Page 1

IK700 SERIES

HB0119

INTENDED FOR DOMESTIC COOKING ONLY

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER.

HOMEOWNER: USE AND CARE INFORMATION

ON PAGES 15 TO 17.

READ AND SAVE THESE INSTRUCTIONS

Venmar Ventilation ULC, 550 Lemire Blvd., Drummondville QC J2C 7W9

1-800-567-3855

REGISTER YOUR PRODUCT ONLINE AT: www.bnv.ca

For additional information, visit

www.venmar.ca

21227 rev. 02

!

INSTALLATION INSTRUCTIONS

!

Page 2

2

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

1. Use this unit only in the manner intended

by the manufacturer. If you have questions,

contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch

power off at service panel and lock service

disconnecting means to prevent power from

being switched on accidentally. When the

service disconnecting means cannot be

locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

3. Installation work and electrical wiring must

be done by qualified personnel in accordance

with all applicable codes and standards,

including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion

and exhausting of gases through the flue

(chimney) of fuel burning equipment to

prevent backdrafting. Follow the heating

equipment manufacturer’s guidelines and

safety standards such as those published

by the National Fire Protection Association

(NFPA) and the American Society for Heating,

Refrigeration and Air Conditioning Engineers

(ASHRAE) and the local code authorities.

5. When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

6. Ducted fans must always be vented to the

outdoors.

7. Do not use this unit with any additional

solid-state speed control device.

8. To reduce the risk of fire, use only metal

ductwork.

9. This unit must be grounded.

10. All tempered glass can experience spontaneous

breakage. If broken, tempered glass falls out of

it’s opening in interlocking clumps. Tempered

glass can, on occasion, break into large shards

rather than the classic tiny piece pattern.

11. When applicable local regulations comprise

more restrictive installation and/or certification

requirements, the aforementioned

requirements prevail on those of this

document and the installer agrees to conform

to these at his own expenses.

TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

a) Never leave surface units unattended at high

settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on

low or medium settings.

b) Always turn hood ON when cooking at high

heat or when flambeing food (i.e.: Crêpes

Suzette, Cherries Jubilee, Peppercorn Beef

Flambé).

c) Clean ventilating fan frequently. Grease

should not be allowed to accumulate on fan,

filters or in exhaust ducts.

d) Use proper pan size. Always use cookware

appropriate for the size of the surface element.

1. For indoor use only.

2. For general ventilating use only. Do not use

to exhaust hazardous or explosive materials

and vapors.

3. To avoid motor bearing damage and noisy

and/or unbalanced impellers, keep drywall

spray, construction dust, etc. off power unit.

4. Your hood motor has a thermal overload

which will automatically shut off the motor if

it becomes overheated. The motor will restart

when it cools down. If the motor continues to

shut off and restart, have the hood serviced.

5. The hood distance above cooktop must not be

less than 30”. A maximum of 36” above cooktop

is highly recommended for best capture of

cooking impurities.

6. Two installers are recommended due to the

weight of this unit and the complexity of the

installation.

7. To reduce the risk of fire and to properly

exhaust air, be sure to duct air outside — Do

not exhaust air into spaces within walls or

ceiling or into attics, crawl space or garage.

8. Because of the high exhausting capacity of

this unit, you should make sure enough air

is entering the house to replace exhausted

air by opening a window close to or in the

kitchen.

9. To reduce the risk of fire and electrical shock,

the Venmar Ispira IK700 series models

should only be installed with their own built-in

blower.

10. Please read specification label on product for

further information and requirements.

11. This hood is equipped with an RF receiver.

See next page for related warning.

WARNING

CAUTION

TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A RANGE TOP

GREASE FIRE, OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting

lid, cookie sheet or metal tray, then turn off

the burner. BE CAREFUL TO PREVENT

BURNS. IF THE FLAMES DO NOT GO OUT

IMMEDIATELY, EVACUATE AND CALL THE

FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You

may be burned.

3. DO NOT USE WATER, including wet

dishcloths or towels — This could cause a

violent steam explosion.

4. Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and

you know how to operate it.

B. The fire is small and contained in the area

where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an

exit.

*Based on “Kitchen Fire Safety Tips” published by NFPA.

WARNING

! !

Page 3

3

TABLE OF CONTENTS

1. INSTALL DUCTWORK ..................................................................................................... 4

2. PREPARE THE INSTALLATION .......................................................................................... 5

3. PREPARE HOOD .......................................................................................................... 6

4. MEASURE INSTALLATION ............................................................................................... 7

5. INSTALL MOUNTING BRACKET ...................................................................................... 8-9

6. ASSEMBLE ANGLE BRACKETS ...................................................................................10-11

7. C ONNECT WIRING ................................................................................................. 11-12

8. INSTALL GLASS PANELS ............................................................................................... 13

9. INSTALL HOOD ..................................................................................................... 13-14

10. REINSTALL HYBRID FILTERS ......................................................................................... 15

11. LED LIGHTING ......................................................................................................... 15

12. CARE ................................................................................................................ 15-16

13. OPERATION ......................................................................................................... 16-17

14. WIRING DIAGRAM ...................................................................................................... 18

15. SERVICE PA R TS ........................................................................................................ 19

16. WARRANTY .............................................................................................................20

WARNING

!

This hood is equipped with an RF receiver (optional remote control sold separately).

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate this product. The remote control has been tested

and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules and the Canadian ICES-003. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. The remote control

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Page 4

4

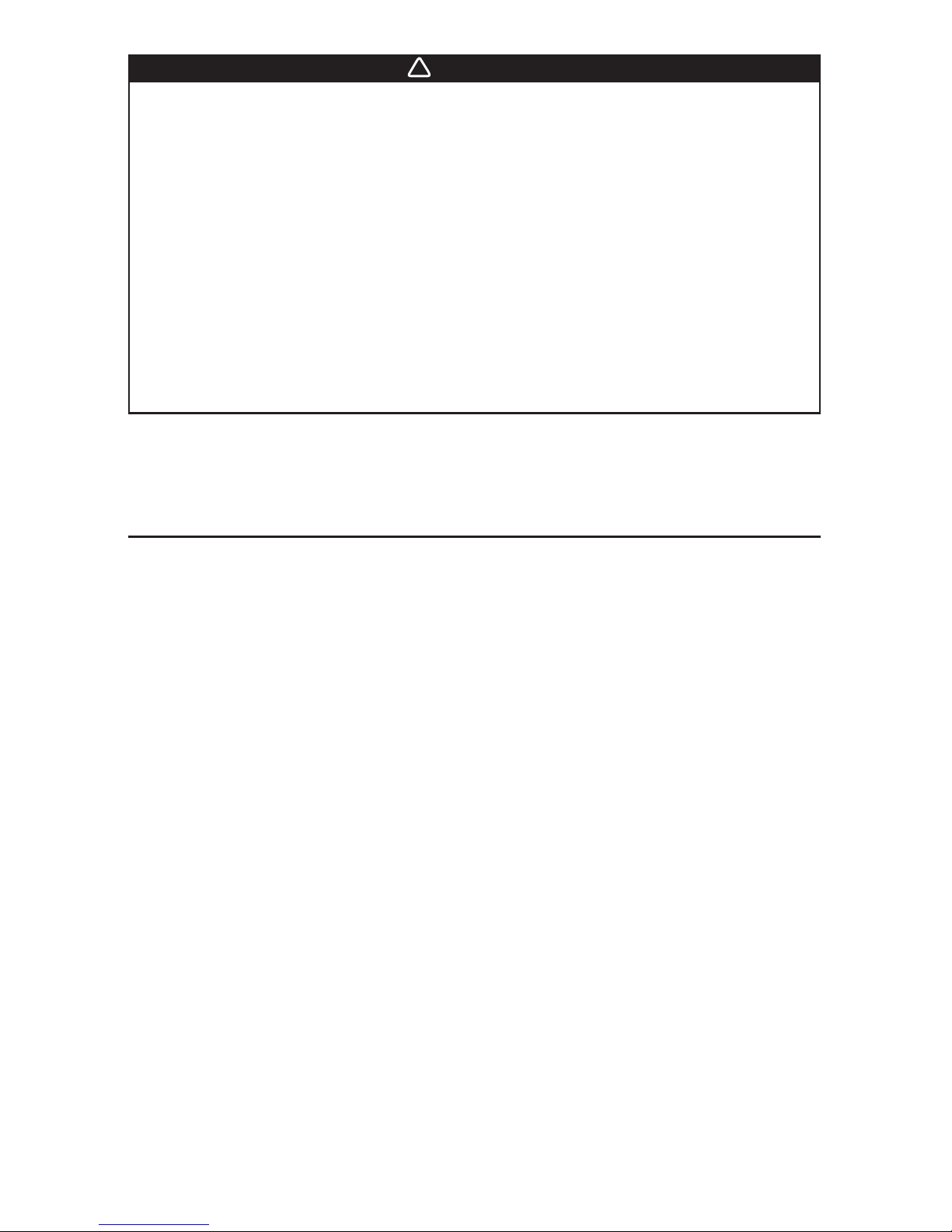

Plan where and how the ductwork will be

installed.

A straight, short duct run will allow the hood to

perform most efficiently.

Install proper-sized ductwork, elbows and roof

cap. Connect metal ductwork to cap and work

back towards the hood location. Use 2” metal foil

duct tape to seal the joints.

Run 3-wire power supply cable to installation

location.

We recommend to install the hood at a

minimum distance of 30” above cooking

surface. A maximum of 36” above cooktop

is highly recommended for best capture of

cooking impurities.

Distances over 36” are at the installer and users

discretion.

10-ft. ceilings require 10-ft flue extension, part

no. 19325 (sold separately).

1. INSTALL DUCTWORK

8" ROUND DUCT

ROOF CAP

HOOD

HH0153A

DECORATIVE

FLUE

8" ROUND

ADAPTER

/DAMPER

30" TO 36" ABOVE

COOKING SURFACE

HH0154A

1" MIN.

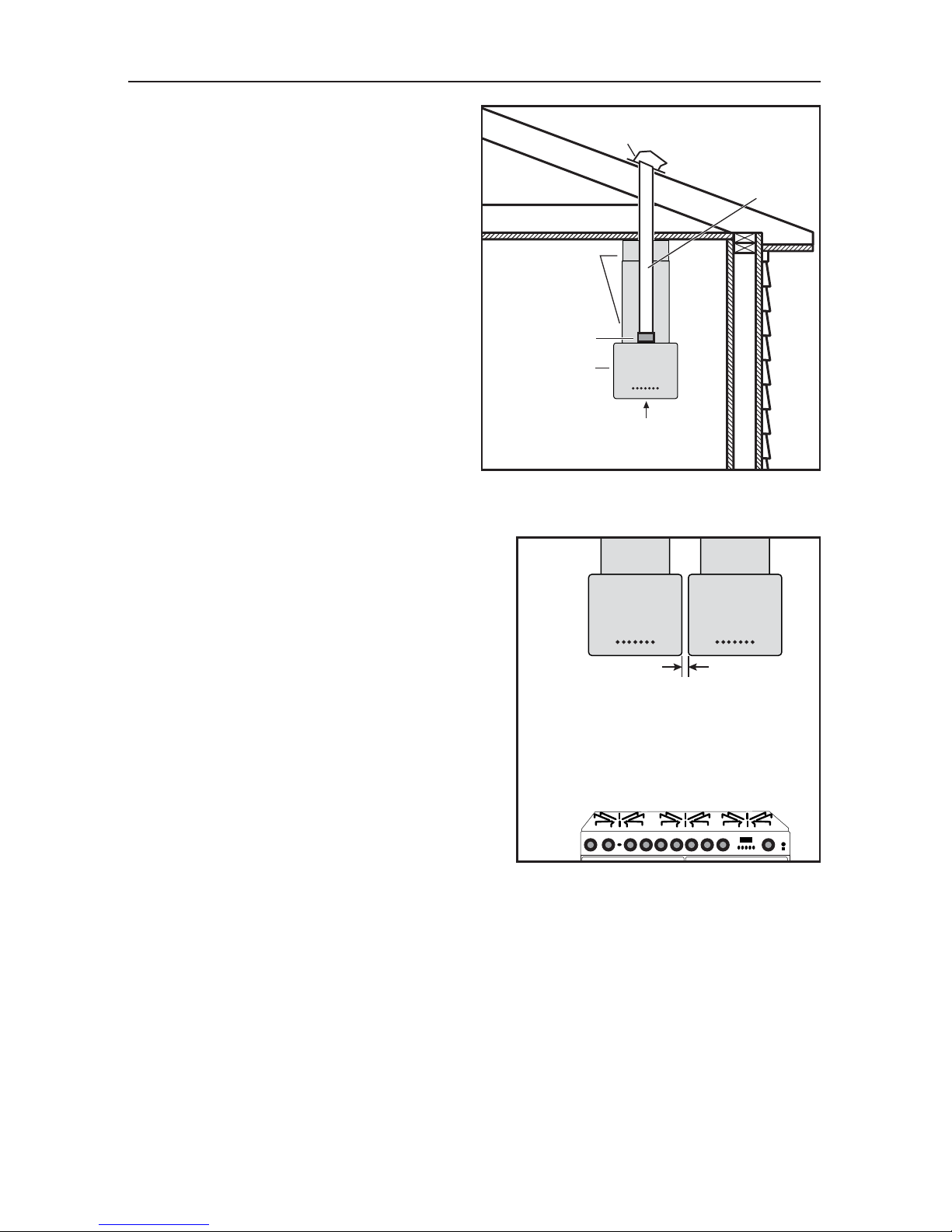

Installation over a gas range:

Refer to gas range manufacturer’s guidelines for

the recommended CFM. If two IK700 Series range

hoods are required, the space between both hoods

should not be less than 1”.

Page 5

5

2. PREPARE THE INSTALLATION

WARNING

!

When performing installation, servicing or cleaning the unit, it is recommended to wear

safety glasses and gloves.

NOTE: Before proceeding to the installation, check the contents of the box. If items are missing or

damaged, contact the manufacturer.

Make sure that the following items are included:

- Hood

- Accessories

• Decorative flue assembly (lower and upper flues)

• 2 Hybrid filters

• 1 Ceiling mounting bracket

• 8 Angle brackets

• 8” Adapter/Damper (in a separate box)

• Installation manual

• Bag of parts including: 2 wire connectors, 1 wire clamp, 8 no. 10 x 1½" wood screws,

8 washers, 2 no. 8 x 1/2" quadrex screws, 10 no. 8 x 3/8" quadrex screws,

17 no. 10-32 locknuts, 50 no. 10-32 x 1/2" quadrex screws

Parts sold separately:

- Ducts, elbows, wall and roof caps.

- Optional flue extension for 10-ft. ceilings model no. 19325.

- Optionnal remote control (model no. 21233).

- Glass panels for IK70016WG model (see service parts list).

NOTE: During installation, protect countertop and/or cooktop.

Page 6

6

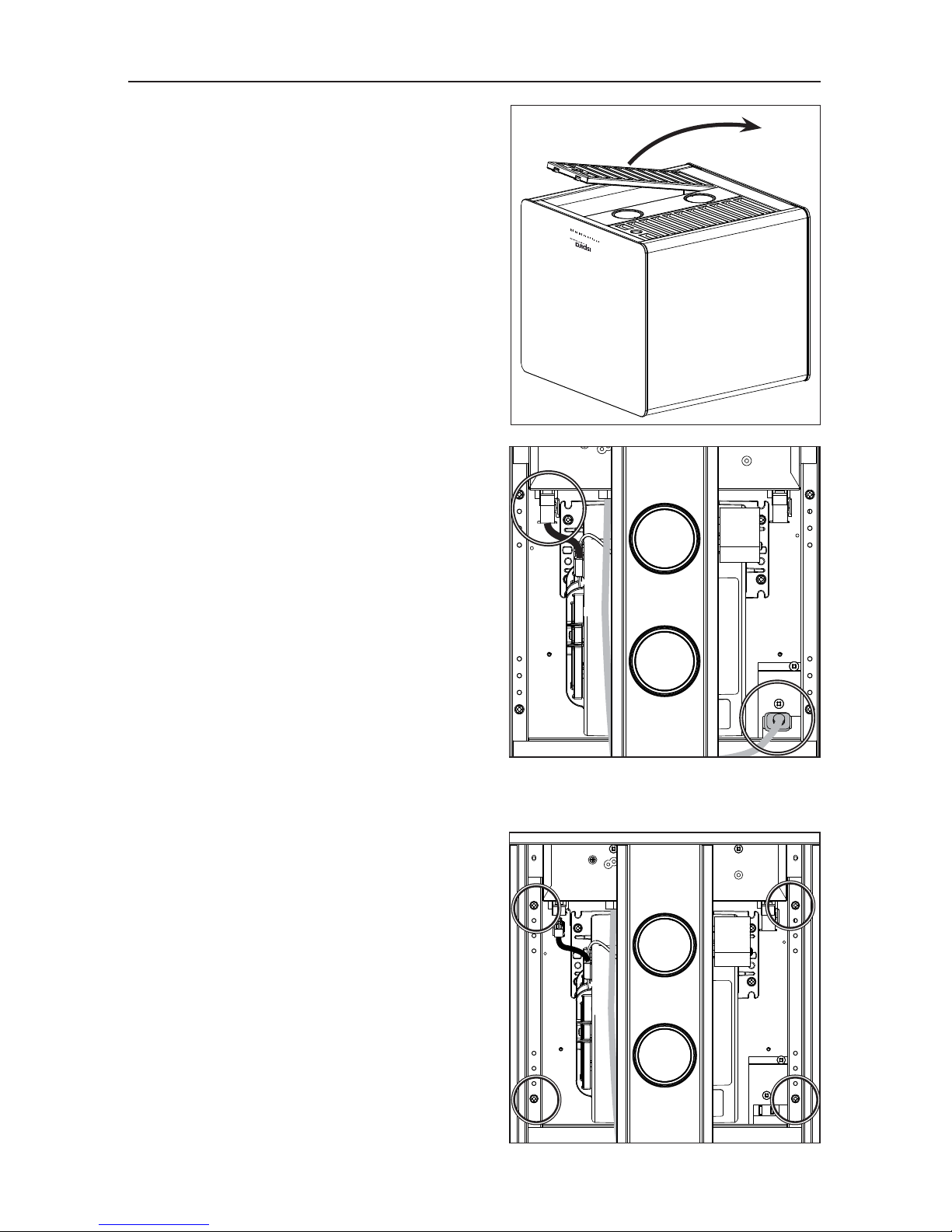

3. PREPARE HOOD

HO0252

1. Rest the range hood on a table. Use a piece of

cardboard to avoid damaging the table or the hood.

Remove tape on filters. Remove filters by pushing

them towards the back of the hood (opposite to

control side) and flipping them up, then set filters

aside.

HE0066

2. Disconnect power cord from electrical box and

disconnect blower.

HE0067

3. Remove the 4 screws retaining the blower box. Lift

hood and set aside with screws.

Page 7

7

4. MEASURE INSTALLATION

HH0156A

C

B

A

CEILING

COOKTOP

BLOWER

BOX

BOTTOM

RANGE HOOD

BOTTOM

93⁄8"

C = B - A - 9

3

⁄8"

Determine angle brackets length needed

based upon ceiling height (B) and desired

height of hood above cooktop (A).

The table below indicates which flue(s) to

use and the number of brackets required

according to height (C).

CREQUIRED COMPONENTS

FROM TO BRACKETS

UPPER

FLUE

LOWER

FLUE

OPTIONAL FLUE

EXTENSION

BEND

TABS

14¾” 18¾” 4 x

19½” 28¼” 8 x x

28¾” 33” 8 x x x*

33½” 40” 12 x x

40¾” 44¾” 12 x x x*

HD0445

45°

* If required, bend

the 4 tabs located

in the corners

of the top of the

hood to a 45°

angle using a

straight blade

screwdriver (as

shown at right).

Page 8

8

5. INSTALL MOUNTING BRACKET

WARNING

!

When building framework, always follow all applicable construction codes and standards.

1. Modify ceiling stucture over hood

location. Install 2" x 4" cross framing

between ceiling joists using ceiling

mounting bracket dimensions shown at

right. The framework must be sized to

support the total weight of the hood and

should not be larger than 9¾" x 9¾".

HD0432

HOUSE

WIRING

CEILING

JOISTS

CROSS

FRAMING

2. Finish ceiling surface, making sure the

ceiling is level in all direction. Be sure

to mark the location of the ceiling joists

and cross framing. Bring house wiring

through finished ceiling.

10¼"

10¼"

9

3

⁄8"

93⁄8"103⁄8"

103⁄8"

HK0062A

MAX. 9¾"

FRAMING INNER EDGE

Page 9

9

3. Remove both screws retaining the ceiling

mounting bracket to the top of the hood.

Discard screws.

Position the mounting plate in such a

way that one of the sides without a “T”

will be facing the front of the hood.

Secure mounting bracket to the ceiling

using 8 no. 10 x 1½" wood screws (2 on

each corner). Make sure screws are driven

into the center of the framing for maximum

strength.

5. INSTALL MOUNTING BRACKET (CONT'D)

HD0442

8” ROUND

DUCTWORK

FRONT OF HOOD

CEILING

MOUNTING

BRACKET

Page 10

10

1. Assemble 4 angle brackets to the

ceiling mounting bracket using at

least two no. 10-32 x 1/2" quadrex

screws per angle bracket.

NOTES: 1. Do not tighten the

screws yet.

2. Depending on the height

needed (C) (previously

determined in section 4),

the angle brackets might

not touch the ceiling as

illustrated at right.

2. If required according to table in

section 4, assemble a second set

of 4 angle brackets to the inner

side of the upper angle bracket set

according to the height needed (C).

Use at least two no. 10-32 x 1/2"

quadrex screws and two no. 10-32

lock nuts per angle bracket connection.

NOTE: Do not tighten the screws yet.

F

OR 10-FT CEILINGS:

Both lower and upper flues are

included with the hood, but for a

10-ft ceiling, discard the provided

upper flue and use the optional

extension flue, part no. 19325

(sold separately). Four additional

angle brackets and additional mounting hardware are included with the

optional extension flue. If required

according to table in section 4, assemble a third set of 4 angle brackets to the second angle bracket set

according to the height needed (C).

Use at least two no. 10-32 x 1/2"

quadrex screws and two no. 10-32

lock nuts per angle bracket.

NOTE: Do not tighten the screws yet.

3. Attach blower box assembly to

lower angle brackets using at least

two no. 10-32 x 1/2" quadrex screws

per angle bracket.

NOTES: 1. Make sure the blower box

bottom is at the desired

height (C) as previously

determined in section 4.

2. Ensure electrical box is

positioned in the back

right corner.

6. ASSEMBLE ANGLE BRACKETS

HD0444

FOR 10-FT

CEILINGS

(IF REQUIRED)

ELECTRICAL BOX

Page 11

11

1. Remove both screws retaining the electrical

box cover. Remove the latter by sliding it in the

direction indicated by the arrow. Set cover and

screws aside.

6. ASSEMBLE ANGLE BRACKETS (CONT'D)

4. Make sure all brackets are straight

and blower box is level and square

(as shown at right), then tighten all

screws.

HD0420

FRONT

OF

THE

HOOD

FRONT

OF

THE

HOOD

CORRECT

INCORRECT

SIDE VIEWS OF THE BLOWER BOX

7. CONNECT WIRING

WARNING

!

Risk of electric shock. Electrical wiring must be done by qualified personnel in accordance

with all applicable codes and standards. Before connecting wires, switch power off at

service panel and lock service disconnecting means to prevent power to be switched on

accidentally.

2. Install wire clamp (included) on top of

blower box. Attach the adapter/damper to

the blower box using 4 no. 8 x 3/8" quadrex

screws (included). Remove tape on damper.

(Angle brackets not illustrated to ease

understanding).

HJ0068

HD0441

SCREW LOCATIONS

Page 12

12

7. CONNECT WIRING (CONT'D)

HD0434

HOUSE

WIRING

3. Run house wiring through wire clamp and into

blower box electrical box. Tighten wire clamp to

secure house wiring cable to blower box.

4. Measure the required length of 8" round metal duct

from the adapter/damper to the ductwork rough-in

in the ceiling. Connect this section of duct to the

adapter/damper, then connect to ceiling duct and

seal both joints with metal foil duct tape.

HE0126

5. Connect hood power cable to house wiring using

provided wire connectors: BLACK to BLACK, WHITE

to WHITE and GREEN or BARE wire to GREEN

ground screw. DO NOT FORGET TO CONNECT

THE GROUND.

6. Reinstall electrical box cover using both screws

previously removed.

Page 13

13

The WG hood model glass panels are sold separately and have to be installed before completing

the hood installation.

For each glass panel:

1. Carefully remove glass panel from its packaging.

Remove glass panel nuts (factory installed) from both studs and set aside.

2. Insert glass panel studs in

appropriate hood holes (some

parts not illustrated to ease

understanding).

NOTE: Install the glass panel with

the control pictograms on

the front of the hood.

3. While holding glass panel,

pre-tighten previously removed

nuts by hand. Ensure glass

panel is centered. Then, using a

3/8" socket, tighten nuts completely.

8. INSTALL GLASS PANELS (WG MODEL ONLY)

HD0438

NUT

GLASS PANEL

STUD

9. INSTALL HOOD

WARNING

!

BE CAREFUL when installing the decorative flue and hood, they may have sharp edges.

CAUTION

DO NOT REMOVE the protective plastic film covering the decorative flue (upper and lower)

and the hood yet.

1

2

HD0435

1. Slide the upper flue up to the ceiling and secure it to the

ceiling mounting bracket using 2 no. 8 x 1/2" quadrex screws.

NOTE: Ensure upper and lower flue seams are aligned B.

Carefully slide the lower flue over the upper flue up to the

ceiling and have the second person hold it up C while

performing step 2.

Page 14

14

9. INSTALL HOOD (CONT'D)

HE0067

2. Slide hood over blower box and attach to blower box

using the 4 screws previously removed in step 3.3

(some parts not illustrated to ease understanding).

NOTE: For more convenience, a total of 16 holes

(4 holes per section) are available to secure

the hood, but only 1 screw per section is

necessary.

3. Slide the lower flue down on top of the hood. Remove protective plastic film from flues.

4. Connect blower and power cord back.

HE0066

Page 15

15

12. CARE

HYBRID FILTERS

Hybrid filters should be cleaned monthly. Remove hybrid filters by pushing them towards the back of

the hood and rotating them downward. Use a warm detergent solution to clean the filters. Let them

dry and reinstall them. Hybrid filters are dishwasher safe. Clean all-metal filters in the dishwasher

using a non-phosphate detergent. Discoloration of the filter may occur if using phosphate detergent

or as a result of local water conditions — but this will not affect filter performance. This discoloration

is not covered by the warranty.

INTERIOR BLOWER

Remove the filters in order to access the blower. Vacuum blower to clean. Do not immerse in water.

WARNING

!

Before servicing or cleaning the unit, switch power off at service panel and lock

service panel to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device, such

as a tag, to the service panel.

10. REINSTALL HYBRID FILTERS

CAUTION

Remove protective plastic film covering filters before reinstalling them.

Rest rear filters edge on filter springs

in the range hood. Tilt up the filters

into position. Make sure filter tabs

are securely engaged in range hood

front edge slots after installation.

HO0253

FILTER TABS

11. LED LIGHTING

The lighting of this hood is produced by two LED modules (included).

WARNING

!

Do not touch lamps during or soon after operation. Burns may occur. Cannot be replaced

by any other type of light bulb or LED module.

Page 16

16

13. OPERATION

Always turn your hood on before you begin cooking to establish an air flow in the kitchen. Let the

blower run for a few minutes to clear the air after you turn off the range.

CAUTION

After a power failure or during the range hood power up, a 5-second booting sequence is

executed. Wait for the control backlighting to turn off before use.

HC0052

A

B

CD

A. DELAY BUTTON/CONTROL LOCK (DOUBLE FUNCTION BUTTON):

i. When a blower speed is selected, press this button to activate the delay function. The

delay button will light to its high intensity, then to its mid intensity to indicate this function

is activated; the selected blower speed button will alternate every 2 seconds between its

high intensity and its mid intensity. The blower will continue to operate for 5 minutes and

will stop automatically. Selecting an other speed while the delay function is activated will

not deactivate the function or reset the timer. To cancel the delay function, press the delay

button once again, or press the selected speed button which will also turn the blower off.

12. CARE (CONT'D)

STAINLESS STEEL

Do:

• Regularly wash with clean cloth or rag

soaked with warm water and mild soap or

liquid dish detergent.

• Always clean in the direction of original

polish lines.

• Always rinse well with clear water (2 or

3 times) after cleaning. Wipe dry completely.

• You may also use a specialized household

stainless steel cleaner.

Don’t:

• Use any steel or stainless steel wool or any

other scrapers to remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction

residues reach the hood. During

construction/renovation, cover the hood to

make sure no dust sticks to stainless steel

surfaces.

GLASS PANEL

Hot water with mild soap or glass cleaner is all that is usually needed.

When using mild soap, rinse with clear water. Wipe dry with a clean, soft cloth to avoid water marks.

Avoid when choosing a detergent:

- Any cleaners that contain bleach. They will attack stainless steel.

- Any products containing chloride, fluoride, iodide, bromide. They will deteriorate surfaces

rapidly.

- Any combustible products used for cleaning such as acetone, alcohol, ether, benzol, etc. They

are highly explosive and should never be used close to a range.

Page 17

17

WARNING

!

The Heat Sentry can change the blower speed when excessive heat is detected above the

cooking surface. If this situation occurs and you must stop the blower, press on the third

speed button or on the master ON/OFF button.

D. LIGHT BUTTON/BACKLIGHTING COLOR (DOUBLE FUNCTION BUTTON):

i. This button allows three different lighting levels according to your needs. Press once for full

intensity, twice for intensity level 2, and once more for nightlight. To turn off the lights, press

once more.

If desired, when the lights are on, press and maintain the light button for 1 second; lights will

be turned off.

NOTE: When only the lights are ON to any intensity and no interaction with the hood is detected for

a 10-second period, the 7 buttons backlighting will fade to its low intensity, acting as a night

light feature.

ii. When lights are off, pressing and holding this button for 1 seconds will switch the

backlighting color from white to blue or from blue to white (default backlighting color is

white) and memorize it. The button will flash three times to indicate that the color change

has been made.

NOTE: Due to the particular sensitivity of the control interface, keep the glass panel clean as dirt

and condensation may cause erratic operation of the hood blower and/or lighting. If this

situation occurs, wipe the glass panel and wait 90 seconds. Then, adjust the blower and/or

lighting at your convenience.

REMOTE CONTROL:

This hood can also be operated using the optional 21233 remote control (purchase separately).

NOTE: For more information, refer to the instructions included with the remote control.

13. OPERATION (CONT'D)

A. DELAY BUTTON/CONTROL LOCK (DOUBLE FUNCTION BUTTON) (CONT'D):

ii. When the blower is off, it is possible to lock the control interface in order to clean the glass

panel.

To lock the control interface: Press and hold this button for 2 seconds. The button will light

to its high intensity and flash three times, it will then stay on its mid intensity to indicate that

the control interface is locked.

To unlock the control interface: Press and hold this button for 2 seconds. The button will light

to its high intensity and flash 3 times, it will then fade out to its low intensity to indicate that

the control interface is unlocked.

B. S

PEED SELECTION BUTTONS:

Press the button corresponding to the desired blower speed (from 1 for low speed to 4 for

high speed). The chosen speed button will light to its high intensity then fade to its mid

intensity. To turn off the blower, press once more on the corresponding blower speed button;

the button light will fade to its low intensity.

NOTE: When blower is off, pressing on blower speed 1 button will cause the blower to start on

second speed for a very short lapse of time, and then resume to speed 1.

C. MASTER ON/OFF:

When the blower and lights are off, press this button to turn the hood on to the last

memorized speed level and light intensity. If there are no memorized speed level and light

intensity, speed will be set at level 1 and light intensity at 3. To turn off the blower and the

light simultaneously, press this button once.

HEAT SENTRY™: The hood is equipped with a HEAT SENTRY thermostat. If blower is ON at a lower

speed setting and excessive heat is detected above the cooking surface, it turns

the blower up to third speed. When the temperature level drops to normal, the

blower will return to its original setting.

NOTE: When Heat Sentry is activated, the “DELAY OFF” function is inactivated.

Page 18

18

14. WIRING DIAGRAM

WARNING

!

Risk of electric shock. Electrical wiring must be done by qualified personnel in accordance

with all applicable codes and standards. Before connecting wires, switch power off at

service panel and lock service disconnecting means to prevent power from being switched

on accidentally.

Line

Neutral

Ground

120 V AC

16 Pins

LED driver

Input

Output

LED

LED

User Interface

T1 (10 VAC)

FAN MOTOR

1

3

2

5

4

User Interface

J1

10VAC

J8

Aux. Input

3

2

1

RP1

J3

Programmer

header

Triac Ext

J7

J11

12VDC

+

-

J4

Motor Speed

J2

120V-

Motor-Lamp

1

RF communication

J10

J9

Serial Com

5

4

32

1

J5

Output

J6

External

Triac

2

3

4

5

1

2

3

4

1

2

1

2

1

2

3

4

1

2

3

1

2

YEL

BLK

BLK

WHT

WHT

WHT

RED

RED

RED

BLU

WHT

ORG

BLK

WHT

BLK

WHT

RED

RED

WHT

BLK

WHT

RED

GRY

BRN

BLU

WHT

ORG

BLK

BLK BLACK

BLU BLUE

BRN BROWN

GRN GREEN

GRY GREY

ORG ORANGE

RED RED

WHT WHITE

YEL YELLOW

COLOR CODE

HE0057A

REPLACEMENT PARTS AND REPAIRS

In order to ensure your unit remains in good working condition, you must use Venmar Ventilation

ULC genuine replacement parts only. Venmar Ventilation ULC genuine replacement parts

are specially designed for each unit and are manufactured to comply with all the applicable

certification standards and maintain a high standard of safety. Any third party replacement part

used may cause serious damage and drastically reduce the performance level of your unit,

which will result in premature failing. Venmar Ventilation ULC recommends to contact a certified

service depot for all replacement parts and repairs.

Page 19

19

KEY

NO.

P

ART NO.DESCRIPTION QTY.

1 SV09958XX* F

RONT GLASS PANEL 1

2 21221 P

OWER UNIT 1

3 SV20816 PCB

FOR REMOTE CONTROL 1

4 09550 E

LECTRONIC CONTROL 1

5 09022 T

RANSFORMER 1

6 62248 LED

DRIVER AND CONNECTION HARNESS 1

7 62612 LED

MODULE (1) 2

8 62240 H

YBRID FILTER 13.38” X 5.15” x 0.5” (1) 2

9 SV09959XX* B

ACK GLASS PANEL 1

10 SV08582 INTERNAL BLOWER 1

11 08543 8”

ROUND ADAPTER/DAMPER 1

12 19253 A

NGLE BRACKET 8

13 SV19239 L

OWER FLUE COVER 1

14 SV19240 U

PPER FLUE COVER 1

15 19232 I

NSTALLATION BRACKET 1

** 21227 I

NSTALLATION MANUAL 1

** 09871 P

ARTS BAG 1

*P

ART NUMBER ACCORDING TO GLASS PANEL COLOR, PLEASE CONTACT CUSTOMER SERVICE OR REFER TO WEB SITE.

**ITEM NOT SHOWN.

15. SERVICE PARTS

1

4

2

3

5

6

7

8

9

10

11

12

13

14

15

HL0228

Page 20

20

16. WARRANTY

VENMAR VENTILATION FIVE-YEAR WARRANTY

Venmar Ventilation ULC warrants to the original consumer purchaser of the Venmar Ispira IK700

Series range hood that such product will be free from defects in materials or workmanship for a

period of five (5) years from date of original purchase, except the LED modules and LED driver,

which are covered for a period of three (3) years. This warranty includes in-home service for the

first year and workshop service for the four (4) remaining years.

THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. VENMAR VENTILATION ULC WILL NOT BE HELD RESPONSIBLE

FOR ANY CLAIMS OVER THE ORIGINAL PURCHASE PRICE OF A VENMAR ISPIRA IK700

SERIES RANGE HOOD NOR HELD RESPONSIBLE FOR SUBSEQUENT DAMAGE OR

INCIDENT.

During the period stated above, Venmar Ventilation ULC will, at its option, repair or replace without

charge any product or part which is found to be defective under normal use and service. THIS

WARRANTY DOES NOT EXTEND TO FUSE, FILTERS, DUCTS, ROOF CAPS, WALL CAPS

AND OTHER ACCESSORIES FOR DUCTING.

This warranty does not cover a) normal maintenance and service b) any products or parts

which have been subject to misuse, negligence, accident, improper maintenance or repairs

made by other than Venmar Ventilation ULC, or c) a faulty installation or installation contrary to

recommended installation instructions.

Warranty service is to be completed by an authorized Service Center designated by Venmar

Ventilation ULC. Where applicable, in-home service will be made available only in areas where a

contracted service provider offers service. If in-home service is not available, the product will be

repaired or replaced, at Venmar Ventilation ULC’s discretion, by the nearest authorized service

provider. The unit removal and reinstallation works are under the customer responsibility, and

Venmar Ventilation ULC cannot be charged for them.

The duration of any implied warranty is limited to the 5-year period as specified for the express

warranty. Some provinces do not allow limitation on how long an implied warranty lasts, so the

above limitation may not apply to you.

VENMAR VENTILATION ULC'S OBLIGATION TO REPAIR OR REPLACE AT VENMAR

VENTILATION ULC'S OPTION, SHALL BE THE PURCHASER'S SOLE AND EXCLUSIVE

REMEDY UNDER THIS WARRANTY. VENMAR VENTILATION ULC SHALL NOT BE LIABLE

FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN

CONNECTION WITH PRODUCT USE OR PERFORMANCE. SOME PROVINCES DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

This warranty gives you specific legal rights and you may also have other rights, which vary from

province to another. This warranty supersedes all prior warranties.

To contact Venmar Ventilation ULC warranty service, call 1-800-567-3855 in Canada. In order to

qualify for a warranty claim, the owner of a Venmar Ispira IK700 Series range hood must have the

model and serial number along with a proof of the original purchase date. At the time of requesting

service, describe the nature of any defect in the product or part.

Venmar Ventilation ULC, 550 Lemire Blvd., Drummondville, QC J2C 7W9 (1-800-567-3855)

www.venmar.ca

Loading...

Loading...