Page 1

INSTALLATION INSTRUCTIONS

!

!

MB0001

MODELS VJ10430SS & VJ10430WH

INTENDED FOR DOMESTIC COOKING ONLY

READ AND SAVE THESE INSTRUCTIONS

INSTALLER: LEAVE THIS GUIDE WITH HOMEOWNER.

Venmar Ventilation inc., 550 Lemire Blvd., Drummondville QC J2C 7W9 1-800-567-3855

For additional information - visit www.venmar.ca

08816 rev. A

Page 2

IMPORTANT SAFETY INSTRUCTIONS

!

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer at the address or telephone number listed

in the warranty.

2. Before servicing or cleaning unit, switch power off at

service panel and lock service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by

qualifi ed personnel in accordance with all applicable

codes and standards, including fi re-rated construction

codes and standards.

4. Suffi cient air is needed for proper combustion and

exhausting of gases through the fl ue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer’s guidelines and safety

standards such as those published by the National Fire

Protection Association (NFPA) and the American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE) and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any other solid-state speed

control device.

8. To reduce the risk of fi re, use only metal ductwork.

9. The mounting surface must be capable of supporting

the cabinet load, in addition to the added weight of this

46-pound product, plus additional oven loads of up to

50 pounds for a total weight of 96 pounds.

10. This product cannot be installed in cabinet arrangements

such as an island or a peninsula. It must be mounted to

BOTH a top cabinet AND the wall behind the product.

11.Do not mount over a sink.

12. This unit must be grounded. To provide protection

against electric shock, connect to properly grounded

outlets only.

13. When applicable local regulations comprise more

restrictive installation and/or certifi cation requirements,

the aforementioned requirements prevail on those of this

document and the installer agrees to conform to these at

his own expenses.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may

ignite. Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

fl ambeing food (i.e.: Crêpes Suzette, Cherries Jubilee,

Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or fi lter.

d) Use proper pan size. Always use cookware appropriate

for the size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN

THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE

THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fi tting lid, cookie sheet

or metal tray, then turn off the burner. BE CAREFUL

TO PREVENT BURNS. IF THE FLAMES DO NOT GO

OUT IMMEDIATELY, EVACUATE AND CALL THE FIRE

DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You may be

burned.

3. DO NOT USE WATER, including wet dishcloths or towels

— This could cause a violent steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and you know how

to operate it.

B. The fi re is small and contained in the area where it

started.

C. The fi re department has been called.

D. You can fi ght the fi re with your back to an exit.

*Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall spray, construction

dust, etc. off power unit.

4. Your hood motor has a thermal overload which will

automatically shut off the motor if it becomes overheated.

The motor will restart when it cools down. If the motor

continues to shut off and restart, have the hood serviced.

5. Ensure the product meets the minimum ventilation

requirements specifi ed by the range manufacturer.

6. Two installers are recommended because of the weight

of this unit.

7. To reduce the risk of fi re, do not exhaust air into spaces

within walls, ceiling, attics, crawl space or garage.

8. This product is equipped with a thermostat which may

start blower automatically. To reduce the risk of injury and

to prevent power from being switched on accidentally,

unplug the unit power cord or switch power off at service

panel and lock or tag service panel.

9. Because of the high exhausting capacity of this unit, you

should make sure enough air is entering the house to

replace exhausted air by opening a window close to or in

the kitchen.

10. Please read specifi cation label on product for further

information and requirements.

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

FOR INSTALLATION OVER A GAS RANGE

CAUTION (GAS RANGE)

1. The minimum distances given in this installation guide must be observed in order to ensure safe operation.

2. The microwave oven should only be installed in a well ventilated area.

3. The unit must NOT be installed in recirculation (non-ducted).

4. This microwave oven is intended for use over gas range of 50,000 BTU/hr. maximum.

5. Ensure the product meets the minimum ventilation requirements specifi ed by the range manufacturer.

6.

The microwave oven should only be installed as illustrated below, while maintaining the required safety distances. Do

not install the microwave oven between two tall cabinets.

RECOMMENDED NOT RECOMMENDED NOT ALLOWED

MH0004

TABLE OF CONTENTS

1. GROUNDING INSTRUCTIONS ................... 4

2. ELECTRICAL REQUIREMENTS ................. 4

3. HOOD EXHAUST ......................................... 5

3.1 Vertical Discharge ..........................................5

3.2 Horizontal Discharge ......................................5

4. PREPARE THE INSTALLATION ..................7

4.1 Included Parts ...............................................7

4.2 Needed Tools ................................................7

4.3 Mounting Space ............................................8

5. PLACEMENT OF THE MOUNTING PLATE ..8

5.1 Removing Microwave Oven from Carton/

Removing Mounting Plate .............................. 8

5.2 Finding the Wall Studs ...................................9

5.3 Determining Mounting Plate Location ............. 9

5.4 Aligning the Mounting Plate ...........................10

6. SELECT INSTALLATION TYPE ................... 11

7. VERTICAL DISCHARGE .............................. 11

7.1 Attach Mounting Plate to the Wall ..................12

7.2 Prepare Top Cabinet ......................................12

7.3 Install Adapter/Damper ..................................12

7.4 Mount the Microwave Oven ........................... 13

7.5 Connecting Ductwork ....................................14

8. NON-DUCTED (RECIRCULATION)............. 14

8.1 Attach Mounting Plate to the Wall ..................15

8.2 Prepare Top Cabinet ......................................15

8.3 Adjust Blower ................................................15

8.4 Mount the Microwave Oven ........................... 16

8.5 Install the Charcoal Filter ................................18

9. HORIZONTAL DISCHARGE ........................ 18

9.1 Prepare Rear Wall ..........................................18

9.2 Attach Mounting Plate to the Wall ..................19

9.3 Prepare Top Cabinet ......................................19

9.4 Adjust Blower ................................................19

9.5 Mount the Microwave Oven ........................... 21

10. BEFORE USING

THE MICROWAVE OVEN ............................ 22

3

Page 4

1. GROUNDING INSTRUCTIONS

!

This appliance requires a three-prong grounded outlet. In the event of an electrical short circuit, grounding reduces the risk

of electric shock by providing an escape wire for the electrical current. This appliance is equipped with a power cord having

a grounding wire with a grounding plug. The plug must be plugged into an outlet that is properly installed and grounded. No

adapter should be used with this appliance. Plug the three-prong power cord into a properly grounded outlet of standard

115-120 voltage, 60 Hz. Your oven should be the only appliance on this circuit.

Where a standard two-prong wall receptacle is encountered, it is very important to have

it replaced with a properly grounded three-prong wall receptacle, installed by a qualifi ed

electrician.

MD0003

WARNING

Improper use of the grounding plug can result in a risk of electric shock. Consult a qualifi ed

electrician if the grounding instructions are not completely understood, or if doubt exists as to

whether the appliance is properly grounded. Do not use an extension cord. If the power supply

cord is too short, have a qualifi ed electrician install an outlet near the appliance, in accordance

with all applicable codes and standards. Do not cut, deform or remove the third (ground) prong

from the power cord under any circumstances. Connect the unit only to a 20 A dedicated circuit.

2. ELECTRICAL REQUIREMENTS

Product rating is 120 volts AC, 60 Hertz, 13.5 amps and 1.5 kilowatts. This product must be connected to a supply circuit

of the proper voltage and frequency. Wire size must conform to the requirements of the National Electrical Code or the

prevailing local code for this power rating. The power supply cord and plug should be brought to a separate 20-ampere

branch circuit single grounded outlet. The outlet box should be located in the cabinet above the microwave oven. The

outlet box and supply circuit should be installed by a qualifi ed electrician and conform to the National Electrical Code or

the prevailing local code.

4

Page 5

3. HOOD EXHAUST

NOTE: Read these next two pages only if you plan to vent your exhaust to the outside. To recirculate

the air back into the room, proceed to page 14.

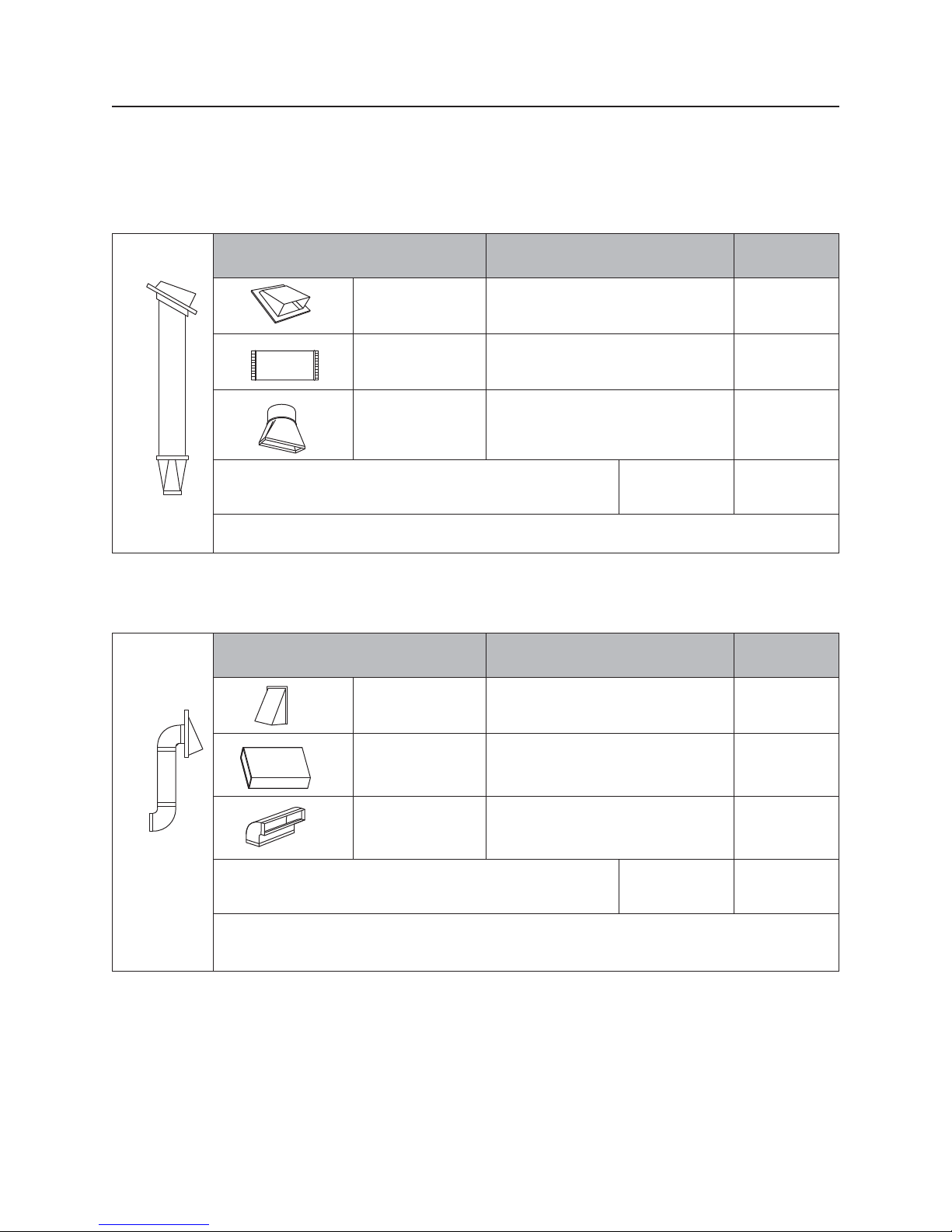

3.1 VERTICAL DISCHARGE (EXAMPLE ONLY)

The following chart describes an example of one possible ductwork installation.

EQUIVALENT

LENGTH

12 ft. x (1) = 12 ft.

5 ft. x (1) = 5 ft.

X

MR0002

DUCT PIECES

Roof cap 24 ft. x (1) = 24 ft.

12 Ft. Straight duct

(6” round)

Rectangularto-Round

Transition adapter*

Equivalent lengths of duct pieces are based on actual tests and

refl ect requirements for good venting performance with any vent

hood.

*If a rectangular-to-round transition adapter is used, the bottom corners of the damper will have to be

cut to fi t, using a tin snips, in order to allow free movement of the damper.

3.2 HORIZONTAL DISCHARGE (EXAMPLE ONLY)

The following chart describes an example of one possible ductwork installation.

DUCT PIECES

EQUIVALENT

LENGTH

X

NUMBER

USED

TOTAL

LENGTH

NUMBER

USED

EQUIVALENT

=

LENGTH

= 41 ft.

EQUIVALENT

=

LENGTH

MR0003

Wall cap 40 ft. x (1) = 40 ft.

3 Ft. Straight duct

(3¼” x 10”

rectangular)

90˚ Elbow 10 ft. x (2) = 20 ft.

Equivalent lengths of duct pieces are based on actual tests and

refl ect requirements for good venting performance with any vent

hood.

NOTE: For back exhaust, care should be taken to align exhaust with space between studs, or wall

should be prepared at the time it is constructed by leaving enough space between the wall

studs to accommodate exhaust.

3 ft. x (1) = 3 ft.

TOTAL

LENGTH

= 63 ft.

5

Page 6

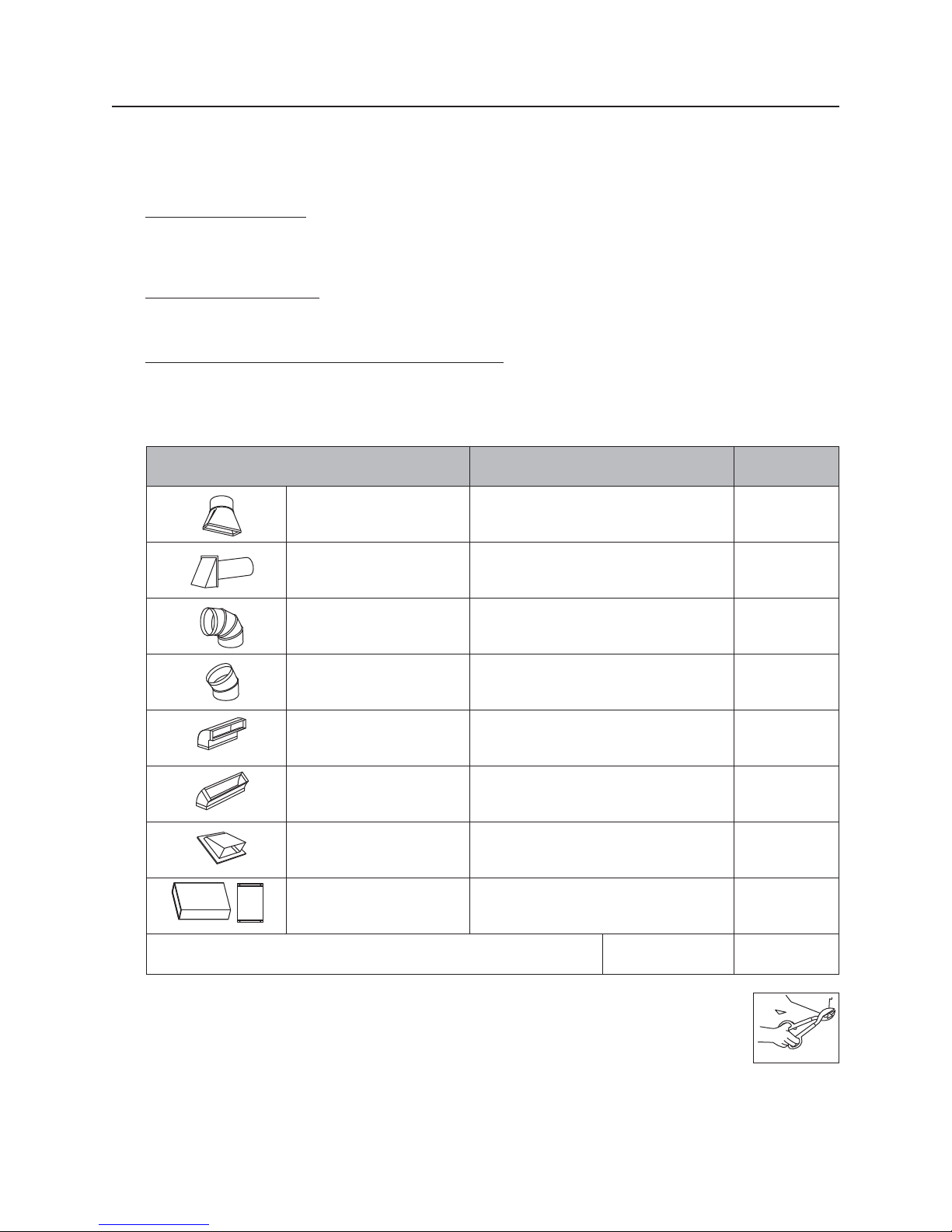

3. HOOD EXHAUST (CONT’D)

Outside ventilation requires a HOOD EXHAUST DUCT. Read the following carefully.

NOTE: It is important that venting be installed using the most direct route and with as few elbows as possible. This ensures

The hood exhaust has been designed to mate with a standard 3¼” x 10” rectangular duct.

If a round duct is required, a rectangular-to-round transition adapter must be used. Do not use less than a 6”

For satisfactory air movement, the total duct length of 3¼” x 10” rectangular or 6” diameter round duct should not

clear venting of exhaust and helps prevent blockages. Also, ensure damper swings freely and nothing is

blocking the ducts.

EXHAUST CONNECTION:

diameter duct.

MAXIMUM DUCT LENGTH:

exceed 140 equivalent feet.

ELBOWS, TRANSITIONS, WALL AND ROOF CAPS, ETC.

These duct pieces present additional resistance to airfl ow and are equivalent to a section of straight duct which

is longer than their actual physical size. When calculating the total duct length, add the equivalent lengths of all

transitions and adapters plus the length of all straight duct sections. The chart below shows you how to calculate

total equivalent ductwork length using the approximate feet of equivalent length of some typical ducts.

MR0004

DUCT PIECES

Rectangular-to-round

transition adapter*

90˚ Elbow 10 ft. x ( ) = ft.

45˚ Elbow 5 ft. x ( ) = ft.

90˚ Elbow 25 ft. x ( ) = ft.

45˚ Elbow 5 ft. x ( ) = ft.

Straight duct 3¼” x 10”

rectangular or 6” round

EQUIVALENT

LENGTH

5 ft. x ( ) = ft.

Wall cap 40 ft. x ( ) = ft.

Roof cap 24 ft. x ( ) = ft.

1 ft. x ( ) = ft.

NUMBER

X

DUCTWORK

USED

TOTAL

EQUIVALENT

=

LENGTH

= ft.

*If a rectangular-to-round transition adapter is used, the bottom corners of the damper will have to

be cut to fi t, using a tin snips, in order to allow free movement of the damper.

Equivalent lengths of duct pieces are based on actual tests and refl ect requirements for good venting performance

with any vent hood.

MR0005

6

Page 7

4. PREPARE THE INSTALLATION

!

WARNING

When performing installation, servicing or cleaning the unit, it is recommended to wear safety

glasses and gloves.

4.1 INCLUDED PARTS

Ensure that the following parts are included:

NO. DESCRIPTION

Top cabinet template 08824 1

1

Rear wall template 08825 1

2

Installation guide 08816 1

3

User guide 08817 1

4

Grease fi lter 08821 1

5

Charcoal fi lter 08820 1

6

Adapter/Damper 08822 1

7

Turntable 08818 1

8

Roller guide ring 08819 1

9

Parts bag including:

1 Wood screw 1/4” x 2” (A),

2 Toggle bolts 3/16” x 3” (B),

2 Self-aligning machine

10

screws 1/4”-28 x 3¼” (C),

1 Nylon strip

for metal cabinets (D)

(to use as grommet)

4.2 NEEDED TOOLS

PAR T

NO.

QTY.

08823 1

1

5

7

MA0010

10

A

A

MR0006

2

B

C

4

3

6

8

9

D

No. 1 and no. 2

Phillips screwdriver

Tin snips (to cut

damper if required)

Safety gloves

MR0008

template, if necessary)

(saber, hole or keyhole)

Pencil

Scissors (to cut

Saw

Level

Ruler or tape measure

and straight edge

Electric drill with 3/16”,

1/2” and 5/8” drill bits

Stud fi nder

or hammer

Metal foil duct tape and tape

7

Carpenter square

(optional)

Safety goggles

Filler blocks or scrap

wood if needed for top

cabinet spacing (used on

recessed bottom cabinet

installations only)

Page 8

4. PREPARE THE INSTALLATION (CONT’D)

!

4.3 MOUNTING SPACE

WARNING

The mounting surface must be able to support the

cabinet load, in addition to the added weight of this

46 lb. product, plus additional oven loads of up to

50 lb. for a total weight of 96 lb.

16½”

MINIMUM DISTANCE

TO COOKTOP*

• The space between the cabinets must be at least 30” wide and

• This microwave oven is for installation over ranges up to 36” wide.

• If you are going to vent your microwave oven to the outside, see

• When installing the microwave oven, be careful to follow the

*Electric range: 30”

Gas range: 36½”

free of obstructions.

“Select Installation Type” Section on pag

preparation.

instructions on the top cabinet template for power cord clearance.

e 11 for exhaust duct

MH0001A

5. PLACEMENT OF THE MOUNTING PLATE

5.1 REMOVING MICROWAVE OVEN FROM CARTON/REMOVING MOUNTING PLATE

1. Remove the adapter/damper, fi lters, turntable,

2. Fold back all 4 carton fl aps fully against carton

3. Pull the carton up and off the oven.

roller guide ring and parts bag. Do not remove

the polystyrene protecting the front of the oven.

sides. Then carefully roll the oven and carton over

onto the top side. The oven should be resting in

the polystyrene.

POLYSTYRENE

CARTON

4. Remove and properly discard plastic bags.

5. Remove the 2 mounting plate retaining screws

and discard. Set the mounting plate aside.

8

MR0009A

MO0011A

SCREW

SCREW

MOUNTING PLATE

Page 9

5. PLACEMENT OF THE MOUNTING PLATE (CONT’D)

5.2 FINDING THE WALL STUDS

1. Find the studs using one of the following methods:

A. Stud fi nder.

OR

B. Use a hammer to tap lightly across the mounting

surface to fi nd a solid sound. This will indicate a stud

location.

WALL STUDS

2. After locating the stud(s), fi nd the center by probing the

3. Draw a line down the center of each stud.

NOTE: The microwave oven must be connected to at

wall with a small nail to fi nd the edges of the stud. Then

place a mark halfway between the edges. The center of

any adjacent studs should be 16” or 24” from this mark.

least one wall stud.

CENTER

MR0010A

5.3 DETERMINING MOUNTING PLATE LOCATION

Your cabinets may have decorative trim that interferes with the microwave installation. Remove the decorative trim to

install the microwave properly and to make it level.

NOTE: The microwave oven must be level.

PLATE POSITION BENEATH FLAT BOTTOM CABINET

FLAT BOTTOM CABINET

1. Draw a vertical line on the wall at the center of the 30”

*Electric range: 30”

Gas range: 36½”

minimum wide space.

2. Tape the rear wall template onto the wall matching the

centerline and touching the bottom of the cabinet.

FRAMED RECESSED BOTTOM CABINET

1. Draw a vertical line on the wall at the center of the 30”

*Electric range: 30”

Gas range: 36½”

minimum wide space.

2. Tape the rear wall template onto the wall matching the

centerline and touching the bottom cabinet frame.

9

MINIMUM DISTANCE TO COOKTOP*

MD0004A

PLATE POSITION BENEATH FRAMED RECESSED

BOTTOM CABINET

MINIMUM DISTANCE TO COOKTOP*

MD0005A

Page 10

5. PLACEMENT OF THE MOUNTING PLATE (CONT’D)

!

5.3 DETERMINING MOUNTING PLATE LOCATION (CONT’D)

PLATE POSITION BENEATH RECESSED

BOTTOM CABINET WITH FRONT OVERHANG

ECESSED BOTTOM CABINET

R

WITH FRONT OVERHANG

1. Measure the inside depth of the front

3. Draw a vertical line on the wall at the center

*Electric range: 30”

Gas range: 36½”

overhang.

2. Draw a horizontal line on the back wall an

equal distance below the cabinet bottom as

the inside depth of the front overhang.

of the 30” minimum wide space.

4. Align the top of the rear wall template with

the horizontal line and tape it onto the wall

matching the centerline.

MD0006A

DRAW A HORIZONTAL LINE

ON THE BACK WALL

EQUAL TO THE DEPTH

OF THE FRONT OVERHANG.

MINIMUM DISTANCE

TO COOKTOP*

5.4 ALIGNING THE MOUNTING PLATE

WARNING

Wear safety gloves as the edges of the mounting plate are sharp.

ENTERLINE

C

NOTCH

C

C

L

DRAW A HORIZONTAL LINE

ON

WALL FROM BOTTOM OF

THE

REAR WALL TEMPLATE

HORIZONTAL LINE

MD0007A

A

AREA E

B

H

ORIZONTAL LINE

1. Draw a horizontal line on the wall at the bottom of the rear wall template.

2. Drill 5/8” holes for toggle bolts on 3 locations (Hole A, B, C) but if the location of hole is same as that of stud, drill

a 3/16” hole for wood screw. In other words, toggle bolt can not be used to the location of stud. Do not mount

the plate at this time.

NOTE: Holes A, B and C are inside area E. If none of A, B or C is in a stud, fi nd a stud somewhere in area E and

draw a fourth circle to line up with the stud. It is important to use at least one wood screw mounted fi rmly in

a stud to support the weight of the microwave oven. Set the mounting plate aside.

10

Page 11

6. SELECT INSTALLATION TYPE

The microwave oven is designed for adaptation to the following three types of ventilation:

Vertical discharge (Section 7). Non-ducted (Recirculation) (Section 8).

MF0001

Horizontal discharge (Section 9).

MF0003

7. VERTICAL DISCHARGE

INSTALLATION OVERVIEW

MF0002

7.1 Attach mounting plate to wall

7.2 Prepare top cabinet

7.3 Install Adapter/damper

7.4 Mount the microwave oven

7.5 Connect ductwork

MH0002

11

Page 12

7. VERTICAL DISCHARGE (CONT’D)

!

!

7.1 ATTACH THE MOUNTING PLATE TO THE WALL

Attach the plate to the wall using toggle bolts. At least one wood screw must be used to attach the plate to a wall stud.

1.

Remove the rear wall template and discard.

2. Remove the toggle wings from the bolts.

3. Insert the bolts into the mounting plate through the holes

designated to go into drywall and reattach the toggle

wings to 3/4” onto each bolt.

MO0012

4. Place the bottom of the mounting plate against the

horizontal line on the wall (previously drawn in step 5.4 )

and insert the toggle wings into the holes in the wall to

mount the plate.

MOUNTING

PLATE

SPACING FOR TOGGLES

MORE THAN WALL THICKNESS

TOGGLE WINGS

TOGGLE

BOLT

5. Tighten the wood screw and all bolts.

WARNING

Be careful to avoid pinching fi ngers between

the back of the mounting plate and the wall.

MO0013A

WALL

BOLT END

7.2 PREPARE TOP CABINET

You need to drill holes for the top support screws, a hole large enough for the power cord to fi t through and a cutout

large enough for the adapter/damper.

WARNING

Wear safety goggles when drilling holes in the

cabinet bottom.

1.

3. Drill the holes following the instructions on the template.

4. Remove the template and discard.

Read the instructions on the top cabinet template.

2. Tape it underneath the top cabinet.

7.3 INSTALL ADAPTER/DAMPER

1. Slide adapter/damper as shown beside.

NOTE: Ensure that the damper hinge is oriented toward the

2. Ensure tape securing damper is removed and damper

back of the microwave oven.

pivots easily before mouting microwave oven.

12

MR0011

MO0014

Page 13

7. VERTICAL DISCHARGE (CONT’D)

!

!

7.4 MOUNT THE MICROWAVE OVEN

WARNING

For easier installation and personal

safety, this unit must be installed by two

people.

WARNING

Do not grip or use door handle during

installation.

NOTES: • If your cabinet is metal, install the nylon strip around the power cord hole to prevent cutting of the cord.

• We recommend using fi ller blocks if the cabinet front hangs below the cabinet bottom shelf.

If fi ller blocks are not used, case damage may occur from over tightening screws.

MO0015

CAUTION

• When mounting the microwave oven, thread power cord through hole in bottom of top cabinet (A). Keep

1. Remove the polystyrene packaging and discard.

2. Lift microwave, tilt it forward, and hook slots

3. Insert 2 self-aligning screws (D) through top

at back bottom edge onto four lower tabs of

mounting plate (B).

3. Rotate front of oven (C) up against cabinet bottom.

cabinet holes. Temporarily secure the oven by

turning the screws at least 2 full turns on each

screw after the threads have engaged. Ensure

to keep power cord tight. Be careful not to

pinch the cord, especially when mounting

fl ush to bottom of cabinet.

it tight throughout steps 1-3. Do not pinch cord or lift oven by pulling cord.

A

C

B

MO0016

D

MO0018

13

Page 14

7. VERTICAL DISCHARGE (CONT’D)

7.4 MOUNT THE MICROWAVE OVEN (CONT’D)

CABINET FRONT

CABINET BOTTOM SHELF

FILLER BLOCK

4. Tighten the 2 screws to the top of the microwave oven.

(While tightening screws, hold the microwave oven in

place against the wall and the top cabinet.)

7.5 CONNECT DUCTWORK

1. Extend the house duct down to connect to the

adapter/damper.

NOTE: Ensure adapter/damper is properly inserted

in your house exhaust duct.

2. Seal the joint with metal foil duct tape.

3. Proceed to step 10 to fi nalize the installation.

MO0017A

HOUSE DUCT

MICROWAVE OVEN TOP

EQUIVALENT

TO DEPTH OF

CABINET RECESS

SELF-ALIGNING SCREW

8. NON-DUCTED (RECIRCULATION)

INSTALLATION OVERVIEW

8.1 Attach mounting plate to wall

8.2 Prepare top cabinet

8.3 Adjust blower

8.4 Mount the microwave oven

8.5 Install charcoal fi lter

NOTE: The adapter/damper

is not needed for a

non-ducted installation,

but it may be saved for

possible future use.

MH0003

MJ0001A

14

Page 15

8. NON-DUCTED (RECIRCULATION) (CONT’D)

!

!

8.1 ATTACH THE MOUNTING PLATE TO THE WALL

Attach the plate to the wall using toggle bolts. At least one wood screw must be used to attach the plate to a wall stud.

1.

Remove the rear wall template and discard.

2. Remove the toggle wings from the bolts.

3. Insert the bolts into the mounting plate through the holes

designated to go into drywall and reattach the toggle

wings to 3/4” onto each bolt.

MO0012

4. Place the bottom of the mounting plate against the

horizontal line on the wall (previously drawn in step 5.4 )

and insert the toggle wings into the holes in the wall to

mount the plate.

MOUNTING

PLATE

SPACING FOR TOGGLES

MORE THAN WALL THICKNESS

TOGGLE WINGS

TOGGLE

BOLT

5. Tighten the wood screw and all bolts.

WARNING

Be careful to avoid pinching fi ngers between

the back of the mounting plate and the wall.

MO0013A

WALL

BOLT END

8.2 PREPARE TOP CABINET

You need to drill holes for the top support screws and a hole large enough for the power cord to fi t through.

WARNING

Wear safety goggles when drilling holes in the

cabinet bottom.

1.

Read the instructions on the top cabinet template.

2. Tape it underneath the top cabinet.

3. Drill the holes following the instructions on the template.

4. Remove the template and discard.

8.3 ADJUST BLOWER

1. Remove and set aside the 2 blower plate retaining

2. Lift up the blower plate.

screws.

15

SCREW

MD0008A

MR0011

SCREW

BLOWER PLATE

MICROWAVE TOP

M

ICROWAVE BACK

Page 16

8. NON-DUCTED (RECIRCULATION) (CONT’D)

!

!

8.3 ADJUST BLOWER (CONT’D)

CAUTION

Do not touch the blower blades to prevent cracks and

breaks. Hold outer case when handling the blower.

3. Remove and set aside the blower motor retaining screw. Carefully

pull out the blower unit. The wires will extend far enough to allow

blower unit adjustment.

BEFORE: FAN BLADE

OPENINGS

FACING UP

BLOWER

MOTOR

RETAINING

SCREW

4. Roll the blower unit 90˚ so that fan blade openings are facing

toward the front of the microwave oven.

5. Install the blower unit back in place.

6. Secure blower unit to microwave with its retaining screw.

CAUTION

Do not pull or stretch the blower unit wiring. Ensure

the wires are not pinched.

A

FTER: FAN BLADE

OPENINGS

MD0010A

FACING FRONT

8.4 MOUNT THE MICROWAVE OVEN

WARNING

For easier installation and personal

safety, this unit must be installed by two

people.

WARNING

Do not grip or use door handle during

installation.

MO0015

16

Page 17

8. NON-DUCTED (RECIRCULATION) (CONT’D)

8.4 MOUNT THE MICROWAVE OVEN (CONT’D)

NOTES: • If your cabinet is metal, install the nylon strip around the power cord hole to prevent cutting of the cord.

• We recommend using fi ller blocks if the cabinet front hangs below the cabinet bottom shelf.

CAUTION

If fi ller blocks are not used, case damage may occur from over tightening screws.

• When mounting the microwave oven, thread power cord through hole in bottom of top cabinet (A). Keep

it tight throughout steps 1-3. Do not pinch cord or lift oven by pulling cord.

A

1. Remove the polystyrene packaging and discard.

2. Lift microwave, tilt it forward, and hook slots

at back bottom edge onto four lower tabs of

mounting plate (B).

3. Rotate front of oven (C) up against cabinet bottom.

C

B

MO0016

D

3. Insert 2 self-aligning screws (D) through top cabinet

holes. Temporarily secure the oven by turning the screws

at least 2 full turns on each screw after the threads

have engaged. Ensure to keep power cord tight.

Be careful not to pinch the cord, especially when

mounting fl ush to bottom of cabinet.

4. Tighten the 2 screws to the top of the microwave oven.

(While tightening screws, hold the microwave oven in

place against the wall and the top cabinet.)

17

MO0018

CABINET FRONT

MO0017A

CABINET BOTTOM SHELF

MICROWAVE OVEN TOP

FILLER BLOCK

EQUIVALENT

TO DEPTH OF

CABINET RECESS

SELF-ALIGNING SCREW

Page 18

8. NON-DUCTED (RECIRCULATION) (CONT’D)

8.5 INSTALL THE CHARCOAL FILTER

1. Using a no. 2 Phillips screwdriver, remove the 3 grille

2.

3. Push the grille left, then pull straight out to remove.

retaining screws (located on top of the grille).

Open the door.

MO0021A

CHARCOAL

FILTER

4. Slide the charcoal fi lter into place. The fi lter should rest at the

5. Reinstall the grille and its screws.

6. Close the door.

7. Proceed to step 10 to fi nalize the installation.

angle shown beside. When properly installed, the wire mesh of

the fi lter is visible.

9. HORIZONTAL DISCHARGE

INSTALLATION OVERVIEW

9.1 Prepare rear wall

9.2 Attach mounting plate to wall

9.3 Prepare top cabinet

9.4 Adjust blower

9.5 Mount the microwave oven

MO0022

9.1 PREPARE REAR WALL

You need to cut an opening in the rear wall for horizontal discharge.

1. Read the instructions on the rear wall template.

2. Cut the opening, following the instructions on the rear

wall template.

MH0002

MD0012

18

Page 19

9. HORIZONTAL DISCHARGE (CONT’D)

!

!

9.2 ATTACH THE MOUNTING PLATE TO THE WALL

Attach the plate to the wall using toggle bolts. At least one wood screw must be used to attach the plate to a wall stud.

1.

Remove the rear wall template and discard.

2. Remove the toggle wings from the bolts.

3. Insert the bolts into the mounting plate through the holes

designated to go into drywall and reattach the toggle

wings to 3/4” onto each bolt.

MO0012

4. Place the bottom of the mounting plate against the

horizontal line on the wall (previously drawn in step 5.4 )

and insert the toggle wings into the holes in the wall to

mount the plate.

MOUNTING

PLATE

SPACING FOR TOGGLES

MORE THAN WALL THICKNESS

TOGGLE WINGS

TOGGLE

BOLT

5. Tighten the wood screw and all bolts.

WARNING

Be careful to avoid pinching fi ngers between

the back of the mounting plate and the wall.

MO0013A

WALL

BOLT END

9.3 PREPARE TOP CABINET

You need to drill holes for the top support screws and a hole large enough for the power cord to fi t through.

WARNING

Wear safety goggles when drilling holes in the

cabinet bottom.

1.

3. Drill the holes following the instructions on the template.

4. Remove the template and discard.

Read the instructions on the top cabinet template.

2. Tape it underneath the top cabinet.

9.4 ADJUST BLOWER

1. Remove and set aside the 2 blower plate retaining

2. Lift up the blower plate.

screws.

19

SCREW

MD0008A

MR0011

SCREW

BLOWER PLATE

MICROWAVE TOP

M

ICROWAVE BACK

Page 20

9. HORIZONTAL DISCHARGE (CONT’D)

9.4 ADJUST BLOWER (CONT’D)

CAUTION

Do not touch the blower blades to prevent cracks and

breaks. Hold outer case when handling the blower.

3. Remove and set aside the blower motor retaining screw. Carefully

pull out the blower unit. The wires will extend far enough to allow

blower unit adjustment.

4. Roll the blower unit 90˚ so that fan blade openings are facing

toward the front of the microwave oven.

5. Flip blower unit 180˚, so that the fan blade openings are facing

toward the back of the microwave oven.

BEFORE: FAN BLADE

FACING UP

OPENINGS

END B

BLOWER

MOTOR

RETAINING

SCREW

END A

E

ND B

AFTER: FAN BLADE

OPENINGS

6. Install the blower unit back in place.

7. Secure blower unit to microwave with its retaining screw.

MD0014A

CAUTION

Do not pull or stretch the blower unit wiring. Ensure the wires are not pinched.

FACING BACK

E

ND A

NOTE: The blower unit exhaust openings should match exhaust openings on rear of microwave oven.

20

Page 21

9. HORIZONTAL DISCHARGE (CONT’D)

K

!

!

9.4 ADJUST BLOWER (CONT’D)

7. Reinstall the blower plate with its top screw only.

ADAPTER/DAMPER

8. Attach the adapter/damper to the rear of the oven by

NOTE: Push in securely until it is in the lower locking tabs.

9. Reinstall the blower plate back screw.

10. Seal the joint with metal foil duct tape.

sliding it into the guides at the top center of the back of

the oven.

Ensure that the damper hinge is located on top

and that the damper swings freely.

MD0015A

GUIDE

MICROWAVE BAC

GUIDE

LOCKING TABS

9.5 MOUNT THE MICROWAVE OVEN

WARNING

For easier installation and personal

safety, this unit must be installed by two

people.

WARNING

Do not grip or use door handle during

installation.

NOTES: • If your cabinet is metal, install the nylon strip around the power cord hole to prevent cutting of the cord.

• We recommend using fi ller blocks if the cabinet front hangs below the cabinet bottom shelf.

MO0015

CAUTION

If fi ller blocks are not used, case damage may occur from over tightening screws.

• When mounting the microwave oven, thread power cord through hole in bottom of top cabinet (A). Keep

1. Remove the polystyrene packaging and discard.

2. Run the house duct to the microwave oven

3.

NOTE: Ensure adapter/damper is properly inserted

location.

Lift microwave, tilt it forward, and hook slots

at back bottom edge onto four lower tabs of

mounting plate (B).

4. Rotate front of oven (C) up against cabinet bottom.

it tight throughout steps 1-3. Do not pinch cord or lift oven by pulling cord.

A

C

in your house exhaust duct after the

microwave oven is installed.

MO0016

B

21

Page 22

9. HORIZONTAL DISCHARGE (CONT’D)

9.5 MOUNT THE MICROWAVE OVEN (CONT’D)

D

3. Insert 2 self-aligning screws (D) through top cabinet

holes. Temporarily secure the oven by turning the

screws at least 2 full turns on each screw after the

threads have engaged. Ensure to keep power cord

tight. Be careful not to pinch the cord, especially

when mounting fl ush to bottom of cabinet.

4. Tighten the 2 screws to the top of the microwave oven.

(While tightening screws, hold the microwave oven in

place against the wall and the top cabinet.)

MO0018

CABINET FRONT

MO0017A

CABINET BOTTOM SHELF

MICROWAVE OVEN TOP

FILLER BLOCK

EQUIVALENT

TO DEPTH OF

CABINET RECESS

SELF-ALIGNING SCREW

10. BEFORE USING THE MICROWAVE OVEN

1. Install grease fi lter. See the Owner’s manual packed with

2. Ensure the microwave oven has been installed according to instructions.

4. Install turntable and ring in cavity.

6. Plug unit power cord into a dedicated 20-amp electrical outlet.

8. Keep installation intructions for the local inspector’s use.

the microwave oven.

MO0019

3. Remove all packing material from the microwave oven.

5. Switch power on at service panel.

7. Read Owner’s manual.

22

Loading...

Loading...