Page 1

Level and Pressure

Operating Instruction

VEGASWING 81, 83 fail safe

and signal conditioning instrument VEGATOR 526 Ex

VEGATOR 526 Ex

on

Page 2

Contents

Safety information ........................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 3

1.2 Approvals ............................................................................. 5

1.3 Recurring test acc. to WHG ................................................. 6

1.4 Technical data and dimensions ........................................... 7

2 Mounting

2.1 VEGASWING ...................................................................... 13

3 Electrical connection

3.1 VEGASWING ...................................................................... 18

3.2 Connection plan VEGATOR 526 Ex ................................... 19

4 Set-up

4.1 VEGASWING 8… W5␣ Ex.C................................................. 22

4.2 Signal conditioning instrument VEGATOR 526 Ex ............ 23

Contents

5 Diagnosis

5.1 Failure removal ................................................................... 26

Safety information

The described module must only be installed

and operated as described in this operating

instruction. Please note that other action can

cause damage for which VEGA does not take

responsibility.

2 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Page 3

Product description

1 Product description

1.1 Function and configuration

VEGASWING 81␣ W5␣ Ex.C and 83␣ W5␣ Ex.C fail

safe vibrating level switches detect levels of

liquids with a viscosity of 0,2 mPa␣ s to

10.000␣ mPa␣ s and a density ≥␣ 0,5␣ g/cm3. The

modular construction enables the use in

vessels, tanks and pipelines. Typical

applications are overfill protections according

to AK5.

Due to the simple and rugged measuring

system, VEGASWING can be used virtually

unaffected by the chemical and physical

features of the liquid. It operates also under

arduous conditions such as turbulences, air

bubbles, foam generation, build-up and

changing medium.

With the mechanical connections thread and

flange, VEGASWING 81␣ W5␣ Ex.C or

83␣ W5␣ Ex.C can be used in manifold

applications.

For the use in very aggressive products,

Hastelloy C4 and ECTFE (halar), Säkaphen

and enamel-coatings are used for

VEGASWING 81 and 83.

VEGASWING 83 F… can be coated with

enamel or up to 1200 mm and Säkaphen up to

4␣ m tube length.

Function

The tuning fork is piezoelectrically energized

and vibrates at a resonance frequency of

approx. 400␣ Hz. A second piezoelectrical

element measures the resonance frequency of

the tuning fork. When the tuning fork is

covered with the medium, the resonance

frequency changes. This frequency change is

continuously detected by the integral oscillator

and converted into a switching command by

the connected signal conditioning instrument.

With a mode switch you can determine the

switching mode (overfill protection or

protection against dry running of pumps).

Note that VEGASWING 8…␣ W␣ Ex.C only meets

the fail safe requirements in mode A (overfill

protection).

Fail safe / Self-monitoring

A special feature of this instrument

configuration VEGATOR 526␣ Ex with

VEGASWING 81␣ W5␣ Ex.C or 83␣ W5␣ Ex.C is the

integral self-monitoring. It is based on a redundant microcomputer system in the signal

conditioning instrument and includes the

complete measuring chain from the tuning fork

via the oscillator, the two-wire line as well as

the signal conditioning instrument (see also

“1.3 Recurring test acc. to WHG“).

For medium temperatures of more than 100°C

to 130°C VEGASWING 81␣ W5␣ Ex.C and

83␣ W5␣ Ex.C must be equipped with a

temperature adapter.

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 3

The self-monitoring includes two routines:

- the permanent monitoring

- the cyclical self-test.

During the permanent monitoring the signal

conditioning instrument induces the oscillator

of the sensor to carry out a test cycle in

960␣ msec-cycle. Hence defined test signals

are transmitted via the two-wire line to the

signal conditioning instrument. Probable errors

in the sensor electronics as well as line break,

shortcircuit and mechanical damages on the

fork are signalled via these test signals.

Page 4

Product description

During the cyclical self-test safety relevant

components and procedures (e.g. level relay,

CPU) are checked in a very narrow time

pattern in the signal conditioning instrument.

The fault monitoring of the level relay is made

without interruption of the circuit of connected

systems.

The integral fault monitoring detects:

- interruption of the connection line to the

piezoelements

- strong abrasion on the tuning fork

- break or damage of the tuning fork

- vibration failure

- all safety relevant components (sensor and

signal conditioning instrument) are

permanently monitored (drift, component

failure, time failure etc.)

- meets requirement class 5 (AK5) acc. to

DIN␣ V␣ 19␣ 250

- two-wire line on line break and shortcircuit.

Overfill protection with VEGASWING 83 W5 Ex.C

If a so called failure is determined or in case

of voltage failure, the electronics takes a

defined switching condition, i.e. the failure is

signalled via a defined current to the

connected signal conditioning instrument

VEGATOR 526␣ Ex and the level and fail safe

relays de-energize.

Configuration

A measuring system consists of:

- a VEGASWING with oscillator

SWING␣ E86␣ Ex

- a signal conditioning instrument VEGATOR

526 Ex

- external instruments switched by VEGATOR

(signallers, horns etc.).

Ex-Zone 1

VEGASWING

Two-wire line

4 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

(intrinsically

safe circuit)

Not Ex-area

VEGATOR 526 Ex

VEGATOR 526 W Ex

on

Relay for

max. signal

Relay for fault

!

signal

Page 5

Product description

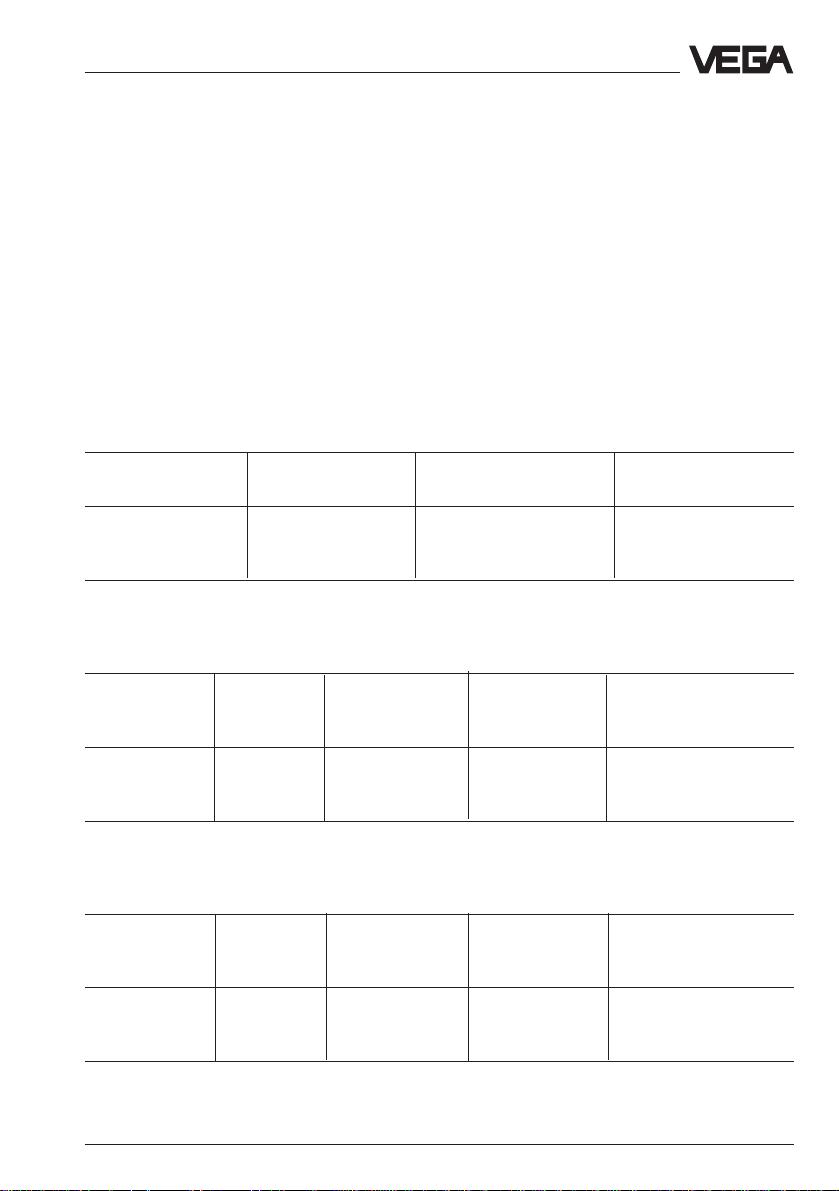

1.2 Approvals

VEGASWING 81 W5␣ Ex.C and 83␣ W5␣ Ex.C fail

safe are certified acc. to CENELEC Exprotective regulations. An approval for the use

in PTB Zone 0 in the scope of ElexV

(Germany) is available.

VEGASWING 81␣ W5␣ Ex.C and 83␣ W5␣ Ex.C fail

safe are approved as part of an overfill

protection acc. to Water Resources Law

(WHG).

Overfill protection acc. to Water Resources Law (WHG)

Level detection with fault monitoring

Instrument Oscillator Level switch General type

VEGASWING SWING E86 Ex 526 Ex Z-65.11-31

81 W5 Ex.C,

83 W5 Ex.C

Level measuring instruments for the use in hazardous areas PTB Zone 0 (Germany)

Level detection with fault monitoring

Instrument Oscillator Conformity Level switch Conformity

certificate VEGATOR certificate

PTB-no. VEGATOR BVS-no.

For these applications, the appropriate legal

documents must be noted (general type

approval and conformity certificates). These

are supplied with the appropriate instrument.

DIN

The overfill protection meets requirement

class 5 (AK5) acc. to DIN␣ V␣ 19␣ 250.

VEGATOR approval

VEGASWING SWING Ex-97.D.2046 526 Ex 93.C.2015 X

81 W5 Ex, E86 Ex

83 W5 Ex

Level measuring instruments acc. to CENELEC for the use in hazardous areas

Level detection with fault monitoring

Instrument Oscillator Conformity Level switch Conformity

VEGASWING SWING Ex-97.D.2046 526 Ex 93.C.2015 X

81 W5 Ex, E86 Ex

83 W5 Ex

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 5

certificate VEGATOR certificate

PTB-no. BVS-no.

Page 6

Product description

1.3 Recurring test acc. to WHG

Acc. to the general type approval Z-65.11-31 the sensor must neither be removed nor controlled

for the annual recurring test acc. to WHG.

Due to the certified fail-safe condition of the overfill protection (AK5 acc. to DIN␣ V 19␣ 250) the

recurring test for the instrument and the transmitter (signal conditioning instrument) is not

required. Hence the test of the overfill protection is reduced to the function test of the

connected system parts. This can be made, e.g. by interruption of the circuit to the signal or

control system.

Note the instruction under “3.4 Connection plan VEGATOR 526 Ex“.

6 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Page 7

Product description

1.4 Technical data and dimensions

VEGASWING 81 W5 Ex.C and 83 W5 Ex.C

Housing

Housing material PBT (Polyester)

Protection IP 66

Cable entry 1 x Pg 13,5

Terminals max. 1 x 1,5 mm

Mechanical connection

Thread G 1 A or 1“ NPT

- material 1.4571 (V4A) or Hastelloy C4 (2.4610)

Flanges DIN and ANSI from DN 50

- material 1.4571, 1.4571 with Hastelloy C4 plated

DN 50 PN 40 steel enamelled

Tuning fork

Material 1.4581, Hastelloy C4, Hastelloy C4 enamelled

1.4581 with Säkaphen or ECTFE plated

Extension tube (VEGASWING 83 W5 Ex)

Material 1.4571, Hastelloy C4, Hastelloy C4 enamelled

1.4571 with Säkaphen or ECTFE plated

Length

- 1.4571, Hastelloy C4 200 mm … 4000 mm

- Hastelloy C4 enamelled 200 mm … 1200 mm

- 1.4571, Halar 200 mm … 1200 mm

- 1.4571, Säkaphen 200 mm … 4000 mm

2

Weight

Plastic housing approx. 1,5 kg

Tube extension approx. 0,11 kg/m (VEGASWING 83 W5 Ex.C)

Ambient conditions

Ambient temperature on housing -40°C … +65°C

Storage and transport temperature -40°C … +70°C

Medium temperature -40°C … +100°C

Medium temperature with temperature

adapter of 1.4571 (option) -40°C … +130°C

Operating pressure

Operating pressure max. 25 bar

(VEGASWING 83 W5 Ex.C: with locking

ARV2EX0.C… to 4 bar, otherwise unpressurized)

Test pressure max. 40 bar

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 7

Page 8

Product description

Medium

Viscosity

- dynamic 0,2 … 10.000 mm2/s

Density 0,5 or 1,0 g/cm3 changeable

Function

Mode A/B-mode via signal conditioning instrument

Integration time approx. 0,5 s

Meas. frequency approx. 400 Hz

CE-conformity

VEGASWING 81 W5 Ex.C and 83 W5 Ex.C vibrating level switches meet the protective

regulations of EMVG (89/336/EWG) and NSR (73/23/EWG). The conformity has been judged

acc. to the following standards:

EMVG Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1992

NSR EN 61 010: 1993

A: Max. detection, overfill protecion

(fail␣ safe)

B: Min. detection, dry run protection

(not fail safe)

Approvals VEGASWING 8… W5 Ex.C

Water Resources Law (WHG)

Approval as overfill protection acc. to WHG

Ambient temperature on the housing -40°C … +65°C

Medium temperature -40°C … +100°C

- with temperature adapter to 130°C

Operating pressure max. 25 bar

(general type approval Z-65.11-31)

Oscillator

Two-wire output (SWING E86 Ex)

Supply voltage 12 … 18,9 V DC (via VEGA-signal conditioning

Output two-wire output

Required signal conditioning instrument VEGATOR 526 Ex

Current consumption 4 … 25 mA

Protection class II

Overvoltage category II

Modes definition via signal conditioning instrument

Classification EEx ia IIC T4

8 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

instrument VEGATOR 526 Ex)

Page 9

Product description

Signal conditioning instrument VEGATOR 526 Ex

General

Series module unit for carrier BGT 596 Ex

Dimensions W = 50,8 mm (10 TE), H = 128,4 mm, D = 162 mm

Weight approx. 440 g

Ambient conditions

Ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +70°C

Power supply

Operating voltage UN = 24 V AC (20 … 28 V AC); 50/60 Hz

Power consumption approx. 11 VA or 8 W

Electrical connection multipoint connector DIN 41 612,

Electrical protective measures

Protection class II (in housing type 589-10 Ex)

Overvoltage category II

Protection

- mounted in housing type 589… IP 30

Protection

(mounted into carrier

BGT 596 Ex with Ex-module)

- front side (completely equipped) IP 30

- upper and lower side IP 20

- wiring side IP 00

UN = 24 V DC (16 … 60 V DC

series F (d, z) 32-pole

Inputs

Number 1

Data transmission analogue, 4 … 20 mA

Current limitation 24 mA (permanently shortcircuit proof)

Sensor supply voltage approx. 15 … 18 V DC

Connection line 2-wire (screened)

Resistance per conductor max. 35 Ω

Function

Integration time

- switch on delay 0,5 s

- switch off delay 1,0 s

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 9

Page 10

Product description

Relay output (fail safe)

Number 1 switching relay (closing contact, floating)

Mode A/B-switch

A - max. detection or overfill protection

B - min. detection or dry run protection

Contact 1 spdt each

Contact material AgNi and Au plated

Turn-on voltage min. 12 V DC

max. 250 V AC, 48 V DC

Switching current min. 10 mA DC

max. 2 A AC, 1 A DC

Breaking capacity max. 125 VA AC, 60 W DC

Fail safe relay (not fail safe)

Number 1 fail safe relay (spdt, floating)

Contact material AgCd and au plated

Turn-on voltage min. 10 mV

max. 250 V AC, 48 V DC

Switching current min. 10 µA

max. 2 A AC, 1 A DC

Breaking capacity max. 125 VA AC, 54 W DC

Indicating elements

LED in front plate

- green on operating voltage on

- yellow switch point control

- red fault signal

Set-up key (green) ready for set-up

Approvals

Max. values UO = 18,9 V; IK = 95 mA; P = 647 mW

Characteristics linear

EEx ia IIC EEx ia IIB

Max. permissible outer inductance (mH) ≤ 0,5 ≤ 1 ≤ 1,5 ≤ 2 ≤ 0,5 ≤ 1 ≤ 1,5 ≤ 2

Max. permissible outer capacitance (nF) ≤ 52 ≤ 40 ≤ 27 ≤ 15 ≤200 ≤190 ≤177 ≤160

EEx ib IIC EEx ib IIB

Max. permissible outer inductance ≤ 4 mH ≤ 15 mH

Max. permissible outer capacitance ≤ 240 nF ≤ 1,1 µF

The intrinsically safe circuits are reliably galvanically isolated from all not-intrinsically safe

circuits up to a peak value of 375␣ V of the nominal voltage.

10 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Page 11

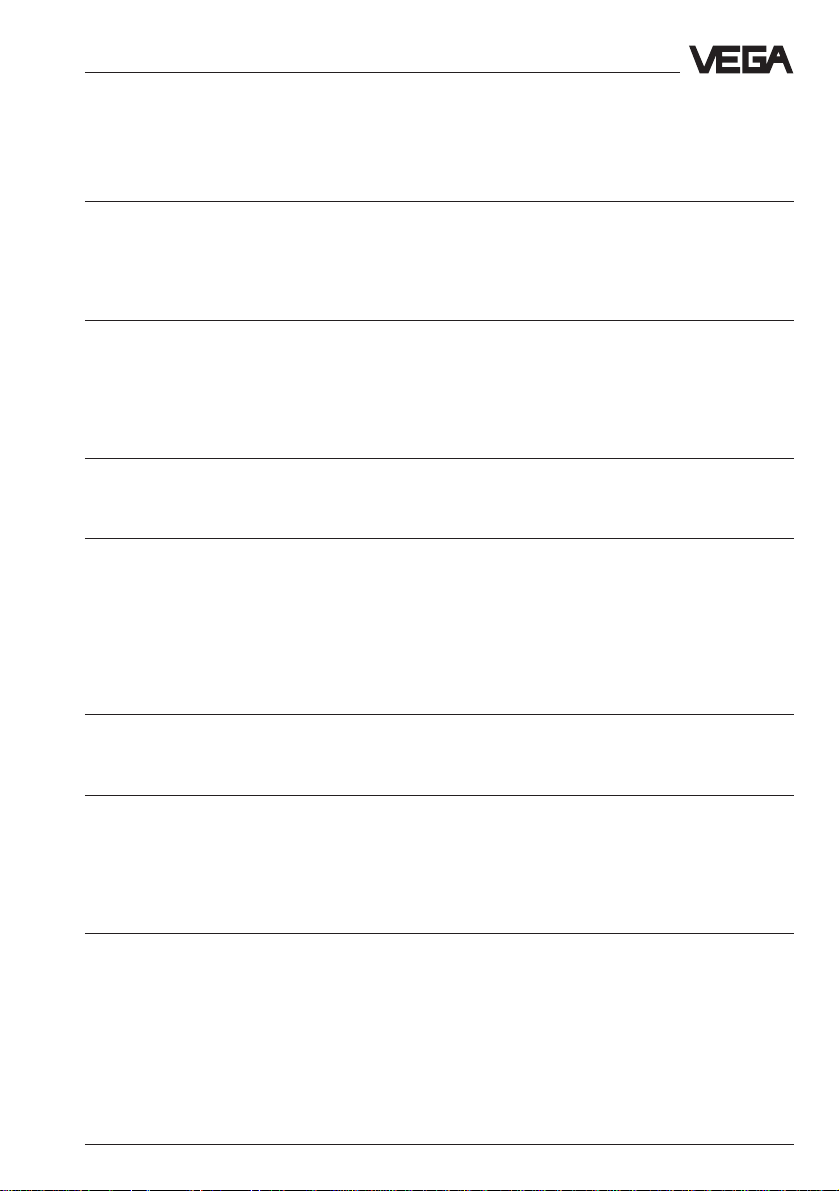

Product description

162

100

12

4

128,4

50,8

10 TE

Electrical connection

Mounted in

- carrier BGT 596 Ex 32-pole multipoint connector, series F (d, z)

- in housing type 589… screw terminal, max. für 1,5 mm

with holes

2

CE-conformity

VEGATOR 526 Ex signal conditioning instrument meets the protective regulations of EMVG

(89/336/EWG) and NSR (73/23/EWG). The conformity has been judged acc. to the following

standards:

EMVG Emission EN 50 081 - 1: 1993

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

Potential stages and galvanic isolation

Sensor

Ex-range

Meas. data input

P1

Microcomputer control and conditioning

P3 P4 P5

Relay contacts

Voltage supply

Power supply unit

P2

Relay contacts

P1 … P5

Potential stages

Fail safe relay

Level relay

Signal conditioning instrument VEGATOR 526 Ex

Circuit board 100 x 160 x 1,5

European size

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 11

Multiple plug

Page 12

VEGASWING 81 W5 Ex.C and 83 W5 Ex.C WHG

Product description

VEGASWING 81 … VEGASWING 83 …

VEGASWING 81 G1 / N1

Thread G 1 A or 1"␣ NPT

153

128

29

Mounting boss acc.

to DIN (accessory)

SW 41

100

26

VEGASWING 81 F

ø60

VEGASWING 81 F

157

118

enamelled

170

~130

75

Flange DN 50

25

25

26

80x110

VEGASWING 83 G1 / N1

Thread G 1 A or 1"␣ NPT

25

Switch

point

L (min. 200, max. 3000 mm)

Switch

point

20

65

~30

Temperature adapter of 1.4571

(option)

51

ø41

ø29

100

26

SW 41

SW 60

G11/2 A or

11/2"␣ NPT

VEGASWING 83 F

Flange DN 50

39

L (min. 200, max. 3000 mm)

39

Switch point

25

VEGASWING 83 F

enamelled

Locking unpressurized

SW 60

SW 60

L (min. 200, max. 1200 mm)

49

20

G11/2 A or

11/2"␣ NPT

26

Switch

25

point

Locking up to 4 bar

12 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Page 13

Mounting

2 Mounting

2.1 VEGASWING

Generally VEGASWING can be mounted in

any individual position. The instrument must

just be mounted such, that the tuning fork is at

the height of the requested switch point.

However note that VEGASWING is only fail

safe as overfill protection (mode A). Note the

following for mounting:

Transport

Do not hold VEGASWING on the tuning fork.

Especially on flange and tube versions the

tuning fork can be damaged by the instrument

weight.

Switch point

Laterally on the tuning fork there are markings

for the switch point in vertical installation in

relation to the medium water. Note when

mounting VEGASWING that the marking is at

the height of the requested level. Note that the

switch point of the instrument is shifted when

the medium has a density deviating from

water (water = 1,0 g/cm3). Adjust the

appropriate density range on VEGATOR

526␣ Ex. See also “4.2 Signal conditioning

instrument VEGATOR 526␣ Ex“ (see fig. 2.1).

Vertical mounting

from top, from bottom

Switch point with

low density

Switch

point

approx.

25 mm

Switch point with

higher density

Switch

point

75 mm

Horizontal mounting

Switch point

recommended installation position for

adhesive products:

Marking on top

Switch point

Fig. 2.2

Adhesive mediums

For horizontal mounting in adhesive and

viscous mediums, the surface of the tuning

fork should be vertical to reduce build-up on

the fork (see fig. 2.2). The position of the

tuning fork is marked on the hexagon of

VEGASWING. Hence you can check the

position of the tuning fork during mounting.

When the hexagon is placed to the seal, the

thread can be turned by half a turn. This is

sufficient to reach the recommended

installation position.

For adhesive and viscous mediums the tuning

fork should protrude into the vessel to avoid

build-up. Sockets for flanges and mounting

bosses should therefore not exceed a certain

length. With flange versions, the socket

should have a length of max. 40␣ mm, with

threads max. 30␣ mm. The slide switch for the

density adjustment must be set to position 2.

Fig. 2.1

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 13

Page 14

Mounting

Pressure

In case of overpressure or gauge pressure in

the vessel, the mounting boss must be sealed

on the thread. Cover the thread with Teflon

tape, hemp etc. or use a seal ring.

Vibrations

Extreme vibrations and shocks e.g. by stirrers

and turbulences in the vessel can energize

the extension tube of VEGASWING 83 to

resonance frequencies. This causes an

increased wear on the upper weld joint.

Therefore provide a suitable support or fixing

directly above the tuning fork to fasten the

extension tube (see fig. 2.3).

This is mainly valid for applications in Ex-area

zone 0 or acc. to VbF. Note that the tube is not

bent by this measure.

Humidity

Turn the cable entry of horizontally mounted

instruments to the bottom to avoid humidity

ingress. The plastic housing is therefore

rotational by approx. 330°. For vertically

mounted instruments loop the connection line

to the instrument housing to the bottom so that

rain and condensation water can drain off.

This is mainly valid for mounting outside, in

humid areas (e.g. by cleaning processes) or

on cooled or heated vessels (see fig. 2.4).

Fig. 2.4

Lockings

For VEGASWING 83…␣ G and 83…␣ N a locking

is available for height adjustment. The switch

point can be adjusted after mounting and

modified afterwards.

Adjust the switch point of the tuning fork to the

requested height. By tightening the pressure

screw you fix the tube to this position.

Fig. 2.3

Stirrers

Due to stirrers etc. the level switch can be

subjected to strong lateral forces. For this

reason the extension tube of VEGASWING

83␣ W5␣ Ex.C should not be too long, better

check if it is possible to mount a level switch

VEGASWING 81␣ W5␣ Ex.C laterally in horizontal position.

14 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

For pressure applications you have to secure

the pressure screw with the fixing screw.

VEGASWING 83…␣ G and 83…␣ N can be used

in vessels with up to 4␣ bar pressure. Therefore

use the locking (G␣ 11/2␣ A, 1/2“␣ NPT) up to 4␣ bar

(ARV2EX0.C…). Note the operating instruction

of the locking.

Page 15

Mounting

Cable entries

Use cable with round cross section area of

conductor and tighten the cable entry. The

cable entry is suitable for cable diameters

from 5␣ mm to 12␣ mm.

Lateral load

Note that the vibrating element is not

subjected to lateral forces. Mount the

instrument on a position in the vessel where

no interfering influences such as e.g. by

stirrers, filling openings etc. occur. This is

mainly due for instrument types with extension

tube (see fig. 2.5). The surfaces of the tuning

fork should be in parallel to the product

movement so that there is only little resistance

by the tuning fork of VEGASWING in case of

product movements.

VEGASWING with enamel

Treat the instruments with enamel-coating very

carefully and avoid strong shocks or impacts.

Unpack VEGASWING just before mounting.

Insert VEGASWING carefully into the provided

vessel opening and avoid any contact with

sharp-edged vessel parts.

Flow

(e.g. in tubes)

When mounting in tubes or in vessels with

certain flow direction, VEGASWING should be

mounted such that the surfaces of the tuning

fork must be along the flow direction.

Mounting boss

VEGASWING has a defined beginning of

thread. This means that each VEGASWING is

always in the same position after screwing in.

Hence remove the supplied seal from the

thread of VEGASWING. This thread is not

necessary when using a mounting boss.

Screw VEGASWING into the mounting boss.

You can determine the later position of

VEGASWING already before welding (see fig.

2.2). Mark the appropriate position of the

mounting boss. Before welding, you have to

unscrew VEGASWING and remove the rubber

ring from the mounting boss.

Optionally a mounting boss is available which

is already provided with the marking. Weld

this mounting boss with the marking to the top

(see fig. 2.6).

Fig. 2.5

Chemical resistance

For applications in Ex-areas or acc. to

WHG and VbF, VEGASWING must

only be used in liquids to which the

materials of the tuning fork system are

sufficiently chemically resistant.

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 15

Marking

(option)

Fig. 2.6

Page 16

Mounting

8

0

Installation examples

Mounting not

suitable for

adhesive

products

Fig. 2.7

Signal conditioning instrument

VEGATOR 526 Ex

VEGATOR can be either mounted with a

module into a carrier BGT 596␣ Ex or into a

single housing type 589-10␣ EX.

Module-Ex (Ex 32)

for VEGATOR 526 Ex

Multipoint connector DIN 41 612, series F, 32pole (d, z) with coded pins, Ex-separating

chamber and mounting material for mounting

in carrier BGT 596 Ex.

The multipoint connection is available as

follows:

- Wire-Wrap standard connection

1,0 x 1,0 mm

- Plug connection 2,8 x 0,8 mm

- Termi-Point standard connection

1,6␣ x␣ 0,8␣ mm

- Soldering connection

- Screw terminals 2 x 0,5 mm

2

For further information concerning mounting,

see the operating instruction of the carrier.

Coding

The multiple plug of the instrument is provided

with a coding hole to avoid interchanging of

the various instruments.

Due to a fixed coded pin on the Ex-module, it

is ensured that only Ex-instruments can be

inserted.

2

4

6

8

10

12

14

16

18

20

(top view)

22

24

26

2

3

32

Fig. 2.8

Coded pin here

Coding of the multipoint connector

Mounting carrier

Mount the appropriate module (Ex-version) to

your carrier BGT 596␣ Ex. Wire the connection

of the multipoint connector according to the

wiring plans on the following pages.

Transparent cover

The front plate of VEGATOR 526 Ex can be

provided with a lockable transparent cover to

avoid unauthorized adjustment. The cover is

attached to the instrument.

16 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Page 17

Mounting

Ex-version

Ex-separating chamber

To ensure sufficient “Air and creeping

distances“, an Ex-separating chamber must

be mounted to the connections of VEGATOR.

Loop the lines through the Ex-separating

chamber and connect the lines. Fasten the

Ex-separating chamber with the lower holding

screw. Note the operating instruction of the

carrier BGT 596␣ Ex.

Module with multipoint

connector acc. to DIN

41␣ 612 for carrier

(back view)

d b z

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

Mounting in carriers

When you mount your VEGATOR with Exapproval in a carrier, you have to use a VEGAEx-module. Keep a distance of at least 10 mm

(2 TE) to modules of other manufacturers.

When you want to mount VEGATOR to the

complete left in the carrier, you have to mount

a blind cover of at least 20 mm (4 TE) in front

of the module of the instrument.

Blind cover

Fig. 2.10

Protection with Ex-applications

In Ex-applications a protection of IP 20 must

be kept in mounted condition. Hence cover

the gaps or free modules from the front by

appropriate blind covers.

Ex-separating

chamber

Fig. 2.9

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 17

Page 18

3 Electrical connection

Electrical connection

3.1 VEGASWING

Danger

Before starting connection work, switch off the

power supply.

Connect mains voltage acc. to the following

connection diagrams.

Note

Generally use screened cable. The screening

of the cable must be earthed at the sensor

side (VEGASWING) via terminal 3.

Overvoltage arresters are recommended in

case of danger of overvoltages. For

connection note the operating instruction of

the overvoltage arresters.

Generally connect VEGASWING to vessel

ground (PA) or in case of plastic vessels to

the next earth potential. Laterally on the

hexagon of the mounting boss or flange there

is a thread (screw M4␣ x␣ 5). This connection is

used to drain off electrostatic charges.

Normally in case of metal vessels, the sensor

has already connection to vessel earth via the

mechanical connection.

For Ex-applications the mounting

regulations for hazardous areas must

be noted.

Two-wire output (SWING E86 Ex)

For connection to a signal conditioning

instrument VEGATOR 526␣ Ex

Voltage supply via the connected signal

conditioning instrument VEGATOR (for further

information see technical data)

When VEGASWING is used in Ex-area or as

part of an overfill protection acc. to WHG, note

the regulations of the conformity certificates,

type approvals and the general construction

approval, see “1.2 Approvals“.

18 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Page 19

Electrical connection

3.2 Connection plan VEGATOR 526 Ex

The following figures show the currentless condition.

Coordination of the

terminal socket or the

multipoint connector

d b z

2 L1 (+)

N (-)

2

8

8

18

20

30

32

10

Fail safe relay

Level relay

+

-

Recurring test acc. to WHG

Supply voltage

Meas. data input

(intrinsically safe

signal circuit)

Terminal socket with multipoint

connector

(part of housing type 589-10 Ex)

Type 589… (WHG etc.)

E Ex i

z

2

4

6

8

10

12

14

16

18

20

22

24

28

30

32

z

d

2

4

6

8

10

12

14

16

18

Coded

20

pin

22

24

28

30

32

d

Separating wall

Key (opener) to interrupt the circuit

to the signalling or control facility

18

20

Not Ex-area

Ex-area

Sensor 1

1

Overvoltage arrester

Overvoltage arrester

2 3

Oscillator of VEGASWING

8… W5 Ex

Connection with

overvoltage arresters

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 19

Page 20

Connection examples for overvoltage arresters

Vessel without cathodic corrosion protection

Electrical connection

VEGASWING

1

E86 Ex

2

Overvoltage arrester

type B62 - 27 Ex 0

or B62 - 27 Ex

Outer

isolation

Line length

≤␣ 50 m

Screen

min. 4 mm

Overvoltage

arrester

A1

Typ

B62-27

A2

2

Cu

Ex-area

Metal housing isolated

mounted or plastic

housing

Outer

isolation

E1

E2

Screen

Earth / PA

Not Ex-area

(control room)

optionally

overvoltage arrester

E1

Typ

B62-27G

A1

A2E2

d30

d32

VEGATOR

526 Ex

connection terminal

External

earth terminal

to potential

equalisation

line

Note :

- Use suitable cable, optionally with metal cover or screen. Cable with metal cover or screen

(as shown) do not require a potential equalization along the complete intrinsically safe circuit.

Just connect the screen or metal cover to the overvoltage arrester (test voltage ≥␣ 500␣ V).

- The capacity of the screen must correspond at least to that of a 1,5 mm2 Cu-line.

20 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Page 21

Electrical connection

Vessel with cathodic corrosion protection

VEGASWING

E86 Ex

External

earth

terminal

Overvoltage arrester

type B62 - 27 Ex 0

or B62 - 27 Ex

Outer

isolation

1

2

Line length

≤␣ 50 m

Screen

Cathodic tank protection

2 … 24 V

(object voltage)

min. 4 mm

Overvoltage

arrester

A1

Typ

B62-27

A2

2

Cu

Ex-area

Metal housing

isolated mounted or

plastic housing

Outer

isolation

E1

E2

Screen

Earth / PA

connection terminal

Not Ex-area

(control room)

optionally

overvoltage arrester

A1

E1

Typ

B62-27G

A2E2

d30

d32

VEGATOR

526 Ex

Note:

- Use suitable cable, optionally with metal cover or screen. Screen or metal cover must only be

connected to the overvoltage arrester. Screen or metal cover must not be earthed.

- The cable must have an outer isolation.

- The capacity of the screen must at least correspond to that of a 1,5 mm2 Cu-line.

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 21

Page 22

Set-up

4 Set-up

4.1 VEGASWING 8… W5 Ex.C

Functional table

The following table gives a survey on the switching conditions dependent on the adjusted mode

and the level.

Level Level Relay Fail safe Fail safe

relay control relay control

(closing lamp (spdt) lamp

contact) VEGATOR

526 Ex

Mode A

(fail safe)

d20d18

Relay Relay

energized energized

d20d18

Relay Relay

de-energize

Mode B

(not

d energized

d20d18

fail safe) Relay Relay

energized energized

d20d18

Relay Relay

de-energized

energized

Failure of the voltage supply

Mode A / B individual

d20d18

Relay Relay

de-energized de-energized

Failure

Mode Acc. to Acc. to

A / B individual mode mode

“see “see Relay

above“ above“

de-energized

z8z10 d8

z10z8 d8

z8z10 d8

z8z10 d8

z8z10 d8

z8z10 d8

22 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Page 23

Set-up

VEGASWING 8… W5 Ex.C

1

2

3

4

1 Type plate (oscillator)

2 Terminals

3 Oscillator

4 Housing

No pre-adjustments must be made on

VEGASWING 8…␣ W5␣ Ex.C.

4.2 Signal conditioning instrument VEGATOR 526 Ex

Adjustment elements

1

2

VEGATOR 526 W Ex

3

on

6

A

B

3

2

1

4

5

1

7

8

9

1 Screw

2 LED-relay control lamps

3 Set-up key

4 LED-fault signal

5 LED-supply voltage

6 Multiple plug

7 Hook switch:

Mode A (overfill protection) fail safe

Mode B (protection against dry running of pumps) not the

fail safe

8 Slide switch:

Position 3 – Density of the product 0,5 … 0,85 g/cm

Position 2 – Density of the product >0,85 g/cm

Position 1 – not allowed

9 Front plate

3

3

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 23

Page 24

Set-up

Pre-adjustments

Before connecting VEGATOR 526␣ Ex to

voltage supply, the mode of the meas. system

and the sensitivity of the sensor must be

adjusted. The adjustment elements are on the

board of the signal conditioning instrument.

Mode

Mode A or B can be adjusted by means of the

hook switch (6).

Mode A (fail safe)

means with covered vibrating element

- Relay de-energizes

- LED-relay output lights

means with uncovered vibrating element

- Relay energizes

- LED-relay output extinguishes

Mode B (not fail safe)

means with covered vibrating element

- Relay energizes

- LED-relay output extinguishes

means with uncovered vibrating element

- Relay de-energizes

- LED-relay output lights

Density of the product

With the slide switch (7) you can modify the

sensitivity of the meas. system. Note that the

switch is never in position 1.

Position 3 - Density of the product

0,5␣ …␣ 0,85␣ g/cm

Position 2 - Density of the product

>␣ 0,85␣ g/cm

Position 1 - not allowed

The information on the position of the switch

point (see “2 Mounting“) relates to water in

conjunction with the slide switch on position 2.

3

3

In case of products with deviating density, this

switch point shifts dependent on the density

and the installation to the direction of the

housing or tuning fork end (see following

table).

A density change by 0,1␣ g/cm3 effects e.g. a

shifting of the switch point by approx. 2,5␣ mm.

To avoid faulty switching by probable

adhesions, the slide switch (7) must be set to

position 2 in case of adhesive, high viscosity

products.

By means of the slide switch (7) you can also

detect products below 1␣ g/cm3 (0,5␣ …␣ 0,85␣ g/

cm3). In this case choose position 3. The

switch point is then again at the height of the

marking (25␣ mm above the tip of the fork).-

Note

- Modifications in the switch position are only

effective after the next voltage change-over.

- Modifications can be carried out any time

after the set-up.

Control lamps

LED in the front plate show on/off, switch

condition and failure.

Green

- mains control lamp (5)

- mains voltage on, instrument in operation

Red

- signal lamp (4)

- failure on the sensor circuit by failure of the

sensor of line defect.

- when the fail safe relay is de-energized, the

red signal lamp lights.

24 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

Page 25

Set-up

Yellow

- relay control lamp (2)

- the yellow control lamp reacts acc. to the

adjusted mode (A/B).

- generally the relay control lamp shows the

safe (currentless) condition of the relays.

- a dark control lamp means that the relay is

in activated (current) condition.

Set-up

After connecting VEGASWING 8…␣ W5␣ Ex and

inserting VEGATOR 526␣ Ex in the carrier or the

single housing, the meas. system is ready for

operation.

• Screw the signal conditioning instrument.

With the lowered set-up key (3) you can setup the level detection.

Yellow LED lights

(= level relay de-energized)

VEGATOR 526 W Ex

Green LED in set-up key

flashes (= set-up not yet

carried out)

on

Green LED lights

(= supply voltage on)

Ready condition before set-up

Pre-requirements to carry out the set-up

- VEGASWING is mounted in its final position

and the tuning fork is not covered with the

medium

- the failure-LED is dark

• Push the lowered set-up key (3) for approx.

4␣ …␣ 6␣ seconds.

With the set-up an adaption of VEGATOR to

VEGASWING is made. The actual resonance

frequency is detected by VEGATOR as

current and saved as reference value.

Condition up to approx. 10 secs. after

set-up

Yellow LED lights

VEGATOR 526 Ex

Green LED in set-up key lights

on

Green LED lights

Condition approx. 10 secs. after set-up

VEGATOR 526 Ex

on

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 25

Green LED lights

Page 26

5 Diagnosis

VEGATOR 526 Ex

on

Diagnosis

5.1 Failure removal

Via the condition of the LED in the front plate

of VEGATOR two failures can be detected:

- failure during set-up

- failure detection within the self-monitoring.

In both cases the level and fail safe relays deenergize.

In case of set-up failures, a new start must be

made (switch off voltage supply and switch on

again) and repeat the set-up.

When failures are detected, first of all switch

off the voltage supply, then remove the failure

(e.g. line break) and switch on the voltage

supply again. It is not necessary to repeat the

set-up.

Failure Reason / Removal

Before pushing the set-up key (3) Check the following failure reasons:

- line break

- interpolation of the sensor lines

lights

- short-circuit

- undefined position of the hook switch (6) or the

slide switch (7)

- electronics defect on VEGASWING or on VEGATOR

off

lights

lights

In case of an electronics defect, call our service department.

After set-up - set-up key was not pushed long enough

Repeat the set-up (push set-up key (3) for 4␣ …␣ 6␣ s)

lights

VEGATOR 526 Ex

flashes

on

26 VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe

off

lights

Page 27

Diagnosis

Failure Reason / Removal

After pushing the

set-up key (3) - set-up was carried out with covered tuning fork.

lights

VEGATOR 526 Ex

tuning fork.

- set-up key was pushed too long (>␣ 6␣ s)

Carry out a new start and repeat the set-up with uncovered

lights for

approx. 2 s

on

off

lights

Carry out a new start and repeat the set-up. Note the correct

period for pushing the set-up key (3).

During operation Check the following reasons:

- line break

- short-circuit

- electronics defect

VEGATOR 526 Ex

on

lights

aus

leuchtet

leuchtet

In case of an electronics defect, call our service department.

VEGASWING 81 W5 Ex.C, 83 W5 Ex.C fail safe 27

Page 28

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail info@vega-g.de

ISO 9001

Technical data subject to alterations 2.21 489 / June ’97

Loading...

Loading...