Page 1

Total solder points: 24

Difficulty level: beginner 1 2 3 4 5 advanc ed

1 A POWER SUPPLY

K1823

r

u

o

y

r

e

w

o

p

o

t

y

a

w

y

s

a

e

e

h

T

Specifications

Great to power your projects and save money on

batteries

Suitable as an adjustable power supply for experiments

Control DC motors, low voltage light bulbs, …

Short-circuit, thermal and overload protection

Dimensions : 52x30mm (2.1” x 1.2”)

ILLUSTRATED ASSEMBLY MANUAL H1823IP-1

o

r

p

.

s

t

c

e

j

Page 2

Features & Specific ations

Features

Just add a suitable transformer (see table)

Great to power your projects and sa ve money on batteries

Suitable as an adjustable power supply for experiments

Control DC motors, low voltage light bulbs, …

Specifications :

Preset any voltage between 1.5 and 35V

Very low ripple (80dB rejection)

Short-circuit, thermal and overload protection

Max input voltage : 28VAC or 40VDC

Max dissipation : 15W (with heatsink)

Dimensions : 52x30mm (2.1” x 1.2”)

Choose the right transformer

Max DC output voltage Transformer rating

3..5V 9VAC / 15VA

5..8V 12VAC / 30VA

8..13V 15VAC / 30VA

13..15V 18VAC / 30VA

15..18V 22VAC / 30VA

18..22V 24VAC / 50VA

22..35V 28VAC / 50VA

2

Page 3

Assembly hints

0

.

0

0

0

1. Assembly (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project successful. Read them carefully.

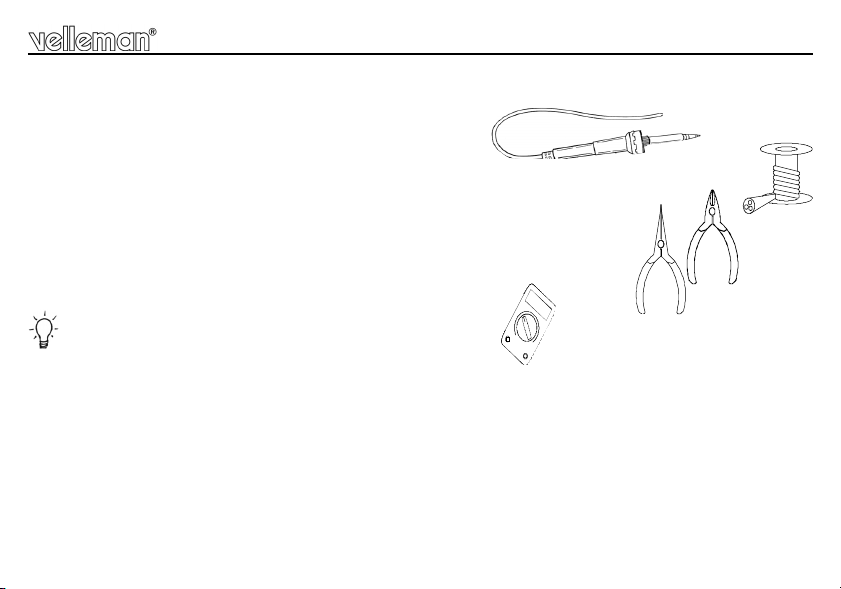

1.1 Make sure you have the right tools:

• A good quality soldering iron (25-40W) with a small tip.

• Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to the tip, to give it a wet look. This is called ‘thinning’ and will

protect the tip, and enables you to make good connections. When solder rolls off the tip, it needs cleaning.

• Thin raisin-core solder. Do not use any flux or grease.

• A diagonal cutter to trim excess wires. To avoid inju ry when cut ting e xcess lea ds, hold t he lead so they

cannot fly towards the eyes.

• Needle nose pliers, for bending leads, or to hold components in place.

• Small blade and Phillips screwdrivers. A basic range is fine.

For some projects, a basic multi-meter is required, or might be handy

1.2 Assembly Hints :

⇒ Make sure the skill level matches your experience, to avoid disappointments.

⇒ Follow the instructions carefully. Read and understand the entire step before you perform each operation.

⇒ Perform the assembly in the correct order as stated in this manual

⇒ Position all parts on the PCB (Printed Circuit Board) as shown on the drawings.

⇒ Values on the circuit diagram are subject to changes.

⇒ Values in this assembly guide are correct*

⇒ Use the check-boxes to mark your progress.

⇒ Please read the included information on safety and customer service

* Typograp hical inaccuracies excluded. A lways look for pos sible last minut e manual updates, indicated as ‘NOTE’ on a separat e leaflet.

3

Page 4

Assembly hints

1.3 Soldering Hints :

1- Mount the component against the PCB surface and carefully solder the leads

2- Make sure the solder joints are cone-shaped and shiny

3- Trim excess leads as close as possible to the solder joint

DO NOT BLINDLY FOLLOW THE ORDER OF THE

COMPONENTS ONTO THE TAPE. ALWAYS CHECK

THEIR VALUE ON THE PARTS LIST!

REMOVE THEM FROM THE TAPE ONE AT A TIME !

4

Page 5

Construction

IC

1. Diodes. Watch the polarity !

D1 : 1N4007

D2 : 1N4007

D3 : 1N4007

D4 : 1N4007

CATHODE

D. . .

2. Resistor

R1 : 120 (1 - 2 - 1 - B)

3. Trim potentiometer

R...

RV1 : 4K7

4. Capacitors.

c...

C1 : 0,1µF, 100nF (104)

5. Terminal blocks

SK1

SK2

6. Electrolytic Capacitor.

Watch the polarity !

C2 : 1µF

C3 : 10µF

C...

7. Voltage regulator

VR1 : LM317

It has not to be cooled if used for

small powers.

8. Electrolytic Capacitor.

Watch the polarity !

C4 : 2200µF

C...

5

Page 6

Connection example

9. Connection example

N

O

E

C

I

S

L

A

I

E

S

R

G

+

-

DC OUTPUT

DC output adjust

Fig. 1.0

6

Mica w asher

TO220

isolato r

ON-OFF SWITCH

ENCLOSURE

TRAN SF ORM ER

Execute the connecti on as

depicted in the figure. Connect

FUSEHOLDER

FUSE 250mA T

the alternating voltage of a

transformer with the ‘AC IN’

connections. Connect the

output voltage with the ‘+’ and

‘-‘ connections. Set the desired

output voltage with trimmer

RV1. Mount VR1 on a suitable

heatsin k for appl ic ati ons

AC P OWER

requiring more power.

Be sure to provide sufficient

electric insulation: fit an

ins ul at or and a pl ast ic

insulation ring between the

VR1 and the heatsink because

STRAIN RELIEF

the metal side of the VR1 is

elec tric ally con nect ed w it h t he

rest of the circuit.

Replac e the t rimm er w ith a

potentiometer of the same

rating if you want to use the

circu it as a perm anently

adjustable power supply.

Page 7

PCB & diagram

10. PCB layout.

11. Diagram 10. PCB layout.

7

Page 8

Modifications and typographical errors reserved - © Velleman nv. H1823IP - 2008 - ED1 (rev3)

5 410329 310363

Loading...

Loading...