Page 1

OM17-P4000 Force/EC

Operating Instructions

EC Force Probe

Table of Contents

Section 1

1-1 Warranty & Safety

Section 2

2-1 System Overview P4000

2-3 System Overview Electronics

Section 3

3-1 Software Installation Guide

Section 4

4-1 Field Operations – Electronics

Section 5

5-1 Probe Platform Installation

5-3 Platform Operation

5-4 EC - Force Probe Operation

5-6 Soil Coring

5-8 Soil Anchoring System

5-10 Probe Removal and Tractor Installation

Section 6

6-1 Maintenance and Lubrication

6-4 Probe Removal

6-5 Case Removal

Section 7

7-1 Troubleshooting

Section 8

8-1 Specifications

1-1

Page 2

OM17-P4000 Force/EC

Warranty

Veris Technologies warrants this product to be free of defects in materials and

workmanship for a period of one (1) year from the date of delivery to the purchaser.

Veris Technologies will repair or replace any product returned to Salina, Kansas, which

appears upon inspection to be defective in materials or workmanship. Veris

Technologies will have shall have no obligation under this warranty for the cost of labor,

down-time, transportation charges, or for the repair or replacement of any product that

has been misused, carelessly handled, modified, or altered.

ALL OTHER WARRANTIES OF ANY KIND, WHETHER EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE AND ALL

CLAIMS FOR CONSEQUENTIAL DAMAGES, ARE SPECIFICALLY DISCLAIMED AND

EXCLUDED.

Safety

1-2

Page 3

OM17-P4000 Force/EC

Important! Read the following SAFETY PROCEDURES before operating the Veris

P4000

• Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid

the hazard by relieving pressure before disconnecting hydraulic lines. Use a piece of

• Use paper or cardboard, NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and

high-pressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must

be surgically removed within a few hours or gangrene may result.

• Pinch point hazard: to prevent injury, stand clear when raising

or lowering any part of the Veris P4000.

• Install all transport locks before transporting or working underneath.

• Detach and store implements in an area where children normally do not play. Secure

implement by using blocks and supports.

• Keep feet clear of foot and probe when lowering.

• Do not probe where utility lines may be present. Use ‘Call Before You Dig’ services.

• Use paper or cardboard, NOT BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and

high-pressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must

be surgically removed within a few hours or gangrene may result.

• Read Operations Manual before operating machine

• Review safety instructions with operators before operating machine and at least

annually

• Riders obstruct the operator’s view. They could be struck by foreign objects or

thrown from the machine.

• Never allow children to operate equipment.

• To prevent possible electrical shock, or damage to the instrument, do not connect to

any power source greater than twelve (12) volts DC.

• Do not grease or oil implement while it is in operation.

• Disconnect battery ground cable (-) before servicing or adjusting electrical systems or

before welding on implement.

• Remove buildup of mud, oil or debris.

• Be prepared if a fire starts

• Keep a first aid kit and fire extinguisher handy.

• Be careful when touching the probe after use, the sapphire window gets hot.

1-3

Page 4

OM17-P4000 Force/EC

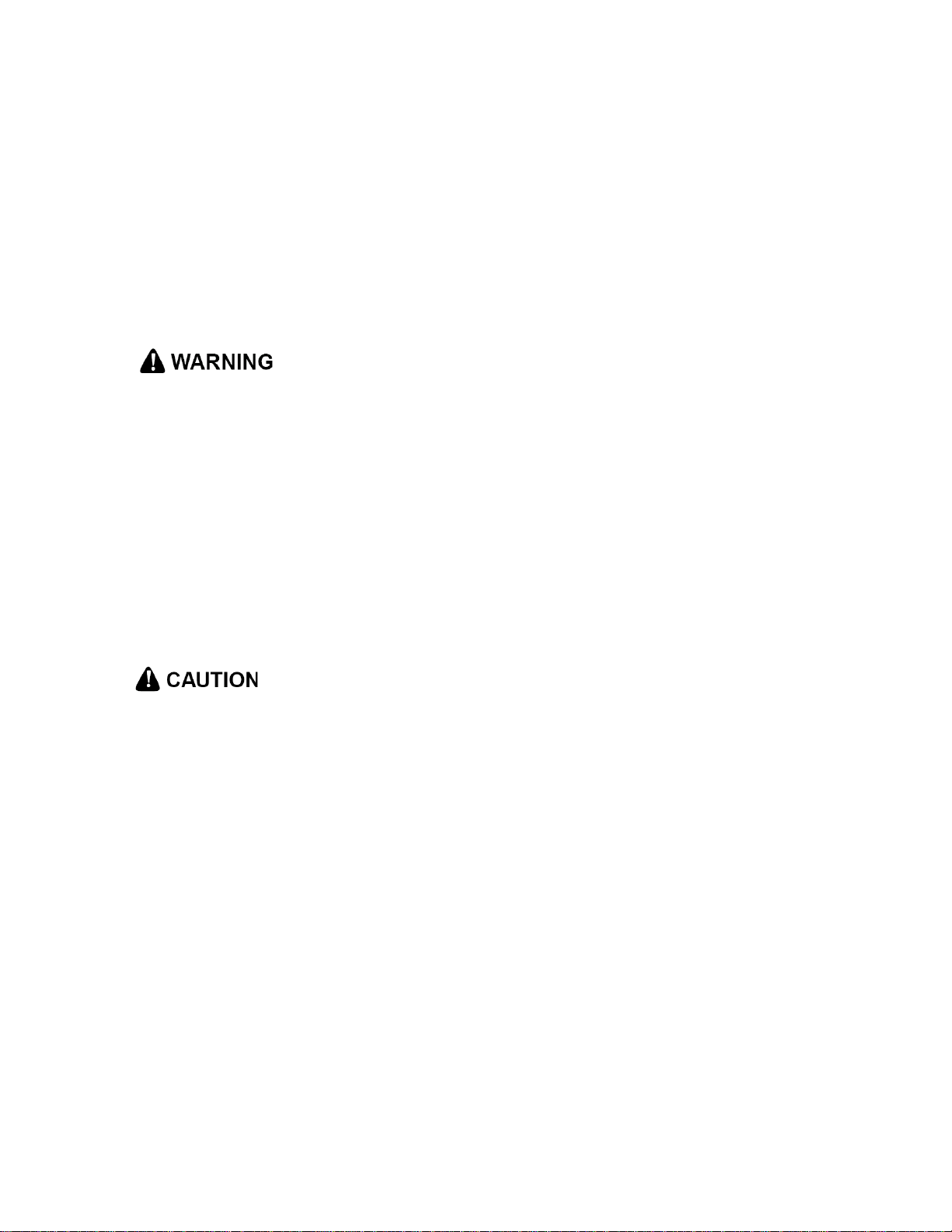

Hyd sight

gauge

Fuel Tank

Figure 1

Starter Switch

Choke

Throttle

Figure 2

Section 2

VERIS P4000 Probe Platform

System Overview

Before you begin using your P4000, it’s important to familiarize yourself with the basic

components and controls

Pre-operation checks:

1) Engine oil Level – refer to Honda GX 670 engine manual

2) Hydraulic fluid -- fluid level should be at or near upper black line on sight gauge

of hydraulic reservoir. (Figure 1). If not add suitable ISO 32 hydraulic fluid with a

viscosity index of 95- 140. Unit is filled at factory with Mobilfluid 424.

3) Check gas level – unleaded gasoline only

4) Check for any loose fasteners or hydraulic leaks.

Controls:

1) Engine controls are located on the engine itself. (figure 2) . Refer to Honda

engine manual for detailed information.

2-1

Page 5

OM17-P4000 Force/EC

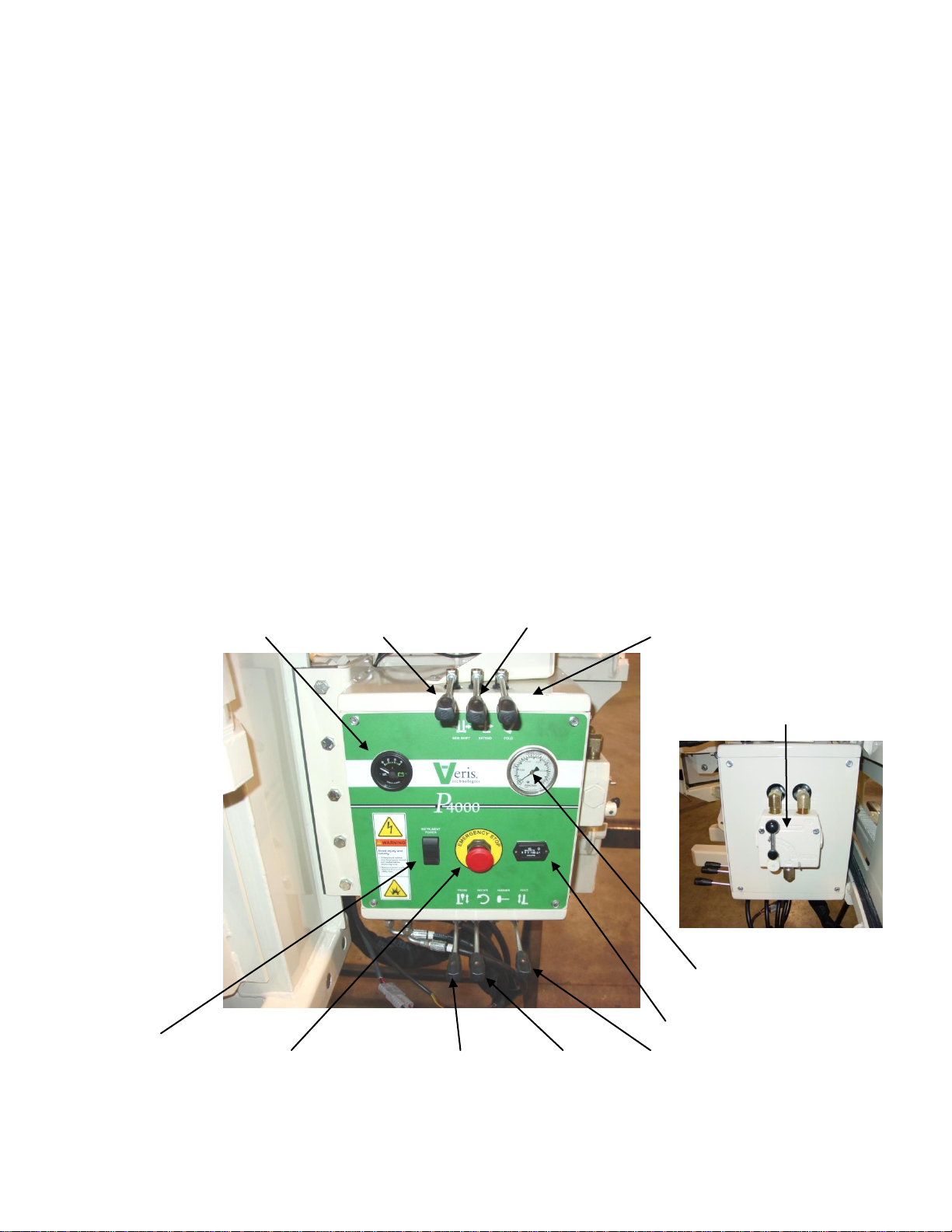

Figure 3

Figure 4

Voltage meter Side Shift control Extension control Fold control

Probe speed

Flow control

12v power switch Engine emergency stop Probe control Rotation control Foot control

Hyd pressure gauge

Engine hour meter

Hydraulic Controls

All system monitoring and probe control functions are contained on the

console mounted to the right of the probe, referred to as the “foot”. (Figures 3,4)

a) Voltage meter – monitors battery voltage

b) Side shift control – allows lateral movement of probe for multiple insertions at

a given location.

c) Extension control -- used to extend probe from transport to field use position

d) Fold control – folds probe from transport to use position

e) Probe speed flow control – controls insertion speed of NIR/EC Force Probe to

operator preference

f) Hydraulic pressure gauge – monitors system pressure during hydraulic

cycling

g) Hour meter—monitors engine operation for routine maintenance

h) Foot Control – Raises and lowers foot

i) Rotation control – aids in soil core insertion in tough soils. Down is clockwise-

direction required for coring.

j) Probe control – Raises and lowers probe assembly

k) Engine emergency stop – immediately shuts down engine if need arises.

l) 12VDC power switch for auxiliary and spectrometer power.

2-2

Page 6

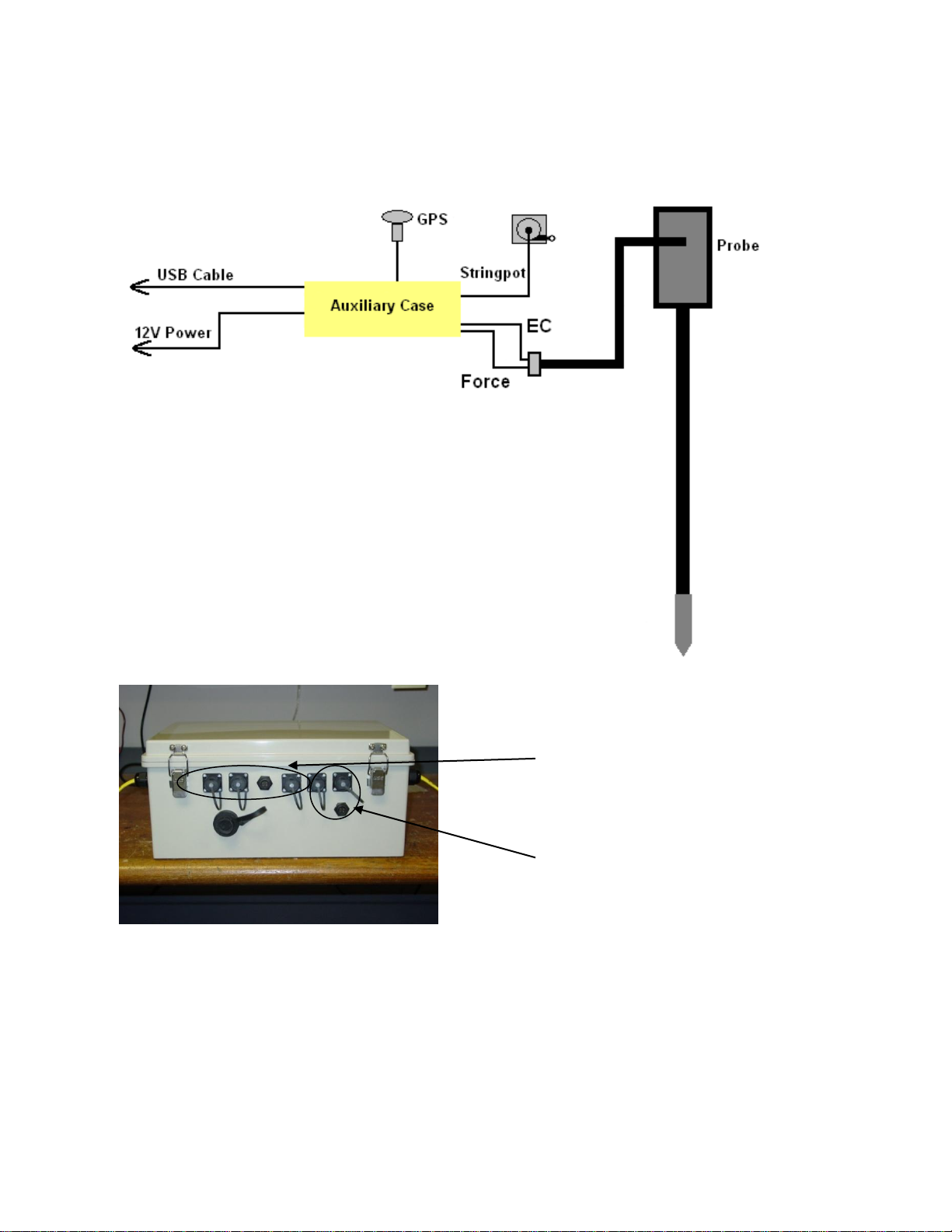

The first four connections are

only used with the VIS NIR

probe

Only these three connections

are used with the Force EC

probe

System diagram

OM17-P4000 Force/EC

Electronics

Figure 5

Figures 6

2-3

Page 7

Figure 7&8

Probe module

#38145

Cable that includes force and EC

connections

Garmin GPS

# 21221

GPS adaptor cable #30727

Note: This adaptor cable is

required in order for

compatibility with the provided

Garmin GPS.

GPS serial adaptor cable

#35482

This will connect the serial port of a GPS to the

GPS port on the auxiliary case, for using an

alternate GPS to the Garmin. External power is

required for the GPS to function.

Figure 11 EC test load

#10447

OM17-P4000 Force/EC

Figure 9

Figure 10

2-4

Page 8

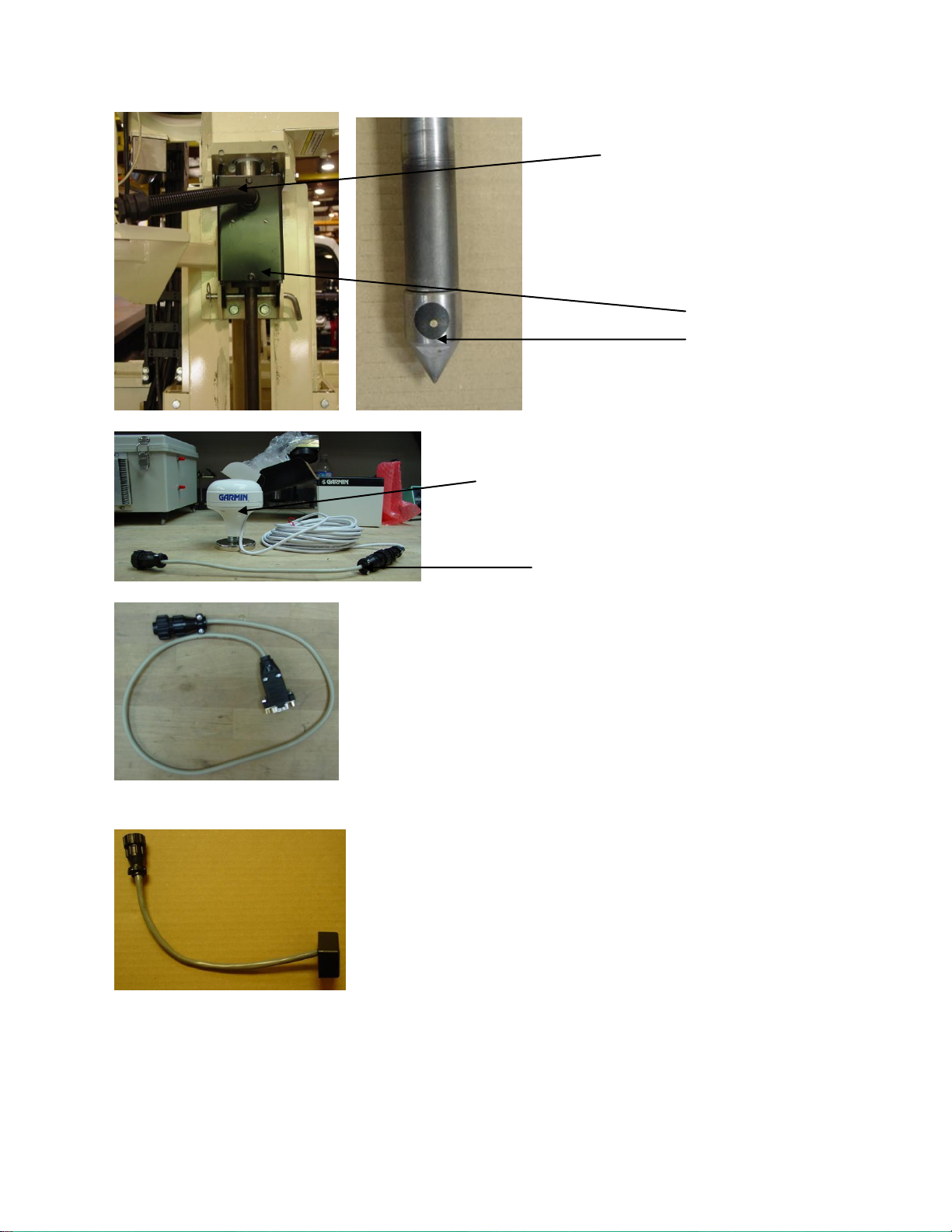

Figure 12

5-meter USB cable

#30281

Power cable

#39985

This is used to power the

instrument from a vehicle (for

field use).

Note: Only use 5-amp fuse

String Pot #SC160

String Pot Cable #38866

Figure 14

Figure 15 EC Dipole Tester #29689

OM17-P4000 Force/EC

Figure 13

2-5

Page 9

OM17-P4000 Force/EC

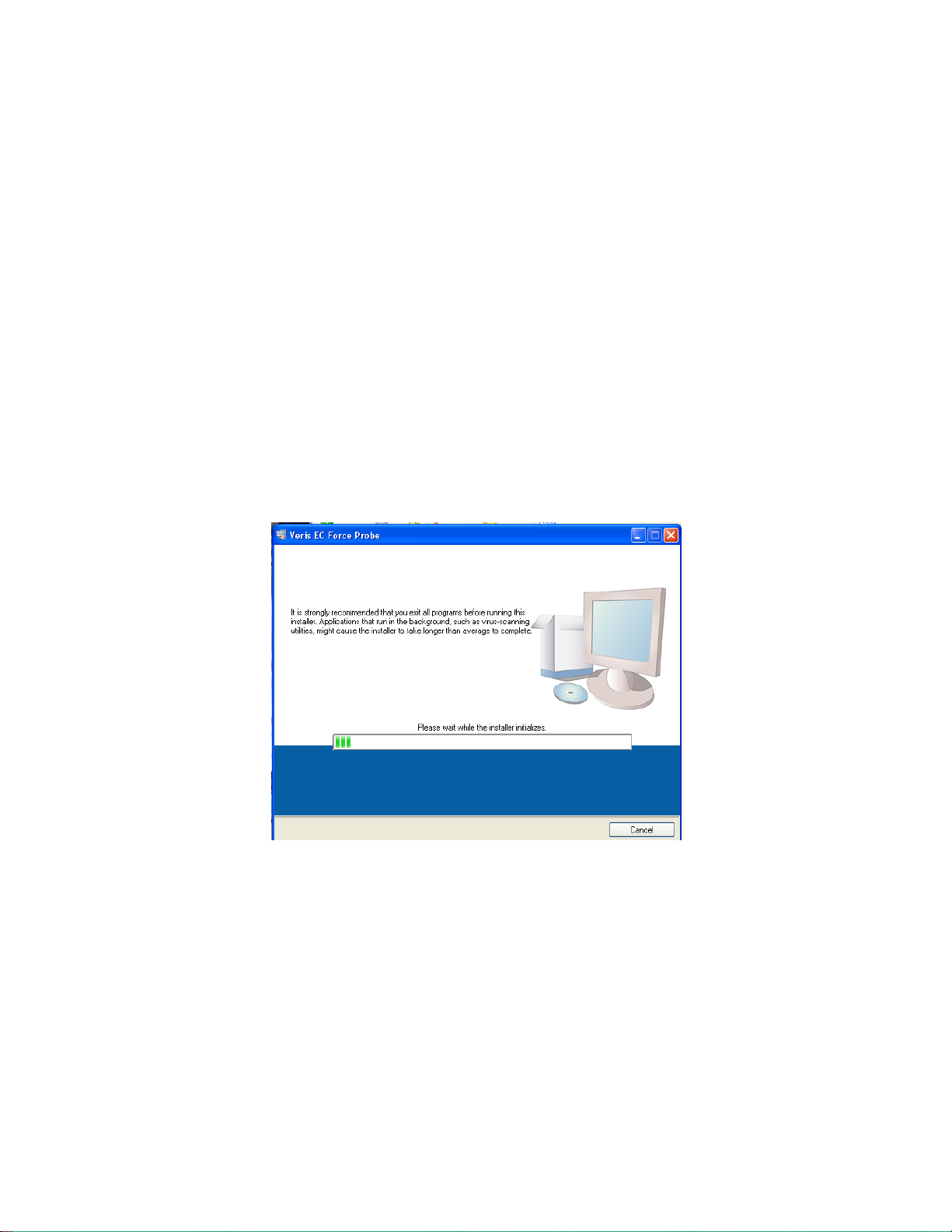

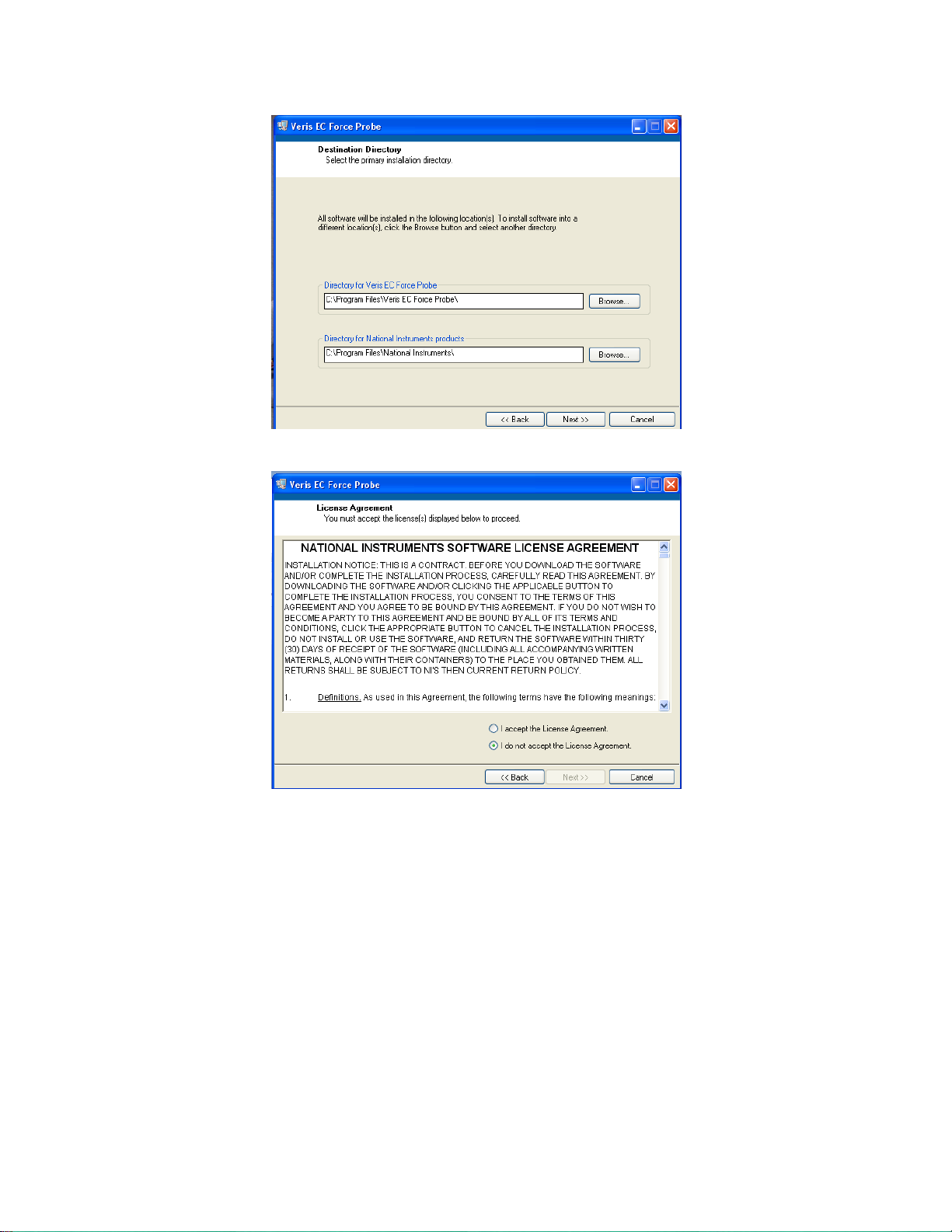

The Veris EC - Force

Software installer will

guide the user through

installation of the Veris

operating software and

the necessary drivers

needed to run the

Auxiliary case. Note:

Do not plug in USB

cable for case at this

time.

Section 3

Software Installation and Setup

Software Installation

Note: For computers outside the United States of America, please make the following

change to the computer’s regional settings before installing the Veris

Spectrophotometer Software.

Step 1: Open control panel and double click on Regional and Language Options

Step 2: Click on Customize, the following screen will appear. The Decimal symbol

needs to be a “.” while the Digit grouping symbol needs to be a “,”. The will ensure

proper operation of the software. Once the changes have been made click OK and

proceed with installation.

Veris EC - Force Software Installation

Figure 1

3-1

Page 10

Figure 2

Only install

software in the

default directory.

If a different

directory is

chosen then the

auxiliary case

will not be able

to find the

correct drivers.

OM17-P4000 Force/EC

Figure 3

3-2

Page 11

Figure 4

Click next to install

software

Click finish to exit installer

Figure 5

Figure 6

OM17-P4000 Force/EC

3-3

Page 12

OM17-P4000 Force/EC

Any name or number can be used for

the file name

After typing name click save to

continue

Figure 1

Figure 2

Figure 3

Section 4

Field Operation - Electronics

The Force EC probe software will acquire a EC and force measurement for every 2cm

the probe is inserted. Before opening software turn on power to the auxilary case and

connect via USB cable to the PC. To begin data acquisition open the software and

select a file to be saved.

Once a file is selected the software will search for connectivity with the auxiliary case.

Three communication ports are used to process the data. After each connection is

established the corresponding light will turn green. If no connection is made, the

software will continue to the next port and try to establish a connection later. If no green

light is given for any of the three ports the software will not be able to aquire data. In

this senario, check for 12V to the case and ensure the USB cable is connected. If a

connection can still not be established, then unplug the USB cable, shut down power to

the instrument, and restart the software. If no connection is made still then unplug the

USB cable and restart the computer. Once the computer is back up, plug in the USB

cable and open the software again.

4-1

Page 13

OM17-P4000 Force/EC

Place the probe tip at the desired

starting point, check to ensure the

GPS signal light is green and press

log or hit Enter and begin to insert

the probe to store data. The log

light will turn green indicating the

software is in log mode. Data is

collected and averaged every 2cm.

Once the 2cm interval is reached

the data light will flash and the data

is written to the output file. Once the

desired depth is reached pull the

probe out and Log will be shut off.

The log button will need to be

pressed for again to start sampling

another location.

Depth will be -1

until log is

pressed.

The EC readings will give the

following error codes:

-1 = Low Current this condition

can occur when the probe is out

of the ground, or in dry soils

-2 = Low Voltage this condition

occurs when the dipole is

shorted. Check EC tip isolation

under the troubleshooting

section

-4 = High Voltage this condition

occurs when the dipole is open.

Check EC tip isolation under the

troubleshooting

Figure 4

.

4-2

Page 14

OM17-P4000 Force/EC

14” from rear edge

to rear of bumper

Section 5

Field Operation

P4000-S

Installation

The P4000-S is designed to be installed in ¾ ton – 1 ton pickups and due to the wide

range of bed and frame dimensions on the market, there are no mounting holes in lower

frame flange. Some drilling and fabrication will be required. You may choose to

perform this on your own, or may wish to have a local welding or truck shop do this for

you.

Steps:

1) Properly lift probe assembly in folded position with a minimum of two nylon straps

and lower into pickup bed.

2) Center side-to-side in bed and so rear portion of skid frame rail is 14” forward of

farthest point on rear bumper (Figure 1). This will ensure that foot will not contact

bumper when the skid is in the retracted position.

3) Ideally 4 mounting bolts (½” Gr5) are adequate for fastening the probe skid to the

frame of the truck. Choose mounting location based on frame obstructions such

as spring hangers, fuel tank hoses, etc. This will take some time, measuring both

top and underneath the bed to make sure bolts will align with skid frame

4) Locate all four positions and fabricate “L” straps from at least 3/8” material and

bolt or weld to frame. Make sure that fuel tanks, fuel line, and brake lines are not

in danger of being drilled or welded. Drilling is preferable and two ½” bolts in the

vertical position are adequate. (Figure 2)

Figure 1

5-1

Page 15

OM17-P4000 Force/EC

Figure 1

Figure 2A & B

Start out with ¼”

pilot hole for

drilling up through

Top View

Figure 3

Figure 4

“L” straps as templates, you can drill the hole through the bottom side of the skid

frame rail. Tip: If you start out with small pilot holes (1/4”or less) it takes less

effort to drill through the bed and frame rail, then drill out to full dimension from

on top.

6) If for some reason you must locate one or two of lower “L” mounts ahead or

behind the skid frame rail, you can fabricate some clips to hold down in place.

Ideally at least two bolts should go through the skid frame to ensure that probe is

properly connected to bed (Figure 3)

5) Using the

7) Securely bolt down and connect power cable to battery of vehicle.

5-2

Page 16

OM17-P4000 Force/EC

Figure 5

Figure 6

KEEP FEET CLEAR OF

FOOT AND PROBE

Field Operation

Probe Platform

- Start engine and allow to warm a minute or two before cycling – a few minutes if

during cold weather.

- Extend to full rear position

- Fold into upright position (figure 5)

- Lower foot to soil

- Raise probe (figure 6)

- Install Probe or core sampling

components

Important! -- When folding and retracting the platform make sure that

probe mast clears engine muffler. This can be achieved by shifting left to right as

you fold the unit.

5-3

Page 17

OM17-P4000 Force/EC

KEEP FEET CLEAR OF

FOOT AND PROBE.

Figure 7

Figure 8

Field Operation

EC - Force Probe

Checking Electrical Signal Continuity and Electrode Isolation

It is recommended that you routinely check the EC signal to verify that all functions are

working properly. See Maintenance and Lubrication Section for a step-by-step

procedure. It is advisable to perform this test on a routine basis (weekly or every 20-25

hours of data collection) to ensure you are obtaining reliable data.

Operation

Begin field operation by lowering the foot to the soil. Remove hairpin from string pot

piston (Figure 7) Set probe speed --- not recommended over 3cm/sec. This is

adjustable via the probe speed flow control on the side of the control panel. (Figure 9)

Lower the EC - Force Probe until the EC tip is at the desired starting point, usually just

below the surface of the soil. Press LOG in the EC – Force software to begin collecting

data. After reaching the desired depth pull probe out to stop logging data.

5-4

Page 18

OM17-P4000 Force/EC

Figure 9

Speed

Probe speed is not recommended over 30mm/sec, for optimal data resolution. This is

adjustable via the probe speed flow control on the side of the control panel. (Figure 9

above) A maximum probe speed of 50mm/sec should not be exceeded or else data

could be missing from the output file.

Field Condition

Field should be in a uniform state. Probe after intensive primary tillage is not

recommended. The soil must have a minimum of 10% available water, and cannot be

frozen.

Vehicle Requirements

The probe may be mounted on a variety of vehicles. The 3 point configuration allows

use on a 30-50hp tractor. While the optional skid platform requires a 4X4 pickup.

5-5

Page 19

OM17-P4000 Force/EC

Figure 10

Figure 11

Figure 12

Field Operations

Soil Coring

Once you have competed probing, remove EC - Force probe as outlined in Section 6.

- Install drive coupler to rotating head by means of drive retainer (Figure 10)

- Install PETG liner onto cutting shoe and thread into sampling tube (Figure 11)

- Install sampling tube into drive coupler and push into soil.

Use slow and steady insertion speed and minimal

rotation to push core sampler into the soil. A brief

rotation at bottom of stroke will snap off the core in

tight clay, giving you a fuller core as you retract.

(Figure 12) Excessive rotation may affect the

condition of your cores.

5-6

Page 20

OM17-P4000 Force/EC

Figure 13

Figure 14 Figure 15

Remove sampler tube and remove cutting shoe from sampling tube by tapping and

rotating, or by use of wrench (provided). (Figure 13)

Cap the lower end of core with black vinyl cap, and the top with red. (Figures 14-15)

5-7

Page 21

OM17-P4000 Force/EC

Figure 16

Figure 17

Field Operations

Optional Anchoring System

In some field conditions it may be necessary to drive soil anchors into the soil to obtain

adequate depth with probe or core sampler. If this is the case, you will need PN 40209

Anchoring Package.

Installation and Removal

- Retract probe until is in the most forward position.

- Side shift to the far right and lower foot.

- Place anchor in center of foot opening and lower probe drive until hex enters hex

drive on probe. (Figure 16)

- Drive in slowly using Probe and Rotation controls. Apply adequate force to push

as you rotate. If you rotate too rapidly, the anchor will simply auger a hole, and

will not anchor properly --- Drive in until all flighting is below ground level and

probe is at bottom of stroke.

- Raise foot, side shift to far left, and repeat this process. (Figure 17)

5-8

Page 22

1. Extend platform out to full extension

Figure 18

2. Attached chain binders on each side of probe

3. Slip anchor plates over anchors and bind down each side (figure 18)

OM17-P4000 Force/EC

- Anchoring will limit your side travel somewhat, but you should still be able to take

multiple cores with the anchors installed.

- Do not use extension control while anchors are connected

- Remove the anchors in reverse sequence.

- If anchors have shifted during use and you are unable to slide the hex head of

the anchor back into the hex drive – use the foot to gently nudge the anchor back

into re-alignment.

Note: Be careful when lowering the probe with the instrument cases in

place. Remove left hand anchor first – otherwise you might push the head

of the anchor into the instrument mount when lowering probe to remove

RH anchor.

5-9

Page 23

OM17-P4000 Force/EC

Figure 19 P & T Hoses

Figure 20

Field Operations

P4000T Removal and Tractor installation

The P4000 is designed to work equally well on a tractor, or as a skid mount unit.

Removing probe from skid –

- Install three point stabilizer stands into probe and temporarily lock in mid position

with ¾” pinch bolt.

- Extend and unfold the probe.

- Lower foot to ground level.

- Remove fold cylinder pin, and carefully retract fold cylinder until it is fully

retracted. You may have to gently move fold control valve back and forth to

relieve pressure on pin for removal.(Figure 19)

- Carefully remove lower link pins and lower probe down by retracting foot cylinder

- Lower stabilizer stands and lock with ¾” bolt

- Retract probe platform and shut of engine. (Figure 20)

- Disconnect wiring and 4 hoses on bottom of console (Figure 21)

- Disconnect main Pressure and Tank hose from platform (Figure 22)

5-10

Page 24

OM17-P4000 Force/EC

Figure 21

Fold and

Extend hoses

Disconnect

wiring

Figure 22

Installing on Tractor –

- All bushings and pins are provided for Category I and II three-point hitches.

- Connect lower links – make sure you include the stabilizer link bushings(Figure

24)

- Connect top link

- Raise three point to desired height and level with top link

- Install lower stabilizer mount on drawbar and tighten 5/8” bolts

- Connect LH and RH stabilizer to upper and lower points, adjust, and lock with

jam nut.

- Connect hydraulic hoses noting P and T

- Retract stabilizer stands and engage hydraulics -- locking valve into detent with

tarp strap or other device. Make sure that flow is correct or controls will be

backward.

5-11

Page 25

OM17-P4000 Force/EC

Figure 1

Section 6

Maintenance and Lubrication

Proper maintenance and lubrication of the Veris P4000G will allow you to collect high

quality EC and force, and greatly extend the useful life of the unit. Veris Technologies

strongly suggests that you follow the following guidelines:

MAINTENANCE: Storage of Auxiliary Instrument and EC – Force Probe

The auxiliary instrument and probe are water resistant; store system indoors or under

roof. Water damage to electronic components is not covered by warranty.

MAINTENANCE: Electrical Continuity and Isolation

It is advisable to perform this test on a routine basis (weekly or every 20-25 hours of

data collection) to ensure you are obtaining reliable data.

1) Probe electrode isolation – Check isolation of the dipole to the point with a

Digital Multi Meter if the dipole is properly isolated, a reading of 12K ohm

should be obtained.

6-1

Page 26

OM17-P4000 Force/EC

Test Load

Figure 3

Instrument EC Signal Testing – The Veris Auxiliary Instrument is shipped with an

Instrument Test Load (Part No. 10447) that will enable you to quickly check the

instrument to ensure that the EC circuit is functioning properly. To perform this test, do

the following:

1) Disconnect the signal cable from the amp pin (signal) terminal on the auxiliary

case.

2) Connect the test load to the signal terminal.

3) Turn on Auxiliary Instrument and start up software.

4) The display should show: (See Figure 3)

EC 193 +/-10

5) If the readings vary significantly (more than 10) contact Veris service

department.

6) Once the test is complete, remove the test load and reinstall the implement

signal cable.

Figure 2

6-2

Page 27

OM17-P4000 Force/EC

Figure 4

Figure 5

Probe EC Signal Testing – The EC – Force probe is shipped with a EC dipole tester

(Part No. 29689) that will enable you to quickly check the probe and instrument to

ensure the EC is functioning correctly. To perform this test, do the following:

1) Press one bolt of the dipole tester to the side of the probe tip and the other to

the center brass dipole. (see figure 5 below) Depending on if the brass or the

silver bolts are used the EC reading will be high or low. The high and low

readings may vary depending on contact with the probe tip and the probe tip

cleanliness. This is fine; the import thing is that the brass reading be lower

than the silver. The difference between the two readings will be hundreds of

EC values.

6-3

Page 28

OM17-P4000 Force/EC

Cables

Loom

Clip

Mounting

Pin

Probe Removal

This procedure is needed when removing the probe for bench top use, road transport,

or for soil coring.

Step 1:

Disconnect the force, EC, USB, and power cables to the auxiliary case.

Step 2:

Remove loom from clip.

Step 3:

Figure 6

Step 3:

Firmly grasp probe, and remove the mounting pin holding the probe on the platform.

6-4

Page 29

OM17-P4000 Force/EC

Auxiliary case

Mounting plate

Case Removal and Installation

When the auxiliary case needs to be removed for storage, repair, or bench top use

follow these instructions.

First disconnect all wires connected to the auxiliary case.

The case is secured with two latches, and case and latch assembly can be removed as

a unit.

Figure 7

Latches

Figure 8

6-5

Page 30

OM17-P4000 Force/EC

Section 7

Troubleshooting

Troubleshooting EC module

Data missing from display reading –

1. Unit must be in contact with soil to record data points

2. Check GPS and DGPS signal; Veris instrument is programmed to eliminate all nonDGPS geo-referenced points.

3. Shut power off and restart

4. Check electrical continuity

5. Check input voltage, 12 v minimum required

No GPS data is coming in during acquisition

1. Check to ensure nothing is obstructing GPS signal (ex. buildings)

2. Is the GPS plugged into the correct port? (second one from the right on auxiliary

case)

3. Check to make sure GPS adaptor is in place

4. Follow the steps of the GPS troubleshooting guide to further diagnose problem

Auxiliary data not updating or ports not setting up correctly

1. Shut down power, and restart cases

2. Unplug USB cables

3. Restart PC

4. Plug in USB cables and restart software

New hardware found wizard appears when I plug in my Auxiliary Instrument

1. Make sure the Veris EC – Force software has been installed properly.

2. If Veris EC – Force software has been installed, then proceed with the new hardware

found wizard. Use the provided Digi EdgePort driver disk and source for driver when

prompted by PC

7-1

Page 31

OM17-P4000 Force/EC

Troubleshooting GPS

If GPS fails to come in it could be for a variety of reasons. If using the provided Garmin

GPS make sure the GPS adaptor is in place (see figure 10 in system overview). Then

following troubleshooting tree to isolate the problem.

Figure 1

7-2

Page 32

OM17-P4000 Force/EC

Fuse holder. Replace only with a

4-amp fuse.

Fuse Replacement

The fuse for the auxiliary case protects the voltage for the electrical conductivity board

and the lamp. To replace the fuse open the case and locate the black fuse holder

Figure 2 Internal wiring of auxiliary case

7-3

Page 33

Section 8

WARNING: Damage to force sensor may occur if

this specification is exceeded

Specifications

Max ambient temperature to operate system: 110 degrees F

Max aux case temperature: 65 degrees C

Max aux case humidity: 90% RH

Max force sensor capacity: 22361 kPa or 3245 PSI

Max probe insertion speed: 50mm/s

OM17-P4000 Force/EC

8-1

Loading...

Loading...