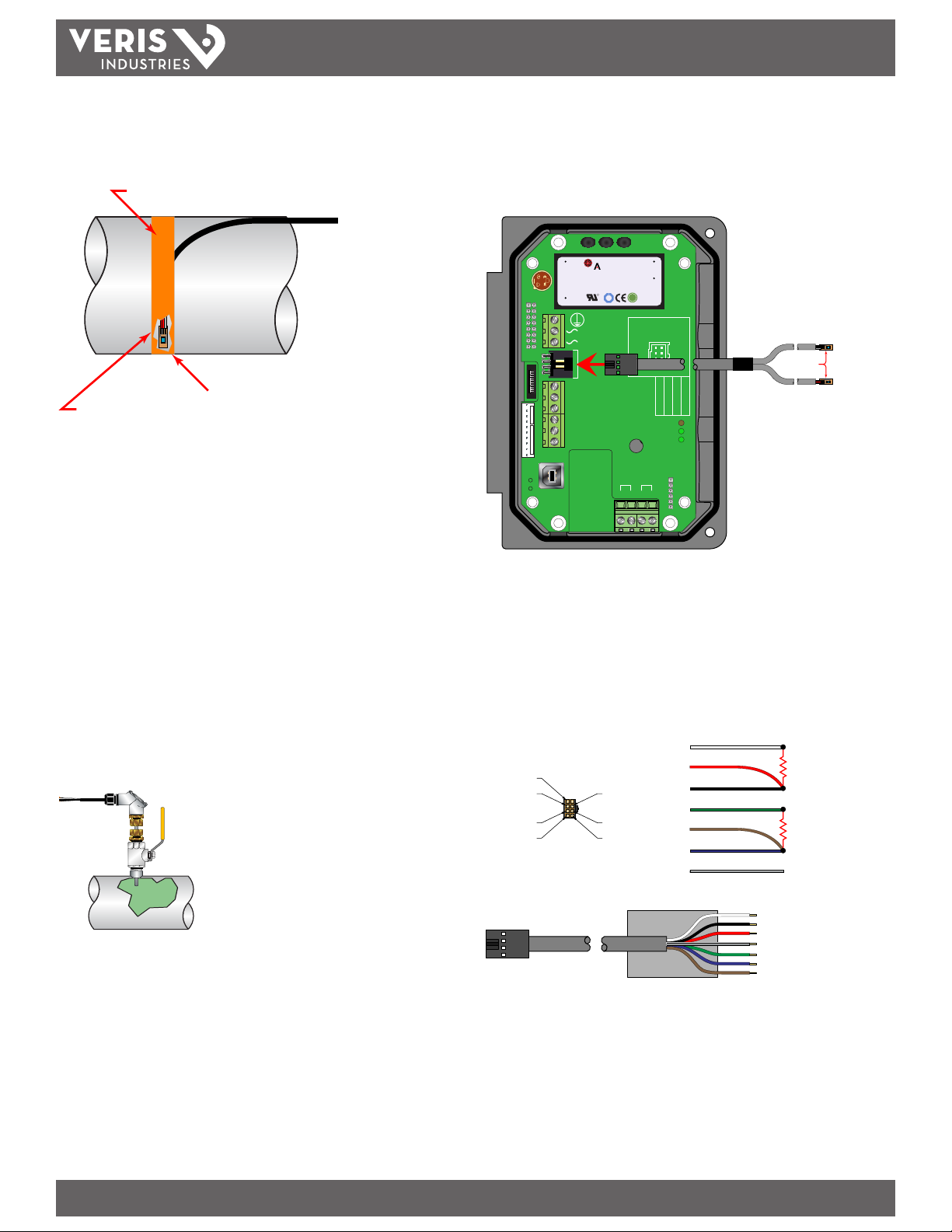

Installation of Surface Mount RTDs

Only use surface mount RTDs on well insulated pipe. Installing the RTD in an

uninsulated area causes inconsistent temperature readings.

Select areas on the supply and return pipes to mount the RTDs. Remove or peel back

the insulation all the way around the pipe in the installation area. Clean an area

slightly larger than the RTD down to bare metal on the pipe.

Place a small amount of heat sink compound on the pipe in the RTD installation

location. See Figure 3.11. Press the RTD rmly into the compound. Fasten the RTD to

the pipe with the included stretch tape.

Z205739-0D PAGE 16 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

TM

Area to Bare Metal Surface

FSRxxxx SERIES

INSTALLATION GUIDE

Route the RTD cables back to the ow meter and secure the cable so that it will not be

pulled on or abraded inadvertently. Replace the insulation on the pipe, ensuring that

the RTDs are not exposed to air currents.

Heat Tape

MINCO

Heat Sink

Clean RTD Mounting

Compound

Figure 3.11 - Surface Mount RTD Installation

Installation of Insertion RTDs

Insertion RTDs are typically installed through ¼ inch (6 mm) compression ttings

and isolation ball valves. Inser t the RTD suciently into the ow stream such that a

minimum of ¼ inch (6 mm) of the probe tip extends into the pipe diameter. Only use

insertion (wetted) RTDs on pipes that are not insulated.

Mount RTDs within ±45 degrees of the side of a horizontal pipe. On vertical pipes the

orientation is not critical. Route the RTD cables back to the ow meter and secure the

cable so that it will not be pulled on or abraded inadvertently.

If the cables are not long enough to reach the meter, route the cables to an elec trical

junction box and add additional cable from that point. Use three-wire shielded cable,

such as Belden® 9939 or equal, for this purpose.

Note: Adding cable adds to the resistance the meter reads and may h ave an eect on absolute

accuracy. If cable is added, ensure that the same length is ad ded to both RTDs to minimize errors

due to changes in cable resistance.

Wiring to Meter

After the RTDs have been mounted to the pipe, route the cable back to the meter

through the middle hole in the enclosure. Connect to the meter inserting the RTD

connector into the mating connector on the circuit board.

ACN

AC IN : 100-240VAC,50/60Hz

DC OUT :

C US

ACL

E167432

95 - 264 VAC

AC Neutral

Signal Gnd.

4-20 mA Out

Reset Total

Modbus Gnd

Modbus B

Modbus A

www.astrodyne.com

PWC-15E

1500mA250V

372

W

C US

VE

D

R

Figure 3.13 - Connecting RTDs

strodyne

+15V / 0.3A

R

+Vo

-Vo

0.15A

R2807

$

TUV

RoHS

PRODUCT SERVICE

RTD 1

RTD 2

Exc.

Exc.

Sig.

Sig.

Gnd.

Gnd.

Shield

Shield

0 to 50°C

TEMP. SET

0 to 100°C

-40 to 200°C

Modbus

TFX Rx

TFX Tx

Downstream

Upstream

-

-

+

+

RTD’s

SUPPLY LINE

MINCO

MINCO

RETURN LINE

RTD #1

RTD #2

Replacement RTDs

Complete RTD kits, including the energy meters plug-in connector and calibration

values for the replacements, are available from the manufacturer.

It is also possible to use other manufacturer’s RTDs. The RTDs must be 1000 Ω

platinum RTDs suitable for a three-wire connection. A connection adapter is available

to facilitate connection to the meter. See Figure 3.14.

WHITE

PIN #8

PIN #6

PIN #4

PIN #2

PIN #5

PIN #3

PIN #1

RED

BLACK

GREEN

BROWN

BLUE

DRAIN

RTD2

RTD1

WHITE

BLACK

RED

DRAIN

Figure 3.12 - Insertion Style RTD Installation

GREEN

BLUE

BROWN

Figure 3.14 - RTD Adapter Connections

Note: It will be necessary to calibrate third par ty RTDs to the meter for proper operation. See the

Appendix of this manual for the calibration procedure.

Z205739-0D PAGE 17 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

PIN#5

PIN#3

PIN#1

PIN#8

PIN#6

PIN#4

PIN#2

TM

FSRxxxx SERIES

PART 4 - STARTUP AND CONFIGURATION

Before Starting the Instrument

Note: Flow meter systems require a full pipe of l iquid before a successful start-up can be

completed. Do not at tempt to make adjustmen ts or change congurations until a full pipe is

veried.

Note: If Dow 732 RTV was used to couple the transducers to the pipe, the adhesive must be

fully cured before readin gs are attempted. Dow 732 requires 24 hours to cure satisfactoril y. If

Sonotemp® acoustic coupling grease was utilized as a coupla nt, curing is not required.

INSTALLATION GUIDE

Instrument Startup

1. Verify that all wiring is properly connec ted and routed, as described in Part 1 of

this manual.

2. Verify that the transducers are properly mounted, as described in Part 2 of this

manual.

3. Apply power. The display briey shows a software version number and then all of

the segments illuminate in succession.

Important!: In order to complete the installation of the ow meter, the

pipe must be full of liquid.

To verify proper installation and ow measurement operation:

1. Go to the SER MENU and conrm that signal strength (SIG STR) is between 5 and

98. If the signal strength is lower than 5, verify that proper transducer mounting

methods and liquid/pipe characteristics have been entered. To increase signal

strength, if a W-Mount transducer installation was selected, re-congure for a

V-Mount installation (standard from factory); if V-Mount was selected, recongure for Z-Mount.

Note: Mounting conguration change s apply only to FST4, FST5 transducer sets.

2. Verify that the actual measured liquid sound speed is within 2% of the value

entered as FLUID SS in the BSC MENU. The measured liquid sound speed (SSPD

FPS and SSPD MPS) is displayed in the SER MENU. The pipe must be full of liquid in

order to make this measurement.

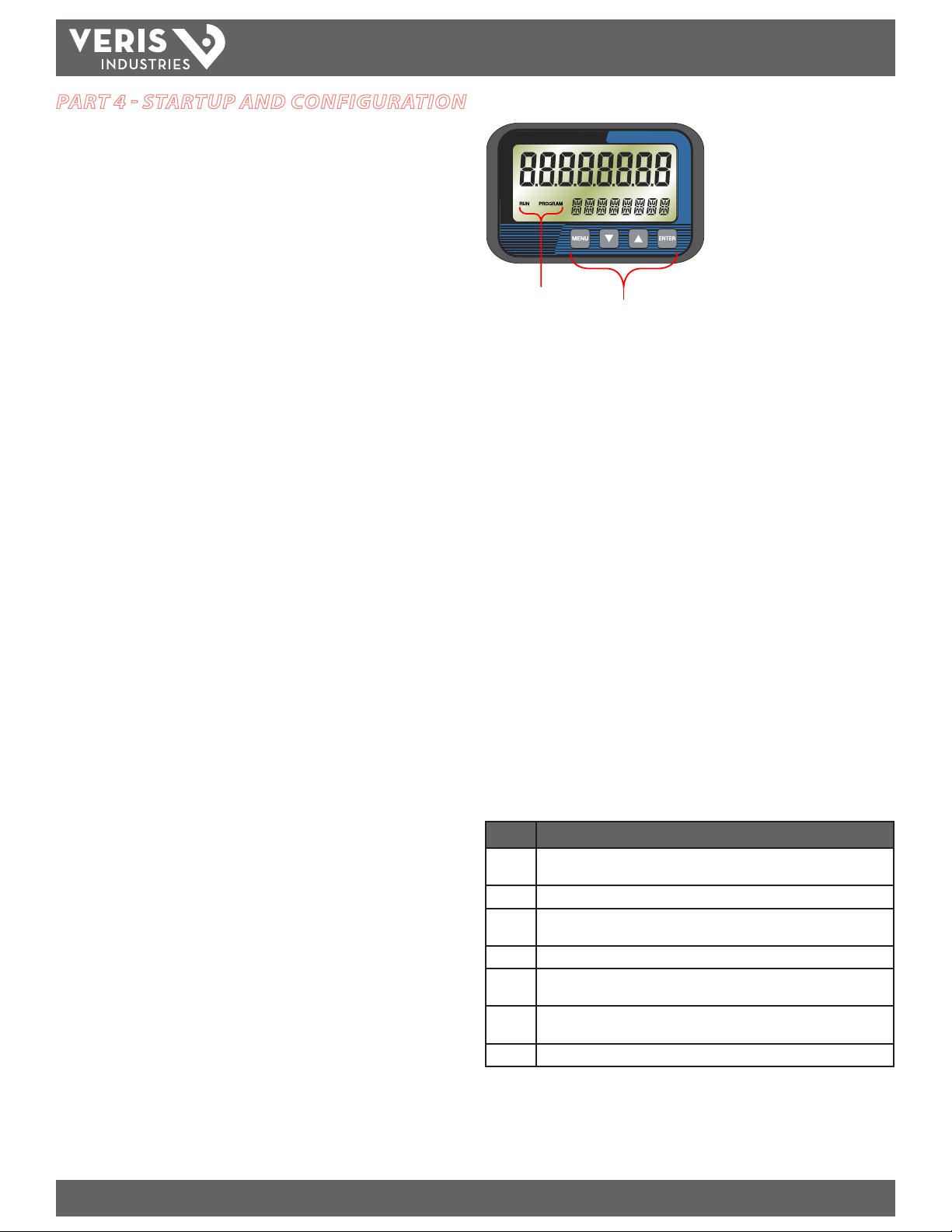

Keypad Programming

Congure units with keypads using the keypad interface or by using the Windows®

compatible software utility. Units without a keypad can only be congured using the

software utility. See Part 5 of this manual for software details. Of the two methods

of conguration, the sof tware utility provides more advanced features and oers

the ability to store and transfer meter congurations between meters. All entries

are saved in non-volatile ash memor y and are retained indenitely in the event of

power loss.

The four-key tactile feedback keypad interface allows the user to view and change

conguration parameters used by the operating system.

Mode

Indicators

Figure 4.1 - Keypad Interface

Keypad

1. Press the MENU key from RUN mode to enter PROGRAM mode. Press the MENU key

in PROGRAM mode to exit from conguration parameter selection and menus. If

changes to any conguration parameters are made, the user is prompted with a

SAVE? when returning to RUN mode. Choose YES to save the new parameters in

program memory.

2. The arrow ▼ keys are used to scroll through menus and conguration

parameters. The arrow keys are also used to adjust parameter numerical values.

3. The ENTER key functions are:

• Pressed from the RUN mode to view the current software version

operating in the instrument.

• Used to access the conguration parameters in the various menus.

• Used to initiate changes in conguration parameters.

• Used to accept conguration parameter changes.

Menu Structure

The ow meter rmware uses a hierarchical menu struc ture. A map of the user

interface is included in the Appendix of this manual. The map provides a visual path

to the conguration parameters that users can access. Employ this tool each time

conguration parameters are accessed or revised.

The seven menus used in the software are as follows:

Menu Description

BSC Basic. Contains all of the conguration parameters necessary to initially program

CH1 Channel 1. Congures the 4-20 mA output.

CH2 Channel 2. Congures the type and operating parameters for channel 2 output

SEN Sensor. Used to select the sensor type (i.e. FST1, FST2, etc.).

SEC Security. Used for resetting totalizers, returning ltering to factory settings, and

SER Service. Contains system settings used for advanced conguration and zeroing

DSP Display. Used to congure meter display functions.

the meter to measure ow.

options. Channel 2 parameters are specic to the model used.

revising the security password.

the meter on the pipe.

Z205739-0D PAGE 18 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Loading...

Loading...