Veris EA10 Installation Instructions

TM

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices.

See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

DANGER

operated in a residential environment. This equipment generates, uses,

CURRENT MONITORING

EA10 SEriES EA10 SEriES

RoHS

Compliant

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

NOTICE

DISCONNECT ALL POWER TO THIS UNIT BEFORE CONNECTING

OR DISCONNECTING SENSOR MODULES

Failure to disconnect power will result in permanant

equipment damage.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found

to comply with the limits for a class B digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area may cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Modifications to this product without the express authorization of

Veris Industries nullify this statement.

For use in a Pollution Degree 3 or better environment only. A Pollution Degree

3 environment has conductive pollution or dry nonconductive pollution that

becomes conductive due to condensation. Consider the enclosure, the correct use

of ventilation, thermal properties of the equipment, and the relationship with the

environment. Installation category: CAT IV

ZL0102-0A PAGE 1 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countri es.

INSTALLATION GUIDE

DC String Monitor

Installer’s Specifications

Inputs:

Control Power Class 2/SELV 24 VDC to 42 VDC

Maximum Power Consumption 7 W at 32 channels

Current Sensing Range 0.1 A to 20 A (+20% over)

Accurac y:

Current ±0.5% full scale (combined linearity, hysteresis, and repeatability)

Outputs:

Communication 2-wire RS-485, 1200 to 38400 baud, Modbus RTU

Available Information Current per point, both instantaneous amps and

cumulative amp-hours, events

Update Rate 2 sec

Maximum Measurement Points 8, 16, 24, or 32

Mechanical:

Mounting T35 (35 mm) DIN Rail per EN50 022

Terminal Block Screw Torque 0.37 ft-lb (0.5 N·m) nominal/0.44 ft-lb (0.6 N·m) max.

Terminal Block Wire Size 24 to 12 AWG (0.205 to 3.31 mm2)

Stop Clip Screw Torque 0.37 to 0.59 ft-lb (0.5 to 0.8 N·m)

Sensed Wire Diameter 0.31” (8 mm) max.

Environmental:

Operating Temperature Range -30° to 75°C (-22° to 167°F)

Storage Temperature Range -40° to 85°C (-40° to 185°F)

Humidity Range <95% RH noncondensing

Altitude of Operation 3 km

Agency Approvals:

US and Canada Recognized (cRUus) UL61010-1, Acceptable in UL1741 Combiner Box

Europe (CE) EN61010-1

Insulation (from current sensor to control power or RS -485 interface) Up to 1000 VDC

(insulated conductor)

Dielectric Strength 10000 VDC

Installation Categor y Cat. IV, pollution degree 3

EMC:

Conducted and Radiated Emissions FCC part 15 Class B, EN55011 / EN61000 Class B

(residential and light indus trial)

Conducted and Radiated Immunity EN61000 Class A (heavy industrial)

TABLE OF CONTENTS

Product Identication 2

Dimensions 2

Operation 2

Installation Example 2

Product Diagram 2

Installation 3

DIP Switch Settings 5

LED Indicators 6

Communications Unit Modbus Point Map 7

Accessories 14

Troubleshooting 15

China RoHs Compliance Information (EFUP Table) 15

This symbol indicates an electrical shock haz ard exists.

Documentation must be consulted where this symbol is used

on the product.

TM

EA10 SERIES

INSTALLATION GUIDE

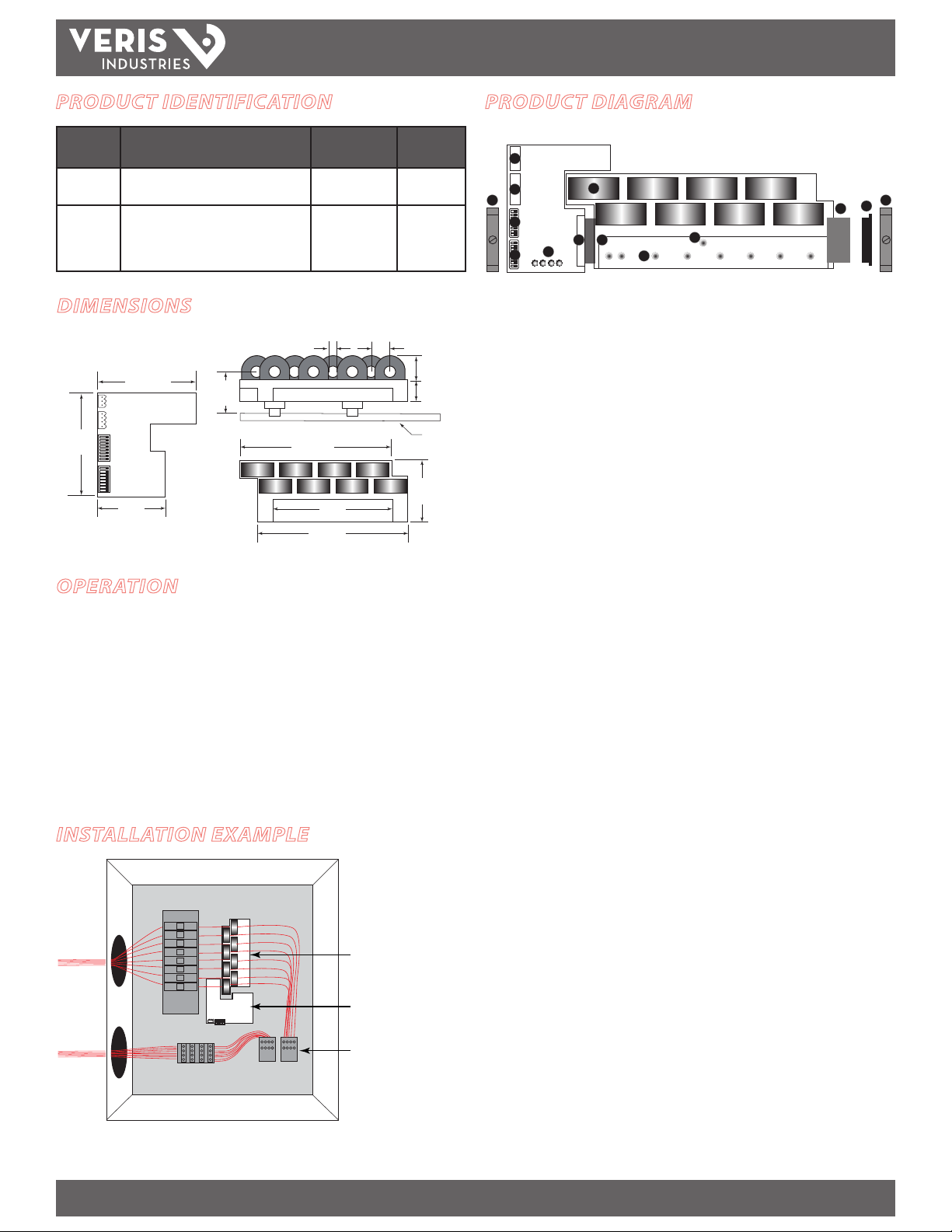

PRODUCT IDENTIFICATION

Model Description Amperage

Range

EA10DD08B DC current sensing module with 8 strings,

encapsulated

EA10HC1AB Communications unit, Modbus RTU,

encapsulated, 24 VDC, supports up to

four EA10DD08B units (up to 32 strings

per communication unit)

Up to 20A per CT

Output

Modbus RTU

DIMENSIONS

3.88”

(98.5 mm)

(93.5 mm)

2.72”

(68.6 mm)

3.68”

1.57”

(39.9 mm)

(8.0 mm)

5.37”

(136.4 mm)

(110.0 mm)

5.49”

(139.5 mm)

0.31”

4.33”

0.69”

(17.5 mm)

0.87”

(22.2 mm)

0.77”

(19.5 mm)

DIN Rail

2.48”

(63.0 mm)

OPERATION

The EA10 DC string monitoring system measures current in combiner boxes or other

DC applications. The system includes a communications unit that supplies power

to the DC current sensing modules and provides Modbus RTU communication. Up

to four DC current sensing modules connect serially to one communications unit,

each with eight DC current sensors, to monitor a total of 32 strings (channels) per

communications unit. Connec t up to 63 communications units in a daisy chain

for large system monitoring. All boards can be mounted on standard 35 mm

DIN rail for easy installation. Pulse Reset Technology in the current sensor oers

protection against output drif t and immunity to power spikes and surges up to

20 kA. All components are fully encapsulated to protect from moisture and other

environmental conditions

PRODUCT DIAGRAM

Communications Unit

1

2

3

4

8

6

5

7

1. RS-485 Connection: The communications unit provides an RS-485 2-wire (+

shield) serial interface that supports Modbus RTU to 38.4 kb/s. Used for Modbus

serial communications. Connect Shield (S) to ground at a single point on the

RS-485 bus.

2. Control Power Connection: The communications unit requires user-supplied

24 to 42 VDC, 7 W (must be safety isolated, non-hazardous, limited power source

(LPS), Class 2 source or better).

3. Communications Setting DIP Switches: congures baud rate and parity.

4. Communications Address DIP Switches: congures Modbus address. Each

Modbus device must have a unique address.

5. Communications Unit LEDs: Status, TX, RX, and Power. See LED Indicators

section, page 6.

6. Male 20-Pin Connector: for connection to current sensing modules. Conrm

that the o-ring is installed to ensure a proper seal for the product’s environmental

ratings.

Note: Disconnect power to panel and strings before connecting or

disconnecting current sensing modules.

7. Female 20-Pin Connector: provides a connection between the communications

unit and successive current sensing modules.

8. Current Sensor: 8 sensors per sensing module. Each current sensor is capable of

monitoring conductors with a maximum outer diameter of 0.31” (8 mm) and 0.1 A

to 20 A (+20% over) the current sensing range.

Current Sensing Module

10

1212

11

6

9

INSTALLATION EXAMPLE

9. Current Sensing Module Status LED: indicates status of the sensing module.

See LED Indicators section, page 6.

Fuse Block

EA10 DC Current

Sensing Module

10. Current Sensor LED: one LED for each of the eight sensors on the module. See

LED Indicators section, page 6.

11. End Ca p: environmentally seals the female 20-pin connector on the last current

sensing module. Conrm that the o-ring is installed on the end cap to ensure a

proper seal for the product environmental ratings. The end cap ships installed on

EA10 Communications

Unit

Summing Block

the communications unit.

12. DIN Stop Clips: Install stop clips in front of the communications unit and after

the last current sensing module to ensure a snug t. Two DIN stop clips are

included with the communications unit. Additional stop clips are available from

Veris (model number AV02).

ZL0102-0A PAGE 2 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countri es.

TM

EA10 SERIES

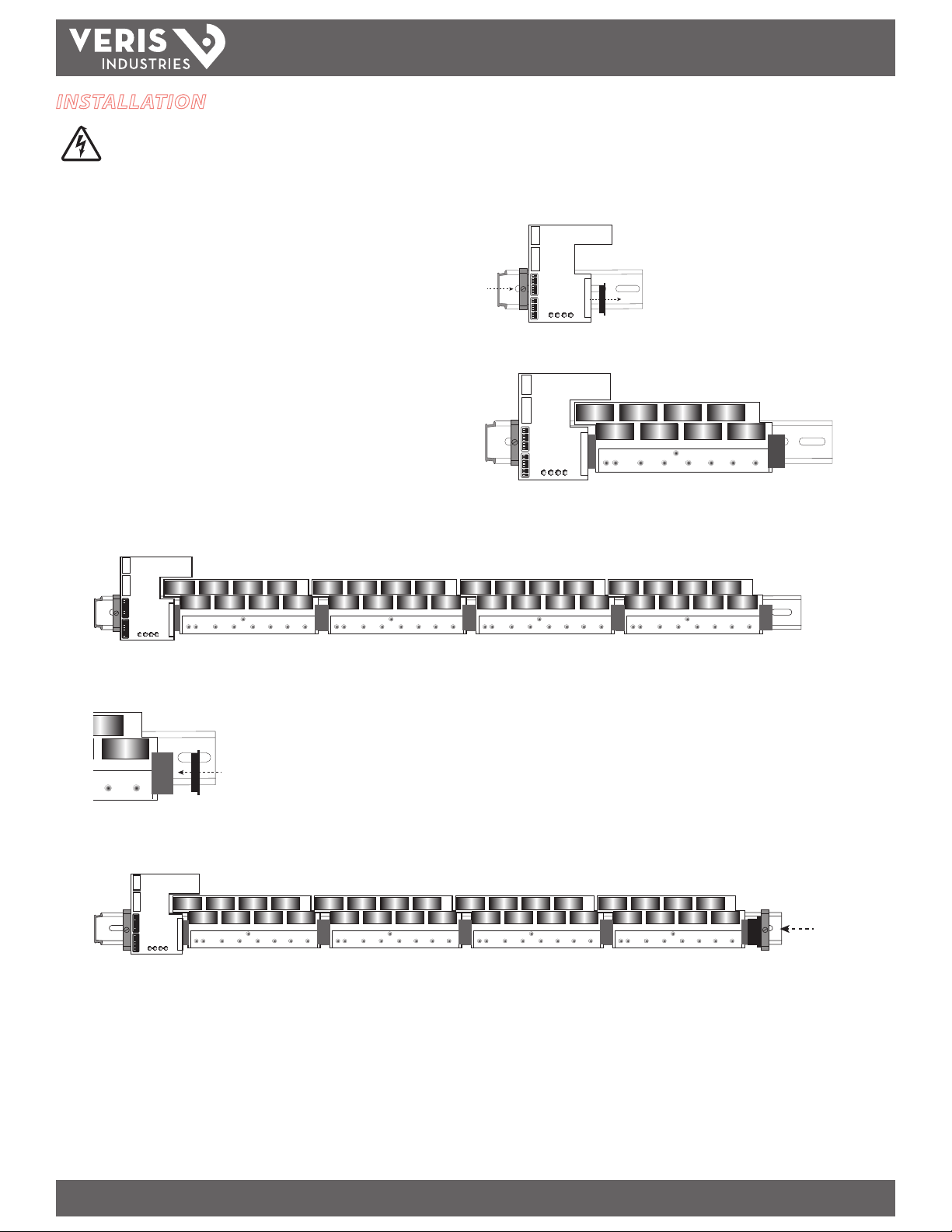

INSTALLATION

Disconnect and lock out power to panel or combiner box,

including power to all strings.

1. Select a location in a panel, adjacent to the fuse block to be monitored.

2. Install and tighten a DIN rail stop clip (included) near the end of the 35 mm DIN

rail (sold separately) in the panel or combiner box. Apply the correct torque to the

stop clip screw: 0.37 to 0.59 ft-lb (0.5 to 0.8 N·m).

3. Mount the communications unit onto the DIN rail and slide it up against the stop

clip.

4. Remove the end cap from the communications unit 20-pin connector. Retain for

later use.

5. Mount DC current sensing module(s) onto the DIN rail. Connect the rst current

sensing module to the communications unit via the 20-pin connector plug.

Conrm that the o-ring is installed in the plug to ensure a tight t.

Note: Disconnect power to panel and strings before connecting or

disconnecting current sensing modules.

6. Connect up to three additional current sensing modules, as needed, to produce

one continuous string of up to four modules per communications unit. For each

module, conrm that the o-ring is installed in the plug.

INSTALLATION GUIDE

7. Place the end cap on the open 20-pin connector on the last DC current sensing

module. Conrm that the o-ring is installed in the end cap to ensure a tight t.

8. Install and tighten the second DIN stop clip (included) to the end of of the

assembled EA10 DC String Monitoring System to prevent movement over time.

ZL0102-0A PAGE 3 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countri es.

TM

Power

20-Pin Connector

Red

Black

Gray

Use 14-24 gauge wire

EA10 SERIES

INSTALLATION GUIDE

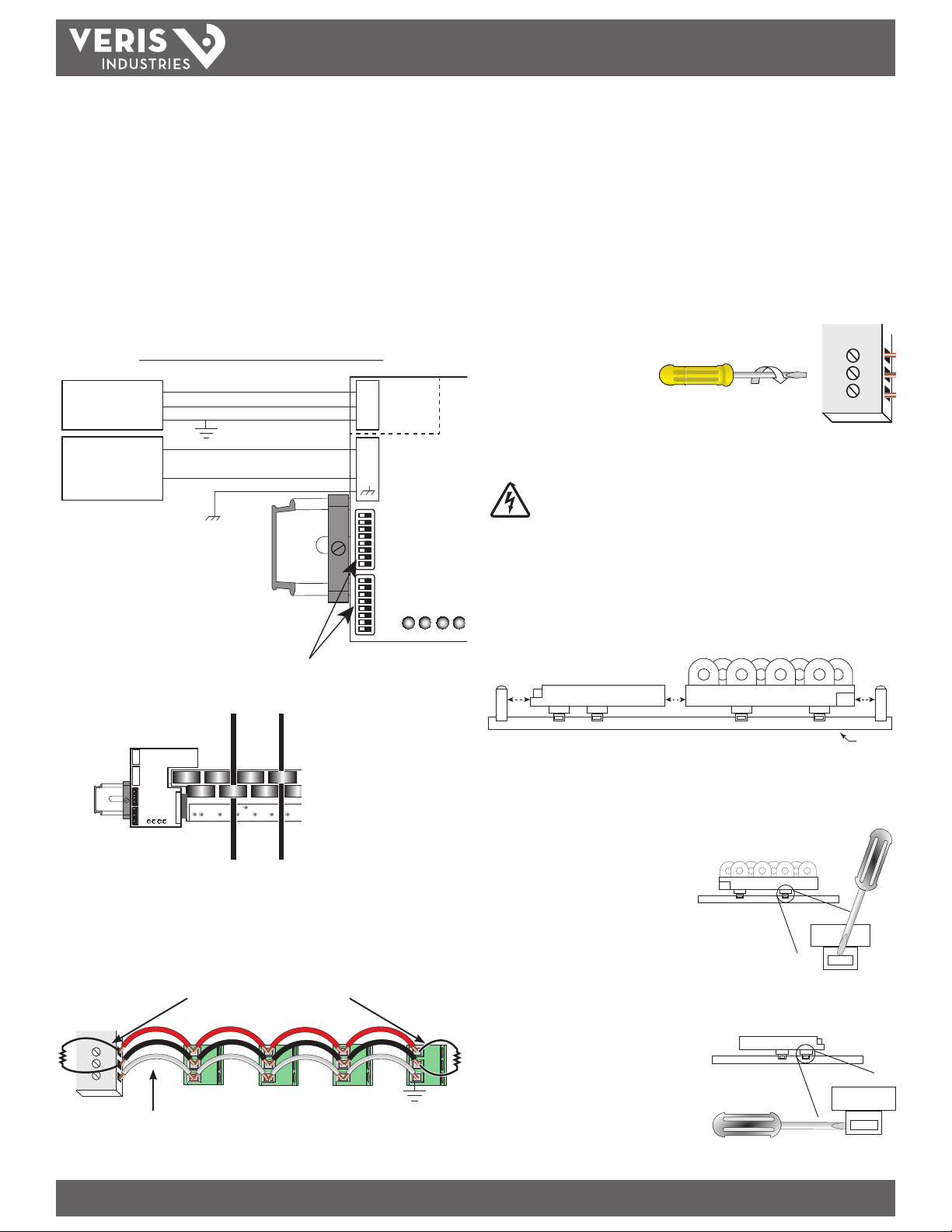

9. Congure communications unit using DIP switches (see page 5 to set the DIP

Switches).

10. Wire RS-485 communications to communications unit using the 3-pin connector

provided.

11. Wire 24 to 42 VDC control power to the communications unit using the 4-pin

connector provided.

Caution: Do not apply control power to the 3-pin RS-485 connector.

12. Wire the communications unit to the enclosure’s chassis ground using the 4-pin

connector. Ensure that the enclosure’s chassis ground is tied to earth ground.

Wiring for RS-485 and Control Power Connectors

Modbus

Master

RS-485

24 VDC

Power

Supply

+

–

S

+

–

+

–

S

+

–

RS-485

(isolated)

DC Power

• The terminal’s voltage and current ratings are compliant with the

requirements of the EIA RS-485 communications standard.

• The RS-485 transceivers are ¼ unit load or less.

• RS-485+ has a 47 kΩ pull up to +5V, and RS-485- has a 47 kΩ pull down

to Shield (RS-485 signal ground).

• Wire the RS-485 bus as a daisy chain from device to device, without

any stubs. Use 120 Ω termination resistors at each end of the bus (not

inc luded).

• Shield is not internally connected to earth ground.

• Connect Shield to earth ground somewhere on the RS-485 bus.

For all terminals on EA10 devices:

• When tightening

0.37–0.44 ft•lb

(0.5–0.6 N•m)

terminals, apply the

correct torque: 0.37-

0.44 ft·lb (0.5-0.6 N·m).

• Use 12-24 gauge wire.

To Remove Sensing Modules and Communications Unit From DIN Rail

Disconnect and lock out power to panel or combiner box,

including power to all strings.

1. Unplug the RS-485 and control power connectors from the communications unit.

Disconnect strings and remove them from the current sensing module(s).

StatusTxRx/Error

2. Loosen or remove the DIN stop clips. Separate the EA10 components by sliding

them apart along the DIN rail. Ensure that the current sensing modules are fully

disconnected from adjacent modules and from the communications unit.

DIP switches

13. Route each insulated conductor through a DC current sensor.

DIN Rail

3. If there is sucient space on one end of the DIN rail, continue sliding each

component along the rail until they slide o one end.

4. If space is limited, and step 3 is not

possible, then insert a screwdriver into

the groove on the DIN rail clips on one

14. Restore power to the panel and commission the device for operation.

side of a current sensing module. Use

the screwdriver to pry the clip away

Connecting Multiple Communications Units in a Daisy Chain

The RS-485 slave port allows connection of multiple EA10 communications units in a

daisy chain with up to 63 2-wire devices.

120 Ω terminator on the rst an d

last device of the da isy chain

+

from the DIN rail. Repeat with the

second clip on the same module. The

current sensing module lifts o of the

DIN rail when both clips are loosened.

5. Repeat with any other current sensing modules on the rail.

6. To remove the communications unit, turn

the screwdriver so that it is parallel to the

–

S

DIN rail and insert it between the clip and

the DIN rail. Pry the clip away from the DIN

rail. Repeat with the second clip on the

Shield wire

ZL0102-0A PAGE 4 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countri es.

unit. The communications unit lifts o the

DIN rail when both clips are loosened.

TM

Reverse O,

Unit reports positive current

Reverse On,

Unit reports positive current

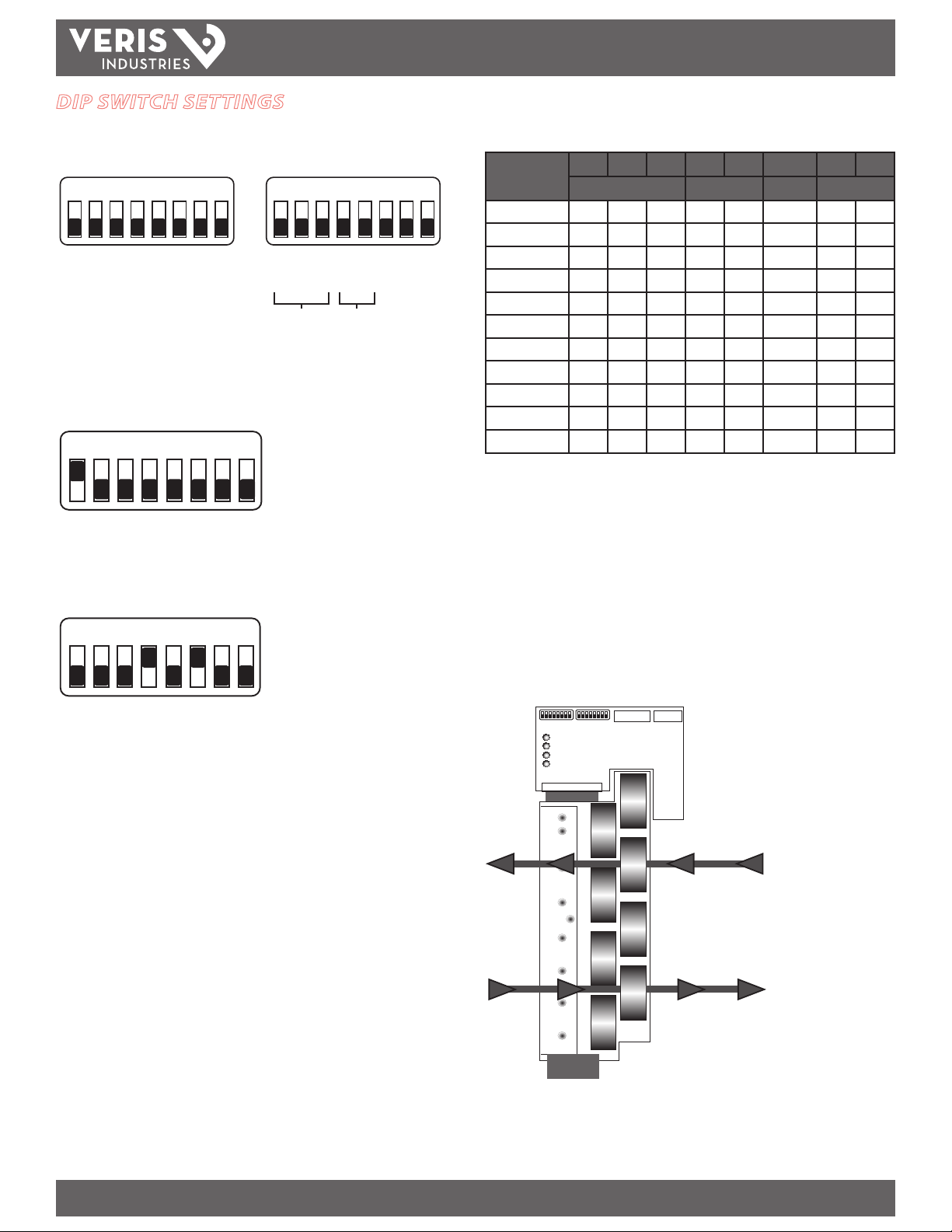

DIP SWITCH SETTINGS

The communications unit serial interface can be congured for Modbus address, baud

rate, and parity. No other conguration is supported.

EA10 SERIES

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

On

O

128

64

32

16

8

4

2

1

Reverse

Even/Odd

On/O

LSB MSB

Address

Baud Parity

How to Set Address DIP Switches

Each DIP switch has a numerical value as shown below. The EA10 default address is 1,

as illustrated below.

1 2 3 4 5 6 7 8

On

Unused

Unused

On

O

INSTALLATION GUIDE

Communications and Parity DIP Switches

Switch

Function

1200 Baud OFF OFF OFF X X

2400 ON OFF OFF X X

4800 OFF ON OFF X X

9600 ON ON OFF X X

19200 OFF OFF ON X X

38400 ON OFF ON X X

No Parity OFF X X X

Odd Parity ON OFF X X

Even Parity ON ON X X

Current Flow

Current Flow

Reverse Current Switch

1 2 3 4 5 6 7 8

Baud Parity Reverse Not Used

OFF X X

ON X X

O

1 2 4 8 16 32 64 128 (DIP Switch Values)

To determine an address, add the values of any switch that is in the ON position.

For example:

1 2 3 4 5 6 7 8

On

O

1 2 4 8 16 32 64 128 (DIP Switch Values)

Switches 4 and 6 are in the ON position, with values of 8 and 32, respectively.

8 + 32 = 40, so the EA10 address is 40.

The reverse current switch allows the user to dene the polarity of the instantaneous

current reported by the unit. In the default O position, the unit reports positive

current when the conductor is routed through the CT with current owing towards

the DC current sensing module LEDs (see drawing below). Negative current ows

away from LEDs towards the CT, indicating a diagnostic event. When the reverse

current switch is On, the opposite is true (see drawing below). This feature allows the

product to be installed in a variety of congurations.

The state of the reverse current switch can be overridden by writing to the

conguration register via Modbus (see EA10 Modbus Point Map, System Conguration

Register 40357). To reactivate the switch, clear the Modbus register.

ZL0102-0A PAGE 5 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 05126

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and /or other countri es.

Loading...

Loading...