Page 1

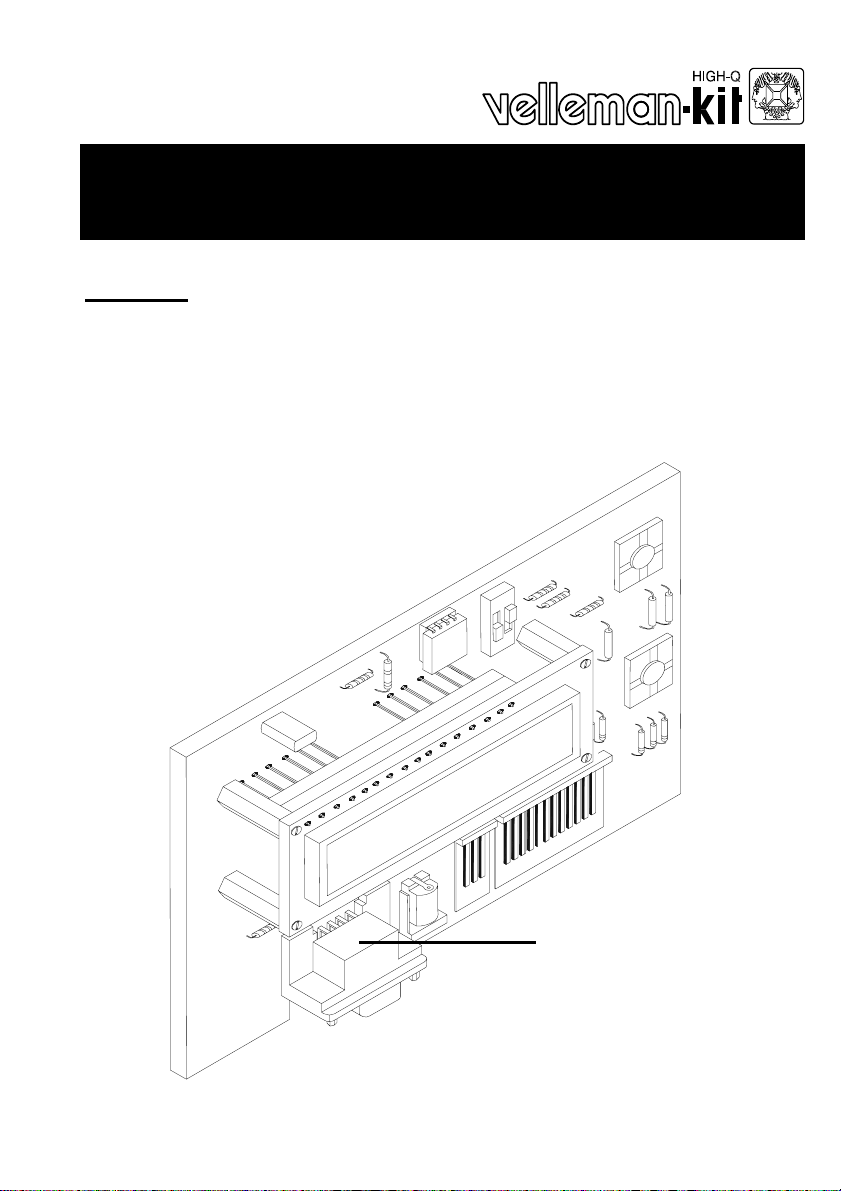

Total solder points: 239

Difficulty level:

beginner 1 2 3 4 5 advanced

8 Input programmable messageboard

with LCD & serial interface

Features :

Add an LCD display to any low-tech application and make it look high-te ch !

Replace up to 9 indicators or lamps by one single backlit LC D.

Recall messages simply by pressing a button.

Inputs accept dry contacts, open collectors and logic levels .

No programming skills required !

Store up to 9 sixteen-character messages in non-volatile E EPROM memor y .

4 operating modes :

1) Display the status of all inputs simult aneously .

2) Display all active inputs.

3) Display active input with highest priority .

4) Display text messages in a ‘tickertape’-fashi on.

A default message can be entered and is display ed when no inputs are active.

Messages can be transferred to the K8045 from any PC or terminal.

Free message transfer software and source code for the K8045 is availabl e

from www.velleman.be

Wireless data transfer between PC/terminal and K 8045 is possible with op-

tional RX/TX433 modules.

1 on-board pushbutton available for y our application.

K8045

Specifications :

Inputs : 8 inputs (24Vmax)

Display : 16 character 1 line supertwist backlit LCD

Communication : RS232 2400/N/8/1 no handshaking

Power supply : 9-12VDC/150mA adapter or

2x9VAC/150mA transformer

Modifications reserved

ILLUSTRATED ASSEMBLY MANUAL H8045IP-1

Dimensions : 124x73x30mm max.

Page 2

Assembly hints

0

.

0

0

0

1. Assembly (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project

successful. Read them carefully.

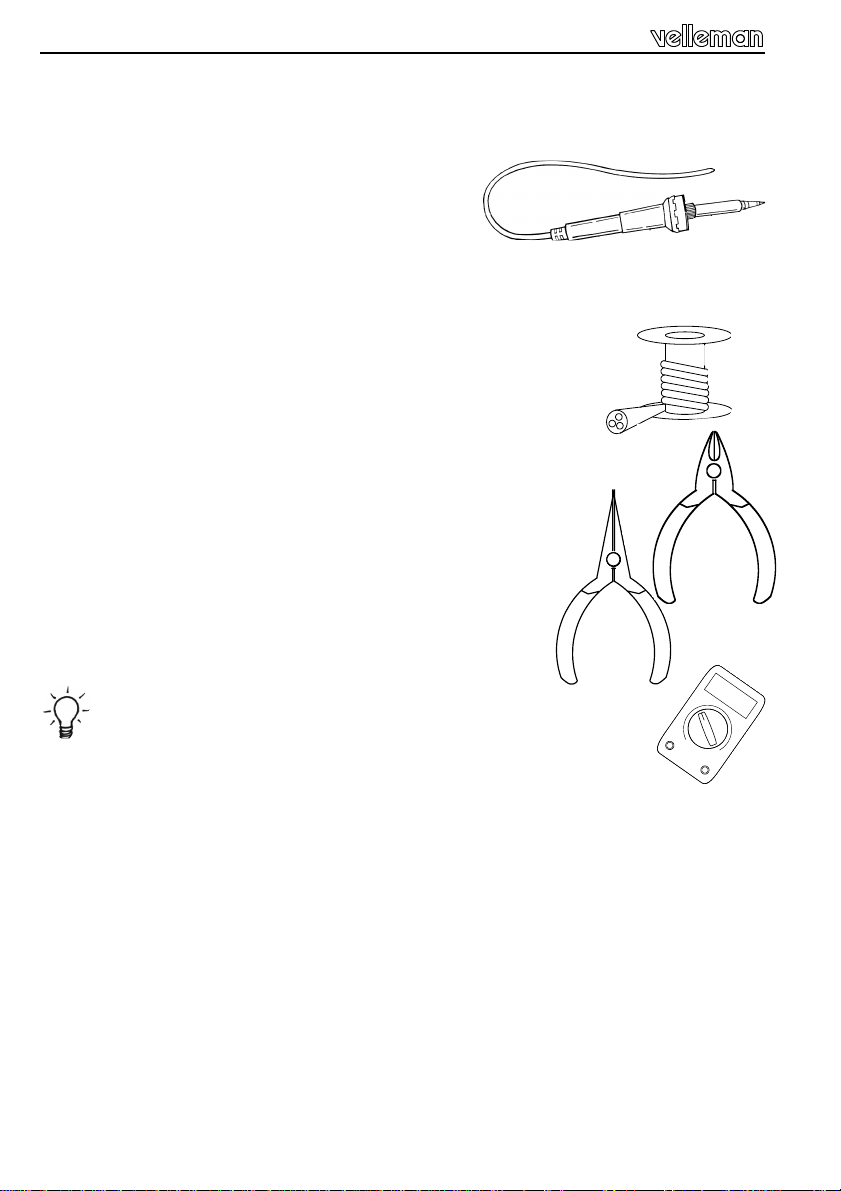

1.1 Make sure you have the right tools:

• A good quality soldering iron (25-40W) with a

small tip.

• Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to

the tip, to give it a wet look. This is called ‘thinning’ and will protect the tip,

and enables you to make good connections. When solder

rolls off the tip, it needs cleaning.

• Thin raisin-core solder. Do not use any flux or grease.

• A diagonal cutter to trim excess wires. To avoid injury when cutting

excess leads, hold the lead so they cannot fly towards the eyes.

• Needle nose pliers, for bending leads, or to hold components in place.

• Small blade and phillips screwdrivers. A basic range

is fine.

For some projects, a basic multi-meter is required, or might

be handy

1.2 Assembly Hints :

⇒ Make sure the skill level matches your experience, to avoid disappointments.

⇒ Follow the instructions carefully. Read and understand the entire step before

you perform each operation.

⇒ Perform the assembly in the correct order as stated in this manual

⇒ Position all parts on the PCB (Printed Circuit Board) as shown on the draw-

ings.

⇒ Values on the circuit diagram are subject to changes.

⇒ Values in this assembly guide are correct*

⇒ Use the check-boxes to mark your progress.

⇒ Please read the included information on safety and customer service

* Typographical inaccuracies excluded. Always look for possible last minute

manual updates, indicated as ‘NOTE’ on a separate leaflet.

2

Page 3

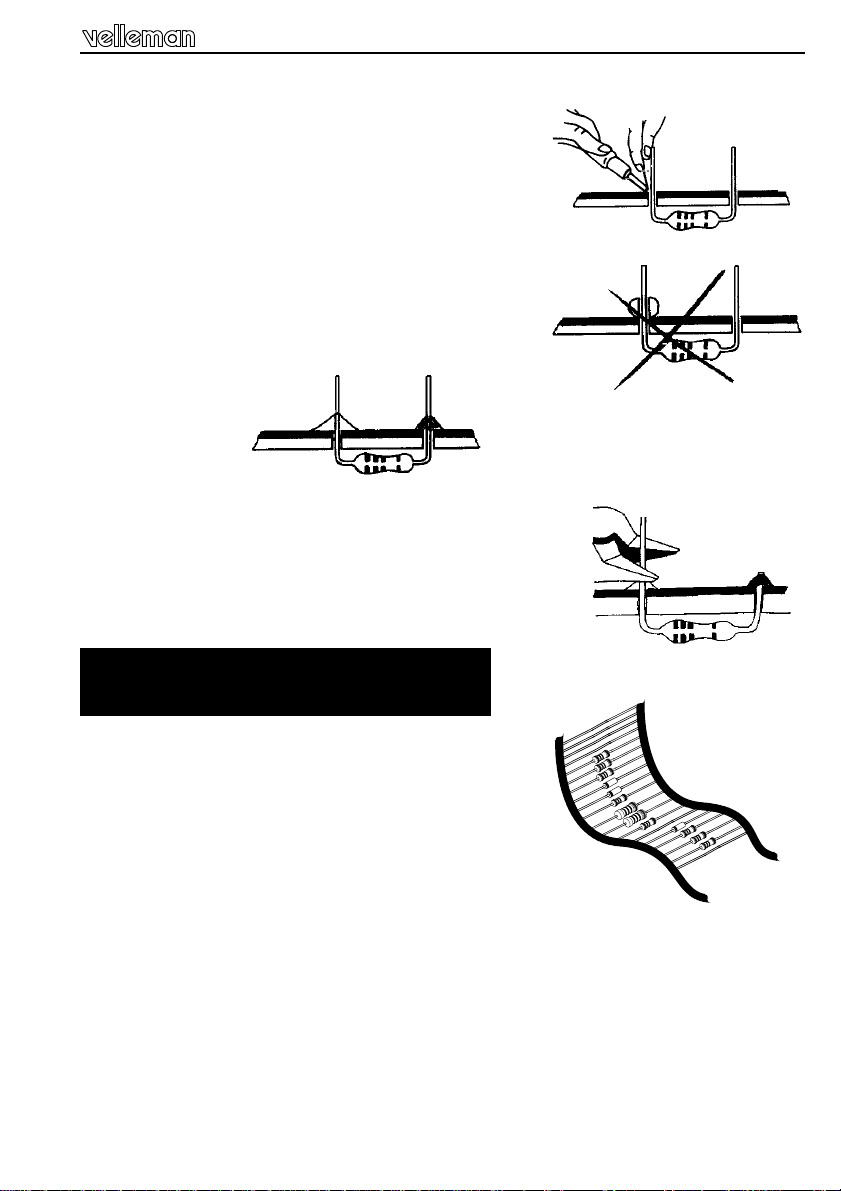

1.3 Soldering Hints :

1- Mount the component against the PCB surface

and carefully solder the leads

2- Make sure the solder joints are cone-shaped

and shiny

3- Trim excess leads as close as possible to the solder joint

AXIAL COMPONENTS ARE TAPED IN

THE CORRECT MOUNTING SEQUENCE !

REMOVE THEM FROM THE TAPE ONE AT A TIME !

Assembly hints

3

Page 4

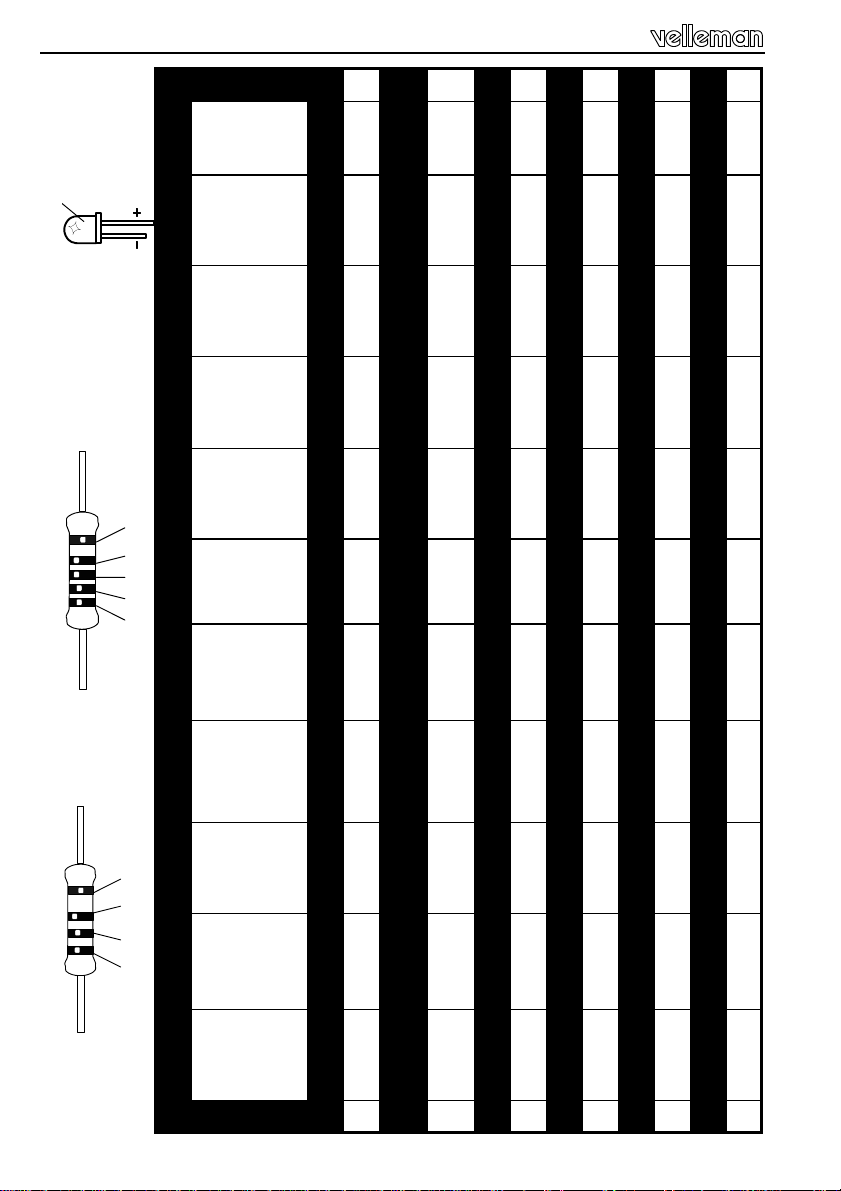

Color code table

COLOR= 2...5

CO LO R = 2… 5

1%

C O D

KLEUR

CODIFI-

COLOUR

FARB

FARGE-

FARVE-

E

KODE

CATION

DES

COU-

CODE

KODE

KODE

KODE

LEURS

4

5%

4K7= ( 4 - 7 - 2 - B )

4K7= ( 4 - 7 - 0 - 1 - 1 )

FÄRG

VÄRI

CODIGO

CODIGO

I P E SF S DK N D GB F NL

CODICE

C O D E

SCHEMA

KOODI

ORES

DE COL-

DE

CORES

COLORE

0 Nero Preto Negro Musta Svart Sort Sort Schwarz Black Noir Zwart 0

1 Marrone Castanho Marrón Ruskea Brun Brun Brun Braun Brown Brun Bruin 1

Rojo Punainen Röd Rød Rød Rot Red Rouge Rood 2

nado

2 Rosso Encar-

Oranssi Orange Orange Orange Orange Orange Orange Oranje 3

jado

Laranja Naran-

ciato

3 Aran-

4 Giallo Amarelo Amarillo Keltainen Gul Gul Gul Gelb Yellow Jaune Geel 4

5 Verde Verde Verde Vihreä Grön Grøn Grønn Grün Green Vert Groen 5

6 Blu Azul Azul Sininen Blå Blå Blå Blau Blue Bleu Blauw 6

7 Viola Violeta Morado Purppura Lila Violet Violet Violet Purple Violet Paars 7

8 Grigio Cinzento Gris Harmaa Grå Grå Grå Grau Grey Gris Grijs 8

9 Bianco Branco Blanco Valkoinen Vit Hvid Hvidt Weiss White Blanc Wit 9

A Argento Prateado Plata Hopea Silver Sølv Sølv Silber Silver Argent Zilver A

B Oro Dourado Oro Kulta Guld Guld Guldl Gold Gold Or Goud B

Page 5

Construction

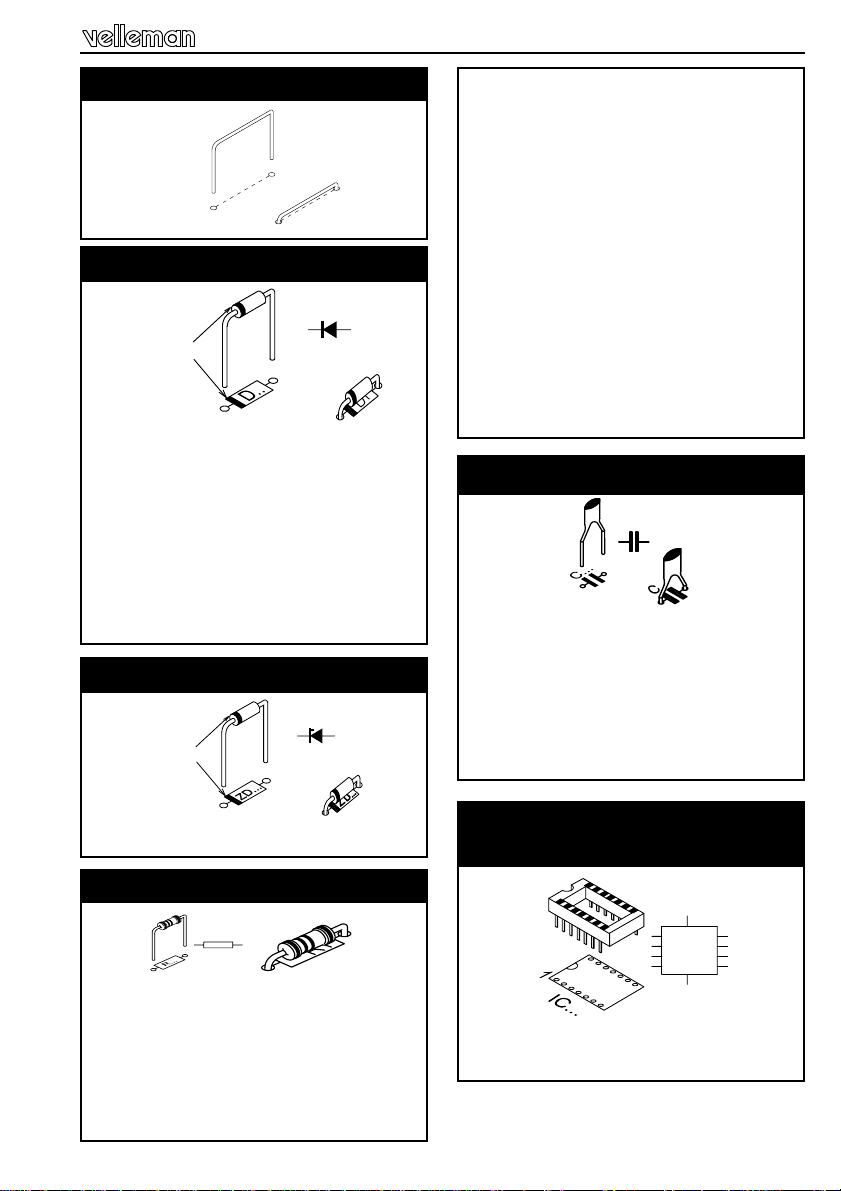

1. Jumperwire

J1

J2

J3

2. Diodes (Check the polarity)

CATHODE

D...

D1 : 1N4007

D2 : 1N4007

D3 : 1N4148

D4 : 1N4148

D5 : 1N4148

D6 : 1N4148

D7 : 1N4148

D8 : 1N4148

D9 : 1N4148

D10 : 1N4148

3. Zenerdiodes (Check the polarity)

CATHODE

ZD...

R10 : 1K (1 - 0 - 2 - B)

R11 : 1K (1 - 0 - 2 - B)

R13 : 1K (1 - 0 - 2 - B)

R14 : 1K (1 - 0 - 2 - B)

R16 : 1K (1 - 0 - 2 - B)

R17 : 1K (1 - 0 - 2 - B)

R19 : 1K (1 - 0 - 2 - B)

R20 : 1K (1 - 0 - 2 - B)

R22 : 1K (1 - 0 - 2 - B)

R23 : 1K (1 - 0 - 2 - B)

R25 : 1K (1 - 0 - 2 - B)

R26 : 1K (1 - 0 - 2 - B)

R28 : 1K (1 - 0 - 2 - B)

R29 : 1K (1 - 0 - 2 - B)

R30 : 22E0 (2 - 2 - 0 - B)

R31 : 10K (1 - 0 - 3 - B)

5. Capacitors

C...

C2 : 100nF (104)

C3 : 100nF (104)

C4 : 100nF (104)

C5 : 100nF (104)

C7 : 15pF (15)

C8 : 15pF (15)

ZD1 : 5v1

4. Resistor

R...

R1 : 10K (1 - 0 - 3 - B)

R2 : 10K (1 - 0 - 3 - B)

R3 : 10K (1 - 0 - 3 - B)

R4 : 100K (1 - 0 - 4 - B)

R5 : 1K (1 - 0 - 2 - B)

R7 : 1K (1 - 0 - 2 - B)

R8 : 1K (1 - 0 - 2 - B)

6. IC socket

(Watch the position of the notch)

1

IC...

IC1 : 28p

IC2 : 8p

5

Page 6

Construction

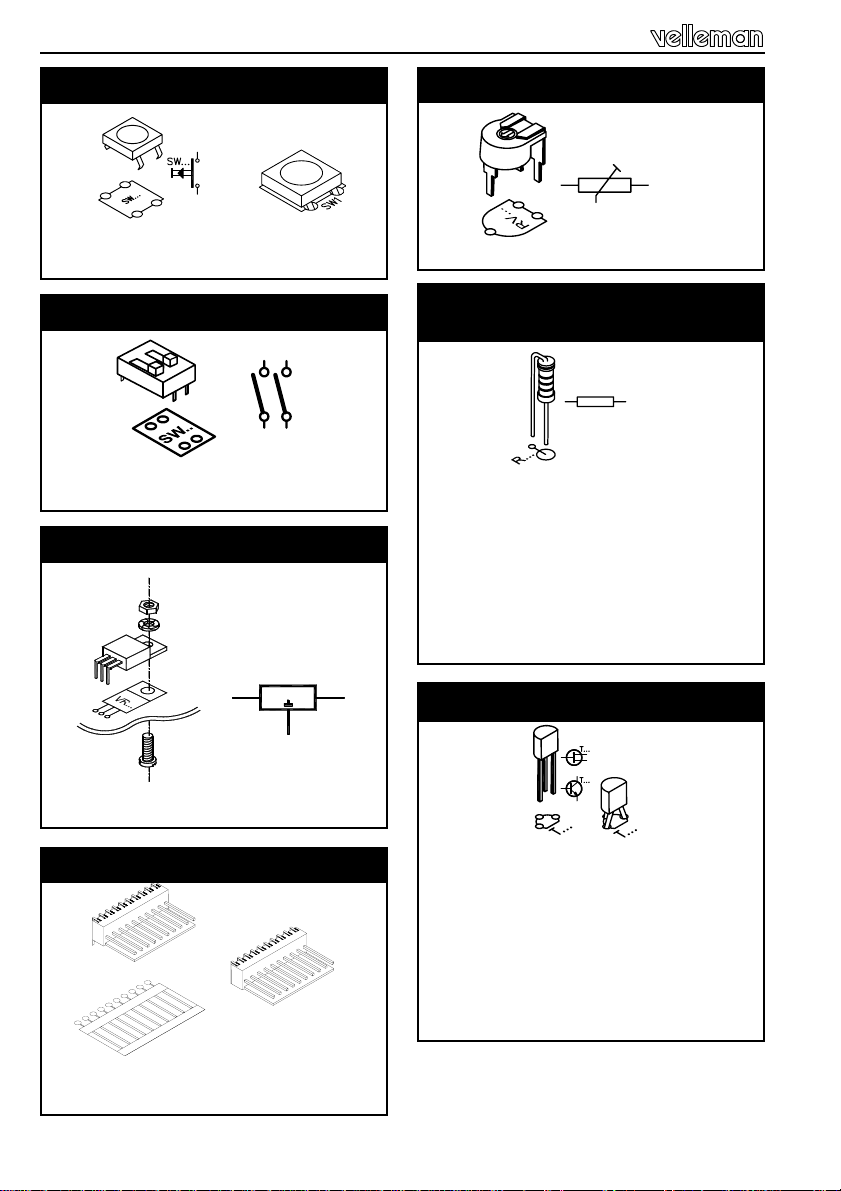

7. Push buttons

SW2

SW3

8. DIP switch

2

1

SW...

1

SW1 : DIP-2

9. Voltage regulator

M3 NUT

M3 LOCK WASHER

VOLTAGE REGULATOR

PCB

M3 BOLT

VR1 : UA7805

10. Connector

1

VR...

I O

11. Trim potentiometer

RV...

RV1 : 10K

12. 1/4W Resistors

(check the color code)

R...

R6 : 1K (1 - 0 - 2 - B)

R9 : 1K (1 - 0 - 2 - B)

R12 : 1K (1 - 0 - 2 - B)

R15 : 1K (1 - 0 - 2 - B)

R18 : 1K (1 - 0 - 2 - B)

R21 : 1K (1 - 0 - 2 - B)

R24 : 1K (1 - 0 - 2 - B)

R27 : 1K (1 - 0 - 2 - B)

13. Transistors

T1 : BC557

T2 : BC557

T3 : BC557

T4 : BC557

T5 : BC557

T6 : BC557

T7 : BC557

T8 : BC557

SK1 : 3p

SK8 : 12p

6

Page 7

Construction

14. Header

SK3 : 3p

15. DC-jack

SK2

16. SUB-D connector

SK5 : SUB-D 9p female

17. Electrolytic capacitors

C...

C6 : 10µF

C1 : 220µF/35V

18. Quartz chrystal

X...

X1 : 4MHZ

19. IC’s

IC1 : VK8045 (PIC16C57)

IC2 : 24C02A

20. Shunt selection

RS232 cable operation

1

E

BL

A

C

1

Wireless link

F

R

1

1

7

Page 8

LCD assembling

21. LCD assembling

Cut the 20 pole connector to a 16 pole connector.

Diagonal cutter

Mount the 16 pole female connector. (see fig. 2.0)

Mount 2x 6 pole male connectors.

Pay attention : The four center connections of the LCD remain unused.

Make sure that the longest pins aim towards the main PCB. (See Fig. 3.0)

FIG.1.0

FIG.2.0

FIG.3.0

8

Page 9

Assembly

22. Assembly

Fit the display at the component side of the base PCB using four M2,5 bolts together with four 15mm spacers. Fix the display using four M2,5 bolts at the solder side of the base PCB and check that the display is at right angles to the

base PCB.

Now you can solder the pinheader.

Diagonal cutter

9

Page 10

Connection

23. Connection

1. Hook-up when using an adapter :

2. Hook-up when using a transformer

9 –12VDC / 150mA

10

K8045

SW3

GND

8

7

6

5

4

3

2

1

VB

VA

GND

120 - 220 VAC

L

Fuse : 250mA T

2 X 9VAC/150mA

N

TRANSFORMER

Page 11

Control options

24. Control options

How to construct an RS232 cable :

3

5

3

5

TO PC

SUBD 9 pole fem a le

TO K8045

SUBD 9 pole male

2-3 meter max.

Or you can buy a pre-assembled cable. Careful : this is not a null-modem cable

How to establish a wireless link :

Wireless data transfer between the PC/terminal and the K8045 is possible by

means of optional RF transmitter/receiver modules (Velleman part# TX433/

RX433). Transmission quality depends on your environment. Other RF sources

might interfere with your signal (and will cause occasional ‘garbage’ on-screen).

TX433

A

9V Battery

+

-

3

Z

5

R

Z : 5V1 zenerdiode 0,6W

A : antenna (30 - 40cm)

R : 3K9 resistor (orange - white - red)

To pc

SUBD 9 pole female

The receiver is mounted on the left hand side of the K8045 board. Watch the

position, the coils point to the LCD of the K8045. If you choose wireless operation, make sure to set jumper SK3 to ‘RF’

11

Page 12

Testing

25. Testing

Turn RV1 (contrast) fully anti-clockwise.

Set dipswitches SW1 (mode) to the ‘off’-position.

Set jumper SK3 for ‘cable’-operation but do not connect a serial cable

Connect the supplied wired female connector to SK8

Apply power (for power requirements, see pag. 10)

The LCD should initialise and the following text should appear :

K8045 Vxxxxxxxx (‘x’ indicates software version)

If the message ‘EEPROM FAILURE’ appears, check the position of IC2 and/or

re-check the complete assembly

Next, the display will show : 1 2 3 4 5 6 7 8

Check input 1 by shorting the left hand brown and the black wire. An ‘x’ appears

next to the ‘1’ on the screen, indicating ‘input active’

Check all inputs (brown to grey) in a similar fashion.

Next, flip dipswitch 2 of SW1 to the ‘ON’ position.

The display should display ‘9’ (the ninth message is displayed when no inputs

are active). Repeat the input test as above, but now the display will show the

active input only

RS232 interface setup :

Hook-up a serial cable (for details, see pag. 11) between a free serial port of

your computer/terminal and the K8045. You can download free software from

our website www.velleman.be, which allows you to transfer messages from the

PC to your K8045 and which allows you to display messages on you K8045.

You can also use a terminal or terminal emulation program to manually enter

messages. Terminal settings are :

Baudrate : 2400

Parity : none

Databits : 8

Stopbits : 1

No handshaking

12

Page 13

Message entering

26. Entering messages with a terminal program :

The K8045 can store 9 sixteen-character messages, 1 for each input and a 9th

which is displayed when no inputs are active.

Briefly press SW2 ‘PROG’ to enter program mode

The display shows ‘INPUT 1...9 / S / Q : ‘ and a flashing cursor

To enter a message for input 1 :

Type ‘1’ ‘ENTER’

The unit now displays ‘TRIGGER (1/0):’ and a flashing cursor

If you want the message to appear when the input is active (grounded),

type ‘0’ ‘ENTER’

In case you want the message to appear when the input is not active (left open),

Type ‘1’ ‘ENTER’

(If you do not want to change the settings for this input, press ‘BACKSPACE’ to

return to the previous menu)

The display now show the current message for this input.

If you do not wish to change the message for this input, press ‘BACKSPACE’ to

return to the input selection menu

If you wish to change the current message, simply type a new message and

press ‘ENTER’

Your message is now stored and the unit returns to the input selection menu

You can now enter messages for all inputs (1..9).

Message 9 is displayed when no input is active and does not allow you to enter

a trigger setting.

To exit programming mode, type ‘Q’ (capital).

(Note : You can download software from our

website www.velleman.be which makes it very

easy to store, edit and transfer messages, without the need for a terminal program)

13

Page 14

Operating modes

27. Operating modes :

The K8045 features 4 operatin g modes, se lectable w ith dipsw itch S W1.

To ensure correct operation, disconnect p ower before changing dip switch posi tion.

(Program mode can be selected at all ti mes, no need to disconnect pow er)

1) Display the sta tus of all in puts simulta neously

2) Display all active inputs

3) Display active inp ut with highe st priority

4) Display text mess ages in a ‘tickertap e’-fashion

1) Display the status of all inputs simultaneously :

All inputs are displayed. An ‘x’ appears on the right hand side of an active (ground ed) input.

2) Display all active inputs :

MODE 1 2

1

2

3

4

DIPSWITCH SW1

OFF OFF

OFF ON

ON OFF

ON ON

For every active i nput, a corr esponding mes sage is dis played. The re is a del ay between

each message, to allow the user to read the message. Message 9 is displ ayed when no

inputs are active.

3) Display active input with highest priority :

Message 1 has highest priority , message 8 has lowest p riority .

Only one message w ill be display ed. Message 9 is displ ayed when no inputs are active.

4) Display text messages in a ‘tickertape’-fashion :

This mode allows you to send messages to the K8045 from a remote location by either

RS232 cable or opt ional wireles s link (see page 11) a nd display them on-scr een. If the

message exceeds 16 ch aracters, th e message scro lls to the le ft.

An ID# can be assigne d to the K8045 r anging fro m 0 to 9 (de fault : 0). Th is allows y ou to

determine which K8 045 will recei ve and disp lay the mess age, which i s handy for w ireless

link applications. In this w ay, up to ten K8 045 units can be indiv idually addressed.

You can download a small program from our

website www.velleman.be which allows you to

set the ID # and send messages in a simple

fashion to your K8045. The source code is supplied, for users who w ould like to mod ify the code

for their proper applications.

14

Page 15

Options & examples

28. Options & examples

Options :

RF wireless link : ......................................................................... RX433/TX433

HQ supertwist LCD display : .........................................................LCD1601ASL

Application examples :

1. Home alarm system : let your alarm system tell you what sensor has

been triggered

2. Replace car indicator lamps

15

Page 16

Options & examples

3. Application with K8023 “Two wire 10-channel remote control”

GND

+ Vext

10

9

8

7

6

5

4

3

2

1

- VTX

+ VTX

P8023S

10

9

8

7

6

5

4

3

2

1

COM

+ VTX

K8023

K8045

12 ... 15Vin

P8023R

12V / 300mA

GND

GND

8

7

6

5

4

3

2

1

VB

VA

GND

2 x 9 VAC / 150mA

16

Page 17

PCB

&

DIAGRAMS

17

Page 18

PCB

PCB

18

Page 19

Diagram

Diagrams

19

Page 20

VELLEMAN COMPONENTS NV

Legen Heirweg 33

9890 Gavere

Belgium Europe

Info & support: www.velleman.be

Modifications and typographical errors reserved

© Velleman Components NV

H8045IP - 2002 - ED1

Loading...

Loading...