OPERATING PROCEDURES

for the

MODEL DMOM-200

10-200 Amperes True DC

Digital Micro-Ohm Meter

Part Number VIC-9000-100

Vanguard Instrument Company

1710 Grevillea Court Ontario, California 91761

TEL: 909/923-9390 AUGUST 2001

FAX: 909/923-9391 REV. 0

Operating Procedures DMOM-200™

SAFETY SUMMARY

The following safety precautions must be

observed during all phases of test set-up, test

hookups, testing, and test-lead disconnects.

Do Not Service or Test Alone

Do not perform test procedures or service

unless another person is also present who is

capable of rendering aid and resuscitation.

Avoid Contact with High Voltage

Because electrical utility station

environments contain high voltages and

currents, there is always the possibility of

personal contact with an unexpected lethal

voltage generated by magnetic induction

and/or electrostatic leakage from nearby live

circuitry. When test units are connected to

deenergized (“dead”) power lines, regardless

of how short they are, always discharge the

lines before attaching any test lead. Because

of the possibly deadly consequences of

physical contact with such high-voltage lines,

engineers and technicians must always treat

electrical equipment and hookups as though a

lethal condition will eventually occur.

Therefore, no matter how unlikely it may

seem, never assume anything about the safety

of any test setup.

Ensure the safety of personnel by checking

first-hand to eliminate all possible hazards!

Do Not Test Inductive Winding Resistance

Because the DMOM-200 produces test

currents up to 100 amperes, it is able to build

up large magnetic fields in iron-core

transformers. The interruption of such test

currents can produce a high voltage spike

that can cause severe injury, death, and/or

equipment damage. Therefore, do not

attempt to measure the resistance of iron-core

transformer windings (use equipment

designed specifically for that purpose).

Do Not Modify Test Equipment

Because of the added risk of introducing

additional or unknown hazards, do not install

substitute parts or perform any unauthorized

modification to the DMOM-200. To

ensure that designed safety features are

maintained, it is recommended that all

DMOM-200 repairs be done at Vanguard

Instruments Company or by an authorized

repair-service. Unauthorized DMOM-200

modifications can create unknown safety

hazards and will void the warranty.

Follow Exact Operating Procedures

Any deviation from the operating procedures

described in this manual may create one or

more safety hazards, damage the DMOM200 or cause test errors; Vanguard

Instruments Co. assumes no liability for

unsafe or improper use of the DMOM-200.

ii

Operating Procedures DMOM-200™

TABLE OF CONTENTS

Safety Summary

1.0 INTRODUCTION .................................................................................................................. 1

1.1 Applicability ....................................................................................................................... 1

1.2 Supersedure Notice ............................................................................................................. 1

1.3 General Description ............................................................................................................ 1

1.4 Functional Description........................................................................................................ 1

1.5 Furnished Test Accessories ................................................................................................ 1

2.0 DMOM-200 Specifications ................................................................................................. 2

3.0 CONTROLS AND INDICATORS......................................................................................... 3

4.0 PRETEST SETUP .................................................................................................................. 5

4.1 Operating Voltages ............................................................................................................. 5

4.2 DMOM-200 Printer Paper............................................................................................... 6

4.3 DMOM-200 Cable Connections ..................................................................................... 6

5.0 OPERATING PROCEDURES............................................................................................... 7

5.1 Operating Overview............................................................................................................ 7

5.2 Preparation .......................................................................................................................... 7

5.3 Keying-in Data Characters.................................................................................................. 7

5.4 Run Test Procedure...........................................................................................................10

5.5 Enter ID Procedure ...........................................................................................................13

5.6 Review Record Procedure ................................................................................................ 15

5.7 Restore Record Procedure ................................................................................................ 17

5.8 Print Test Record Directory Procedure............................................................................. 19

5.9 Test Record Procedure...................................................................................................... 20

5.10 Computer Interface Procedure ...................................................................................... 21

5.11 Set Clock Procedures .................................................................................................... 21

5.12 Calibration Check ......................................................................................................... 22

Appendix A DMOM-200 Troubleshooting Guide

Appendix B DMOM-200Cable Accessories

ii

Operating Procedures DMOM-200™

LIST OF TABLES

Table 1.0 DMOM-200 Specifications and Leading Particulars.................................................. 2

Table 2.0 DMOM-200 Controls and Indicators .......................................................................... 4

Table 3.0 Voltage Selection............................................................................................................ 5

Table 4.0 Run Test Procedure (Measure an Unknown Resistance).............................................. 10

Table 5.0 Run Setup Procedure (test-record, site, and equipment identification)........................ 13

Table 6.0 Review Record Procedure ............................................................................................ 15

Table 7.0 Restore Record Procedures........................................................................................... 17

Table 8.0 Print Test Record Directory.......................................................................................... 19

Table 9.0 Erase Test Record Procedure........................................................................................ 20

Table 10.0 Computer Interface Procedures ................................................................................ 21

Table 11.0 Set Clock Procedures................................................................................................ 21

Table 12.0 Calibration Check Procedure.................................................................................... 22

LIST OF FIGURES

Figure 1.0 DMOM-200 Control Panel (Controls and Indicators) ............................................ 3

Figure 2.0 90 to 130Vac Jumper Setting...................................................................................... 5

Figure 3.0 210 to 240Vac Jumper Setting.................................................................................... 5

Figure 4.0 DMOM-200 Cable Connection............................................................................... 6

Figure 5.0 Step-by-Step Procedures for DMOM-200 Operations............................................ 8

Figure 6.0 Typical DMOM-200 Tabulated Report Printout................................................... 12

Figure 7.0 Typical Directory Printout ........................................................................................ 19

Figure 8.0 Bus Bar Connection .................................................................................................. 23

iii

Operating Procedures DMOM-200™

1.0 INTRODUCTION

1.1 Applicability

This manual applies to the Model DMOM200™, part number VIC-9000-100, which is

made by Vanguard Instruments Company.

1.2 Supersedure Notice

This manual is the basic issue for the Model

DMOM-200 and does not supersede any

published document.

1.3 General Description

The DMOM-200™ is a Digital Micro-Ohm

Meter for precisely measuring non-inductive

resistances from 1 micro-ohm to 300 milliohms. Applications include resistance

measurement of circuit-breaker contacts,

bushing joints, or any other low resistance.

It is field-portable, rugged, and easily

operated by first-time users having little

training (its microprocessor-driven, which

automates many functions). It has a 16-key

pushbutton pad for entering test parameters

and control functions, and a 4-line by 20character LCD readout for displaying

control-option menus, measured resistance

values, and related identifying data. The

DMOM-200 has a built-in thermal printer,

which prints test data on 2.5-inch-wide

thermally sensitive paper.

Operation requires little more than

connecting the test leads to an unknown

resistance and selecting the test parameters;

It requires no calculation of lead-loss, handwritten notes, or the memorizing of detailed

routines. Operators select the test current

(10 to 200 amperes) and test time (5 to 60

seconds). Measured resistance data is

displayed and can be printed on the thermal

printer. The measured resistance data can

also be stored (up to 63 records of 96

readings each) in FLASH EEPROM

memory; Operators can recall the stored

resistance-measurements and related data at

a later time for review and printing.

1.4 Functional Description

DMOM-200 operation is based on the

electrical relationships described by Ohm’s

law: R=V/I, where I is a known test current

and V is the voltage across the unknown

resistance (e.g., breaker contacts). Since the

test current through the unknown resistance

is known and voltage across it is read by the

microprocessor, the resistance is calculated

using Ohm’s law.

The DMOM-200 test voltage is supplied

by a filtered direct-current power supply. A

precisely regulated constant-current source

controls the current ramps up/down time and

the test current. The dc test current (10 to

200 amps) slowly ramps up/down, which

virtually eliminates magnetically induced

transients; thus, the risk of inductively

tripping a circuit-breaker’s bus differential

relay is virtually non-existent.

DMOM-200 voltmeter test leads are run

separately from the current-bearing test

leads to the resistive load; thus, voltages are

measured at the terminals of the resistance

being measured, eliminating error from the

I•R voltage drop in the test current cables.

The DMOM-200 makes precise microohm measurements possible without

calculating compensation for test-currentlead resistance errors.

1.5 Furnished Test Accessories

The DMOM-200 is supplied with a power

cord, a roll of 2.5-inch-wide printer paper,

and one 35-foot test cable set with quickdisconnect plugs to the unit and heavy-duty

alligator clamps to the load. Heavy-duty

welding-type C-clamps (see Appendix B)

are also available as optional accessories (Cclamps allow test- lead connection to a wide

variety of bushing sizes, bus bars, and many

other junctions that require low-contact

resistance).

1

Operating Procedures DMOM-200™

2.0 DMOM-200 SPECIFICATIONS

Table 1.0 DMOM-200 Specifications and Leading Particulars

MODEL .............................................DMOM-200 (part number VIC-9000-100)

TYPE..……… ..................................Special-purpose test equipment, portable; 100-ampere,

Digital Micro-Ohm Meter

POWER ............................................85 to 132 V ac or 200-240 V ac (selectable), 50/60 Hz

SIZE (inches) ....................................16.8 wide by 12.6 high by 10.6 deep

WEIGHT............................................ Less than 21 lbs

TEST CURRENT .............................. 10 to 200 amperes

RESISTANCE READING RANGE ...1 micro-ohm to 300 milliohms

ACCURACY .....................................±1% reading, ± 1 count

DISPLAY ..........................................LCD, 4-line by 20-character, back lighted

CONTROLS......................................Keypad: 10 number keys and 6 function keys

COMPUTER INTERFACE ................RS-232C

PRINTER ..........................................Thermal printer (prints on 2.5-inch-wide thermal paper)

ENVIRONMENT ...............................Operating: 0°C to 55°C; Storage: -40°C to 65°C

FURNISHED ..................................... One power cord, one 35-foot test cable set,

One cable bag

EXPENDABLES ............................... Paper, thermally sensitive, 2.5-inch wide roll

(VIC part # TP-3)

WARRANTY ..................................... One-year warranty on parts and labor; post warranty

service contracts available

NOTE:

THE ABOVE SPECIFICATIONS ARE VALID AT NOMINAL OPERATING VOLTAGE AND AT A TEMPERATURE OF 25°C

°

F)

(77

DMOM-200 SPECIFICATIONS MAY BE UPGRADED AND CHANGED WITHOUT PRIOR NOTICE.

2

Operating Procedures DMOM-200™

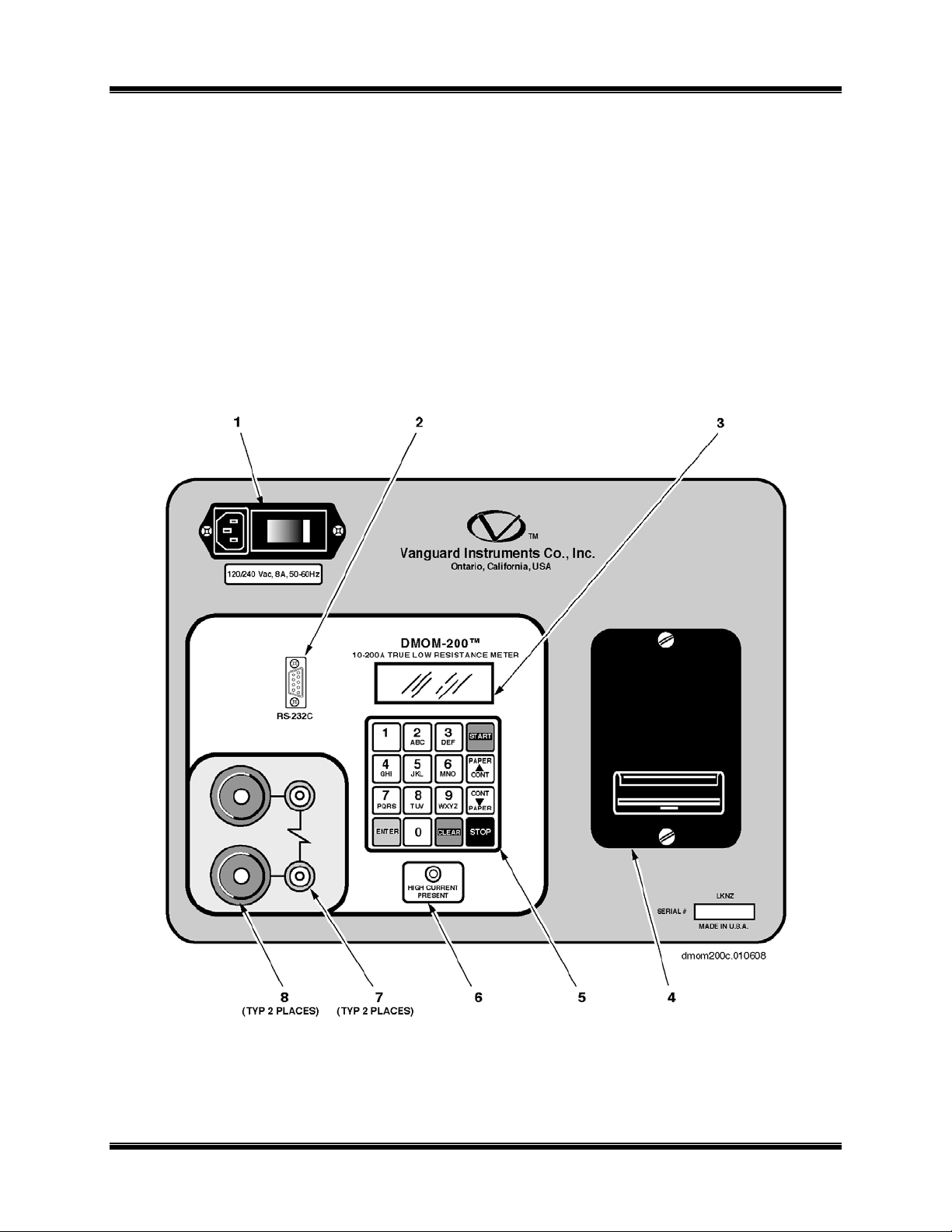

3.0 CONTROLS AND INDICATORS

(See Figure 1.0 and refer to Table 2.0).

The DMOM-200 controls and indicators

are shown in a panel illustration (see Figure

1.0). Pointing leader lines reference each

item in the figure with an index number.

Each index number is cross-referenced to a

functional description in Table 2.0, which

describes the purpose of each item on the

control panel. Although the purpose of

these controls and the display may seem

obvious, users should become familiar with

them before attempting to use the DMOM200. However, accidental misuse of the

controls will usually cause no serious loss of

data or equipment damage. First-time users

should review and become familiar with the

Safety Summary located in the front section

of this manual.

Figure 1.0 DMOM-200 Control Panel (Controls and Indicators)

3

Operating Procedures DMOM-200™

Table 2.0 DMOM-200 Controls and Indicators

Fig. 1

Index PANEL MARKING FUNCTIONAL DESCRIPTION

1

2

3

4

5

6

7

8

3.1 DMOM-200 LCD Contrast Control

To Darken the LCD display, press and hold

the “Paper ∧ Contrast” switch for two

seconds; to lighten the LCD display, press

and hold the “Paper ∨ Contrast” switch for

two seconds.

(no overall marking; keys are

individually marked—see

ON/OFF

RS-232C

(no marking) Display, back-lighted liquid crystal (LCD); 4-line

(no marking) Built-in thermal printer; prints test result data on

Figure 1)

HIGH CURRENT

PRESENT

(no marking) Voltage-sensing test-lead plug-in sockets (2), red;

(no marking) Test-current lead plug-in sockets (2), red;

Input power connector with third-wire safety

ground and 10A built-in circuit breaker.

Connector, 9-pin; Serial interface-port connector

(female DB type) to allow the DMOM-200 to

be controlled by an IBM-compatible PC.

PIN SIGNAL

2 Tx

3 Rx

5 Signal Gnd

by 20-character; sunlight readable; displays test

menus (operator options), status, and test results

(See Figure 2 for operating displays of control

steps in logical flow sequence).

2.5-inch-wide thermal paper.

Operating key-pad controls; 10 alpha-numeric

keys and 6 function keys (i.e., START, STOP,

CLEAR, ENTER, & CONTRAST/PAPER

positioning ∧ & ∨).

Warning indicator; red LED; Lights when high

current is running through the test leads.

reads voltage at test load.

conducts up to 100 amperes through unknown

resistances.

3.3 RS-232C Computer-Interface port

An IBM PC software package is supplied

with each DMOM-200 allows the user to

retrieve test records stored in the DMOM200 memory.

3.2 DMOM-200 Printer Control

To advance printer paper, press “Paper ∧

Contrast” switch once. Paper will advance

from printer. Press “Paper ∨ Contrast”

switch once, paper will advance backward

from printer.

4

Operating Procedures DMOM-200™

PRETEST SETUP

4.1 Operating Voltages

The DMOM-200 operating voltages are

selectable between 90-130Vac, 50/60Hz or

210-240, 50/60Hz. Voltage selection is set

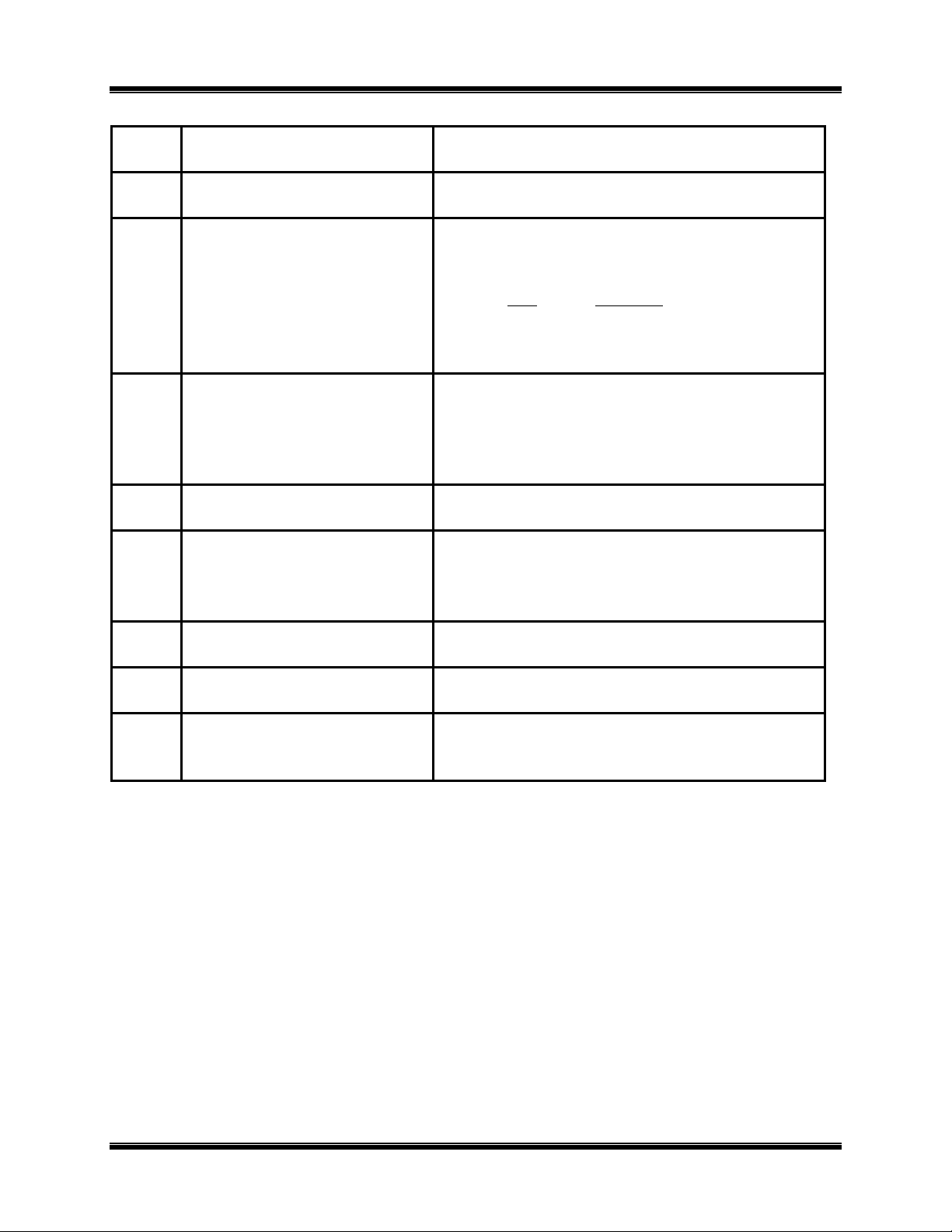

Table 3.0 Voltage Selection

VOLTAGE SELECTION TERMINAL BLOCK JUMPERS

90-130Vac Brown to blue & yellow to green

210-240Vac Blue to yellow

by the placement of jumpers on the power

terminal block as listed in Table 3.0 below

and Figures 2.0 and 3.0.

120Vac Jumper Installation

Figure 2.0 90 to 130Vac Jumper Setting

Figure 3.0 210 to 240Vac Jumper Setting

5

220Vac Jumper Installation

Operating Procedures DMOM-200™

4.2 DMOM-200 Printer Paper

The DMOM-200 printer uses 2.5-inch

wide thermal paper for printing test results.

We recommend that to maintain the highest

quality printing and to avoid paper jamming,

use paper supplied by our factory. Paper

can be ordered from two sources, as follows:

Vanguard Instruments Co, Inc.

1710 Grevillea Court

Ontario, CA 91761

Tel: 909-923-9390

Fax: 909-923-9391

Part Number: TP-3 Paper

OR

BG Instrument Co.

Route 1, Box 258

Mead, WA 99201

Tel: 509-893-9881

Fax: 509-893-9803

Part Number: TP-3 paper

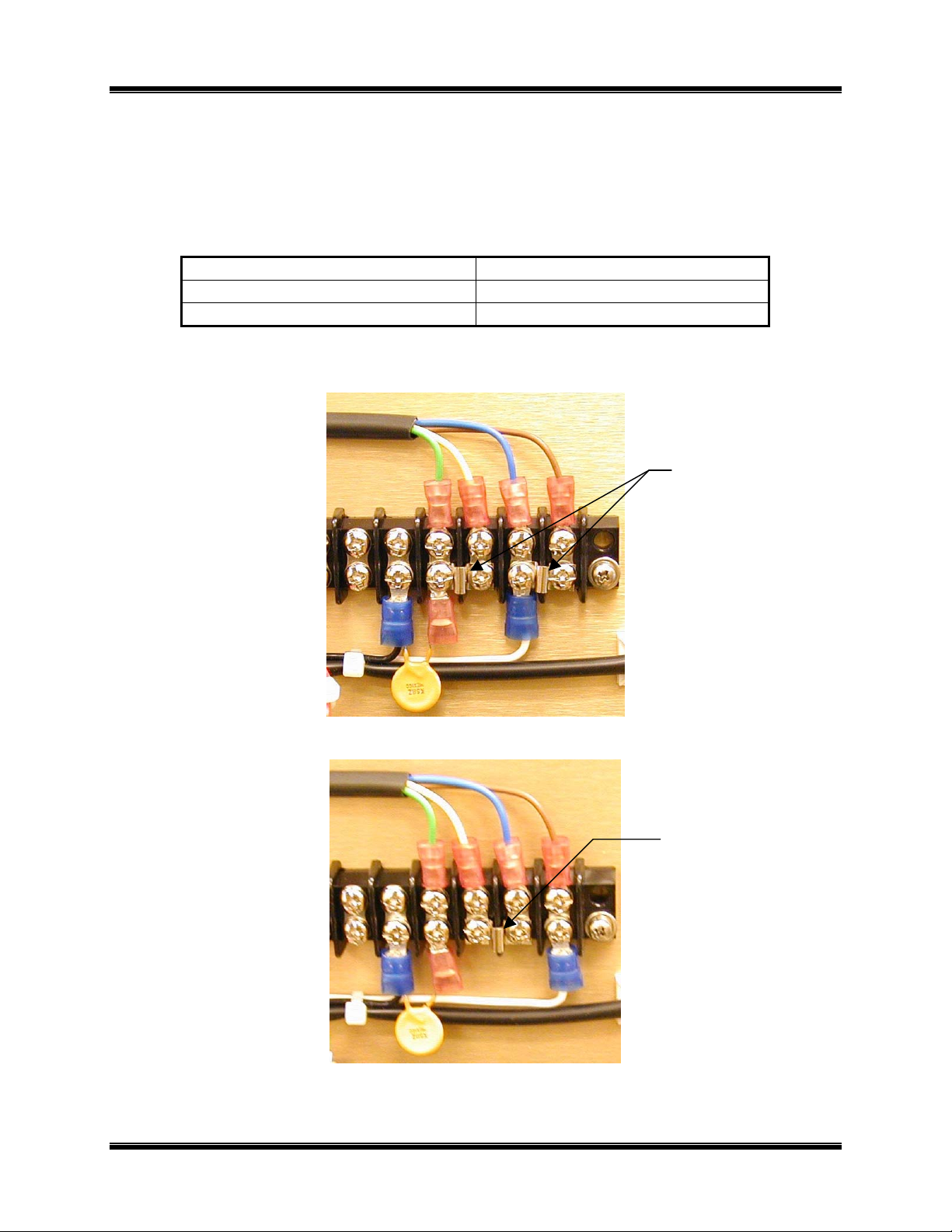

4.3 DMOM-200 Cable Connections

The DMOM-200 is supplied with a 35foot test cable set. Each cable consists of a

current-carrying cable and a voltage-sensing

cable. The current-carrying cable is

terminated with a 100-ampere male plug.

The sensing cable is terminated with a 25ampere female plug. Insert the current-cable

plugs and voltage-sensing plugs into their

respective control-panel jacks (see Figure

4.0 below). Ensure that voltage plugs

(smaller) are inserted into jacks adjacent to

their companion current jacks (larger).

Figure 4.0 DMOM-200 Cable Connection

6

Loading...

Loading...