Page 1

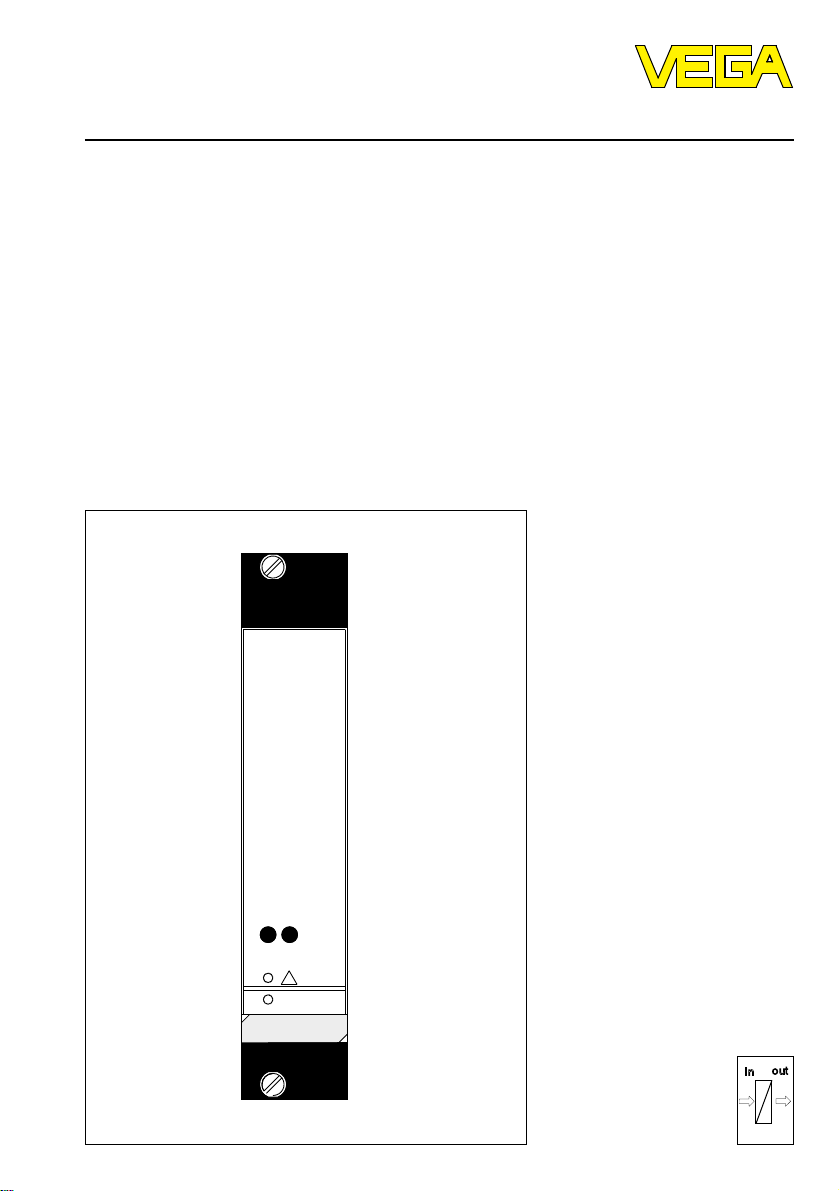

Operating Instruction

VEGATRENN 544 Ex

Level and Pressure

!

on

VEGATRENN

CONNECT

544 Ex

out

in

Page 2

Contents

Safety information ........................................................................................ 2

1 Product description

1.1 Function and configuration ................................................................. 3

1.2 Application .......................................................................................... 4

1.3 Approval ............................................................................................. 4

1.4 Technical data ..................................................................................... 5

1.5 Dimensions ......................................................................................... 7

2 Mounting

2.1 Mounting versions............................................................................... 8

2.2 Instrument address ............................................................................. 9

3 Electrical connection ......................................................................... 10

4 Set-up

4.1 Indicating and operating elements ................................................... 10

4.2 Adjustment via PC ............................................................................ 11

4.3 Set-up sequence .............................................................................. 11

Contents

5 Diagnosis

5.1 Maintenance ..................................................................................... 11

5.2 Repair ............................................................................................... 11

5.3 Fault signal........................................................................................ 11

Safety information

The described module must only be inserted and operated as described in this operating instruction. Please

note that other action can cause damage for which VEGA

does not take responsibility.

2 VEGATRENN 544 Ex

Page 3

Product description

1 Product description

1.1 Function and configuration

VEGATRENN 544 Ex Ex-separator powers via an

intrinsically safe circuit the respectively connected

sensor and processes in addition the measured data

of the sensor.

Function

The measured data of 4 ... 20 mA directly adjusted on

the sensor are processed in VEGATRENN 544 Ex into

a current and volt output as well as in a digital signal

output (DISBUS).

VEGATRENN 544 Ex is equipped with sockets for

connection of a VEGACONNECT connection cable. A

communication to a PC can be provided via

VEGACONNECT.

If necessary this combination enables in a very simple

way a parameter adjustment of the processing or

outputs or editing of linearization curves.

Configuration

VEGATRENN 544 Ex is mechanically designed in 19"technology (width 5 TE = 24,5 mm).

Electronically the instrument is microcomputer controlled and consists function technically out of software

components, see following sketch.

Sketch

Function component

- Measuring point MST

- 4 … 20 mA

neutral parameter

- Sensor

Input component

- Sensor 4 … 20 mA

FB

1

EB

1

VEGATRENN 544 Ex 3

AB

mA

V

AB

AB

PC

DIS

Output component

Current output 0 … 20 mA

Volt output 0 … 10 V

Fail safe relay

Digital output

- PC-/DCS-output

- DISBUS-output

Page 4

A

A

A

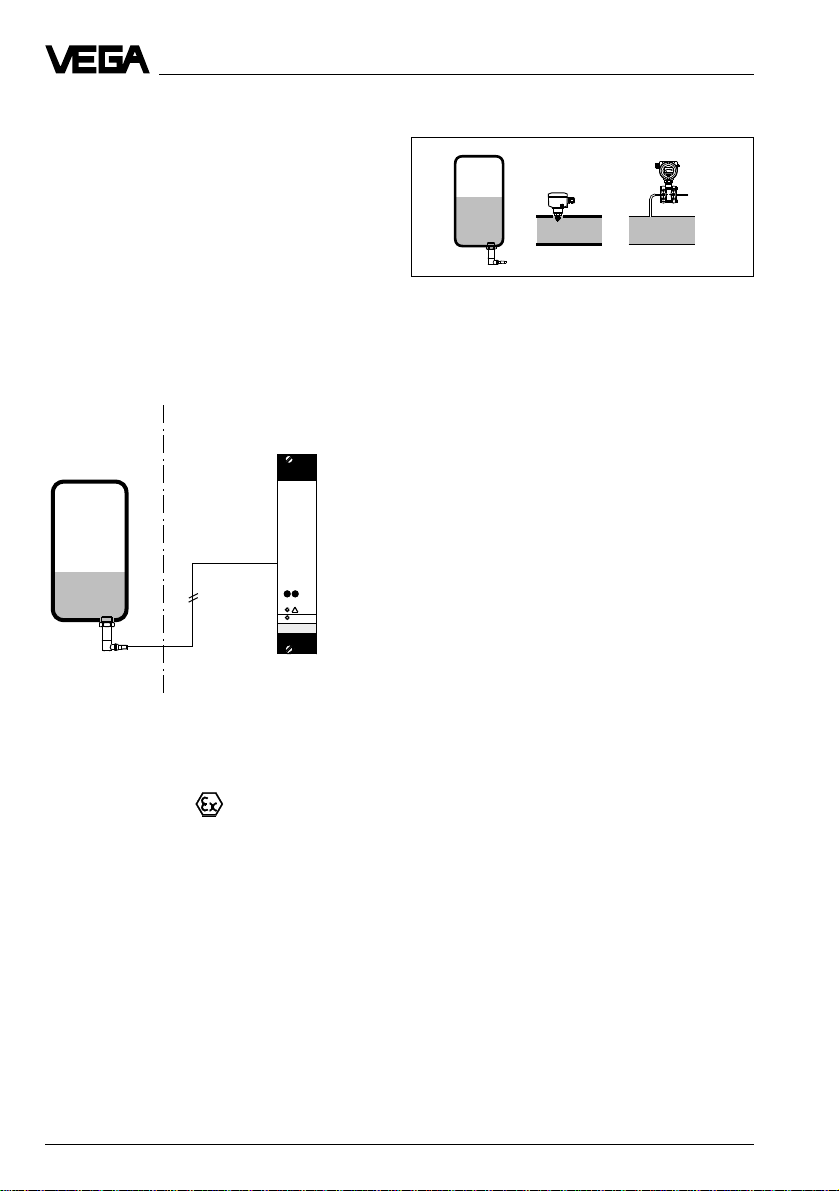

1.2 Application

Application: Level

Sensor: Range 4 … 20 mA

Hydrostatic pressure transmitter

Process pressure transmitter

Differential pressure transmitter

Parameter: MST1 4 … 20 mA neutral parameter

Exemplary application

Product description

Fig. 1.1 Level measurement

Ex-area

Ex-Sensor

4 … 20 mA

Not-Ex-area

intrinsically safe

circuit

VEGATRENN 544 Ex

Measuring point MST processing

- Current output

- Volt output

- DISBUS

- Fail safe relay

Parameter

- 4 … 20 mA neutral parameter

1.3 Approval

Ex-approval

For hazardous areas, certification to CENELEC defined in conformity certificate PTB-no. Ex-95.D.2145 X.

4 VEGATRENN 544 Ex

Page 5

Product description

1.4 Technical data

Power supply

Operating voltage U

Power consumption appr. 7 VA or appr. 5 W

Measuring data input

Number 1 input

Kind of input active two-wire input, analogue

Range 4 … 20 mA

Sensor hydrostatic pressure transmitter,

Voltage at 4 mA ca. 18 V DC, at 20 mA appr. 15 V DC

Current limitation at appr. 26 mA, shortcircuit proof

Detection line break < 2 mA

Detection shortcircuit > 23 mA

Connection line 2-wire (standard line)

Resistance per conductor max. 35 Ω

Resolution 1 µA

Linearity error 0,025 % at 4 … 20 mA

Temperature error 0,04 %/10 K at 4 … 20 mA

Measuring data input, Ex-technical data

Classification [EEx ia] IIC, [EEx ia] IIB, [EEx ib] IIC or [EEx ib] IIB

Max. values

- Voltage UO = 20 V

- Current I

- Power P

Characteristics linear

Effective inner inductance L

Effective inner capacitance C

i

i

Max. permissible outer inductance LO (mH) 0,5 1 1,5 2 2 9

Max. permissible outer capacitance CO (nF) 97 78 68 486 200 1000

= 24 V AC (20 … 53 V), 50/60 Hz

nenn

= 24 V DC (20 … 72 V)

process pressure transmitter,

differential pressure transmitter

= 128 mA

O

= 640 mW

O

negligible

negligible

EEx ia IIC EEx ia IIB EEx ib IIC EEx ib IIB

The intrinsically safe circuits are reliably separated from the not-intrinsically safe circuits up to a peak value of

the nominal voltage of 375 V.

The max. voltage on the not-intrinsically safe circuits must not exceed 250 V

in case of failure.

eff

Current output

Number 1 output

Function analogue output of processing results

Range 0/4 … 20 mA

Load max. 500 Ω

Resolution 0,05 % of range

Linearity error 0,05 % of range

Temperature error 0,05 %/10 k of range

>>

VEGATRENN 544 Ex 5

Page 6

Product description

Voltage output

Number 1 output

Function analogue output of processing results

Range 0/2 … 10 V

Current max. 1 mA

Resolution 0,05 % of range

Linearity error 0,05 % of range

Temperature error 0,06 %/10 k of range

Fail safe relay

Contact 1 floating spdt

AgNiO and hard gold plated

Turn-on voltage min. 10 mV DC

max. 250 V AC/DC

Switching current min. 10 µA

max. 3 A AC, 1 A DC

Breaking capacity max. 500 VA, 54 W

DISBUS-output

Function digital transmission of processing results and

system informations to VEGADIS 174 or

VEGACOM 557

Connection line 2-wire (screened)

Line length max. 1000 m

Indicating element

LED in front plate green on: operating voltage on

red: fault signal

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +80°C

Electrical connection

Multiple plug component to DIN 41 612, series F, 36-pole triple row d, b, z

(partly equipped)

Carrier BGT 596 (Ex) connection to appropriate module

Housing type 505 connection to screw terminals (max. 2,5 mm

Electrical protective measures

Protection

- not mounted IP 00

- mounted in carrier BGT 596 Ex.M

front completely equipped: IP 40

upper and lower side: IP 20

wiring side: IP 00

- mounted into housing type 505

- terminal side IP 20

- housing in general IP 30

Protection class II (in housing type 505)

Overvoltage category II

2

)

>>

6 VEGATRENN 544 Ex

Page 7

Product description

Electrical separating measures

Reliable separation acc. to VDE 0106,

part 1 between power supply, measuring data input

- Limit voltage 250 V

- Isolation resistance 2,3 kV

Common reference potential at voltage/current output

Mechanical data

Series module unit for carrier BGT 596 Ex.M

or housing type 505

Dimensions unassembled W = 25, 4 mm (5 TE), H = 128,4 mm, D = 162 mm

CE-approval, conformity judgement

VEGATRENN 544 Ex signal conditioning instrument meets the protective regulations of EMVG (89/336/EWG)

and NSR (73/23/EWG). The conformity has been judged acc. to the following standards by means of a typical

configuration:

EMVG Emission EN 50 081 - 2: 1993

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

1.5 Dimensions

Circuit board 100 x 160 x 1,5

European size Multiple plug

5 TE

128,4

CONNECT

on

544 Ex

25

14,5

100

VEGATRENN

Ser.No.12345678

9

3

162

VEGATRENN 544 Ex 7

Page 8

2 Mounting

2.1 Mounting versions

VEGATRENN 544 Ex separator can be either mounted

with a module in a carrier BGT 596 Ex.M or in a single

housing type 505.

Module Ex

Multipoint connector DIN 41 612, series F, 33-pole (d,

b, z) with coded pins, Ex-separating chamber and

mounting material for mounting in carrier

BGT 596 Ex.M.

Single housing

Plastic housing type 505 for single mounting.

Mounting carrier

Mount the respective module (Ex-version) in the

carrier. Wire the connections of the multipoint connector according to the wiring plan on the following

pages.

The multipoint connector is available as follows:

- Wire-Wrap standard connection 1,0 x 1,0 mm

- plug connection 2,8 x 0,8 mm

- Termi-Point Standard connection 1,6 x 0,8 mm

- soldering connection

- screw terminals 2 x 0,5 mm

For further information concerning mounting see

operating instruction of the carrier.

Mounting single housing

You can either screw the housing socket directly to the

mounting plate or plug on a carrier rail (TS 35 x 7,5

acc. to EN 50 022 or TS 32 acc. to EN 50 035). Connect the terminals according to the wiring plan on the

following pages. For further information to mounting

see operating instruction of the housing.

Transparent cover

To protect the housing against unauthorized operation,

the front plate of VEGATRENN can be provided with a

lockable transparent cover.

2

Mounting

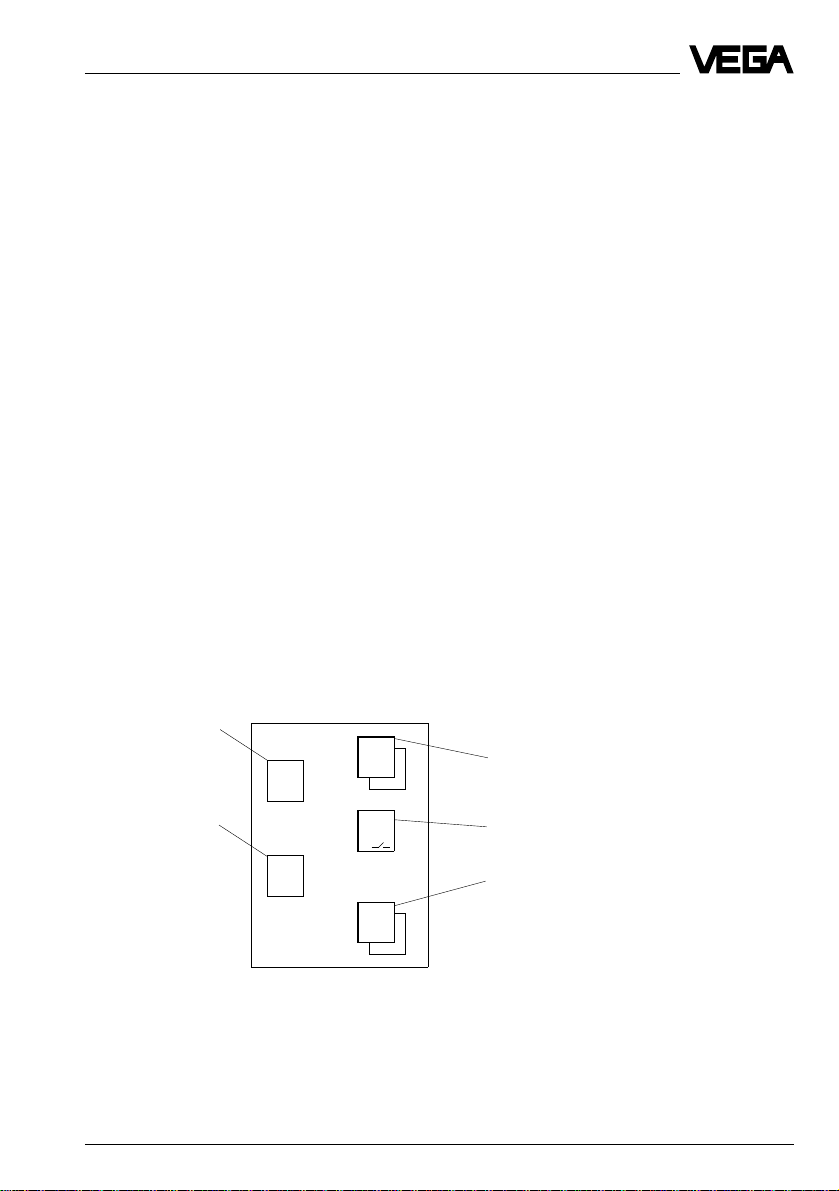

Coding

To avoid interchanging of the various signal conditioning instruments, the multipoint connector of the carrier

or the housing is provided with pins and the multiple

plug of VEGATRENN with holes (mechanical coding).

An Ex-coding with fixed coded pin ensures that not-Ex

and Ex-instruments are not interchanged.

An instrument coding ensures that the various signal

conditioning instruments are not interchanged. The

respective coded pins are attached to each module or

housing. Provide the multipoint connector with these

coded pins acc. to the following schedule and figure.

Instrument Ex-

coding coding

VEGAMET 514 D a5 / c5

VEGAMET 514 D Ex a5 / c5 c23

VEGAMET 514 VD a7 / c5

Fig. 2.1 Coding schedule

Instrument coding Function coding

z b d

544

a1

a c

o 1 o

o 3 o

o 5 o

o 7 o

o 9 o

o11o

o13o

o15o

o17o

o19o

o21o

o23o

o25o

o27o

o29o

o31o

c5

c23

VEGATRENN

Ex-coding

Fig. 2.2 Module coding, VEGATRENN

8 VEGATRENN 544 Ex

Page 9

Mounting

Ex-version

Note!

VEGATRENN must be generally mounted outside

hazardous areas or special Ex-protective measures

must be taken.

Ex-separating chamber

To ensure suffcient "air and creeping distances", an

Ex-separating chamber must be mounted to the

connections of VEGATRENN. Loop the wires through

the Ex-separating chamber and connect them. Fasten

the Ex-separating chamber with the lower screw.

Observe the operating instruction of carrier

BGT 596 Ex.M.

Protection for Ex-applications

In Ex-applications a protection of IP 20 must be kept.

Cover the spaces or not used modules from the front

by appropriate blind covers.

Mounting in carriers

If you mount your VEGATRENN with Ex-approval in a

carrier, you have to use a VEGA-Ex-module. Keep a

distance of at least 10 mm (2 TE) to modules of other

manufacturers. If you want to mount the VEGATRENN

in the extreme left position in the carrier, you have to

mount a blind cover of at least 20 mm (4 TE) in front of

the module of the instrument.

2.2 Instrument address

Adjust on the respective switch on the circuit board

the instrument address. Address range 1 … 15. Observe that no double coordination is made. Factory

setting = instrument address 0

8

9

7

A

6

5

4

33

E

2

F

1

0

corresp.

B

C

D

10

11

12

13

14

15

on

VEGATRENN

544 Ex

Blind cover

VEGATRENN 544 Ex 9

Page 10

3 Electrical connection

Electrical connection / Set-up

VEGA TRENN 544 Ex

d b z

+-

10

12

16

18

20

22

24

28

30

32

2

6

+

+

+

-

Fail safe relay

+

DISBUS-output

-

Supply

voltage

Current output

Voltage output

L (+)

N (-)

+

-

Sensor

4 Set-up

4.1 Indicating and operating elements

Ex-version

For connection of Ex-certified instruments observe the

instructions in the attached legal documents as well as

in the valid mounting instructions. Note that the Exseparating chamber is mounted on the multipoint

connector. Always loop the wires through the Exseparating chamber. Observe the operating instruction

of the carrier BGT 596 Ex.M and the Ex-instructions.

1

8

1 Fixing screw lockable

2 Connection for VEGACONNECT

connection cable

3 LED fault signal

4 LED supply voltage

5 Ledge

7

6

6 Multiple plug with wiring plan

7 Position of the switch for adjustment

of the instrument address

8 Transparent cover

2

3

4

5

1

CONNECT

!

on

VEGATRENN

544 Ex

Ser.No.12345678

Fig. 4.1

10 VEGATRENN 544 Ex

Page 11

Set-up / Diagnosis

5 Diagnosis

4.2 Adjustment via PC

Parameter adjustment and editing

- exclusively by means of a PC, provided

with VVO-Software (VEGA Visual Operating) and a VEGACONNECT connection cable

CONNECT

!

on

VEGATRENN

Ser.No.12345678

544 Ex

VEGACONNECT

connection cable

PC with VVO-Software

4.3 Set-up sequence

- Prepare electrical connection

- Adjust sensor (4 … 20 mA)

- Adjust instrument address

if necessary via PC and VEGACONNECT

5.1 Maintenance

The instrument is maintenance-free.

5.2 Repair

Due to safety and guarantee reasons repair work

beside the wiring must only be made by VEGA-staff.

In case of a defect please return the respective instrument with a short description of the error to our repair

department.

5.3 Fault signal

The instrument and the connected sensor are permanently monitored during operation.

In case of failure the fail safe relay de-energizes, the

failure LED lights and the outputs react according to

the given control reaction.

In case of failure information texts can be displayed on

the PC as described under "4.2 Adjustment via PC".

Parameter adjustment of the processing

- scaling (allocation of a multiplication factor)

- linearization

- integration time

Parameter adjustment of the outputs

- relation and range of the current output

- failure reaction of the current output

- relation and range of the Volt output

- failure reaction of the Volt output

- relation and unit of the PC/DCS-output

- relation and unit of the DISBUS-output

Additional functions

- parameter adjustment of the password

- edit linearization curve 1 … 3

VEGATRENN 544 Ex 11

Page 12

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

Fax (0 78 36) 50 - 203

ISO 9001

12 VEGATRENN 544 Ex

Technical data subject to alterations 2.20 174 / April '96

Loading...

Loading...