Page 1

TM

EZCT-2000

DIGITAL CURRENT-TRANSFORMER TESTER

USER’S MANUAL

Vanguard Instruments Company, Inc.

1520 S. Hellman Ave.

Ontario, California 91761, USA

TEL: (909) 923-9390

FAX: (909) 923-9391

March 2014

Revision 3

Page 2

EZCT-2000 USER’S MANUAL REV 3

SAFETY SUMMARY

FOLLOW EXACT OPERATING PROCEDURES

Any deviation from the procedures described in this User’s Manual may create one or more

safety hazards, may damage the EZCT-2000, or cause errors in the test results. Vanguard

Instruments Company, Inc. assumes no liability for unsafe or improper use of the EZCT-2000.

All safety precautions provided in this manual must be observed during all phases of testing

including test preparation, test lead connection, actual testing, and test lead disconnection.

SAFETY WARNINGS AND CAUTIONS

The EZCT-2000 can produce a voltage up to 2,000 Vac that can cause severe injury and/or

equipment damage. Due to this reason, the EZCT-2000 shall be used only by trained operators.

The EZCT-2000’s X output terminals are rated to 2,000 Vac working voltage. Any voltage above

2,000 Vac will damage the input circuitry. Please see section 3.2 for further information.

All devices under test shall be off-line and fully isolated. Never attempt to test any current

transformer still connected to a circuit. All current transformer terminals shall be isolated

before conducting any test with the EZCT-2000.

Always ground the EZCT-2000 to a substation ground before connecting the test cables to a

transformer.

DO NOT MODIFY TEST EQUIPMENT

To avoid the risk of introducing additional or unknown hazards, do not install substitute parts or

perform any unauthorized modification to any EZCT-2000 test unit. To ensure that all designed

safety features are maintained, it is highly recommended that repairs be performed only by

Vanguard Instruments Company factory personnel or by an authorized repair service provider.

Unauthorized modifications can cause safety hazards and will void the manufacturer’s

warranty.

WARNING

Do not remove test leads during a test. Failure to heed this warning can result in electrical

shock to personnel and damage to the equipment.

i

Page 3

REV 3 EZCT-2000 USER’S MANUAL

TABLE OF CONTENTS

CONVENTIONS USED IN THIS DOCUMENT ....................................................................... 1

1.0 INTRODUCTION .................................................................................................................. .. 2

1.1 General Description and Features ................................................................................... 2

1.2 Furnished Accessories ...................................................................................................... 3

1.3 Technical Specifications ................................................................................................... 4

1.4 EZCT-2000 Controls and Indicators .................................................................................. 5

2.0 PRE-TEST SETUP ................................................................................................................... 7

2.1 Operating Voltages .......................................................................................................... 7

2.2 LCD Screen Contrast Control ............................................................................................ 7

2.3 Printer Paper Control ....................................................................................................... 7

2.4 Printer Paper .................................................................................................................... 7

3.0 OPERATING PROCEDURES ................................................................................................... 9

3.1 EZCT-2000 Cable Connections ......................................................................................... 9

3.2 EZCT-2000 X Input Voltage Warning .............................................................................. 11

3.3 Performing Tests ............................................................................................................ 12

3.3.1. Entering Test Record Header Information ............................................................. 12

3.3.2. Performing Resistance, Excitation, and Ratio Tests ............................................... 15

3.4 Working With Test Records ........................................................................................... 24

3.4.1. Restoring and Printing a Test Record From Flash EEPROM ................................... 24

3.4.2. Printing a Restored Test Record ............................................................................. 27

3.4.3. Printing a Directory of Test Records Stored in the EZCT-2000’s Memory ............. 28

3.4.4. Erasing Test Records From the Flash EEPROM ...................................................... 30

3.5 Working With Test Plans ................................................................................................ 32

3.5.1. Extracting the Test Plan From a Test Record ......................................................... 32

3.5.2. Printing a Directory of Test Plans Stored in the EZCT-2000’s Memory .................. 34

3.5.3. Printing a Test Plan ................................................................................................. 36

3.5.4. Erasing Test Plans From the Flash EEPROM ........................................................... 38

3.5.5. Loading a Test Plan from the EZCT-2000’s Flash EEPROM ..................................... 40

3.5.6. Running a Test Using a Loaded Test Plan ............................................................... 41

3.5.7. Unloading a Test Plan from the Working Memory ................................................ 44

4.0 CHANGING SETUP PARAMETERS ....................................................................................... 45

4.1 Setting the Knee Point Marker ...................................................................................... 45

4.2 Selecting the Buried CT in Transformer Delta Option ................................................... 47

4.3 Setting the Clock ............................................................................................................ 50

5.0 DIAGNOSTICS, VERIFICATION, AND TROUBLESHOOTING ................................................. 51

5.1 Performing a Diagnostics Test ....................................................................................... 51

5.2 Verifying the EZCT-2000’s Vx Sense Circuit Using an External Meter ............................ 53

5.3 Verifying the EZCT-2000’s Ix Sense Circuit Using an External Meter ............................. 54

5.4 Quickly Verifying the EZCT-2000’s Turns Ratio Circuit .................................................. 55

5.5 Troubleshooting Guide .................................................................................................. 56

6.0 Appendix A - Calculating Turns Ratio on a Shunt Reactor ................................................. 57

ii

Page 4

EZCT-2000 USER’S MANUAL REV 3

LIST OF TABLES

Table 1. EZCT-2000 Technical Specifications .................................................................................. 4

Table 2. Functional Descriptions of EZCT-2000 Controls and Indicators ........................................ 6

Table 3. Descriptions of Tabulated Test Results Elements ........................................................... 22

Table 4. Description of Test Plan Elements .................................................................................. 37

LIST OF FIGURES

Figure 1. EZCT-2000 Controls and Indicators .................................................................................. 5

Figure 2. Typical EZCT-2000 Excitation and Ratio Test Cable Connection ...................................... 9

Figure 3. Bushing CT Connection on Delta Transformer .............................................................. 10

Figure 4. Bushing CT Connection on Y Transformer ..................................................................... 10

Figure 5. Sample CT Name Plate ................................................................................................... 11

Figure 6. Typical EZCT-2000 Tabulated Report Printout ............................................................... 21

Figure 7. Typical EZCT-2000 Graphic Report ................................................................................. 23

Figure 8. Typical EZCT-2000 Graphic Report with Multiple Plot Curves ....................................... 23

Figure 9. Typical Internal Test Record Directory Printout ............................................................ 29

Figure 10. Typical EZCT-2000 Flash EEPROM Test Plan Directory Printout .................................. 35

Figure 11. Typical Test Plan Printout ............................................................................................ 37

Figure 12. Graphic Report Showing Knee Point Marker ............................................................... 46

Figure 13. Buried CT in a Delta Transformer Illustration 1 ........................................................... 48

Figure 14. Buried CT in a Delta Transformer Illustration 2 ........................................................... 48

Figure 15. EZCT-2000 Vx Verification Test Connections ............................................................... 53

Figure 16. EZCT-2000 Ix Verification Test Connections ................................................................. 54

Figure 17. EZCT-2000 Turns Ratio Verification Test Connections ................................................ 55

Figure 18 ....................................................................................................................................... 57

Figure 19 ....................................................................................................................................... 58

Figure 20 ....................................................................................................................................... 59

Figure 21 ....................................................................................................................................... 60

Figure 22 ....................................................................................................................................... 61

Figure 23 ....................................................................................................................................... 62

Figure 24 ....................................................................................................................................... 63

Figure 25 ....................................................................................................................................... 63

iii

Page 5

REV 3 EZCT-2000 USER’S MANUAL

CONVENTIONS USED IN THIS DOCUMENT

This document uses the following conventions:

•

A key or switch on the EZCT-2000 is indicated as

[KEY]

and

[SWITCH].

Menu options are referenced as (MENU OPTION).

•

Screen and menu names are referenced as “SCREEN/MENU NAME”.

•

The terms “test record” and “test shot” are used interchangeably.

•

• EZCT-2000 LCD screen output is shown as:

1. OPTION 1

2. OPTION 2

3. OPTION 3

4. OPTION 4

• When instructions are provided, the menu item that should be selected is shown in bold as

shown below (option 3 should be selected):

1. OPTION 1

2. OPTION 2

3. OPTION 3

4. OPTION 4

• Warning messages are indicated as:

Warning message

WARNING

• Important notes are indicated as:

Note details

NOTE

1

Page 6

EZCT-2000 USER’S MANUAL REV 3

1.0 INTRODUCTION

1.1 General Description and Features

The EZCT-2000 is Vanguard’s second-generation microprocessor-based current transformer test

set. The EZCT-2000 can perform the current transformer (CT) excitation test, measure the CT

winding resistance and CT current-ratio automatically. All of the EZCT-2000’s test leads can be

connected to the CT output terminals (X1, X2, X3, X4 and X5), eliminating the need for lead

switching during testing. Test voltage output is automatically raised and lowered by the EZCT2000 without any operator intervention. With up to 2000 Vac excitation test voltage available,

the EZCT-2000 can easily perform excitation tests on very large CT’s.

Excitation Test

The CT excitation test is performed using the ANSI/IEEE C57.13.1, IEC 60044-1 test method. The

AC test voltage range for the CT excitation test (50 Vac, 300 Vac, 500 Vac, 1200 Vac or 2000

Vac) can be selected, and then the test voltage is raised and lowered automatically by the EZCT-

2000. The excitation test voltage and current data is collected and stored in the unit’s internal

memory. Any of the 10 possible combinations of X1 to X5 can be tested since all of the unit’s

test leads can be connected to all of the CT output terminals at the same time. Up to 10

excitation tests can be stored in one record. Once the test is completed, test results can be

printed and excitation curves can be plotted on the built-in 4.5-inch wide thermal printer.

CT Ratio and Polarity Test

The EZCT-2000 determines the CT current-ratio using the ANSI/IEEE C57.12.90 measurement

method. An AC test voltage is applied on any two terminals of the CT (X1 to X5), and the

induced voltage is measured through the CT’s H1 and H2 terminals. The CT current-ratio is

displayed on the screen and stored in memory. The current-ratio measuring range is from 0.8 to

5,000 to 1. The CT winding polarity is displayed as a “+” sign (in-phase) or a “-” sign (out-ofphase) and is annotated with the phase angle in degrees.

CT Winding Resistance Test

The EZCT-2000 can also measure the DC resistance of the CT winding under test. The DC

winding resistance measuring range is from 100 micro-ohms to 10 ohms.

User Interface and Display

The EZCT-2000 features a back-lit LCD screen (4 lines by 20 characters) that is viewable in both

bright sunlight and low-light levels. A rugged, alpha-numeric, membrane keypad is used to

control the unit.

Built-in Thermal Printer

A built-in 4.5-inch wide thermal printer can print the current transformer test report and plot

the excitation curves.

2

Page 7

REV 3 EZCT-2000 USER’S MANUAL

Test Record Header Information

Test record header information can include the company name, substation name, circuit ID,

manufacturer, CT serial number, operator’s name and test record comments. In addition to the

test record header, a 20-character test description for each test in the record (10 tests per

record) can also be entered.

Internal Test Record Storage Capacity

The EZCT-2000 can store up to 140 test records in Flash EEPROM. Each test record may contain

up to 10 excitation curves, current-ratio readings, polarity and DC resistance readings. Test

records can be recalled and printed on the built-in thermal printer.

Internal Test Plan Storage Capacity

The EZCT-2000 can store up to 128 CT test plans in Flash EEPROM. A test plan defines the

excitation test voltage and current range selection, CT nameplate ratio, and CT winding

terminals (X1 to X5) for each of the tests. Up to 10 test definitions can be stored per test plan.

The use of a test plan greatly simplifies the CT testing process; the EZCT-2000 is connected to

the CT terminals and a test plan is simply selected and run. Test plans can be created on the

EZCT-2000 itself or created on a PC and downloaded to the EZCT-2000 via the unit’s built-in RS232C or USB interfaces.

Computer Interface

The EZCT-2000 can be used as a stand-alone unit or can be computer-controlled via the built-in

RS-232C or USB interfaces. A Windows® XP/Vista-based Current Transformer Analysis software

application is provided with each EZCT-2000. This software can be used to retrieve test records

from the EZCT-2000, create test plans, download test plans to the EZCT-2000, and can also be

used to run CT tests from the PC. Tabulated test records can be exported in Microsoft® Excel

format.

1.2 Furnished Accessories

The EZCT-2000 comes furnished with the following:

• 1 Power Cord

• 5 20-foot X Cable Sets

• 1 35-foot H Cable Set

• One RS-232C serial cable

• One USB cable

• Ground Cables

• Duffel bag

• Transportation Case

3

Page 8

®

1.3 Technical Specifications

Table 1. EZCT-2000 Technical Specifications

TYPE Portable current-transformer test set

PHYSICAL SPECIFICATIONS 16.8”W x 12.6”H x 14”D (42.7 cm x 32.0 cm x 35.6 cm); Weight: 56 lbs

(25.4 Kg)

INPUT POWER 100 – 120 Vac or 200 – 240 Vac (factory pre-set), 50/60 Hz

MEASUREMENT METHOD ANSI/IEEE C57.12.90, IEC 60044-1 and ANSI/IEEE C57.13.1 standards

TEST OUTPUT VOLTAGES 0 – 50 Vac @ 10A max, 0 – 300 Vac @ 10A max, 0 – 500 Vac @ 5A max

0 – 1200 Vac @ 2A max, 0 – 2000 Vac @ 1.2 A max

VOLTAGE READING RANGE 0 – 2,200 Vac; Accuracy: ±1.0% of reading, ±1 volt

CURRENT READING RANGE 0 – 10A; Accuracy: ±1.0% of reading, ±0.02A

CURRENT-RATIO RANGE 0.8 – 999: 0.1%, 1000 – 1999: 0.3%, 2000 – 5000: 1%

PHASE ANGLE

MEASUREMENT

RESISTANCE READING

RANGE

DISPLAY Back-lit LCD Screen (20 characters by 4 lines); viewable in bright sunlight

PRINTER Built-in 4.5-inch wide thermal printer

COMPUTER INTERFACES One RS-232C port (115k baud), One USB port

PC SOFTWARE Windows

INTERNAL TEST RECORD

STORAGE

INTERNAL TEST PLAN

STORAGE

SAFETY Designed to meet UL 61010A-1 and CAN/CSA C22.2 No. 1010.1-92

ENVIRONMENT Operating: -10˚ to 50˚ C (15˚F to +122˚ F); Storage: -30˚ C to 70˚ C (-22˚F

CABLES Five 20-foot X cable sets, One 35-foot H cable set, power cord, One cable-

WARRANTY One year on parts and labor

0 – 360 degrees; Accuracy: ±1.0 degree

100 micro-ohms – 10 ohms; Accuracy: 2% of reading, ±1 count, ±10 μohms

and low-light levels

price

Stores 140 test records. Each test record may contain up to 10 sets of

excitation, resistance and ratio data

Stores 128 test plans. Each test plan can store 10 excitation test voltage

and current settings

standards

to +158˚ F)

carrying duffel bag

EZCT-2000 USER’S MANUAL REV 3

XP/Vista-based CT Analysis software is included with purchase

The above specifications are valid at nominal operating voltage and at a

temperature of 25°C (77°F). Specifications may change without prior notice.

NOTE

4

Page 9

REV 3 EZCT-2000 USER’S MANUAL

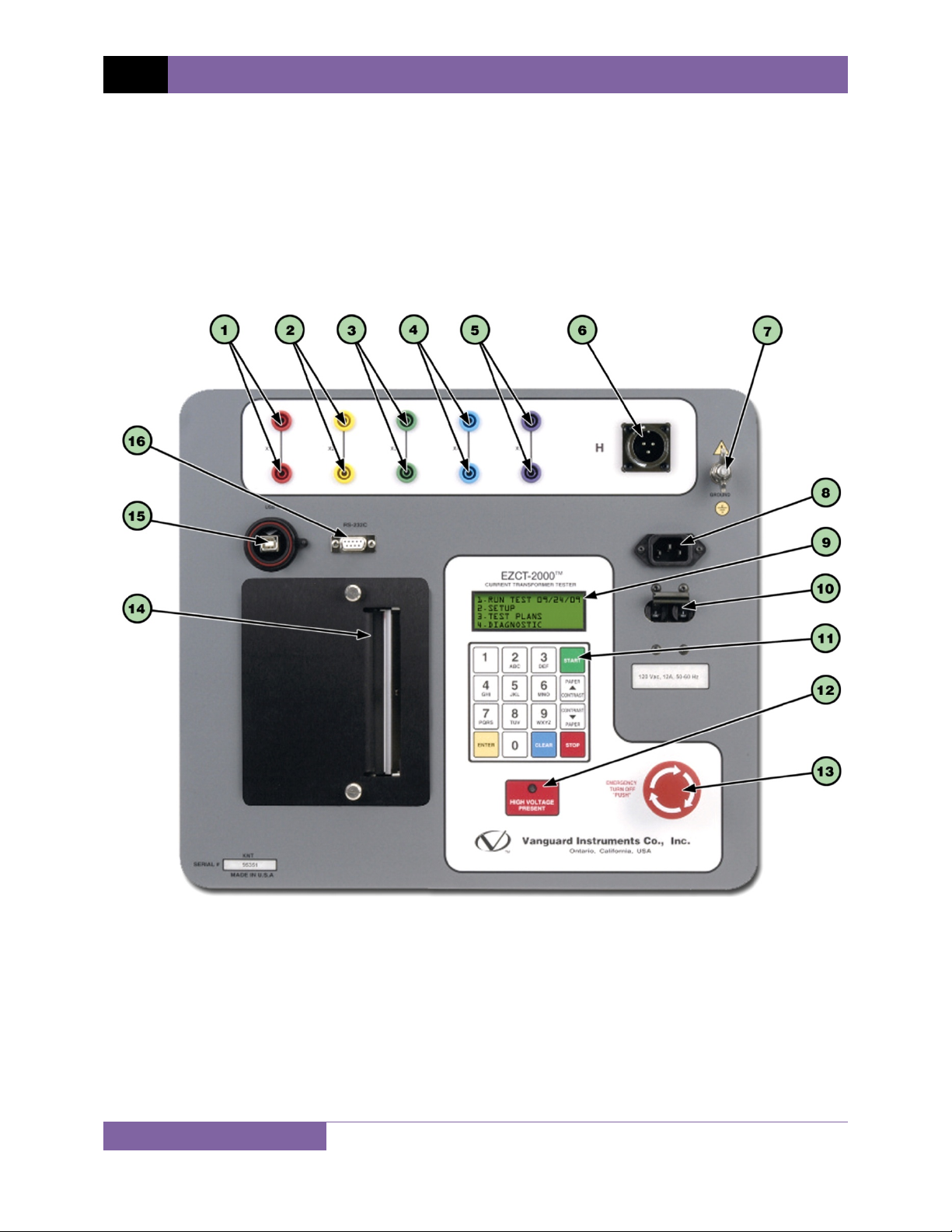

1.4 EZCT-2000 Controls and Indicators

The EZCT-2000’s controls and indicators are shown in Figure 1 below. A leader line with an

index number points to each control and indicator, which is cross-referenced to a functional

description in Table 2. The table describes the function of each item on the control panel. The

purpose of the controls and indicators may seem obvious, but users should become familiar

with them before using the EZCT-2000. Accidental misuse of the controls will usually cause no

serious harm. Users should also be familiar with the safety summary found on the front page of

this User’s Manual.

5

Figure 1. EZCT-2000 Controls and Indicators

Page 10

EZCT-2000 USER’S MANUAL REV 3

Table 2. Functional Descriptions of EZCT-2000 Controls and Indicators

Item

Number

1-5

6

7

8

9

10

11

12

13

14

15

16

Panel Markings Functional Description

Current transformer excitation voltage connectors. Each set of connectors

X1, X2, X3, X4, X5

H Current transformer primary input test cable connector.

GROUND Grounding stud.

AC receptacle.

110-120 Vac,

12A, 50-60Hz

Rugged, alpha-numeric membrane keypad

HIGH VOLTAGE

PRESENT

EMERGENCY

TURN OFF

“PUSH”

Built-in 4.5-inch wide thermal printer.

USB USB PC interface.

RS-232C RS-232C PC interface. Baud rate is set for 115KB, 8 data bits, 2 stop bits.

contains a test voltage connector and sensing connector. The EZCT-2000’s X

output terminals are rated to 2000 Vac working voltage. Any voltage above

2000 Vac will damage the input circuitry.

Back-lit graphic LCD screen (128 x 64); viewable in bright sunlight and low light

levels.

Power switch with built-in circuit breaker.

LED warning indicator that is illuminated when high voltage is present.

Emergency turn off switch.

6

Page 11

REV 3 EZCT-2000 USER’S MANUAL

2.0 PRE-TEST SETUP

2.1 Operating Voltages

The EZCT-2000’s operating voltage is preset at the factory for 100-120 Vac, 50/60 Hz or 200-240

Vac, 50/60 Hz.

2.2 LCD Screen Contrast Control

To increase the LCD screen contrast, press and hold the [PAPER ∧ Contrast] key for two

seconds. Release the button when the desired contrast level has been reached.

To decrease the LCD screen contrast, press and hold the [PAPER ∨ Contrast] key for two

seconds. Release the button when the desired contrast level has been reached.

2.3 Printer Paper Control

To advance the thermal printer paper, press and release the [PAPER ∧ Contrast] key.

To retract the thermal printer paper, press and release the [PAPER ∨ Contrast] key.

2.4 Printer Paper

The EZCT-2000’s built-in thermal printer uses 4.5-inch wide thermal paper for printing test

results. To maintain the highest print quality and to avoid paper jams, the use of thermal paper

supplied by Vanguard Instruments Company is highly recommended. Additional paper can be

ordered from the following sources:

Vanguard Instruments Co, Inc.

1520 S. Hellman Avenue

Ontario, CA 91761

Tel: 909-923-9390

Fax: 909-923-9391

Part Number: VIC TP-4 paper

BG Instrument Co.

13607 E. Trent Avenue

Spokane, WA 99216

Tel: 509-893-9881

Fax: 509-893-9803

Part Number: VIC TP-4 paper

7

Page 12

EZCT-2000 USER’S MANUAL REV 3

2.5 Replacing the Thermal Printer Paper

The roll of thermal paper is housed inside a dispenser underneath the printer cover. To replace

the paper, follow the steps below:

• Unscrew the two large printer cover screws and remove the printer cover.

• Remove the leftover thermal paper roll from the paper holder.

• Unroll the new thermal paper roll.

• Feed the thermal paper into the slot between the paper pocket and the rubber roller.

The printer will automatically pull the paper under the thermal head.

• Place the paper roll into the paper holder.

• Lift the thermal head and align the thermal paper if necessary.

• Re-install the printer cover.

Thermal paper has a chemical coating on one side of the paper. This side should be

facing the thermal print head. Incorrect paper loading may result in blank output on

NOTE

the thermal paper.

The thermal paper will show a red stripe to indicate that the roll is about to run out

of paper.

2.6 Computer Interface Ports

The EZCT-2000 features one USB and one RS-232C PC interface port. A Windows-based

“Current Transformer Analysis” software application is supplied with the EZCT-2000. For further

information, please see the software user’s manual.

8

Page 13

REV 3 EZCT-2000 USER’S MANUAL

3.0 OPERATING PROCEDURES

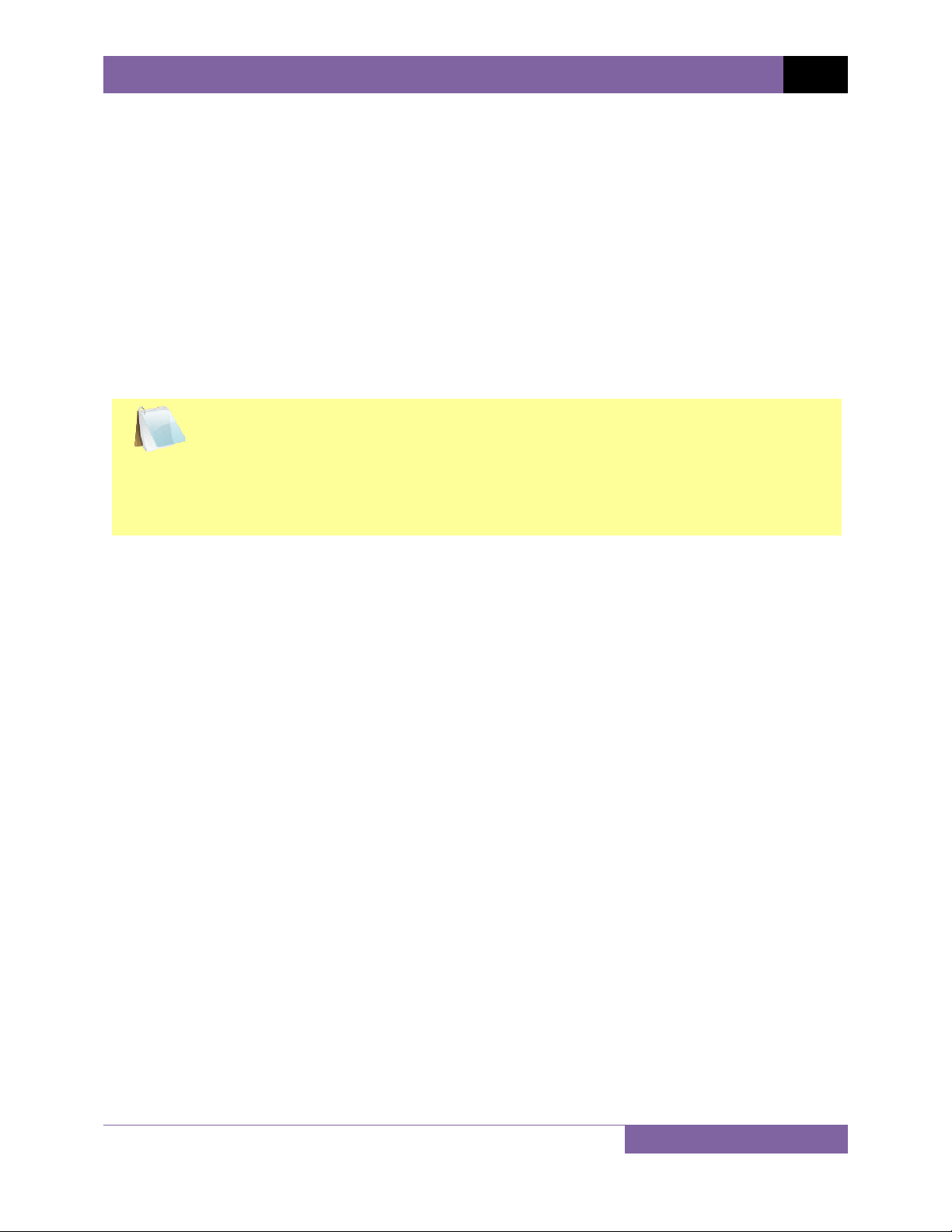

3.1 EZCT-2000 Cable Connections

Always connect the EZCT-2000 to the substation ground before connecting any test cables. The

EZCT-2000 is supplied with five 20-foot X test cables and one 35-foot H cable. The X cable

connections are required to run the current transformer excitation test. The H and X cable

connections are required to run the transformer turns-ratio test. A typical excitation and ratio

test connection is shown in Figure 2. Transformer bushing CT connections for Delta and Y

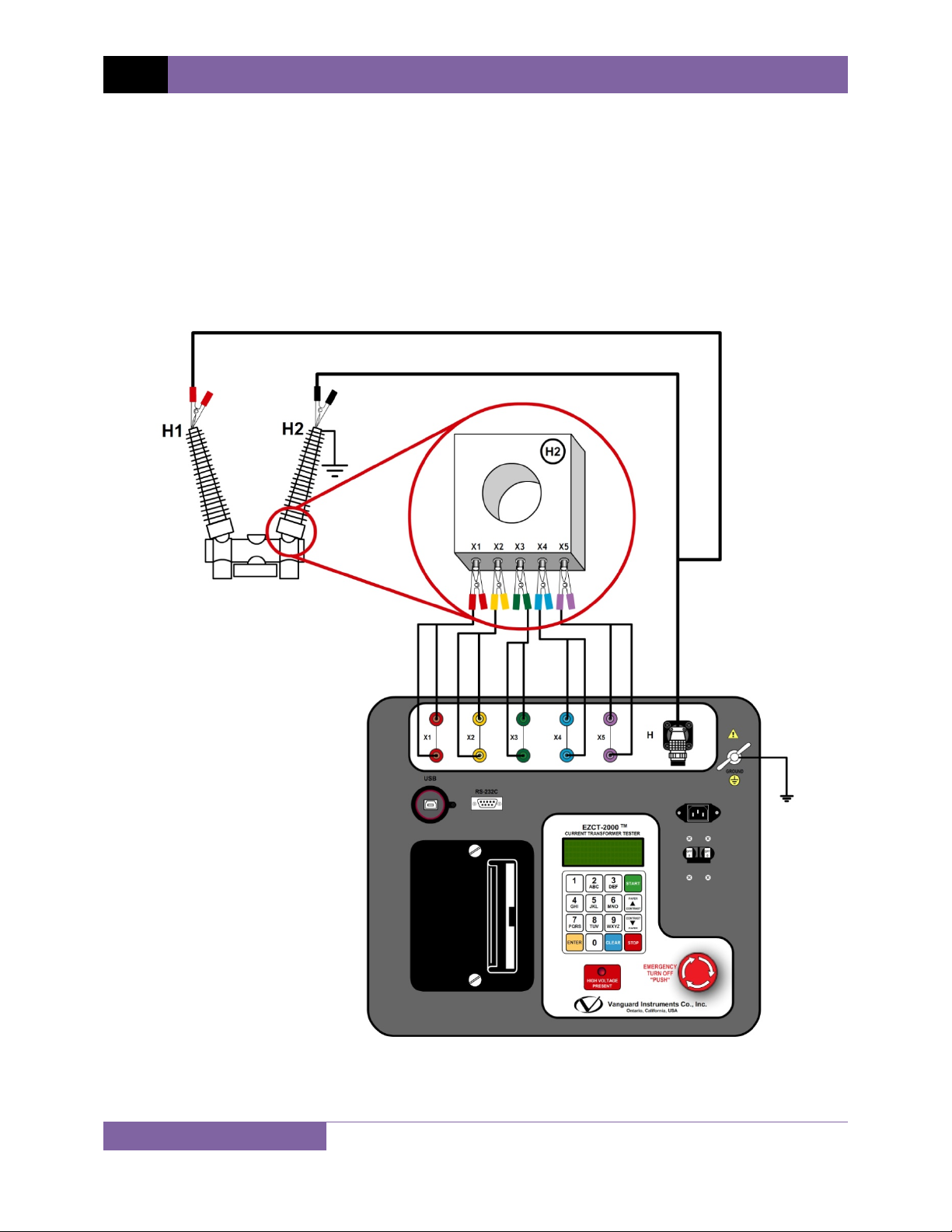

transformers are shown in Figure 3 and Figure 4, respectively.

Figure 2. Typical EZCT-2000 Excitation and Ratio Test Cable Connection

9

Page 14

EZCT-2000 USER’S MANUAL REV 3

Figure 3. Bushing CT Connection on Delta Transformer

Figure 4. Bushing CT Connection on Y Transformer

10

Page 15

REV 3 EZCT-2000 USER’S MANUAL

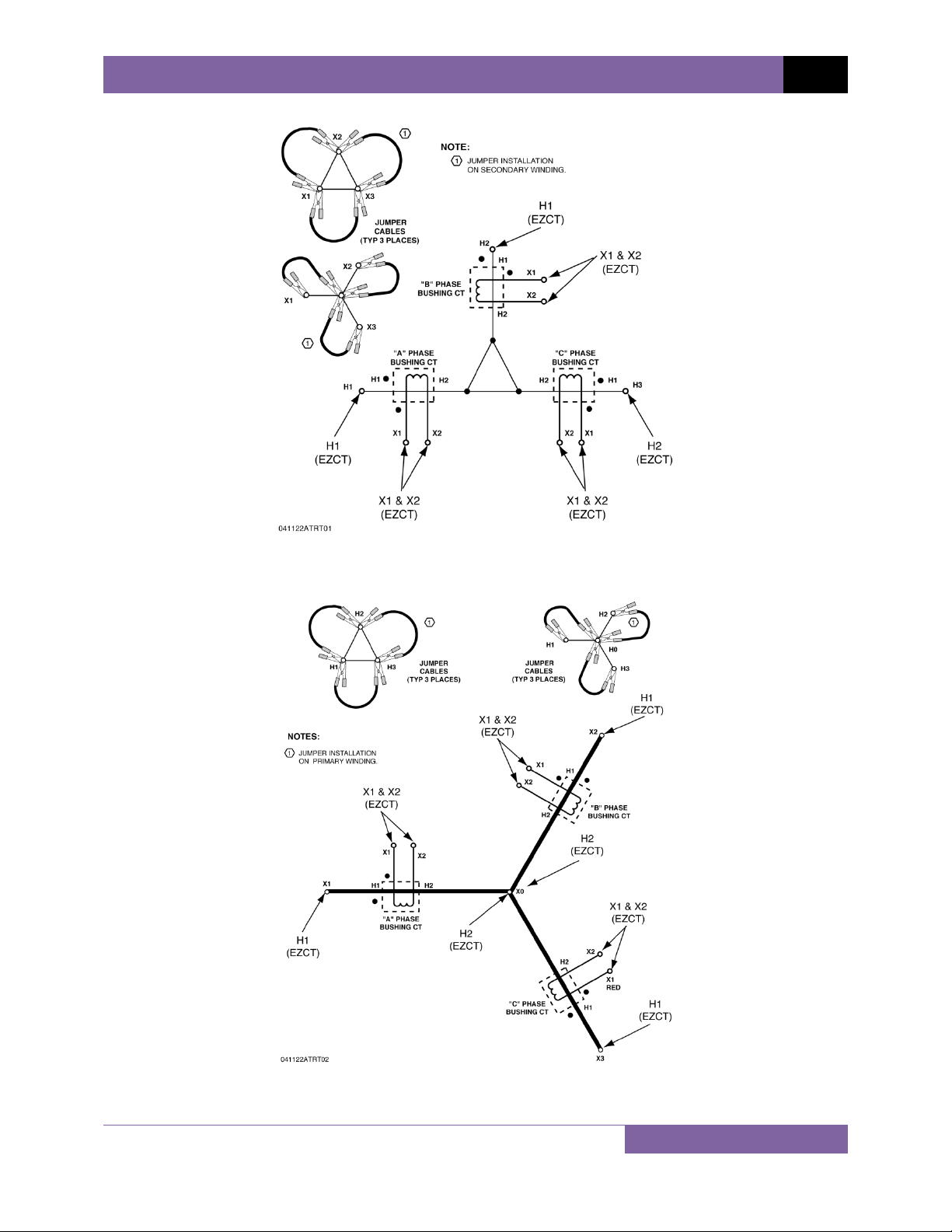

3.2 EZCT-2000 X Input Voltage Warning

The EZCT-2000 X output terminals are rated to 2,000 Vac working voltage. Any voltage present

at these terminals above 2,000 Vac may damage the X sense circuitry, cause false readings, or

both. An example of a typical situation where this may occur is shown in Figure 5 below.

Figure 5. Sample CT Name Plate

For the above example CT, the turns ratio between X1-X4 is 3150 to 1. The turns ratio between

X1-X2 is 400 to 1. The turns ratio between X1-X4 and X1-X2 is 7.88 (3150/400). If a test voltage

of 300 Vac is applied to the X1-X2 terminals, a voltage of 2,364 Vac (300 Vac x 7.88) will be

induced at the X1-X4 terminals. If all the test leads are connected to the EZCT-2000 and the

excitation test is performed on the X1-X2 terminals, the voltage induced at the X1-X4 terminals

will exceed 2,000 Vac as the voltage across the X1-X2 terminals increases above 250 Vac. A

“Flash-Over” condition may occur and damage the EZCT-2000. In this case, the user should only

connect the X1-X2 leads and run its excitation test, then connect the X4 lead before running the

X1-X4 excitation test.

11

Page 16

EZCT-2000 USER’S MANUAL REV 3

3.3 Performing Tests

3.3.1. Entering Test Record Header Information

You can enter the test record header information before performing tests. The record header

includes identifying information such as the company, station, circuit, model number, etc. Once

the header information has been entered, it will apply to all subsequent test records. To enter

the header information:

a. When the unit is turned on and the firmware has been loaded, you will be presented

with the “START-UP” menu as shown below:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. RECORD ID

2. PRINT RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [1] key (RECORD ID)

c. The following screen will be displayed:

COMPANY:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Type the company name using the alpha-numeric keypad.

When pressing a key, the corresponding number on the key will be displayed first.

Pressing the key again will display the first letter on the key. Pressing the key again will

display the second letter on the key. For example, to type the letter “A”, you must press

the [2] key twice. To erase the character at the cursor position, press the [CLEAR] key.

Press the [PAPER ∧ Contrast] key to move to the next character. Press the [PAPER

∨ Contrast]

key to move to the previous character. Press the [ENTER] key when you

are done typing the company name.

12

Page 17

REV 3 EZCT-2000 USER’S MANUAL

d. The following screen will be displayed:

STATION:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Type the station name using the alpha-numeric keypad and then press the [ENTER]

key.

e. The following screen will be displayed:

CIRCUIT:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Type the circuit information using the alpha-numeric keypad and then press the

[ENTER] key.

f. The following screen will be displayed:

MANUFACTURER:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Type the manufacturer name using the alpha-numeric keypad and then press the

[ENTER] key.

g. The following screen will be displayed:

MODEL:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Type the model information using the alpha-numeric keypad and then press the

[ENTER] key.

h. The following screen will be displayed:

SERIAL NUMBER:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Type the serial number using the alpha-numeric keypad and then press the

key.

13

[ENTER]

Page 18

i. The following screen will be displayed:

COMMENTS:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Enter any relevant comments using the alpha-numeric keypad and then press the

[ENTER] key.

j. The following screen will be displayed:

OPERATOR:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Type the operator’s name using the alpha-numeric keypad and then press the [ENTER]

key. All header information will be saved, and you will be returned to the “START-UP”

menu.

EZCT-2000 USER’S MANUAL REV 3

14

Page 19

REV 3 EZCT-2000 USER’S MANUAL

3.3.2. Performing Resistance, Excitation, and Ratio Tests

The following procedure describes the general steps for performing excitation, resistance, and

ratio tests.

a. When the EZCT-2000 is turned on, it will first go through a start-up cycle and load the

firmware. Then the “START-UP” menu will be displayed as shown below:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [1] key (RUN TEST) to start a test.

b. The following screen will be displayed:

1. RES, EXCIT & RATIO

2. EXCITATION & RATIO

3. EXCITATION ONLY

4. RATIO 5.RES,EXC

Select the test type by pressing the corresponding key ([1] - [5])

c. The following screen will be displayed:

SELECT TAP:

1. X1-X2 3. X1-X4

2. X1-X3 4. X1-X5

5. NEXT PAGE

Select the tap connection by pressing the corresponding key ([1] - [4]). If the tap

connection is not listed, press the [5] key to view the next page of options.

d. If the selected test included an excitation test, the following screen will be displayed:

SELECT VOLTAGE RANGE

1. 50V 4. 1200V

2. 300V 5. 2000V

3. 500V

Select a test voltage range by pressing the corresponding key ([1] - [5]).

15

Page 20

EZCT-2000 USER’S MANUAL REV 3

e. If the selected test included an excitation test, the following screen will be displayed:

SET TEST CURRENT:

1. 0.2A 2. 0.5A

3. 1A 4. 2A

5. 5A 6. 10A

Select the maximum test current for the excitation test by pressing the corresponding

key (

[1] - [6]

).

Most CT’s will saturate before the excitation current reaches 1A. To reduce

stress on CT’s, a maximum test current of 1A is recommended.

NOTE

f. If the selected test included a ratio test, the following screen will be displayed:

XFMR NAME PLATE RAT.

1. YES

2. NO

1. YES

Press the

[1]

key if you would like to enter the CT nameplate values. The

following screen will be displayed:

ENTER PLATE RATIO:

0 :

Type the first number using the keypad.

You can press the

Press the

[ENTER]

[CLEAR]

key. The following screen will be displayed:

key to restart a field entry if necessary.

ENTER PLATE RATIO:

1000 : 0.0

Type the second number using the keypad. The screen will be updated as shown:

ENTER PLATE RATIO:

1000 : 5.0

Press the

[ENTER]

key. Continue to step g.

16

Page 21

REV 3 EZCT-2000 USER’S MANUAL

2. NO

Press the

[2]

key if you do not want to enter the CT nameplate values. Continue

to step g.

g. The following screen will be displayed:

ENTER TEST 1 NOTE:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Use the alpha-numeric keys on the keypad to enter a test note. The test note field is 20

characters long. One test note can be saved for each test.

When pressing a key, the corresponding number on the key will be displayed first.

Pressing the key again will display the first letter on the key. Pressing the key again will

display the second letter on the key. For example, to type the letter “A”, you must press

the

[2]

key twice. To erase the character at the cursor position, press the

Press the

[PAPER ∨ Contrast]

[PAPER ∧ Contrast]

button to move to the next character. Press the

key to move to the previous character. Press the

[CLEAR]

[ENTER]

when you are done typing the note.

h. The following screen will be displayed if the selected test included a resistance test:

key.

key

CALC ERR VS BURDEN?

1. YES

2. NO

Press the

[1]

key (YES). Selecting this option will print the current ratio error table as

part of the tabulated test results. Please see item 19 in Figure 6.

i. The following screen will be displayed:

If you had selected a test current greater than 1 Amp in step e, the following

screen will be displayed:

NOTE

SATURATION CUR WILL

BE REDUCED TO 1 AMP.

(PRESS ANY KEY...)

Press any key to continue.

ENTER BURDEN VA:

(500.0 MAX)

0.0

Type the burden value using the keypad and then press the

17

[ENTER]

key.

Page 22

j. The following screen will be displayed:

ENTER COS ϕ:

(0.00 – 1.00)

0.0

EZCT-2000 USER’S MANUAL REV 3

Type the Cos ϕ value using the keypad and then press the

[ENTER]

key.

k. The following screen will be displayed:

RATED SECONDARY CUR:

1. 5A 2.1A

Select the rated secondary current by pressing the

[1]

key (5A) or

[2]

key (1A).

l. The following screen will be displayed showing a summary of the test parameters:

TEST 1 PARAMETERS:

1200V 1.0A X1-X2

“START” TO BEGIN

Press the

[START]

key to start the test.

m. If the selected test included a resistance test, the following screen will be displayed

momentarily:

CABLES ENERGIZED:

1200V 1.0A X1-X2

DC RESISTANCE TEST

The following screen will then be displayed:

CABLES ENERGIZED:

1200V 1.0A X1-X2

RESISTANCE = 215.1Ω

The “HIGH VOLTAGE PRESENT” light will be illuminated to indicate that high

voltage is present.

NOTE

n. If the selected test included a ratio test, the following screen will be displayed

momentarily:

18

Page 23

REV 3 EZCT-2000 USER’S MANUAL

CABLES ENERGIZED:

1200V 1.0A X1-X2

I=0.0004 AMPS

V=34.2 VAC

The following screen will then be displayed:

RATIO TEST

Vx= 79.5 Vh= 0.3970

I=0.0532 RAT=+200.09

When the ratio test is complete, the final results will be displayed:

ANY KEY TO CONTINUE

Vx= 79.5 Vh= 0.3970

I=0.0532 RAT=+200.09

Press any key on the keypad to continue.

o. The following screen will be displayed:

PRINT TEST RESULTS?

1. YES

2. NO

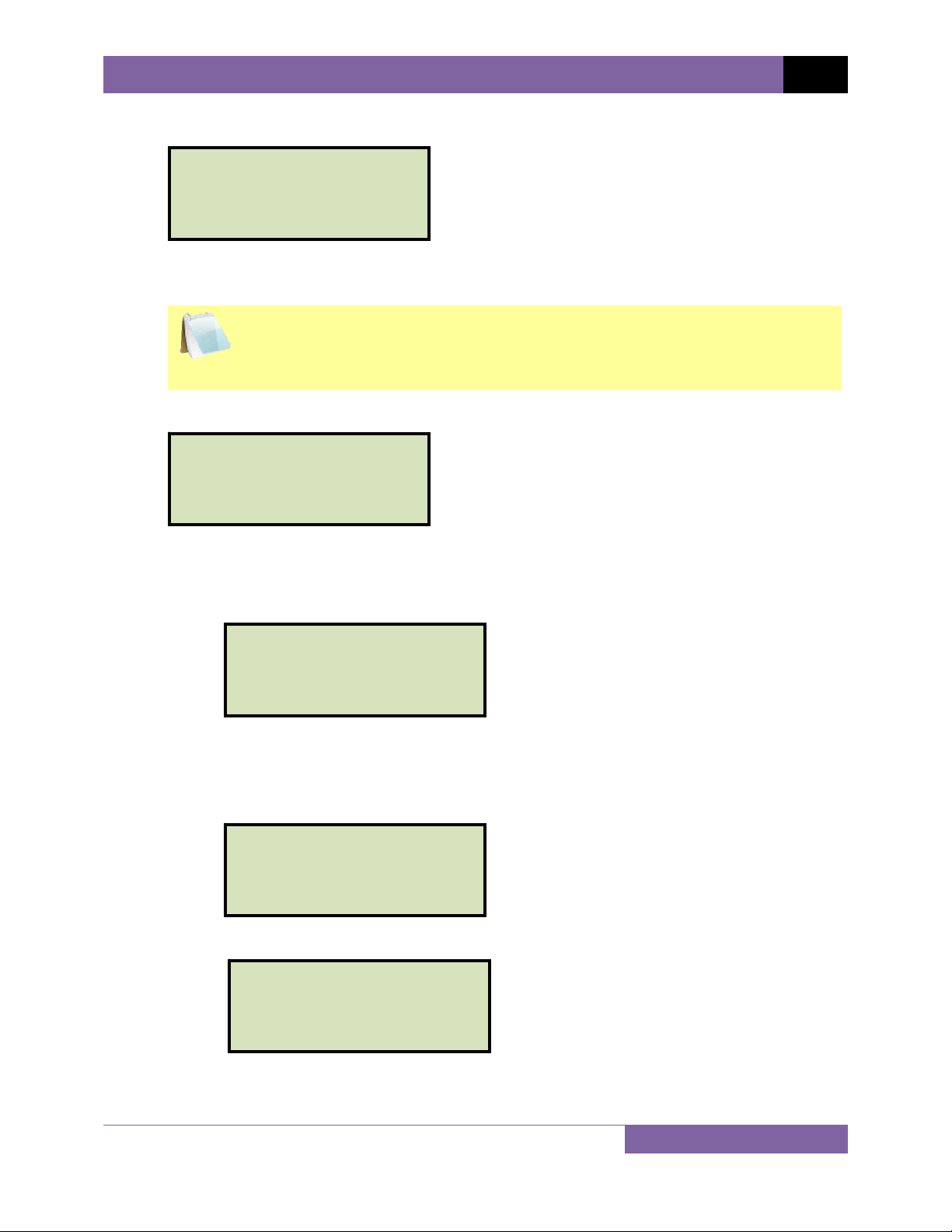

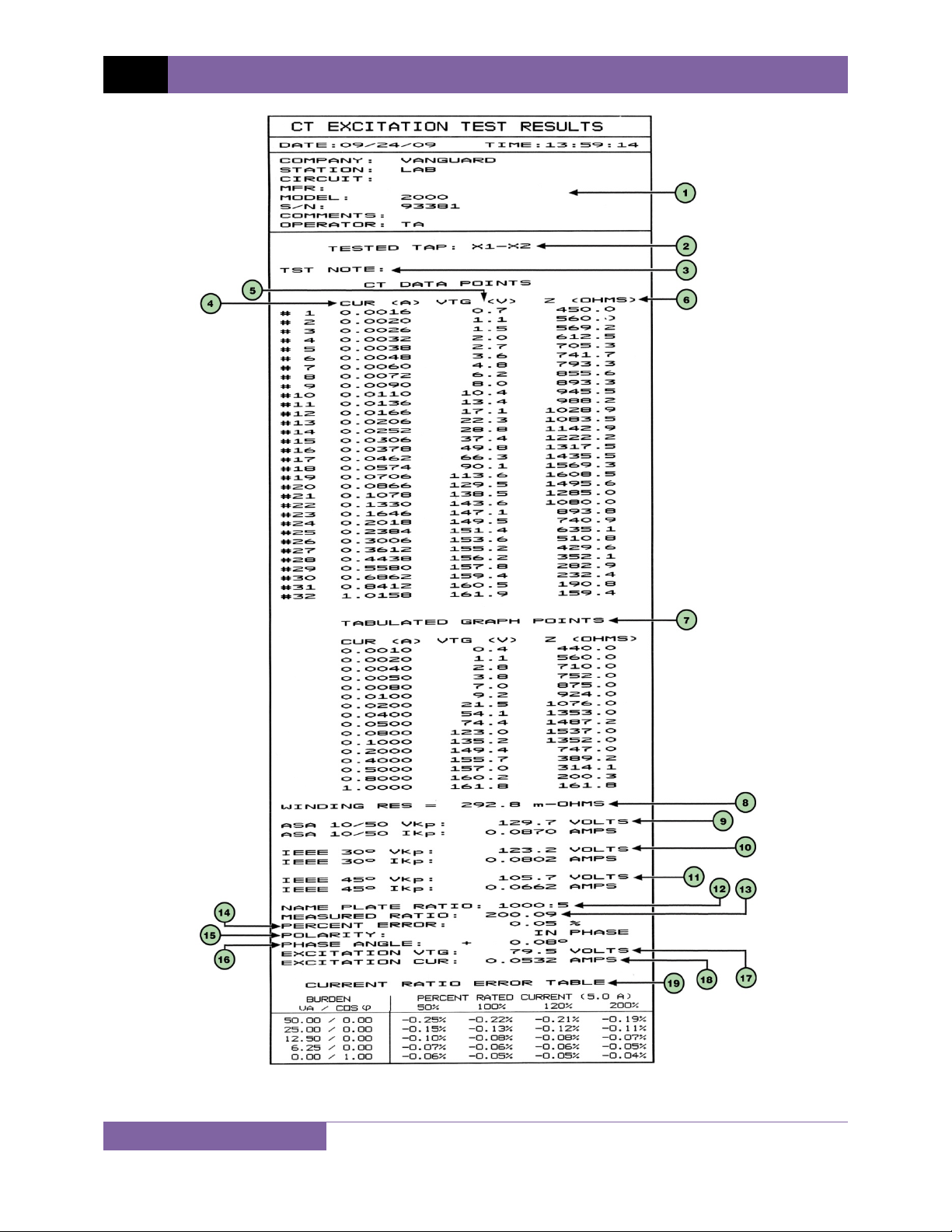

Press the [1] key (YES) if you would like to print the test results. The test results will be

printed on the thermal printer. A typical EZCT-2000 tabulated test report printout is

shown in Figure 6. Typical graphic reports are shown in Figure 7 and Figure 8.

Press the [2] key (NO) if you do not want to print the test results.

p. The following screen will be displayed:

KEEP THIS TEST?

1. YES

2. NO

Press the

[1] key (YES) to keep the test results.

19

Page 24

q. The following screen will be displayed:

TEST 1 SAVED

Press any key to continue.

r. The following screen will be displayed:

RUN ANOTHER TEST?

1. YES

2. NO

EZCT-2000 USER’S MANUAL REV 3

Press the

[2]

key (NO).

s. The following screen will be displayed:

SAVE THIS RECORD?

1. YES

2. NO

Press the

[1]

key (YES) to save the record.

The following screen will be displayed momentarily:

SAVING RECORD...

PLEASE WAIT...

t. The following confirmation screen will then be displayed:

RECORD NUMBER 1

HAS BEEN SAVED!

The test record number is automatically assigned to each test record stored in

the EZCT-2000’s Flash EEPROM.

NOTE

Press any key to return to the “START-UP” menu.

20

Page 25

REV 3 EZCT-2000 USER’S MANUAL

21

Figure 6. Typical EZCT-2000 Tabulated Report Printout

Page 26

EZCT-2000 USER’S MANUAL REV 3

Table 3. Descriptions of Tabulated Test Results Elements

Item

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Description

Test record header information.

The EZCT-2000 X terminals (taps) that were selected for this test.

Test note for this particular test. The test note can be up to 20-characters long.

Recorded excitation current readings on the CT secondary winding.

Recorded excitation test voltages applied to the CT secondary winding.

Impedance calculated at each data point.

The voltage, current, and impedance data points recorded on the graph grid-marks.

Measured DC resistance value of CT under test.

ASA 10/50 knee point voltage and excitation current

(This is equivalent to the IEC 10/50 and ANSI 10/50 knee point voltage and excitation current)

IEEE 30° knee point voltage and excitation current.

IEEE 45° knee point voltage and excitation current.

CT nameplate turns ratio.

Measured turns ratio.

Turns ratio percentage error.

Polarity of the CT.

Measured phase angle.

Excitation voltage used in CT turns ratio test.

Excitation current in turns ratio test.

Current ratio error table. This information will be printed only if you selected “YES” for the “CALC ERR

VS BURDEN?” option when running a test. See section 3.3.2, step h for details.

22

Page 27

REV 3 EZCT-2000 USER’S MANUAL

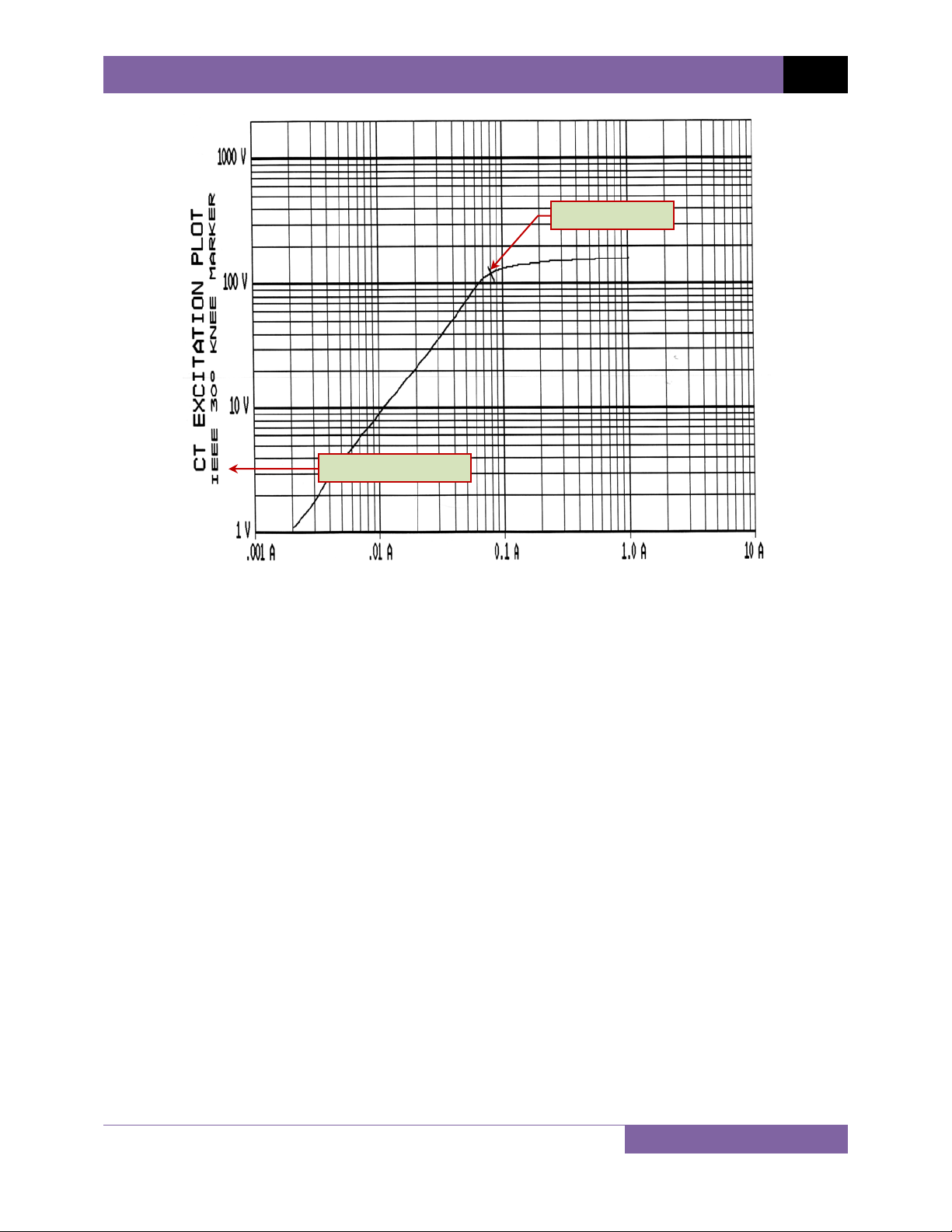

Knee Point Marker

Figure 7. Typical EZCT-2000 Graphic Report

Figure 8. Typical EZCT-2000 Graphic Report with Multiple Plot Curves

23

Page 28

EZCT-2000 USER’S MANUAL REV 3

3.4 Working With Test Records

3.4.1. Restoring and Printing a Test Record From Flash EEPROM

You can restore a test record from the EZCT-2000’s Flash EEPROM to the working memory. You

can then print the restored test record on the unit’s built-in thermal printer. To restore a test

record:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. RECORD ID

2. PRINT RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [3] key (RESTORE RECORD).

c. The following screen will be displayed:

RESTORE RECORD

1. ENTER RECORD NUMBER

2. SCROLL TO SELECT

1. ENTER RECORD NUMBER

If you know the record number that you would like to restore, press the [1] key.

The following screen will be displayed:

RESTORE RECORD

NUMBER:

Type the record number using the alpha-numeric keypad and then press the

[ENTER] key. The following screen will be displayed:

RECORD RESTORED!

PRINT RECORD?

1. YES

2. NO

24

Page 29

REV 3 EZCT-2000 USER’S MANUAL

If you do not want to print the test record, press the [2] key (NO). The test record

will be restored to the working memory, and you will be returned to the “STARTUP” menu.

If you would like to print the test record, press the [1] key (YES). Continue to step d.

2. SCROLL TO SELECT

Press the [2] key if you would like to scroll through a directory of the stored test

records. The following screen will be displayed:

RECORD DIRECTORY

“UP” TO SCROLL FWD

“DWN” TO SCROLL RVS

Press the [PAPER ∧ Contrast] button or the [PAPER ∨ Contrast] key to

display the next or previous test record, respectively. The test record information

will be displayed as shown:

#1 09/24/09 13:16

5 TESTS

SHA 586

MITSUBISHI ELECTRIC

When you have located the test record that you would like to restore, press the

[ENTER] key.

The following screen will be displayed:

RECORD RESTORED!

PRINT RECORD?

1. YES

2. NO

If you do not want to print the test record, press the [2] key (NO). The test record

will be restored to the working memory, and you will be returned to the “STARTUP” menu.

If you would like to print the test record, press the

[1] key (YES). Continue to step d.

25

Page 30

d. The following screen will be displayed:

PRINT OPTIONS:

1. FULL DATA

2. ABBREVIATED DATA

EZCT-2000 USER’S MANUAL REV 3

Press the

[1] key to print the tabulated data and graphics results on the thermal printer.

The test record will be restored to the working memory and will be printed on the

thermal printer, and then you will be returned to the “START-UP” menu.

Press the

[2] key to print the test report and graphic results on the thermal printer,

without the excitation voltage and current data points. The test record will be restored

to the working memory and will be printed on the thermal printer, and then you will be

returned to the “START-UP” menu.

26

Page 31

REV 3 EZCT-2000 USER’S MANUAL

3.4.2. Printing a Restored Test Record

You can print a test record at the time that it is restored from the Flash EEPROM (see section

3.4.1), or you can restore it to the working memory and print it later. To print the current test

record in the working memory:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the

[2]

key (SETUP).

b. The following screen will be displayed:

1. RECORD ID

2. PRINT RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the

[2]

key (PRINT RECORD).

c. The following screen will be displayed:

PRINT OPTIONS:

1. FULL DATA

2. ABBREVIATED DATA

If there is no test record in the working memory, the following screen will be

displayed:

NOTE

NO SHOTS TO PRINT!

Press any key to return to the “START-UP” menu. Please see section 3.4.1 for

instructions on how to restore a test record.

Press the

[1]

The test record will be printed on the thermal printer and you will be returned to the

“START-UP” menu.

Press the

[2]

without the excitation voltage and current data points. The test record will be printed

on the thermal printer and you will be returned to the “START-UP” menu.

27

key to print the tabulated data and graphics results on the thermal printer.

key to print the test report and graphic results on the thermal printer,

Page 32

EZCT-2000 USER’S MANUAL REV 3

3.4.3. Printing a Directory of Test Records Stored in the EZCT-2000’s Memory

You can print a directory of all the test records stored in the EZCT-2000’s Flash EEPROM using

the steps below:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. RECORD ID

2. PRINT RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

c. The following screen will be displayed:

1. RECORD DIRECTORY

2. ERASE RECORD

3. KNEE POINT MARKER

4. NEXT PAGE

Press the [1] key (RECORD DIRECTORY).

d. The following screen will be displayed:

PRINT DIRECTORY

1. FULL DIRECTORY

2. SHORT DIRECTORY

Press the [1] key to print a full directory listing of all the test records stored in the EZCT2000’s Flash EEPROM. The directory listing will be printed on the thermal printer and

you will be returned to the “START-UP” menu. A sample directory listing printout is

shown in Figure 9.

Press the [2] key to print a short directory listing of the stored test records. The short

directory option prints the last 10 records stored in the EZCT-2000’s Flash EEPROM. The

short directory listing will be printed on the thermal printer and you will be returned to

the “START-UP” menu.

28

Page 33

REV 3 EZCT-2000 USER’S MANUAL

29

Figure 9. Typical Internal Test Record Directory Printout

Page 34

EZCT-2000 USER’S MANUAL REV 3

3.4.4. Erasing Test Records From the Flash EEPROM

You can erase individual or all test records stored in the EZCT-2000’s Flash EEPROM. To erase a

test record:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. RECORD ID

2. PRINT RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

c. The following screen will be displayed:

1. RECORD DIRECTORY

2. ERASE RECORD

3. KNEE POINT MARKER

4. NEXT PAGE

Press the [2] key (ERASE RECORD).

d. The following screen will be displayed:

ERASE RECORD

1. ERASE SINGLE REC.

2. ERASE ALL RECORDS

1. ERASE SINGLE REC.

Press the [1] key (ERASE SINGLE REC.) if you would like to erase a single record.

The following screen will be displayed:

ERASE RECORD

NUMBER:

Type the record number to be erased and press the

[ENTER] key.

30

Page 35

REV 3 EZCT-2000 USER’S MANUAL

• You can press the

• If you do not know the record number, you can first print a test

NOTES

record directory using the instructions in section 3.4.3.

The following screen will be displayed momentarily:

ERASING RECORD

NUMBER: 01

PLEASE WAIT...

Then the following confirmation screen will be displayed:

RECORD NUMBER 1

ERASED!

Press any key to return to the “START-UP” menu.

[STOP]

key to cancel the process.

2. ERASE ALL RECORDS

Press the

[2]

key if you would like to erase all of the test records stored in the

EZCT-2000’s flash EEPROM. The following confirmation screen will be displayed:

ERASE ALL RECORDS!

ARE YOU SURE?

“ENTER” TO CONTINUE

If you would like to cancel the erasure process, press the

[STOP]

key. No

records will be erased and you will be returned to the “START-UP” menu.

Press the

[ENTER]

key to continue with the erasure process. The following

screen will be displayed while the records are being erased:

ERASING RECORDS

PLEASE WAIT...

The following screen will be displayed after all of the test records have been

erased:

Press any key to return to the “START-UP” menu.

31

RECORDS ERASED

Page 36

EZCT-2000 USER’S MANUAL REV 3

3.5 Working With Test Plans

A test plan is comprised of the saturation test voltage, current range selection, CT nameplate

ratios, and CT winding terminal combinations (X1 to X5) for each test. Up to 10 test definitions

can be stored per test plan, and up to 128 CT test plans can be stored in the EZCT-2000’s Flash

EEPROM. The ability to use test plans makes CT testing an extremely simple process. To

perform a test, the EZCT-2000 is connected to the CT terminals and a test plan is selected to

run.

3.5.1. Extracting the Test Plan From a Test Record

A test plan can be extracted from a test record for immediate or future use. You can extract the

test plan immediately after performing a test or you can extract the test plan from a restored

test record (see section 3.4.1 for instructions on how to restore a test record). To extract a test

plan from a test record:

a. Either perform a test (see section 3.3) or restore a test record (see section 3.4.1) that

you would like to extract the test plan from.

b. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the

[3]

key (TEST PLANS).

c. The following screen will be displayed:

1. LOAD TEST PLAN

2. UNLOAD TEST PLAN

3. PLAN DIRECTORY

4. NEXT PAGE

Press the

[4]

key (NEXT PAGE)

d. The following screen will be displayed:

1. EXTRACT TEST PLAN

2. PRINT TEST PLAN

3. ERASE TEST PLAN

Press the

[1]

key (EXTRACT TEST PLAN)

If there is no test record in the working memory, the following screen will be

displayed:

NOTE

32

Page 37

REV 3 EZCT-2000 USER’S MANUAL

NO RECORD LOADED!

Press any key to return to the “START-UP” menu. You must first restore a test

record to the working memory before a test plan can be extracted. Please see

section 3.4.1

e. The following screen will be displayed:

TEST PLAN NUMBER 1

HAS BEEN SAVED!

The test plan will be extracted from the test record in the working memory and will be

saved to the EZCT-2000’s Flash EEPROM as a new test plan. The test plan number will be

automatically incremented by the EZCT-2000.

Press any key to return to the “START-UP” menu.

33

Page 38

EZCT-2000 USER’S MANUAL REV 3

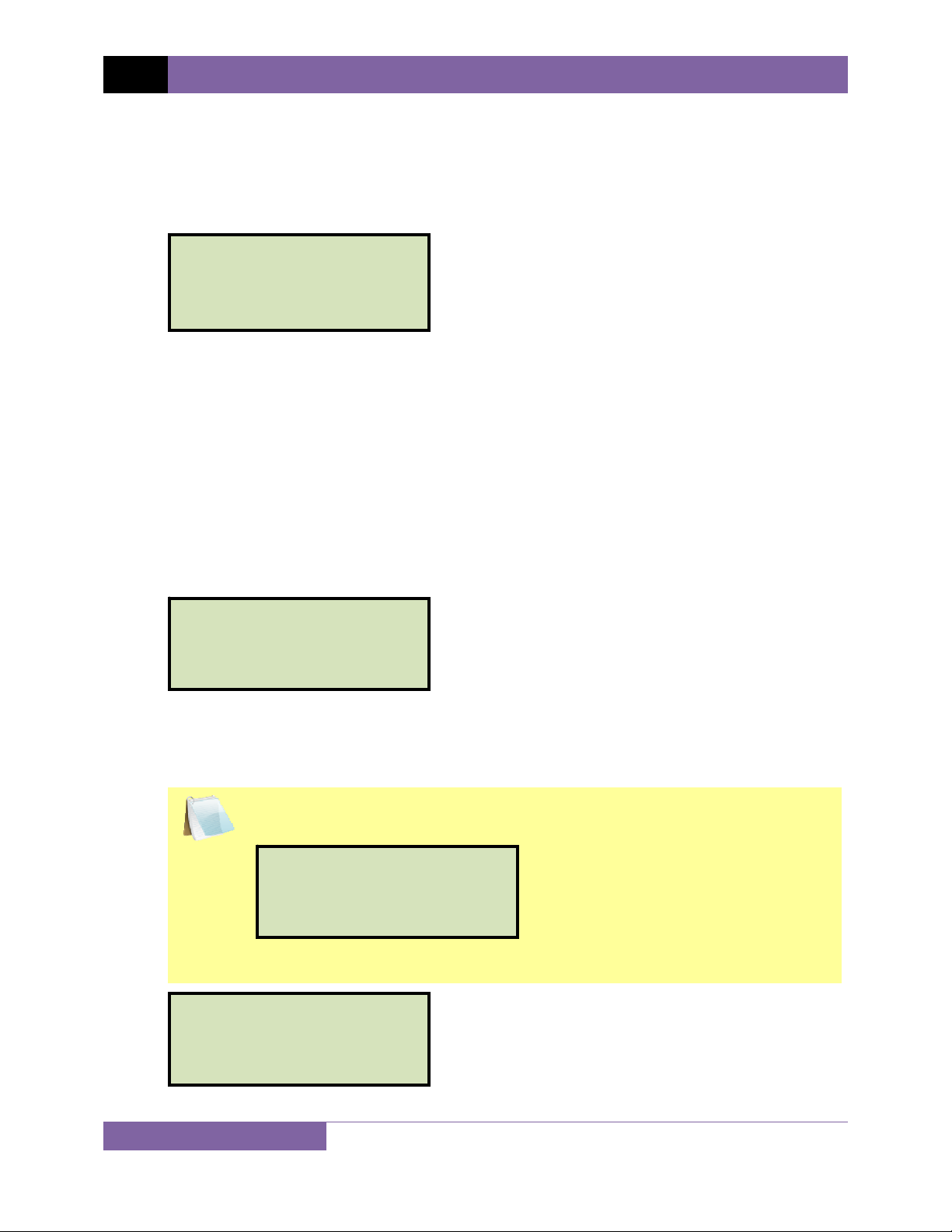

3.5.2. Printing a Directory of Test Plans Stored in the EZCT-2000’s Memory

You can print a directory of all the test plans stored in the EZCT-2000’s Flash EEPROM using the

steps below:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [3] key (TEST PLANS).

b. The following screen will be displayed:

1. LOAD TEST PLAN

2. UNLOAD TEST PLAN

3. PLAN DIRECTORY

4. NEXT PAGE

Press the [3] key (PLAN DIRECTORY).

c. The following screen will be displayed while the test plan directory is printed on the

thermal printer:

PRINTING DIRECTORY

You will be automatically returned to the “START-UP” menu after the directory printing

is finished. A typical Flash EEPROM test plan directory printout is shown in Figure 10.

34

Page 39

REV 3 EZCT-2000 USER’S MANUAL

Figure 10. Typical EZCT-2000 Flash EEPROM Test Plan Directory Printout

35

Page 40

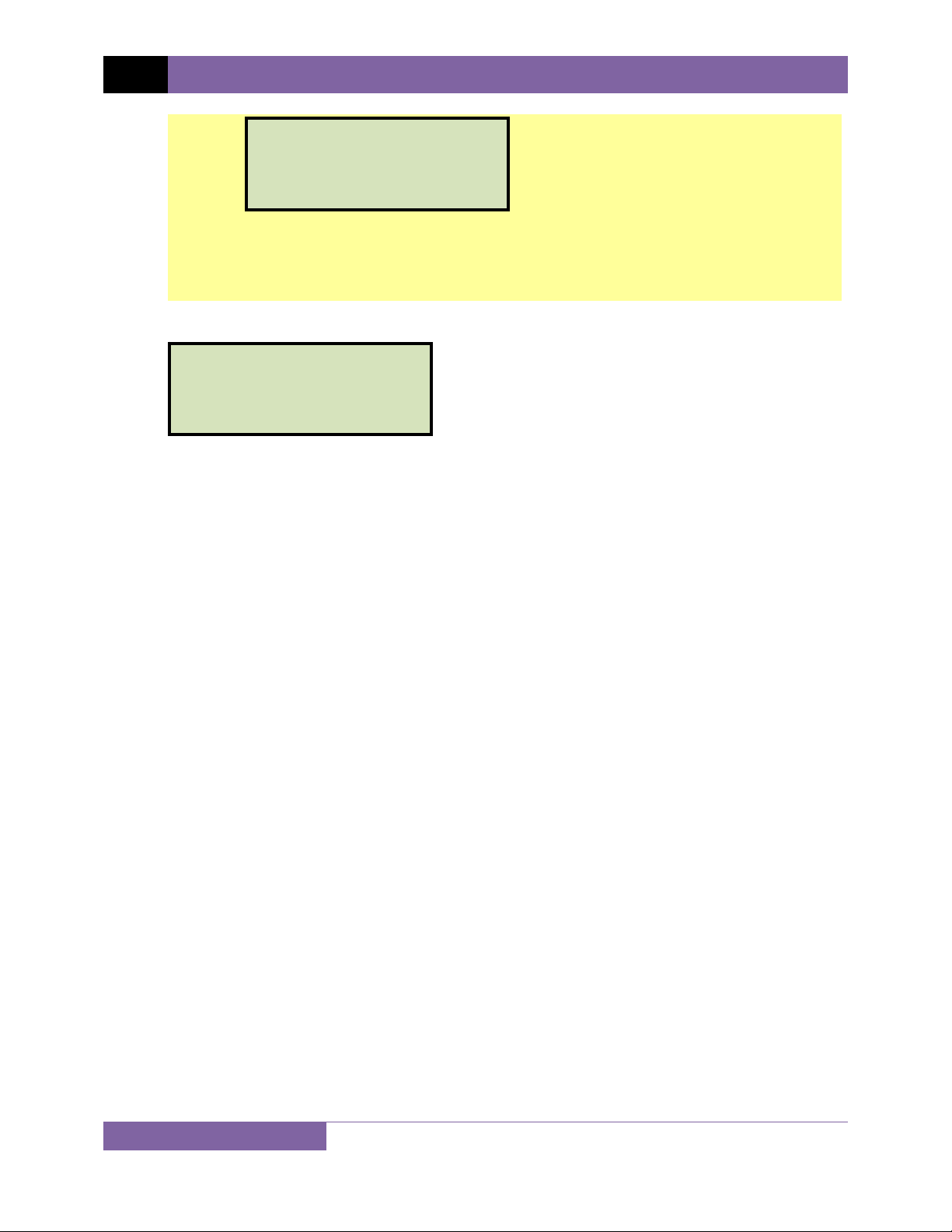

3.5.3. Printing a Test Plan

To print a test plan:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [3] key (TEST PLANS).

b. The following screen will be displayed:

1. LOAD TEST PLAN

2. UNLOAD TEST PLAN

3. PLAN DIRECTORY

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

c. The following screen will be displayed:

EZCT-2000 USER’S MANUAL REV 3

1. EXTRACT TEST PLAN

2. PRINT TEST PLAN

3. ERASE TEST PLAN

Press the [2] key (PRINT TEST PLAN).

d. The following screen will be displayed:

PRINT TEST PLAN

NUMBER:

Type the test plan number that you would like to print and press the

[ENTER] key. If

you do not know the test plan number, you can first print the test plan directory using

the instructions in section 3.5.2.

The test plan will be printed on the thermal printer and you will be returned to the

“START-UP” menu. A typical test plan printout is shown in Figure 11. Test plan elements

are described in Table 4.

36

Page 41

REV 3 EZCT-2000 USER’S MANUAL

Figure 11. Typical Test Plan Printout

Item

Number

1

2

3

4

5

6

7

Table 4. Description of Test Plan Elements

Description

Number of tests in test plan (2)

Tests to be performed (Excitation and Turns Ratio)

Terminals used for excitation test (X2-X3)

Maximum excitation voltage (300 V)

Maximum excitation current (2.0 A)

CT nameplate ratio (100:5)

Test notes (if any)

37

Page 42

EZCT-2000 USER’S MANUAL REV 3

3.5.4. Erasing Test Plans From the Flash EEPROM

To erase one or all test plans from the EZCT-2000’s Flash EEPROM:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [3] key (TEST PLANS).

b. The following screen will be displayed:

1. LOAD TEST PLAN

2. UNLOAD TEST PLAN

3. PLAN DIRECTORY

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

c. The following screen will be displayed:

1. EXTRACT TEST PLAN

2. PRINT TEST PLAN

3. ERASE TEST PLAN

Press the [3] key (ERASE TEST PLAN).

d. The following screen will be displayed:

ERASE TEST PLAN

1. ERASE SINGLE PLAN

2. ERASE ALL PLANS

1. ERASE SINGLE PLAN

Press the [1] key if you would like to erase a single test plan. The following

screen will be displayed:

ERASE TEST PLAN

NUMBER:

Type the test plan number that you would like to erase and press the [ENTER]

key.

38

Page 43

REV 3 EZCT-2000 USER’S MANUAL

• You can press the

• If you do not know the test plan number, you can print a test

NOTES

plan directory using the instructions in section 3.5.2.

The selected test plan will be erased and the following screen will be displayed:

TEST PLAN NUMBER 1

ERASED!

Press any key to return to the “START-UP” menu.

2. ERASE ALL PLANS

[STOP]

key to cancel the process.

Press the

[2]

key if you would like to erase all test plans. The following screen

will be displayed:

ERASE ALL PLANS!

Are you sure?

“ENTER” TO CONTINUE

If you would like to cancel the erasure process, press the

[STOP]

key. No test

plans will be erased and you will be returned to the “START-UP” menu.

Press the

[ENTER]

key to continue with the erasure process. The following

screen will be displayed while the test plans are being erased:

ERASING ALL TEST PLANS

PLEASE WAIT...

The following screen will be displayed after all of the test plans have been

erased:

PLANS ERASED!

Press any key return to the “START-UP” menu.

39

Page 44

EZCT-2000 USER’S MANUAL REV 3

3.5.5. Loading a Test Plan from the EZCT-2000’s Flash EEPROM

To use a test plan for running a test, it must first be loaded into the working memory. To load a

test plan from the EZCT-2000’s Flash EEPROM into the working memory:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [3] key (TEST PLANS).

b. The following screen will be displayed:

1. LOAD TEST PLAN

2. UNLOAD TEST PLAN

3. PLAN DIRECTORY

4. NEXT PAGE

Press the [1] key (LOAD TEST PLAN).

c. The following screen will be displayed:

LOAD TEST PLAN

NUMBER:

Type the test plan number that you would like to load and press the [ENTER] key. If

you do not know the test plan number, you can print a test plan directory using the

instructions in section 3.5.2.

d. The following screen will be displayed:

TEST PLAN LOADED!

Press any key to return to the “START-UP” menu.

40

Page 45

REV 3 EZCT-2000 USER’S MANUAL

3.5.6. Running a Test Using a Loaded Test Plan

Once a test plan has been loaded into the working memory (see section 3.5.5 for directions), it

can be used to run a test. To run a test using a loaded test plan:

a. Make sure a test plan has been loaded into the working memory and then start from the

“START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [1] key (RUN TEST).

b. The following screen will be displayed (this screen will only be displayed if a test plan

has been loaded first):

TEST PLAN LOADED

1. RUN WITH PROMPTS

2. RUN AUTONOMOUSLY

3. UNLOAD TEST PLAN

1. RUN WITH PROMPTS

Press the [1] key to run the test with prompts. Continue to step c.

2. RUN AUTONOMOUSLY

Press the [2] key to run the test autonomously. The following screen will be

displayed:

CABLES WILL BE

ENERGIZED!

“START” TO BEGIN

Press the [START] key and the EZCT-2000 will start running the test per the

test plan settings. The screen will be updated with the test status.

When the test has finished, the following screen will be displayed:

SAVE THIS RECORD?

1.YES

2.NO

Press the

[1] key (YES) to save the record.

The following screen will be displayed momentarily:

41

Page 46

SAVING RECORD...

PLEASE WAIT...

Then the following confirmation screen will be displayed:

RECORD NUMBER 2

HAS BEEN SAVED!

Press any key to return to the “START-UP” menu.

3. UNLOAD TEST PLAN

Press the [3] key to unload the test plan and run a test without a test plan. This

will unload the test plan from the working memory and bring up the standard

“RUN TEST” menu. Please see section 3.3.2, step b.

c. The following screen will be displayed:

EZCT-2000 USER’S MANUAL REV 3

ENTER TEST 1 NOTE:

↑/↓ TO POSITION

“ENTER” TO ACCEPT

Use the alpha-numeric keys on the keypad to enter a test note and press the [ENTER]

key.

d. The following confirmation screen will be displayed showing the test parameters:

TEST 1 PARAMETERS:

300V 2.0A X1-X2

“START” TO BEGIN

Press the

[START] key to begin the test.

e. The EZCT-2000 will start performing the test per the test plan parameters. When the

test has finished, the following screen will be displayed:

ANY KEY TO CONTINUE

Vx=77.6 Vh=0.3876

I=0.0522 RAT=+200.08

Press any key to continue.

42

Page 47

REV 3 EZCT-2000 USER’S MANUAL

f. The following screen will be displayed:

PRINT TEST RESULTS?

1.YES

2.NO

Press the

Press the

[1] key (YES) if you would like to print the test results.

[2] key (NO) if you do not want to print the test results.

g. The following screen will be displayed:

KEEP THIS TEST?

1.YES

2.NO

Press the

[1] key (YES) to keep the test results.

h. The following screen will be displayed:

TEST 2 SAVED

Press any key to continue.

i. The following screen will be displayed:

KEEP THIS RECORD?

1.YES

2.NO

Press the [1] key (YES) to save the record.

The following screen will be displayed momentarily:

SAVING RECORD...

PLEASE WAIT...

The following confirmation screen will then be displayed:

RECORD NUMBER 2

HAS BEEN SAVED!

Press any key to return to the “START-UP” menu.

43

Page 48

EZCT-2000 USER’S MANUAL REV 3

3.5.7. Unloading a Test Plan from the Working Memory

To unload the test plan from the working memory and clear all the test plan parameters:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [3] key (TEST PLANS).

b. The following screen will be displayed:

1. LOAD TEST PLAN

2. UNLOAD TEST PLAN

3. PLAN DIRECTORY

4. NEXT PAGE

Press the [2] key (UNLOAD TEST PLAN).

c. The following screen will be displayed:

TEST PLAN UNLOADED!

Press any key to return to the “START-UP” menu.

44

Page 49

REV 3 EZCT-2000 USER’S MANUAL

4.0 CHANGING SETUP PARAMETERS

4.1 Setting the Knee Point Marker

Use the steps below to change the knee point marker for the excitation graph:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. RECORD ID

2. PRINT RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

c. The following screen will be displayed:

1. RECORD DIRECTORY

2. ERASE RECORD

3. KNEE POINT MARKER

4. NEXT PAGE

Press the [3] key (KNEE POINT MARKER)

d. The following screen will be displayed:

1. IEEE 30 DEGREE

2. IEEE 45 DEGREE

3. ASA 10%V --> 50%I

Press either the

(ASA 10%V-->50%I) to select the desired knee point marker. The knee point marker will

be set and you will be returned to the “START-UP” menu. A graphic report showing the

knee point marker is shown in Figure 12.

[1] key (IEEE 30 DEGREE), the [2] key (IEEE 45 DEGREE), or the [3] key

45

Page 50

EZCT-2000 USER’S MANUAL REV 3

Knee Point Marker

Knee Point Marker Type

Figure 12. Graphic Report Showing Knee Point Marker

46

Page 51

REV 3 EZCT-2000 USER’S MANUAL

4.2 Selecting the Buried CT in Transformer Delta Option

The EZCT-2000 can be used to measure the turns ratio of a CT buried in the transformer Delta

windings (see Figure 13 and Figure 14 for further information). However, in order for the unit to

correctly calculate the turns ratio of a CT buried in the transformer Delta windings, the “CT

Buried in Delta” option must first be selected. Use the steps below to set the “Buried CT in

Delta” option:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. RECORD ID

2. PRINT RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

c. The following screen will be displayed:

1. RECORD DIRECTORY

2. ERASE RECORD

3. KNEE POINT MARKER

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

d. The following screen will be displayed:

1. SET TIME

2. BURIED CT IN DELTA

Press the [2] key (BURIED CT IN DELTA).

e. The following screen will be displayed:

-BURIED CT IN DELTA-

RATIOS ADJUSTED BY

TWO-THIRDS.

Press any key to return to the “START-UP” menu.

47

Page 52

EZCT-2000 USER’S MANUAL REV 3

The “Buried CT in Delta” option will stay active for all subsequent tests

performed. Turning off the EZCT-2000 will reset this option.

NOTE

Figure 13. Buried CT in a Delta Transformer Illustration 1

Figure 14. Buried CT in a Delta Transformer Illustration 2

48

Page 53

REV 3 EZCT-2000 USER’S MANUAL

• The CT turns ratio is ideally measured as: Ratio =

NOTES

• Since the induced voltage (V) is sensed through the H1-H2 terminals of

the Delta winding, this induced voltage is measured as V = (

• The CT turns ratio is now measured as Ratio =

). This measured turns ratio is

• The EZCT-2000 will display the correct CT turns ratio by adjusting the

measured turns ratio by

Vx

.

Vh

2

) Vh.

3

Vx

or Ratio = (

V

3

higher than the actual turns ratio.

2

2

.

3

3

Vx

)(

2

Vh

49

Page 54

4.3 Setting the Clock

To set the EZCT-2000’s internal clock:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [2] key (SETUP).

b. The following screen will be displayed:

1. RECORD ID

2. PRINT RECORD

3. RESTORE RECORD

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

c. The following screen will be displayed:

EZCT-2000 USER’S MANUAL REV 3

1. RECORD DIRECTORY

2. ERASE RECORD

3. KNEE POINT MARKER

4. NEXT PAGE

Press the [4] key (NEXT PAGE).

d. The following screen will be displayed:

1. SET TIME

2. BURIED CT IN DELTA

Press the

[1] key (SET TIME).

e. The following screen will be displayed:

ENTER

MM-DD-YY HH:MM:SS

Enter the month, date, time, hours, minutes, and seconds (in 24-hour format) using the

alpha-numeric keypad. When the last digit is entered, the clock will be set and you will

be returned to the “START-UP” menu.

50

Page 55

REV 3 EZCT-2000 USER’S MANUAL

5.0 DIAGNOSTICS, VERIFICATION, AND TROUBLESHOOTING

5.1 Performing a Diagnostics Test

The Diagnostics test mode displays the output voltage at the selected X leads (Vx), the voltage

sensed by the H leads (Vh), and the X voltage excitation current (Ix). These values can then be

verified using an external volt meter and ampere meter.

To perform a diagnostic test:

a. Start from the “START-UP” menu:

1. RUN TEST 09/24/09

2. SETUP 08:20:19

3. TEST PLANS

4. DIAGNOSTIC

Press the [4] key (DIAGNOSTIC).

b. The following screen will be displayed:

SELECT TAP:

1. X1-X2 3. X1-X4

2. X1-X3 4. X1-X5

5. NEXT PAGE

Select the tap connection by pressing the corresponding key ([1] – [4]). If the tap

connection is not listed, press the [5] key to view the next page of options and then

select the correct tap connection.

c. The following screen will be displayed:

SELECT VOLTAGE RANGE

1. 50V 4. 1200V

2. 300V 5. 2000V

3. 500V

Select the maximum output voltage on the X terminals by pressing the corresponding

[1] – [5]).

key (

d. The following screen will be displayed:

CAUTION! CABLES WILL

BE ENERGIZED!

“ENTER” TO CONTINUE

Press the

[ENTER] key to continue.

e. The following screen will be displayed and the V

, Vh, and Ix values will be continuously

x

updated for 15 seconds:

51

Page 56

EZCT-2000 USER’S MANUAL REV 3

DIAGNOSTIC

Vx = 2.2 Ix = 0.001A

Vh = 0.07

↑/↓ - “STOP” TO EXIT

You can press the [PAPER ∧ Contrast] or [PAPER ∨ Contrast] key to increase or

decrease the Vx voltage, respectively. You can press the [STOP] key to end the test

immediately and return to the “START-UP” menu.

The test will automatically end after 15 seconds, and you will be returned to the

“START-UP” menu.

52

Page 57

REV 3 EZCT-2000 USER’S MANUAL

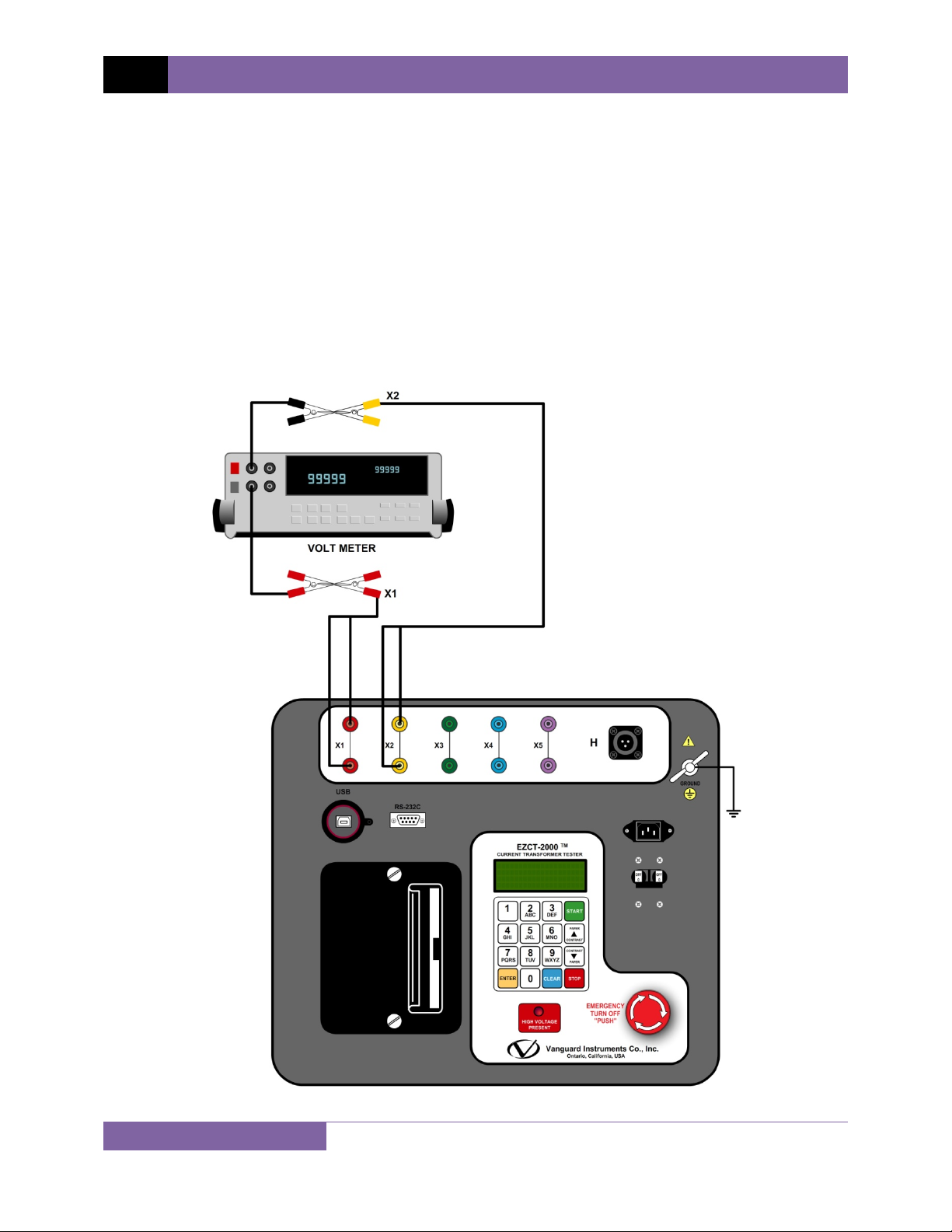

5.2 Verifying the EZCT-2000’s Vx Sense Circuit Using an External Meter

The excitation voltage (Vx) sensed by the EZCT-2000 can be verified using an external RMS volt

meter. Follow the steps below to verify the EZCT-2000’s Vx sense circuit:

a. Connect the X cables to an RMS volt meter as shown in Figure 15.

b. Select the EZCT-2000’s Diagnostics mode (see section 5.1).

c. Press the

d. Verify the V

[PAPER ∧ Contrast] key to raise the V

voltage displayed on the EZCT-2000 LCD screen against the value displayed

x

on the external volt meter.

e. Press the [STOP] key to end the test.

voltage.

x

53

Figure 15. EZCT-2000 Vx Verification Test Connections

Page 58

EZCT-2000 USER’S MANUAL REV 3

5.3 Verifying the EZCT-2000’s Ix Sense Circuit Using an External Meter

You can verify the excitation current (Ix) sensed by the EZCT-2000 by using an external RMS

ampere meter. Follow the steps below to verify the EZCT-2000’s Ix sense circuit:

a. Connect the X cables to a power resistor and an RMS ampere meter as shown in Figure

16.

b. Select the EZCT-2000’s Diagnostics mode (see section 5.1).

c. Press the [PAPER ∧ Contrast] key to raise the Vx voltage.

d. Verify the Ix voltage displayed on the EZCT-2000’s LCD screen against the value

displayed on the external RMS ampere meter.

e. Press the

[STOP] key to end the test.

Figure 16. EZCT-2000 Ix Verification Test Connections

54

Page 59

REV 3 EZCT-2000 USER’S MANUAL

5.4 Quickly Verifying the EZCT-2000’s Turns Ratio Circuit

You can quickly verify the EZCT-2000’s turns ratio circuit by performing the following ratio test:

a. Connect the X1 test lead to the H1 test lead as shown in Figure 17.

b. Connect the X2 test lead to the H2 test lead as shown in Figure 17.

c. Run a turns ratio test (see section 3.3.2).

d. Observe the turns ratio test on the LCD screen. The turns ratio should be 1.000 since the

excitation voltage is the same as the sensed voltage.

Figure 17. EZCT-2000 Turns Ratio Verification Test Connections

55

Page 60

EZCT-2000 USER’S MANUAL REV 3

5.5 Troubleshooting Guide

PROBLEM DESCRIPTION Probable Cause Suggested Solution

When running the

excitation test, the Vx

voltage is always zero.

The excitation current can

be raised during a test.

When running the

excitation test, the Vx

voltage can be raised but

the excitation current is

always zero during a test.

CT excitation knee point

voltages and turns ratio

readings are incorrect.

• The EZCT-2000 X cables are driving a

short circuit.

• The EZCT-2000 X cable is driving an

opened circuit.

• CT may not be completely de-

magnetized.

• If the user runs a dc resistance test,

the CT will be magnetized. The next

test the EZCT-2000 executes is an

excitation test. If the excitation

current did not reach at least 0.8A,

the CT is not completely demagnetized.

• Check CT shorting screws.

• Check X lead connections.

• Check the CT terminal connection.

• Raise the excitation voltage

setting in the test plan.

• Re-run the excitation test.

• You can quickly verify if the CT

was de-magnetized by looking at

the last excitation graph.

When running the

excitation test, the Vx

reading is erratic.

Saturation test is correct

but turns ratio test is

erroneous.

Turns ratio test of a CT

mounted on a

transformer bushing is

incorrect.

• The EZCT-2000 X cable may be

opened. Each X cable has two

conductors going from the clip end to

the banana jacks. If one of the

conductors is opened, the Vx readings

will be erratic.

• VH cables problem. • Check the VH cable connection.

• Transformer windings opposite side of

CT windings is not shorted.

• Remove X cables from the EZCT-

2000 and the CT terminals.

• Check cable integrity using an

Ohm Meter.

• Check the VH cable integrity with

an Ohmmeter

• See Figure 4.

56

Page 61

REV 3 EZCT-2000 USER’S MANUAL

6.0 Appendix A - Calculating Turns Ratio on a Shunt Reactor

The Vanguard EZCT line of products use the voltage method to measure the turns-ratio on

current transformers. A typical connection for a stand-alone CT is shown in Figure 18.

Figure 18

The EZCT applies a test voltage (V1) to the CT secondary winding. The induced voltage (V2) is

sensed through the CT primary winding. In this case a single conductor is used. By definition,

the turns-ratio is the voltage ratio:

Ratio=

57

Page 62

EZCT-2000 USER’S MANUAL REV 3

Figure 19 shows a typical connection of a CT mounted on the primary bushing of a single phase

transformer. When the voltage V1 is introduced to the CT's secondary winding, there is an

induced voltage (V3) on the primary winding of this single phase transformer. Since the only

access to the transformer is between terminals H1-H0, The V3 voltage will be included and the

turns-ratio will be:

Ratio=

()

Figure 19

Ideally, we would like to eliminate the V3 voltage and only see the V2 voltage. If the induced V3

voltage on the transformer winding cannot be eliminated, the turns-ratio measured will be

wrong!

58

Page 63

REV 3 EZCT-2000 USER’S MANUAL

Since this is a single phase transformer, and the transformer secondary winding is accessible,

the user can apply a jumper to short out the transformer secondary winding as shown in Figure

20. By shorting out the transformer secondary winding, the user can eliminate most of the V3

voltage (V3=0V).

Now the turns-ratio will be:

Ratio=

59

Figure 20

Page 64

EZCT-2000 USER’S MANUAL REV 3

Figure 21 show a CT mounted on a typical shunt reactor. This configuration is very similar to

the CT mounted on a single phase transformer, the main difference being the lack of the

secondary winding! The turns-ratio in this case will be:

Ratio=

()

Figure 21

Since there is no secondary winding on the shunt reactor, the turns-ratio measurement from

using this method will always have some built-in error. The amount of error depends on the

size of the reactor winding and the number of turns on the CT's secondary winding. The user

does not have an alternative method for verifying the CT turns-ratio in this situation since there

is no secondary winding and a jumper can't be used.

60

Page 65

REV 3 EZCT-2000 USER’S MANUAL

Figure 22 show a CT with 5 taps. The turns-ratio of the CT can be measured by treating the CT

secondary winding as an auto-transformer. When using this method, the effect of the shunt

reactor winding is totally eliminated.

The turns-ratio measured by the EZCT or any electronic TTR is calculated as follows:

Ratio =

Figure 22

From the name plate of the CT show in table below, the turns-ration can be calculated as

follows:

Ratio Terminal

1200-5A X1-X5

1000-5A X2-X5

61

Calculated Ratio =

()

(

=

= 1.20

Page 66

EZCT-2000 USER’S MANUAL REV 3

A common practice for verifying the CT turns-ratio in the field is to apply an AC voltage to the

CT secondary full winding (X1-X5). A volt meter can be used to verify the voltage drop across

the CT terminals.

For example, if a 120Vac voltage is applied to the X1-X5 of this CT, the voltage reading across

X2-X5 shall be expected as follows:

Voltage (X2-X5) = 120 V x (

) = 100 V

Figure 23

This method also eliminates the effect of the (reactor) winding on the H1 – H2 terminals.

62

Page 67

REV 3 EZCT-2000 USER’S MANUAL

Figure 24

63

Figure 25

Page 68

1520 S. Hellman Ave • Ontario, CA 91761 • USA

Phone: 909-923-9390 • Fax: 909-923-9391

www.vanguard-instruments.com

Copyright © 2014 by Vanguard Instruments Company, Inc.

EZCT-2000 User’s Manual • Revision 3.5 • March 25, 2014 • TA

Loading...

Loading...