Valtra T 140 Repair Manual

10

General

M120 M130

M150

T120 T130

T140, T160

T170 T180

T190

20

30

40

50

Engine

Electrical system

Power

transmission

Brakes

Service Manual

Tractors

Val tra Inc.

FIN---44200 Suolahti, FINLAND

Phone +358 2045501

Telefax +358 204550387

www.valtra.com

60

70

80

90

Front axle and

steering system

Frame and

wheels

Cab and

shields

Hydraulics

100

Tools

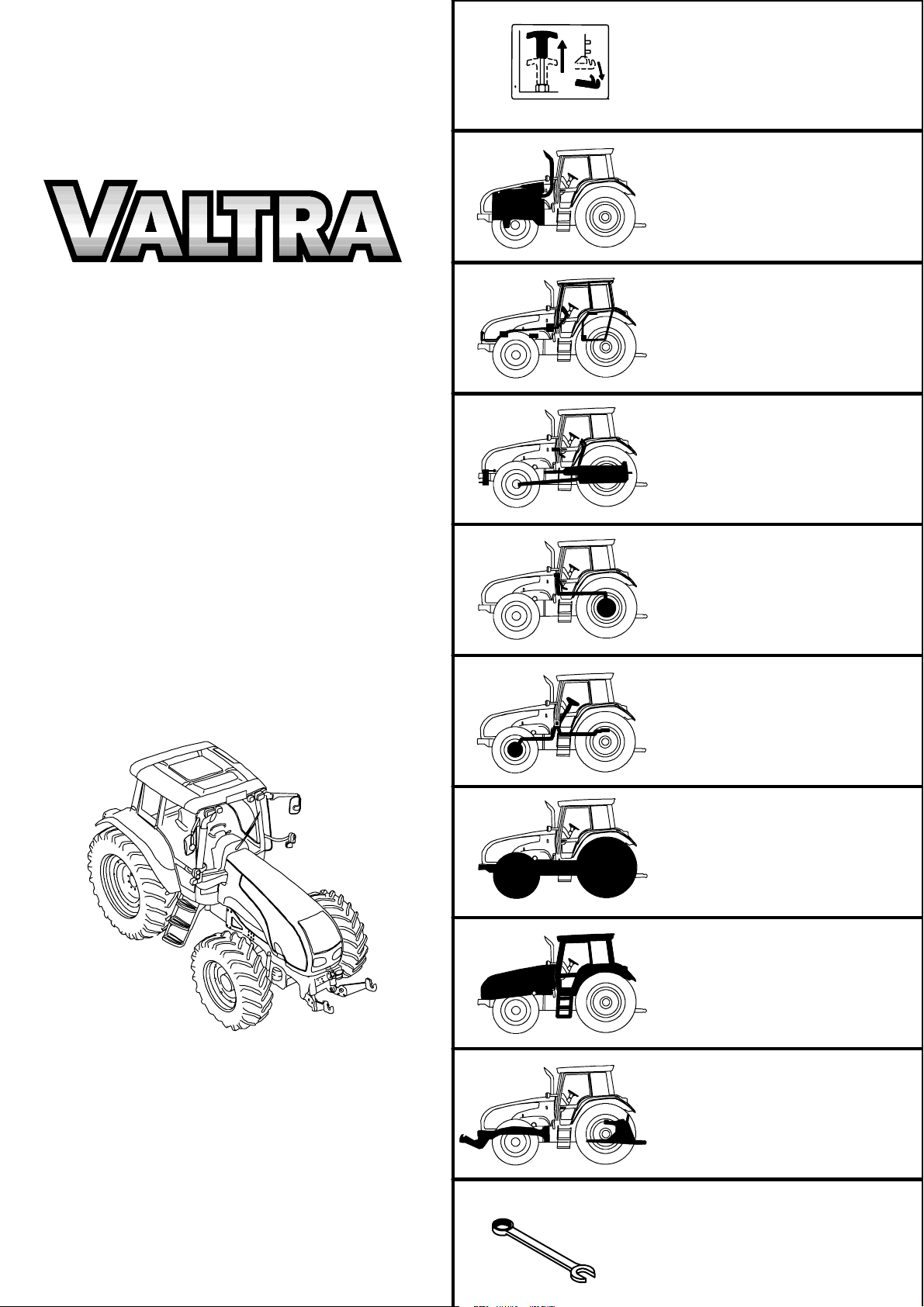

10. General

11. Layout

12. Construction

13. Maintanance

14. General technical

specifications

Model Code Page

11. Layout

2.1.2004

The following supplements have been published for the Valtra T and M---series Service Manual:

T120-- T190

M120-- M150

110 1

Order number

Date of publication Notes

7

Model Code Page

11. Layout

2.1.2004

T120-- T190

M120-- M150

110 3

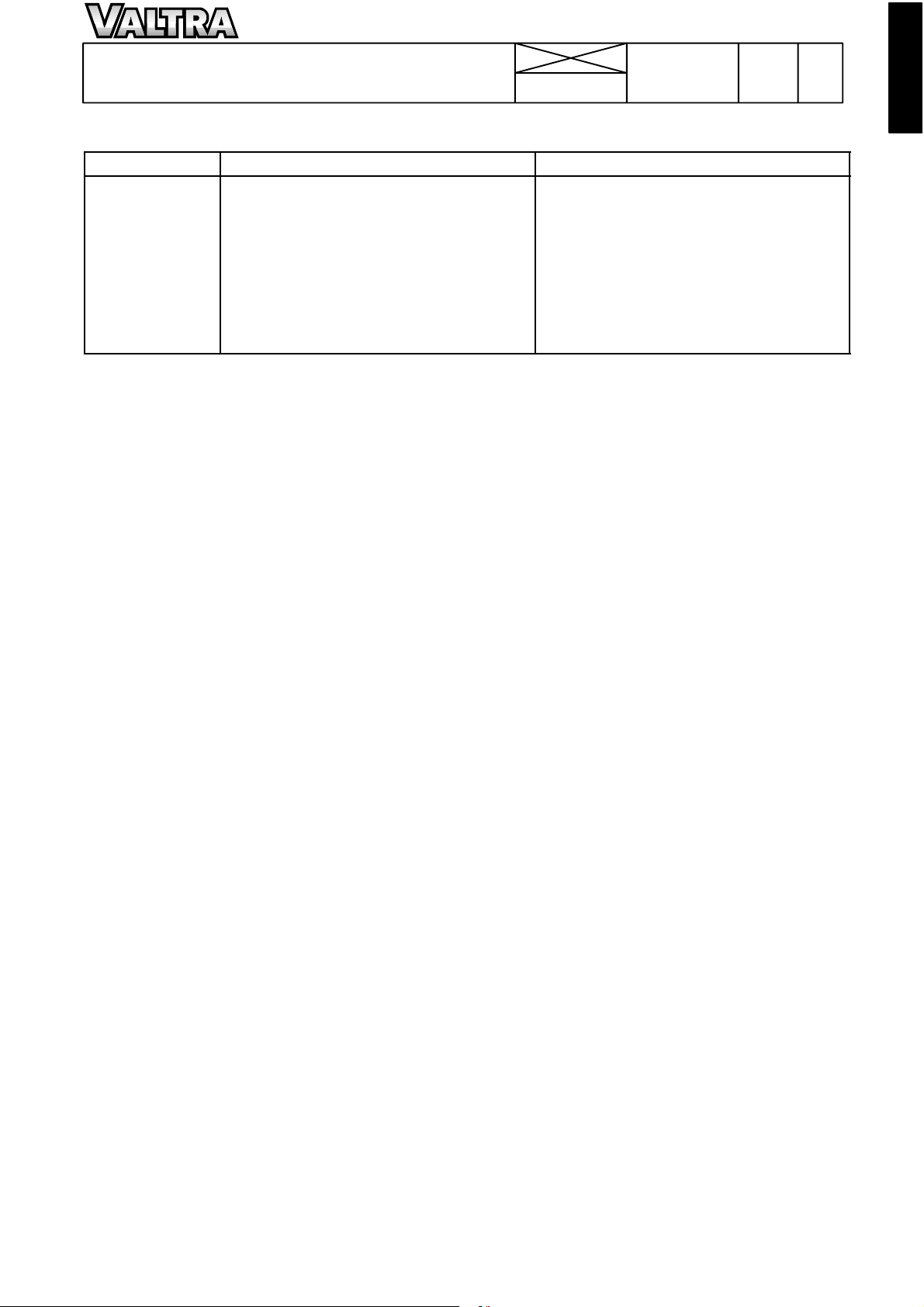

Layout of Service Manual

Division into groups

The manual is divided into groups (10 ---100) which are based on the make---up of the tractor. The groups are listed on the first

index leaf.

Example. 10. General

20. Engine, fuel and cooling systems

30. Electrical system

40. Power transmission

a.s.o.

The number designation for each group is given in the top left box of the respective pages (and the first figure inthe code designation).

Code

410 1

Page

50

60

70

80

90

100

Division into components or sub-- groups

Each group is further divided into components or sub ---groups. The number and the name of each component is given in the top

left box on each page (and comprise the two first figures in the code designation).

Example. 41. Clutch

42. Gearbox

44. Low gear

45. Final drives etc.

9

Model Code Page

11. Layout

2.1.2004

T120-- T190

M120-- M150

110 4

Tractor m odel

At the top of each page it is indicated for which tractor the page is valid.

Code designation

Three --- digit code designations are used to separate the different document groups for the respective components. The same

code is also used in the Time list as a reference to the text in this manual. The code designation numbers appear in the box at

thetopofthepageandalsointheheadings.

Example: Code 410

--- Group: power transmission (4)

--- Component: clutch (41)

--- Document group: general (410)

Page numbers

The instructions for all components are numbered in consecutive order in the right--- hand box at the top of the page. The page

numbers begin with page 1 for each component.

Page

41. Clutch

15. 5. 1993

Model Code

205---665 410 1

Date

At the top of each page there are two boxes for dates. In a case of revised issue, the date of the earlier issue is printed in the

crossed--- over box and and the date of the current issue is printed in the proper date box.

Additions and amendments of the service manual

New and up --- dated pages will be continuously added to the service manual. The new pages should be inserted as indicated by

the code: the first digit (also the first digit on the index leaf) indicates the group:

--- the two first digits indicate the component or sub---group.

--- the third digit indicates the document group for the respective components

---thepagenumberindicatesthedefiniteposition of the page within the service manual.

If there are two pages with the same code and page number, it is the page with the later date in the date box and the old date

in the crossed--- over box which is valid or which is the current page.

When an entirely new set of repair instructions is issued, it will be accompanied by instructions on where the pages should be

inserted in the file.

10

11. Layout

Code designations in the Service Manual

2.1.2004

Model Code Page

T120-- T190

M120-- M150

110 5

10. General

110 Layout

120 Repairs

130 Maintenance

20. Engine

21. Engine

210 General

211 Cylinder block

212 Flywheel housing

213 Cylinder head and valve mechanis m

214 Crankshaft engine

215 Counterbalance

216 Timing gear assembly

217 Lubrication system

218 Inlet and exhaust sys tem

219 Safety instructions

22. Fuel system

220 General

222 Fuel feed pump and fuel filters

223 Injection pump and injectors

23. Cooling system

230 General

231 Cooling system

24. Engine control system

240 General

241 Changing of co ntrol unit

40. Power transmission

41. Clutch

410. General

411. Repair instructions of the clutch

42. Gearbox

420. General

421. Repair instructions of the selector

forks

423. Repair instructions of the gearbox

424. Repair instructions of the differential

44. Quick-- -shift gear (DPS)

Reverse shuttle

4WD clutch

440. General

441. Repair instructions of the quick ---shift

gear. (DPS) and reverse shuttle

442. Repair instructions of the 4WD clutch

45. Final drives

450. General

451. Repair instructions of the final drives

46. Power take off

460. General

462. Repair instructions of the rear PTO

462. Repair instructions of the front PTO

50. Brake system

30. Electrical system

31. Autocontrol 5.3

310. Electrical system

311. Wiring diagram

32. Autocontrol 5.5

33. Autocontrol 6.1

330. Electrical system

331. Wiring diagram

34. Service codes

340. Autocontrol system

341. Power lift system

35. Power lift electrical system

350. General

351. Services and fault codes

36. Working hydraulics electrical system

360. General

37. Service software

370. General

51. Service brakes

510. General

511. Repair instructions of the

service brakes

52. Parking brake

521. Repair instructions of the

parking brake

11

11. Layout

60. Front axle and steering system

61. Steering system

610 Technical data, description, tools

611 Reconditioning steering system

612 Priority valve

613 Steering cylinder

62. Powered front axle

620 Technical data, description, tools

621 Axle housing and central pivot bearing

brackets

622 Drive shaft

623 Hub reduction gear

624 Differential

63. Powered front axle

630 Technical data, description, tools

64. Powered front axle

640 Technical data, description, tools

642 Drive shafts

643 Hubs

644 Differential

2.1.2004

Model Code Page

T120-- T190

M120-- M150

110 6

70 Frame and wheels

710 Frame

720 Wheels

80 Cab and shields

90. Hydraulics, power lift

91. Hydraulics

910. General

911. Repair instructions of the hydraulics

92. Valves for auxil iary hydraulics and front loader

920. General

921. Repair instructions of the auxiliary

hydraulics

93. Power lift

930 General

931. Repair instructions of the front and

rear power lift

100 Special tools

12

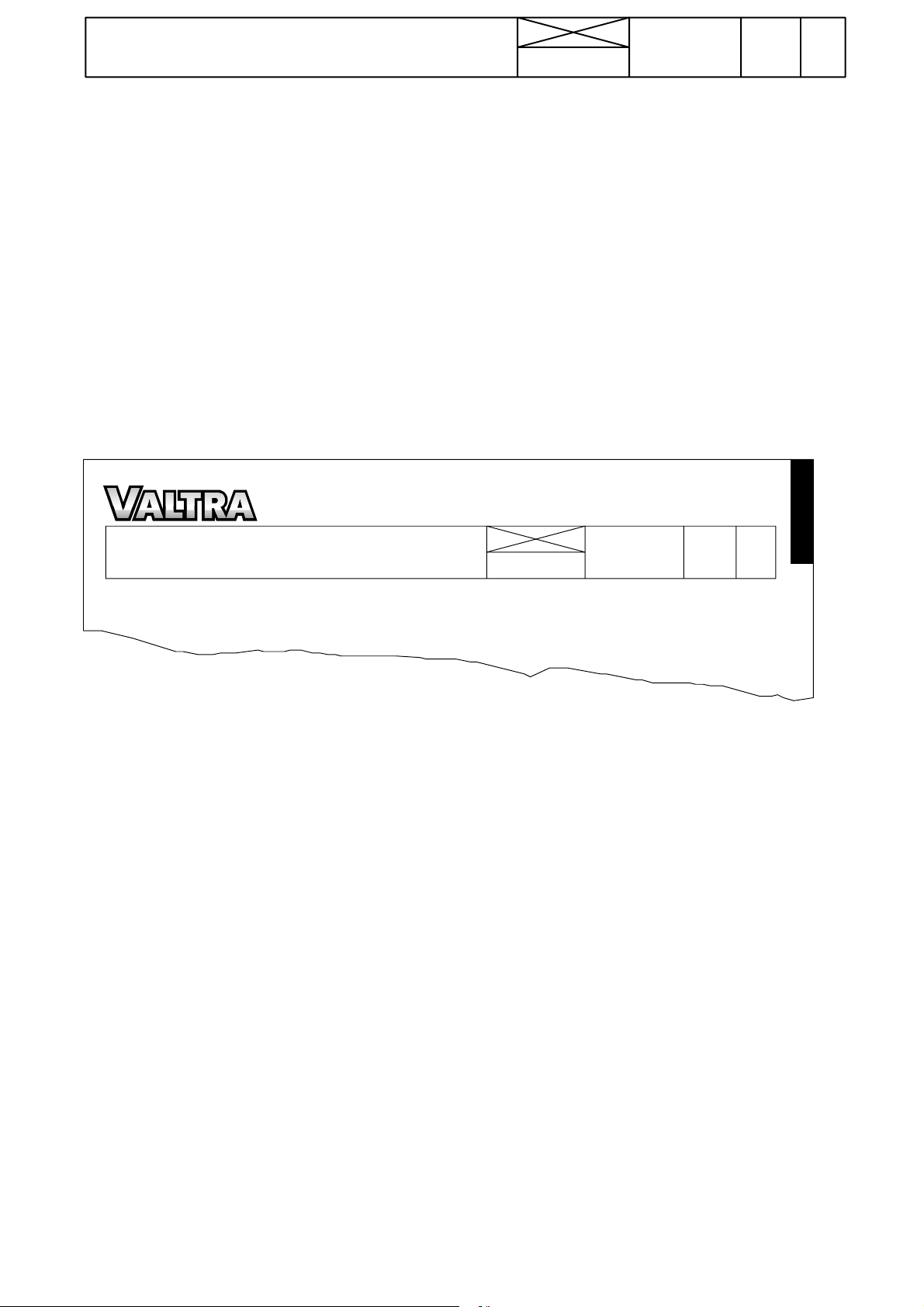

12. Construction

T120---T190 series, construction

2.1.2004

Model Code Page

T120-- T190

M120-- M150

120 1

13

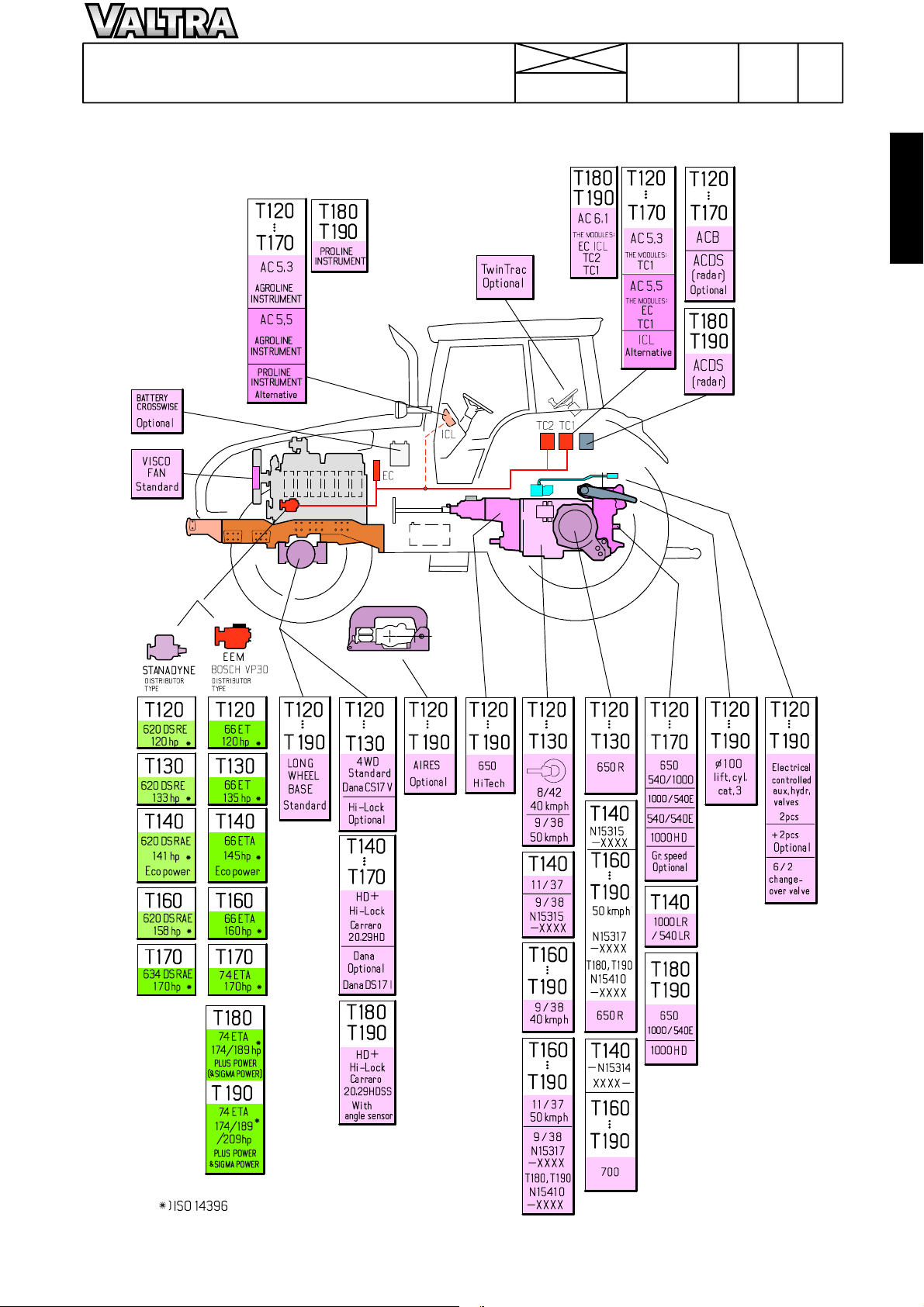

12. Construction

M120---M150 series, construction

2.1.2004

Model Code Page

T120-- T190

M120-- M150

120 2

14

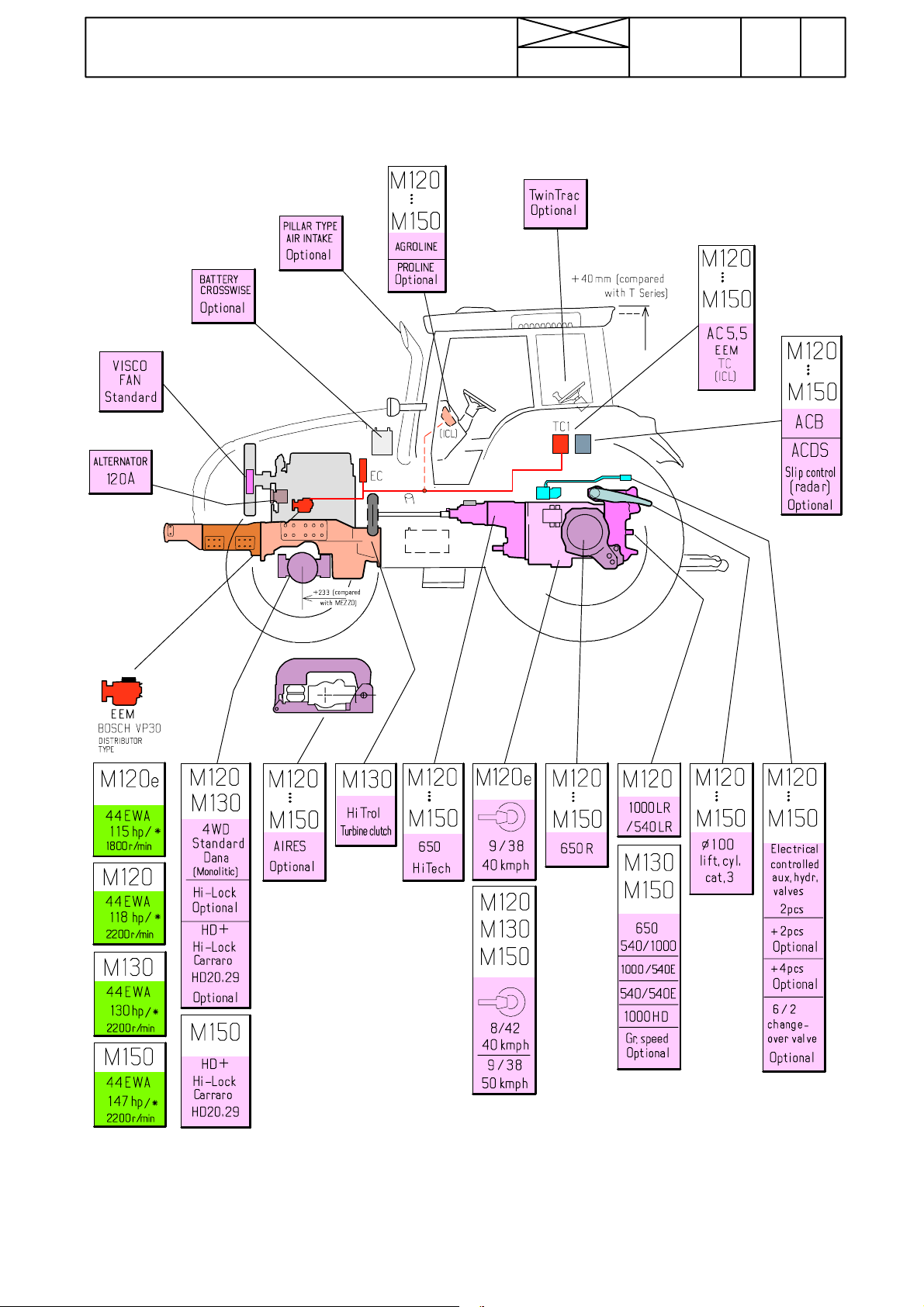

12. Construction

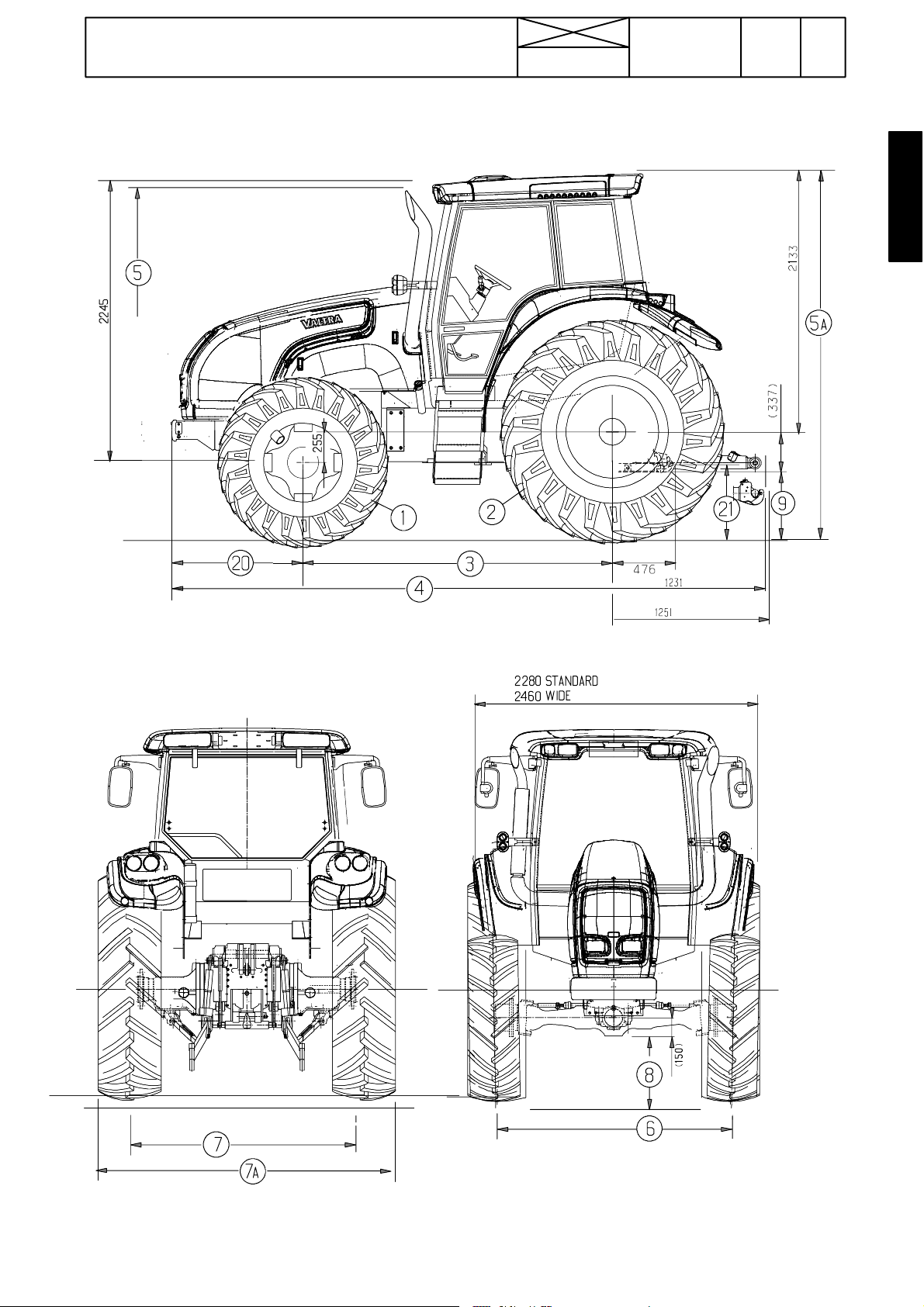

T120---T190 series, dimensions

2.1.2004

Model Code Page

T120-- T190

M120-- M150

121 1

15

Model Code Page

12. Construction

2.1.2004

T120-- T190

M120-- M150

121 2

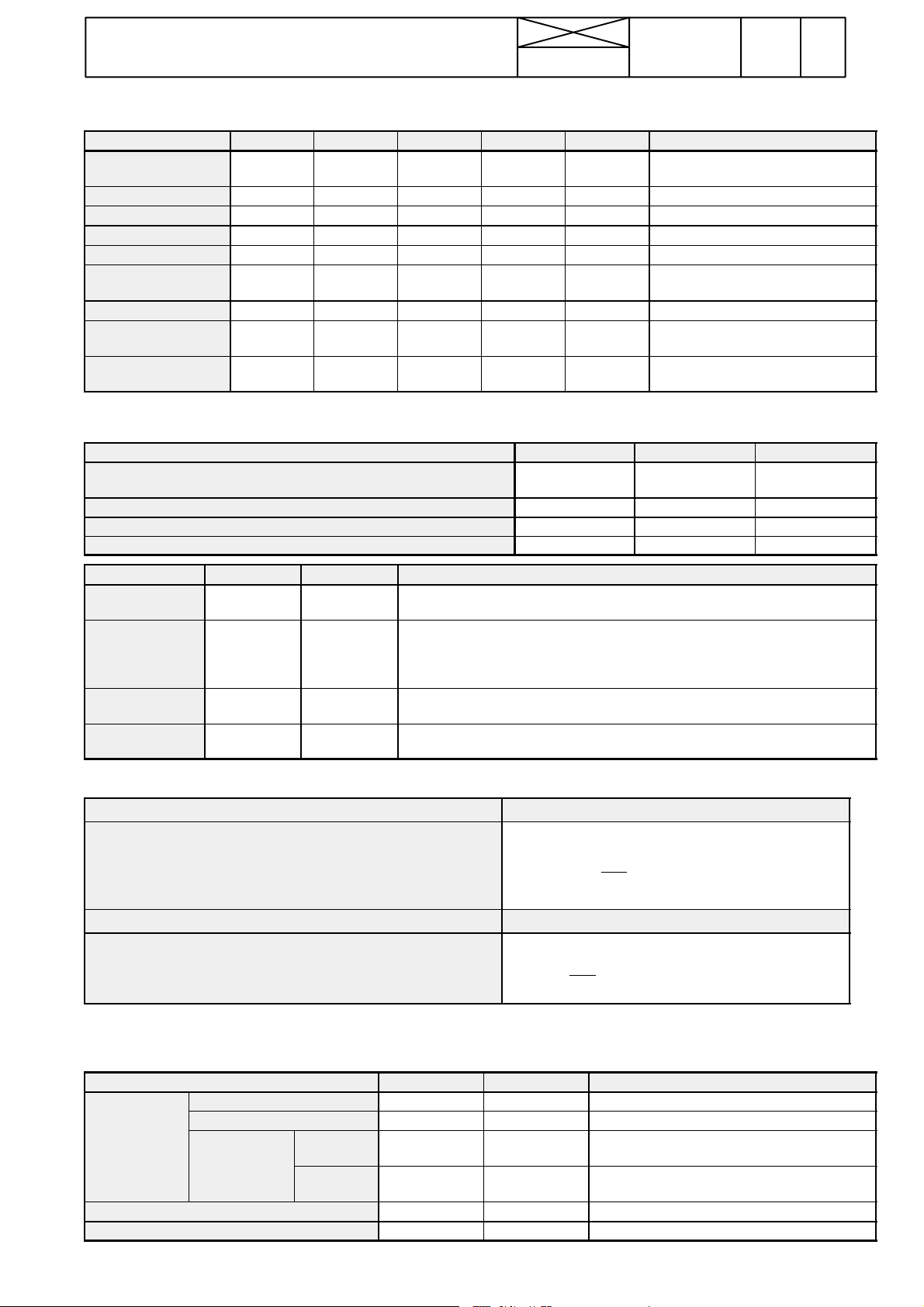

Dimensions (mm) T 120 T 130 T 140 T 160 T 170 T 180, T190

1. With front

16.9R28 16.9R28 16.9R28 460/85R30 460/85R30 460/85R30

tyres/tires

2. With rear tyres/tires 20.8R38 20.8R38 20.8R38 20.8R42 20.8R42 20.8R42

4. Length 5148 5148 5148 5148 5148 5148

7a. Width 2338 2338 2338 2338 2338 2338

5a. Height to the roof 2960 2960 2960 3030 3030 3030

5. Height to the

2900 2900 2900 2965 2965 2910

exhaust pipe

3. Wheel base 2748 2748 2748 2748 2748 2748

8. Ground clearance

555/515

1)

555/515

1)

555/515

1)

600/560

1)

600/560

1)

600/560

1)

(front axle)

9. Ground clearance

535 535 535 600 600 600

(rear axle)

1)

With front axle suspension.

Dimension from the rear axle mid point to the cab roof part is 2093 mm.

Weights kg T 120 T 130 T 140

With tyres/tires 16.9R28,

20.8R38

16.9R28,

20.8R38

16.9R28,

20.8R38

Total weight (with full fuel tank and without ballast weights) 5530 5530 5650

Frontaxleweight(%) 2480 (45) 2480 (45) 2600 (46)

Rear axle weight (%) 3050 (55) 3050 (55) 3050 (54)

Weights kg T 160 T 170 T 180, T190

With tyres/tires 540/65R30,

650/65R42

540/65R30,

650/65R42

650/65R42, 540/65R30

Total weight (with

full fuel tank and

without ballast

5950 5950 5990

weights)

Front axle weight

(%)

Rear axle weight

(%)

2700 (45) 2700 (45) 2740 (46)

3250 (55) 3250 (55) 3250 (54)

Track widths:

Front

14.9--28/6, 14.9R28, 380/70R28, 380/85R28, 420/70R28, 420/85R28,

440/65R28, 16.9R28, 16.9--28/8, 480/65R28, 480/65R28E1, 480/70R28,

540/65R28, 540/65R28E1

+ more: see operator’s manual

Rear

8.4R38, 18.4--38/8, 18.4R42, 460/85R38, 480/70R38, 20.8R38,, 20.8--38/10,

520/70R38, 520/85R38, 520/85R42 540/65R38, 580/70R38, 480/80R42

+ more: see operator’s manual

6. Track width

1540, 1635, 1740, 1835, 1940, 2035

7. Track w id th

1610, 1715, 1810, 1910, 2010, 2115

Maximum permissible front--- and rear axle loadings, kg

Regardless of any limitations due to the tyres/tires, with standard track widths max. speed.

Tra ctor T120, T130 T140--- T170 T180,T190

Front 4WD

max 40 km/h 3300

max 8 km/h 5500

industrial front

axle

max 40

km/h

max 8

4500 4500 4500

6200 6200 6200

km/h

Rear, max 40 km/h 8000 9000 9000

Total weight, max 40 km/h 9000 11000 11000

16

12. Construction

www.agrimanuals.bigcartel.com

M120---M150 series, dimensions

2.1.2004

Model Code Page

T120-- T190

M120-- M150

121 3

17

Model Code Page

14.9R28,14.9R28IND,14.928FOR,16.9R28,16.9R28IND,16.928FOR

,

187

0,189

0

F

W

D

12. Construction

2.1.2004

T120-- T190

M120-- M150

121 4

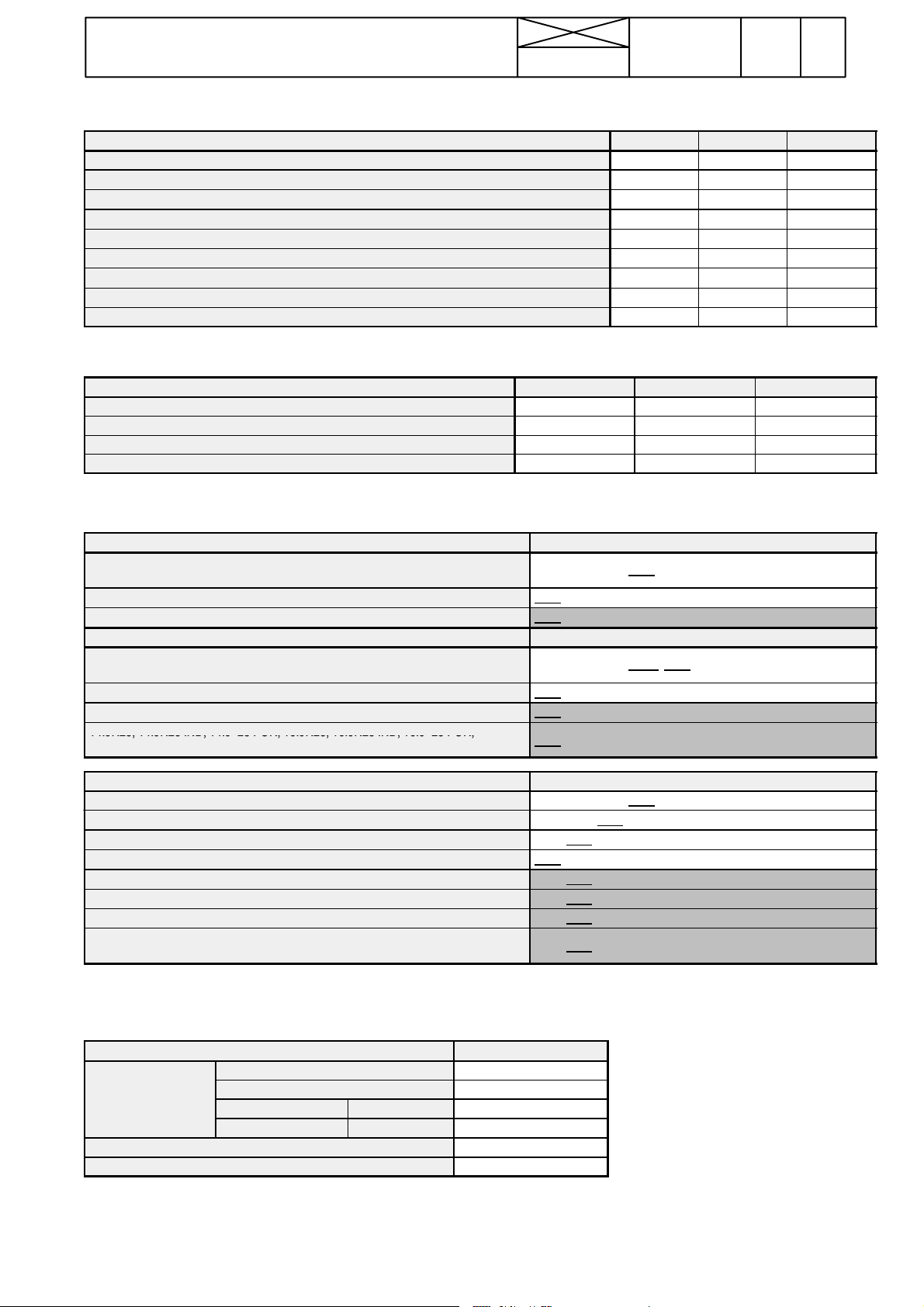

Dimensions (mm) M120 M130 M150

1. With front tyres/tires 16.9R28 16.9R28 16.9R28

2. With rear tyres/tires 20.8R38 20.8R38 20.8R38

4. Length 4898 4898 4898

7a. Width 2338 2338 2338

5a. Height to the roof 3000 3000 3000

5. Height to the exhaust pipe 2930 2930 2930

3. Wheel base 2559 2559 2559

8. Ground clearance (front axle) 530/490

1)

530/490

1)

530/490

9. Ground clearance (rear axle) 535 535 535

1)

With front axle suspension

Dimension from the rear axle mid point to the cab roof part is 2133 mm.

Weights kg M120 M130 M150

With tyres/tires 20.8R38 20.8R38 20.8R38

Total weight (with full fuel tank and without ballast weights) 5290

Frontaxleweight(%) 2320 (44)

2)

2)

5290

2320 (44

2)

2)

5450

2480 (46)

Rear axle weight (%) 2970 (56) 2970 (56) 2970 (54)

2)

With industrial front axle 160 kg heavier, standard on model M150.

1)

Track widths:

Front 6. Track width

13.6R28, 14.9R28, 14.9--28, 16.9R28, 16.9 --28, 340/85R28, 380/85R28, 420/70R28,

420/85R28, 440/65R28, 480/65R28, 480/70R28, 540/65R28

230/95R36 1504, 1580, 1602, 1702, 1880, 1980, 2002, 2102

14.9R28, 14.9R28 IND, 16.9R28, 14.9--28/14 FOR, 420/85R28, 480/65R28 IND 1840, 1745

Industrial front axle 6. Track width

14.9R28*, 14.9--28*, 16.9R28, 16.9--28, 380/85R28*, 420/70R28*, 420/85R28,

480/65R28, 480/70R28, 540/65R28

230/95R36 1500, 1545, 1810, 1855, 1900, 1940, 2210, 2255

500/60--26,5 FOR 1890, 1880

14.9R28, 14.9R28 IND, 14.9--28 FOR, 16.9R28, 16.9R28 IND, 16.9--28 FOR,

420/85R28, 480/65R28 IND, 500/65R28 FO R, 540/65R28, 540/65R28 FOR

Rear 7. Track width

16.9R38, 18.4R38, 18.4--38/8, 420/85R38, 460/85R38 1510, 1610, 1715, 1810, 1910, 2010, 2115

20.8R38, 20.8--38/10, 520/70R38, 520/85R38, 540/65R38, 580/70R38 1610, 1715, 1810, 1910, 2010, 2115

600/65R38, 650/65R38 1715, 1810, 1910, 2010, 2115

270/95R48 1500, 1520, 1600, 1620, 1900, 1920, 2000, 2020

680/75R32 1714, 1810

18.4--38/14 FOR, 18.4R38, 18.4R38 IND 1650, 1875

600/65--34 FOR 1630, 1900

20.8R38, 20.8R38 IND, 20.8--38/14 FOR, 520/85R38, 600/65R38 FOR, 600/65R38

IND, 650/65R38, 650/65R38 FOR

1530, 1645, 1735, 1840, 1930, 2045, 2135

1530, 1625, 1730, 1830*, 1930, 2025, 2130, 2230

1675, 1850

Maximum permissible front--- and rear axle loadings, kg

Regardless of any limitations due to the tyres/tires, with standard track widths max. speed.

Tra ctor M120---M150

max 40 km/h 3300

ront 4

max 8 km/h 5500

industrial front axle max 40 km/h 4500

Industrial front axle max 8 km/h 6200

Rear, max 40 km/h 8000

Total weight, max 40 km/h 9000

18

Model Code Page

13. Maintanance

2.1.2004

T120-- T190

M120-- M150

130 1

General instructions for repairs

Outer oil seals

The Service Manual contains instructions for changing all outer oil seals, (e.g. oil seals on the PTO shaft end, on the output shaft

to the front wheel drive and on the pinion shaft on the powered front axle, and so on).

Sealing compound and glue

If sealing compounds or glue are required for the repair work, the instructions will specify a sealing compound or glue which is

readily available through special ist dealers. Some seals should be greased before fitting and the space between the lips of the

seal should be filled with universal grease. If the seal is to be pushed over splines or sharp edges the seal should be protected

with for example a thin plastic foil.

Tightening torques and setting values

All necessary tightening torques and setting values for each repair operation are given at the beginning of each repair section

under the heading Technical Data. The most important values can also be found in the repair instructions.

Table 1 later gives the tightening torques in order of dimension, quality and surface treatment. The values given in the table should

be used if the tightening torque is not given in the repair instructions.

Safety

Always bear safety in mind when repairing or servicing the tractor. Use tools and lifting devices in the correct way . When you are

removing tractor components or splitting the tractor, every tractor part must be supported in such a way, that no risk of accident

exists. Avoid working under the supported tractor part if it is not absolutely necessary. When supporting the tract or the centre of

gravity of the frame part must always be checked. For instance the wedges must always be fitted between front axle and engine

to prevent axle oscillation when splitting the front frame of the tractor.

Trouble---shooting

The following procedure, combined with the information contained in the workshop manual will be helpful in tracing faults accurately. It consists of following a number of logical steps to locate and correct the problem.

a) Determine the problem

b) List possible causes

c) Differentiate the causes

d) Conduct checks in logical order to determine the exact cause

e) Consider approximate remaining service life against cost of parts and labour.

f) Make any necessary repairs.

g) Recheck the parts and functions for correct operation

19

Loading...

Loading...