Page 1

Operating Instructions

VEGATOR 536 Ex

TEST

2

on

VEGATOR

536 Ex

Page 2

Contents

Safety information ........................................................................ 2

Note Ex-area ................................................................................ 2

1 Product description .................................................................. 3

1.1 Configuration ........................................................................ 3

1.2 Technical data ....................................................................... 3

1.3 Dimensions ........................................................................... 5

2 Mounting ..................................................................................... 6

3 Electrical connection ................................................................ 8

3.1 Connection plan ................................................................... 9

4 Set-up ........................................................................................ 10

5 Diagnosis .................................................................................. 13

5.1 Recurring test acc. to WHG .............................................. 13

5.2 Failure removal ................................................................... 13

Contents

Safety information

The described module must only be installed

and operated as described in these operating

instructions. Please note that other action can

cause damage for which VEGA does not take

responsibility.

2 VEGATOR 536 Ex

Note Ex-area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the operating instructions manual and come with the Ex

approved instruments.

Page 3

Product description

1 Product description

1.1 Configuration

A measuring system with signal conditioning

instrument consisting of:

- a VEGAVIB series 50 with oscillator

VIB E50 Z (Ex)

- a VEGATOR 536 Ex signal conditioning

instrument

- external instruments switched by

VEGATOR

or

- a VEGASWING series 60 or 80A with oscillator SW E60ZEx, SW E82Z or SW E82ZEx

- a VEGATOR 536 Ex signal conditioning

instrument

- external instruments switched by

VEGATOR

1.2 Technical data

General

Series module unit for carrier BGT 596 Ex

Dimensions W = 25,4 mm (5 TE), H = 128,4 mm, D = 162 mm

Weight approx. 180 g

Test key (per channel) for function test

Ambient conditions

Ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +70°C

Power supply

Operating voltage 20 … 53 V AC, 20 … 72 V DC

Power consumption max. 3 W

Electrical connection multiple plug DIN 41 612,

Electrical protective measures

Protection class II

Overvoltage category II

Protection

- mounted into housing type 505 Ex IP 30

Protection

(mounted into carrier

BGT 596 Ex with Ex-module)

- front side (completely equipped) IP 30

- upper and lower side IP 20

- wiring side IP 00

VEGATOR 536 Ex 3

series F (d, b, z) 33-pole

Page 4

Product description

Inputs

Number 1 sensor input

Data transmission analogue

Switching threshold 12 mA

Current limitation 24 mA (permanently shortcircuit proof)

Sensor supply voltage 15 … 18 V DC

Connection line 2-wire

Resistance per conductor max. 35 Ω

Integration time 0,2 … 20 s

(adjustment via DIL-switch)

Relay output

Number, function 1 switching relay (spdt), 1 fail safe relay

Mode A/B-switch

A - max. detection or overfill protection

B - min. detection or dry run protection

Contact 1 spdt each

Contact material AgCdO and Au plated

Turn-on voltage min. 10 mV

max. 250 V AC, 250 V DC

Switching current min. 10 µA

max. 3 A AC, 1 A DC

Breaking capacity max. 500 VA AC, 54 W DC

Transistor output

Number, function 2, synchronously switching with the relays

Galvanic isolation floating

Max. values UB max. 36 V DC

IB max. 60 mA

Transistor voltage loss UCE min. - 1,5 V at IB 60 mA

Blocking current < 10 µA

Indicating elements

LED in the front plate

- green on operating voltage on

- yellow switch point control

- red fault signal

Explosion protection

Certificate conformity certificate

TÜV 01 ATEX 1781

Classification ATEX II GD EEx ia IIC/IIB

Please note the attached safety instructions containing important information on installation and

operation in Ex areas.

These safety instructions are part of the operating instructions manual and come with the Ex

approved instruments.

4 VEGATOR 536 Ex

Page 5

Product description

Electrical connection

Mounted into

- carrier BGT 596 Ex 33-pole multipoint connector, series F (d, b, z)

- in housing type 505 Ex screw terminal, max. for 1,5 mm

with coding holes

2

CE-conformity

VEGATOR 536 Ex signal conditioning instrument meets the protective regulations of EMVG

(89/336/EWG) and NSR (73/23/EWG). The conformity has been judged acc. to the following

standards:

EMVG Emission EN 50 081 - 1: 1993

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

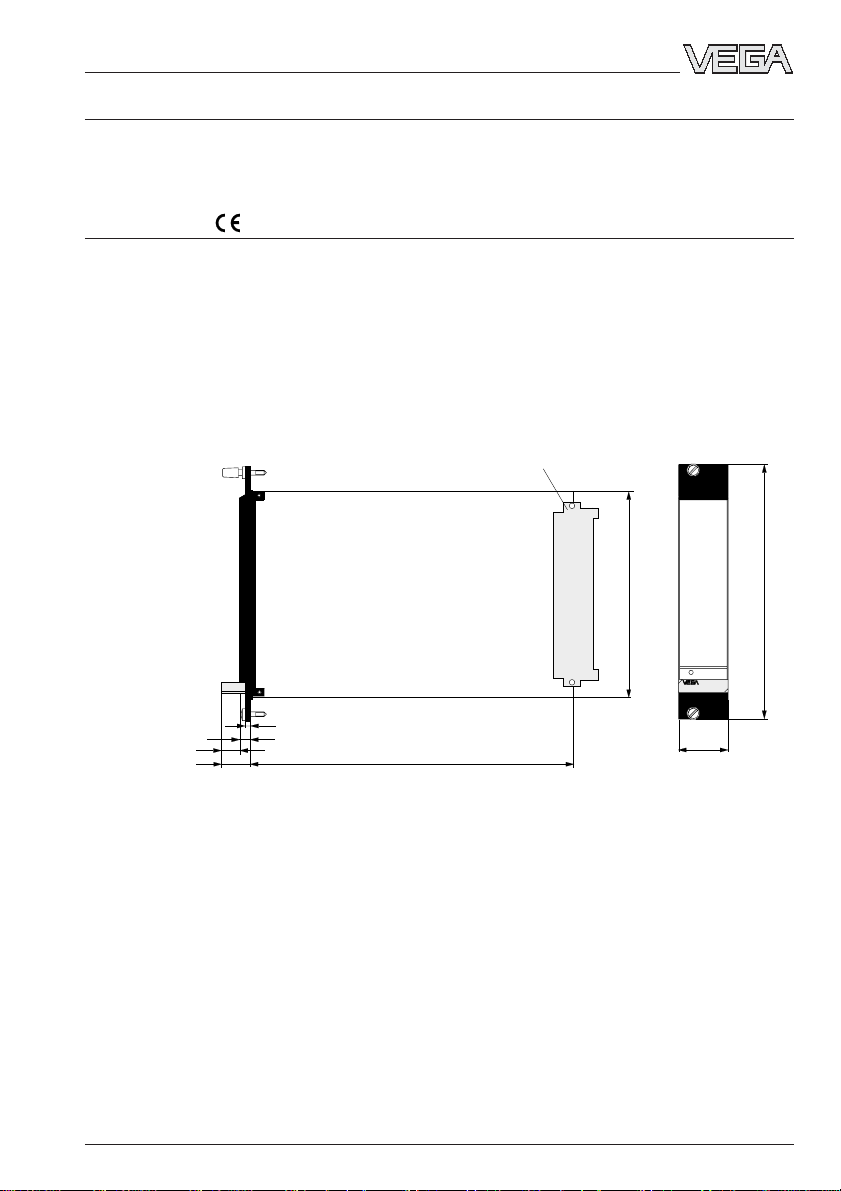

1.3 Dimensions

Circuit board 100 x 160 x 1,5

European size

Multiple plug

100

5 TE

128,4 (3 HE)

on

5,5

9

15

VEGATOR 536 Ex 5

3

162

25,4

Page 6

2 Mounting

VEGATOR can be either mounted with a

module in a carrier BGT 596 or in a single

housing type 505.

Mounting

Mounting single housing

Module (33)

for VEGATOR 536

Multipoint connector DIN 41 612, series F, 33pole (d, b, z) with coded pin and mounting

material for mounting in carrier BGT 596.

Module-Ex (33 Ex)

for VEGATOR 536 Ex

Multipoint connector DIN 41 612, series F, 33pole (d, b, z) with coded pin and mounting

material for mounting in carrier BGT 596 Ex.

Single housing

Plastic housing type 505 for single mounting

of signal conditioning instruments with an

instrument width of 5 TE (25,4 mm).

Mounting carrier

Mount the appropriate module (standard or

Ex-version) to your carrier BGT 596. Please

wire the connections of the multiple plug

according to the connection plans on the

following pages.

The multipoint connection is available as

follows:

- Wire-Wrap standard connection

1,0 x 1,0 mm

- Plug connection 2,8 x 0,8 mm

- Termi-Point standard connection

1,6 x 0,8 mm

- Soldering connection

- Screw terminals 2 x 0,5 mm

2

You can either screw the socket directly to

your mounting plate or plug on a carrier rail

(TS 35 x 7,5 acc. to EN 50 022 or TS 32 acc.

to EN 50 035). Connect the terminals of the

basic plate according to the connection plans

on the following pages. For further information

concerning mounting, see the operation instructions of the housing.

Transparent cover

The front plate of VEGATOR can be provided

with a lockable transparent cover to protect

the instrument against unauthorised adjustment. The cover is attached to the instrument.

For further information concerning mounting,

please see the operating instructions of the

carrier.

6 VEGATOR 536 Ex

Page 7

Mounting

Coding

The multiple plug of the instrument is provided with one or several coding holes to

avoid the interchanging of different instruments.

A fixed coded pin on the Ex-module ensures

that only the Ex-instrument can be inserted.

Two additional coded pins are attached to the

module to avoid the interchanging of different instruments. Insert the attached coded

pins into the appropriate holes on the

multipoint connector. The coded pins must be

inserted in the following positions:

Instrument Ex-coding

coding

VEGATOR 536 a17 / c7 ––

VEGATOR 536 Ex a17 / c7 c23

z b d

a c

o 1 o

o 3 o

o 5 o

o 7 o

o 9 o

o11o

o13o

o15o

VEGATOR 536

o17o

o19o

o21o

o23o

o25o

o27o

o29o

o31o

Fig. 2.8 Module 33 (Ex)

c7

c23

VEGATOR

Ex-coding

Ex-version

Ex-separating chamber

To ensure sufficient air and creeping distances, an Ex-separating chamber must be

mounted to the VEGATOR connections. Loop

the lines through the Ex-separating chamber

and connect the lines. Fasten the Ex-separating chamber with the lower hold screw.

Please note the operating instructions of the

BGT 596 carrier.

Mounting in carriers

When mounting VEGATOR with Ex-approval

in a carrier, you have to use a VEGA-Exmodule. Keep a distance of at least 10 mm (2

TE) to module cards of other manufacturers.

If you want to mount VEGATOR in the far left

position in the carrier, you have to mount a

blind cover of at least 20 mm (4 TE) first, and

then you can mount the instrument module.

2

on

VEGATOR

Blind cover

Protection in Ex-applications

In Ex-applications, a protection of IP 20

should be maintained. Cover the gaps or free

modules at the front by appropriate blind

covers.

Fig. 2.9

VEGATOR 536 Ex 7

Page 8

3 Electrical connection

Electrical connection

Danger

Please switch off the power supply before

starting connection. Connect mains voltage

according to the following diagram.

When connecting to the supply voltage or

reconnecting the sensor, the instrument

passes a function test. See also 5.1 Recurring test acc. to WHG.

In addition, two transistor outputs are available switching synchronously with the relays.

Reset of alarm functions

Module with multipoint connector acc. to

DIN 41 612 for carrier (rear view)

d b z

2

4

6

8

10

12

14

16

18

20

22

24

Ex-separating chamber

26

28

30

32

You can use the fail safe relay of VEGATOR

536 Ex as second level relay for a signaller

(horn etc.). To deactivate the connected

signaller (horn, lamp etc.) in case of a level

alarm (e.g. reaching of the max. permissible

level), an additional key (opener) can be

connected to VEGATOR 536 Ex. This key can

deactivate a level alarm. In case of failure

(e.g. line break), the alarm is not deleted.

When the key is connected, the fail safe relay

has the same function as the level relay, however the fail safe relay can be reset by

pressing the key for reset of alarm functions.

When, on reaching the max. level, e.g. an

acoustic warning system is activated, this

can be switched off by pressing the key for

reset of alarm functions. The second output

(level relay) still signals the reaching of the

max. level to the processing system.

Note

If very strong electromagnetic interferences

are expected, we recommend the use of

screened cable. The screening of the cable

must only be earthed on one sensor end. The

following connection plans show the

currentless condition.

Sensor 1

2 3

1

Sensor

channel 1

8 VEGATOR 536 Ex

Page 9

Electrical connection

Double-pole double-throw switch

(DPDT)

VEGATOR 536 Ex can also be operated with

double-pole double-throw switch output

(DPDT). The fail safe relay has the same

function as the level relay. To achieve this

function, the contacts z16 and z18 (reset of

alarm functions) must be bridged.

If you neither need the reset of alarm functions nor the function of the double-pole double-throw switch, the connections Z16 and

Z18 will be free.

Level relay

Level relay

Supply

voltage

Fail safe transistor

Level transistor

L1 (+)

N (–)

d b z

+–

2

6

10

12

+

16

–

18

+

20

–

22

24

3.1 Connection plan

All contacts in release condition

d b z

+–

2

6

10

12

+

16

–

18

+

20

–

22

24

28

+

30

–

32

+

–

L1 (+)

N (–)

Supply

voltage

Fail safe transistor

Level transistor

Fail safe relay

Level relay

Reset of

alarm

functions

28

+

+

–

30

–

32

VEGATOR 536 Ex 9

Page 10

4 Set-up

Indicating and adjustment elements

off

1

1 2 3 4 5 6

on

10

1 Connection plan

2 Lockable screw

3 Test key 1) channel 1

4 LED-level relay 1

5 LED-fault signal channel 1

9

1

2

3

TEST

4

5

on

VEGATOR

6

7

8

6 LED-supply voltage

7 Screw

8 Multiple plug

9 DIL-switch block for channel 1

10 Transparent cover

Set-up

1

536

1)

Recurring test acc. to WHG

In accordance with the type approval acc. to WHG (Z-65.11-154, Z-65.11-285) the recurring test acc. to

WHG can be carried out by pressing the test key on the VEGATOR signal conditioning instrument. The

sensor must neither be removed nor a response be triggered by filling the vessel. This applies to

VEGASWING 61Ex, 63Ex, 81AEx and 83AEx with two-wire oscillator SW E60ZEx, SW E82ZEx.

10 VEGATOR 536 Ex

Page 11

Set-up

Signal lamps

LEDs in the front plate show operation,

switching condition and failures.

Green

- Operating control lamp (6)

- Mains voltage on, instrument in operation.

Red

- Failure lamp (5)

- Failure on the individual sensor current

circuit by sensor failure or line defect.

- When the fail safe relay is denergised, the

red signal lamp lights.

Yellow

- Relay control lamp (4)

- The yellow signal lamp reacts depending

on the adjusted mode (A/B).

- The relay control lamps indicate the activated (energised) condition of the relay.

- A dark relay control lamp means that the

relay is in denergised condition.

DIL-switch block and potentiometer

The switch on and/or off delay can be adjusted independently with the switches 2 and

3. The switch on or off delay refers to the

switching conditioning of the relay and transistor outputs.

On the illustrated example mode A (max.

detection or overfill protection) is selected

(switch 1). The switch on delay is activated

(switch 3) and the integration time is adjusted

to 8 seconds (switch 4, 5 and 6).

sec

0

00

zaze26

sec

12

1 A/B-mode

2 Switch off delay

3 Switch on delay

4 Integration time +2 s

5 Integration time +6 s

6 Integration time +12 s

B- -

123456

A

The integration time can be adjusted appropriately with the switches 4,5 and 6. The

times of the activated time switches. When

the switch on (ze) and off delay (za) are

switched on at the same time, the adjusted

time applies to both delay modes.

Mode and integration time

A DIL-switch block with 6 switches (9) is

located on the circuit board of VEGATOR.

The individual switches are cordinated as

follows:

1 A/B-switch

A - max. detection or overfill protection

B - min. detection or dry run protection

2 Switch off delay

3 Switch on delay

4 Integration time 2 s

5 Integration time 6 s

6 Integration time 12 s

Switch123456

Time za ze 2 s 6 s 12 s

0,2 s A/B off off off off off

0,5 s A/B off off off

2 s A/B on off off

6 s A/B off on off

8 s A/B on on o f f

12 s A/B off off on

14 s A/B on off on

Optionally switch 2 and/

or 3 to "on“. The times

are valid for the appro-

priately adjusted delay

18 s A/B off on on

20 s A/B on on on

mode.

The mode can be adjusted (A - overfill protection or B - dry run protection) with

switch 1.

VEGATOR 536 Ex 11

Page 12

Set-up

Fault monitoring

The measuring system is monitored continuously. The following criteria are checked:

- two-wire line on line break and shortcircuit

- interruption of the connection line to the

piezoelements

- corrosion or damage of the tuning fork

(vibrating rod)

- break age of the tuning fork (vibrating rod)

- stop of vibration

- vibrating frequency too low

- corrosive medium penetrated into the sensor

Test key

A function test can be carried out with measuring systems in conjunction with two-wire

oscillators (VIB E50Z(Ex), SW E60ZEx,

SW E82ZEx).

The VEGATOR 536 Ex signal conditioning

instrument has an integral test key. The test

key is lowered in the front plate of the signal

conditioning instrument. Press the test key

with a suitable object (screwdriver, pen etc.).

By pressing the test the key measuring system is checked according to the following

criteria:

- switching function of the switching outputs

- potential separation of the outputs

- signal processing of the signal conditioning

instrument.

After pressing the test key, the complete

measuring system is checked for correct

function. During the test, the following operating conditions are simulated:

- fault signal

- empty signal (only with VEGASWING)

- full signal.

Check if all three switching conditions occur

in the correct sequence and the stated duration. If this is not the case, there is a failure in

the measuring system (see 5.2 Failure removal).

Please note that the connection instruments

are activated during the function test, which

means that you can check the correct function of the measuring system.

Due to this fault monitoring, the combination

of the following instruments corresponds to

classes 1 to 3 (AK 3) acc. to DIN 19 251.

AK 3 means that the system is fail safe.

- VEGASWING 61Ex, 63Ex, 81AEx, 83AEx

- SW E60ZEx, SW E82ZEx oscillator

- VEGATOR 536 Ex, 537 Ex, 636 Ex signal

conditioning instrument

VEGAVIB also passes the function test, however it is not approved acc. to WHG and

AK acc. to DIN 19 251.

Test course A-mode B-mode

1 Simulation of a fault signal (after release of the key approx. 3 s)

1)

Level relay deenergised

Fail safe relay deenergised

2 Simulation of an empty signal (approx. 1,5 s) only with VEGASWING

Level relay energised

Fail safe relay energised

3 Simulation of a full signal (approx. 1,5 s)

Level relay deenergised

Fail safe relay energised

4 Return to the actual operating condition (covered/uncovered)

1)

As long as the test key is pressed, the instrument remains at failure

12 VEGATOR 536 Ex

Page 13

Diagnosis

5 Diagnosis

5.1 Recurring test acc. to WHG

The implementation of the recurring test acc.

to WHG is regulated in the general type approval no. Z-65.11-154, (see item 8 of the

certificate).

Note the additional approvals when VEGASWING 81A and 83A are used as part of an

overfill protection acc. to WHG.

VEGASWING 61Ex, 63Ex, 81AEx and 83AEx

with signal conditioning instruments

VEGATOR 536 Ex, 537 Ex, 636 Ex meet the

fail safe requirements acc. to AK 3 in mode A

(overfill protection).

Recurring test acc. to WHG

In accordance with the type approval acc. to

WHG (no. Z-65.11-154, Z-65.11-285) the

recurring test acc. to WHG can be carried

out by pressing the test key on the

VEGATOR 536 Ex, 537 Ex, 636 Ex signal

conditioning instrument. The sensor must

neither be removed, nor should a response

be triggered by filling the vessel. This applies to VEGASWING 61, 63, 81AEx and

83AEx with SW E60ZEx and SW E82ZEx the

two-wire oscillator.

The implementation and the switching sequence of the function test is stated under

"Test key“ and the following table in the operating instructions of the appropriate

VEGATOR signal conditioning instrument.

5.2 Failure removal

Failure Measure, failure removal

The red failure- Check the sensor inputs on the following failures:

LED of the signal - shortcircuit on the input

conditioning instrument lights - sensor not correctly connected

- sensor line interrupted

- supply voltage too low

Check if the sensor is connected correctly.

- Failures on the sensor effecting a current change below 2 mA or

above 23 mA, cause a fault signal in the signal conditioning instruments.

Measure the current on the connection line to the sensor.

In normal condition, the terminal voltage of the sensor is at least 12 V.

4 … 20 mA 12 … 20 V

mA

+

–

Sensor

V

28

+

+

30

–

–

32

VEGATOR

series 500

Please note that in Ex-applications, the Ex-protection is not influenced by the measuring instruments.

VEGATOR 536 Ex 13

Page 14

Diagnosis

a. Current value < 2 mA

- Check the supply voltage on the connection line to the sensor. The

voltage should be approx. 17 … 20 V.

Should you measure a value below 17 V, then this shows a defect in

the signal conditioning instrument. In this case please send the instrument to VEGA for repair.

- Should the red failure lamp continue to light, separate the connection

line from the signal conditioning instrument and connect a resistor of

1 kΩ to the sensor inputs of the signal conditioning instrument.

If the failure lamp continues to light, the signal conditioning instrument

is defective. In this case please return the instrument to VEGA for

repair.

- Should the failure lamp extinguish, connect the signal conditioning

instrument again. Separate the sensor from the connection line and

connect a resistor of 1 kOhm instead .

- Should the failure lamp continue to light, the connection line probably

is interrupted. Check the connection line to the sensor.

- When the failure lamp extinguishes, the sensor is defective. Check

the connected sensor.

b.Current value > 22 mA

- Check all connections and the connection line to the sensor.

- Should the red failure lamp continue to light, separate the sensor from

the connection line and connect a resistor of 1 kΩ instead.

If the failure lamp extinguishes, the sensor is defective. Check the

connected sensor.

- Should the failure lamp continue to light, connect the sensor again.

Separate the signal conditioning instrument from the connection line

and connect a resistor of 1 kΩ to the sensor input instead.

- Should the failure lamp continue to light, the signal conditioning instrument is defective. In this case please send the instrument to VEGA

for repair.

- When the failure lamp extinguishes, there is probably a shortcircuit in

the connection line. Check the connection line to the sensor.

Malfunction during After pressing the test key, the switching conditions are not in the

function test correct sequence or of the correct duration, e.g. a full signal is not

triggered.

- Measure the line resistance

When the line is high-resistance, you have to reduce it to a standard

resistor by appropriate measures. Check for example terminals and

cable connections for corrosion.

14 VEGATOR 536 Ex

Page 15

VEGATOR 536 Ex 15

Page 16

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Phone 07836 50-0

Fax 07836 50-201

E-mail info@de.vega.com

www.vega.com

ISO 9001

The statements on types, application, use and operating conditions

of the sensors and processing systems correspond to the actual

knowledge at the date of printing.

Technical data subject to alteration.

23460-EN-030718

Loading...

Loading...