PLEASE READ INSTRUCTIONS IN CONJUNCTION WITH ILLUSTRATIONS.

PLEASE SAVE THESE INSTRUCTIONS.

IPX4

220-240V~50Hz

Stock Ref. N°

Centrif Duo P 25 61 20D

Centrif Duo T 25 62 20D

Centrif Duo DP 25 63 20D

Centrif Duo HTP 25 64 20D

Centrif Duo Plus P 43 16 13B

Centrif Duo Plus T 43 16 14B

Centrif Duo Plus DP 43 16 15B

Centrif Duo Plus HTP 43 16 16B

Centrif Duo &

Centrif Duo Plus

Installation and Wiring Instructions

Centrif Duo Plus

Centrif Duo

Centrif Duo and Centrif Duo Plus

Features

P T DP

HTP

Surface mountable

● ● ●

●

Flush mountable with accessory kit (available

separately)

● ● ●

●

Washable filter (available separately for

Centrif Duo Plus)

● ● ●

●

Pullcord

● ●

●

Trickle speed

● ● ●

●

LS connection (to boost from a remote switch

from off or trickle speed).

● ● ●

●

Two boost speed options available (selectable

during installation)

● ● ●

●

Adjustable timer overrun (1-30 mins approx)

●

●

Adjustable humidity sensor (default 75%RH

approx)

●

2

Installation and wiring instructions for the Centrif Duo and Centrif Duo Plus extract fans.

IMPORTANT:

READ THESE INSTRUCTIONS

BEFORE COMMENCING THE

INSTALLATION

DO NOT install this product in areas where the following may be present or occur:

• Excessive oil or a grease laden atmosphere.

• Corrosive or flammable gases, liquids or vapours.

• Ambient temperatures higher than 40°C or less than –5°C.

• Possible obstructions which would hinder the access or removal of the fan.

SAFETY AND GUIDANCE NOTES

A. All wiring to be in accordance with the current I.E.E.

Regulations, or the appropriate standards of your country

and MUST be installed by a suitably qualified person.

B. The fan should be provided with a local isolator switch

capable of disconnecting all poles, having a contact

separation of at least 3mm.

C. Ensure that the mains supply (voltage, frequency, and

phase) complies with the rating label.

D. The fan should only be used in conjunction with the

appropriate Vent-Axia products.

E. It is recommended that the connection to the fan connector

terminals is made with flexible cable.

F. When the fan is used to remove air from a room containing a

fuel-burning appliance, ensure that the air replacement is

adequate for both the fan and the fuel-burning appliance.

G. Precautions must be taken to avoid the backflow of gases

into the room from the open flue of gas or other fuel burning

appliances

H. The fan should not be used where it is liable to be subject to

direct water spray for prolonged periods of time.

I. Where ducted fans are used to handle moisture-laden air, a

condensation trap should be fitted. Horizontal ducts should

be arranged to slope slightly downwards away from the fan.

J. This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

3

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

K. Children should be supervised to ensure that they do not

play with the appliance.

DESCRIPTION

As standard, the Centrif Duo and Centrif Duo Plus are suitable for panel/wall installations, surface mounting, either in a

horizontal or vertical plane. A Flush Mount Kit (439256) is available as an accessory. Ø100mm ducting (flexible or

rigid) can be attached providing rear exit as standard or side exit with the Flush Mount Kit. Adaptors for rectangular

ducting can be used. For wall installations a Wall Kit (25 41 02 White / 25 41 00 Brown) can be used. Please see our

catalogue or web site (www.vent-axia.com) for more information on ducting and termination options.

A. INSTALLATION

A Backdraught Shutter Assembly is supplied. It is packed inside the product during transport. It is designed to block

the duct when the fan is off in order to prevent cold draughts from outside entering the building. To use it, push it on to

the end of the exhaust Spigot (fig.1) with the hinges on the flaps vertical. It is not required when the fan is set up to run

continuously.

SURFACE MOUNTING (PANEL/CEILING)

1. Remove the Front Cover Assembly by slackening the two screws by two turns (fig.2.) Lift the front assembly away

from the bottom edge first, then the top edge.

2. Cut a 105mm hole, then suitable screw holes in the panel, ensuring that there is sufficient space for the product

to be installed and that the filter (sold separately for the Centrif Duo Plus) can be removed for maintenance. Either

the cardboard fitment or the fan chassis can be used as a template. The Spigot can be removed temporarily to

make it easier. (Fig 1 & 3).

3. Set-up the appropriate speed selection and other features as outlined in Section B SETUP.

4. Remove the small Terminal Block Cover in the top right corner (fig 3).

5. Attach the ducting to the Spigot and locate the fan into the hole in the panel. Feed the wiring through the hole in

the Chassis next to the Terminal Block as you do so. (fig. 4)

6. Secure into position using appropriate fixtures.

7. Select and follow the appropriate wiring diagram in Section C WIRING.

8. Replace the little Terminal Block Cover over the Terminal Block (fig.4).

9. Ensure the Impeller rotates freely (fig.3).

10. Replace the Front Cover Assembly and tighten the two screws (fig.2.).

11. Make sure that all covers are on correctly to ensure the optimum performance and water ingress protection of the

fan.

12. Switch the mains power supply on and check the fan is operating correctly.

SURFACE MOUNTING (WALL)

For through-the-wall installations, a Wall Kit (25 41 02 White / 25 41 00 Brown) can be used.

1. Remove the Front Cover Assembly by slackening the two screws by two turns (fig.2.) Lift the Front Cover

Assembly away from the bottom edge first, then the top edge.

2. Cut a 115mm hole through the wall, ensuring that there is sufficient space for the product to be installed and that

the Filter (fig.3) can be removed for maintenance.

3. Insert the wall sleeve with the larger diameter sleeve on the room-side and cement the ends into position flush

with the wall faces. The wall sleeve should be angled downwards, away from the fan, to allow any condensation to

drain to the outside.

4. Outside Grille: Using the Grille’s back plate as a template, mark the fixing hole centres on the wall. Drill and plug

the wall and fix the Grille into position. Ensure the louvres are pointing downwards.

5. Set-up the appropriate speed selection and other features as outlined in Section B SETUP.

6. Remove the little Terminal Block Cover in the top right corner (fig 3).

7. Using the fan chassis as a template, carefully sliding the Spigot into the Wall Liner, mark the fixing hole centres on

the wall. Alternatively, the cardboard fitment can be used as a template.

8. Drill and plug the wall using the fixings provided.

9. Feed the wiring through the hole near the Terminal Block and secure the fan into position using the screws

provided.

10. Select and follow the appropriate wiring diagram in Section C WIRING.

11. Replace the Terminal Block Cover (fig.4).

12. Ensure the Impeller (fig.3) rotates freely.

13. Replace the Front Cover Assembly and tighten the two screws (fig.2).

4

14. Make sure that all covers are on correctly to ensure the optimum performance and water ingress protection of the

fan.

15. Switch the mains power supply on and check the fan is operating correctly.

FLUSH MOUNTING (PANEL/CEILING)

A Flush Mount Kit (439256) is required.

1. Remove the Front Cover Assembly by slackening two screws by two turns (fig.2). Lift the front assembly slowly

from the bottom edge first, then the top edge.

2. Mark and cut a rectangular hole 222mm (w) x 253mm (h) through the panel ensuring that there is sufficient space

for the product to be installed and that the Filter (fig.3) can be removed for maintenance. IMPORTANT: Be careful

to avoid joists and hidden pipes or cables.

3. Remove the Back Box pieces by removing the four screws (fig 5). Replace it with the Frame from the Flush Mount

Kit.

4. Pass each of the long Panel Clip Screws (fig.6) supplied in the kit fully through the flange of the Chassis and

screw in to the four Panel Clips allowing enough space between the clip and the flange for the thickness of the

panel (so that the clips can spring open behind the panel).

5. Set-up the appropriate speed selection and other features as outlined in Section B SETUP.

6. Remove the Terminal Block Cover in the top right corner (fig 3).

7. Attach the ducting to the Spigot and locate the fan into the hole in the panel, ensuring the cable is fed into the fan

Chassis and the Panel Clips spring out behind the panel.

8. Secure into position by carefully tightening the four Panel Clip Screws. IMPORTANT: If power tools are used,

set them to the minimum torque setting or preferably use a manual screwdriver. Do not over tighten.

9. Select and follow the appropriate wiring diagram in Section C WIRING.

10. Replace the Terminal Block Cover.

11. Ensure the Impeller rotates freely (fig.3).

12. Replace the Front Cover Assembly and tighten the two screws (fig.2).

13. Make sure that all covers are on correctly to ensure the optimum performance and water ingress protection of the

fan.

14. Switch the mains power supply on and check the fan is operating correctly.

B. SETUP

WARNING: THE FAN AND ANCILLARY CONTROL EQUIPMENT MUST BE ISOLATED FROM THE

POWER SUPPLY DURING INSTALLATION OR MAINTENANCE.

TO ACCESS THE SPEED CONTROLS/PCB, REMOVE THE 2 SCREWS HOLDING THE PCB COVER

IN PLACE (SEE FIG 4).

1. SELECTING THE CONSTANT TRICKLE (with Boost) OPTION

All models have the ability to have a constant trickle speed with an option to boost if required. To enable

constant trickle, please refer to fig 7 and below:

i) P model: Link terminals 5 and 6.

ii) DP model: Pull pullcord until in the trickle speed has been selected. If you want to just use the LS to switch

the DP model between trickle and boost, first set the fan running to trickle speed with the pull cord, then

remove the pull cord string.

iii) T and HTP models: Move dip switch 4 into the ON position.

2. SELECTING THE BOOST SPEED.

All models can boost to a higher speed via LS connection or Pullcord (pullcord not available on T model). The

HTP model can boost to different speeds for Timer (LS) and Automatic Humidistat functions.

i) P Model: Link terminal 4 to one of the following:

a. Terminal 1 = Low speed (same as trickle speed)

b. Terminal 2 = Medium (Utility) speed

c. Terminal 3 = High (Kitchen) speed

ii) DP model: Link terminal 3 to one of the following:

a. Terminal 1 = Medium (Utility) speed

b. Terminal 2 = High (Kitchen) speed

iii) T model: Move one of the following dip switches into the ON position.

a. Dip switch 1 = Low speed (same as trickle speed)

b. Dip switch 2 = Medium (Utility) speed

c. Dip switch 3 = High (Kitchen) speed

5

iv) HTP model: The HTP model has two boost speed options, one speed option for the Timer function

(via LS) or pullcord and another speed selection for the Humidistat function. Move one dip switch into

the ON position for LS/pullcord and one for Humidity speed selection. It is recommended for both

Kitchen and Utility room installations to set the Humidity Boost speed to Medium (utility). This will

ensure the room is kept dry but reduce the noise from the fan.

a. Dip switch 5 = Humidity Boost Low speed (same as trickle speed)

b. Dip switch 6 = Humidity Boost Medium (Utility) speed

c. Dip switch 7 = Humidity Boost High (Kitchen) speed

d. Dip switch 1 = LS/Pullcord Boost Low speed (same as trickle speed)

e. Dip switch 2 = LS/Pullcord Boost Medium (Utility) speed

f. Dip switch 3 = LS/Pullcord Boost High (Kitchen)

3. TIMER ADJUSTMENT (T and HTP models only)

The overrun time period is factory set to about 15 minutes. The overrun time period may be adjusted from about

1-30 minutes by altering the lower adjuster of the two on the control PCB (fig.4 & 7).

i. To REDUCE the operating time, turn the timer adjuster ANTI-CLOCKWISE.

ii. To INCREASE the operating time, turn the timer adjuster CLOCKWISE.

4. RELATIVE HUMIDITY ADJUSTMENT (HTP model only)

NOTE:- On installation it is possible that the humidity controller will run continuously until it has acclimatized

to the environment.

The fan’s relative humidity (RH) set-point is factory set to switch the fan on at about 75%RH. This set point can

be raised or lowered by altering the upper adjuster of the two on the PCB (fig.4 & 7).

i. To LOWER the set-point, turn the humidity adjuster (fig.4 & 7 ) CLOCKWISE. This makes the fan more sensitive

to RH, i.e. the fan will come on at a lower RH.

ii. To RAISE the set-point, turn the humidity adjuster (fig.4 & 7) ANTI-CLOCKWISE. This makes the fan less

sensitive to RH, i.e. the fan will come on at a higher RH.

The fan will continue to run at boost after the RH has dropped below the set point for the time period set by the

timer adjustment (see 3. TIMER ADJUSTMENT, above)

C. WIRING.

WARNING: THE FAN AND ANCILLARY CONTROL EQUIPMENT MUST BE ISOLATED FROM THE

POWER SUPPLY DURING INSTALLATION OR MAINTENANCE.

Use 0.75mm2 cable

1. Select and follow the appropriate wiring diagram (fig. 9 or 10).

2. Use the Cable Clamp provided (fig.4).

3. Check all connections have been made correctly and ensure all terminal connections are securely fastened.

D. SERVICING AND MAINTENANCE.

WARNING: THE FAN AND ANCILLARY CONTROL EQUIPMENT MUST BE ISOLATED FROM THE

POWER SUPPLY DURING SERVICING AND MAINTENANCE.

1. At intervals appropriate to the installation, the fan should be inspected and cleaned to ensure there is no build up

of dirt or other deposits.

2. If fitted, remove the Filter (fig.2 & 3) and wash it and the front cover assembly in warm soapy water. Dry them

before replacing.

3. Wipe the inlets and front face with a damp (not dripping wet) cloth until clean.

4. Replace the filter.

5. Turn the power to the fan back on.

The fan has sealed for life bearings, which do not require lubrication.

6

Fig.1.

Backdraught shutter assembly.

Flaps vertical.

Spigot.

Fig.2.

Centrif Duo Plus

Centrif Duo

Cover Assembly.

Cover Screws.

Retaining edge for optional

filter (Centrif Duo Plus only).

Insert flat bladed screwdriver

in here and pull Filter out to

remove it.

7

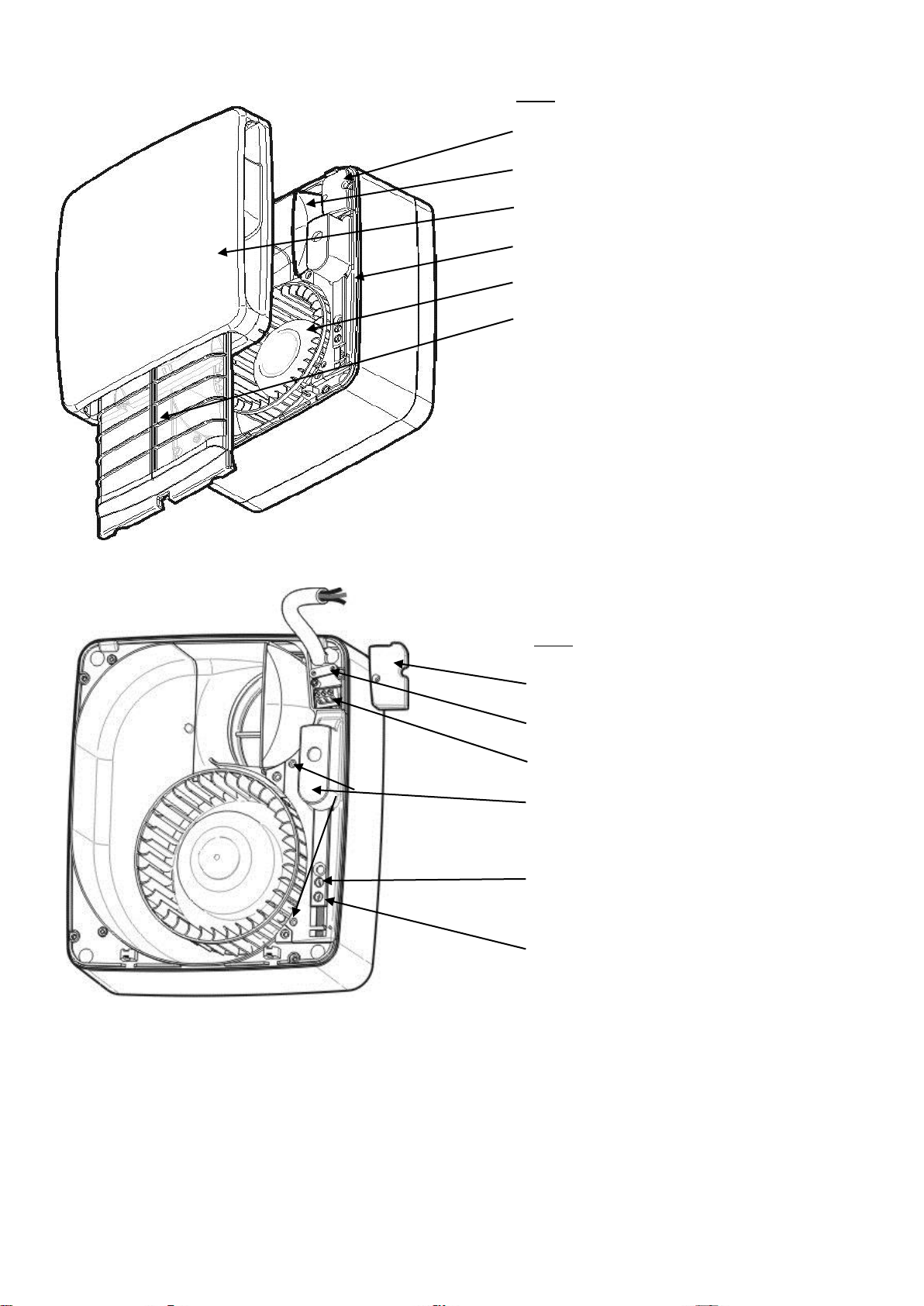

Centrif Duo Plus shown

Fig.3.

Terminal Block Cover.

Spigot.

Cover Assembly.

Chassis Assembly.

Impeller.

Centrif Duo Plus Optional Filter.

(The Centrif Duo models have a metal

mesh filter clipped on to the rear of the

cover. It can be removed easily and

washed too.)

Fig.4.

Terminal Block Cover.

Cable Clamp.

Terminal Block.

PCB Cover and Screws.

Humidity Adjustment (HTP models

only). Turn Anti-clockwise to raise set

point (decrease sensitivity).

Timer Adjustment (T and HTP models

only). Turn clockwise to increase

overrun timer length.

8

Fig.5.

Frame from optional Flush Mount Kit.

4 screws

Back Box.

Fig.6.

Panel Clip Screw (4 off).

Panel Clip (4 off).

Chassis.

9

Fig 7. Setup

WARNING: THE FAN AND

ANCILLARY CONTROL

EQUIPMENT MUST BE ISOLATED

FROM THE POWER SUPPLY

DURING INSTALLATION OR

MAINTENANCE.

TO ACCESS THE SPEED

CONTROLS/PCB, REMOVE THE

TWO SCREWS HOLDING THE PCB

COVER IN PLACE (SEE FIG 4).

10

Fig 8. Siting of the fan.

N

L

Ls

1 Phase Supply

(220-240V 50 Hz)

3A

Fuse

Pull Cord

Lamp

3 Pole Isolator Switch

Ceiling Junction

Pull Cord

(if applicable)

Fan

~

N

L

L

N

1 Phase Supply

(220-240V 50 Hz)

3A Fuse

2 Pole Isolator Switch

Pull Cord

(if applicable)

Fan

Fig 9. Wiring diagram without LS connection.

Fig 10. Wiring diagram with LS connection.

Other accessories, like pullcords, PIR sensors or humidistats, can be fitted in line with the mains live connection (L) in

order to turn the fan or off.

11

Name:

Vent-Axia

Vent-Axia

Vent-Axia

Vent-Axia

Model ID (Stock Ref.) :

Centrif Duo P -

256120

Centrif Duo T -

256220

Centrif Duo DP -

256320

Centrif Duo HTP -

256420

SEC Class D D D D

SEC Value ('Average')

26.23

26.23

26.23

26.23

SEC Value ('Warm')

11.86

11.86

11.86

11.86

SEC Value ('Cold')

51.31

51.31

51.31

51.31

Label Required? (Yes/No=Out of scope)

Yes

Yes

Yes

Yes

Declared as: RVU or NRVU/UVU or BVU

RVU-UVU

RVU-UVU

RVU-UVU

RVU-UVU

Speed Drive

2-Speed

2-Speed

2-Speed

2-Speed

Type HRS (Recuperative, Regenerative,

None)

None

None

None

None

Thermal Eff: [ (%), NA(if none)]

N/A

N/A

N/A

N/A

Max. Flow Rate (m3/h)

219.60

219.60

219.60

219.60

Max. Power Input (W): (@Max.Flow

Rate)

60.00

60.00

60.00

60.00

LWA: Sound Power Level (dB)

60.42

60.42

60.42

60.42

Ref. Flow Rate (m3/s)

0.04

0.04

0.04

0.04

Ref. Pressure Diff. (Pa)

135.00

135.00

135.00

135.00

SPI [W/(m3/h)]

0.27

0.27

0.27

0.27

Control Factor & Control Typology:

(CTRL/ Typology)

Control Factor; CTRL

0.65

0.65

0.65

0.65

Control Typology

Local Demand

Control

Timer control

Local Demand

Control

Local Demand

Control

Declared: -Max Internal & External

Leakage Rates(%) for BVUs or carry over

(for regenerative heat exchangers only),

-&Ext. Leakage Rates (%) for Ducted

UVUs;

N/A

N/A

N/A

N/A

Mixing Rate of Non-Ducted BVUs not

intended to be equipped with one duct

connection on either supply or extract

air side;

N/A

N/A

N/A

N/A

Position and description of visual filter

warning for RVUs intended for use with

filters, including text pointing out the

importance of regular filter changes for

performance and energy efficiency of

the unit

N/A

N/A

N/A

N/A

For UVUs (Instructions Install Regulated

Supply/Extract Grilles Façade)

In F&W

In F&W

In F&W

In F&W

Internet Address (for Disassembly

Instructions)

www.vent-

axia.com

www.vent-

axia.com

www.vent-

axia.com

www.vent-

axia.com

Sensitivity p. Variation@+20/-20 Pa: (for

Non-Ducted Vus)

N/A

N/A

N/A

N/A

Air Tightness-ID/OD-(m3/h) (for NonDucted Vus)

N/A

N/A

N/A

N/A

Annual Electricity Consumption: AEC

(kWh/a)

2.19

2.19

2.19

2.19

Annual Heating Saved: AHS (kWh/a)

AHS: Average

26.23

26.23

26.23

26.23

AHS: Warm

11.86

11.86

11.86

11.86

AHS: Cold

51.31

51.31

51.31

51.31

PRODUCT FICHE

For Residential Ventilation Units (Complying Commission Delegated Regulation (EU)

No 1254/2014)

12

Name:

Vent-Axia

Vent-Axia

Vent-Axia

Vent-Axia

Model ID (Stock Ref.) :

Centrif Duo Plus

P - 431613

Centrif Duo Plus

T - 431614

Centrif Duo Plus

DP - 431615

Centrif Duo Plus

HTP - 431616

SEC Class D D D D

SEC Value ('Average')

26.23

26.23

26.23

26.23

SEC Value ('Warm')

11.86

11.86

11.86

11.86

SEC Value ('Cold')

51.31

51.31

51.31

51.31

Label Required? (Yes/No=Out of scope)

Yes

Yes

Yes

Yes

Declared as: RVU or NRVU/UVU or BVU

RVU-UVU

RVU-UVU

RVU-UVU

RVU-UVU

Speed Drive

2-Speed

2-Speed

2-Speed

2-Speed

Type HRS (Recuperative, Regenerative,

None)

None

None

None

None

Thermal Eff: [ (%), NA(if none)]

N/A

N/A

N/A

N/A

Max. Flow Rate (m3/h)

219.60

219.60

219.60

219.60

Max. Power Input (W): (@Max.Flow Rate)

60.00

60.00

60.00

60.00

LWA: Sound Power Level (dB)

60.42

60.42

60.42

60.42

Ref. Flow Rate (m3/s)

0.04

0.04

0.04

0.04

Ref. Pressure Diff. (Pa)

135.00

135.00

135.00

135.00

SPI [W/(m3/h)]

0.27

0.27

0.27

0.27

Control Factor & Control Typology: (CTRL/

Typology)

Control Factor; CTRL

0.65

0.65

0.65

0.65

Control Typology

Local Demand

Control

Timer control

Timer control

Local Demand

Control

Declared: -Max Internal & External

Leakage Rates(%) for BVUs or carry over

(for regenerative heat exchangers only),

-&Ext. Leakage Rates (%) for Ducted UVUs;

N/A

N/A

N/A

N/A

Mixing Rate of Non-Ducted BVUs not

intended to be equipped with one duct

connection on either supply or extract air

side;

N/A

N/A

N/A

N/A

Filter Warning (RVU)

N/A

N/A

N/A

N/A

For UVUs (Instructions Install Regulated

Supply/Extract Grilles Façade)

In F&W

In F&W

In F&W

In F&W

Internet Address (for Disassembly

Instructions)

www.vent-

axia.com

www.vent-

axia.com

www.vent-

axia.com

www.vent-

axia.com

Sensitivity p. Variation@+20/-20 Pa: (for

Non-Ducted Vus)

N/A

N/A

N/A

N/A

Air Tightness-ID/OD-(m3/h) (for NonDucted Vus)

N/A

N/A

N/A

N/A

Annual Electricity Consumption: AEC

(kWh/a)

2.19

2.19

2.19

2.19

Annual Heating Saved: AHS (kWh/a)

AHS: Average

26.23

26.23

26.23

26.23

AHS: Warm

11.86

11.86

11.86

11.86

AHS: Cold

51.31

51.31

51.31

51.31

13

Notes:-

14

15

The Guarantee

Applicable only to products installed and used in the United Kingdom. For details of guarantee outside the United

Kingdom contact your local supplier.

Vent-Axia guarantees its products for two years from date of purchase against faulty material or workmanship. In the

event of any part being found to be defective, the product will be repaired, or at the Company’s option replaced, without

charge, provided that the product:-

Has been installed and used in accordance with the instructions given with each unit.

Has not been connected to an unsuitable electricity supply. (The correct electricity supply voltage is shown on

the product rating label attached to the unit).

Has not been subjected to misuse, neglect or damage.

Has not been modified or repaired by any person not authorised by the company.

IF CLAIMING UNDER TERMS OF GUARANTEE

Please return the complete product, carriage paid to your original supplier or nearest Vent-Axia Centre, by post or

personal visit. Please ensure that it is adequately packed and accompanied by a letter clearly marked “Guarantee Claim”

stating the nature of the fault and providing evidence of date and source of purchase.

The guarantee is offered to you as an extra benefit, and does not effect your legal rights

Head Office: Fleming Way, Crawley, West Sussex, RH10 9YX. Tel: 01293 526062 Fax: 01293 551188

UK NATIONAL CALL CENTRE, Newton Road, Crawley, West Sussex, RH10 9JA

SALES ENQUIRIES: Tel: 0844 8560590 Fax: 01293 565169

TECHNICAL SUPPORT: Tel: 0844 8560594 Fax: 01293 539209

Web:-www.vent-axia.com Email:- info@vent-axia.com

As part of the policy of continuous product improvement Vent-Axia reserves the right to alter specifications without notice.

446141 F 0219

16

Loading...

Loading...