Page 1

Installation Guide

the FCC Rules. These limits are designed to provide reasonable protection

residential environment. This equipment generates, uses, and can radiate

Power Monitoring

RoHS

Compliant

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Any covers that may be displaced during the installation must be reinstalled

before powering the unit.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and the installation, and has received safety

training to recognize and avoid the hazards involved. NEC2009 Article 100

No responsibility is assumed by Veris Industries for any consequences arising out of the

use of this material.

Control system design must consider the potential failure modes of control paths and, for

certain critical control functions, provide a means to acheive a safe state during and after a

path failure. Examples of critical control functions are emergency stop and over-travel stop.

TM

E51C2, E51C3

Compact Bi-Directional

Power and Energy Meter

Product Overview

The E51 DIN Rail Power Meter provides a solution for measuring energy data with a single device. Inputs include

Control Power, CTs, and 3-phase voltage. The E51 supports multiple output options, including solid state relay

contacts, Modbus (with or without data logging), and pulse. The LCD screen on the faceplate allows instant output

viewing.

The E51 Meter is capable of bidirectional metering. Power is monitored in both directions (upstream and

downstream from the meter). The meter is housed in a plastic enclosure suitable for installation on T35 DIN rail

according to EN50022. The E51 can be mounted either on a DIN rail or in a panel. Observe correct CT orientation

when installing the device.

Product Identification

Model Description Output Data Logging

Pulse RS-485 Alarm

E51C2 Modbus output, full data set

E51C3 Modbus output, data logging

• • •

• • • •

WARNING

LOSS OF CONTROL

∙ Assure that the system will reach a safe state during and after a control path failure.

∙ Separate or redundant control paths must be provided for critical control func tions.

∙ Test the eect of transmission delays or failures of communication links.

∙ Each implementation of equipment using communication links must be individually

and thoroughly tested for proper operation before placing it in service.

Failure to follow these instructions may cause injury, death or equipment damage.

1

For additional information about anticipated transmission delays or failures of the link, refer to

NEMA ICS 1.1 (latest edition). Safety Guidelins for the Application, Installation, and Maintenance

of Solid-State Control or its equivalent in your specic country, language, and/or location.

1

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found to

comply with the limits for a class B digital device, pursuant to part 15 of

against harmful interference when the equipment is operated in a

radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation.

Modifications to this product without the express authorization of the

manufacturer nullify this statement.

For use in a P ollution D egree 2 or be tter envi ronment on ly. A Pollutio n Degree 2

environment must control conductive pollution and the possibility of condensation or

high hum idity. Cons ider the enc losure, th e correc t use of venti lation, the rmal prop erties

of the equ ipment, an d the relati onship wi th the envir onment. In stallati on categor y:

CAT II or CAT III. P rovide a di sconnec t device to di sconnec t the meter f rom the sup ply

source. P lace this de vice in clos e proximit y to the equ ipment and w ithin eas y reach of

the oper ator, and mark i t as the disc onnecti ng device. T he disconn ecting de vice shall

meet th e relevant r equireme nts of IEC 60 947-1 and IEC 60947-3 and sh all be suit able for

the appl ication. I n the US and Can ada, discon nectin g fuse hold ers can be us ed. Provi de

overcu rrent prot ection a nd discone cting dev ice for sup ply conduc tors wit h approved

current limiting devices suitable for protecting the wiring. If the equipment is used in a

manner n ot specie d by the manu facture r, the protec tion prov ided by the d evice may

be impaired.

ZL00 67-0C Page 1 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Specifications

MEASUREMENT ACCURACY

Real Power and Energy

Reactive Power and Energy

Current

Voltag e

Sample Rate

Data Update Rate

Type of Measurement

Measured AC Voltage

Metering Over-Range

Impedance

Frequency Range

CT Scaling

Measurement Input Range

Impedance

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

IEC 620 53 -22 Class 0.2S, A NSI C12.20 0.2%

IEC 620 53 -23 Class 2, 2%

0.2% (+ 0.0 05% per ° C deviation from 25°C ) from 1% to 5% of range ;

0.1% (+0.0 05% per °C deviation from 25°C ) from 5% to 100% of range

0.1% (+0.0 05% per °C deviation from 25°C ) from 90 VAC

2520 samples per second; no blind time

1 sec.

True RMS; one to three phase AC system

INPUT VOLTAGE CHARACTERISTICS

Minimum 90 V

UL Maximums: 600 V

+20%

2.5 MΩ

45 to 65 Hz

INPUT CUR RENT CHARACTER ISTICS

Primar y: Adjustable from 5 A to 32,00 0 A

0 to 0.333 VAC or 0 to 1.0 VAC (+20 % over-range)

10.6 kΩ (1/3 V mode) or 32.1 kΩ (1 V mode)

/5 M Ω

L-N

(156 V

L-N

L-L

) for stated accuracy;

L-L

(3 47 V

L-L

); CE Maximums: 3 00 V

L-N

to 600 VAC

L-N

(520 V

L-N

L-L

)

L-L

Page 2

Installation Guide

Power Monitoring

EC, EC

TM

Specifications (cont.)

CONTROL POWE R

AC

5 VA max.; 9 0V min.;

DC*

Ride Through Time

Alarm Contacts

Real Energy Pulse Contacts

RS-485 Port

Weight

IP Degree of Protection

(IEC 6 0529 )

Display Characteristics

Terminal Block Screw Torque

Terminal Block Wire Size

Rail

Operating Temperature Range

Storage Temperature Range

Humidity Range

Altitude of Operation

US and Canada

CE

Dielectric Withstand

Conducted and Radiated

Emissions

Conducted and Radiated

Immunity

US and Canada (cULus)

Europe (CE)

UL Maximums: 600 V

3 W max.; U L and CE: 125 to 300 VDC

100 msec at 120 VAC

OUTPUT

N.C., static output ( 30VAC/DC, 100mA max. @ 25°C,

derate 0.56mA per °C above 25°C)

N.O., static output ( 30 VAC/ DC, 100 mA max. @ 25°C,

derate 0.56 mA per ° C above 25°C)

2-wire, 120 0 to 38400 baud, Modbus RTU

MECHAN ICAL CHARACTERI STICS

0.62 lb ( 0.28 kg)

IP40 front display; IP 20 Meter

Back-lit blue LCD

0.37 to 0.44 ft-lb ( 0.5 to 0.6 N ·m )

26 to 14 AWG (0.13 to 2.08 mm2)

T35 ( 35mm ) DIN Rail per EN50022

ENVIRONMENTAL

-30° to 70°C (22° to 158°F )

-4 0° to 85°C (- 40 ° to 185°F )

<95% RH noncondensing

3000 m

METERING CATEGORY

CAT III; for distribution systems up to 3 47 V

CAT III; for distribution systems up to 300 V

Per UL 50 8, EN61010

FCC par t 15 Class B, EN55011/EN61000 Class B (residential and light

industrial)

EN61000 Class A ( heavy industrial)

AGENCY APPROVALS

UL508 (open type device) /C SA 22. 2 No. 14- 05

EN6 1010-1:2001

(3 47 V

L-L

* External DC current limiting is required, see fuse recommendations.

); CE Maximums: 3 00 V

L-N

/600 VAC

L-N

L-N

(520 V

L-N

L-L

)

L-L

SunSpec Alliance

Interoperability

This meter implements the draft SunSpec 1.0 common elements starting at base 1 address 40001, and the proposed SunSpec 1.1

meter model at 40070 (these addresses are not in Modicon notation). See www.veris.com or www.sunspec.org for copies of these

specications.

Specification

Compliance

ZL00 67-0C Page 2 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

The SunSpec Alliance logo is a trademark or registered trademark of the SunSpec Alliance.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 3

Installation Guide

Power Monitoring

EC, EC

TM

Table of Contents

Dimensions 4

Application Example 4

Data Outputs 5

Product Diagram 5

Display Screen Diagram 5

Installation 6

Supported System Types 7

Wiring Symbols 7

Wiring 8

Control Power Diagrams 9

Quick Setup Instructions 10

Solid State Pulse Output 11

User Interface Menu Abbreviations Dened 11

User Interface for Data Conguration 12

Alert/Reset Information 13

User Interface for Setup 15

RS-485 Communications 17

Data Logging (E51C3 Only) 17

Modbus Point Map Overview 18

Standard Modbus Default Settings 19

Modbus Point Map 20

SunSpec Register Blocks 30

Troubleshooting 34

China RoHS Compliance Information (EFUP Table) 34

ZL00 67-0C Page 3 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 4

Installation Guide

Power Monitoring

EC, EC

TM

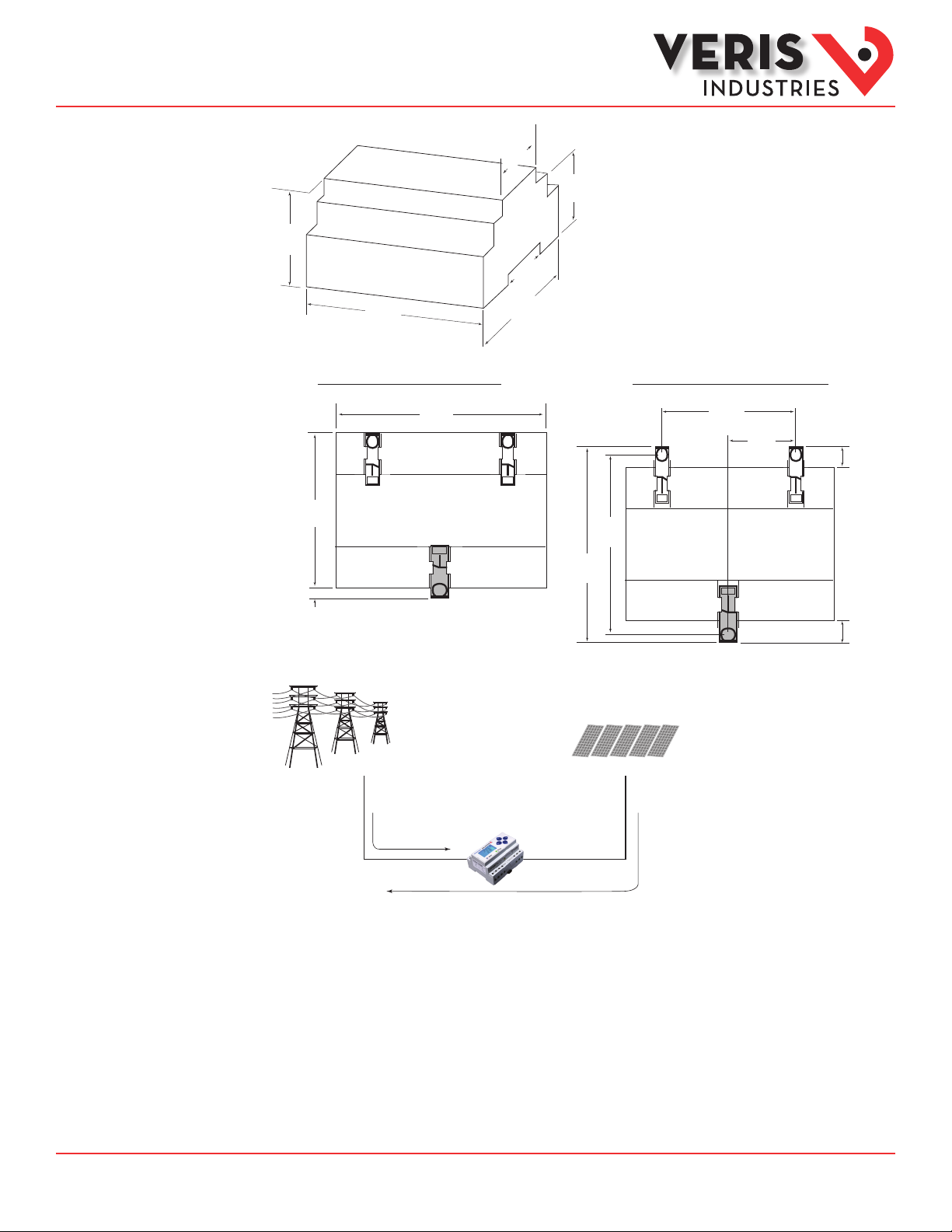

Dimensions

1.8”

(45mm)

1.9”

(48mm)

2.3”

(59mm)

1.5”

(39mm)

4.2”

(107mm)

3.6”

(91mm)

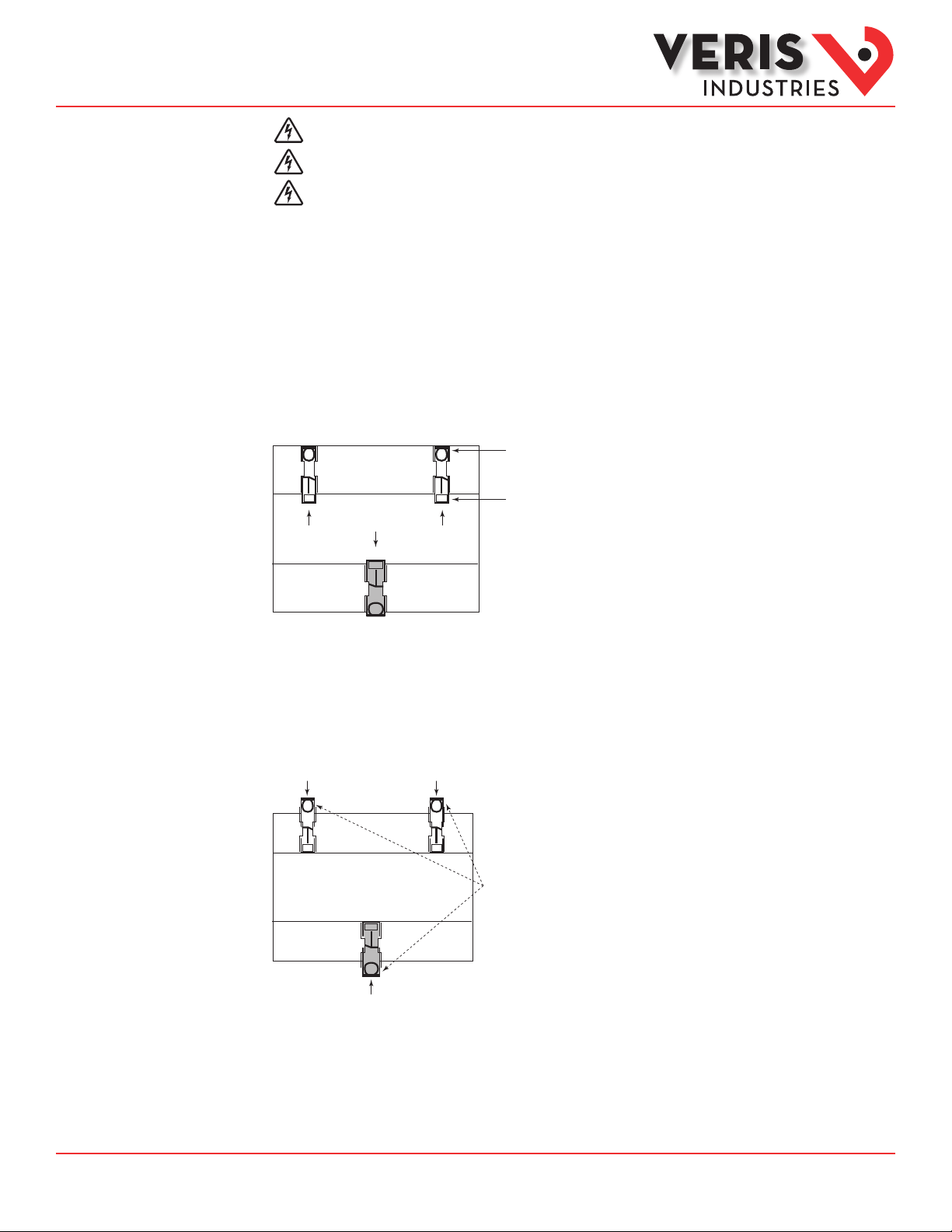

Bottom View (DIN Mount Option) Bottom View (Screw Mount Option)

2.4 “

(61 mm)

+

0.2 “

(4 mm)

3.6 “

(91 mm)

4.2 “

(107 mm)

3.9“

(99 mm)

4.3 “

(109 mm)

1.2 “

(31 mm)

++

0.3 “

(8 mm)

0.4 “

(10 mm)

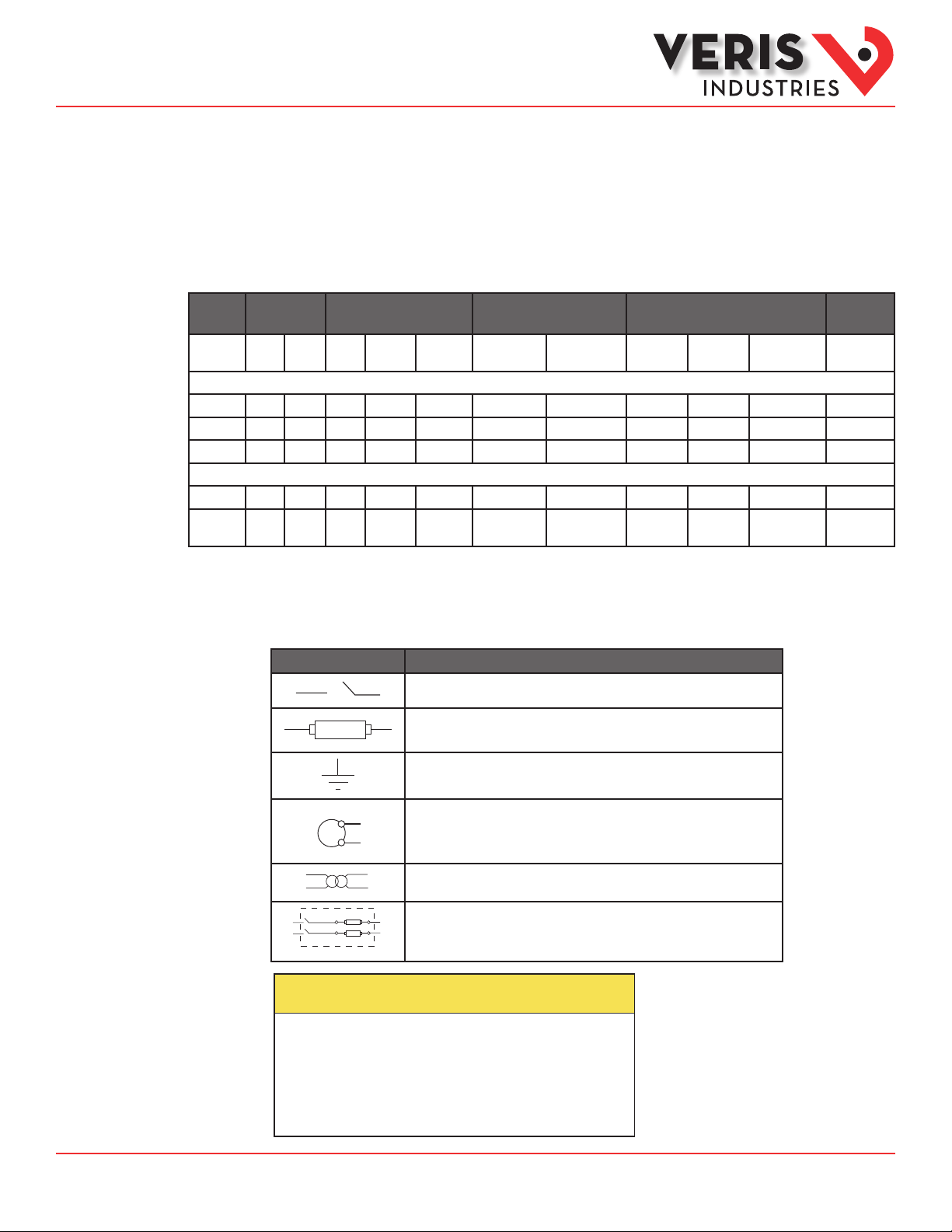

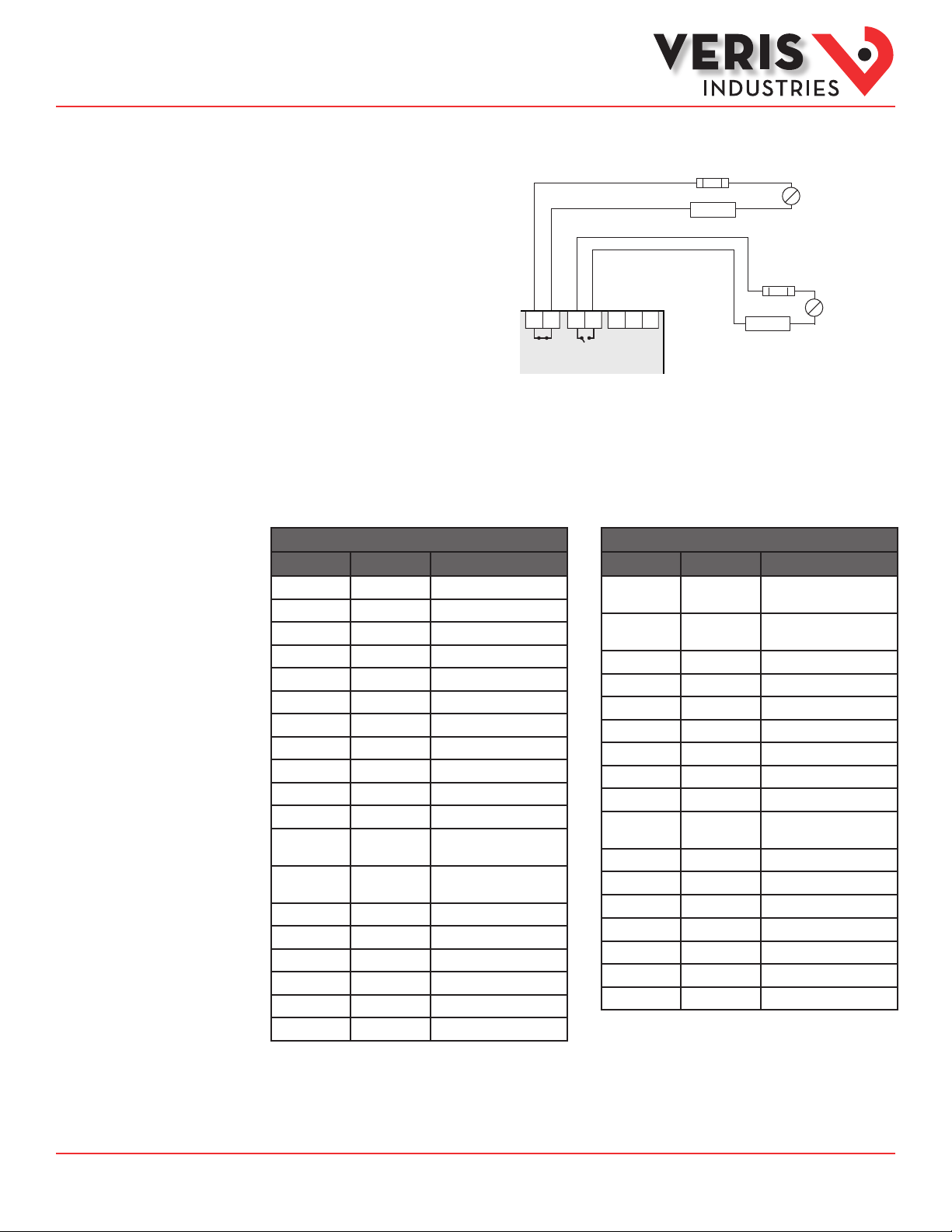

Application Example

Main Utility Grid Solar Panels

Imported Power

Exported Power

ZL00 67-0C Page 4 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 5

Installation Guide

kWh

1234.5

Power Monitoring

EC, EC

TM

Data Outputs

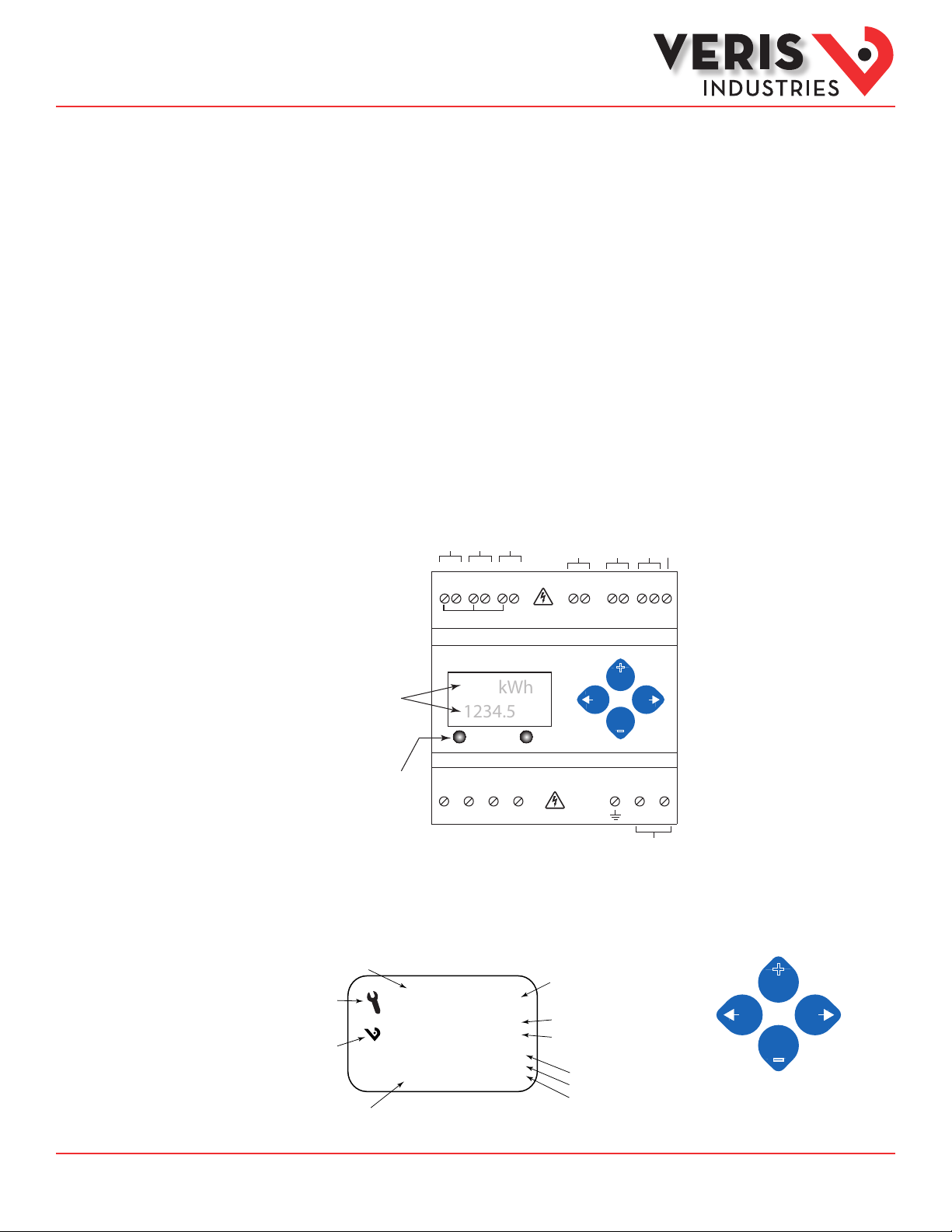

Product Diagram

Signed Power: Real, Reactive, and Apparent 3-phase total and per phase

Real and Apparent Energy Accumulators: Import, Export, and Net; 3-phase total and per phase

Reactive Energy Accumulators by Quadrant: 3-phase totals and per phase

Congurable for CT & PT ratios, system type, and passwords

Diagnostic alerts

Current: 3-phase average and per phase

Volts: 3-phase average and per phase Line-Line and Line-Neutral

Power Factor: 3-phase average and per phase

Frequency

Power Demand: Most Recent and Peak (Import and Export)

Demand Conguration: Fixed, Rolling Block, and External Sync (Modbus only)

Data Logging (E51C3 only)

Real Time Clock: user congurable

10 user congurable log buers: each buer holds 5760 16-bit entries

(User congures which 10 data points are stored in these buers)

User congurable logging interval

(When congured for a 15 minute interval, each buer holds 60 days of data)

Continuous and Single Shot logging modes: user selectable

Auto write pause: read logs without disabling the meter’s data logging mode

IA

IB

IC

-+-+-

A B C Alarm Energy

+

Phase Loss

Alarm

Pulse

Modbus

OUTPUT

Shield

Display Screen

Diagram

- 600V

CE: 90V

L-L

NC NO + - S

+

–

CONTROL POWER

- 300V

L-N

L-N

0.1A 50/60 Hz

Earth

Control

Power

Two 5-character rows

of display text.

Top row alphanumeric;

Bottom row numeric only

The red Alarm LED lights when

any of the 3 phase voltages

drop below the selected thresh-

old. The green Energy LED lights

momentarily each time the

Energy output pulse is active.

Common - 1 or 1/3 VAC Input

Alarm Energy

VOLTAGE INPUTS

CAT III 50/60 Hz

A B C N 1 2

VA

UL: 90V

L-N

VB

VC

Neutral

LCD Screen: Buttons:

Screen Name or Units

Alive Indicator

Diagnostic Alert

Logo

Numeric Data

♥

Tx

Rx

ERR

Export

Import

Transmit Data

Receive Data

Receive Data Error

(Left)

Back

(Up)

Select

+

(Right)

Next

–

(Down)

Select

ZL00 67-0C Page 5 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 6

Installation Guide

Power Monitoring

EC, EC

TM

Installation

Disconnect power prior to installation.

Reinstall any covers that are displaced during the installation before powering the unit.

Mount the meter in an appropriate electrical enclosure near equipment to be monitored.

Do not install on the load side of a Variable Frequency Drive (VFD), aka Variable Speed Drive (VSD)

or Adjustable Frequency Drive (AFD).

Observe correct CT orientation.

The meter can be mounted in two ways: on standard 35 mm DIN rail or screw-mounted to the interior surface of the enclosure.

A. DIN Rail Mounting

1. Attach the mounting clips to the underside of the housing by sliding them into the slots from the inside. The stopping pegs

must face the housing, and the outside edge of the clip must be ush with the outside edge of the housing.

2. Snap the clips onto the DIN rail. See the diagram of the underside of the housing (below).

Clip flush with

outside edge

Snap onto

Insert clips from inside

DIN rail

3. To reduce horizontal shifting across the DIN rail, use two Veris AV02 end stop clips.

B. Screw Mounting

1. Attach the mounting clips to the underside of the housing by sliding them into the slots from the outside. The stopping pegs

must face the housing, and the screw hole must be exposed on the outside of the housing.

2. Use three #8 screws (not supplied) to mount the meter to the inside of the enclosure. See the diagram of the underside of the

housing (below).

Insert clips from outside

Screw holes

exposed for

mounting

ZL00 67-0C Page 6 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 7

Installation Guide

Power Monitoring

EC, EC

TM

Supported System

Types

Number

of wires

Single-Phase Wiring

2 1 A 2 A, N L-N 10 1L + 1n AN 1

2 1 A 2 A, B L- L 11 2L AB 2

3 2 A, B 3 A, B, N L-L with N 12 2L + 1n AB AN, BN AN-BN 3

Three-Phase Wiring

3 3 A, B, C 3 A, B, C Delta 31 3L AB, BC, CA AB-BC-CA 4

4 3 A, B, C 4 A, B, C, N Grounded

The meter has a number of dierent possible system wiring congurations (see Wiring Diagrams section). To congure the meter,

set the System Type via the User Interface or Modbus register 130 (if so equipped). The System Type tells the meter which of its

current and voltage inputs are valid, which are to be ignored, and if neutral is connected. Setting the correct System Type prevents

unwanted energy accumulation on unused inputs, selects the formula to calculate the Theoretical Maximum System Power,

and determines which phase loss algorithm is to be used. The phase loss algorithm is congured as a percent of the Line-to-Line

System Voltage (except when in System Type 10) and also calculates the expected Line to Neutral voltages for system types that

have Neutral (12 & 40).

Values that are not valid in a particular System Type will display as “----” on the User Interface or as QNAN in the Modbus registers.

CTs Voltage Connections System Type Phase Loss Measurements Wiring

Diagram

Qty ID Qty ID Type Modbus

Register 130

40 3L + 1n AB, BC, CA AN, BN, CN AN-BN-CN &

Wye

User Interface:

SETUP>S SYS

VLL VLN Balance Diagram

number

5, 6

AB-BC-CA

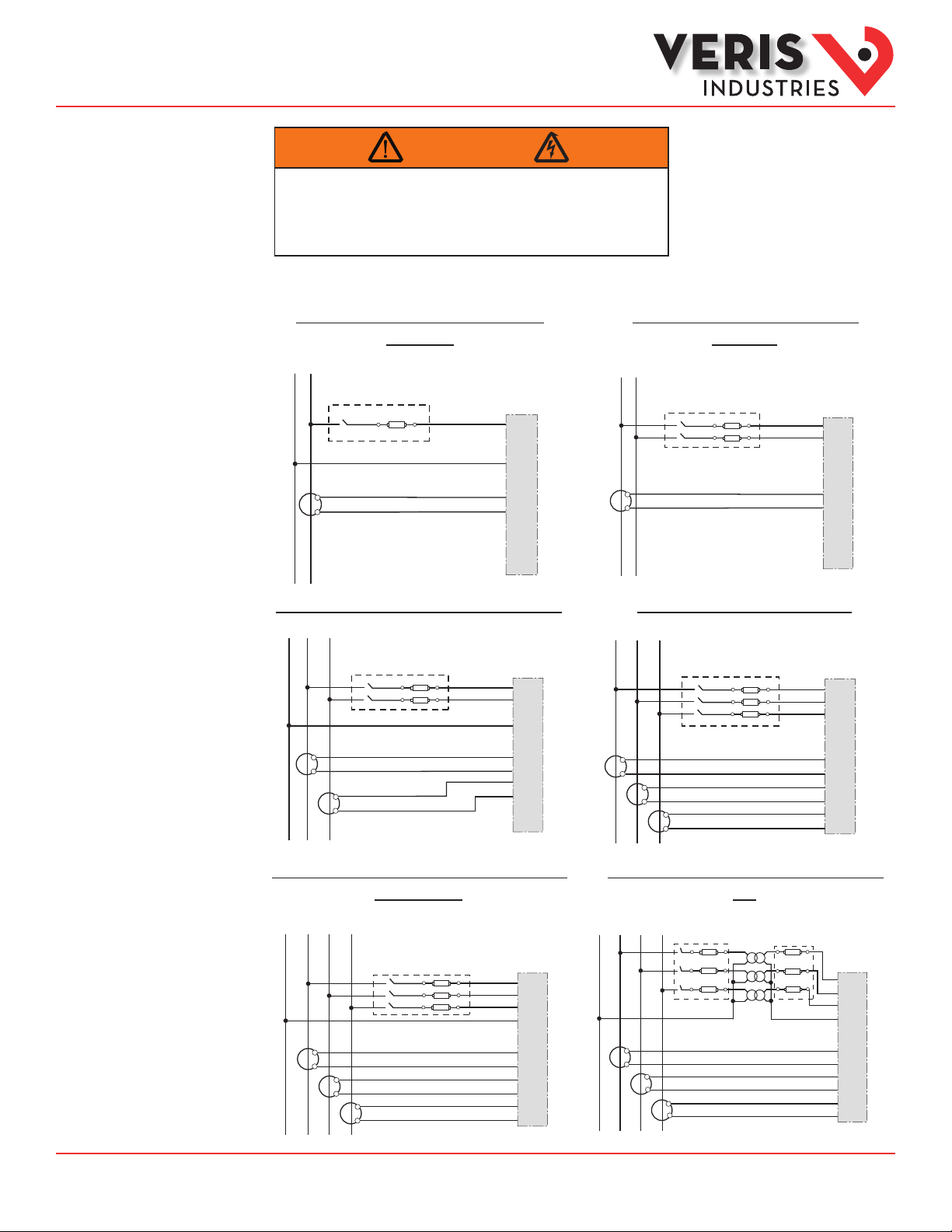

Wiring Symbols

To avoid distortion, use parallel wires for control power and voltage inputs.

The following symbols are used in the wiring diagrams on the following pages.

Symbol Description

Voltage Disconnect Switch

Fuse (installer is responsible for ensuring compliance with local requirements. No

fuses are included with the meter.)

Earth ground

X1

Current Transducer

Potential Transformer

Protection containing a voltage disconnect switch with a fuse or disconnect circuit

breaker. The protection device must be rated for the available short-circuit current at

the connection point.

CAUTION

RISK OF EQUIPMENT DAMAGE

• This product is designed only for use with 1V or 0.33V current

transducers (CTs).

• DO NOT USE CURRENT OUTPUT (e.g. 5A) CTs ON THIS PRODUCT.

• Failure to follow these instructions can result in overheating and

permanent equipment damage.

ZL00 67-0C Page 7 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 8

Installation Guide

Power Monitoring

EC, EC

TM

Wiring

WARNING

RISK OF ELECTRIC SHOCK OR PERMANENT EQUIPMENT DAMAGE

CT negative terminals are referenced to the meter’s neutral and may be at elevated voltages

· Do not contact meter terminals while the unit is connected

· Do not connect or short other circuits to the CT terminals

Failure to follow these instructions may cause injury, death or equipment damage.

Observe correct CT orientation.

Diagram 1: 1-Phase Line-to-Neutral 2- Wire

System 1 CT

N L1

Use System Type 10 (1L + 1n)

X1

X2

A

B

C

N

White

Black

+

-

+

-

+

-

A

B

C

Diagram 2: 1-Phase Line-to-Line 2-Wire

L1 L2

X1

X2

System 1 CT

Use System Type 11 (2L)

White

Black

A

B

C

N

+

A

-

+

B

-

+

C

-

Diagram 3: 1-Phase Direct Voltage Connection 2 CT

N

L1 L2

X1

X2

Use System Type 12 (2L + 1n) Use System Type 31 (3L)

A

B

C

N

White

Black

X1

X2

White

Black

+

A

-

+

B

-

+

C

-

Diagram 5: 3-Phase 4-Wire Wye Direct Voltage Input

Connection 3 CT

Use System Type 40 (3L + 1n)

L1N L2 L3

A

B

C

N

X1

X2

X1

X2

X1

X2

White

Black

White

Black

White

Black

+

A

-

+

B

-

+

C

-

Diagram 4: 3-Phase 3-Wire 3 CT no PT

L1 L2 L3

A

B

C

N

X1

X1

X2

X2

White

Black

White

X1

X2

Black

White

Black

+

A

-

+

B

-

+

C

-

Diagram 6: 3-Phase 4-Wire Wye Connection 3 CT

3 PT

Use System Type 40 (3L + 1n)

L1N L2 L3

A

B

C

N

X1

X1

X2

X2

X1

X2

White

Black

White

Black

White

Black

+

A

-

+

B

-

+

C

-

ZL00 67-0C Page 8 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 9

Installation Guide

Power Monitoring

EC, EC

TM

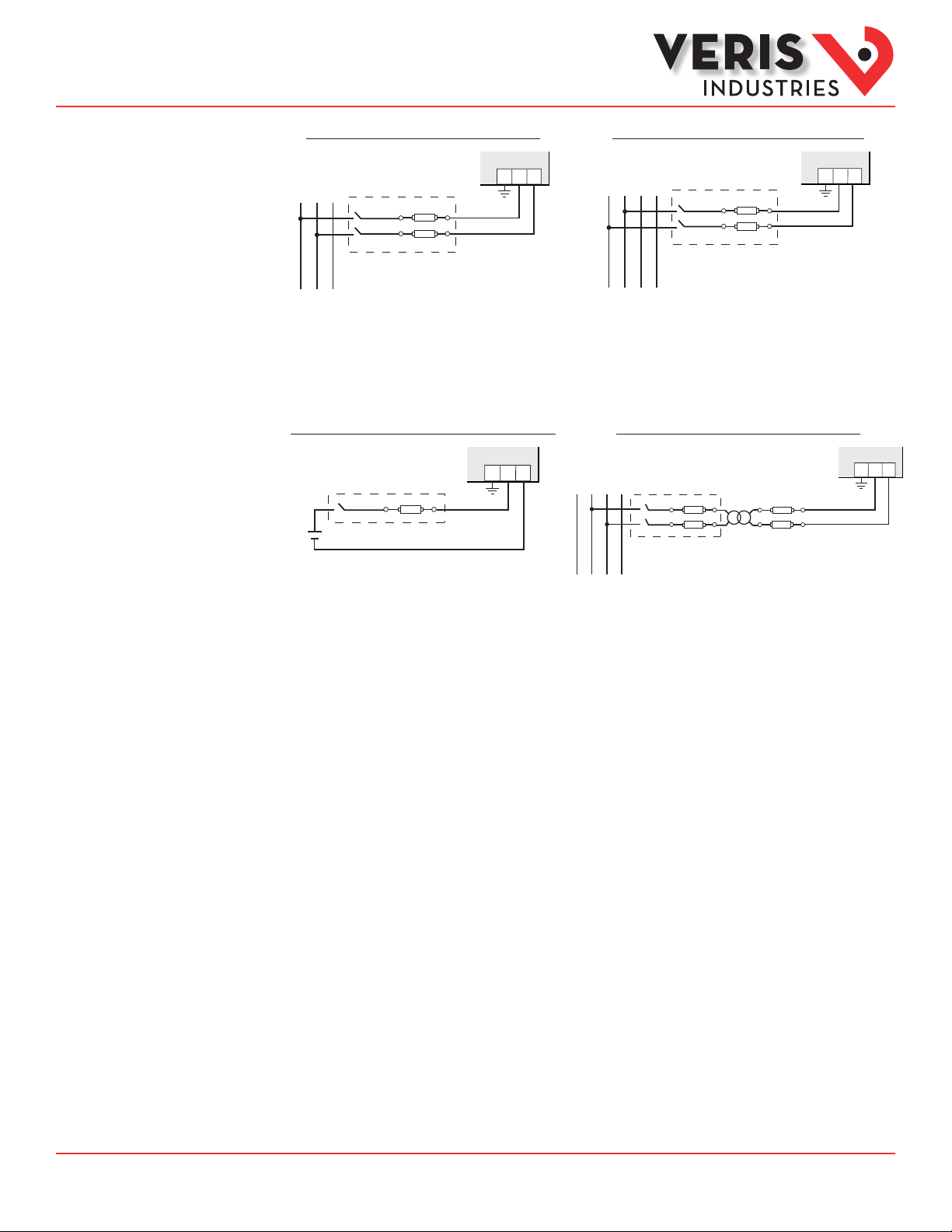

Control Power

Diagrams

Direct Connect Control Power (Line to Line)

L1

L2 L3

Line to Line from 90 VAC to 600 VAC (UL) (520 VAC for CE). In

UL installations the lines may be oating (such as a delta).

If any lines are tied to an ear th (such a s a corner grounded

delta), see the Line to Neutral installation limits. In CE

compliant installations, th e lines must be neutral (earth)

referenced at less than 300 VAC

1 2G

L-N

Direct Connect Control Power (DC Control Power)

1 2G

DC Control Power from 125 VDC to 300 VDC

(UL and CE max.)

Direct Connect Control Power (Line to Neutral)

L1N L2 L3

Line to Neutral from 90 VAC to 347 VAC (UL) or 300 VAC (CE)

Control Power Transformer (CPT) Connection

L1N L2 L3

The Control Power Transformer may be wired L-N or L-L. Output to

meet meter input requirements

1 2G

1 2G

Fuse Recommendations

Keep the fuses close to the power source (obey local and national code requirements).

For selecting fuses and circuit breakers, use the following criteria:

• Select current interrupt capacity based on the installation category and fault current capability.

• Select over-current protection with a time delay.

• Select a voltage rating sucient for the input voltage applied.

• Provide overcurrent protection and disconnecting means to protect the wiring. For AC installations, use Veris AH02,

AH03, AH04, or equivalent. For DC installations, provide external circuit protection. Suggested: 0.5 A, time delay fuses.

• The earth connection is required for electromagnetic compatibility (EMC) and is not a protective earth ground.

ZL00 67-0C Page 9 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 10

Installation Guide

Power Monitoring

EC, EC

TM

Quick Setup

Instructions

These instruc tions assume the meter is set to factory defaults. If it has been previously congured, check all optional values.

+

1. Press the

+

or – button repeatedly until SETUP screen appears.

2. to the PASWD screen.

+

3. through the digits. Use the

+

4. Use the

+

or – buttons to selec t the parameter to congure.

+

or – buttons to selec t the password (the default is 00000). Exit the screen to the right.

5. If the unit has an RS-485 interface, the rst Setup screen is S COM (set communications).

+

a. to the ADDR screen and through the address digits. Use the

+

b. to the BAUD screen. Use the

c. to the PAR screen. Use the

+

or – buttons to selec t the baud rate.

+

+

or – buttons to selec t the parity.

+

or – buttons to select the Modbus address.

d. back to the S COM screen.

–

6.

to the S CT (Set Current Transducer) screen. If this unit does not have an RS-485 port, this will be the rst screen.

+

a. to the CT V screen. Use the

b. to the CT SZ screen and through the digits. Use the

+

or – buttons to selec t the voltage mode Current Transducer output voltage.

+

+

or – buttons to selec t the CT size in amps.

c. back to the S CT screen.

7. – to the S SYS (Set System) screen.

+

a. to the SY STM screen. Use the

+

or – buttons to selec t the System Type (see wiring diagrams).

b. back to the S SYS screen.

8. (Optional) – to the S PT (Set Potential Transformer) screen. If PTs are not used, then skip this step.

+

a. to the RATIO screen and through the digits. Use the

+

or – buttons to selec t the Potential Transformer step down

ratio.

b. back to the S PT screen.

–

9.

to the S V (Set System Voltage) screen.

+

a. to the VLL (or VLN if system is 1L-1n) screen and through the digits. Use the

+

or – buttons to selec t the Line to Line

System Voltage.

b. back to the S V screen.

10. Use the to exit the setup screen and then S ETU P.

11. Check that the wrench is not displayed on the LCD.

+

a. If the wrench is displayed, use the

+

or – buttons to nd the A LERT screen.

b. through the screens to see which alert is on.

For the full setup instructions, see the conguration instruc tions on the following pages.

ZL00 67-0C Page 10 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 11

Installation Guide

Power Monitoring

EC, EC

TM

Solid-State

Pulse Output

User Interface (UI)

Menu Abbreviations

Defined

The meter has one normally open (N.O.) KZ Form

A output and one normally closed (N.C.) KY

solid-state output. One is dedicated to import

energy (Wh), and the other to Alarm.

The relay used for the Phase Loss contact is N.C.,

with closure indicating the presence of an alarm;

either loss of phase if the meter is powered, or

loss of power if the meter is not. The contacts are

open when the meter is powered and no phase

loss alarm conditions are present.

The solid state pulse outputs are rated for 30

VAC/DC nom.

Maximum load current is 100 mA at 25°C. Derate

0.56 mA per °C above 25°C.

See the Setup section for conguration

Alarm

* The over-current pro tective device must be rated for the shor t circuit current at the

connection point.

** All pulse outpu ts and communication circui ts are only intended to be connec ted to

non-hazard ous voltage circuits (SELV or Class 2). Do not connect to hazardous vol tages.

+ – S

Energy Output

information.

The user can set the display mode to either IEC or IEEE notation in the SETUP menu.

Main Menu

IEC IEEE Description

D D Demand

MAX M Maximum Demand

P W Present Real Power

Q VAR Present Reactive Power

S VA Present Apparent Power

A A Amps

UAB, UBC, UAC VAB, VBC, VAC Voltage Line to Line

V VLN Voltage Line to Neutral

PF PF Power Factor

U VLL Voltage Line to Line

HZ HZ Frequency

KSh KVAh Accumulated Apparent

Energy

KQh K VARh Accumulated Reactive

Energy

KPh KWh Accumulated Real Energy

PLOSS PLOSS Phase Loss

LOWPF LOWPF Low Power Factor Error

F ERR F ERR Frequency Error

I OVR I OVR Over Current

V OVR V OVR Over Voltage

IEC IEEE Description

PULSE PULSE kWh Pulse Output Overrun

_PHASE _PHASE Summary Data for 1, 2, or 3

ALERT ALERT Diagnostic Alert Status

INFO INFO Unit Information

MODEL MODEL Model Number

OS OS Operating System

RS RS Reset System

SN SN Serial Number

RESET RESET Reset Data

PASWD PASWD Enter Reset or Setup

ENERG ENERG Reset Energy Accumulators

DEMND DEMND Reset Demand Maximums

PULS_ PULS_ Pulse Counter (if equipped)

Q_ Q_ Quadrant 1-4 per IEEE 1459

n n Net

Over-Current Protective

Device* (not supplied)

≤ 100 mA

Main Menu

Power So urce**

~

=

≤ 100 mA

~

=

(conguration error)

active phases

Password

Import

Export

3-30 VDC

6-3 0 VAC

Power So urce**

3-30 VDC

6-3 0 VAC

ZL00 67-0C Page 11 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 12

Installation Guide

Power Monitoring

EC, EC

User Interface

DEMND

CPHAS

TM

ENRGY

(Export Wh)

PULS2

Pulse Counter 2

for Pulse Value

PULS1

See SETUP > SPULS > Wh/P

(Import Wh)

Pulse Counter 1

_PHAS

KVAh

HZ

Frequency

BPHAS

APHAS

Export

Apparent Energy

Power (S)

M KVA

Export Demand

Maximum Apparent

Power (Q)

MKVAR

Export Demand

Maximum Reactive

Power (P)

M KW

Maximum Real

Export Demand

Power (S)

M KVA

Import Demand

Maximum Apparent

MKVAR

Power (Q)

Import Demand

Maximum Reactive

M KW

IEEE Display Mode

Power (P)

Import Demand

Maximum Real

Present

D KVA

Demand (S)

Apparent Power

C -KWh

C +KWh

C PF

C KVA

CKVAR

C KW

C VLN

B -KWh

B +KWh

B PF

B KVA

BKVAR

B KWB VLN

A -KWh

A +KWh

A PF

A KVA

AKVAR

A KW

A VLN

3 -KWh

Total Export

Total Import

3 +KWh

3 PF

Power Factor

3 KVA

Total Apparent

3KVAR

Total Reactive

3 KW

Total Real

3 VLN

Volts Line-Neutral (V)

Real Energy

Real Energy

(Average of

Active Phases)

Power (S)

Power (Q)

>>> Scroll When Idle >>>

Power (P)

Phases)

(Average of Active

Import

KVAh

Apparent Energy

KVAh

Signed Net

Apparent Energy

Energy

KVAR4

Quadrant 4

Export Reactive

Energy

KVAR3

Quadrant 3

Export Reactive

Energy

KVAR2

Quadrant 2

Import Reactive

Energy

KVAR1

Quadrant 1

Import Reactive

Export

3 -KWh

Real Energy

To:

Present

Demand (Q)

DKVAR

Reactive Power

Present

Real Power

Demand (P)

D KW

SETUP

DEMND

Demand

C VAC

C A

CPHAS

3 Phase

Phase C:

B VBC

B A

BPHAS

Phase B:

2 & 3 Phase

Systems Only

A VAB

A A

APHAS

Phase A:

Systems Only

3 VLL

Phases)

(Average of Active

Volts Line-Line (U)

3 A

Amps (A)

(Average of

Active Phases)

_PHAS

All Systems

Summary Data

1, 2, or 3 Phase

Energy

Import

3 +KWh

3 KWh

ENRGY

and Counters

Accumulators

Real Energy

Signed Net

Real Energy

To:

ALERT

The units for all Power and Energy screens change to preserve resolution as the

accumulated totals increase. For example, energy starts out as Wh, then switches

ZL00 67-0C Page 12 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

to kWh, MWh, and eventually GWh as the accumulated value increases.

Page 13

Installation Guide

Power Monitoring

EC, EC

User Interface

(cont.)

TM

ENRGY

(Export Ph)

PULS2

Pulse Counter 2

for Pulse Value

PULS1

See SETUP > SPULS > Wh/P

(Import Ph)

Pulse Counter 1

_PHAS

Export

HZ

DEMND

CPHAS

BPHAS

APHAS

Frequency

E KSh

Apparent Energy

IEC Display Mode

Power (S)

M KS

Export Demand

Maximum Apparent

Power (Q)

M KQ

Export Demand

Maximum Reactive

Demand

M KP

Power Export

Maximum Real

Power

M KS

Import Demand

Maximum Apparent

Power

M KQ

Import Demand

Maximum Reactive

Demand

M KP

Power Import

Maximum Real

Present

Demand

D KS

Apparent Power

C -KPh

C +KPh

C PF

C KS

C KQ

C KPC V

B -KPh

B +KPh

B PF

B KS

B KQ

B KP

B V

A -KPh

A +KPh

A PF

A KS

A KQ

A KP

A V

3 -KPh

Total Export

Total Import

3 +KPh

3 PF

Power Factor

3 KS

Total Apparent

3 KQ

Total Reactive

3 KP

Total Real

3 V

Volts Line-Neutral (V)

Real Energy

Real Energy

(Average of

Active Phases)

Power (S)

Power (Q)

>>> Scroll When Idle >>>

Power (P)

Phases)

(Average of Active

Import

E KSh

Apparent Energy

E KSh

Signed Net

Apparent Energy

Energy

Q4 Qh

Quadrant 4

Export Reactive

Energy

Q3 Qh

Quadrant 3

Export Reactive

Energy

Q2 Qh

Quadrant 2

Import Reactive

Energy

Q1 Qh

Quadrant 1

Import Reactive

Export

E -KPh

Real Energy

Present

Demand

D KQ

Reactive Power

Present

Demand

Real Power

D KP

To:

SETUP

DEMND

Demand

C U

C A

CPHAS

3 Phase

Phase C:

Volts CA

Systems Only

Phase B:

Volts BC

B U

B A

BPHAS

2 & 3 Phase

Systems Only

A U

A A

APHAS

Phase A:

All Systems

Volts AB

3 U

3 A

_PHAS

Phases)

(Average of Active

Volts Line-Line (U)

Amps (A)

(Average of

Active Phases)

Import

E +KPh

Real Energy

E KPh

Signed Net

Real Energy

To:

ENRGY

ALERT

Energy

and Counters

1, 2, or 3 Phase

Summary Data

Accumulators

The units for all Power and Energy screens change to preserve resolution as the

accumulated totals increase. For example, energy starts out as Wh, then switches

ZL00 67-0C Page 13 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

to kWh, MWh, and eventually GWh as the accumulated value increases.

Page 14

Installation Guide

T

the Reset Password

p menu).

ergy

h, VAh) to 0.

Maximum

, VAR, VA) to the present

to Reset.

lse counters.

Power Monitoring

EC, EC

TM

Alert/Reset

Information

Alert Status

(check if

Wrench on

LCD)

Unit

Information

Reset

Data

Setup

Meter

To: ENRGY

ALERT

INFO

RESET

SETUP

PLOSS

-------A b C

Phase Loss

A B C

LOWPF

-------A b C

Low Power Factor

A B C

F ERR

-------A

Frequency Out

of Range

Display “nOnE” if no alerts

MODEL OS SNRS

Model

Number

Operating

System

System

Back

PASWD

--------

0

0000

Enter Reset

Password

ENERG

--------

rES

Reset Energy

Accumulators to 0

Reset Demand

Maximums to Present

PASWD

--------

0

0000

Enter Setup

Password

A

Reset

DEMND

--------

rES

I OVR

-------A b C

Over Current

(Clipping)

A B C

Serial

Number

COUNT

Reset Pulse

Counters to 0

--------

rES

V OVR

-------A b C

Over Voltage

(Clipping)

A B C

INFO

RESET

To Setup

PULSE

------- Error

Energy Pulse Output:

Error = Overrun Error

ConF = Configuration Error

ALER

PASWD – Enter

(configured in the setu

ENERG – Reset all En

Accumulators (Wh, VAR

Press “+” or “-“ to Reset.

DEMND – Reset all

Demand (W

Demand. Hit “+” or “-“

COUNT – Reset the pu

Press “+” or “-“ to Reset.

To: DEMND

ZL00 67-0C Page 14 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 15

Installation Guide

Power Monitoring

EC, EC

UI for Setup

From:

SETUP > PASWD

To Setup p. 2 “SPASS”

Back S COM

RS-485

Output

ADDR

--------

0

01

BAUD

--------

38400

19200

9600

4800

2400

1200

Next

PAR

--------

nOnE

EvEn

Odd

TM

Set Communications Parameters:

ADDR - Modbus Address: 1 – 247.

+ increments the selected (blinking) digit.

- selects the digit to the left.

BAUD - Baud Rate: 1200 – 38400 Baud

PAR - Parity: Odd, Even, None

+ or – to step through the options.

Transformer

Back To SETUP

Back

Current

Back

System

Type

Back

Potential

Transformer

Back

Sytem

Voltage

S CT

S SYS

S PT

S V

CT V

--------

1.0

.33

SYSTM

--------

3L-1n

3L

2L-1n

2L

1L-1n

RATIO

--------

001

V LL

--------

0

0600

.00

Next

Next

Next

CT SZ

--------

00

1

Next

Set System Configuration:

SYSTM: + or – to step through the following System Type options:

System

3L-1n 40 3 Wye Three Phase: A, B, & C with Neutral (Default).

3L 31 3 Delta Three Phase: A, B & C; no Neutral

2L-1n 12 2 Single Split Phase: A & B with Neutral

2L 11 1 Single Phase: A & B; no Neutral

1L-1n 10 1 Single Phase: A to Neutral

Set Potential Transfomer Ratio:

RATIO – Potential transformer step down is RATIO:1. Default is 1:1

(No PT installed). See Install for wiring diagrams. This value must be

set before the System Voltage (if used).

Set System Voltage:

V LL – The nominal Line to Line Voltage for the system. This is used

by the meter to calculate the theoretical maximum system power, and

as the reference voltage for setting the Phase Loss threshold.

Maximum is 32000 Volts. For system type 1+N (10), this is a Line to

Neutral Voltage, indicated by “V LN”. Note: the meter will reject settings

that are not within the meter’s operating range when divided by the PT

ratio.

Set Current Transducer:

CT V - CT Input Voltage: + or – to Select 1.0 or .33V.

CT SZ - CT Size: in Amps. Maximum is 32000 Amps.

Reg 130 CTs Description

System Power:

MX KW – The theoretical Maximum System Power is calculated by the

meter from the System Voltage, CT size, and System Type. Power

Factor is assumed to be unity. The value of System Power is used to

determine which combinations of pulse weight and duration are valid

and will keep up with the maximum power the meter will see. This value

is read only.

Note: Bold is the Default.

Back

S PWR

Sytem

Voltage

To Setup p. 2 “SPLOS”

MX KW

--------

103.92

Next

ZL00 67-0C Page 15 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 16

Installation Guide

Power Monitoring

EC, EC

UI for Setup

(cont.)

Back To SETUP

To Setup p. 1 “S PWR”

Back

Back

Back

SPLOS

Phase

Loss

SPULS

Pulse

Output

SDMND

Demand

VOLTS

--------

0.1

Wh/P

--------

10000

1000

100

10

INTRV

--------

TM

Set Phase Loss:

VOLTS - Phase Loss Voltage: The fraction of the system

voltage below which Phase Loss Alarm is on. For system

types with neutral, the Line to Neutral voltage is also

IMBAL

--------

0.2

500

250

100

50

25

10

Next

SEC

--------

0

0900

Next

5

Max

PPS

--------

10

20

50

0

mS/P

--------

Next

6

5

4

3

2

1

calculated and tested. If the System Voltage is 600 and the

fraction is set to 0.10, then the Phase Loss threshold will be

60 volts.

IMBAL - Phase Loss Imbalance: The fractional difference

in Line to Line voltages above which Phase Loss Alarm is

on. For system types with neutral, the Line to Neutral

voltages are also tested. For system types 1+N (10) and 2

(11) , imbalance is not tested.

Set Pulse:

The System Type , CT size, PT Ratio, and System Voltage must

all be configured before setting the Pulse Energy. If any of these

parameters are changed, the meter will hunt for a new Pulse

Duration, but will not change the Pulse Energy. If it cannot find a

solution, the meter will display the wrench, show “ConF” in the

ALARM -> PULSE screen, and enable Energy pulse output

configuration error bit in the Modbus Diagnostic Alert Bitmap (if

1

equipped).

2

Wh/P - Set Pulse Energy: In Watt Hours (& VAR Hours, if

5

present) per Pulse. When moving down to a smaller energy, the

meter will not allow the selection if it cannot find a pulse duration

that will allow the pulse output to keep up with Theoretical

Maximum System Power (see S_PWR screen). When moving

up to a larger energy, the meter will jump to the first value where

it can find a valid solution.

mS/P – Minimum Pulse Duration Time: This read only value

is set by the meter to the slowest duration (in mS per closure)

that will keep up with the Theoretical Maximum System Power.

The open time is greater than or equal to the closure time. The

maximum Pulses Per Second (PPS) is shown in yellow.

Set Demand Interval:

INTRV - The number of Sub-Intervals (1 to 6) in a Demand Interval.

Default is 1 (block demand).

SEC - Sub-Interval length in seconds. Default is 900 (15 minutes).

Set to 0 for external sync-to-comms (Modbus units only).

Back

Back

Passwords

To Setup page 1 “S COM”

S DIS

Display

Units

SPASS

Setup

UNITS

--------

IEEE

IEC

Next

SETUP

--------

0

0000

RESET

--------

0

0000

Next

Set Display Units: +/- to switch between:

IEEE – VLL VLN W VAR VA Units.

IEC - U V P Q S Units.

Set Passwords:

SETUP - The Password to enter the SETUP menu.

RESET - The Password to enter the RESET menu.

ZL00 67-0C Page 16 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 17

Installation Guide

Red

Black

Gray

Use 14-24 gauge wire

Power Monitoring

EC, EC

TM

RS-485

Communications

Daisy-chaining Devices to the Power Meter

The RS-485 slave port allows the power meter to be connec ted in a daisy chain with up to 63 2-wire devices.

120 Ω terminator on the rst and last

device of the daisy chain

+

–

S

Shield wire

Notes

• The terminal’s voltage and current ratings are compliant with the requirements of the EIA RS-485 communications

standard.

• The RS-485 transceivers are ¼ unit load or less.

• RS-485+ has a 47 k pull up to +5V, and RS-485- has a 47 k pull down to Shield (RS-485 signal ground).

• Wire the RS-485 bus as a daisy chain from device to device, without any stubs. Use 120 termination resistors at each

end of the bus (not included).

• Shield is not internally connected to Earth Ground.

• Connect Shield to Earth Ground somewhere on the RS-485 bus.

For all terminals:

• When tightening terminals, apply the correct torque: 0.37 to 0.44

ft·lb (0.5-0.6 N·m).

• Use 14-24 gauge (2.1-0.2 mm2) wire.

0.37–0.44 ft•lb

(0.5–0.6 N•m)

Data Logging

(EC only)

The E51C3 includes a data logging feature that records 10 meter parameters, each in its own buer.

Configuration

Use register 150 to set the data logging time subinterval. Writing to the storage buer is triggered by the subinterval timer. The

default subinterval is 15 minutes (at a 15 minute interval setting, the buers hold 60 days of data). An external timer can be used

over Modbus by setting this register to 0.

Use register 159 to turn on data logging and select either Single Shot or Continuous mode. (default is data logging on, Continuous

mode). In Single Shot mode, the meter records data until the buer is full. When the buer is full, the meter stops recording

new readings. Data for this time period is kept, but newer energy information is lost. In Continuous mode, the meter continues

to record energy data as long as the meter is operating. The buer can only hold 5760 entries at one time, however, so when the

number of records exceeds 5760, the oldest entry is deleted to make room for the newest.

Registers 169-178 contain the pointers to 10 data storage buers. Each buer is user-congurable with the Modbus address of the

16-bit data output to be stored. 32-bit data, such as oating point data or 32-bit integer energy accumulators, require two buers.

However, the lower 16 bits of an integer energy accumulator can be stored in a single buer (optional).

When the E51C3 is rst installed, the buers contain QNAN data, with a value of 0x8000. This data is considered invalid. If the

buer is reset at any point, all entries in the buers are overwritten with this 0x8000 value, indicating that it is invalid. All invalid

data is overwritten as the meter lls the buer with new data entries.

Reading Data

Use register 158 to choose which buer to read. When this register value is set to 0, the meter is in data logging mode. Changing

this value from 0 to (1 through 10)switches the meter to reading mode and selects a buer to read. Data from the selected buer

appears in registers 8000 to 13760.

ZL00 67-0C Page 17 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 18

Installation Guide

Power Monitoring

EC, EC

TM

Data Logging

(EC only, cont.)

Modbus Point Map

Overview

Read/Write Collision

If the demand sub-interval timeout occurs while the user is reading a page (register 158 ≠ 0), the log data will be held in RAM

until the next demand subinterval. At that time, both the saved data from the previous cycle and the new data will be written to

the log, whether the page register has been set back to 0 or not. Error bits in the Log Status Register (160) track these conditions.

Subsequent log writes will proceed normally. Provided the log read is concluded in less time than the demand sub-interval, this

mechanism handles the occasional collision and prevents the user from reading data as the buer is being updated.

The Log Status Register has additional error ag bits that indicate whether logging has been reset or interrupted (power cycle,

etc.) during the previous demand sub-interval, and whether the Real-Time Clock has been changed (re-initialized to default date/

time due to a power-cycle or modied via Modbus commands).

The E51C2 Full Data Set (FDS) model features data outputs such as demand calculations, per phase signed watts VA and VAR,

import/export Wh and VAh, and VARh accumulators by quadrant. The E51C3 Data Logging model includes the FDS and adds log

conguration registers 155-178 and log buer reading at registers 8000-13760. The meter supports variable CTs and PTs, allowing

a much wider range of operation from 90V x 5A up to 32000V x 32000A. To promote this, the meter permits variable scaling of the

16-bit integer registers via the scale registers. The 32-bit oating point registers do not need to be scaled.

Integer registers begin at 001 (0x001). Floats at 257 (0x101). Conguration registers at 129 (0x081). Values not supported in a

particular System Type conguration report QNAN (0x8000 in Integer Registers, 0x7FC00000 in Floating Point Registers). Register

addresses are in PLC style base 1 notation. Subtrac t 1 from all addresses for the base 0 value used on the Modbus RS-485 link.

Supported Modbus Commands

Note: ID String information varies from model to model. Text shown here is an example.

Command Description

0x03 Read Holding Registers

0x04 Read Input Registers

0x06 Preset Single Register

0x10 Preset Multiple Registers

Report ID

Return string:

byte0: address

0x11

0x2B

byte1: 0x11

byte2: #bytes following w/out crc

byte3: ID byte = 247

byte4: status = 0xFF if the operating system is used; status = 0x00 if the reset system is used

bytes5+: ID string = “Veris Industries E51xx Power Meter Full Data Set” or “Veris Industries E51xx Power Meter - RESET

SYSTEM RUNNING RS Version x.xxx” last 2 bytes: CRC

Read Device Identication, BASIC implementation (0x00, 0x01 and 0x02 data), Conformity Level 1.

Object values:

0x01: “Veris Industries”

0x02: “ E51xx ”

0x03: “Vxx.yyy”, where xx.yyy is the OS version number (reformatted version of the Modbus register #7001, (Firmware

Version, Operating System).

If register #7001 == 12345, then the 0x03 data would be “V12.345”).

Legend

The following table lists the addresses assigned to each data point. For oating point format variables, each data point appears

twice because two 16-bit addresses are required to hold a 32-bit oat value. Negative signed integers are 2’s complement.

ZL00 67-0C Page 18 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 19

Installation Guide

Power Monitoring

EC, EC

TM

Modbus Point Map

Overview (cont.)

Standard Modbus

Default Settings

R/W

NV Value is stored in non-volatile memor y. The value will still be available if the meter experiences a power loss and reset.

Format

Units Lists the physical units that a register holds.

Scale

Factor

Range Denes the limit of the values that a register can contain.

R=read only

R/W=read from either int or oat formats, write only to integer format.

UInt Unsigned 16-bit integer.

SInt Signed 16-bit integer.

ULong Unsigned 32-bit integer; Upper 16-bits (MSR) in lowest-numbered / rst listed register (001/002 = MSR/LSR).

SLong Signed 32-bit integer; Upper 16-bits (MSR) in lowest-numbered / rst listed register (001/002 = MSR/LSR).

Float 32-bit oating point; Upper 16-bits (MSR) in lowest-numbered / rst listed register (257/258 = MSR/LSR). Encoding is

per IEEE standard 754 single precision.

Some Integer values must be multiplied by a constant scale factor (typically a fraction), to be read correctly. This is done to allow

integer numbers to represent fractional numbers.

Setting Value Modbus

Register

Setup Password 00000

Reset Password 00000

System Type 40 (3 + N) Wye 130

CT Primary Ratio (if CTs are not included) 100A 131

CT Secondary Ratio 1V 132

PT Ratio 1:1 (none) 133

System Voltage 600 V L-L 134

Max. Theoretical Power

(Analog Output: full scale (20mA or 5V))

Display Mode 1 (IEEE units) 137

Phase Loss 10% of System Voltage (60V ), 25% Phase to Phase Imbalance 142, 143

Pulse Energy 1 (kWh/pulse) 144

Demand: number of sub-intervals per interval 1 (block mode) 149

Demand: sub-interval length 900 sec (15 min) 150

Modbus Address 001

Modbus Baud Rate 19200 baud

Modbus Parity None

Log Read Page 0 158

Logging Conguration Register 0 159

Log Register Pointer 1 3 (Impor t Real Energy MSR) 169

Log Register Pointer 2 4 (Impor t Real Energy LSR) 170

Log Register Pointer 3 5 (Expor t Real Energy MSR) 171

Log Register Pointer 4 6 (Expor t Real Energy LSR) 172

Log Register Pointer 5 29 (Real Demand) 173

Log Register Pointer 6 30 (Reactive Demand) 174

Log Register Pointer 7 31 (Apparent Demand) 175

Log Register Pointer 8 155 (Month/Day) 176

Log Register Pointer 9 156 ( Year/Hour) 177

Log Register Pointer 10 157 (Minutes/Seconds) 178

104 kW 135

ZL00 67-0C Page 19 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 20

Installation Guide

Power Monitoring

EC, EC

Modbus Point Map

R/W NV Format Units Scale Range Description

Register

E51C3 Log

E51C2 FDS

Integer Data: Summary of Active Phases

• • 001

• • 002 LSR

• • 003

• • 004 LSR

• • 005

• • 006 LSR

• • 007

• • 008 LSR

• • 009

• • 010 LSR

• • 011

• • 012 LSR

• • 013

• • 014 LSR

• • 015

• • 016 LSR

• • 017

• • 018 LSR

• • 019

• • 020 LSR

• • 021 R SInt kW W -32767 to +32767 Total Instantaneous Real (P) Power

• • 022 R SInt kVAR W 0 to 32767 Total Instantaneous Reactive (Q) Power

• • 023 R UInt kVA W 0 to 32767 Total Instantaneous Apparent (S) Power (vector sum)

• • 024 R SInt Ratio 0.0001 -10000 to +10000 Total Power Factor (total kW / total kVA)

• • 025 R UInt Volt V 0 to 32767 Voltage, L-L (U), average of active phases

• • 026 R UInt Volt V 0 to 32767 Voltage, L-N (V), average of active phases

• • 027 R UInt Amp I 0 to 32767 Current, average of active phases

• • 028 UInt Hz 0.01 4500 to 6500 Frequency

• • 029 R SInt kW W -32767 to +32767 Total Real Power Present Demand

• • 030 SInt kVAR W -32767 to +32767 Total Reactive Power Present Demand

• • 031 R SInt kVA W -32767 to +32767 Total Apparent Power Present Demand

• • 032 R NV SInt kW W -32767 to +32767 Total Real Power Max. Demand

• • 033 R NV SInt kVAR W -32767 to +32767 Total Reactive Power Max. Demand

• • 034 R NV SInt kVA W -32767 to +32767 Total Apparent Power Max. Demand

• • 035 R NV SInt kW W -32767 to +32767 Total Real Power Max. Demand

• • 037 R NV SInt kVA W -32767 to +32767 Total Apparent Power Max. Demand

• • 038 R UInt Reserved, returns 0x8000 (QNAN)

• • 039

• • 040 LSR

• • 041

• • 042 LSR

R NV SLong kWh E

R NV ULong kWh E 0 to 0xFFFFFFFF

R NV ULong kWh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV SLong kVAh E

R NV ULong kVA h E 0 to 0xFFFFFFFF

R NV ULong kVA h E 0 to 0xFFFFFFFF

R NV ULong 0 to 0xFFFFFFFF

R NV ULong 0 to 0xFFFFFFFF

-2147483647 to

+2147483647

-2147483647 to

+2147483647

Real Energy: Net (Import - Export)

Real Energy: Quadrants 1 & 4

Import

Real Energy: Quadrants 2 & 3

Export

Reactive Energy - Quadrant 1:

Lags Import Real Energy (IEC) Inductive (IEEE)

Reactive Energy - Quadrant 2:

Leads Export Real Energy (IEC) Inductive (IEEE)

Reactive Energy - Quadrant 3:

Lags Export Real Energy (IEC) Capacitive (IEEE)

Reactive Energy - Quadrant 4:

Leads Import Real Energy (IEC) Capacitive (IEEE)

Apparent Energy: Net (Import - Export)

Apparent: Quadrants 1 & 4

Import

Apparent: Quadrants 2 & 3

Export

Pulse Counter 1

(Import Real Energy)

Pulse Counter 2

(Export Real Energy)

MSR

MSR

MSR

Accumulated

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

Import

Export• • 036 R NV SInt kVAR W -32767 to +32767 Total Reactive Power Max. Demand

Contact Closure Counters. Valid for both pulse

Real Energy

(Ph)

Accumulated

Reactive Energy

(Qh):

Quadrants 1 + 2

= Import

Quadrants 3 + 4

= Export

Accumulated

Apparent

Energy (Sh):

Import and

Export

correspond

with Real

Energy

inputs and outputs. E51Cx counts are shown in

(). See register 144 - Energy Per Pulse for the

Wh per pulse count.

Clear via reset

register 129

Reset via register

129

TM

ZL00 67-0C Page 20 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 21

Installation Guide

Power Monitoring

EC, EC

Modbus Point Map (cont.)

R/W NV Format Units Scale Range Description

Register

E51C3 Log

E51C2 FDS

Integer Data: Per Phase

• • 043

• • 044 LSR

• • 045

• • 046 LSR

• • 047

• • 048 LSR

• • 049

• • 050 LSR

• • 051

• • 052 LSR

• • 053

• • 054 LSR

• • 055

• • 056 LSR

• • 057

• • 058 LSR

• • 059

• • 060 LSR

• • 061

• • 062 LSR

• • 063

• • 064 LSR

• • 065

• • 066 LSR

• • 067

• • 068 LSR

• • 069

• • 070 LSR

• • 071

• • 072 LSR

• • 073

• • 074 LSR

• • 075

• • 076 LSR

• • 077

• • 078 LSR

R NV ULong kWh E 0 to 0xFFFFFFFF

R NV ULong kWh E 0 to 0xFFFFFFFF

R NV ULong kWh E 0 to 0xFFFFFFFF

R NV ULong kWh E 0 to 0xFFFFFFFF

R NV ULong kWh E 0 to 0xFFFFFFFF

R NV ULong kWh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

R NV ULong kVARh E 0 to 0xFFFFFFFF

Accumulated Real Energy,

Phase A

Accumulated Real Energy,

Phase B

Accumulated Real Energy,

Phase C

Accumulated Real Energy,

Phase A

Accumulated Real Energy,

Phase B

Accumulated Real Energy,

Phase C

Accumulated Q1 Reactive

Energy, Phase A

Accumulated Q1 Reactive

Energy, Phase B

Accumulated Q1 Reactive

Energy, Phase C

Accumulated Q2 Reactive

Energy, Phase A

Accumulated Q2 Reactive

Energy, Phase B

Accumulated Q2 Reactive

Energy, Phase C

Accumulated Q3 Reactive

Energy, Phase A

Accumulated Q3 Reactive

Energy, Phase B

Accumulated Q3 Reactive

Energy, Phase C

Accumulated Q4 Reactive

Energy, Phase A

Accumulated Q4 Reactive

Energy, Phase B

Accumulated Q4 Reactive

Energy, Phase C

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

MSR

TM

Import

Accumulated Real

Energy (Ph), per

phase

Export

Import

Accumulated

Reactive Energy

(Qh), Per Phase

Export

ZL00 67-0C Page 21 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 22

Installation Guide

Power Monitoring

EC, EC

Modbus Point Map (cont.)

R/W NV Format Units Scale Range Description

Register

E51C3 Log

E51C2 FDS

TM

• • 079

• • 080 LSR

• • 081

• • 082 LSR

• • 083

• • 084 LSR

• • 085

• • 086 LSR

• • 087

• • 088 LSR

• • 089

• • 090 LSR

• • 091 R SInt kW W -32767 to +32767 Real Power (P), Phase A

• • 093 R SInt kW W -32767 to +32767 Real Power (P), Phase C

• • 094 R SInt kVAR W -32767 to +32767 Reactive Power (Q), Phase A

• • 096 R SInt kVAR W -32767 to +32767 Reactive Power (Q), Phase C

• • 097 R UInt kVA W 0 to 32767 Apparent Power (S), Phase A

• • 099 R UInt kVA W 0 to 32767 Apparent Power (S), Phase C

• • 100 R SInt Ratio 0.0001 -10000 to +10000 Power Factor (PF), Phase A

• • 102 R SInt Ratio 0.0001 -10000 to +10000 Power Factor (PF), Phase C

• • 103 R UInt Volt V 0 to 32767 Voltage (U), Phase A-B

• • 105 R UInt Volt V 0 to 32767 Voltage (U), Phase A-C

• • 106 R UInt Volt V 0 to 32767 Voltage (V), Phase A-N

• • 108 R UInt Volt V 0 to 32767 Voltage (V), Phase C-N

• • 109 R UInt Amp I 0 to 32767 Current, Phase A

• • 111 R UInt Amp I 0 to 32767 Current, Phase C

• • 112 R UInt Reserved, Returns 0x8000 (QNAN)

R NV ULong kVA h E 0 to 0xFFFFFFFF

R NV ULong kVA h E 0 to 0xFFFFFFFF

R NV ULong kVA h E 0 to 0xFFFFFFFF

R NV ULong kVA h E 0 to 0xFFFFFFFF

R NV ULong kVA h E 0 to 0xFFFFFFFF

R NV ULong kVA h E 0 to 0xFFFFFFFF

Accumulated Apparent Energy,

Phase A

Accumulated Apparent Energy,

Phase B

Accumulated Apparent Energy,

Phase C

Accumulated Apparent Energy,

Phase A

Accumulated Apparent Energy,

Phase B

Accumulated Apparent Energy,

Phase C

MSR

MSR

MSR

MSR

MSR

MSR

Import

Accumulated

Apparent Energy

(Sh), Per Phase

Export

Real Power (P)• • 092 R SInt kW W -32767 to +32767 Real Power (P), Phase B

Reactive Power (Q)• • 095 R SInt kVAR W -32767 to +32767 Reactive Power (Q), Phase B

Apparent Power (S)• • 098 R UInt kVA W 0 to 32767 Apparent Power (S), Phase B

Power Factor (PF)• • 101 R SInt Ratio 0.0001 -10000 to +10000 Power Factor (PF), Phase B

Line to Line Voltage (U)• • 104 R UInt Volt V 0 to 32767 Voltage (U), Phase B-C

Line to Neutral Voltage ( V)• • 107 R UInt Volt V 0 to 32767 Voltage (V), Phase B-N

Current• • 110 R UInt Amp I 0 to 32767 Current, Phase B

ZL00 67-0C Page 22 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 23

Installation Guide

Power Monitoring

EC, EC

Modbus Point Map (cont.)

R/W NV Format Units Scale Range Description

Register

E51C3 Log

E51C2 FDS

Conguration

Reset:

- Write 30078 (0x757E) to clear all Energy Accumulators to 0 (All).

- Write 21211 (0x52DB) to begin new Demand Sub-Interval calculation cycle. Takes eect at the end of the

next 1 second calculation cycle. Write no more frequently than every 10 seconds.

• • 129 R/W UInt N/A

10,

11,

• • 130 R/W NV UInt

• • 131 R/W NV UInt Amps 1-32000 CT Ratio – Primary

• • 132 R/W NV UInt 1, 3 CT Ratio – Secondary Interface (1 or 1/3 V, may not be user congurable)

• • 133 R/W NV UInt 100 0.01-320.00

• • 134 R/W NV UInt 82-32000

• • 135 R NV UInt kW W 1-32767

• • 136 R UInt Reserved, always returns 0

• • 137 R/W NV UInt 0,1 Display Units: 0 = IEC (U, V, P, Q, S), 1 = IEEE (default: VLL, VLN, W, VAR, VA)

• • 138 R SInt

• • 139 R SInt Scale Factor V (Voltage)

• • 140 R SInt Scale Factor W (Power)

• • 141 R SInt Scale Factor E (Energy)

12,

31,

40

-4 0.0001

-3 0.001

-2 0.01

-1 0.1

0 1.0

1 10.0

2 100.0

3 1000.0

4 10000.0

- Write 21212 (0x52DC) to reset Max Demand values to Present Demand Values. Takes eect at the end of the

next 1 second calculation cycle. Write no more frequently than every 10 seconds.

- Write 16640 (0x4100) to reset Logging (E51C3 only).

- Write 16498 (0x4072) to clear Pulse Counts to zero.

- Read always returns 0.

Single Phase: A + N

Single Phase: A + B

Single Split Phase: A + B + N

3 phase ∆, A + B + C, no N

3 phase Y, A + B + C + N

PT Ratio: The meter scales this value by 100 (i.e. entering 200 yields a potential transformer ratio of 2:1).

The default is 100 (1.00:1), which is with no PT attached. Set this value before setting the system voltage

(below)

System Voltage: This voltage is line to line, unless in system type 10 (register 130), which is line to neutral.

The meter uses this value to calculate the full scale power for the pulse conguration (below), and as full

scale for phase loss (register 142). The meter will refuse voltages that are outside the range of 82-660 volts

when divided by the PT Ratio (above).

Theoretical Maximum System Power – This read only register is the theoretical maximum power the meter

expects to see on a service. It is calculated by the meter from the System Type (register 130), CT size (register

131), and System Voltage (register 134) and is updated whenever the user changes any of these parameters.

It is used to determine the maximum power the pulse outputs can keep up with. This integer register has the

same scale as other integer power registers (see register 140 for power scaling).

Scale Factor I (Current)

TM

System Type

(See Manual. Note: only the

indicated phases are monitored

for Phase Loss)

Current Inputs

Scale Factors

Note: These registers contain a signed

integer, which scales the corresponding

integer registers. Floating point

registers are not scaled. Scaling

is recalculated when the meter

conguration is changed.

ZL00 67-0C Page 23 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131

Alta Labs, E nercept, Ensp ector, Hawkeye, Trus tat, Aerospo nd, Veris, and th e Veris ‘V’ log o are tradema rks or registe red tradema rks of Veris Ind ustries, L. L.C. in the USA and /or other countri es.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Page 24

Installation Guide

Power Monitoring

EC, EC

Modbus Point Map (cont.)

R/W NV Format Units Scale Range Description

Register

E51C3 Log

E51C2 FDS

• • 142 R/W NV UInt % 1-99

• • 143 R/W NV UInt % 1-99

• • 144 R/W NV UInt Wh

• • 145 R NV UInt msec

• • 146 R UInt

10000,

1000,

100,

10

500,

250,

100,

50,

25,

10

Phase Loss Voltage Threshold in percent of system voltage (register

134). Default value is 10 (%). Any phase (as congured in register

130) whose level drops below this threshold triggers a Phase Loss

alert, i.e., if the System voltage is set to 480 V L-L, the L-N voltage

for each phase should be 277 V. When the threshold is set to 10%,

if any phase drops more than 10% below 277 V, (less than 249 V),

or if any L-L voltage drops more than 10% below 480 V (less than

432 V) the corresponding phase loss alarm bit in register 146 will

be true.

Phase Loss Imbalance Threshold in Percent. Default is 25% phase

to phase dierence. For a 3-phase Y (3 + N) system type (40 in

register 130), both Line to Neutral and Line to Line voltages are

tested. In a 3-phase System type (31 in register 130), only Line

to Line voltages are examined. In a single split-phase (2 + N)

system type (12 in register 130), just the line to neutral voltage

are compared.

Wh (& VARh, if equipped)

Energy per Pulse Output

Contact Closure. If the meter

cannot nd a pulse duration

that will keep up with the

max. system power (register

135), it will reject the new

value. Check the meter

conguration and/or try a

larger value.

Pulse Contact Closure Duration

in msec. Read-only. Set to

the slowest duration that will

keep up with the theoretical

max. system power (register

135). The open time ≥ the

closure time, so the max.

pulse rate (pulses per sec)

is the inverse of double the

pulse time.

Error Bitmap. 1 = Active:

Bit 0: Phase A Voltage out of range

Bit 1: Phase B Voltage out of range

Bit 2: Phase C Voltage out of range

Bit 3: Phase A Current out of range

Bit 4: Phase B Current out of range

Bit 5: Phase C Current out of range

Bit 6: Frequency out of the range of 45 to 65 Hz -OR- insucient voltage to determine frequency.

Bit 7: Reserved for future use

Bit 8: Phase Loss A

Bit 9: Phase Loss B

Bit 10: Phase Loss C

Bit 11: Low Power Factor on A with one or more phases having a PF less than 0.5 due to mis-wiring of phases

Bit 12: Low Power Factor on B

Bit 13: Low Power Factor on C

Bit 14: Energy pulse output overrun error. The pulse outputs are unable to keep up with the total real power

(registers 3 and 261/262). To x, increase the pulse energy register (register 144) and reset the energy

accumulators (see reset register 129).

Bit 15: Energy pulse output conguration error (present pulse energy setting may not keep up with the

theoretical max. system power; see register 135). To x, increase the pulse energy (register 144).

kWh (& VARh, if equipped) Pulse Contacts

Note: The kWh pulse contact can keep up with a maximum power (Watts) of

1800000 x Wh pulse weight ÷ contact closure duration (in msec)

Phase Loss Output

Note: The phases tested are determined

by the System Type.

TM

ZL00 67-0C Page 24 of 34 ©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06131