Page 1

TM

the user will be required to correct the interference at his own expense.

E8950

Modbus-to-BACnet Protocol Converter

e

h

i

n

R

l

a

V

n

d

U

T

o

f

.

N

NETWORK INTEGRATION

c

n

o

I

r

,

US

t

C

h

a

c

i

A

r

m

e

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

Control system design must consider the potential failure modes of control paths and, for

certain critical control functions, provide a means to acheive a safe state during and after a

path failure. Examples of critical control functions are emergency stop and over-travel stop.

RoHS

Compliant

INSTALLATION GUIDE

SPECIFICATIONS

Downstream (Device) Interfaces:

Physical Layer 2-wire RS-4 85

Line Termination Internal, 120 Ω

Line Polarization Internal

Protocol Modbus RTU

Baud Rate 9600 to 384 00 (selections var y with Modbus devices used)

Number of Devices Supported up to 32 devices

(not to exceed 1000 tot al BACnet data objects)

Upstream (Controller) Ethernet Interface:

Physical Layer 10/100 Mb Ethernet

Protocol BACnet IP

Upstream (Controller) Serial Interface:

Physical Layer 2-wire RS -485

Protocol BACnet MS/TP

Baud Rate 9600, 19200, 38400, and 7680 0

Input Power Requirements:

Supply Voltage Class 2 9-30VDC or 12-24VAC

Nominal Current Draw @ 12V 240mA

Environmental:

Operating Temperature Range -40°C to 122°C (-40°F to 50°F)

Operating Humidity Range 5-90% RH noncondensing

Agency Approvals CE; TUV approved to UL916

WARNING

LOSS OF CONTROL

∙ Assure that the system will reach a safe state during and after a control path failure.

∙ Separate or redundant control paths must be provided for critical control functions.

∙ Test the eect of transmission delays or failures of communication links.

∙ Each implementation of equipment using communication links must be individually

and thoroughly tested for proper operation before placing it in service.

Failure to follow these instructions may cause injury, death or equipment damage.

1

For additional information about anticipated transmission delays or failures of the link, refer to

NEMA ICS 1.1 (latest edition). Safety Guidelins for the Application, Installation, and Maintenance

of Solid-State Control or its equivalent in your specic country, language, and/or location.

Veris Industries assumes no responsibility for any consequences arising out of the use

of this material.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found

to comply with the limits for a class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case

Modifications to this product without the express authorization of

Veris Industries nullify this statement.

1

PRODUCT IDENTIFICATION

E8950 Modbus-to-BACnet Protocol Converter

Supported Veris Meters***: H8035, H8036, E50C2,

E50C3*, E51C2, E51C3*, H81xx Series (with the

H8163-CB Modbus RTU Communication Board), H8238

Series, H8436 Series, H8437 Series, and E30Ax42**,

E30Bxxx**, E30Cxxx**, E31Bxxx**, E31Cxxx** Series

* The E8950 does not support the logging fu nctionality of these meters.

** Must include rmware version 1.011 or later.

*** E31A42 is suppor ted also, but requires some manua l conguration. Contact Veris Customer

Support for details.

Refer to Appendix 3 to determin e how many meters of each type can be supported.

PRODUCT OVERVIEW

The E8950 is a protocol conversion gateway that adapts supported Veris Modbus

RTU energy meters to building automation systems using BACnet protocol over

either IP or MS/TP physical layer interfaces. The E8950 supports up to 32 meters or

1000 total measurement points (number of output points varies by meter model). It

is pre-programmed to discover any supported meters and automatically congure

them for BACnet MS/TP and BACnet/IP. Each Modbus meter is presented as a BACnet

device, with a unique BACnet device_ID and a full set of measurement data and

conguration objects. Little conguration is required. The user sets up the system

using DIP switches and a built-in webserver graphical user interface (GUI).

ZL0105-0B PAGE 1 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 2

E8950

TM

INSTALLATION GUIDE

TABLE OF CONTENTS

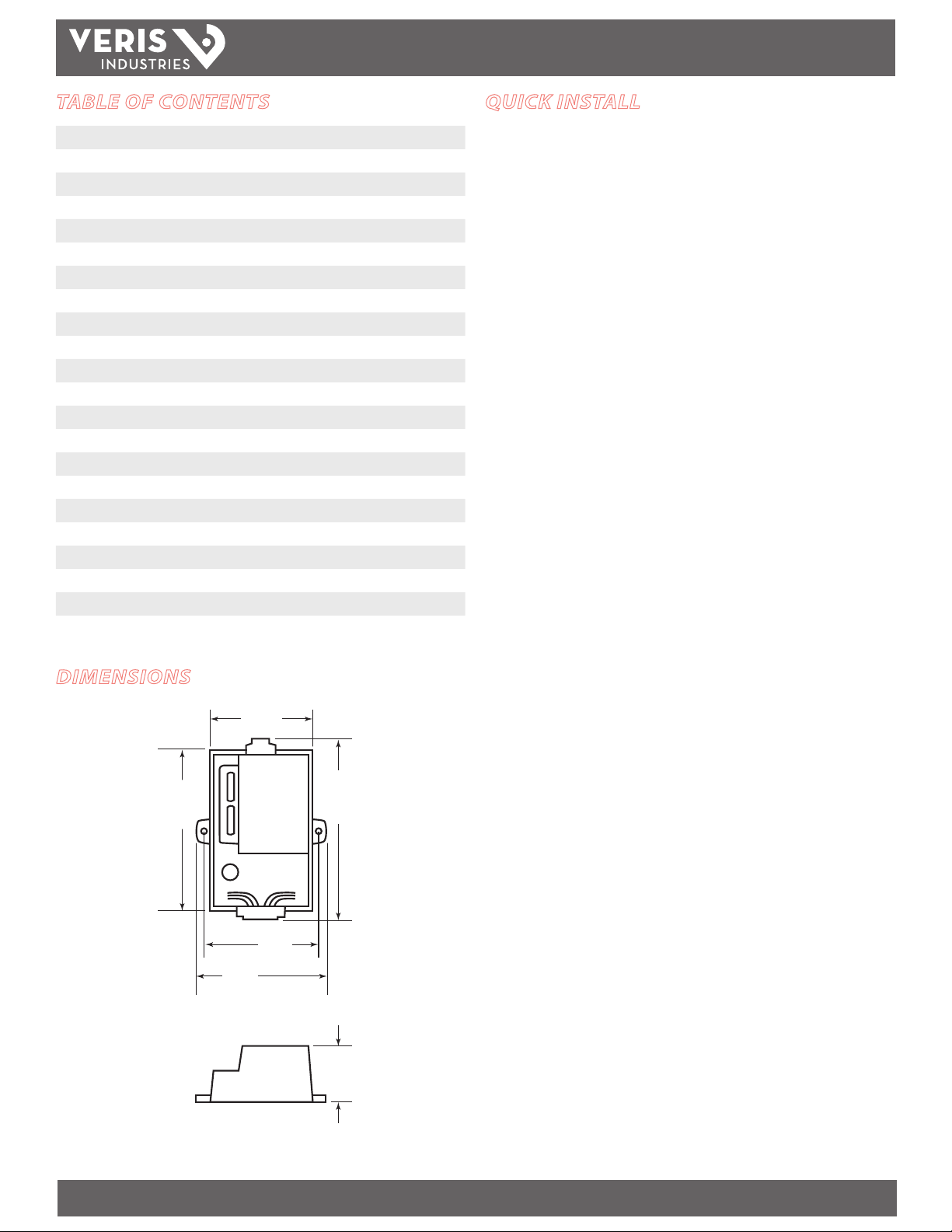

Dimensions 2

Quick Install 2

Product Diagram 3

LED Blink Codes 3

Installation 3

BACnet Programming Information 8

Troubleshooting 9

China RoHS Compliance Information 9

Appendix 1: Data Objects for Supported Metering Devices

Enercept H8035 Series Meter 10

Enercept H8036 Series Meter 11

E50C2 and E50C3 (without logging) Uni-Directional Meter 12

E51C2 and E51C3 (without logging) Bi-Directional Meter 15

H8436 Series Meter 20

H8437 Series Meter 21

H8238 Multi-Circuit Meter 24

H8163 Energy Meter with H8163-CB Modbus Communication Board 28

E30A042, E30A142 Branch Circuit Power Meter 31

E30Bxxx, E30Cxxx, E31Bxxx, E31Cxxx Branch Circuit Power Meter 62

Appendix 2: DIP Switch Address Settings 81

Appendix 3: Quick Guide to Calculate the Number of Meters Supported 83

QUICK INSTALL

1. Connect the Modbus outputs of the metering devices to the Modbus terminals on

the 6-pin connec tor of the E8950. Daisy chain up to 32 metering devices to the

E8950 (provided that the total number of data points from all devices does not

exceed 1000).

2. Connect 9-30 VDC or 12-24 VAC to the power terminals on the 6-pin connector.

3. Use DIP switches S0 to S2 to set the Modbus baud rate on the E8950 to the same

rate as on all metering devices in the chain (factory default is 9600 baud).

4. Use DIP switch A7 to select the BACnet physical layer (MS/TP or IP).

5. If using BACnet MS/TP, connect the MS/TP connections to the BACnet interface.

Use DIP switches A0 to A6 to set the MAC address, and use DIP switches B0 to B3 to

set the MS/TP baud rate (factory default is 76800).

6. If using BACnet/IP, connect the E8950 to a PC using an ethernet cable and use the

GUI to set the IP address.

7. If the default network number (50) or the default Device_ID oset will cause

conicts, connect the E8950 to a PC using an ethernet cable and use the GUI to set

them appropriately.

8. Apply power to the E8950 and allow time to map all Modbus devices in the chain.

9. If the conguration is nal and will not change (no Modbus devices will be added,

removed, or changed), set the conguration mode to Normal (slide DIP switch A7

to the right) to speed future power-up cycles and prevent the auto-conguration

mechanism from overwriting when power is cycled.

DIMENSIONS

4.5”

(115 mm)

2.9”

(74 mm)

5.1”

(129 mm)

3.25”

(83 mm)

3.6”

(92 mm)

1.6”

(41 mm)

ZL0105-0B PAGE 2 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 3

E8950

TM

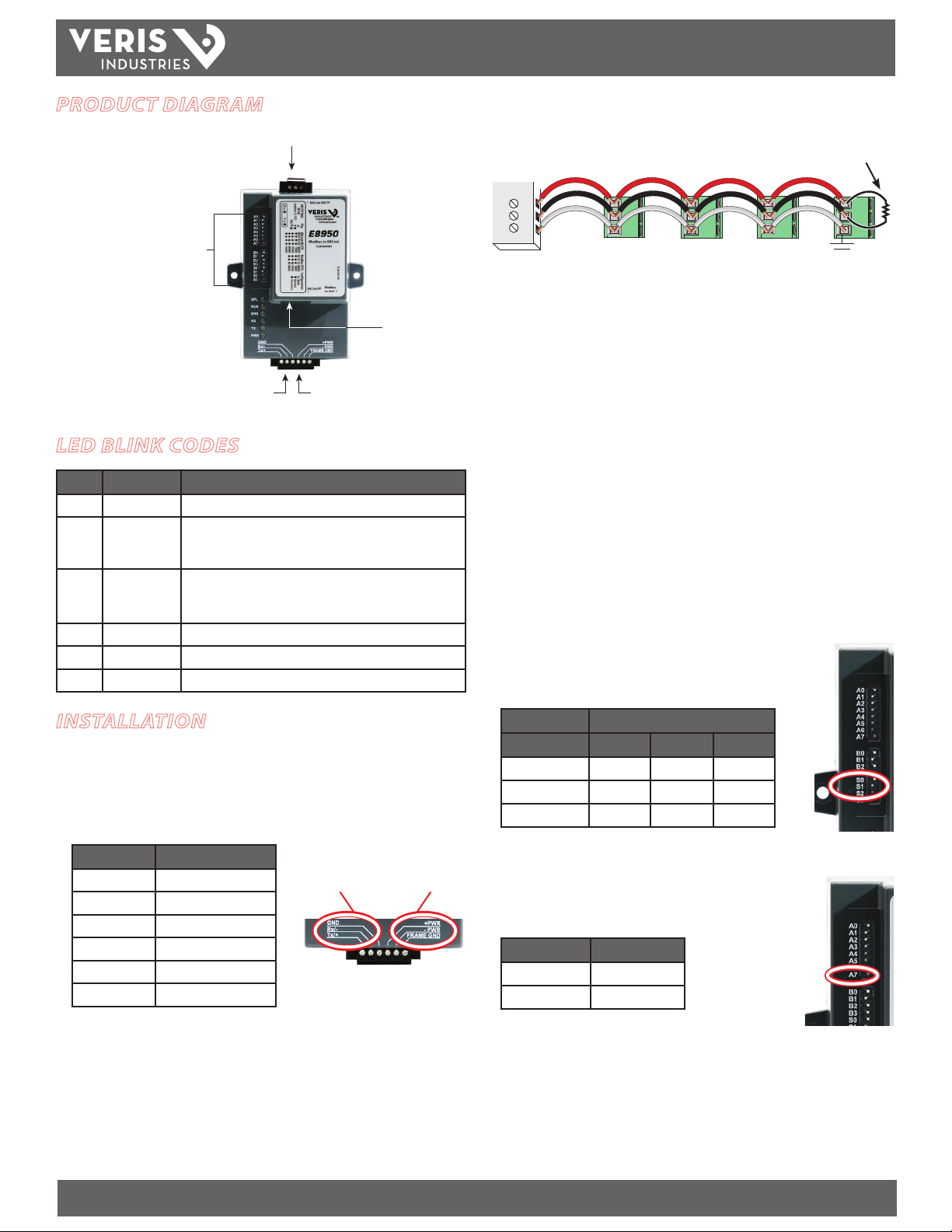

PRODUCT DIAGRAM

BACnet MS/TP RS-485

DIP switches for setting MS/TP

MAC address, physical interface

type, MS/TP baud rate, Modbus

baud rate, and enabling auto-

discovery of meters

BACnet

IP/Ethernet

Port

Modbus RTU port RS-485 +, -, Shield

Power 9-30 VDC, 12-24 VAC

LED BLINK CODES

LED Color Description

SPL Blue Reserved for future use. It may be on or o when the unit is on.

RUN Dark Green Slow blink (one second on, one second o) after the product

ERR Red • This illuminates blink briey when the Run LED rst comes on

RX Yellow Indicates the device is receiving data on the Modbus link.

TX Orange Indicates the device is transmitting data on the Modbus link.

PWR Light Green This is always on when the unit is powered.

has initialized (approximately 40 seconds after the unit is

powered or reset). This indicates normal operation.

(about 15 seconds after the unit is powered or reset).

• A steady red light indicates the unit needs attention.

INSTALLATION GUIDE

2. Connect the Modbus outputs of the devices to the Modbus side of the E8950.

120 Ω resistor on the last device in the daisy chain.

+

–

S

E8950 Meters

• Wire the RS-485 bus as a daisy chain from device to device (up to 32

supported devices) without any stubs. Use a 120 Ω termination resistor

(not included) on the device farthest from the E8950. An additional 120 Ω

termination and Modbus line polarization are provided internal to the

E8950.

• Connect shield to earth ground somewhere on the RS-485 bus. The shield

is not internally connected to earth ground.

• Use wire with an insulation rating sucient for the location where the

meter is installed (e.g. Belden 1120A for installation in panels with up to

60 0 VAC).

3. Connect 9-30 VDC or 12-24 VAC to the +PWR/-PWR terminals of the 6-pin

connector.

Modbus Setup

Use DIP switches S0 to S2 to set the Modbus baud rate to 9600, 19200, or 38400. The

default baud rate is 9600, because this rate is available on all the devices supported

by the E8950. If all connected devices support a faster rate, use the highest rate in

common to improve performance. Set the E8950 and all Modbus

devices in the series to the same rate. Set all devices to NO parity.

INSTALLATION

The E8950 can be DIN rail mounted, using the supplied DIN rail mounting clip, or

screw-mounted directly to a wall or other at sur face using the mounting holes on

either side of the housing.

6 Pin Connector

Pin # Pin Assignment

Pin 1 RS-485 + (Modbus)

Pin 2 RS-485 - (Modbus)

Pin 3 RS-485 GND

Pin 4 V +

Pin 5 V -

Pin 6 FRAME GND

1. Refer to the Installation Guides for the specic meter devices used to locate

instructions on connecting the meters and changing the conguration settings.

Modbus Power

Baud Rate S0 – S2 DIP Switches

S0 S1 S2

9600 Baud

19200 Baud

38400 Baud

BACnet Physical Layer Selection

Use DIP switch A7 to select the BACnet physical layer. See

Appendix 2: DIP Switch Addresses section at the back of this

document for physical layer switch settings.

Layer Switch Position

BACnet/IP

BACnet MS/TP

ZL0105-0B PAGE 3 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 4

E8950

TM

INSTALLATION GUIDE

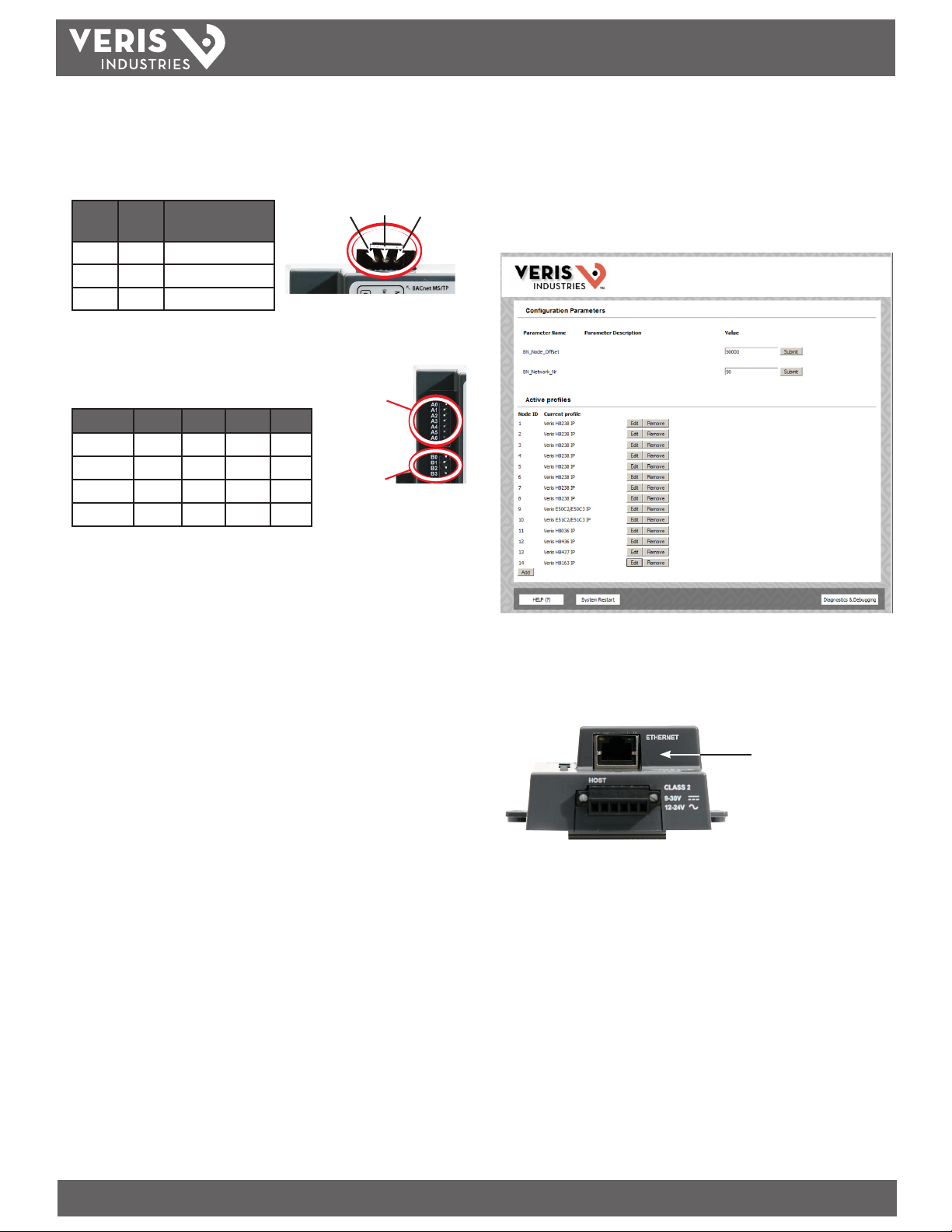

MS/TP Setup (if using BACnet/IP, skip this section)

1. Connect the MS/TP connections on the E8950 to the eld controller or other

BACnet MS/TP interface according to its guidelines.

Pin

Pin # Pin assignment

Label

+ Pin 1 RS-485 + (MS/TP)

- Pin 2 RS-485 - (MS/TP)

G Pin 3 RS-485 Shield

2. Set the MAC address using DIP switches A0-A6. See Appendix 2: DIP Switch

Addresses section at the back of this document for a full table of valid address

switch settings.

3. Set the MS/TP baud rate using DIP switches B0-B3.

Baud B0 B1 B2 B3

9600

19200

38400

76800

G (Shield) – +

MAC

Address

Baud

Rate

Accessing the Graphical User Interface (GUI)

If the E8950 IP address parameters are already congured to work on the network

and the E8950 is being accessed from a PC on that same network, open a web

browser and enter the IP address of the E8950 into the address/URL led on the

browser. Press enter. The GUI will launch and appear, as shown, in the browser

window.

If the E8950 IP address parameters are not congured for the network, connect a PC

directly and access the GUI from it as follows:

4. Connect a standard CAT5 ethernet cable between a PC and E8950.

Ethernet/BACnet IP

port location

ZL0105-0B PAGE 4 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 5

E8950

TM

INSTALLATION GUIDE

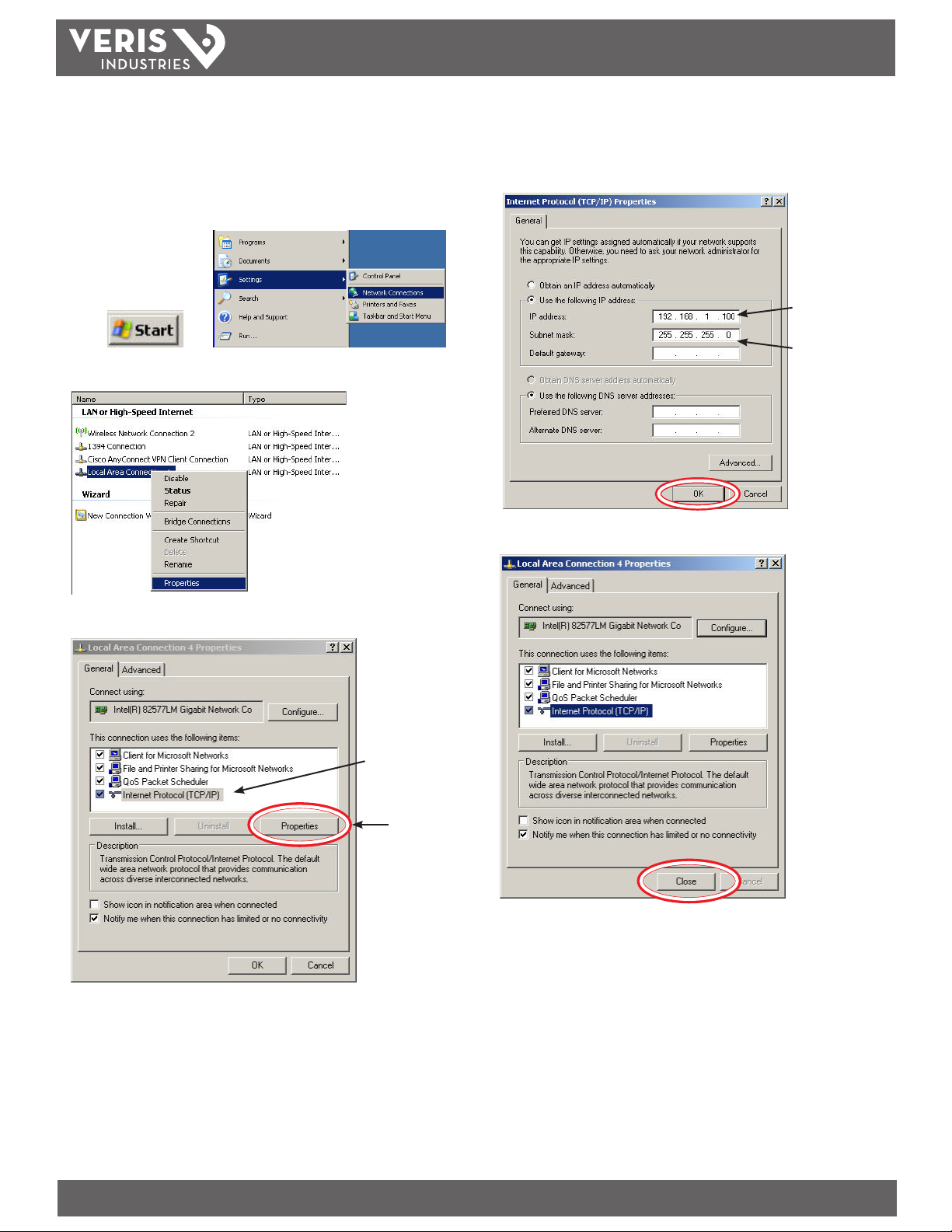

5. Temporarily change the IP address of the PC to a static value on the same subnet

as the E8950. For example: If the E8950 is set to its factory default IP address of

192.168.1.24, set the PC to an unused static IP address on the 192.168.1.xxx subnet

(where xxx is any value between 1 and 255, except 24). Set the subnet mask to

255.255.255.0 (the screen captures in this example were taken using Windows XP;

other operating systems will look dierent).

a. Click , then

b. Right-click on the local area connection you are using and select Proper ties

d. Select <Use the following IP Address>. Make note of the IP address that

appears, then enter the static IP address (e.g. if the E8950 is still set to its

default address of 192.168.1.24, then change it to 192.168.1.100). Enter for the

255.255.255.0 subnet mask. Click OK.

Enter static

IP address

Enter subnet

mask

e. Click Close.

c. Highlight Internet Protocol (TCP/IP) and select Properties

Select protocol

Click Properties

6. Open a PC web browser and enter the IP address of the E8950 (default address

is 192.168.1.24) to access the E8950 GUI. The GUI will launch and appear in the

browser window.

7. When nished using the GUI, unplug the ethernet cable from the PC and restore

the IP settings as needed.

ZL0105-0B PAGE 5 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 6

E8950

TM

INSTALLATION GUIDE

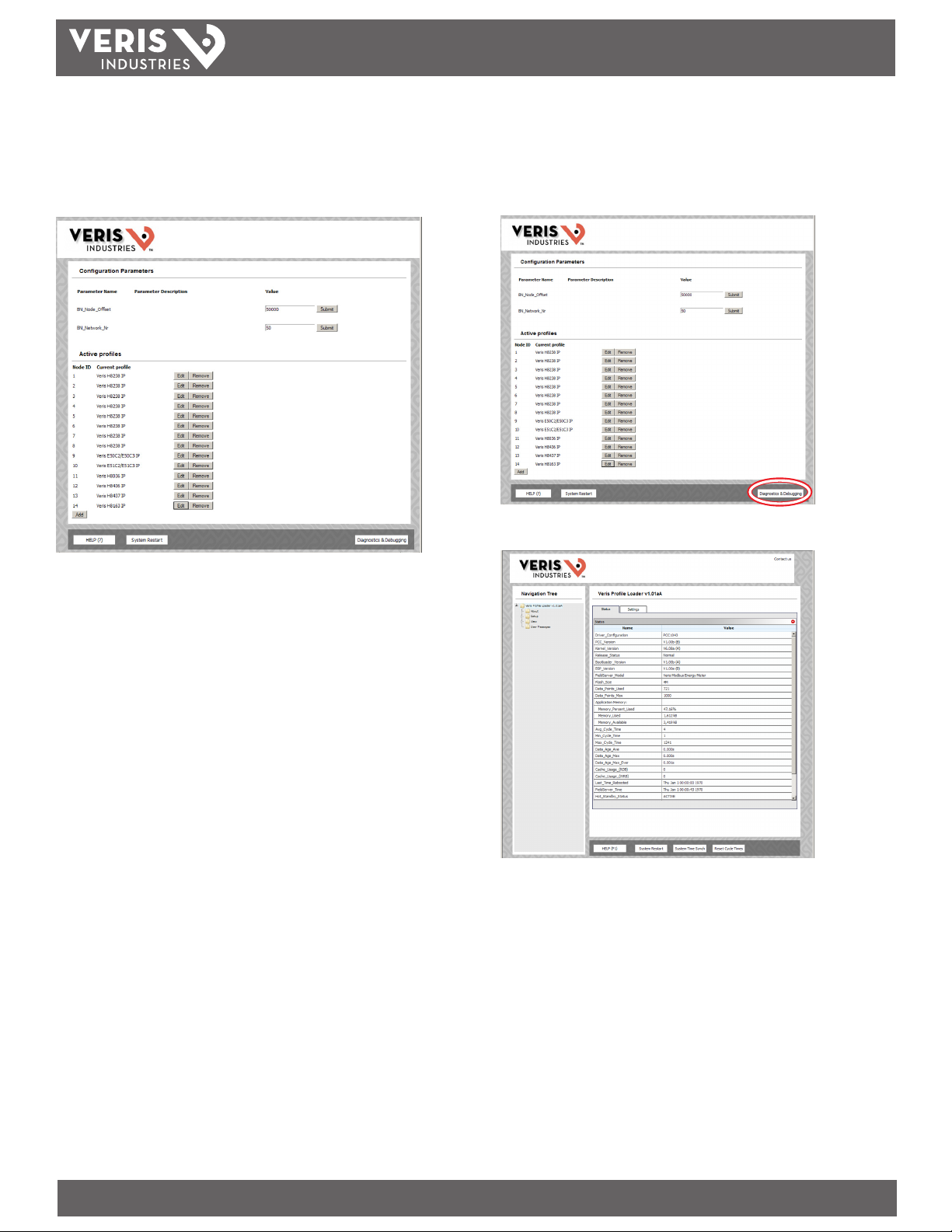

Using the GUI to Set the E8950 Internal Network Number or the Device_ID

Offset

Access the GUI according the instructions in the “Accessing the Graphical User

Interface (GUI)” section.

The home screen on the GUI shows the current values used for the oset used to

assign Device_IDs in discovery mode and the network number assigned to the

internal virtual network used by the E8950 to manage the Modbus devices attached.

Using the GUI to set up the E8950 IP address for use on your network

1. Access the GUI according the instructions in the “Accessing the Graphical User

Interface (GUI)” section. To set IP address parameters, click the button labeled

“Diagnostics and Debugging.”

The Diagnostics screen appears.

The oset used to assign Device_IDs in discovery mode is the variable labeled BN_

Node_Oset. Enter a dierent value here and click submit. The new value is rst used

at the next power-up or system restart. Valid Device_ID numbers range from 1 to

4194303. Since the numbers assigned during discovery are the sum of the Oset and

the Modbus address (which can be any value from 1-255), the Oset values entered in

the GUI must be less than 4194057.

The internal virtual network used by the E8950 to manage the Modbus devices

attached is the variable labeled BN_Network_Nr. Enter a dierent value here and

click submit. Valid network numbers range from 1 to 65534; if other values are

entered, the network number defaults to 5. The new value is rst used at the next

power-up or system restart. If using a BACnet router, it is recommended that the

router also be restarted after the E8950 has completed discovery, when the network

number is changed.

2. Have the desired IP settings ready in advance (contact the system administrator).

IP parameters for use with BACnet IP are static, not dynamic.

3. Set the IP address for use on the BACnet/IP network:

a. From the navigation tree (lef t column) on the GUI, click on Setup and then

Network Set tings to enter the Edit IP Address Settings menu.

b. Enter the desired IP address in the N1_IP_Address eld (in the format xxx.xxx.

xxx.xxx)

c. If necessary, change the Subnet Mask by entering the appropriate new value in

the N1_Netmask eld

ZL0105-0B PAGE 6 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 7

E8950

TM

INSTALLATION GUIDE

d. If the E8950 is connected to an ethernet gateway, enter its IP address in the

Default Gateway eld.

e. Click the Update IP settings button. The E8950 will change its settings and

restart. The GUI will not connect again until the E8950 is installed on the network

that matches those settings and the new IP address is entered into a web browser

on a PC properly congured for that network.

Profile Assignment

Prole assignment is automatic. Upon power-up/reset, with the device in Discovery

mode (DIP switch S3 is to the right), each Modbus address is queried for a slave ID.

Any devices that respond with a slave ID matching a supported device are given a

unique device object and a full set of data objects to match the device.

All supported Veris meters are discovered and assigned one of the proles (see

Appendix 1) if they are connected, powered, and congured properly.

The Add/Remove/Edit buttons on the GUI can be used to alter the assignments,

but this is not recommended for general use, as the proles could be assigned to

products they do not support. If a meter is not discovered because it is not connected,

powered, or congured properly, adding the prole manually will not make it work.

Any changes to the prole assignments made manually through the GUI will be

discarded when the E8950 is power-cycled or reset in Discovery mode.

Turn on the E8950

1. Set the conguration mode switch (S3) to the Discovery

position.

2. Apply power to the E8950. It can take up to 2-3 minutes to

discover all the Modbus RTU meters, build a conguration

le, and install the device on BACnet MS/TP. Scanning begins

at address 1 and continues in numerical sequence, mapping

meters as they are discovered. To shorten this time, use

lower Modbus addresses for the meters so that they will be

discovered and mapped more quickly. After the meters at the

lower addresses are discovered, the E8950 continues scanning

the remaining addresses in the background, without aecting

operation.

BACnet Network Management – Important Steps to Avoid Conflicts

BACnet conguration uses two default settings that might need to be changed,

depending on the application.

a. Network ID number. Every logical network segment (IP subnet, MS/TP trunk, etc.)

in an entire system must have a (16-bit) network ID number that is unique from

all other BACnet networks in the enterprise. The BACnet network administrator

assigns this network ID so that no two ID numbers conict (whether using

BACnet/IP or MS/TP). Within each segment, every device is physically identied by

the combination of its 8-bit MAC address and the 16-bit network ID number.

To support multiple meters with a single E8950, the E8950 presents multiple

BACnet devices using a single (its own) MAC address. Each E8950 has its own

(internal) network ID, and it assigns a unique MAC address to each Modbus meter

attached, derived from the unique Device_IDs.

The E8950 factory default network address is 50 (decimal). If that number is

already in use in the system, assign a unique address using the graphical user

interface (GUI) on the built-in web server (this requires an ethernet connection

to a web browser; see BACnet/IP Setup section for instruc tions on changing

conguration settings using the GUI). Valid network numbers range from 1 to

65534; if other values are entered, the network number defaults to 5.

b. Device ID. Every BACnet device must have a BACnet Device_ID number that is

unique throughout the entire enterprise. Since the E8950 presents every Modbus

meter as a BACnet device, each connected meter that has a Modbus address must

have a BACnet Device_ID.

By default, each device discovered receives a Device_ID number that is the sum

of an oset value (default is 50000) and the Modbus address of the device. If

these Device_ID numbers cause a conict with existing devices in the system, or

if the system includes multiple E8950s, change the Device_ID numbers before

connecting the E8950 to the system. This can be managed one of two ways:

i. Connect to the E8950 directly (oine from the system) with the devices

(meters) connected to the E8950. After the E8950 discovers the devices

and assigns their default ID numbers, the user can choose new Device_ID

values and write these to each device using BACnet software. Subsequent

discoveries will not overwrite these values with defaults even if the E8950 is

then set to Discovery mode.

3. Optional: Lock the conguration. If no more devices will be added to or removed

from the Modbus trunk, lock the device mapping by setting the mode from

Discovery to Normal (slide DIP switch S3 to the left). This causes the E8950 to

set up the same devices at power-up, without repeating the Discovery process.

In Normal mode, the power-up time improves, but BACnet devices are created

whether the device responds or not, and new devices are not discovered.

ii. Use the GUI on the built-in web server to modify the oset value used

to calculate default Device_IDs in the discovery process (this requires an

ethernet connection to a web browser; see BACnet/IP Setup section for

instructions on changing conguration settings using the GUI). The E8950

retains this oset value and uses it to assign Device_ID numbers ever y time

power is cycled if the E8950 is in Discovery mode. Valid Device_ID numbers

range from 1 to 4194303. Since the numbers assigned during discovery are

Configuration Mode S3

Normal

Discovery

the sum of the Oset and the Modbus address (which can be any value from

1-255), any Oset values entered in the GUI must be less than 4194057.

Determine the best mode for the application. Discovery mode queries and rediscovers devices each time the E8950 is power-cycled or reset, so use this mode

when you anticipate adding, removing, or changing Modbus devices. Normal

mode creates the same set of BACnet device objects when the E8950 is powercycled or reset, even if objects change, are removed, or cease to communicate.

Power-up time is faster in Normal mode.

ZL0105-0B PAGE 7 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 8

E8950

TM

BACNET PROGRAMMING INFORMATION

INSTALLATION GUIDE

BACnet PICS (Protocol Implementation Conformance Statement)

Vendor Name: Veris Industries

BACnet Vendor ID 133

Product Name: E8950 Modbus-to-BACnet Protocol Converter

Product Model Number: E8950 w/Modbus Energy Meter

Product Description: Modbus-to-BACnet Protocol Converter

Protocol Conversions: Converts Modbus RTU to BACnet IP and BACnet MS/TP for supported products from Veris Industries

BACnet Protocol Version: Version 1 Revision 12

BACnet Standardized Device Prole (Annex L) – [Note: E8950 is a gateway device]

• BACnet Application Specic Controller (B‐ASC)

BACnet Interoperability Building Blocks Supported (Annex K):

• K.1.2 BIBB ‐ Data Sharing ‐ ReadProperty‐B (DS‐RP‐B)

• K.1.4 BIBB ‐ Data Sharing ‐ ReadPropertyMultiple‐B (DS‐RPM‐B)

• K.1.8 BIBB ‐ Data Sharing ‐ WriteProperty‐B (DS‐WP‐B)

• K.1.10 BIBB ‐ Data Sharing ‐ WritePropertyMultiple‐B (DS‐WPM‐B)

• K.1.12 BIBB ‐ Data Sharing ‐ COV‐B (DS‐COV‐B)

• K.2.2 BIBB ‐ Alarm and Event‐Notication Internal‐B (AE‐N‐I‐B)

• K.2.5 BIBB ‐ Alarm and Event‐ACK‐B (AE‐ACK‐B)

• K.2.11 BIBB ‐ Alarm and Event‐Information‐B (AE‐INFO‐B)

• K.5.2 BIBB ‐ Device Management ‐ Dynamic Device Binding‐B (DM‐

DDB‐B)

• K.5.4 BIBB ‐ Device Management ‐ Dynamic Object Binding‐B (DM‐DOB‐B)

• K.5.6 BIBB ‐ Device Management ‐ DeviceCommunicationControl‐B (DM‐

DCC‐ B)

• K.5.12 BIBB ‐ Device Management ‐ TimeSyncronization‐B (DM‐TS‐B)

• K.5.22 BIBB ‐ Device Management – List Manipulation‐B (DM‐LM‐B)

Standard Object Types Supported

• Device Object

• Analog Input

• Analog Output*

• Analog Value

• Binary Input*

• Binary Output*

• Binary Value*

• Multi State Input*

• Multi State Output*

• Multi State Value*

• Notication Class Object*

* Supported by device driver, but not used by current device proles

Unsupported Properties and Restrictions

• Does not support BACnet CreateObject

• Does not support BACnet DeleteObject

• Does not support any proprietary properties

• No proprietary properties exist

• No range restrictions exist

• Max_Master is writable, but it reverts to 127 when the E8950 is reset or

powered-up.

Data Link Layer Options:

• BACnet IP, (Annex J)

• MS/TP master (Clause 9), baud rate up to 76.8 kbps

Networking Options:

• BACnet/IP Broadcast Management Device (BBMD)

• Registrations by Foreign Devices

Character Sets Supported:

• ISO 10646 (UTF-8) / ANSI X3.4

General Programming Information

The E8950, in Discovery mode, queries each Modbus address, from 1 to 247 for a slave

ID. For each address queried, if a meter responds with a slave_ID that matches those

supported by the E8950, a BACnet device object and a full set of data objects are

created (see Appendix 1).

The initial Object_Identier (Device_ID) property value of each device objec t

discovered is the sum of the Device_ID oset programmed into the E8950 and the

Modbus address of the meter. The factory default value of the oset is 50000; use

the GUI to change this value. The new value will be applied the next time the E8950

is power cycled or reset. Once a device’s Object_Identier is overwritten, changes

to the ID Oset will no longer aect that Object_Identier, even in Discovery mode.

Make further changes to the value by writing the Object_Identier property.

The default Object_Name property value of each device object is an abbreviated

name of the meter series discovered with an underscore and the Modbus address of

the meter appended to it. The Object_Name is a writable property. Once a device’s

Object_Name is overwritten, the Object_Name will not rever t to the initial default,

even in Discovery mode. Make fur ther changes to the value by writing the Object_

name property.

The default description property value of each device object is the rst 40 characters

of the Modbus slave ID returned by the meter discovered. The description is not a

writable property.

The E8950 supports Subscribe_COV, with default COV increment values assigned

as shown in the data object tables (see Appendix for value tables for each meter).

If these values are not appropriate for a specic application, write them as needed

when they are subscribed. On subsequent power c ycles, no subscriptions are active

and the COV increments return to their default values.

With few exceptions, any data values written to AV objects are accepted (without

error) by the data object and passed through to the corresponding Modbus register.

There is no direct indication via the BACnet protocol if invalid values are rejected.

After an invalid value is written to the Present_Value of an AV, subsequent reads

of that propert y return the new (invalid) value until the next time the E8950 scans

and updates the AV objects (this may take several seconds, depending on the overall

conguration and timing of the scan sequence). The tables in Appendix 1 specify valid

values for AV objects of each supported model.

ZL0105-0B PAGE 8 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 9

E8950

TM

TROUBLESHOOTING

Problem Solution

Use the main screen of the E8950 GUI to conrm which meters have been discovered.

Verify that the Modbus device is a model specically supported by the E8950 (see Appendix 1).

Verify that the meter is connected to a control power source and is operating normally.

Verify that the Modbus 2-wire RS-485 connection is correctly wired from the E8950 to all

Modbus device is not discovered as expected.

other Modbus devices and that the chain is terminated at both ends with 120 Ω resistors (not

included).

Verify that the Modbus RTU baud is set to the same rate on all Modbus devices and that parity

on all devices is set to “none.”

Verify that the E8950 is powered and operating (the light green LED is on).

Verify that the E8950 is in Discovery mode.

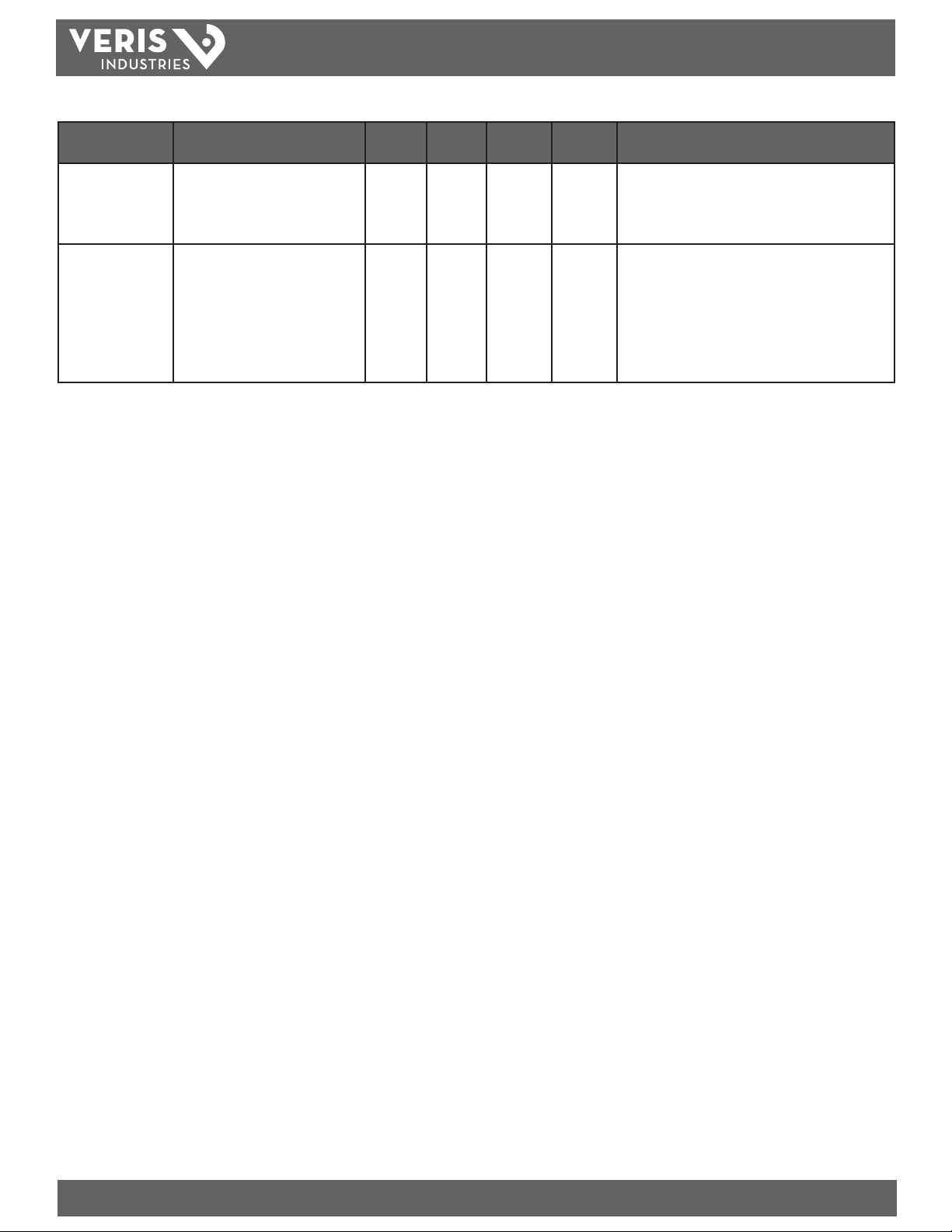

CHINA ROHS COMPLIANCE INFORMATION (EFUP TABLE)

产品中有毒有害物质或元素的名称及含量Substances

INSTALLATION GUIDE

部件名称

铅 (Pb) 汞 (Hg) 镉 (Cd) 六价铬 (Cr(VI)) 多溴联苯(PBB) 多溴二苯醚(PBDE)

电子线路板 X O O O O O

O = 表示该有毒有害物质在该部件所有均质材料中的含量均在 SJ/T11363-2006 标准规定的限量要求以下.

X = 表示该有毒有害物质至少在该部件的某一均质材料中的含量超出SJ/T11363-2006标准规定的限量要求.

Z000057-0A

ZL0105-0B PAGE 9 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 10

E8950

TM

INSTALLATION GUIDE

APPENDIX 1: DATA OBJECTS FOR SUPPORTED METERING DEVICES

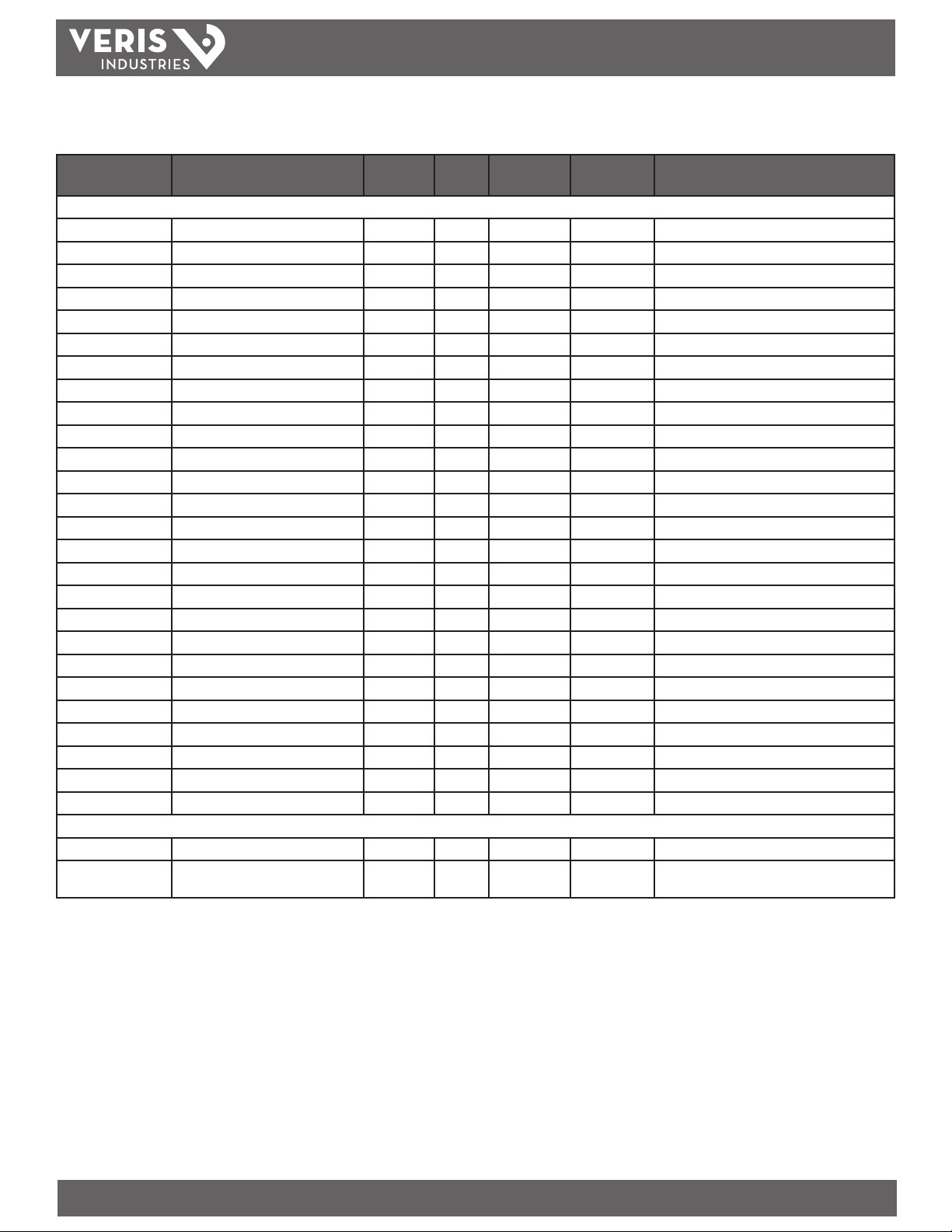

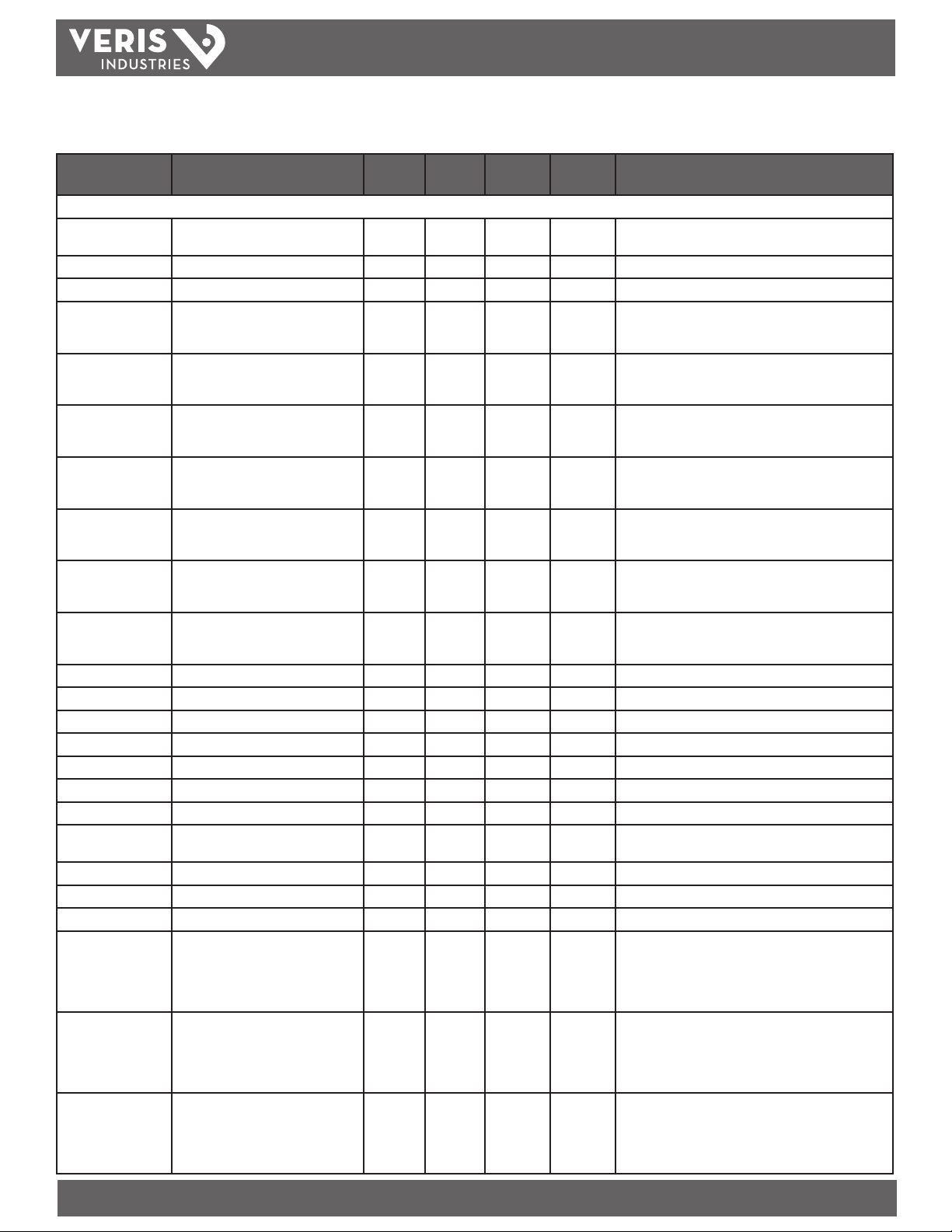

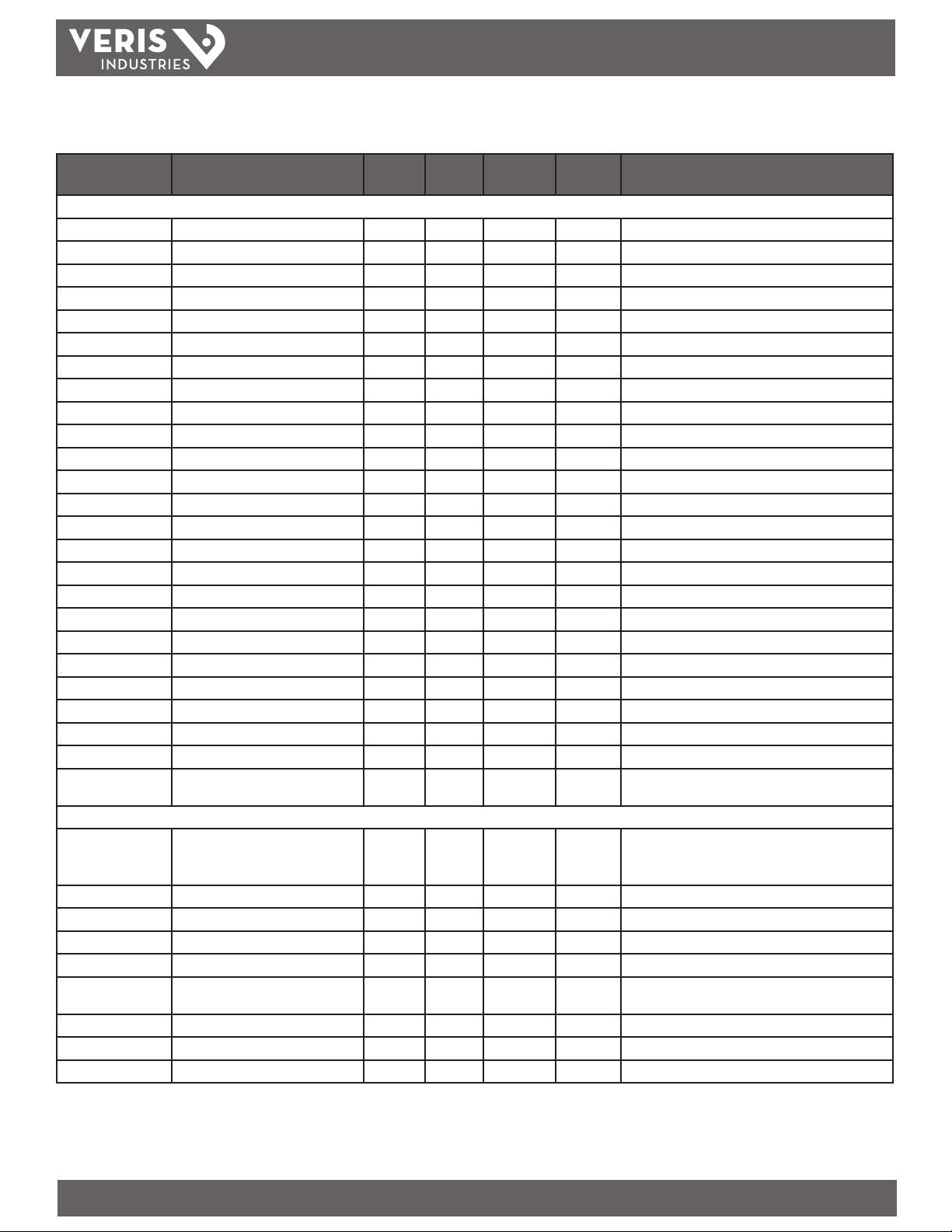

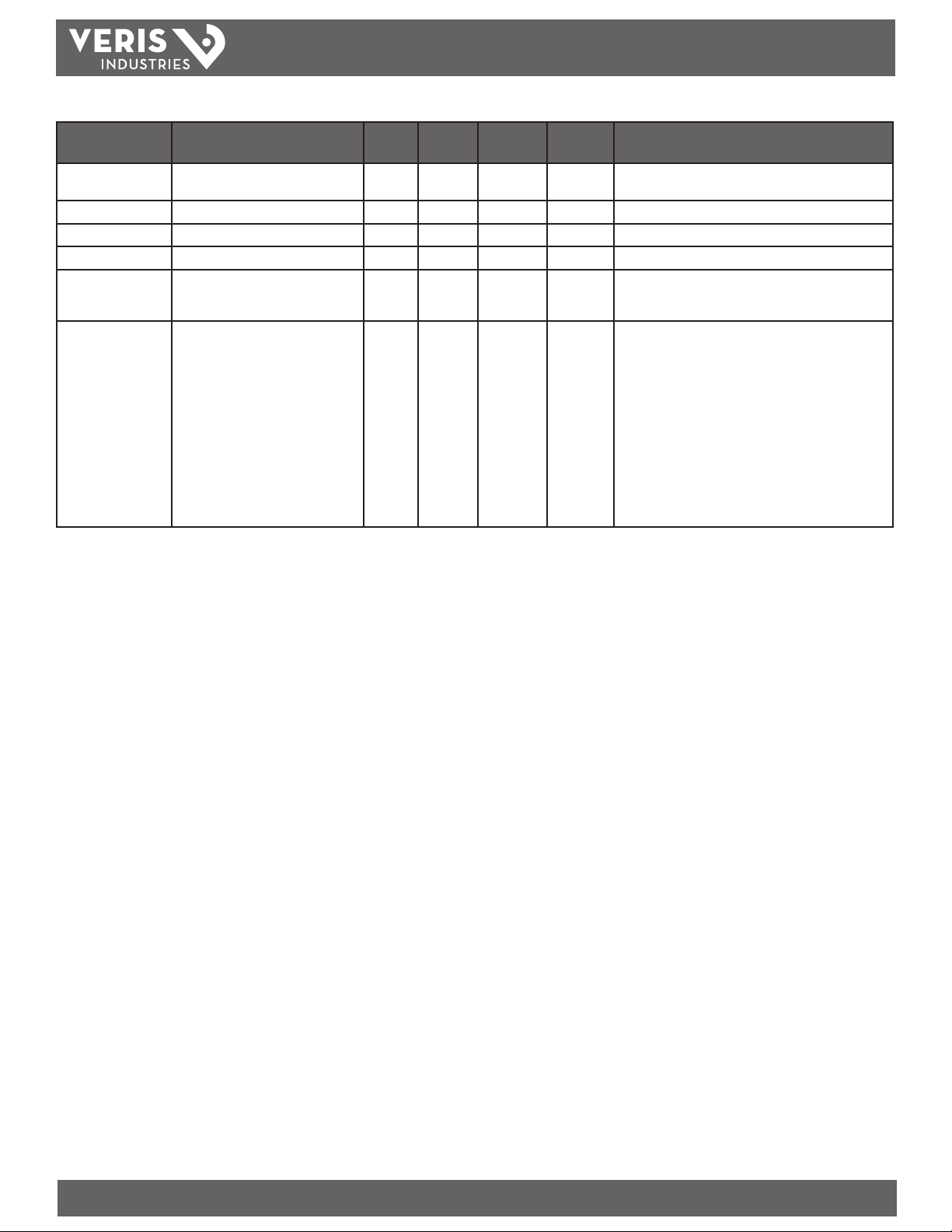

Enercept H8035 Series Energy Meters (all models)

The H8035 Series has 3 data objects and operates at 9600 baud.

Data Variable Description BACnet

Object

Analog_input objects: (Read-only)

kWh Energy: Total Accumulated Real Energy AI1 kWH 0 40259/40260

kW: Total Total Instantaneous Real Power AI2 kW 1 40261/40262

Analog_Value objects: (can be written as well as read)

kWh Energy Reset Write zero to reset AV1 n/a 32767 40001

Units COV_

Increment

Modbus

Address

Comments

ZL0105-0B PAGE 10 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 11

TM

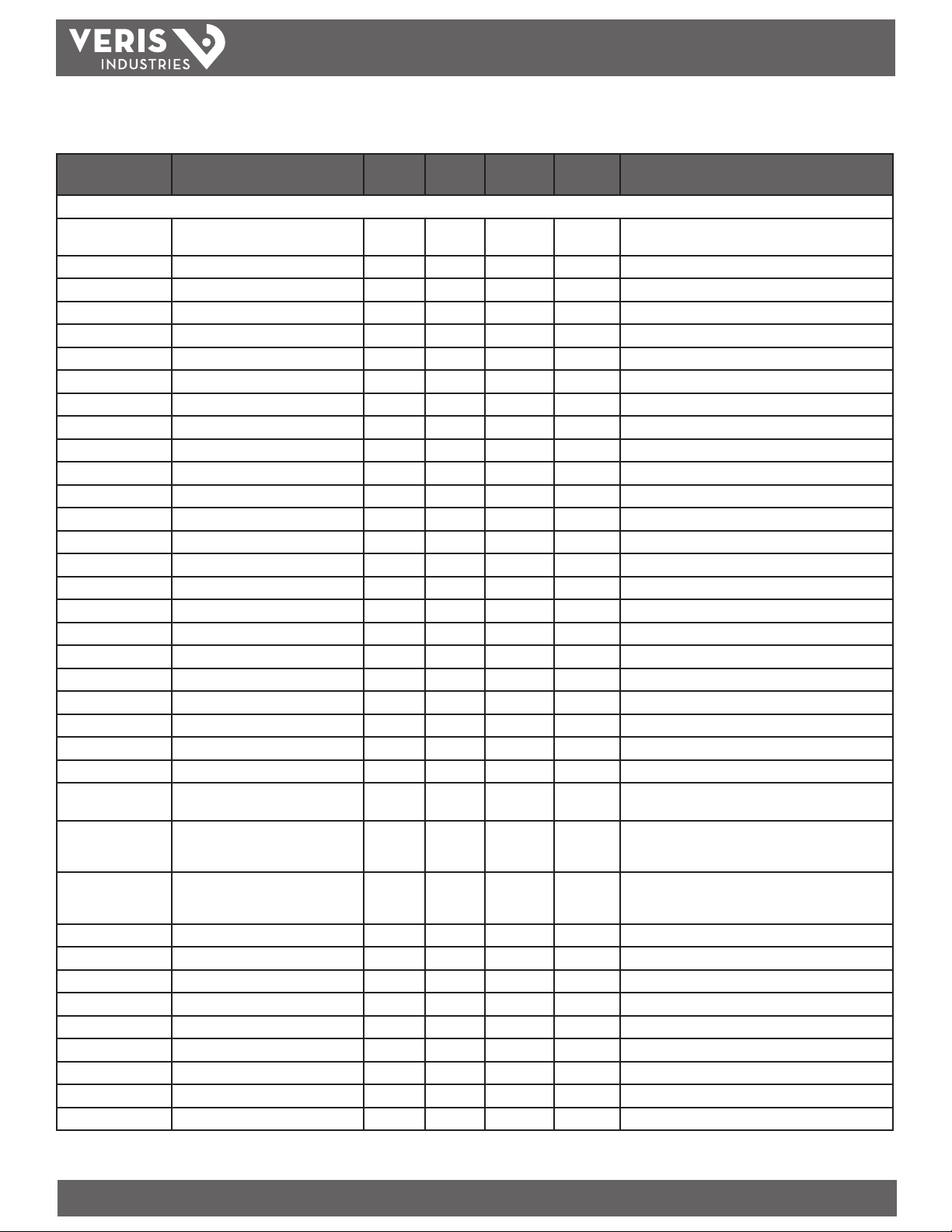

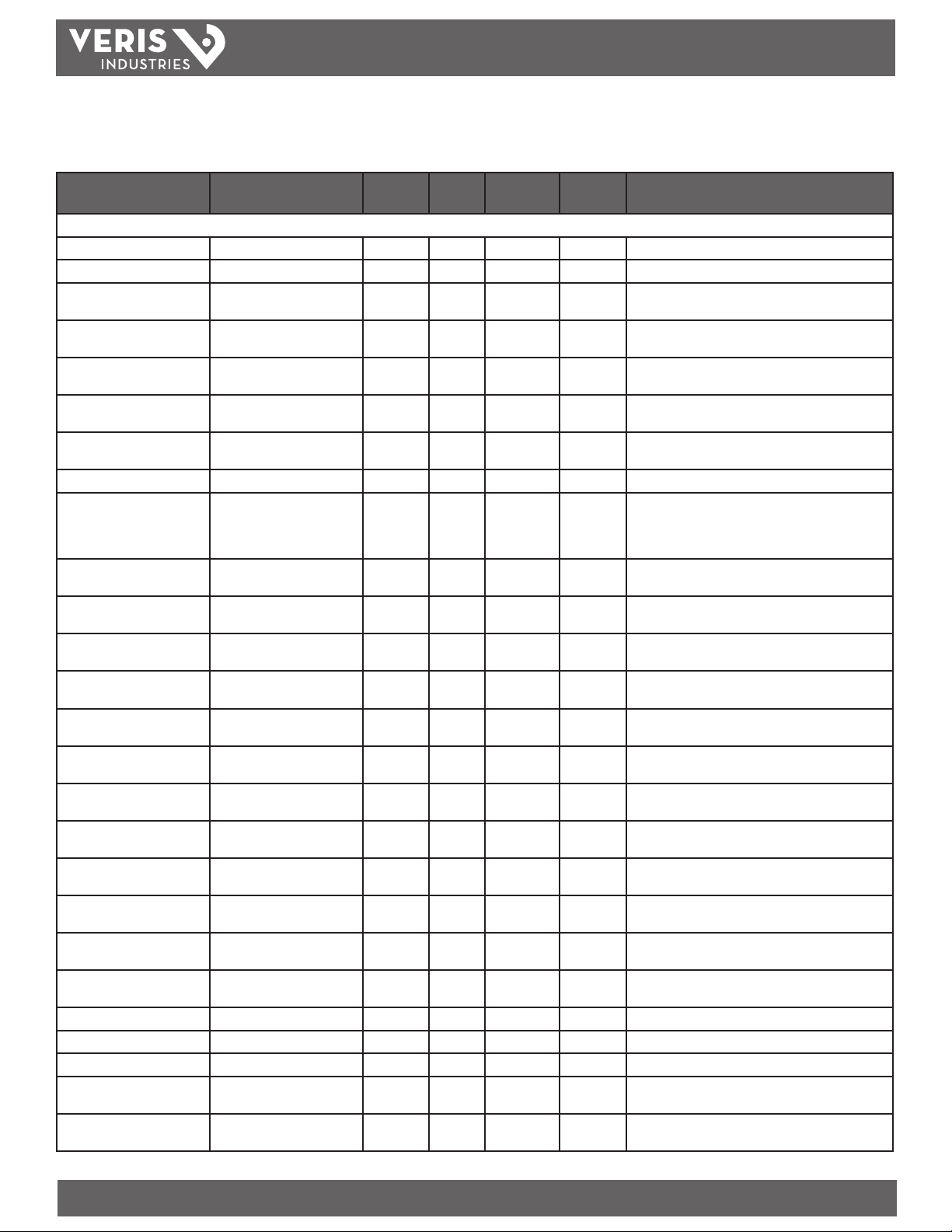

Enercept H8036 Series Energy Meters (all models)

The H8036 Series has 28 data objects and operates at 9600 baud.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Object

Analog_input objects: (Read-only)

kWh Energy: Total Accumulated Real Energy AI1 kWh 0 40259/260

kW: Total Total Instantaneous Real Power AI2 kW 1 40261/262

kVAR: Total Total Instantaneous Reactive Power AI3 kVAR 1 40263/264

kVA: Total Total Instantaneous Apparent Power AI4 kVA 1 40265/266

PF: Total Total Power Factor AI5 PF 0.01 40267/268

Volts: L-L Avg Voltage L-L average of active phases AI6 Volts 5 40269/270

Volts: L-N Avg Voltage L-N average of active phases AI7 Volts 5 40271/272

Amps: Avg Current Avg of active phases AI8 Amps 5 40273/274

kW: Ph A Instantaneous Real Power Phase A AI9 kW 1 40275/276

kW: Ph B Instantaneous Real Power Phase B AI10 kW 1 40277/278

kW: Ph C Instantaneous Real Power Phase C AI11 kW 1 40279/280

PF: Ph A Instantaneous Power Factor Phase A AI12 PF 0.01 40281/282

PF: Ph B Instantaneous Power Factor Phase B AI13 PF 0.01 40283/284

PF: Ph C Instantaneous Power Factor Phase C AI14 PF 0.01 40285/286

Volts: Ph A-B Instantaneous Voltage Phase A to Phase B AI15 Volts 5 40287/288

Volts: Ph B-C Instantaneous Voltage Phase B to Phase C AI16 Volts 5 40289/290

Volts: Ph A-C Instantaneous Voltage Phase A to Phase C AI17 Volts 5 40291/292

Volts: Ph A-N Instantaneous Voltage Phase A to Neutral AI18 Volts 5 40293/294

Volts: Ph B-N Instantaneous Voltage Phase B to Neutral AI19 Volts 5 40295/296

Volts: Ph C-N Instantaneous Voltage Phase C to Neutral AI20 Volts 5 40297/298

Amps: Ph A Instantaneous Current Phase A AI21 Amps 5 40299/300

Amps: Ph B Instantaneous Current Phase B AI22 Amps 5 40301/302

Amps: Ph C Instantaneous Current Phase C AI23 Amps 5 40303/304

kW: Average Average Real Power since last reset AI24 kW 1 40305/306

kW: Min Minimum Real Power since last reset AI25 kW 1 40307/308

kW: Max Maximum Real Power since last reset AI26 kW 1 40309/310

Analog_Value objects: (can be written as well as read)

kWh Energy Reset Write Zero to reset AV1 n/a 32767 40001

kW Average, Min, Max

Reset

Write Zero to reset AV 2 n/a 32767 40026

Units COV_

Increment

Modbus

Address

Comments

ZL0105-0B PAG E 11 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 12

E8950

TM

INSTALLATION GUIDE

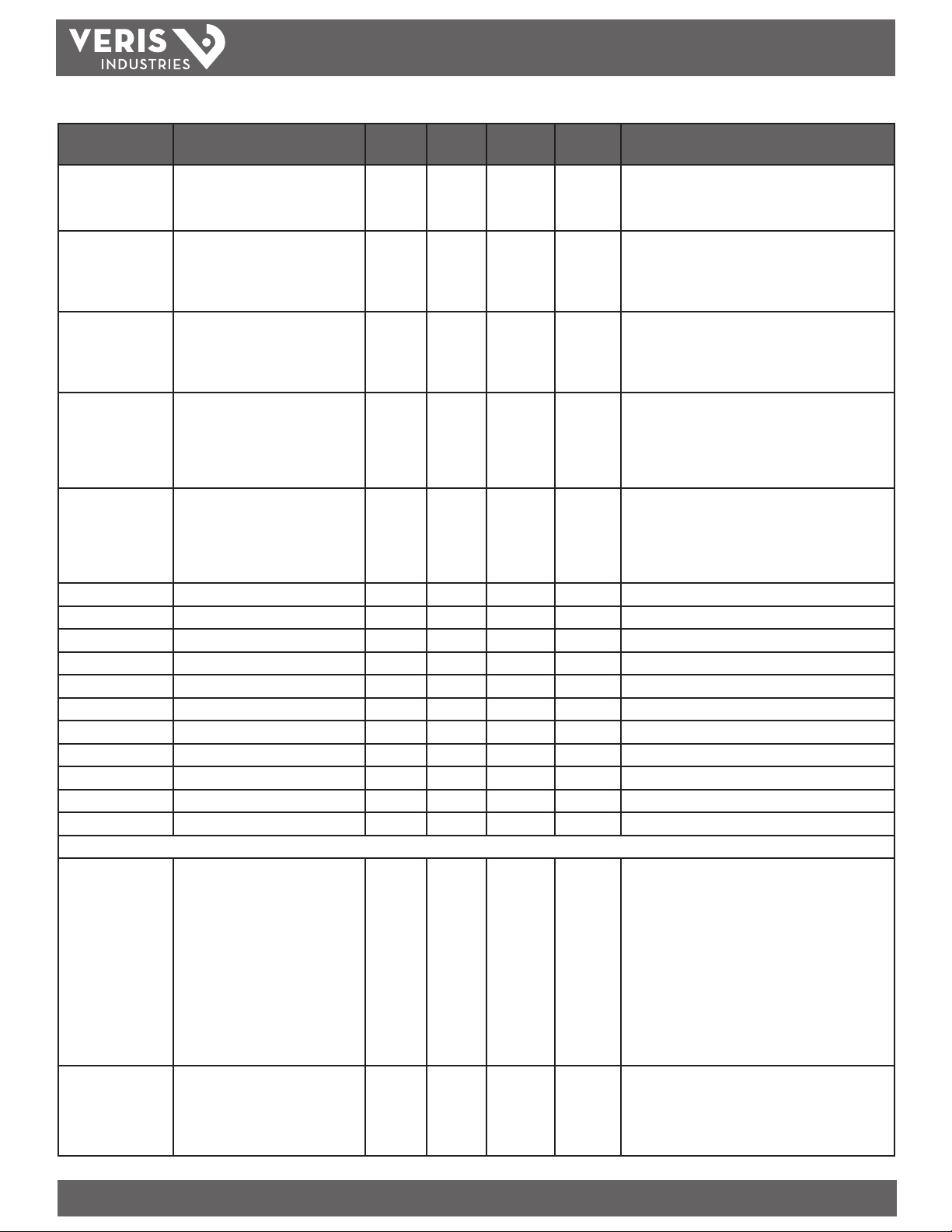

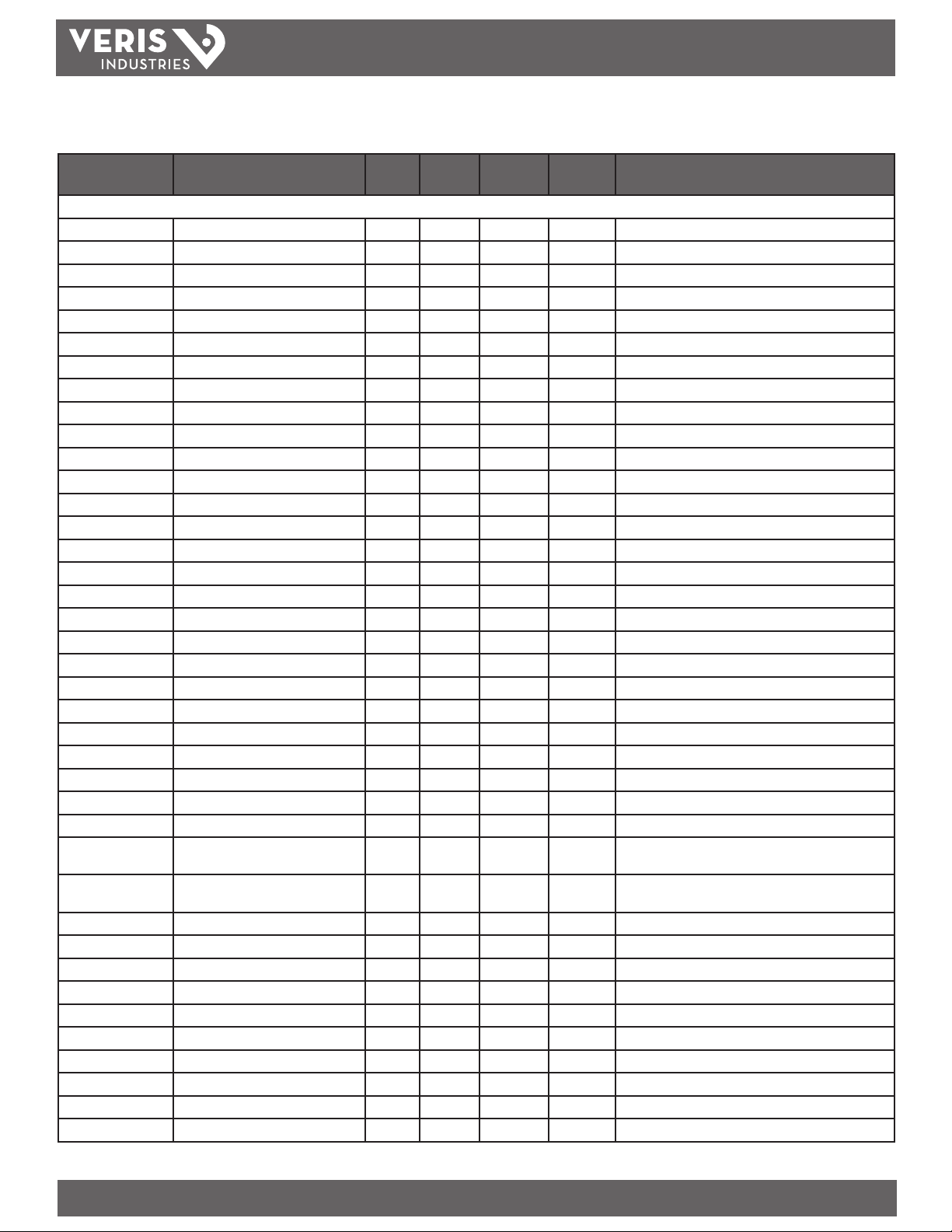

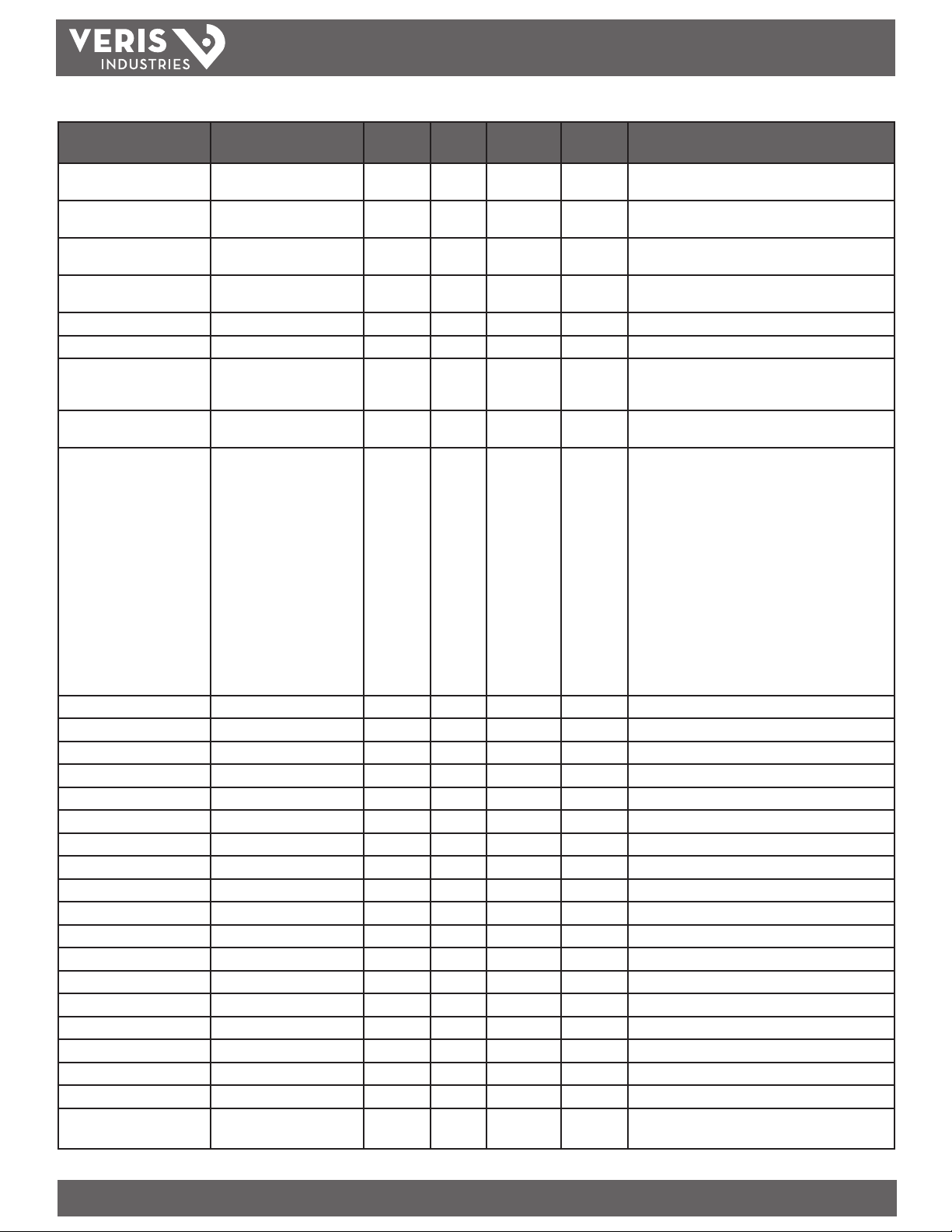

E50C2 and E50C3 Uni-Directional Energy Meter

The E50C2/C3 has 63 data objects and operates at 9600, 19200 or 38400 baud. The E8950 does not support the logging functionality of the E50C3.

Data Variable Description BACnet

Object

Analog_input objects: (Read-only)

kWh Energy: Total Accumulated Real Energy AI1 kWh 0 259/260 Resolution is limited by data type (when value exceeds 7

kW: Total Total Instantaneous Real Power AI2 kW 1 261/262

kVAR: Total Total Instantaneous Reactive Power AI3 kVAR 1 263/264

KVA: Total Total Instantaneous Apparent Power AI4 kVA 1 265/266

PF: Total Total Instantaneous Power Factor AI5 PF 0.01 267/268

Volts: L-L Avg Voltage L-L average of active phases AI6 Volts 5 269/270

Volts: L-N Avg Voltage L-N average of active phases AI7 Volts 5 271/272

Amps: Avg Current Avg of active phases AI8 Amps 5 273/274

kW: Ph A Instantaneous Real Power Phase A AI9 kW 1 275/276

kW: Ph B Instantaneous Real Power Phase B AI10 kW 1 277/278

kW: Ph C Instantaneous Real Power Phase C AI11 kW 1 279/280

PF: Ph A Instantaneous Power Factor Phase A AI12 PF 0.01 281/282

PF: Ph B Instantaneous Power Factor Phase B AI13 PF 0.01 283/284

PF: Ph C Instantaneous Power Factor Phase C AI14 PF 0.01 285/286

Volts: Ph A-B Instantaneous Voltage Phase A to Phase B AI15 Volts 5 287/288

Volts: Ph B-C Instantaneous Voltage Phase B to Phase C AI16 Volts 5 289/290

Volts: Ph A-C Instantaneous Voltage Phase A to Phase C AI17 Volts 5 291/292

Volts: Ph A-N Instantaneous Voltage Phase A to Neutral AI18 Volts 5 293/294

Volts: Ph B-N Instantaneous Voltage Phase B to Neutral AI19 Volts 5 295/296

Volts: Ph C-N Instantaneous Voltage Phase C to Neutral AI20 Volts 5 297/298

Amps: Ph A Instantaneous Current Phase A AI21 Amps 5 299/300

Amps: Ph B Instantaneous Current Phase B AI22 Amps 5 301/302

Amps: Ph C Instantaneous Current Phase C AI23 Amps 5 303/304

Reserved Reserved AI24 n/a 0 305/306

Frequency Instantaneous Frequency AI25 Hz 0.01 307/308 Returns QNAN if frequency is out of range (or no voltage

kVAh: Total Accumulated Apparent Energy

Consumption

kVARh: Total Accumulated Reactive Energy

Consumption

kVA: Ph A Instantaneous Apparent Power Phase A AI28 kVA 1 313/314

kVA: Ph B Instantaneous Apparent Power Phase B AI29 kVA 1 315/316

kVA: Ph C Instantaneous Apparent Power Phase C AI30 kVA 1 317/318

kVAR: Ph A Instantaneous Reactive Power Phase A AI31 kVAR 1 319/320

kVAR: Ph B Instantaneous Reactive Power Phase B AI32 kVAR 1 321/322

kVAR: Ph C Instantaneous Reactive Power Phase C AI33 kVAR 1 323/324

kW: Demand Total Real Power Present Demand AI34 kW 1 325/326

kVAR: Demand Total Reactive Power Present Demand AI35 kVAR 1 327/328

kVA: Demand Total Apparent Power Present Demand AI36 kVA 1 329/330

AI26 kWh 0 309/310 The UNITS property of this object reports kWh because there

AI27 kWh 0 311/312 The UNITS property of this object reports kWh because there

Units COV_

Increment

Modbus

Address

Comments

digits, reset more often to maximize resolution)

input present on Phase A)

is no unit type in this verision of the BACnet standard for

kVARh.

is no unit type in this verision of the BACnet standard for

kVARh.

ZL0105-0B PAGE 12 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 13

TM

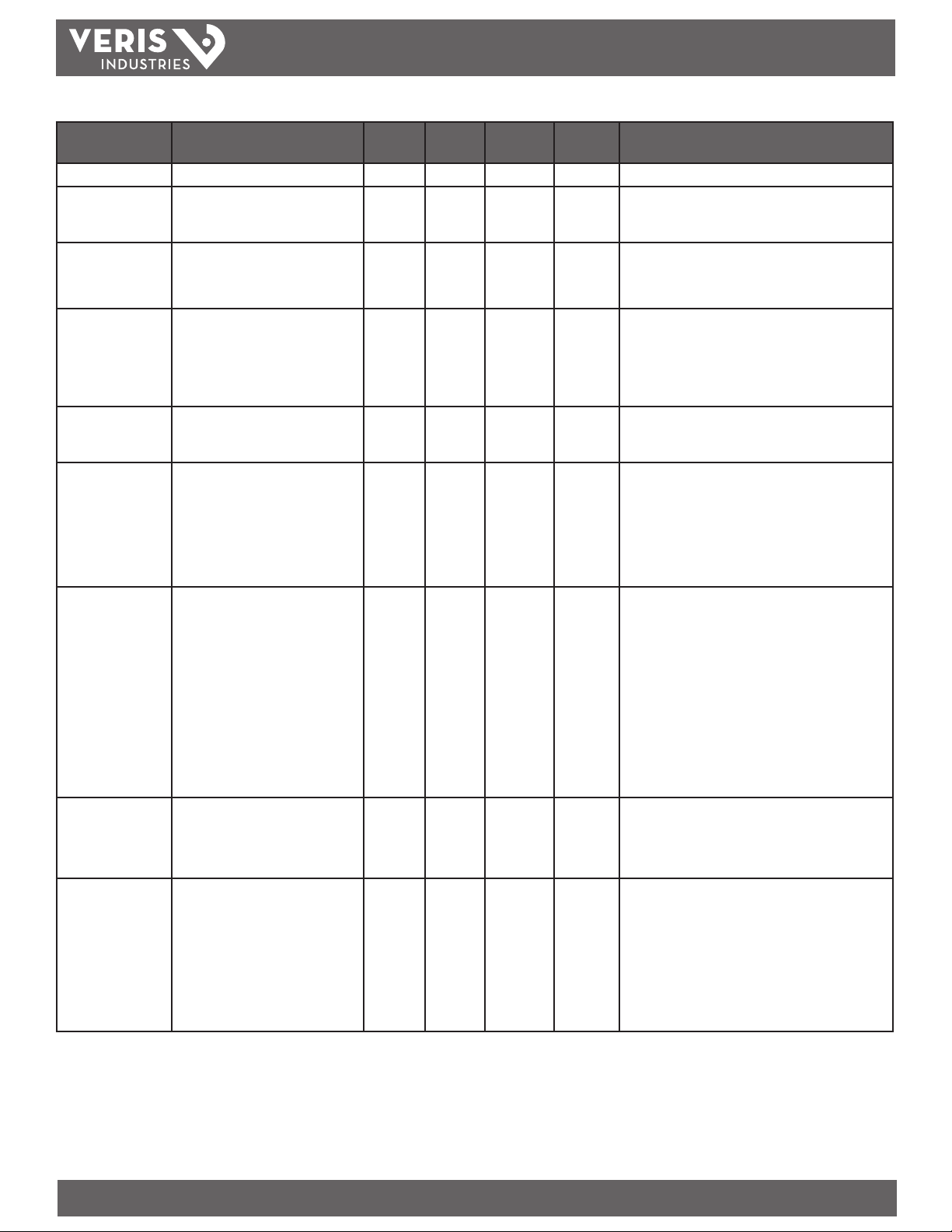

E50C2 and E50C3 Uni-Directional Energy Meter, cont.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Object

kW: Max Demand Total Real Power Max. Demand AI37 kW 0 331/332 This retains the largest value measured for Total Real Power

kVAR: Max Demand Total Reactive Power Max. Demand AI38 kVAR 0 333/334 This retains the largest value measured for Total Reactive

kVA: Max Demand Total Apparent Power Max. Demand AI39 kVA 0 335/336 This retains the largest value measured for Total Apparent

Pulse Counter 1 (Real

Energy)

Pulse Counter 2 Pulse Counter 2 AI41 n/a 0 339/340 Contact closure counter for Reactive Energy pulse output.

kWh: Ph A Real Energy Consumption - Phase A AI42 kWh 1 341/342

kWh: Ph B Real Energy Consumption - Phase B AI43 kWh 1 343/344

kWh: Ph C Real Energy Consumption - Phase C AI44 kWh 1 345/346

Max_Power Max Power AI45 kW 0 135

Reserved_AI77 (Reserved AI77) AI46 n/a 65535 136

Energy_Resets Count of Energy_Resets AI47 n/a 0 147

Reserved_AI79 Reserved_AI79 AI48 n/a 65535 148

Reserved_AI80 Reserved_AI80 AI49 n/a 65535 151

Power_Up_Count Count of Power Up Cycles AI50 n/a 0 152

Output_Cong Output Conguration AI51 n/a 0 153

Alarm Error Bitmap Bitmap of all alarm bits AI52 n/a 0 146

Analog_Value objects: (can be written as well as read)

Reset: write values to

reset congs

System Type (being

metered)

Pulse Counter 1 (Real Energy) AI40 n/a 0 337/338 Contact closure counter for Real Energy pulse output. Check

30078=Acc 21211=Dmd 21212=Max

16498=Puls

10=1ph 11=2ph 12=2ph+N 31=3ph-Y

40=3ph+N

AV1 n/a 0 129 Reset (aka Command Register):

AV2 n/a 0 130 10 = Single Phase: A + N

Units COV_

Increment

Modbus

Address

Comments

Demand (AI34) for any single demand interval since the

Max Demand was last explicitly reset via AV1 (this also

resets when the demand interval changes).

Power Demand (AI35) for any single demand interval since

the Max Demand was last explicitly

reset via AV1 (this also resets when the demand interval

changes).

Power Demand (AI36) for any single demand interval since

the Max Demand was last explicitly

reset via AV1 (this also resets when the demand interval

changes).

Pulse setup on the LCD display for the weight of each pulse

output count. These values are derived from 32 bit integer

counter and roll over to 0 when the integer counters do.

Write 16498 (0x4072) to the Present_Value property of

Analog_Value object AV1 to reset both Pulse Counters to 0.

Check Pulse setup on the LCD display for the weight of each

pulse output count. These values are derived from 32 bit

integer counter and roll over to 0 when the integer counters

do. Write 16498 (0x4072) to the Present_Value property of

Analog_Value object AV1 to reset both Pulse Counters to 0.

- Write 30078 (0x757E) to clear all Energy Accumulators to

0 (All).

- Write 21211 (0x52DB) to begin new Demand Sub-Interval

calculation cycle. Takes eect at the end of the next 1

second calculation cycle. Write no more frequently than

every 10 seconds.

- Write 21212 (0x52DC) to reset Max Demand values to

Present Demand Values. Takes eect at the end of the next

1 second calculation cycle. Write no more frequently than

every 10 seconds.

- Write 16498 (0x4072) to clear Pulse Counts to zero.

- Read always returns 0.

11 = Single Phase: A + B

12 = Single Split Phase: A + B + N

31 = 3 phase Δ, A + B + C, no N

40 = 3 phase Y, A + B + C + N

ZL0105-0B PAGE 13 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 14

TM

E50C2 and E50C3 Uni-Directional Energy Meter, cont.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Object

CT Ratio Primary CT Ratio Primary (5A to 32000A) AV 3 Amps 0 131 Current Transducer Size - Primary Current Range

CT Ratio Secondar y CT Ratio Secondary (1=1VAC 3=1/3VAC) AV4 n/a 0 132 Current Transducer Type – Secondar y Interface

PT Ratio Potential Transformer Ratio (1 = no PT) AV 5 n/a 0 133 PT Ratio: The meter scales this value by 100 (i.e. entering 200

System Voltage Line-Line Voltage of Service Metered AV 6 Volts 0 134 System Voltage: This voltage is line to line, unless in system

Display Units Display Units (0=IEC 1=iEEE) AV 7 n/a 0 137 Display Units:

Phase Loss Voltage

Threshold

Phase Loss Imbalance

Threshold

Num of Sub-Intrvl per

Dem Intrvl

Sub-Interval Length 10 to 32767 seconds (0= Sync-to-

Phase Loss Thresh (% of System Voltage) AV 8 Percent 0 142 Phase Loss Voltage Threshold in percent of System Voltage

Phase Loss Imbalance (% L-L variation) AV9 Percent 0 143 Phase Loss Imbalance Threshold in Percent. Default is 25%

1=most recent; n(2-6)=avg of last n AV10 n/a 0 149 Number of Sub-Intervals per Demand Interval. Sets the

AV11 Seconds 0 150 Sub-Interval Length in hundredths of a second. For sync-to-

Comms)

Units COV_

Increment

Modbus

Address

Comments

- Enter 1 for CTs with 1V outputs

- Enter 3 for CTs with 1/3V outputs

yields a potential transformer ratio of 2:1). The default is

100 (1.00:1), which is with no PT attached. Set this value

before setting the system voltage (below)

type 10 (AV2), which is line to neutral.

The meter uses this value to calculate the full scale power

for the pulse conguration (below), and as full scale for

phase loss (AV8). The meter will refuse voltages outside the

range of 82-660 volts when divided by the PT Ratio (above).

0 = IEC (U, V, P, Q, S)

1 = IEEE (default: VLL, VLN, W, VAR, VA)

(in object AV6). Default is 10 (10%). Any phase (as

congured in AV2) whose level drops below this threshold

triggers a Phase Loss alert. E.g., if the System voltage is set

to 480 V L-L, the nominal L-N voltage for each phase should

be 277 V. When the threshold is set to 10%, if any phase

drops below 27.7 V, or if any L-L voltage drops below 48 V

the corresponding phase loss alarm bit is true.

phase to phase dierence. For a 3-phase Y (3 + N) system

type (40 in object AV2), both Line to Neutral and Line to

Line voltages are tested. In a 3-phase Δ System type (31 in

object AV2), only Line to Line voltages are examined. In a

single split-phase (2 + N) system type (12 in object AV2),

just the line to neutral voltage are compared. E.g., if the

System Type is 40 (3-phase with Neutral) and the Phase

Loss Imbalance Threshold is 25%, a Phase Imbalance is

indicated when the L-L voltage between any t wo phases

drops to less than 75% of the L-L voltage between any

other two phases or when the L-N voltage of any phase

drops to less than 75% of the L-N voltage of any other

phase.

number of sub-intervals that make a single demand

interval. For block demand, set this to 1. Default is 1. When

Sub-Interval Length (in object AV11) is set to 0 (sync-tocomms mode), the value of this object is ignored.

comms mode, which allows manual triggering of demand

intervals and the logging of another Trend_Log record, set

this value to 0 and write 21211 to the reset register (object

AV1) each time the sub-interval must be externally reset.

Default is 90000 (15 minutes). This variable is tied directly

to the Log_Interval property of all three Trend_Log objects

(their value is always the same as this one). Changing any

of these four properties

changes all of them.

ZL0105-0B PAGE 14 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 15

E8950

TM

INSTALLATION GUIDE

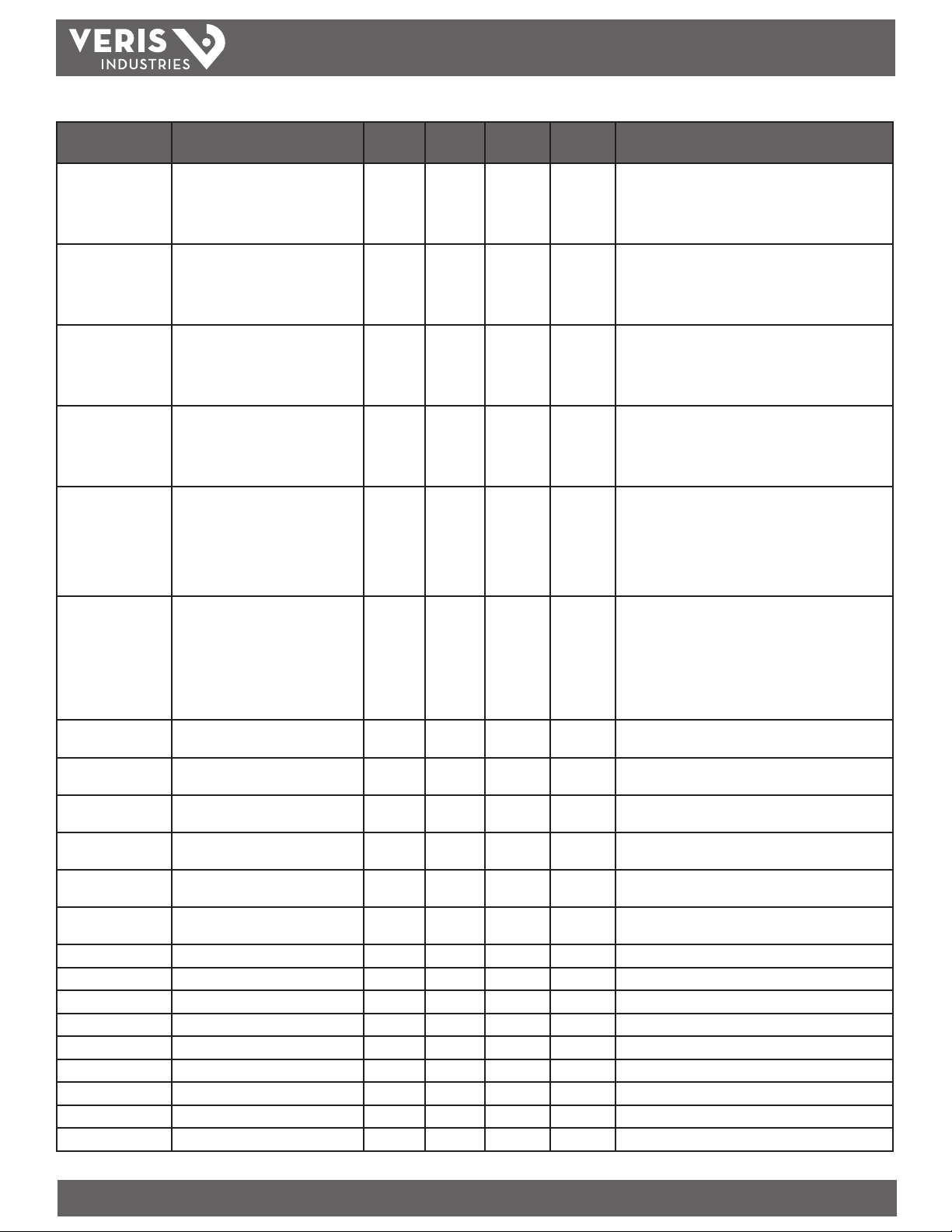

E51C2 and E51C3 Bi-Directional Energy Meter

The E51C2/C3 has 94 data objects and operates at 9600, 19200 or 38400 baud. The E8950 does not support the logging functionality of the E51C3.

Data Variable Description BACnet

Object

Analog_input objects: (Read-only)

kWh: Net Accumulated Net Real Energy AI1 kWh 0 257/258 Resolution is limited by data type (when value exceeds 7

kWh: Import Real Energy: Import (Quadrants 1 & 4) AI2 kWh 0 259/260

kWh: Export Real Energy: Export (Quadrants 2 & 3 ) AI3 kWh 0 261/262

kVARh: Quad 1 Reactive Energy: Quad 1 (Lags Import) AI4 n/a 0 263/264 The UNITS property of this object will report n/a because

kVARh: Quad 2 Reactive Energy: Quad 2 (Leads Export) AI5 n/a 0 265/266 The UNITS property of this object will report n/a because

kVARh: Quad 3 Reactive Energy: Quad 3 (Lags Export) AI6 n/a 0 267/268 The UNITS property of this object will report n/a because

kVARh: Quad 4 Reactive Energy: Quad 4 (Leads Import) AI7 n/a 0 269/270 The UNITS proper ty of this object will report n/a because

kVAh: Net Apparent Energy: Net AI8 n/a 0 271/272 The UNITS property of this object will report n/a because

kVAh: Import Apparent Energy: Import (Quads 1 & 4) AI9 n/a 0 273/274 The UNITS property of this object will report n/a because

kVAh: Export Apparent Energy: Export (Quads 2 & 3 ) AI10 n/a 0 275/276 The UNITS property of this object will report n/a because

kW: Total Net Total Net Instantaneous Real Power AI11 kW 1 277/278

kVAR: Total Net Total Net Instantaneous Reactive Power AI12 kVAR 1 279/280

kVA: Total Net Total Net Instantaneous Apparent Power AI13 kVA 1 281/282

PF: Total Total Instantaneous Power Factor AI14 PF 0.01 283/284

Volts: L-L Avg Voltage L-L average of active phases AI15 Volts 5 285/286

Volts: L-N Avg Voltage L-N average of active phases AI16 Volts 5 287/288

Amps: Avg Current Avg of active phases AI17 Amps 5 289/290

Frequency Instantaneous Frequency AI18 Hz 0.01 291/292 Will return QNAN if frequency is out of range (or no voltage

kW: Demand Total Real Power Present Demand AI19 kW 1 293/294

kVAR: Demand Total Reactive Power Present Demand AI20 kVAR 1 295/296

kVA: Demand Total Apparent Power Present Demand AI21 kVA 1 297/298

kW: Total Import Max.

Demand

kVAR: Total Import Max.

Demand

kVA: Total Import Max.

Demand

Total Import Real Power Max. Demand AI22 kW 0 299/300 This retains the largest positive (Impor t) value measured for

Total Import Reactive Power Max.

Demand

Total Import Apparent Power Max.

Demand

AI23 kVAR 0 301/302 This retains the largest positive (Import) value measured for

AI24 kVA 0 303/304 This retains the largest positive (Import) value measured

Units COV_

Increment

Modbus

Address

Comments

digits; reset more often to maximize resolution)

there is no unit type in this verision of the BACnet standard

for kVARh.

there is no unit type in this verision of the BACnet standard

for kVARh.

there is no unit type in this verision of the BACnet standard

for kVARh.

there is no unit type in this verision of the BACnet standard

for kVARh.

there is no unit type in this verision of the BACnet standard

for kVAh.

there is no unit type in this verision of the BACnet standard

for kVAh.

there is no unit type in this verision of the BACnet standard

for kVAh.

input present on Phase A)

Total Real Power Demand (AI19) for any single demand

interval since the Max Demand were last explicitly reset

via AV1 (this is also reset when the demand interval is

changed).

Total Reactive Power Demand (AI20) for any single demand

interval since the Max Demand were last explicitly reset

via AV1 (this is also reset when the demand interval is

changed).

for Total Apparent Power Demand (AI21) for any single

demand interval since the Max Demand were last explicitly

reset via AV1 (this is also reset when the demand interval is

changed).

ZL0105-0B PAGE 15 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 16

TM

E51C2 and E51C3 Bi-Directional Energy Meter, cont.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Object

kW: Total Export Max.

Demand

kVAR: Total Export Max.

Demand

kVA: Total Export Max.

Demand

Reserved_AI28 (Reserved_AI28) AI28 kVA 1 311/312 This retains the largest negative (Export) value measured

Pulse Counter 1 Import

Real Energy

Pulse Counter 2 Export

Real Energy

kWh Energy: Import

Ph A

kWh Energy: Import

Ph B

kWh Energy: Import

Ph C

kWh Energy: Export

Ph A

kWh Energy: Export

Ph B

kWh Energy: Export

Ph C

kVARh: Q1 Ph A Accumulated Q1 Reactive Energy Ph A AI37 kWh 0 329/330

kVARh: Q1 Ph B Accumulated Q1 Reactive Energy Ph B AI38 kWh 0 331/332

kVARh: Q1 Ph C Accumulated Q1 Reactive Energy Ph C AI39 kWh 0 333/334

kVARh: Q2 Ph A Accumulated Q2 Reactive Energy Ph A AI40 kWh 0 335/336

kVARh: Q2 Ph B Accumulated Q2 Reactive Energy Ph B AI41 kWh 0 337/338

kVARh: Q2 Ph C Accumulated Q2 Reactive Energy Ph C AI42 kWh 0 339/340

kVARh: Q3 Ph A Accumulated Q3 Reactive Energy Ph A AI43 kWh 0 341/342

kVARh: Q3 Ph B Accumulated Q3 Reactive Energy Ph B AI44 kWh 0 343/344

kVARh: Q3 Ph C Accumulated Q3 Reactive Energy Ph C AI45 kWh 0 345/346

Total Export Real Power Max. Demand AI25 kW 0 305/306 This retains the largest negative (Export) value measured

Total Export Reactive Power Max.

Demand

Total Export Apparent Power Max.

Demand

Pulse Counter 1 Import Real Energy AI29 n/a 0 313/314 Contact closure counter for Real Energy Import pulse output.

Pulse Counter 2 Export Real Energy AI30 n/a 0 315/316 Contact closure counter for Real Energy Export pulse output

Accumulated Real Energy Import Ph A AI31 kWh 0 317/318

Accumulated Real Energy Import Ph B AI32 kWh 0 319/320

Accumulated Real Energy Import Ph C AI33 kWh 0 321/322

Accumulated Real Energy Export Ph A AI34 kWh 0 323/324

Accumulated Real Energy Export Ph B AI35 kWh 0 325/326

Accumulated Real Energy Export Ph C AI36 kWh 0 327/328

AI26 kVAR 0 307/308 This retains the largest negative (Export) value measured for

AI27 kVA 0 309/310 This retains the largest negative (Export) value measured

Units COV_

Increment

Modbus

Address

Comments

for Total Real Power Demand (AI19) for any single demand

interval since the Max Demand were last explicitly reset

via AV1 (this is also reset when the demand interval is

changed).

Total Reactive Power Demand (AI20) for any single demand

interval since the Max Demand were last explicitly reset

via AV1 (this is also reset when the demand interval is

changed).

for Total Apparent Power Demand (AI21) for any single

demand interval since the Max Demand were last explicitly

reset via AV1 (this is also reset when the demand interval is

changed).

for Total Apparent Power Demand (AI21) for any single

demand interval since the Max Demand were last explicitly

reset via AV1 (this is also reset when the demand interval is

changed).

Check Pulse setup on the LCD display for the weight of each

pulse output count. These values are derived from 32 bit

integer counter and roll over to 0 when the integer counters

do.

Write 16498 (0x4072) to the Present_Value property of

Analog_Value object AV1 to reset both Pulse Counters to 0.

(there is no physical output for this, but the pulses are

counted anyway). Check Pulse setup on the LCD display

for the weight of each pulse output count. These values

are derived from 32 bit integer counter and roll over to 0

when the integer counters do. Write 16498 (0x4072) to the

Present_Value property of Analog_Value object AV1 to reset

both Pulse Counters to 0.

ZL0105-0B PAGE 16 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 17

TM

E51C2 and E51C3 Bi-Directional Energy Meter, cont.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Object

kVARh: Q4 Ph A Accumulated Q4 Reactive Energy Ph A AI46 kWh 0 347/348

kVARh: Q4 Ph B Accumulated Q4 Reactive Energy Ph B AI47 kWh 0 349/350

kVARh: Q4 Ph C Accumulated Q4 Reactive Energy Ph C AI48 kWh 0 351/352

kVAh: Import Ph A Accumulated Appar. Energy Import Ph A AI49 kWh 0 353/354

kVAh: Import Ph B Accumulated Appar. Energy Import Ph B AI50 kWh 0 355/356

kVAh: Import Ph C Accumulated Appar. Energy Import Ph C AI51 kWh 0 357/358

kVAh: Export Ph A Accumulated Appar. Energy Export Ph A AI52 kWh 0 359/360

kVAh: Export Ph B Accumulated Appar. Energy Export Ph B AI53 kWh 0 361/362

kVAh: Export Ph C Accumulated Appar. Energy Export Ph C AI54 kWh 0 363/364

kW: Ph A Instantaneous Real Power Phase A AI55 kW 1 365/366

kW: Ph B Instantaneous Real Power Phase B AI56 kW 1 367/368

kW: Ph C Instantaneous Real Power Phase C AI57 kW 1 369/370

kVAR: Ph A Instantaneous Reactive Power Phase A AI58 kVAR 1 371/372

kVAR: Ph B Instantaneous Reactive Power Phase B AI59 kVAR 1 373/374

kVAR: Ph C Instantaneous Reactive Power Phase C AI60 kVAR 1 375/376

kVA: Ph A Instantaneous Apparent Power Phase A AI61 kVA 1 377/378

kVA: Ph B Instantaneous Apparent Power Phase B AI62 kVA 1 379/380

kVA: Ph C Instantaneous Apparent Power Phase C AI63 kVA 1 381/382

PF: Ph A Instantaneous Power Factor Phase A AI64 PF 0.01 383/384

PF: Ph B Instantaneous Power Factor Phase B AI65 PF 0.01 385/386

PF: Ph C Instantaneous Power Fac tor Phase C AI66 PF 0.01 387/388

Volts: Ph A-B Instantaneous Voltage Phase A to Phase B AI67 Volts 5 389/390

Volts: Ph B-C Instantaneous Voltage Phase B to Phase C AI68 Volts 5 391/392

Volts: Ph A-C Instantaneous Voltage Phase A to Phase C AI69 Volts 5 393/394

Volts: Ph A-N Instantaneous Voltage Phase A to Neutral AI70 Volts 5 395/396

Volts: Ph B-N Instantaneous Voltage Phase B to Neutral AI71 Volts 5 397/398

Volts: Ph C-N Instantaneous Voltage Phase C to Neutral AI72 Volts 5 399/400

Amps: Ph A Instantaneous Current Phase A AI73 Amps 5 401/402

Amps: Ph B Instantaneous Current Phase B AI74 Amps 5 403/404

Amps: Ph C Instantaneous Current Phase C AI75 Amps 5 405/406

Max_Power Max Power AI76 kW 0 135

Reserved_AI77 (Reserved AI77) AI77 n/a 65535 136

Energy_Resets Count of Energy_Resets AI78 n/a 0 147

Reserved_AI79 Reserved_AI79 AI79 n/a 65535 148

Reserved_AI80 Reserved_AI80 AI80 n/a 65535 151

Power_Up_Count Count of Power Up Cycles AI81 n/a 0 152

Output_Cong Output Conguration AI82 n/a 0 153

Alarm Error Bitmap Bitmap of all alarm bits AI83 n/a 0 146

Units COV_

Increment

Modbus

Address

Comments

ZL0105-0B PAGE 17 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 18

TM

E51C2 and E51C3 Bi-Directional Energy Meter, cont.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Object

Analog_Value objects: (can be written as well as read)

Reset: write values to

reset congs

System Type (being

metered)

CT Ratio Primary CT Ratio Primary (5A to 32000A) AV 3 Amps 0 131 Current Transducer Size - Primary Current Range

CT Ratio Secondar y CT Ratio Secondary (1=1VAC 3=1/3VAC) AV4 n/a 0 132 Current Transducer Type – Secondary Interface

PT Ratio Potential Transformer Ratio (1= no PT) AV5 n/a 0 133 PT Ratio: The meter scales this value by 100 (i.e. entering 200

System Voltage Line-Line Voltage of Service Metered AV 6 Volts 0 134 System Voltage: This voltage is line to line, unless in system

Display Units Display Units (0=IEC 1=iEEE) AV 7 n/a 0 137 Display Units: 0 = IEC (U, V, P, Q, S), 1 = IEEE (default: VLL,

Phase Loss Voltage

Threshold

Phase Loss Imbalance

Threshold

30078=Acc 21211=Dmd 21212=Max

16498=Puls

10=1ph 11=2ph 12=2ph+N 31=3ph-Y

40=3ph+N

Phase Loss Thresh (% of System Voltage) AV 8 Percent 0 142 Phase Loss Voltage Threshold in percent of System Voltage (in

Phase Loss Imbalance (% L-L variation) AV9 Percent 0 143 Phase Loss Imbalance Threshold in Percent. Default is 25%

AV1 n/a 0 129 Reset (aka Command Register):

AV2 n/a 0 130 10 = Single Phase: A + N

Units COV_

Increment

Modbus

Address

Comments

- Write 30078 (0x757E) to clear all Energy Accumulators to

0 (All).

- Write 21211 (0x52DB) to begin new Demand Sub-Interval

calculation cycle. Takes eect at the end of the next 1 second

calculation cycle. For proper operation, write no more

frequently than every 10 seconds.

- Write 21212 (0x52DC) to reset Max Demand values to

Present Demand Values. Takes eect at the end of the next

1 second calculation cycle. For proper operation, write no

more frequently than every 10 seconds.

- Write 16498 (0x4072) to clear Pulse Counts to zero.

- Read always returns 0.

11 = Single Phase: A + B

12 = Single Split Phase: A + B +

31 = 3 phase Δ, A + B + C, no N

40 = 3 phase Y, A + B + C + N

- Enter 1 for CTs with 1V outputs

- Enter 3 for CTs with 1/3V outputs

yields a potential transformer ratio of 2:1). The default is 100

(1.00:1), which is with no PT attached. Set this value before

setting the system voltage (below)

type 10 (AV2), which is line to neutral.

The meter uses this value to calculate the full scale power for

the pulse conguration (below), and as full scale for phase

loss (AV8). The meter will refuse voltages that are outside

the range of 82-660 volts when divided by the PT Ratio

(above).

VLN, W, VAR, VA)

object AV6). Default is 10 (10%). Any phase (as congured in

AV2) whose level drops below this threshold triggers a Phase

Loss alert. E.g., if the System voltage is set to 480 V L-L,

the L-N voltage for each phase should be 277 V. When the

threshold is set to 10%, if any phase drops below 27.7, or if

any L-L voltage drops below 48 V, the corresponding phase

loss alarm bit will be true.

phase to phase dierence. For a 3-phase Y (3 + N) system

type (40 in object AV2), both Line to Neutral and Line to Line

voltages are tested. In a 3-phase Δ System type (31 in object

AV2), only Line to Line voltages are examined. In a single

split-phase (2 + N) system type (12 in object AV2), just the

line to neutral voltage are compared. E.g., if the System Type

is 40 (3-phase with Neutral) and the Phase Loss Imbalance

Threshold is 25%, a Phase Imbalance is indicated when the

L-L voltage between any two phases drops to less than 75%

of the L-L voltage between any other two phases or when

the L-N voltage of any phase drops to less than 75% of the

L-N voltage of any other phase.

ZL0105-0B PAGE 18 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 19

TM

E51C2 and E51C3 Bi-Directional Energy Meter, cont.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Num of Sub-Intrvl per

Dem Intrvl

Sub-Interval Length 10 to 32767 seconds (0= Sync-to-

1=most recent; n(2-6)=avg of last n AV10 n/a 0 149 Number of Sub-Intervals per Demand Interval. Sets the

Comms)

Units COV_

Object

AV11 Seconds 0 150 Sub-Inter val Length in hundredths of a second. For sync-to-

Increment

Modbus

Address

Comments

number of sub-intervals that make a single demand

interval. For block demand, set this to 1. Default is 1. When

Sub-Interval Length (in object AV11) is set to 0 (sync-tocomms mode), the value of this object is ignored.

comms mode, which allows manual triggering of demand

intervals and the logging of another Trend_Log record, set

this value to 0 and write 21211 to the reset register (object

AV1) each time the sub-interval must be externally reset.

Default is 90000 (15 minutes). This variable is tied directly

to the Log_Interval property of all three Trend_Log objects

(their value is always the same as this one). Changing any of

these four properties changes all of them.

ZL0105-0B PAGE 19 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 20

TM

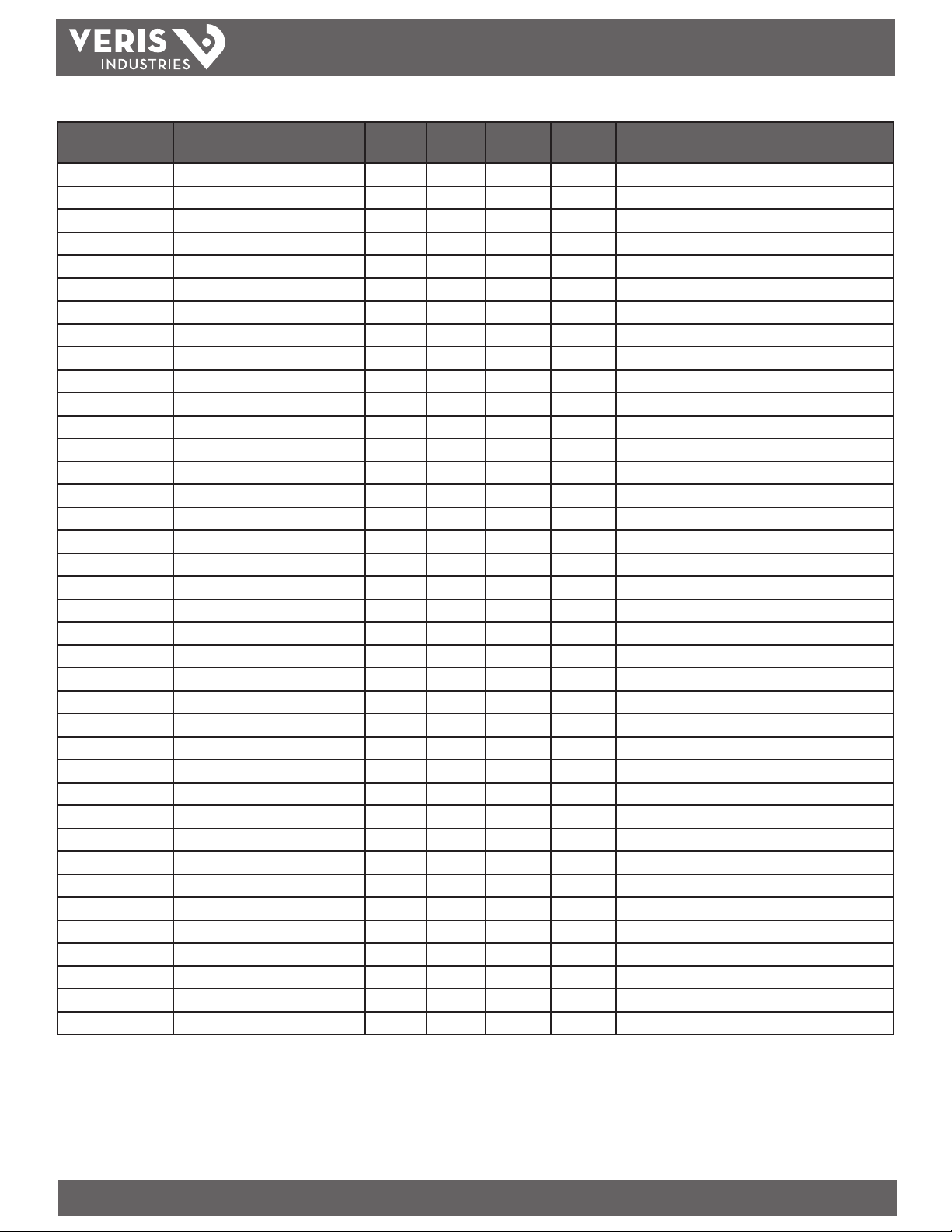

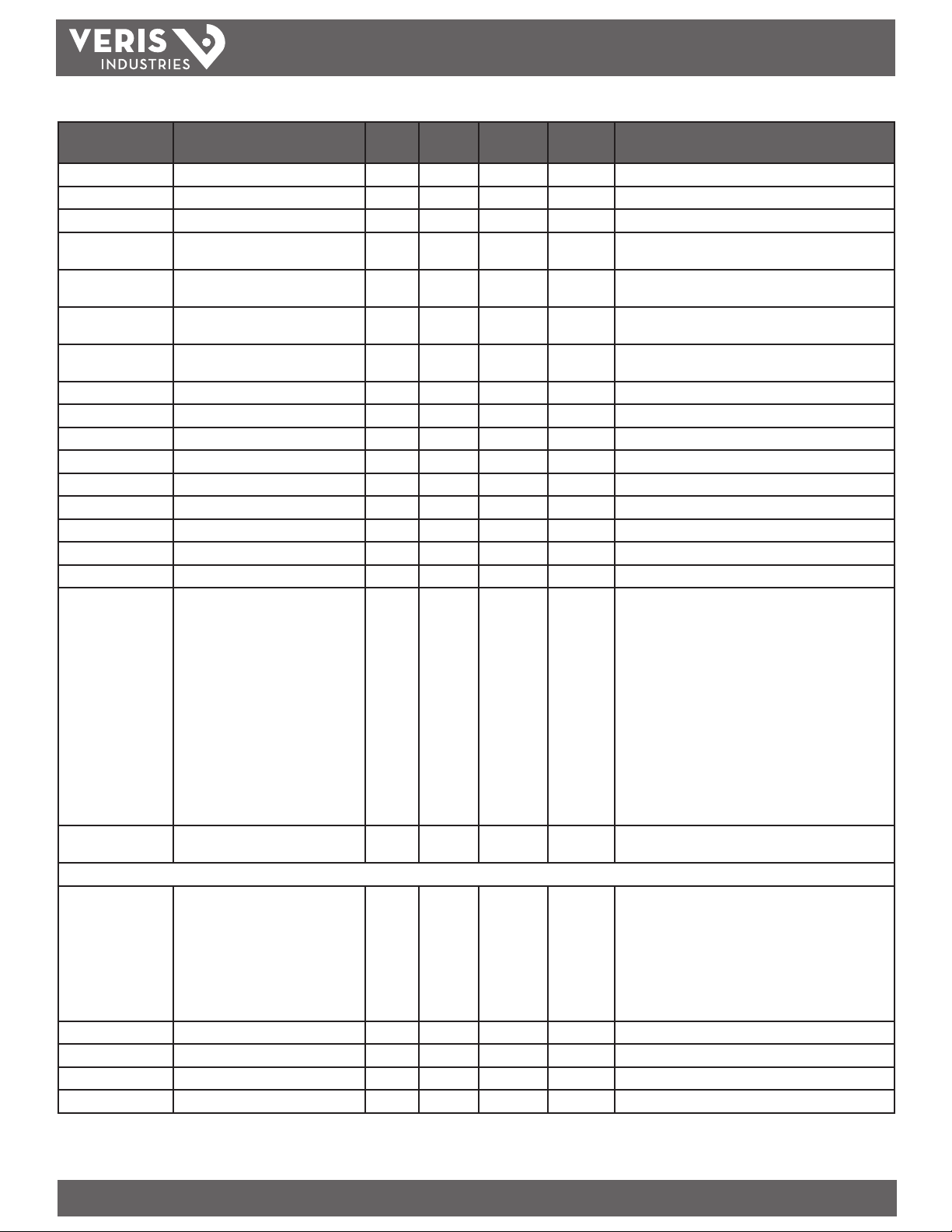

H8436 Series Energy Meters (H8436V, H8436VB & H8436VBS)

The H8436 has 34 data objects and operates at 9600 or 19200 baud.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Object

Analog_input objects: (Read-only)

kWh Energy: Total Accumulated Real Energy AI1 kWh 0 259/260

kW: Total Total Instantaneous Real Power AI2 kW 1 261/262

kVA: Total Total Instantaneous Apparent Power AI3 k VA 1 263/264

kVAR: Total Total Instantaneous Reactive Power AI4 kVAR 1 265/266

PF: Total Total Instantaneous Power Factor AI5 PF 0.01 267/268

Volts: L-L Avg Voltage L-L average of active phases AI6 Volts 5 269/270

Volts: L-N Avg Voltage L-N average of active phases AI7 Volts 5 271/272

Amps: Avg Current Avg of active phases AI8 Amps 5 273/274

kW: Ph A Instantaneous Real Power Phase A AI9 kW 1 275/276

kW: Ph B Instantaneous Real Power Phase B AI10 kW 1 277/278

kW: Ph C Instantaneous Real Power Phase C AI11 kW 1 279/280

PF: Ph A Instantaneous Power Factor Phase A AI12 PF 0.01 281/282

PF: Ph B Instantaneous Power Factor Phase B AI13 PF 0.01 283/284

PF: Ph C Instantaneous Power Factor Phase C AI14 PF 0.01 285/286

Volts: Ph A-B Instantaneous Voltage Phase A to Phase B AI15 Volts 5 287/288

Volts: Ph B-C Instantaneous Voltage Phase B to Phase C AI16 Volts 5 289/290

Volts: Ph A-C Instantaneous Voltage Phase A to Phase C AI17 Volts 5 291/292

Volts: Ph A-N Instantaneous Voltage Phase A to Neutral AI18 Volts 5 293/294

Volts: Ph B-N Instantaneous Voltage Phase B to Neutral AI19 Volts 5 295/296

Volts: Ph C-N Instantaneous Voltage Phase C to Neutral AI20 Volts 5 297/298

Amps: Ph A Instantaneous Current Phase A AI21 Amps 5 299/300

Amps: Ph B Instantaneous Current Phase B AI22 Amps 5 301/302

Amps: Ph C Instantaneous Current Phase C AI23 Amps 5 303/304

Alarm Error Bitmap Alarm Error Bitmap AI24 n/a 0 146

Count of Energy

Accumulator Resets

Analog_Value objects: (can be written as well as read)

Reset: write values to

reset congs

System Type 10, 11, 12, 30, 31, 32, 40, 42, 44 AV2 n/a 0 130

CT Ratio Primary CT Ratio Primar y (1A to 32767A) AV3 n/a 0 131

CT Ratio S econdary CT Ratio Secondary (1=1AC 5=5A) AV4 n/a 0 132 Not used on H84xx-V models (reads 32768)

PT Ratio Primary Potential Transformer Ratio Primary AV5 n/a 0 133

PT Ratio Scale (0 =

No PT)

PT R atio Secondar y 100, 110, 115, 120 AV7 n/a 0 135

Service Frequency 50 or 60 Hz AV 8 Hz 0 136

Display Units Display Units (0=IEC 1=IEEE) AV 9 n/a 0 137

Count of Energy Accumulator Resets AI25 n/a 0 147

30078= Clear All Accumulators AV 1 n/a 0 129 Reset:

0, 1, 10, 100 (0 = no PT) AV6 n/a 0 134

Units COV_

Increment

Modbus

Address

Comments

- Write 30078 to clear all energy accumulators to 0 (All).

- Read always returns 0

ZL0105-0B PAGE 20 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 21

TM

H8437 Series Energy Meters (H8437V, H8437VB & H8437VBS)

The H8437 has 66 data objects and operates at 9600 or 19200 baud.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Object

Analog_input objects: (Read-only)

kWh Energy: Total Accumulated Real Energy AI1 kWh 0 259/260

kW: Total Total Instantaneous Real Power AI2 kW 1 261/262

KVA: Total Total Instantaneous Apparent Power AI3 k VA 1 263/264

kVAR: Total Total Instantaneous Reactive Power AI4 kVAR 1 265/266

PF: Total Total Instantaneous Power Factor AI5 PF 0.01 267/268

Volts: L-L Avg Voltage L-L average of active phases AI6 Volts 5 269/270

Volts: L-N Avg Voltage L-N average of active phases AI7 Volts 5 271/272

Amps: Avg Current Avg of active phases AI8 Amps 5 273/274

kW: Ph A Instantaneous Real Power Phase A AI9 kW 1 275/276

kW: Ph B Instantaneous Real Power Phase B AI10 kW 1 277/278

kW: Ph C Instantaneous Real Power Phase C AI11 kW 1 279/280

PF: Ph A Instantaneous Power Factor Phase A AI12 PF 0.01 281/282

PF: Ph B Instantaneous Power Factor Phase B AI13 PF 0.01 283/284

PF: Ph C Instantaneous Power Factor Phase C AI14 PF 0.01 285/286

Volts: Ph A-B Instantaneous Voltage Phase A to Phase B AI15 Volts 5 287/288

Volts: Ph B-C Instantaneous Voltage Phase B to Phase C AI16 Volts 5 289/290

Volts: Ph A-C Instantaneous Voltage Phase A to Phase C AI17 Volts 5 291/292

Volts: Ph A-N Instantaneous Voltage Phase A to Neutral AI18 Volts 5 293/294

Volts: Ph B-N Instantaneous Voltage Phase B to Neutral AI19 Volts 5 295/296

Volts: Ph C-N Instantaneous Voltage Phase C to Neutral AI20 Volts 5 297/298

Amps: Ph A Instantaneous Current Phase A AI21 Amps 5 299/300

Amps: Ph B Instantaneous Current Phase B AI22 Amps 5 301/302

Amps: Ph C Instantaneous Current Phase C AI23 Amps 5 303/304

Amps: Neutral Instantaneous Neutral Current AI24 Amps 0.1 305/306

Frequency Instantaneous Frequency AI25 Hz 0.01 307/308

kW: Total Min Total Real Power Minimum Value AI26 kW 0 309/310

kW: Total Max Total Real Power Maximum Value AI27 kW 0 311/312

kVAh: Total Accumulated Apparent Energy

Consumption

kVARh: Total Accumulated Reactive Energy

Consumption

kVA: Ph A Instantaneous Apparent Power Phase A AI30 k VA 1 317/318

kVA: Ph B Instantaneous Apparent Power Phase B AI31 kVA 1 319/320

kVA: Ph C Instantaneous Apparent Power Phase C AI32 kVA 1 321/322

kVAR: Ph A Instantaneous Reactive Power Phase A AI33 kVAR 1 323/324

kVAR: Ph B Instantaneous Reactive Power Phase B AI34 kVAR 1 325/326

kVAR: Ph C Instantaneous Reactive Power Phase C AI35 kVAR 1 327/328

kW: Demand Total Real Power Present Demand AI36 kW 0 329/330

kVA: Demand Total Apparent Power Present Demand AI37 kVA 0 331/332

kVAR: Demand Total Reactive Power Present Demand AI38 kVAR 0 333/334

kW: Max Demand Total Real Power Max. Demand AI39 kW 0 335/336

AI28 n/a 0 313/314

AI29 n/a 0 315/316

Units COV_

Increment

Modbus

Address

Comments

ZL0105-0B PAGE 21 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

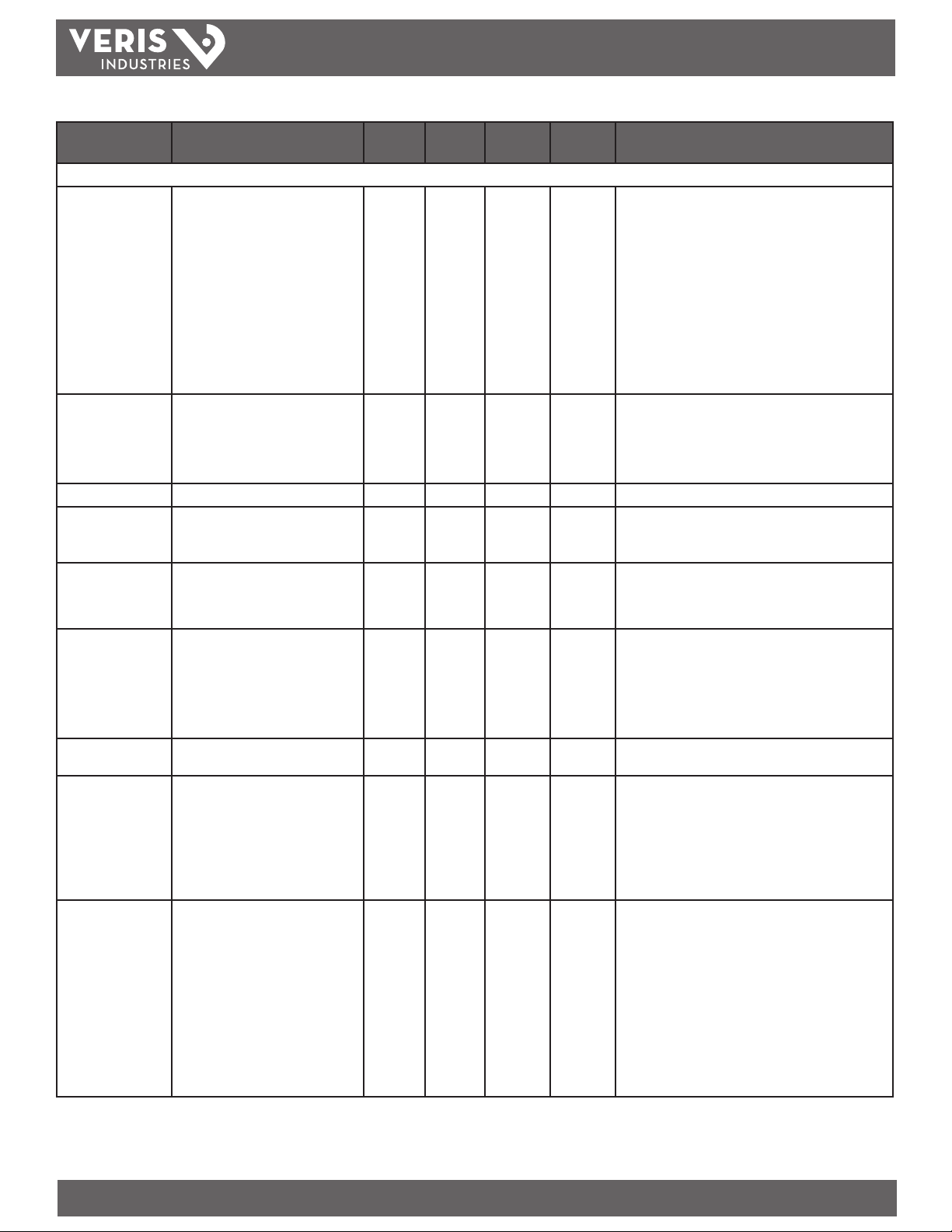

Page 22

E8950

TM

H8437 Series Energy Meters (H8437V, H8437VB & H8437VBS), cont.

INSTALLATION GUIDE

Data Variable Description BACnet

Object

kVA: Max Demand Total Apparent Power Max. Demand AI40 kVA 0 337/338

kVAR: Max Demand Total Reactive Power Max. Demand AI41 kVAR 0 339/340

Usage Hours Hours: >0.1A on at least one phase AI42 Hours 0 341/342

Usage Minutes (0.0-

59.9)

Total Hours Total Hours since last timer reset AI44 Hours 0 345/346 This combination timer counts the total time for which the

Total Minutes (0.0-

59.9)

Percent Usage Usage Hours / Total Hours AI46 Percent 5 349/350 This timer counts the total time since the usage timer was

Volts THD: Ph A-N Instantaneous THD Voltage Ph A - Neutral AI47 Percent 5 351/352 Percent Usage = Usage Time / Total Time .

Volts THD: Ph B-N Instantaneous THD Voltage Ph B - Neutral AI48 Percent 5 353/354

Volts THD: Ph C-N Instantaneous THD Voltage Ph C - Neutral AI49 Percent 5 355/356

Volts THD: Ph A-B Instantaneous THD Voltage Ph A - Ph B AI50 Percent 5 357/358

Volts THD: Ph B-C Instantaneous THD Voltage Ph B - Ph C AI51 Percent 5 359/360

Volts THD: Ph A-C Instantaneous THD Voltage Ph A - Ph C AI52 Percent 5 361/362

Amps THD: Ph A Instantaneous THD Current Phase A AI53 Percent 5 363/364

Amps THD: Ph B Instantaneous THD Current Phase B AI54 Percent 5 365/366

Amps THD: Ph C Instantaneous THD Current Phase C AI55 Percent 5 367/368

Alarm Error Bitmap Alarm Error Bitmap AI56 n/a 0 146 Error Bitmap:

Count of Energy

Accumulator Resets

Analog_Value objects: (can be written as well as read)

Reset: write values to

reset congs

System Type 10; 11; 12; 30; 31; 32; 40; 42; 44 AV2 n/a 0 130

CT Ratio Primary CT Ratio Primar y (1A to 32767A) AV3 n/a 0 131

CT Ratio S econdary CT Ratio Secondary (1=1AC 5=5A) AV4 n/a 0 132 Not used on H84xxV (reads 32768)

PT Ratio Primary Potential Transformer Ratio Primary AV5 n/a 0 133

Minutes: >0.1A on at least one phase AI43 Minutes 10 343/344

Total Minutes since last timer reset AI45 Minutes 10 347/348 This combination timer counts the total time for which the

Count of Energy Accumulator Resets AI57 n/a 0 147

30078=Acc 14255=MnMx 21212=Dmd

10001=Tmr

AV1 n/a 0 129 Reset:

Units COV_

Increment

Modbus

Address

Comments

absolute current on at least one phase is >0.1 Amp.

absolute current on at least one phase is >0.1 Amp.

reset.

bit 0: Phase A Voltage out of range

bit 1: Phase B Voltage out of range

bit 2: Phase C Voltage out of range

bit 3: Phase A Current out of range

bit 4: Phase B Current out of range

bit 5: Phase C Current out of range

bit 6: Frequency out of range or insucient voltage on Phase

A to determine frequency range of 45-65 Hz.

bit 7: Reserved for future use

bit 8: Phase Loss A

bit 9: Phase Loss B

bit 10: Phase Loss C

bit 11-15: Reserved for future use

- Write 30078 to clear all Energy Accumulators to 0 (All).

- Write 14255 to reset all Power Min/Max to Present Values

(H84xx EDS Only).

- Write 21212 to reset Peak Demand values to Present Demand

Values (H84xx EDS Only).

- Write 10001 to clear the Usage Timers to 0 (H84xx EDS Only).

- Read always returns 0

ZL0105-0B PAGE 22 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 02131

Alta Labs, Ene rcept, Enspector, Hawk eye, Trustat, Aerospon d, Veris, and the Veris ‘V ’ logo are tradem arks or registe red trademarks o f Veris Industries, L .L.C. in the USA and/or ot her countries.

Page 23

TM

H8437 Series Energy Meters (H8437V, H8437VB & H8437VBS), cont.

E8950

INSTALLATION GUIDE

Data Variable Description BACnet

Object

PT Ratio Scale (0 =

No PT)

PT R atio Secondar y 100; 110; 115; 120 AV7 n/a 0 135

Service Frequency 50 or 60 Hz AV 8 Hz 0 136

Display Units Display Units (0=IEC 1=IEEE) AV 9 n/a 0 137

(Power) Demand Block

Interval

Num of Power Dem.

Block Sub-Intrvl.

0; 1; 10; 100 (0 = no PT) AV6 n/a 0 134

1 to 60 Minutes AV10 n/a 0 149 (Power) Demand Block Interval – Used for PQS (P=Real Power

Subset of Block interval AV11 n/a 0 150 Number of Power Demand Block Sub-Intervals - Sets the

Units COV_

Increment

Modbus

Address

Comments

KW, Q=Reactive Power KVAR, and S=Apparent Power KVA)

demand calculations.

number of sub-intervals per Demand Block Interval (above).

The method of demand calculation is set as follows:

0 = Sliding Block. Like rolling block, but with a subinterval of

15 seconds; used for Demand Intervals ≤ 15 minutes, or 60

seconds for intervals > 15 minutes

1 = Block. Fixed block with no sub-intervals.

>1 = Rolling Block. The number of sub-intervals per block.

This value must divide evenly into the Block Demand Interval

(above).

For example, if the Demand Block Interval is 15 minutes, valid

Sub-Interval values are: 3, 5, or 15. If the value of 3 is chosen,

then there will be 3 subintervals of 5 minutes each.