Page 1

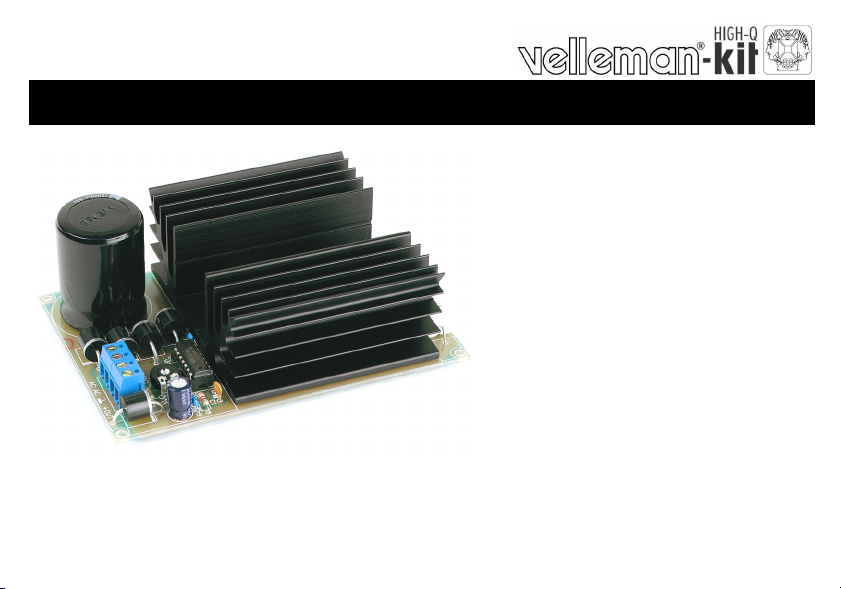

Total solder points: 57

Difficulty level: beginner 1 2 3 4 5 advanced

3 TO 30VDC / 3A POWER SUPPLY

K7203

d

e

s

a

b

,

s

t

i

k

r

u

o

l

l

a

o

p

A

ILLUSTRATED ASSEMBLY MANUAL H7203IP-1

s

a

n

o

e

s

i

l

i

b

a

t

v

C

D

d

p

u

s

r

e

w

o

e

g

a

t

l

o

r

fo

y

l

p

.

V

0

3

f

Page 2

Features

This kit is meant as an auxiliary or as a permanent power supply for all common Velleman kits based on a

stabilized DC voltage between 3 and 30V provided that the consumption does not exceed 3A.

Of course this power supply unit can be used for other purposes, as long as the maximum specifications are

taken into account.

Technical data :

Short circuit protected

Overload protected

Heatsink included

Output voltage: adjustable 3 to 30V stabilized.

Output current: max. 3A

Output ripple voltage: 0.5mV.

Input: 9 to 30V transformer, depending on the desired output

Dimensions (LxWxH): 130x91x50mm

Transformer not included

2

Page 3

Assembly hints

0

.

0

0

0

1. Assembly (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project successful. Read them carefully.

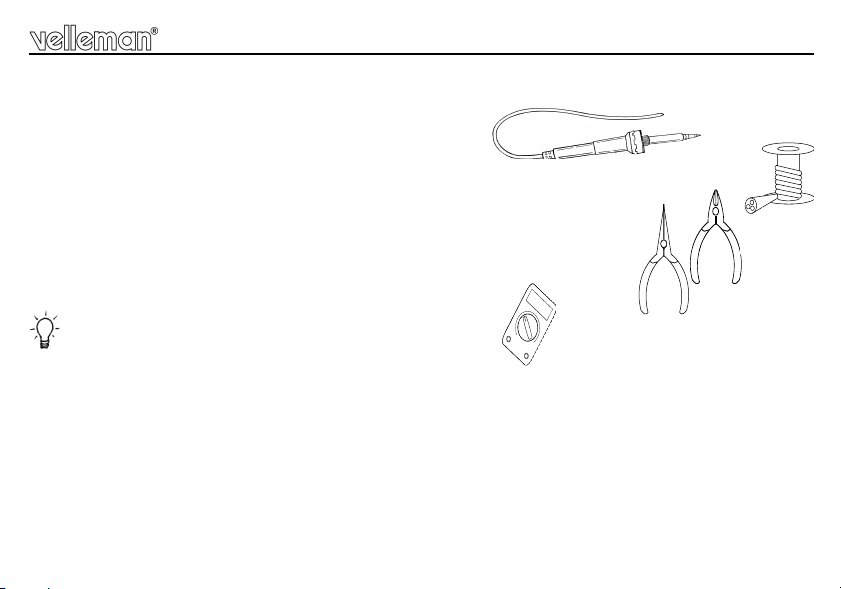

1.1 Make sure you have the right tools:

• A good quality soldering iron (25-40W) with a small tip.

• Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to the tip, to give it a wet look. This is called ‘thinning’ and will

protect the tip, and enables you to make good connections. W hen solder rolls off the tip, it needs cleaning.

• Thin raisin-core solder. Do not use any flux or grease.

• A diagonal cutter to trim excess wires. To avoid injury when cutting excess leads, hold the lead so they

cannot fly towards the eyes.

• Needle nose pliers, for bending leads, or to hold components in place.

• Small blade and Phillips screwdrivers. A basic range is fine.

For some projects, a basic multi-meter is required, or might be handy

1.2 Assembly Hints :

⇒ Make sure the skill level matches your experience, to avoid disappointments.

⇒ Follow the instructions carefully. Read and understand the entire step before you perform each operation.

⇒ Perform the assembly in the correct order as stated in this manual

⇒ Position all parts on the PCB (Printed Circuit Board) as shown on the drawings.

⇒ Values on the circuit diagram are subject to changes.

⇒ Values in this assembly guide are correct*

⇒ Use the check-boxes to mark your progress.

⇒ Please read the included information on safety and customer service

* Typographical inaccuracies excluded. Always look for possible last minute manual updates, indicated as ‘NOTE’ on a separate leaflet.

3

Page 4

Assembly hints

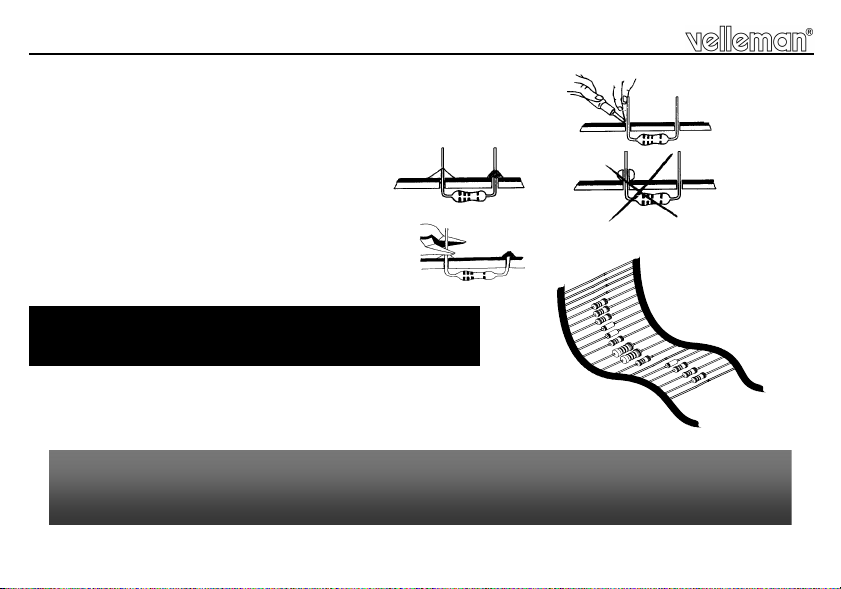

1.3 Soldering Hints :

1- Mount the component against the PCB surface and carefully solder the leads

2- Make sure the solder joints are cone-shaped and shiny

3- Trim excess leads as close as possible to the solder joint

AXIAL COMPONENTS ARE TAPED IN THE CORRECT

MOUNTING SEQUENCE !

REMOVE THEM FROM THE TAPE ONE AT A TIME !

You will find the colour code for the resistances and the LEDs in the HALG

(general manual) and on our website: http://www.velleman.be/common/service.aspx

4

Page 5

Construction

RV1

D.

CATHODE

1. Resistors

R1 : 8K2 (8 - 2 - 2 - B)

(Uout = output voltage)

R2

Uout 3...8V : 5K6 (5 - 6 - 2 - B)

Uout 8...30V : 2K2 (2 - 2 - 2 - B)

R3 : 680 (6 - 8 - 1 - B)

R4 : 1K (1 - 0 - 2 - B)

R5 : 82K (8 - 2 - 3 - B)

R...

2. IC sockets, Watch the

position of the notch !

IC1 : 14P

3. Capacitors.

C...

C1 : 470pF (471)

C2 : 100nF (104)

C3 : 100nF (104)

4. Resistor trimmer

RV1 : 10K

5. Diodes. Watch the polarity!

D1 : 6A2 or 6A6

D2 : 6A2

D3 : 6A2

6A6

D4 : 6A2

D5 : 6A2

D6 : 6A2

or 6A6

or

or 6A6

or 6A6

or 6A6

6. 5W resistor.

R6 : 0.18E

R...

2mm

7. Screw connectors

J1 : 2 x 2p

8. Electrolytic Capacitor.

Watch the polarity !

C4 : 100µF

C5 : 10.000µF

C...

5

Page 6

Construction

9. Power transistor

T1 : MJ3001 or 2N6284G

Apply some thermo-conducting

pasta to the bottom side of the

transistor and mount it on the

PCB simultaneously with the

cooling profile following the

instructions in the figure 1.0.

PCB

M3 NUT

LOCK WASHER

TRANSISTOR

HEATSINK

10. IC. Watch the position of

the notch!

IC1 : UA723D

Fig 1.0

6

M3 BOLT

Page 7

Assembly into a housing

11. Assembly into a housing

Depending on the transformer used, one may chose one of two housings with the following reference nr. for

ordering: L750 or L760.

If the circuit is to be integrated into another housing, it must be provided with ventilation holes (one may

make these holes oneself), necessary for the release of the heat developed.

If a metal housing is used, it must be earthed for security purposes.

Make sure the cooling body does not touch the housing. This might cause a short circuit.

When mounting a toroidal transformer, it must be seen to that the fixation bolt does not touch the cover. This

might cause the burning of the transformer

7

Page 8

Connection

12. Connection

Depending on the output voltage needed, one should chose the right transformer for connection to the circuit

according to the table in the parts list. If one choses too high an input voltage, it may well be so that the

power transistor is overheated.

The secondary winding of the transformer is connected to the AC points. It may be that the transformer has

two secondary windings which should be connected either in parallel or in series. The colour code can be

found on the packaging.

For safety reasons, the primary winding of the transformer is connected to the mains voltage via a mains

switch and a fuse. The rating of the fuse can be selected from the table in the parts list.

Connect a voltage meter to the points ‘GND’ and ‘+OUT’ and adjust ‘RV1’ until the desired output voltage

is reached.

Connect the circuit to be supplied by the present unit between the points ‘GND’ and ‘+OUT’. Watch the

polarity!

8

Page 9

Connection

F

L

MAINS

N

Desired

regulated

output voltage

3...5V

5...8V 5K6 12V / 50VA - 5012 250mA Slow 500mA Slow

8...13V 2K2 15V / 50VA - 5015 250mA Slow 500mA Slow

13...15V 2K2 18V / 80VA - 8018 400mA Slow 800mA Slow

15...18V 2K2 22V / 80VA - 80220 400mA Slow 800mA Slow

18...22V 2K2 24V / 80VA - 8024 400mA Slow 800mA Slow

22...30V 2K2 30V /120VA - 12030 800mA Slow 1.5A Slow

TRANSFORMER

LOAD

-

+

R2 Desired transformer

5K6

9V / 30VA - 309 160mA Slow 315mA Slow

ordercode

only @230VAC

AC

AC

GND

+OUT

Desired fuse

230VAC

K7203

Desired fuse

110VAC

9

Page 10

PCB

13. PCB layout.

10

Page 11

14. Diagram

AC

T

Diagram

NPUT

AC

D2

6A6

D1

6A6

6A6

6A6

D3

D4

10000u

C5

VOLTAGE ADJUST

RV1

10K

R3

680

C2

100n

NC

NC

NC

NC

REF

NON INV

12 11

10

VC

2

3

OUT

CL

CS

V+

1

8

9

14

IC1

723

13

INV

C1

470p

COMP

64

5

7

V-

82K

R5

MJ3001

R4

1K

0.18/5W

R6

8K2

R2

2K2

R1

T1

D5

6A6

C3

100n

C4

100u

D6

6A6

+

OUTPU

GND

11

Page 12

Modifications and typographical errors reserved

2928974

4

© Velleman Components nv.

H7203IP - 2010 - ED1 (Rev.1)

VELLEMAN Components NV

Legen Heirweg 33

9890 Gavere

Belgium Europe

www.velleman.be

www.velleman-kit.com

54103

Loading...

Loading...