Page 1

TH LINK

Doc. Version 1.1

Installation Guide

English

Page 2

Dear Customer,

This installation Guide will help you to install the hardware. If you have any

further questions, please contact our Technical Support:

Trebing & Himstedt Prozeßautomation GmbH & Co. KG

Technical Support

Wilhelm-Hennemann-Str. 13

19061 Schwerin | Germany

Phone: +49 385 39572-500

Fax: +49 385 39572-22

E-mail: support@t-h.de

Internet: http://www.t-h.de

All brand and product names are trademarks or registered trademarks of

their respective owners.

© Trebing & Himstedt Prozeßautomation GmbH & Co. KG

All rights reserved, including rights to the translation. This inst allation guide

as well as extracts thereof may be duplicated or forwarded to third parties

only after written permission has been obtained from Trebing & Himstedt

Prozeßautomation GmbH & Co. KG.

The installation guide is intended for use by the owner of the

Trebing

product owner's operating personnel. It must not be passed on or made

accessible to third parties. If this installation guide should refer directly or

indirectly to laws, regulations or directives (e.

from them, Trebing & Himsted t Prozeßautomation GmbH & Co. KG cannot

assume responsibility for the correctness, completeness or up-to-date

nature of the same. If required, we recommend obtaining the respectively

valid versions of the complete regulations or directives for your own work.

We reserve the right to make technical changes.

& Himstedt Prozeßautomation GmbH & Co. KG product or the

g. DIN, VDE, ...) or quote

Doc. Version 1.1 | May 2012

Page 3

Content

About this Installation Guide ....................................................................4

Intended use .............................................................................4

Explanation of safety instructions .............................................4

Menu and keyboard commands ................................................5

For your safety .........................................................................................5

Performance and functioning ...................................................................8

Features ....................................................................................8

Scope of delivery ......................................................................8

Configuration requirements .......................................................9

Ethernet network presettings ....................................................9

Design of the TH LINK ...........................................................................10

Connections and indicating elements .....................................12

Mounting .................................................................................12

Start-up guideline ..................................................................................13

Note regarding the application software ..................................13

Installing the TH LINK ............................................................................14

Installing the TH LINK .............................................................14

Uninstalling the TH LINK .........................................................15

Connecting to Ethernet ..........................................................................15

Connecting the power supply ................................................................16

Configuring the TH LINK in the Ethernet network .................................18

Establish a connection to the TH LINK ...................................18

User administration .................................................................20

TH LINK description ................................................................20

Network configuration .............................................................20

TH SCOPE settings ...............................................................................25

Measurement ..........................................................................26

Alert .........................................................................................26

Parameter distribution .............................................................26

Connecting the PROFIBUS ...................................................................28

Bus terminating resistors .........................................................30

Setting PROFIBUS parameters ..............................................30

Firmware update ....................................................................................31

Troubleshooting .....................................................................................32

Technical data .......................................................................................34

General conditions .................................................................................35

Page 4

About this Installation Guide

About this Installation Guide

Please read this installation guide carefully prior to installation. It

facilitates installation and setup of your system and provides you

with important information.

Intended use

The TH LINK is designed to be used as an interface between

PROFIBUS and Ethernet networks. Any other use is deemed

non-intended use.

Explanation of safety instructions

The following symbols and signal words used are intended to

draw your attention to special situations:

Danger!

Warning of personal injury from high voltage.

Warning!

Warning of damage to the device.

Note!

Useful tips.

4

Disposal

Notes on disposal.

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 5

For your safety

Menu and keyboard commands

The following conventions apply to menu and keyboard

commands:

Courier font

<Key> Press the indicated key.

Window names, menu items, fields

and descriptions of combo boxes,

check boxes, radio buttons and icons.

For your safety

Strictly observe the following safety instructions before

connecting the device:

Danger!

Small objects or liquids must not enter the case

of the TH

slots). This may damage the device.

Never cover the ventilation slots on the device.

LINK (e. g. through the ventilation

Warning!

Never open the case of the TH LINK or carry out

any mechanical modifications on the device.

Otherwise, this may lead to damages on the

device as well as to loss of warranty.

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

5

Page 6

For your safety

Warning!

The TH LINK contains electronic components

sensitive to electrostatic discharges. Damages

due to electrostatic discharge can lead to

premature failure of components or intermittent

faults at a later stage.

Before installing the TH LINK, divert the

electrostatic discharge away from your body and

the tools used.

– Carefully plan the integration of the TH LINK into an existing

system and ensure proper function of the system after

installation.

– The TH LINK may only be installed or uninstalled by qualified,

trained electrical engineering personnel.

When installing the TH LINK, observe the regulations for

handling electric components in accordance with VDE 0100. In

addition, you must also observe the valid safety and accident

prevention regulations (UVV) when operating the device within

the jurisdiction of the Federal Republic of Germany.

– Observe the IEC 61158 standard.

– Always install the TH LINK on a suitable top-hat rail (mounting

rail).

– Cables used for the connection must not apply any mechanical

forces to the TH

LINK.

6

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 7

For your safety

– High temperature differences between the storage site and

installation site can result in condensation within the case,

which may cause the TH

LINK to become damaged.

In case of high temperature differences, please wait at least

three hours before operating the TH

LINK.

– Lock the connected plug (PROFIBUS) using the srew

connections intended for this purpose.

Disposal

The TH LINK must be disposed of separately

from normal household waste in accordance

with the 2002/96/EC (WEEE) directive.

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

7

Page 8

Performance and functioning

Performance and functioning

The TH LINK provides access to the communication system and

connects the higher-level network structure with the field level. It

forms the basis for the Trebing + Himstedt products TH SCOPE,

PROFIBUS Scope, Trebing + Himstedt DTM Library, TACC and

TH OPC Server DP.

The TH LINK is quick to assemble/install and to put into

operation. The delivered default configuration allows start-up in

only a few minutes. In order to prevent network disruptions by

unauthorized configuration changes, all configuration functions

are protected by user administration.

The TH LINK includes the free-of charge TH SCOPE easy.

Features

– Connection between higher-level network and field level

– Access to the PROFINET/Industrial Ethernet network

– Basis for TH SCOPE, PROFIBUS Scope, Trebing + Himstedt

DTM Library, TACC and TH OPC Server DP

– Access protection through integrated user administration

– TH SCOPE easy preinstalled

Scope of delivery

–TH LINK

– Installation Guide

– Release Note (per download at www.t-h.de)

8

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 9

Performance and functioning

Configuration requirements

(not included in the scope of delivery)

– Web browser with Adobe Flashplayer 10.0 or higher

– Enabling port 80 and IP 224.0.5.128 port 2364 UDP

– Application software for PROFIBUS configuration

Ethernet network presettings

–The TH LINK is preset to Ethernet network operation with a

DHCP server. No Ethernet network configuration settings are

required in this operating mode.

– In case of manual allocation of IP addresses the TH LINK has

the following standard IP configuration:

IP address 169.254.0.1

Subnet mask 255.255.0.0

Default gateway 0.0.0.0

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

9

Page 10

Design of the TH LINK

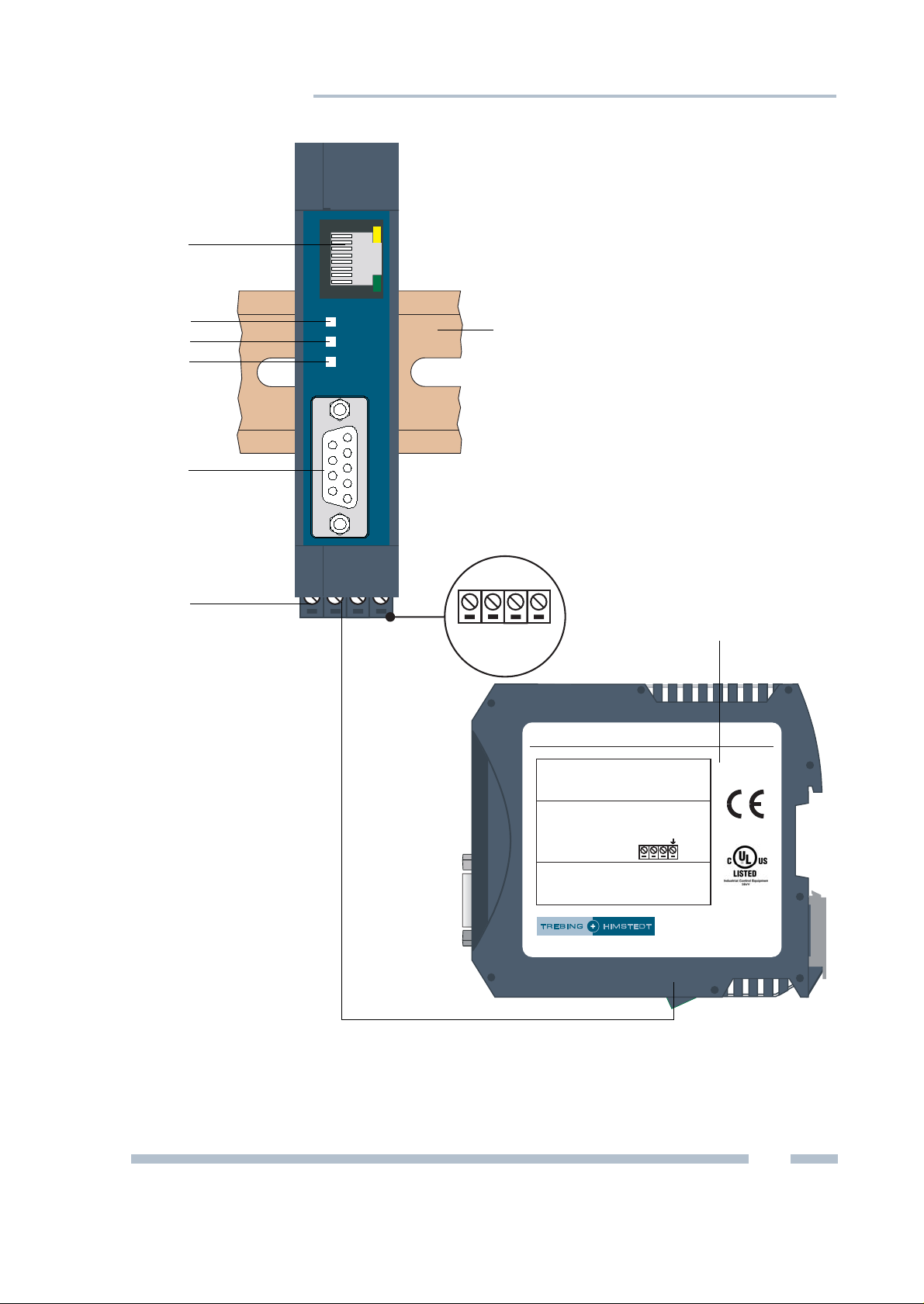

Design of the TH LINK

(see figure 1)

1 Ethernet interface

2LED ETH

3LED RUN

4LED BUS

5 PROFIBUS interface

6 Terminal strip for power supply

7 Type label

8 Top-hat rail (not included in the scope of delivery)

10

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 11

Design of the TH LINK

TH LINK

Trebing & Hi mstedt Prozeßau tomation GmbH & Co. KG

www.t-h.de

Made in Germany

Part No.: 10003006

HW-Release: 2.0

Serial No.: 000000

Temperature: 0 to +50 °C

Current: 190 mA max.

Power Supply: 19.2 to 28.8 V DC

ETH: Ethernet (green/red)

RUN: OK (green) | Error (red)

BUS: PROFIBUS (green/red)

24 V DC

+–

[1]

[2]

[3]

[5]

[7]

[4]

[6]

[8]

ETH

RUN

BUS

TREBING + HIMSTEDT

PROFIBUS

A B C D

Fig. 1: TH LINK (front and side view)

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

11

Page 12

Design of the TH LINK

Connections and indicating elements

[1] Ethernet interface: RJ-45 (10Base-T/100Base-TX)

– LED lights yellow: Ethernet data communication

– LED lights green: physical connection available

[2] LED ETH

– ETH lights red: first start phase

– ETH flashes red: boot procedure

– ETH lights red or flashes red or green in case of an error:

internal firmware failure

– ETH lights green: connection to application via Ethernet

[3] LED RUN

– RUN lights red: internal failure identified

– RUN lights green: 24V power supply is fed

[4] LED BUS

– BUS lights green: device communicates active via

PROFIBUS

[5] PROFIBUS interface: D-Sub socket

[6] Terminal strip for +24 VDC power supply

– A: 24 V (+)

–B: 0 V (-)

– C: not assigned

– D: Earth conductor

Mounting

[8] 35 mm DIN top-hat rail (not included in the scope of

delivery)

12

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 13

Start-up guideline

Start-up guideline

The following steps are required for start-up:

1. Install the TH LINK (see "Installing the TH LINK" on

page 14).

2. Connect to Ethernet (see "Connecting to Ethernet" on

page 15).

3. Connect to the power supply (see "Connecting the power

supply" on page 16)

4. Configure Ethernet (see "Configuring the TH LINK in the

Ethernet network" on page 18)

Note!

To set the IP address manually you must

connect your PC/notebook to the TH

crossover cable.

5. Connect the PROFIBUS (see "Connecting the PROFIBUS"

on page 28).

6. If you use the TH LINK as a class 2 master you have to

configure PROFIBUS parameters of the TH

application software (

on page 30).

see "Setting PROFIBUS parameters"

LINK via

LINK using an

Note regarding the application software

For operating the TH LINK as a class 2 master, an application

software with the appropriate drivers is required. For more

information about purchasing and operating the software please

check our website at http://www.t-h.de or contact our sales

department (sales-ic@t-h.de).

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

13

Page 14

Installing the TH LINK

TH LINK

Trebing & Himstedt Prozeßau tomation GmbH & Co. KG

www.t-h.de

Made in Germany

Part No.: 10003006

HW-Release: 2.0

Serial No.: 000000

Temperature: 0 to +50 °C

Current: 190 mA max.

Power Supply: 19.2 to 28.8 V DC

ETH: Ethernet (green/red)

RUN: OK (green) | Error (red)

BUS: PROFIBUS (green/red)

24 V DC

+–

TH LINK

Trebing & Hi

m

stedt Prozeßauto

mation GmbH & Co . KG

www.t-h.de

Made in Germany

Part No.: 10003006

HW-Release: 2.0

Serial No.: 000000

Temperature: 0 to +50 °C

Current: 190 mA max.

Power Supply: 19.2 to 28.8 V DC

ETH: Ethernet (green/red)

RUN: OK (green) | Error (red)

BUS: PROFIBUS (green/red)

24 V DC

+

–

[1]

[3]

[2]

[4]

Installing the TH LINK

Installing the TH LINK

Warning!

Above and below the TH LINK, a minimum of 2

inches head space for heat dissipation needs to

be available.

Fig. 2: Installing and removing of the TH LINK

1 Device with notch on top-hat rail

2 Top-hat rail

3 TH LINK on top-hat rail

4Stop lever

Place the notch of the TH LINK on the top-hat rail and move the

LINK downward until the stop lever locks into place on the

TH

top-hat rail.

14

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 15

Connecting to Ethernet

Uninstalling the TH LINK

1. Remove the connected supply and signal lines (Ethernet,

PROFIBUS, voltage).

2. Place the screwdriver into the stop lever on the TH LINK

see figure 2).

(

3. Press the screwdriver in the direction of the TH LINK and

simultaneously swing the device off the top-hat rail.

Connecting to Ethernet

– Insert the patch cable plug (RJ-45, not included in the scope of

delivery) into the Ethernet socket (

TH LINK until the plug locks into place.

– The green LED on the Ethernet socket lights as soon as the

TH

LINK is energized and an Ethernet network is available.

see figure 1 no. [1]) on the

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

15

Page 16

Connecting the power supply

Connecting the power supply

Danger!

Electrical voltage.

Only qualified electricians are allowed to work

on the electrical equipment.

Danger!

Incorrect TH LINK earthing can cause injury to

personnel or device damage. Ensure correct

and proper earthing of the TH

Warning!

Reverse polarity in the power supply can

damage the device. Make sure the power

supply is connected with correct polarity.

LINK.

16

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 17

Connecting the power supply

+24 V not assigned0 V

Earth conductor

Fig. 3: Terminal strip for power supply on the TH LINK

1. Connect the cable of a 24 V power supply and the earth

conductor (earth terminal) to the terminal strip on the device.

The terminal strip can be plugged and lifted out for

installation using a screwdriver.

2. Switch on the power supply. The LED RUN is green and the

LED ETH flashes red until the TH

LINK's initiation procedure

is completed. Afterwards only the LED RUN lights green.

17

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

Page 18

Configuring the TH LINK in the Ethernet network

Configuring the TH LINK in the Ethernet

network

Establish a connection to the TH LINK

1. Connect the TH LINK to a PC/notebook via crossover cable.

The PC/notebook has to be in the same subnet as the

TH

LINK.

2. Start a web browser on your PC/notebook.

3. Enter the IP address http://169.254.0.1 and press

<Enter>. The TH SCOPE website is loaded.

Login

1. Click on Login.

2. Enter the password. The default password is the six-figure

serial number of the device.

at the case

3. Click on OK.

Note!

We recommend changing the password after

login (

Note!

Log out after changing settings (Click on

Logout). Otherwise you have to wait about 10

minutes to get access to this TH

or at Info.

see "User administration" on page 20).

You can find it on the type label

LINK, if you

18

have left the site or closed the browser.

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 19

Configuring the TH LINK in the Ethernet network

Settings

Click on settings and then on TH LINK.

Here you can change the settings for user administration,

LINK description and network configuration.

TH

Fig. 4: TH LINK settings

Note!

For detailed information about each setting,

click on the question mark.

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

19

Page 20

Configuring the TH LINK in the Ethernet network

User administration

Here you can change the password. Proceed as follows:

1. Enter the old password.

2. Select a new password and confirm it by re-entering.

3. Finally, click Change password.

TH LINK description

Here you can enter a tag name, a location, an installation date

and a description of the TH

LINK.

Network configuration

Here you have to set the operation mode and the configuration

method. You can also make time settings.

Operation mode

Select at network configuration the operation mode of

the TH

In the operation mode Passive PROFIBUS station the

TH

needs no own PROFIBUS address.

In the operation mode Active/Passive PROFIBUS station

the TH

LINK.

LINK is a passive station in the bus. Therefore the TH LINK

LINK can be used as a class 2 master in connection with

an external master application (FDT or Emerson's AMS Suite).

The TH LINK is passive until a PROFIBUS address is set in the

master application and the communication is started. Then the

TH

LINK is an active station.

20

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 21

Configuring the TH LINK in the Ethernet network

Configuration method (DHCP/Manual)

There are two connecting options to choose from, depending on

your network:

– Connection in an Ethernet network with DHCP server –

automatic and dynamic allocation of IP addresses (connection

with patch cable via hub or switch)

– Connection in an Ethernet network with manual IP address

assignment (peer-to-peer) – manual allocation of IP addresses

(connection with crossover cable)

Connection in a network with DHCP

(Dynamic Host Configuration Protocol)

The TH LINK is preset to network operation with a DHCP server

and in this case it is automatically assigned an IP address.

Therefore, no further configuration settings are necessary.

Note!

If you connect to Ethernet network with the

power supply already connected, the DHCP

may fail to be identified. The routine for the

DHCP identification only runs during TH

start-up.

LINK

Briefly switch off the power supply for a new

DHCP identification.

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

21

Page 22

Configuring the TH LINK in the Ethernet network

Connection in a network with manual IP address assignment

If you use the TH LINK in an Ethernet network without DHCP

server, you need the following for configuration:

– TCP/IP settings for this network

– a PC/notebook with a web browser and Adobe Flash Player

– a crossover cable between PC/notebook and TH LINK (peer-

to-peer connection)

Note!

Always notify your system administrator prior to

allocating IP addresses.

If you set an address already assigned, other

devices in the network may be deactivated and

communication may be affected.

Note!

The PC/notebook must be in the same subnet

as the TH

LINK.

The TH LINK has the following manual default IP addresses

(default settings at the time of delivery):

IP address 169.254.0.1

Subnet mask 255.255.0.0

Default gateway 0.0.0.0

22

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 23

Configuring the TH LINK in the Ethernet network

Setting new IP and network addresses

1. Change the Configuration method from DHCP to

Manual (

see figure 5).

Fig. 5: Setting IP and network addresses

2. Enter the new IP address.

Note!

Note down the set IP address. You can only

access the TH

LINK by using this IP address.

3. Enter the new addresses for Subnet mask and Default

gateway.

23

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

Page 24

Configuring the TH LINK in the Ethernet network

4. If you want to use a DNS server, select Yes and enter the

DNS server IP addresses.

5. Click on the floppy disk sign to save the settings.

Thereafter the TH LINK restarts and you will be logged out

as administrator automatically.

Note!

If you use several TH LINK, you can facilitate

the configuration by using the parameter

distribution (

see "Parameter distribution" on

page 26).

Checking the connection to the TH LINK

You can check the TH LINK in the network when:

–the TH LINK is integrated into the Ethernet network

–the TH LINK is energized

– the PC/notebook is in the same subnet

Procedure

Start a web browser on your PC/notebook.

– For DHCP: Enter the host name (basic setting:

THLINK_+serial number) found on the TH LINK's type label

(e.g.:

THLINK_000075) and press <Enter>.

– Manual IP configuration: Enter the set IP address (basic

setting: 169.254.0.1) and press <Enter>.

The TH SCOPE website is displayed in the web browser.

24

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 25

TH SCOPE settings

TH SCOPE settings

Click on settings > TH SCOPE.

Here you can change the settings for measurement, alert and pa-

rameter distribution.

Fig. 6: TH SCOPE settings

Note!

Log in as administrator to change settings (see

"Login" on page 18).

Note!

For detailed information about each setting,

click on the question mark.

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

25

Page 26

TH SCOPE settings

Measurement

The measurement settings include among other settings for baud

rate and Start/Stop of the TH SCOPE measurement.

Alert

The alert settings include among other settings for activating the

email alert function, when an email should be sent, SMTP server ,

subject, email sender and receiver.

Parameter distribution

The parameter distribution serves for a quick and easy

configuration of several TH

be set a parameter provider. All other units can request the

parameters from this TH

LINK. Therfore one TH LINK has to

LINK.

Set parameter provider

The TH LINK from which all other units can take over the set

parameters is called parameter provider.

Select the distribution role Parameter provider and save your

settings by clicking on the

Note!

Only one "parameter provider" is allowed in the

entire network.

In TH SCOPE network overview > network

list

the parameter provider is marked with the

floppy disk sign.

26

following icon.

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 27

TH SCOPE settings

Apply parameters

By default all TH LINK are set as parameter receiver. Before

taking over the parameters of a TH LINK, make sure that this

TH LINK is set as a parameter provider.

Click on Request at Apply parameters to query the parameters from the parameter provider.

Thereafter the TH LINK restarts and you will be logged out as

administrator automatically.

Parameters

The following data will be assigned:

TH LINK TH SCOPE

– Default language

– Operation mode

–DNS server

– Time server settings /

PC system time

– Type of measurement

– Measurement

– Slave has never responded

– Sorting of diagnostics list

– Alert settings

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

27

Page 28

Connecting the PROFIBUS

Connecting the PROFIBUS

The 9-pin D-Sub socket is used for connection.

– Only use standard PROFIBUS plugs and cables.

– Wire the PROFIBUS plug according to the details for pin

assignment (

– If the TH LINK is installed at the beginning or end of the

PROFIBUS cable segment, you will need a bus terminating

resistor (

see "Technical data" on page 34).

see "Bus terminating resistors" on page 30).

Warning!

Do not use branch lines for the connection.

If local conditions do not allow a direct

connection, use a repeater (connection

according to PROFIBUS norm).

1. Attach the PROFIBUS connector onto the PROFIBUS

socket on the TH

2. Secure the plug with screws.

3. Switch the switch for the bus terminating resistor on the

LINK.

PROFIBUS connector to the required position (ON/OFF).

28

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 29

Connecting the PROFIBUS

PROFIBUS DP

PROFIBUS PA

HART

Diagnostic

Repeater

TH LINK

PA Link Remote IO

Field Device

Field Device

Field Device

Field Device

PLC

Ethernet

TH LINK

TH LINK

[1] [2]

Fig. 7: Interface connection possibilities in the PROFIBUS network

[1] Connection behind a master (SPS)

[2] Connection in a separate PROFIBUS segment behind a repeater.

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

29

Page 30

Connecting the PROFIBUS

Data+

(Pin 3)

Data–

(Pin 8)

GND

DC/DC

(Pin 5)

[2] [3][1]

+5 V

DC/DC

(Pin 6)

Bus terminating resistors

Terminations of a PROFIBUS segment must each be terminated

with a bus terminating resistor. Use standardised plugs

containing terminating resistors.

Fig. 8: Bus termination configuration (see standard IEC 61158)

[1] 390 Ω Pull-up resistance from pin 3 to positive supply volt age at pin 6

[2] 220

[3] 390

Ω Cable terminating resistor between pin 3 and pin 8

Ω Pull-down resistance from pin 8 to data reference potential at

pin 5

Setting PROFIBUS parameters

Depending on the used application software (not included in the

scope of delivery), the TH

an own station address) or an active station (class 2 PROFIBUS

master).

The setting of the PROFIBUS parameters is only required, if you

use the TH

LINK as a class 2 master in the operation mode

active/passive PROFIBUS station.

are given by the class 1 master.

LINK can be a passive station (without

The PROFIBUS parameters

30

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 31

Firmware update

Firmware update

Firmware updates for the TH LINK are available free of charge at

our website, www.t-h.de. Proceed as follows.

1. Y ou have to log in as administrator to perform a firmware update (see "Login" on page 18).

2. Click on settings and then on Firmware update.

3. Check if the requirements for a firmware update are met.

Therefore the measurement and the external applikation

must be stopped.

4. Download the latest firmware version from www.t-h.de and

save it in your local directory.

5. Click on [...] and select the firmware.

6. Click on Start.

Note!

Do not not turn off the power, during the entire

firmware update process! After the firmware

update the TH

LINK restarts automatically.

Fig. 9: Firmware update

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

31

Page 32

Troubleshooting

Troubleshooting

TH LINK is not found in the Ethernet network

– Check the power supply (LED RUN must light green).

– Check for correct connection (RJ-45, see "Connecting to

Ethernet" on page 15).

– The TH LINK is preset to network operation with a DHCP

server (IP address for the TH

server). If your network server does not support DHCP, you

need to set the IP address for the TH

(see "Connection in a network with manual IP address

assignment" on page 22).

– When a crossover cable is used between PC/notebook and

LINK, both devices must be in the same subnet.

TH

PROFIBUS network is not found

TH LINK as Passive PROFIBUS station:

– Check for proper connection (see "Connecting the

PROFIBUS" on page 28) and switch at Settings >

TH SCOPE > Measurement the baud rate on Automatic

detection.

LINK is assigned by the DHCP

LINK yourself

TH LINK as Active/Passive PROFIBUS station:

– Check the PROFIBUS parameters for the used TH LINK (see

application software, not included in the scope of delivery).

Each station has its own station address, which can only be

assigned once in the network.

32

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 33

Troubleshooting

LED ETH lights red or flashes red or green in case of failure

or

LED RUN lights red – internal error

– Internal error or defect: Please contact the Technical Support:

Trebing & Himstedt Prozeßautomation GmbH & Co. KG

Technical Support

Wilhelm-Hennemann-Str. 13

19061 Schwerin | Germany

Phone: +49 385 39572-500

Fax: +49 385 39572-22

E-mail: support@t-h.de

Internet: http://www.t-h.de

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

33

Page 34

Technical data

15

69

Technical data

Electrical data

Nominal supply voltage

(limit values)

Current consumption max. mA 190

Protection class IP 20

Operating conditions

Ambient temperature range °F 32...122

Relative humidity % 20...80 (no condensation)

Case data

Dimensions W × H × D in 0.9 x 3.9 x 4.5

Weight (approx.) l 0.3

PROFIBUS interface

Interface Type RS 485

VDC 24 (19.2...28.8)

Transmission rate bps 9,600...12M

Sub-D plug pin assignment Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Other

Ethernet connection Type RJ-45 (10Base-T/100Base-TX)

Certificates CE, UL

not assigned

not assigned

B line data+ (RxD/TxD-P)

RTS

GND (0 V)

Potential (+5 VDC)

not assigned

A line data– (RxD/TxD-N)

not assigned

34

Trebing & Himstedt Prozeßautomation GmbH & Co. KG | TH LINK

Page 35

General conditions

General conditions

Right to make additions or alterations

Trebing & Himsted t Prozeßautomation GmbH & Co. KG reserves the right

to continue development of this installation guide and the properties of the

hardware and software at any time, also without releasing information

about this or about alterations prior to doing so.

Exclusion from liability

Trebing & Himstedt Prozeßautomation GmbH & Co. KG assumes no

warranty for proper function of the hardware and software in all conceivable

situations. Currently available technical means do not enable the

development of software which is completely free of errors in all conceivable

applications. Trebing & Himstedt Prozeßautomation GmbH & Co. KG does

not accept any liability for damages, both direct and indirect, arising from the

use of the hardware and software and the information contained in this

manual.

Duty to monitor products

As part of our duty to monitor products, we strive to warn about dangers

we have identified which can result from the interaction of hardware and

software and product use with third-party products. Monitoring is only

possible if we receive sufficient information from our customers on the

planned application(s) and the existing hardware and software

components. As a result of the complex interactions, it is no longer

possible for us to accurately identify all dangers and to check the effect on

the overall system and in particular on our hardware and software, if the

conditions of application have changed and/or hardware or software has

been exchanged. This installation guide does not describe all technical

characteristics of the hardware and software and their variants. For more

information please contact Trebing & Himstedt Prozeßautomation GmbH

& Co. KG.

Warranty

Our products are subject to warranty in accordance with our general

business and delivery terms.

TH LINK | Trebing & Himstedt Prozeßautomation GmbH & Co. KG

35

Page 36

Doc.Nr . 10003010 © Trebing & Himstedt Prozeßautomation GmbH & Co. KG

Loading...

Loading...