Page 1

TM

(61 mm)

CD SerieS CD SerieS

CDE

CDL

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• Read and understand the instructions before installing

this product.

• Turn off all power supplying equipment before working on it.

• The installer is responsible for conformance to all applicable codes.

PRODUCT IDENTIFICATION

DELUXE MODEL:

ENVIRONMENTAL SENSORS

RH Option

CDL

S

H = RH2%

X = NO RH

ECONOMY MODEL:

CDE (no options)

Temp

T = Temp

X = No Temp

(Stop Here)

Sensor Type

A = Transmitte r

B = 100R Platinu m, RTD

C = 1k Platinum, RTD

D = 10k T2, RTD, Ther mistor

E = 2.2k, Ther mistor

F = 3k, Therm istor

G = 10k CPC, Ther mistor

H = 10k T3, Thermi stor

J = 10k Dale, Ther mistor

K = 10k w/11k shunt, Thermist or

M = 20k NTC, Ther mistor

N = 1800 ohm, Ther mistor

R = 10k US, Thermis tor

S = 10k 3A221, Thermis tor

T = 100k, The rmistor

U = 20k “D”, Thermis tor

Optional Cal Cert.

Blank = None

1 = 1 pt Temp Cert

2 = 2 pt Temp Cert

INSTALLATION GUIDE

Duct Mounted Environmental CO2 Sensors

Installer’s Specifications

Input Voltage 20 to 30VDC, 24AC

Analog Output CDE models: 4-20mA (clippe d & capped)/0-10VDC (selectable)

CDL models: 4-20mA (clipped & capped)/0-5VDC /0-10VDC (selectable)

Sensor Current Draw 100mA Maximum

Operating Temperature Range 0° to 50°C (32° to 122°F)

Operating Humidity Range 0-95% (noncondensing)

Housing Material High impac t ABS plastic

CO2 Transmitter:

Sensor Type Non-dispersive infrared (NDIR), diusion sampling

Output Range 0-2000 ppm or 0 -5000 ppm, user selectable on CDL models,

0-2000 ppm on CDE mo dels

Accuracy ±30 ppm ±2% of measured value*

Repeatability ±20 ppm ±1% of measured value

Response Time <60 seconds for 90% step c hange

RH Transmitter**:

HS Sensor Digitally pr oled thin-lm capacitive (32-bit mathematics); U.S. Patent 5,844,138

Accuracy ±2% from 10 to 80% RH @ 25°C; Multi-point calibration NIST

Hysteresis 1.5% typical

Linearity Included in Accuracy spec.

Stability ±1% @ 20°C (68°F) annually, for two years

Output Range 0 to 100% RH

Temperature Coecient ±0.1% RH/°C above or below 25°C (typical)

Temperature (Transmitter)**:

Sensor Type Solid-state, integrated circuit

Accuracy ±0.5°C (±1°F) typical

Resolution 0.1°C (0.2°F)

Output Range 10° to 35°C (50° to 95°F)

Relay Contacts**:

1 Form C 1A@30VDC, resistive; 30W max.

Specied accuracy with 24VDC supplied power with rising humid ity. RTD/Thermistors in wall

packages are not compensated for internal heating of product.

EMC Conformance: EN 61000- 6-3:2001 (Amended by A11:2004) Class B, EN 61000- 6-1:2001

EMC Test Methods: CISPR 22:2006, IEC 61000-4-2:2001, IEC 61000-4 -3:2006, IEC 61000-4- 4:2004,

IEC 61000-4-6:2006, IEC 61000-4-8:2001, IEC 61000-4-11:2004

EMC Special Note: Connect this produc t to a DC distribution network or an AC/DC powe r adaptor

with proper Surge protection (EN 61000-6-1:2001 specication requirements).

* Measured at NTP

** Not available on CDE

Note: Rough handling and transp ortation may cause a temporary reduction of CO2 sensor

accuracy. With time, the ABC function will tun e the readings back to the correct accuracy range.

The default tuning speed is li mited to 30 ppm per week.

QUICK INSTALL

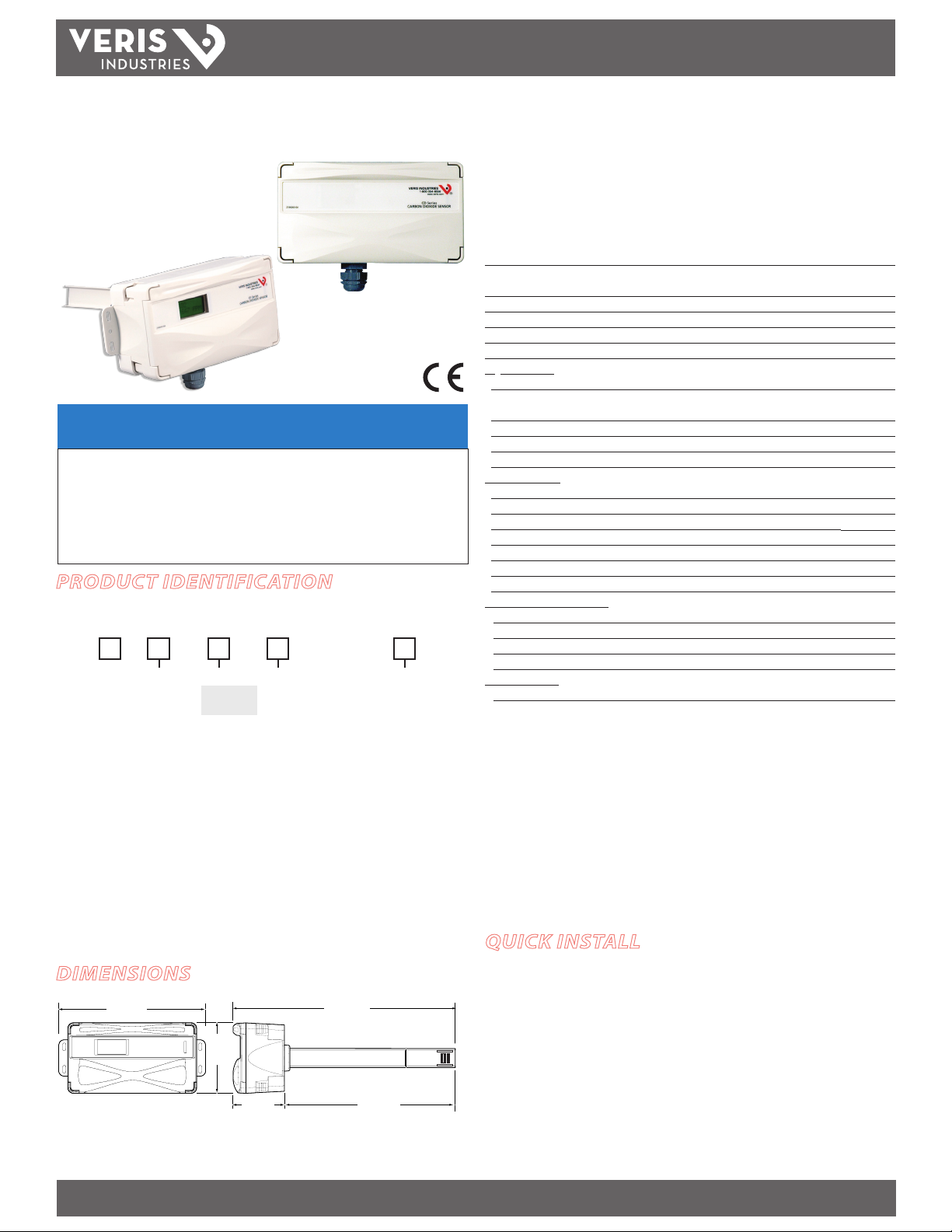

DIMENSIONS

6.7"

(170 mm)

3.1"

(78 mm)

2.4"

Z204900-0K PAGE 1 ©2011 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06114

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

10.2"

(258 mm)

7.8"

(97 mm)

1. Using the mounting diagram on page 2, or using the housing as a template, mark

and drill the four mounting holes on the duct. The centerline through the housing

must be parallel to the air ow through the duct.

2. Rotate the duct probe so that its widest sur face is perpendicular to the air ow in

the duct.

3. Insert the probe and secure the sensor to the duct with the sheet metal screws

provided, making sure that the provided gasket material is compressed between

the sensor housing and the air duct.

4. Wiring. See wiring diagrams on next page.

Page 2

TM

would not be covered under the factory warranty.

(78 mm)

Rotate the duct probe

so the channeled side is

perpendicular to the

air flow of the duct

Air Flow

Air Flow

CD SERIES

INSTALLATION GUIDE

OPERATION

CD series duct mount CO2 sensors measure the levels of CO2, RH (if equipped), and

temperature (if equipped) of air inside a duct. The CO2 sensor operates within

accuracy specications for an interval of 5 years and can be eld calibrated. The

temperature element is warranted to meet accuracy specications for a period of

5 years. RH equipped models feature a replaceable HS Series humidity element

that is warranted to meet accuracy specications for a period of 1 year. To maintain

accuracy, all vents must remain clear and free of dust, debris, etc.

INSTALLATION

Observe handling precautions for static sensitive

devices to avoid damage to the circuitry which

1. Choose a location to mount the sensor. The centerline of the housing must be

parallel to the direction of air ow in the duct.

2. Use the mounting diagram to drill the four holes in the duct for securing the

sensor.

6.7"

(175 mm)

1" diameter

3.1"

C

L

2.2"

(56 mm)

0.4" x .0.2"

(typical)

1"

(26 mm)

typ

0.3"

(6 mm)

typ

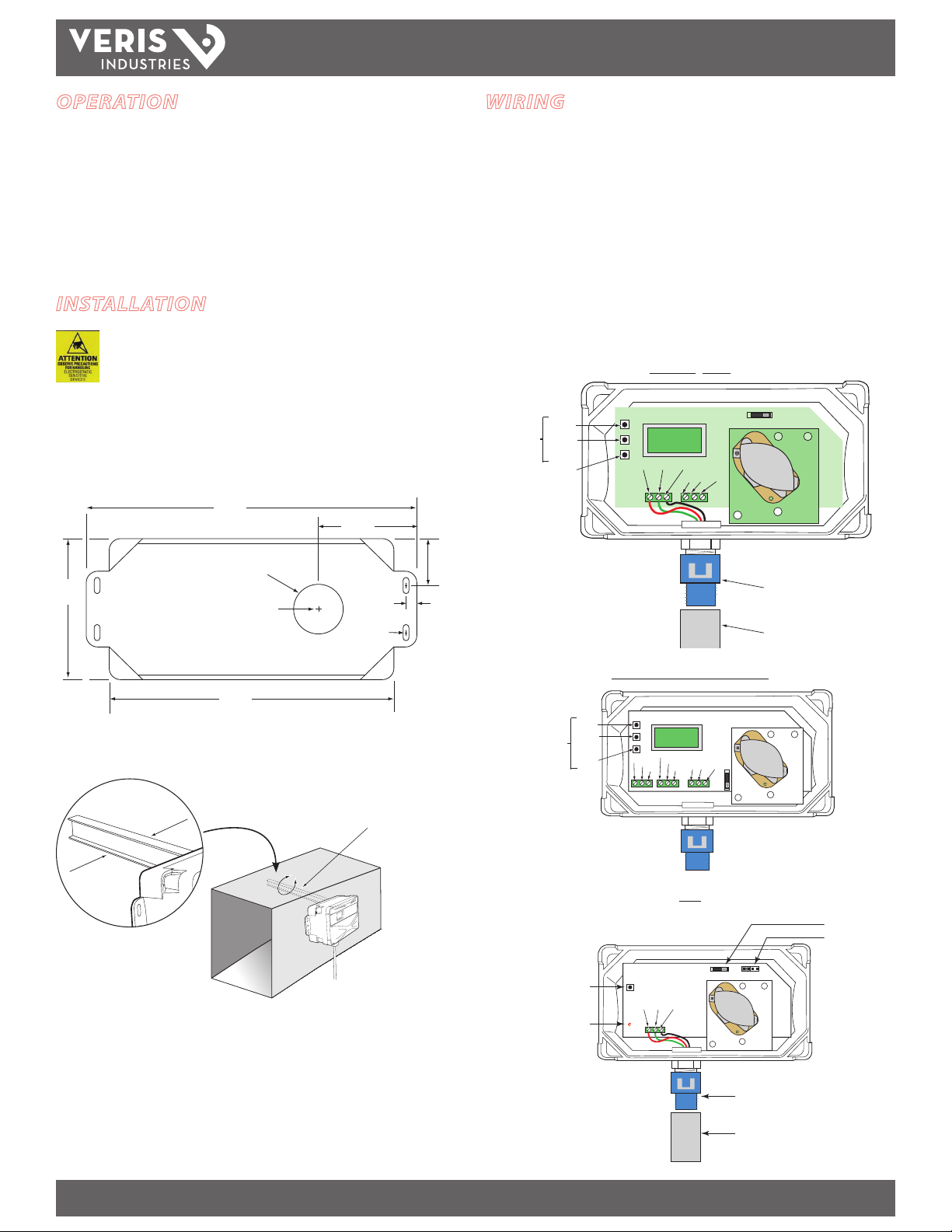

WIRING

1. Feed control wire through conduit adapter and grommeted compression tting on

the bottom of the housing.

2. Remove terminal blocks by pulling straight up on the green assemblies.

3. Connect wires as shown and push terminal blocks back in to black receptacles.

4. Tighten compression t ting around control wire until sealed.

5. Snap conduit adapter onto compression tting.

6. Refer to specications for power requirements and relay rating.

7. Select mA or Volt output using selector switch.

CDL - CO2 Only

Configuration

Pushbuttons

PLUS

ENTER

MINUS

V+ CO2-OUT GND

NC COMM NO

mA Volt

1/2” NPT MALE CONDUIT ADAPTER

1/2” NPT FEMALE COUPLER

5.7"

(144 mm)

3. Insert the probe into the hole. Rotate the housing so that the widest surface is

perpendicular to the air ow.

4. Attach the sensor to the duct using the sheet metal screws provided. Make sure

that the gasket on the back of the housing is compressed between the housing

and the duct for a secure t.

5. Wire the device. See Wiring section.

6. Congure the system using the menu (CDL only; see Conguration section).

7. Calibrate using 0 ppm CO2 gas (see Calibration section).

CONFIGURATION

PUSHBUTTONS

Calibration

Pushbutton

CDL with Temp & RH Options

PLUS

ENTER

RH OUT

V+

MINUS

CO2 OUT

TEMP OUT/RTD

RTD

GND

CDE

V+ CO2-OUT GND

LED

NC COMM NO

mA

Volt

mA Volt

mA/Volt Selection Switch

ABC Jumper

Conduit Adapter

1/2” NPT male/female

Z204900-0K PAGE 2 ©2011 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06114

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

Page 3

TM

XX

SA

IT

ENAD

XXX

AM

BDOE

–+

–0

OU

V+

CX

OE

PM

PM00150P

O.O

%R H

PM

˚F

XX

OU

RX

.X

–+

CA

*:00

WN

CA

CD SERIES

INSTALLATION GUIDE

CONFIGURATION: CDL MODELS

RUN MODE:

100

*

*INDICATES RELAY STATUS

0

7

XX.

X

CO2/R H/T COM BO MOD EL

TOGGLE %RH AND DEGREES

0

CO2 ONLY MODEL

CO2/R H COMBO M ODEL

0010

.

0

CO2/T COMBO M ODEL

0010

P

CO2

P

PPM

X

CONFIGURATION MODE:

PRESS [ENTER] FOR CONFIGURATION MODE.

PRESS PLUS OR MINUS TO CHANGE SETTING.

SPOT

E

O2C

RANGE 500 TO 1500

50PPM INC REMENT

80 0

DDBA

2CO 010

RANGE 10 TO 500

5 PPM INCREMENT

RGEN

A

CO

2

OPTIONS ARE 2000 OR 5000

X

C

XX +X–

OPTIONS ARE ON, LOW, OFF

SEE NEXT PAGE FOR EXPLANATION

CALIBRATION MODE:

PUSH AND HOLD PLUS AND MINUS FOR 5 SECONDS

TO ENTER MODE. PRESS ARROW TO CHANGE OPTION.

N

PUSH ENTER FOR N EXT SELECTIO N.

E

R

XX

X

DISPLAYS SERIAL NUMBER

X

X

XX

XXX

DISPLAYS MO DEL NUMBER

F.XS

F

X

LI

XXX

T

º

RANGE IS -5 TO 5ºC

0.1ºC INCREMENT

(CO2/temp combo models)

F

FO

%

S

TE

HX

RANGE -10 TO 10%

0.1% INCREMENT

(CO2/RH combo models)

U

N

SIXT

º

(TEMP MODELS ONLY)

OPTIONS ARE ºF or ºC

U

T

–1

0

(VOLTAGE MODE ONLY)

OPTIONS: 0-10V OR 0-5V

DEFAULT IS 0-10V

U

T

40

–2

(mA MODE ONLY)

m

TP

TP

A

2

O

OPTIONS ARE YES, NO

L

A

OPTIONS ARE NONE, 0, 400

RI

C

X

XLX

G

X–

XSXX+

KO

?

?

G

5

Unit will automatically retu rn to run mode

when calibration is complete.

NOTE: This product is factory calibrated. The typical CO2 sensor

calibration interval is 5 years , depending on specic site

installation factors. A s of the date of this document, compliance

with ANSI/ASHRAE 62-2001 requires minimum on-site accuracy

verication intervals of 6 months or per the building operation

and maintenance manual. Verif y accuracy using a comparison

to a known reference or the CO2 gas calibration kit available

from Veris Industries as AA01.

Z204900-0K PAGE 3 ©2011 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06114

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

WARNING: CO2 sensor calibration requires gas calibration kit.

Performing calibration with out gas kit or at an incorrect gas

ow rate will cause erroneous readings.

Page 4

TM

ABC Settings (CWE only)

CD SERIES

INSTALLATION GUIDE

ABC CALIBRATION ALGORITHM

ABC (Automatic Baseline Calibration) is a patented self-calibration feature that

automatically adjusts the CO2 sensor to compensate for drift. When ABC is enabled,

the sensor records the lowest reading within every 24-hour interval and compares

these values over a running 7-day or 28-day period. If a statistically signicant

amount of drift is detected, the ABC applies an automatic correction factor. This

enables the sensor to operate within specications for the 5-year calibration interval.

ON POSITION. Recommended Setting. Use the ON setting for applications where the

building is unoccupied within a 24-hour timeframe.

LOW POSITION. Use the LOW setting for buildings occupied 24 hours a day.

OFF POSITION. Not Recommended.

NOTE: After changing the ABC setti ngs, power cycle the unit for changes to take eect.

To set the ABC mode for CDL models, refer to the Conguration section on page 3.

To set the ABC mode for CDE models, position the ABC jumper as shown:

ON LOW

ON

LOW

OFF

ON

LOW

OFF

OFF

ON

LOW

OFF

CDL MODELS ONLY

CDL versions have optional RH and temperature sensors.

Observe handling precautions for static sensitive

devices to avoid damage to the circuitry which

would not be covered under the factory warranty.

To Replace Humidity Sensor:

1. Power down unit

2. Remove CDL from duct to

access probe tip.

3. Open tip of duct probe

4. Slide old RH sensor o pins

5. Slide new RH sensor onto pins.

6. Re-install CDL in duc t and re-secure with screws provided.

7. Power unit back on

Lift to open

tip of probe

Pins

HS Sensor

OUTPUT SCALING

Output scaling: 0-2000 ppm

CO2 ppm 0-5 Volt

Output

Outside 300-500 0.75 to 1.25 1.5 to 2.5 6.4 to 8

Over Ventilated Under 600 under 1.5 Under 3 Under 8.8

Ideal Ventilation 600-900 1.5 to 2.25 3 to 4.5 8.8 to 11.2

Under Ventilated Over 900 over 2.25 Over 4.5 Ov er 11.2

0-10 Volt

Output

mA

Output

Z204900-0K PAGE 4 ©2011 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06114

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

Page 5

TM

CD SERIES

INSTALLATION GUIDE

CALIBRATION PROCESS: CDL MODELS

1. Remove cover and connect gas cylinder hose to the plastic port located on sensing

module. Note: only connect one sensor to the calibration gas cylinder at a time.

Connect hose here

2. Start owing nitrogen gas (0 ppm CO2). Use a ow rate of 0.3 to 0.5 liter/minute.

Regulator

Valve

NITROGEN

GAS

CALIBRATION PROCESS: CDE MODELS

1. Remove cover and connect gas cylinder hose to the plastic port located on sensing

module. Note: only connect one sensor to the calibration gas cylinder at a time.

Connect hose here

2. Start owing nitrogen gas (0 ppm CO2). Use a ow rate of 0.3 to 0.5 liter/minute.

Regulator

Valve

NITROGEN

GAS

3. Calibrate for 5 min. Unit will return to working display when nished.

4. When unit returns to working display, remove hose from calibration port and

enter Calibration mode as described on page 3.

3. Push and hold down calibration button until the LED illuminates.

Push and

hold down

calibration

button

Green L ED

4. Continue owing gas through the sensor until the LED is o. Estimated calibration

time is 5 minutes. Remove hose from calibration port when complete.

For more complete calibration instructions using the

AA01 Calibration Kit, see the AA01 Installation Guide.

Z204900-0K PAGE 5 ©2011 Veris Industries USA 800.354.8556 or +1.503.598.4564 / support@veris.com 06114

Alta Labs, Enercep t, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘ V’ logo are trademark s or registered tradema rks of Veris Industries, L.L .C. in the USA and/or othe r countries.

Loading...

Loading...