Page 1

Operating Instructions

VEGASWING 81A, 83A

Level and Pressure

Page 2

Safety information

Safety information

The described module must only be installed

and operated as described in these operating

instructions. Please note that other action can

cause damage for which VEGA does not take

responsibility.

2 VEGASWING 81A and 83A

Note Ex-area

Please note the approval documents attached

(yellow binder), and especially the included

safety data sheet.

Page 3

Contents

Contents

Safety information ........................................................................ 2

Note Ex-area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 4

1.2 Approvals ............................................................................. 5

1.3 Technical data ....................................................................... 7

1.4 Dimensions ......................................................................... 11

1.5 Type plate ........................................................................... 15

2 Mounting

2.1 VEGASWING ...................................................................... 16

3 Electrical connection .............................................................. 20

4 Set-up

4.1 Functions table ................................................................... 26

5 Diagnosis

5.1 Recurring test acc. to WHG .............................................. 27

5.2 Replacement of electronics ............................................... 28

5.3 Failure removal ................................................................... 29

VEGASWING 81A and 83A 3

Page 4

1 Product description

Product description

1.1 Function and configuration

VEGASWING series 80 A vibrating level

switches detect the levels of liquids with a

viscosity between 0,2 mPa s and

10.000 mPa s and densities ³ 0,5 g/cm3.

Their modular design allows them to be used

in vessels, tanks and pipelines. T ypical applications involve overfill and dry run protection.

Thanks to its simple and rugged measuring

system, VEGASWING can be used in almost

any liquid regardless of its chemical and

physical properties. It also works well under

difficultconditions such as turbulence, air

pockets, foam formation, or changes in material, and is insensitive to external vibrations.

VEGASWING with their mechanical connection thread, cone, bolting and flange are also

suitable for level detection of liquids in the

food processing industr y. The tuning fork

and the extension tube are polished for such

applications.

For the use in very aggressive products,

Hastelloy C4 and coatings ECTFE (Halar)

and enamel are used for VEGASWING 81 A

and 83 A.

For product temperatures of more than

100°C up to 150°C, VEGASWING 81 A and

83 A can be equipped with a temperature

adapter.

Function

The tuning fork is piezoelectrically energised

and vibrates at a resonance frequency of

approx. 400 Hz. The resonance frequency

changes when the tuning fork is covered by

the material. This frequency change is detected by the integral oscillator and converted into a switching command.The

switching condition (overfill or dry run protection) can be selected using the mode switch.

The oscillator of VEGASWING continuously

monitors the instrument for the following

faults:

- tuning fork corrosion or damage,

- absence of vibration,

- piezo drive cable malfunction,

- vibrating frequency too low ,

- corrosive medium penetrating the sensor

from the vessel.

With a connected signal conditioning instrument (oscillator SWING E82 Z) in addition

more functions can be monitored. With oscillator SWING E82 Z and appropriate signal

conditioning instrument, the function of the

complete measuring chain can be monitored

at the touch of a button. This is valid according to the general type approval acc. to WHG

as recurring test. More information is provided with the particular signal conditioning

instrument.

Should one of the above-mentioned faults

occur, or the power supply fails, the electr onics react by switching to a defined switching

state, i.e. dependent on the electr onics version

- opening the non-contact switch,

- de-energising the r elay, or

- blocking the output transistor .

With the two-wire output version, the failure is

signalled via a defined current to the connected VEGATOR signal conditioning instrument.

4 VEGASWING 81A and 83A

Page 5

Product description

Recurring test acc. to WHG

According to the type approval WHG

(Z-65.11-154) the recurring test acc. to WHG

can be carried out by pressing a key on the

VEGATOR 536 EX, 537 EX, 636 EX signal

conditioning instrument. The sensor must not

be removed, nor made to respond by filling

the vessel. This is valid for VEGASWING

81 A EX and 83 A EX with two-wire

SWING E82 Z EX oscillator .

VEGASWING 81 A EX and 83 A EX meet the

fail-safe requirements to class 3 (AK 1 … 3)

acc. of DIN 19 251 in mode A (overfill protection).

Configuration

A measuring system consists of:

- a VEGASWING with SWING E82 C,

SWING E82 R or SWING E82 T oscillator

- external instruments, switched by VEGASWING

or

- a VEGASWING with SWING E82 Z or

SWING E82 Z EX oscillator

- VEGATOR 536 EX, 537 EX or 636 EX signal

conditioning instrument or an already

mounted instrument, e.g. VEGA TOR

425 EX, 534 EX, 825 EX

- external instruments switched by VEGATOR.

1.2 Approvals

Explosion protection

Only certified VEGASWING 81A EX0, 83A

EX0 vibrating level switches should be used

in hazardous areas caused by combustible

gases, vapours or fog, . VEGASWING

81A EX0, 83A EX0 are suitable for use in

hazardous areas zone 1 and zone 0.

The EU-type approval issued by the approval authority is attached to the instruments

as proof of explosion protection. Ex-mounting

regulations should be noted when VEGASWING 81A EX0, 83A EX0 vibrating level

switches are mounted and operated in hazardous areas. The information and conditions

of the supplied certificates (EU-type approval, conformity certificate) for VEGASWING 81A EX0, 83A EX0 as well as the

appropriate electrical equipment (VEGA TOR

signal conditioning instrument, separator ,

safety barrier) must be taken into account.

• The mounting of Ex-systems must always

be carried out by skilled staff.

• VEGASWING 81A EX0, 83A EX0 must be

powered by an intrinsically safe circuit; the

permissible electrical values are stated in

the appropriate Ex-type approval certificate.

• VEGASWING 81A EX0, 83A EX0 with

enamelled tuning fork or plastic parts acquiring static electricity have a warning

label stating the measures to be taken to

avoid dangers due to electrostatic discharges. The contents of the warning label

should be noted.

• The explosion protection of the electrical

equipment used is only ensured when the

limit temperatures stated in the certificate

are not exceeded.

• In the case of dangers due to oscillation

and vibrations, the appropriate parts of

VEGASWING 83A EX0 should be secured

effectively against these dangers.

VEGASWING 81A and 83A 5

Page 6

Product description

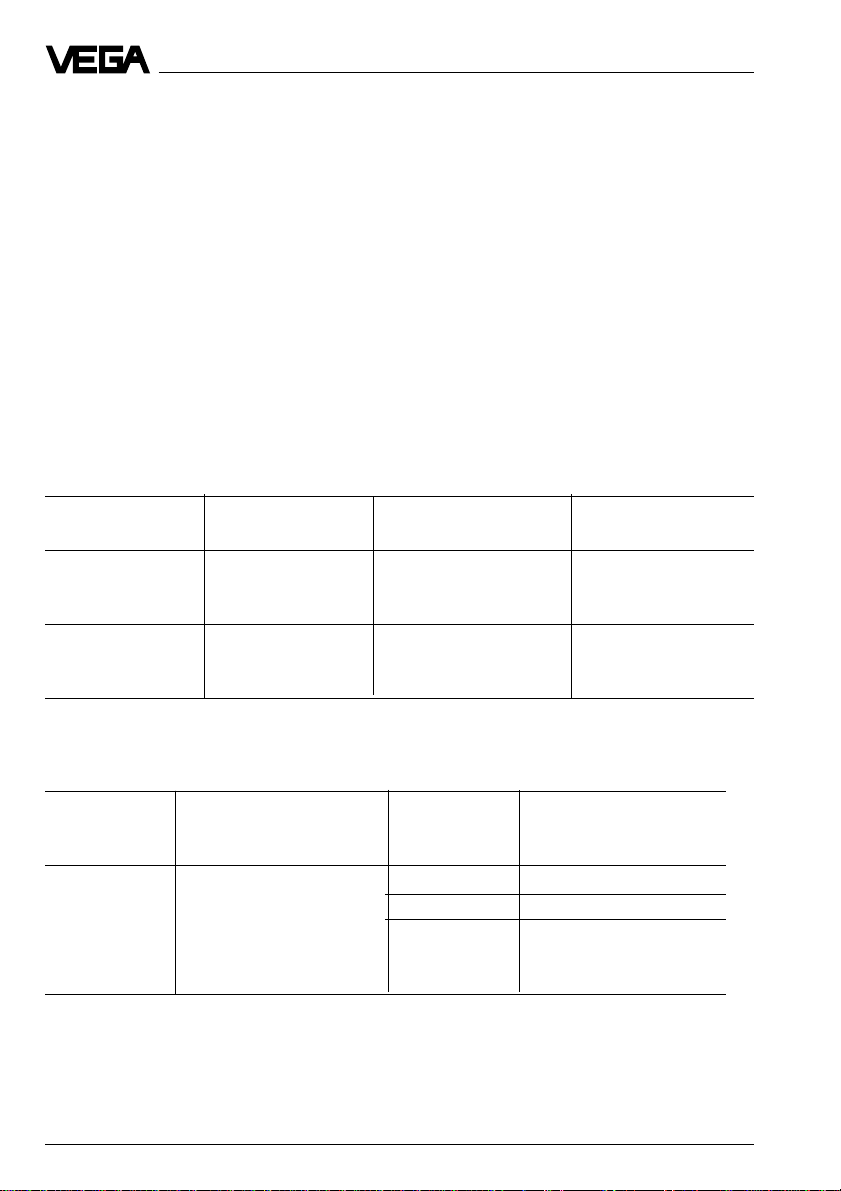

Overfill protection

The information and conditions of the supplied general type approvals must be noted

when a VEGASWING is used as part of an

overfill protection for vessels storing water endangered liquids. The general type approval should be available at the place of

installation place.

VEGASWING should only be used in liquids

against which the materials of the wetted

parts of VEGASWING are sufficiently chemically resistant.

Overfill protection according to WHG

Level detection with fault monitoring

Instrument Oscillator VEGATOR Test certificate no.

VEGASWING SWING E82Z EX 536 EX, Z-65.11-154

81A EX, 83A EX 537 EX

VEGASWING SWING E82 C Compact instrument Z-65.11-163

81A and 83A SWING E82 R

(C, R, T) SWING E82 T

DruckbehV (pressure vessel regulations)

VEGASWING was tested acc. to TRB 801 no.

45 on its suitability for use in pressurized

vessels (DruckbehV).

level switch

636 EX

Level measuring instruments for use in hazardous areas

Level detection with fault monitoring

Instrument EU-type approval VEGATOR Conformity

VEGASWING TÜV 98 ATEX 1320 X 536 EX PTB no. Ex 95.D.2065 X

81A EX, 83A EX 537 EX PTB no. Ex 95.D.2073 X

with 636 EX PTB no. Ex 96.D.2068

oscillator

SWING E82Z EX

VEGATOR 425 EX, 534 EX and 825 EX signal conditioning instruments meet the r equired

connection values and can also be used.

6 VEGASWING 81A and 83A

certificate level certificate

switch

Page 7

Product description

1.3 T echnical data

VEGASWING 81A and 83A

Housing

Housing material plastic PBT (Polyester) or

Protection

- plastic housing IP 66

- aluminium housing IP 66 and IP 67 (meets both categories)

Cable entry 1 M20x1,5 unit

Terminals max. 1 x 1,5 mm2 cable cross-section

Mechanical connection

Thread G 1 A or 1“ NPT

- material 1.4571 (stst) or Hastelloy C4

Flanges DIN and ANSI from DN 32

- material 1.4571, 1.4571 plated with Hastelloy C4

Hygienic fittings

Material 1.4571

- cone DN 25

- bolting DN 40, DN 50

- Tri-Clamp 11/2“, 2“

- Tuchenhagen Varivent DN 50 PN 10

- hyg. connection with compression nut F40 PN 25, 14571, 14581

- hyg. connection with tension flange DN 32 PN 25, 1.4571, 1.4581

aluminium (plastic-coated)

(SWING E82 R: 2 M20x1,5 units)

DN 50 PN 40 enamelled steel

or 1.4571 ECTFE-coated

Tuning fork

Material 1.4581, Hastelloy C4, Hastelloy C4 enamelled

Extension tube (VEGASWING 83 A)

Material 1.4571, Hastelloy C4, Hastelloy C4 enamelled

Length

- 1.4571, Hastelloy C4 140 mm … 4000 mm

- Hastelloy C4 enamelled 140 mm … 1200 mm

- 1.4571, ECTFE (Halar) 140 mm … 1600 mm

Weight

Plastic housing approx. 1,5 kg

Tube extension (VEGASWING 83A) approx. 0,11 kg/m

VEGASWING 81A and 83A 7

1.4581 with ECTFE coating

1.4571 with ECTFE coating

Page 8

Product description

Ambient conditions

1)

Ambient temperature on housing -40°C … +70°C

Storage and transport temperature -40°C … +70°C

Product temperature -40°C … +100°C

short-term (30 min.) also over 100°C

(max. 150°C) only valid for instrum ents without

approval.

Product temperature with 1.4571

temperature adapter (optional) -40°C … +150°C

'

'

'

Permissible ambient

temperature

Operating pressure

'

1)

Operating pressure -1 bar to 40 bar

(with locking ARV2EX0.C…

up to 25 bar , other lockings un pressurised)

With flange versions note nominal pressure

of the flange.

Product

Viscosity

- dynamic 0,2 … 10.000 mNs/m² (or cSt)

- cineatic 0,2 … 10.000 mNs/m² (or cP) relating to

Density 0,5 … 2,5 g/cm

density 1

3

0,5 … 0,7 g/cm3 must be readjusted

(factory setting 1,0)

Product temperature

with temperature

adapter

Function

Mode A/B-modes in oscillator or definition via the

signal conditioning instrument (SWING E82Z)

A: max. detection, overfill protection

B: min. dete ction, dry run protection

Integration time approx. 0,5 s

Meas. frequency approx. 400 Hz

Hysteresis approx. 4 mm with vertical installation

Signal lamp

- SWING E82 C, R, T LED for indication of switching condition

- SWING E82Z, SWING E82Z EX LED lights when tuning fork covered

CE-conformity

VEGASWING 81 A and 83 A vibrating level switches meet the protective regulations of

EMC (89/336/EWG) and NSR (73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 -1: 1992

Susceptibility EN 50 082 -2: 1995

NSR EN 61 010 -1: 1993

1)

Note the information of the conformity certificate or the EU-type approval certificate.

8 VEGASWING 81A and 83A

Page 9

Product description

Approvals VEGASWING 80 A

WHG

Approval as overfill protection acc. to WHG

Ambient temperature on the housing -40°C … +70°C

Product temperature -40°C … +100°C

- test report Z-65.11-154 VEGASWING 81A EX/83A EX with oscillator

- test report Z-65.11-163 VEGASWING 81A EX / 83A EX with oscillator

- with temperature adapter up to 150°C

Operating pressure max. 40 bar

Recurring test acc. to WHG

According to the type approval to WHG (Z-65.11-154) the recurring test acc. to WHG can

be carried out by pr essing the test key on the VEGA TOR 536 EX, 537 EX, 636 EX signal

conditioning instrument. The sensor must not be removed, nor can a response be triggered by filling the vessel. This is valid for VEGASWING 81 A EX and 83 A EX with two-wire

oscillator SWING E82 Z EX.

Explosion protection VEGASWING 81A EX0, 83A EX0

Certificate EU-type approval certificate acc. to ATEX 100 a

Classification mark II 1 G EEx ia IIC T6

Permissible application range Ex Zone 1, Ex Zone 0

Ambient temperature dependent on temperature class and Ex-Zone:

see EU-type approval certificate

Electrical safety characteristics:

see EU-type approval certificate

SWING E82Z EX and suitable signal

conditioning instrument

SWING E82 C, R, T

TÜV 98 ATEX 1320 X

Oscillators

C - Non-contact switch (SWING E82 C)

Supply voltage 20 … 250 V AC, 50/60 Hz or 20 … 250 V DC

Output non-contact switch

Current consumption approx. 3 mA (via the load circuit)

Load current min. 10 mA

Protection class I

Overvoltage category III

Modes A: max. level detection, overfill protection

VEGASWING 81A and 83A 9

max. 400 mA (at I > 300 mA the ambient

temperature can be max. 60°C)

max. 4 A to 40 ms (not WHG specified)

B: min. level detection, dry run protection

Page 10

Product description

R - Relay output (SWING E82 R)

Supply voltage 20 … 250 V AC, 50/60 Hz or 20 … 72 V DC

(at U > 60 V DC the ambient temperature can

be max. 50°C)

Power consumption 1 … 9 VA AC, max. 1,5 W DC

Output relay output (DPDT), 2 floating spdt

Relay data

- potential separation min. 500 V DC

- contact material AgCdO and Au-plated

- turn-on voltage min. 10 mV

max. 250 V AC, 250 V DC

- switching current min. 10 µA

max. 5 A AC, 1 A DC

- breaking capacity max. 750 VA AC, 54 W DC‘

Protection class I

Overvoltage category II

Modes A: max. level detection, overflow protection,

overfill protection

B: min. level detection, dry run protection

T - Transistor output (SWING E82 T)

Supply voltage 10 … 55 V DC

Power consumption max. 0,5 W

Output floating transistor output

overload and permanently short-circuit proof

Load current max. 400 mA

Voltage loss max. 1 V

Turn-on voltage max. 55 V DC

Blocking current < 10 µA

Protection class II

Overvoltage category III

Modes A: max. detection, overflow protection,

overfill protection

B: min. detection, dry run protection

Z - Two-wire output (SWING E82Z)

Supply voltage 12 … 36 V DC (via VEGA-signal conditioning

instrument)

Output two-wire output

Required signal conditioning instrument VEGATOR 536 EX, 537 EX, 636 EX,

VEGALOG 571

Current consumption

- tuning fork free approx. 8 mA

- tuning fork covered approx. 16 mA

- fault signal > 22 mA

Protection class II

Overvoltage category III

Modes definition via signal conditioning instrument

10 VEGASWING 81A and 83A

Page 11

VEGASWING 81A and 83A 11

75

85

VEGASWING 81A EX

Product description

1.4 Dimensions

Thread

G 1 A or 1" NPT

20

129

100

30,5

Ø 60

Ø 29

25

SW 41

Cone DN 25

116 55

25

Ø 55

Ø 80

Ø 29

90

Ø 44

Ø 35,1

Ø 38,1

Ø 29

1

/2"

TRI-Clamp 1

119 30

21,5

Temperature adapter made of

1.4571 (optional)

Ø 41

TRI-Clamp 2"

Ø 29

119 30

21,5

Ø 47,8

Ø 50,8

50

Bolting

DN 40/50, DIN 11 851

31

Ø 29

117

1

/

Rd 65x

6

33

Ø 38

Ø 43

1

/

Rd 78x

6

35

Ø 50

Ø 55

Switching point

Page 12

12 VEGASWING 81A and 83A

75

85

90

Temperature adapter made of

1.4571 (optional)

Ø 44

50

VEGASWING 81A EX

Tuchenhagen

Varivent

58

117

100

40

Rd 65x

Ø 79,6

Compression nut

F40 PN 25

Tension flange

F32 PN 25

Ø 41

Enamelled flange

DN 50

Flange DN 50

40

Ø 29

120

Ø 90

Ø 72/6xM6

Ø 29

Ø 29

120 29

120 40

Ø 29

117 58

25

1

/

6

Ø 31

Switching point

Product description

40

Ø 79,6

Page 13

VEGASWING 81A and 83A 13

75

85

VEGASWING 83A EX

Product description

Thread G 1 A or

1“ NPT

20

L (min. 180, max. 4.000 mm)

100

30,5

Ø 60

Ø 29

25

SW 41

90

Ø 44

Cone PN 25

55

Ø 29

L (min. 180, max. 4.000 mm)

25

Ø 55

Ø 80

Ø 35,1

Ø 38,1

Ø 29

1

/2“

Tri-Clamp 1

30

L (min. 180, max. 4.000 mm)

21,5

Temperature adapter made

of 1.4571 (optional)

50

Ø 41

Tri-Clamp 2“

30

Ø 29

L (min. 180, max. 4.000 mm)

21,5

Ø 47,8

Ø 50,8

Bolting DN40/50 DIN

11851

31

Ø 29

L (min. 180, max. 4.000 mm)

Switching

point

Rd 65 x 1/6

33

Ø 38

Ø 43

35

Rd 78 x 1/6

Ø 50

Ø 55

Page 14

Locking for height adjust-

ment up to 25 bar

½

½

Temperature adapter made

of 1.4571 (optional)

Ø

VEGASWING 83A EX

Compression nut

Locking for height

adjustment

½

½

F40 PN 25

Ø

Ø

Tension flange

F32 PN 25

Ø

Ø

Ø

Ø

Tuchenhagen

Varivent

Ø

Ø

Flange DN 50

Ø

Enamelled flange

DN 50

Ø

Page 15

Product description

1.5 T ype plate

Please check that the correct instrument is

being used before mounting and electrical

connection. Note the type plate which is located as follows:

Type plate

The type plate contains important data required for mounting and connection. The

layout and the parts of the type plate are

explained in the following example.

Layout of the type plate (example)

®

1

2

3

4

SWING 8. AEX

type: SWING8.AEX0...

electronic: SWING E82Z EX

TÜV 98ATEX .... II 1G EEx ia IIC T6

techn. data see document./certificates

PN: see flange, max. 40bar

IP66/67 length: ... mm

Ord. no. 123456/000

®

D-77757 Schiltach

Z-65.13.XXX

ser.no.

6

XXXXXXXX

0032

1998

1 Order no. master data

2 Ex-certification number

Explosion protected version - note the

information and conditions in the certificate

3 Electronics data / Approvals

4 No. of the order confirmation/Pos. no.

5 Serial number

6 Test mark when used as par t of an over fill

protection for vessels storing water -endan-

gering liquids - note the information and

conditions of the general type approval

7 Year of manufactur e

8 CE test authority no.

8

7

5

Order code

Detailed information on the order code is

provided in the "Product Information Vibration“ or in the "VEGA pricelist “.

VEGASWING 81A and 83A 15

Page 16

2 Mounting

Mounting

2.1 VEGASWING

In principle, VEGASWING can be mounted in

any position. The instrument must be

mounted such that the tuning fork is at the

height of the required switching point. Note

the following installation instructions:

Transport

Do not hold VEGASWING by the tuning fork

as particularly with flange or tube versions,

the tuning fork can be damaged by the instrument’s weight. Transport enamelled and

ECTFE-coated instruments very carefully and

avoid touching the tuning fork.

Switching point

The tuning fork is provided with lateral markings (notches) marking the switching point

with vertical installation for the medium water.

When installing VEGASWING note that the

marking is at the required height. Note that

the switching point of the instrument shifts

when the medium has a density differing from

water (water = 1,0 g/cm3). The switching

point can be adapted using a potentiometer

to set it to the marking (notch). With the adjustment 1,0 g/cm3 a switching point from a

density of > 0,7 g/cm3 is ensured. For products with a density < 0,7 g/cm3 the potentiometer must be readjusted on the SWING

E82 C, R, T oscillator as follows: 0,5 … 1,5 g/

cm3, oscillator SWING E82 Z: 0,5 … 1,0 g/cm

(see fig. 2.1).

Vertical installation

from top, from bottom

Switching point

with low density

Switching

point

approx.

25 mm

Switching point

higher density

Horizontal installation

Switching point

Recommended installation position for adhesive products:

Top marking

Switching

point

approx.

15 mm

3

Adhesive products

In the case of horizontal mounting in adhesive

and viscous products, the surfaces of the

tuning fork should be vertical to reduce buildup on the tuning fork (see fig. 2.2). The position of the tuning fork is marked by a notch

on the hexagon of VEGASWING. Therefore

you can check the position of the tuning fork

when screwing in. When the hexagon is on

the seal, the thread can be still turned by

approx. half a turn. This is sufficient to reach

the recommended installation position.

Switching

point

75 mm

Fig. 2.1

Fig. 2.2

16 VEGASWING 81A and 83A

Page 17

Mounting

In the case of adhesive and viscous products, the tuning fork should protrude into the

vessel to avoid build-up. Sockets for flanges

and mounting bosses should not exceed a

certain length. For flange versions, the socket

should have a length of max. 40 mm, for

threads max. 30 mm, see also Mounting

boss.

Pressure

In the case of gauge or low pressure in the

vessel, the mounting boss must be sealed on

the thread. Cover the thr ead with Teflon tape,

hemp or something similar , or use a suf ficiently resistant seal ring.

Vibrations

Extreme vibrations and shocks, e.g. by stir rers and turbulence in the vessel, can cause

resonance vibrations in the extension tube of

VEGASWING 83 A. This causes increased

wear on the upper weld joint.

Provide an appropriate fixing or fastening

directly above the tuning fork to fasten the

extension tube (see fig. 2.3).

This is mainly valid for applications in

Ex-area category 1G or WHG. Note

that the tube will not be bent by this

measure.

Stirrers

The level switch can be subjected to strong

lateral forces by stirrers etc. Therefore do not

choose too long an extension tube for

VEGASWING 83 A, but check whether it is

possible to mount a VEGASWING 81 A level

switch laterally in a horizontal position.

Cable entries

Use cable with a circular conductor crosssection and tighten the cable entr y. The cable

entry is suitable for cable diameters of 4 mm

to 12 mm.

Two seal rings ar e attached to the instrument:

- for cable diameters of 4 … 9 mm

- for cable diameters of 5 … 12 mm.

Careful sealing of the cable entry is very

important when mounting outdoors, in humid

areas (e.g. for cleaning processes) or on

cooled or heated vessels (see fig. 2.4).

Humidity

Turn the cable entr y of horizontally mounted

instruments to the bottom to avoid humidity

ingress. The plastic housing can be rotated

by approx. 330 °. On vertically installed instruments loop the connection cable to the

instrument housing to the bottom, so that rain

or condensation can drain off. This is mainly

important when mounting outdoors, in humid

areas (e.g. for cleaning processes) or on

cooled or heated vessels (see fig. 2.4). When

lowering the housing cover checkthat the

transparent light guide (inspection glass) is

above the LED. When the housing cover is

lowered in the wr ong way, the switching point

of the sensor is no longer visible from outside

and the housing will not be perfectly sealed.

Fig. 2.3

VEGASWING 81A and 83A 17

Page 18

Fig. 2.4

Mounting

Lockings

A locking is available for height adjustment on

the VEGASWING 83 A with screw connection.

This locking allows adjustment and modification of the switching point after installation.

Bring the switching point of the tuning fork to

the requireded height. Lock the tube in this

position by tightening the pr essure scr ew.

Secure the pressure screw against loosening

with the fixing screw.

You can use VEGASWING 83 A in vessels

with up to 25 bar pressure. Use the locking

(G 11/2 A, 11/2“ NPT) up to 25 bar

(ARV2EX0.C…). Follow the operating instructions for the locking.

Lateral load

Ensure that the vibrating element is not subjected to lateral forces. Mount the instrument

at a location in the vessels wher e no interfering influences such as those caused by

stirrers, filling openings etc. can occur . This is

particularly important for instrument types

with cables or extension tubes (see fig. 2.5).

The surfaces of the tuning fork should be

parallel to the product movement, so that the

tuning fork of VEGASWING offers only little

resistance.

Fig. 2.5

VEGASWING with enamel or ECTFE

Treat instruments with enamel or ECTFEcoating very carefully and avoid shocks.

Unpack VEGASWING just before mounting.

Insert VEGASWING carefully into the vessel

opening provided and avoid contact with

sharp-edged vessel parts.

Flow

(e.g. in pipes)

When mounting in pipes or in vessels with

certain flow direction, you should mount

VEGASWING such that the surfaces of the

tuning fork follow the flow direction, see also

"Welded socket“.

18 VEGASWING 81A and 83A

Page 19

Mounting

VEGASWING’s thread start is defined. This

means that each VEGASWING is in the same

position after screwing in. Therefore remove

the supplied seal from the thread of VEGASWING. This seal is not required when using a

welded socket. Screw VEGASWING into the

welded socket.

You can deter mine the subsequent position

of VEGASWING before welding (see fig. 2.2).

Mark the appropriate position of the welded

socket. Before welding unscrew VEGASWING and remove the rubber ring from the

welded socket.

An optional welded socket is available which

is already provided with a marking. Weld this

welded socket with the marking facing upwards (see fig. 2.6).

Marking

Fig. 2.6

Installation examplesWelded socket

Mounting not

suitable for

adhesive products

Fig. 2.7

VEGASWING 81A and 83A 19

Page 20

3 Electrical connection

Danger

Note

Note

Overvoltage protection

•

• °

“

•

•

•

Page 21

Non-contact switch (SWING E82 C)

–

–

…

…

Floating relay output (SWING E82 R)

… …

T wo-wire output (SWING E82 Z)

…

Page 22

Floating transistor output

(SWING E82 T)

Connection examples

…

Page 23

Control of alternating current loads

…

Note

Page 24

4 Set-up

Indicating and adjustment elements

“

“

Note

Switching point adaptation

“

Page 25

Set-up

Fault monitoring

VEGASWING’s oscillator continuously monitors the instrument for the following faults:

- tuning fork corrosion or damage

- absence of vibration

- line break for vibration actuation

- vibrating frequency too low

- corrosive medium penetrating the sensor

from the vessel side.

More functions can be monitored. The correct

functioning of the complete measurement

chain canbe monitored at the touch of a button when the SWING E82 Z oscillator is used

in conjunction with an appropriate signal

conditioning instrument.

VEGASWING 81A and 83A 25

Page 26

4.1 Functions table

Mode A

Mode B

Level Switching condition Control Current Control Control

SWING SWING SWING lamp consump. lamp lamp

E82 C

1)

E82 R

1)

E82 T VEGA- SWING VEGA- VEGA-

SWING E82 Z SWING TOR

Failure of

the voltage

supply(mode

A/B)

Failure

Note:

Page 27

Diagnosis

5 Diagnosis

5.1 Recurring test acc. to WHG

The implementation of the recurring test acc.

to WHG is stated in the general type approval no. Z-65.11-154 or Z-65.11-163, see

paragraph 8 of the certificate.

Note these approvals when VEGASWING

81A and 83A are used as part of an overfill

protection acc. to WHG.

VEGASWING 81A EX and 83A EX with VEGATOR 536 EX, 537 EX, 636 EX signal conditioning instruments meet the requirements

acc. to AK 3 in mode A (overfill protection).

Recurring test acc. to WHG

According to the type approval to acc. WHG

(no. Z-65.11-154) the recurring test can be

carried out by pushing the test key on the

VEGATOR 536 EX, 537 EX, 636 EX signal

conditioning instrument. The sensor must not

be removed, nor made to respond by filling

the vessel. This is valid for VEGASWING

81A EX and 83A EX with two-wire SWING

E82 Z EX oscillator.

With the current values provided you can

carry out the function test also directly via a

PLC or a processing system.

The implementation and the switching sequence of the function test are stated under

"Test key“ and the following table in the oper ating instructions of the appropriate VEGATOR signal conditioning instrument.

Test key

For setting-up meassuring instruments in

conjunction with the two-wire oscillator

(SWING E82Z EX) a function test can be

carried out. The VEGA TOR signal conditioning instrument has an integral test

keylowered into the front plate. Push the test

key with a suitable object (scr ewdriver, pen

etc.). When pushing the key , the system is

checked according to the following criteria:

- switching function of the switching outputs

- switching function of the failure outputs

- potential separation of the outputs

- signal processing of the signal conditioning

instrument.

After pushing the test key , the complete

measuring system will be checked for cor rect function. During the test the following

operating conditions are simulated:

- fault signal

- empty signal

- full signal.

Check that all three switching conditions

occur in the correct sequence and for the

stated duration. If this is not the case, there is

a failure in the measuring system (see "5.2

Failure removal“ in the operating instructions

of the signal conditioning instrument). Note

that the connected instruments are activated

during the function test. Thus you can check

the correct function of the measuring system.

Thanks to this fault monitoring, the combination of the following instruments corresponds

to classes 1 to 3 (AK 3) acc. to DIN 19 251.

AK 3 means that the system is fail safe.

- VEGASWING 81A EX, 83A EX

- SWING E82Z EX oscillator

- VEGATOR 536 EX, 537 EX and 636 EX

signal conditioning instrument

VEGASWING 81A and 83A 27

Page 28

Diagnosis

Test procedure A-mode B-mode

1 Simulation of a fault signal ( approx. 3 s after release of key )

Level relay deenergized > 22 mA

Failure relay deenergized < 2,2 mA

1)

2)

2)

2 Simulation of an empty signal (approx. 1,5 s)

Level relay energized 8 mA

2)

Failure relay energized

3 Simulation of a full signal (approx. 1,5 s)

Level relay deenergized 16 mA

2)

Failure relay energized

4 Return to the actual operating condition (covered/uncovered)

1)

as long as the key is pushed, the instrument signals failure.

2)

VEGASWING state

With the provided current values, you can also carry out the function test directly via a PLC or

a processing system.

5.2 Replacement of electronics

• Connect the connection cables again and

switch on the voltage supply .

• Interrupt the voltage supply and disconnect the connection cables and the switching current circuit on the switching cabinet.

• Make sure that there is no Ex-atmosphere.

• Loosen the four screws of the housing

cover with a screwdriver and remove the

cover.

• Disconnect the connection cables on the

oscillator.

• Remove the old oscillator and insert the

new one.

The sensor is immediately ready for operation.

• Replace the housing cover and tighten the

screws.

Note when replacing the housing cover

that the transparent light guide (inspection

glass) is above the LED. When the housing

cover is not r eplaced correctly, the switching condition of the sensor is no longer

visible and the housing is not sealed

optimally.

• Set the A/B-switch to the same position as

on the old oscillator (not with SWING

E82 Z).

• Set the potentiometer for the density adjustment of the new electronics to the same

value as on the old oscillator.

28 VEGASWING 81A and 83A

Page 29

5.3 Failure removal

Failure Measure, failure removal

W

…

Page 30

Diagnosis

b.Current value > 22 mA

- Check all connections and the connection cable to the sensor .

- Should the red failure lamp still light, separate the sensor from the

connection line and connect a resistor of 1 kW instead.

If the failure lamp goes out, the sensor is defective. Check the connected sensor.

- Should the failur e lamp still light, r econnect the sensor. Separate the

signal conditioning instrument from the connection cable and connect

a resistor of 1 kW to the sensor input.

- If the failure lamp still lights, the signal conditioning instrument is defective. In this case r eturn the instrument to VEGA for r epair.

- If the failure lamp goes out, there is probably a short-circuit in the

connection cable. Check the connection cable to the sensor .

Malfunction during After pushing the test key , the switching conditions do not occur in the

function test correct sequence or for the correct period, e.g. there is no full signal

provided.

- Measure cable resistance

When the line is high-resistance, you must take appropriate measures to reach a standard resistance. E.g. check the terminals and

cable connections for corrosion.

30 VEGASWING 81A and 83A

Page 31

Notes

VEGASWING 81A and 83A 31

Page 32

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail: info@vega-g.de

ISO 9001

The statements on types, application, use and operating conditions

of the sensors and processing systems correspond to the actual

knowledge at the date of printing.

Technical data subject to alteration.

2.13 719 / July ’99

Loading...

Loading...