Page 1

TM

EnvironmEntal SEnSorS

EP2 EP2

available

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• Read and understand the instructions before installing

this product.

• Turn off all power supplying equipment before working on it.

• The installer is responsible for conformance to all applicable codes.

inStallation GUiDE

Electropneumatic Transducer

Installer’s Specifications

Power Supply 22-30VDC, 20-30VAC, 47-63 Hz, 150mA max.

Control Input 4-20mA, 0-10V, 0-5V; jumper selectable

Input Impedance 4-20mA, 250 Ω; 0-5/0-10V, 10 kΩ

Manual Override Jumper selectable mode, digital pushbutton adjust

Alarm Contact 100mA@30VAC/DC (If equiped)

Accuracy 1% full sc ale; combined linearity, hysteresis, repeatability

Compensated Temperature Range -4°C to 60°C (2 5° to 140°F)

Temp Coecient ±0.05%/°C

Operating Environment 10-90% RH, non-condensing; -4°C to 60°C (25 ° to 140° F)

SCIM 52 3 in

333 in

Supply Pressure 45 psig max.

Control Range 0-20 psig or 3-15 psig jumper select able

Pressure Dierential 0.1 psig (supply to branch)

Pressure Indication Electronic, 3-1/2 digit LCD

Minimum Tubing Length 15 feet

Port Connection 1/8” i.d. poly tubing

Media Connection Clean dry air or inert gas. Not for use with ox ygen service

EMC Conformance: EN 61000- 6-3:2007 and A1:2011 Class B, EN 61000-6-1:2007

EMC Special Note: Connect this produc t to a DC distribution network or an AC/DC powe r adaptor

with proper surge protection (EN 61000-6-1:2007 specication requirements)

3

/min.@45 psi; 8520 cm3/min@310.3 kPA;

3

/min@20 psi; 5407 cm3/min@137.9 kPA

ProDuct iDentification

EP2

Output

1

= Selectable

3-15 /0-2 0 ps i

Feedback

0 = None

1 = Pressur e

Loss Alarm

2 = Manual

Mode Alarm

Failsafe

0 = None

1 = Vent on

Powe r Fail

US or EU

S = Standard

C = CE (includes cov er

plat e.)

Option

Blank = none

1 = Slide Switch /

Auto/Manual

2 = EP Cover Plate

3 = Slide Switch /

Auto Manual plus

EP cover plate

oPeration

The EP2 electropneumatic pressure transducer uses micro-controlled poppet valve

technology for highly accurate pressure sensing. The poppet valves consume no air,

eliminating unnecessar y air losses in the system and allowing for stable and reliable

operation. The EP2 is comes installed on standard SnapTrack, and an optional cover

is available to protect from dust and other environmental factors. An LCD display and

LED indicators make it easy to read system status at a glance.

installation

Observe precautions for handling static sensitive

devices to avoid damage to the circuitry that

is not covered under the factory warranty.

1. Mount the transducer using the screws provided. Avoid damaging the electronic

components.

2. Wire the transducer and congure the jumpers for desired operation as shown in

the Wiring and Conguration section on the following page.

4. Attach pressure tubing to the hose barbs. Observe MAIN and BRANCH port labels.

Use exible ¼” O.D. poly tubing for the main and branch pneumatic connections.

Main supply pressure must not exceed 45 psig.

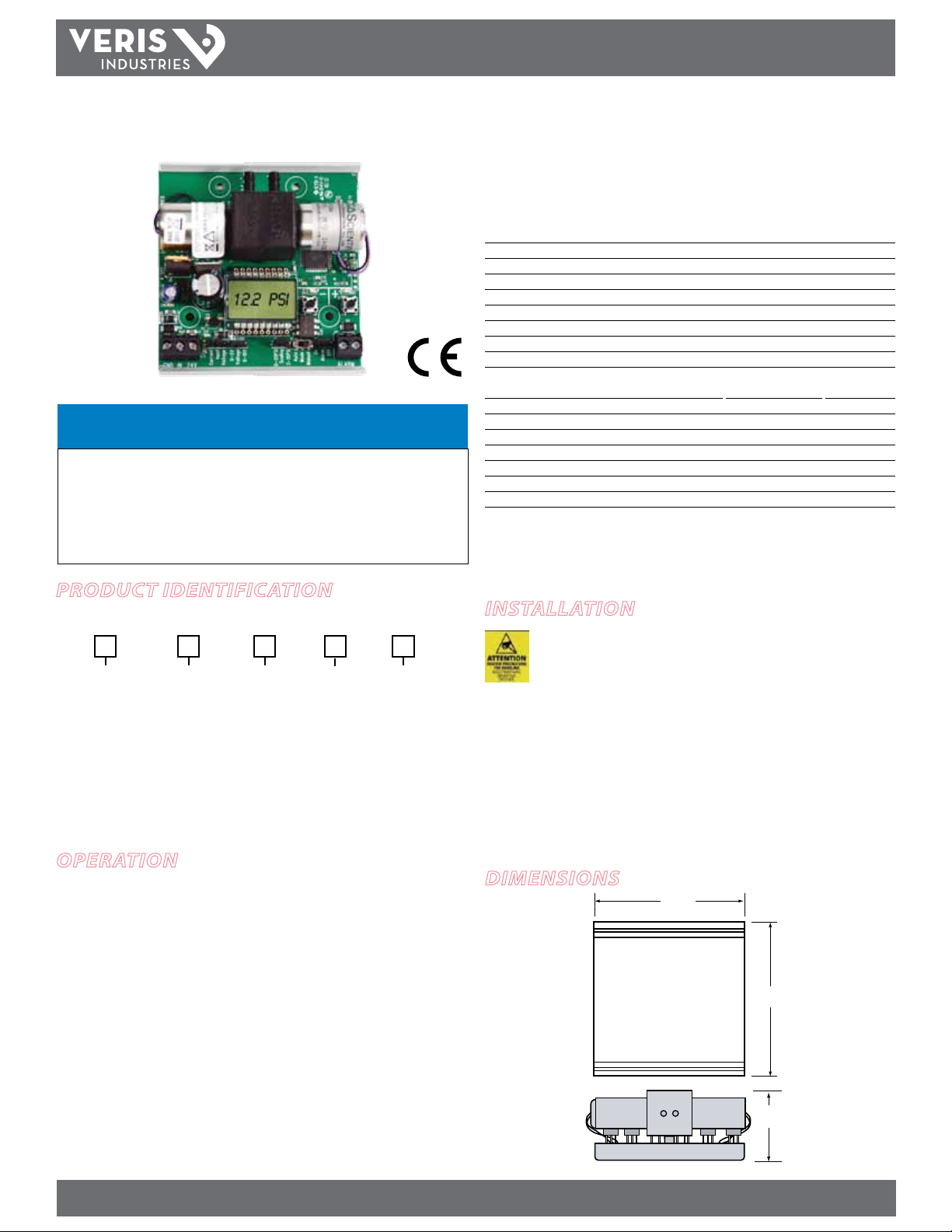

Dimensions

3.3"

(84 mm)

3.5"

(89 mm)

1.9"

(48 mm)

Z203044-0U PAGE 1 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countr ies.

Page 2

TM

ALARM

MODE

MANUAL ADJUST

ON

OFF

Auto

Mode

Manual

0-20psi

3-15psi

0-5V

0-10V

Current

Voltage

GND/COM

INPUT SIGNAL

POWER

PRESSURE

RANGE

PRESSURE

LOSS

ALARM

(OPTIONAL)

OPERATION

MODE

INPUT

MODE

VOLTAGE

MODE

SLIDE

SWITCH

OPTION

AVAILABLE

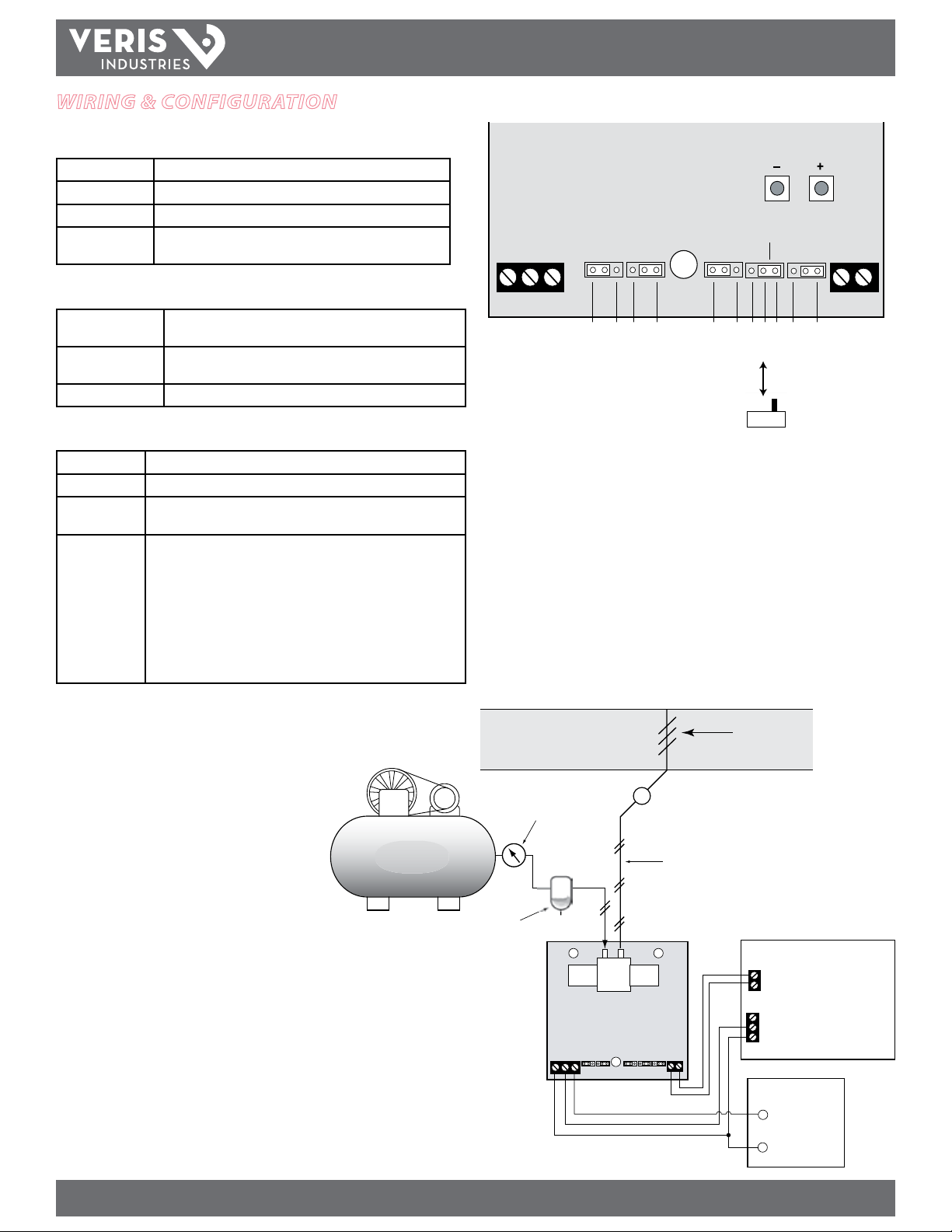

WirinG & confiGuration

Jumper Configuration

Input Current (4-20 mA) or Voltage (0-5 V or 0-10 V)

Voltage For voltage mode of operation, select 0-5 V or 0-10 V

Pressure Range Select 0-20 psi or 3-15 psi scaling

Operation Mode Select AUTO for normal operation or MANUAL to adjust pressure

using the pushbuttons

Options

EP2

inStallation GUiDE

Alarm Mode Relay The alarm contacts open if the EP2 cannot obtain 80% of

commanded pressure within two (2) minutes

Manual Mode Alarm Contacts open when manual mode is selected (auto mode contacts

are closed)

Vent On Power Fail The EP2 vents the branch line pressure on power failure

Terminal Block Connections

GND/Common Power supply ground and signal common.

Input Signal 4-20 mA, 0-10 VDC, or 0-5 VDC input from the control system.

Power 22-30 VDC, 20-30 VAC. From the control system or external power

Pressure Loss

Alarm (optional)

NOTE: In 24 VAC transformer applications, on e side of the transformer secondary is connected to

the signal common. Some control sys tems may require a dedicated power su pply transformer or

isolation transformer.

supply or transformer.

Normally closed, solid-state contacts open if the main supply pressure

fails or if the transducer is otherwise unable to produce the correct

branch pressure. Connect to the digital input of the control system for

alarm status indication. If commanded pressure does not reach 80%

within 2 minutes, the alarm contacts open.

• 0-20 psi alarm contact does not change state when the

commanded pressure is 4 psi or less

• 3-15 psi alarm contact does not change st ate when the

commanded pressure is 5.4 psi or less

DUCT

DAMPER

20-45 PSI OUT

REGULATOR

AIR COMPRESSOR

TO DAMPER

TRAP/FILTER

CONTROL PANEL

EP21XX

GND

INPUT

POWER

Z203044-0U PAGE 2 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 07121

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countr ies.

DIGITAL IN

PRESSURE LOSS ALARM

DIGITAL INPUT

(CONTACT CLOSURE)

ANALOG OUT (0-5/0-10, 4-20mA)

COMMON

VERIS PS-24 Series

+

POWER SUPPLY

24VAC/DC

-

Loading...

Loading...