Page 1

Operator's Manual

A3 Series

HiTech

Page 2

Page 3

About this manual

This operator's manual is for Valtra A3 Series tractors. The A3 models are A83 h

and A93 h.

The manual is meant for agricultural tractors only. If the tractor is used for other

applications, it is the owner's responsibility to ensure compliance with local

regulations. In this case, always contact your dealer first.

The purpose of this manual is to enable the owner and operator to use the tractor

in a proper manner. Providing that the instructions are followed carefully, the

tractor will provide years of service in the tradition of Valtra.

WARNING: Before using the tractor, read and understand all the

instructions in this manual.They must then be strictly followed when

operating and maintaining the tractor.

IMPORTANT: When using the tractor, always follow all valid laws and regulations

even if they are not specifically pointed out in this manual.

The manual contains detailed instructions for operating, servicing and

maintaining the tractor.

Alternative equipment in the manual refers to equipment that can be selected

when ordering the tractor.

Extra equipment refers to equipment which can be bought and installed on the

tractor later.

Due to the continual development of the products, the content of this manual may

not always correspond to the new product. Therefore, we retain the right to make

alterations without prior notification.

Maintenance, repairs and adjustments which are not described in this manual

require special tools and exact technical data. For such work contact your dealer

who has specially trained personnel to help you.

Valtra Inc.

- 1 -

Page 4

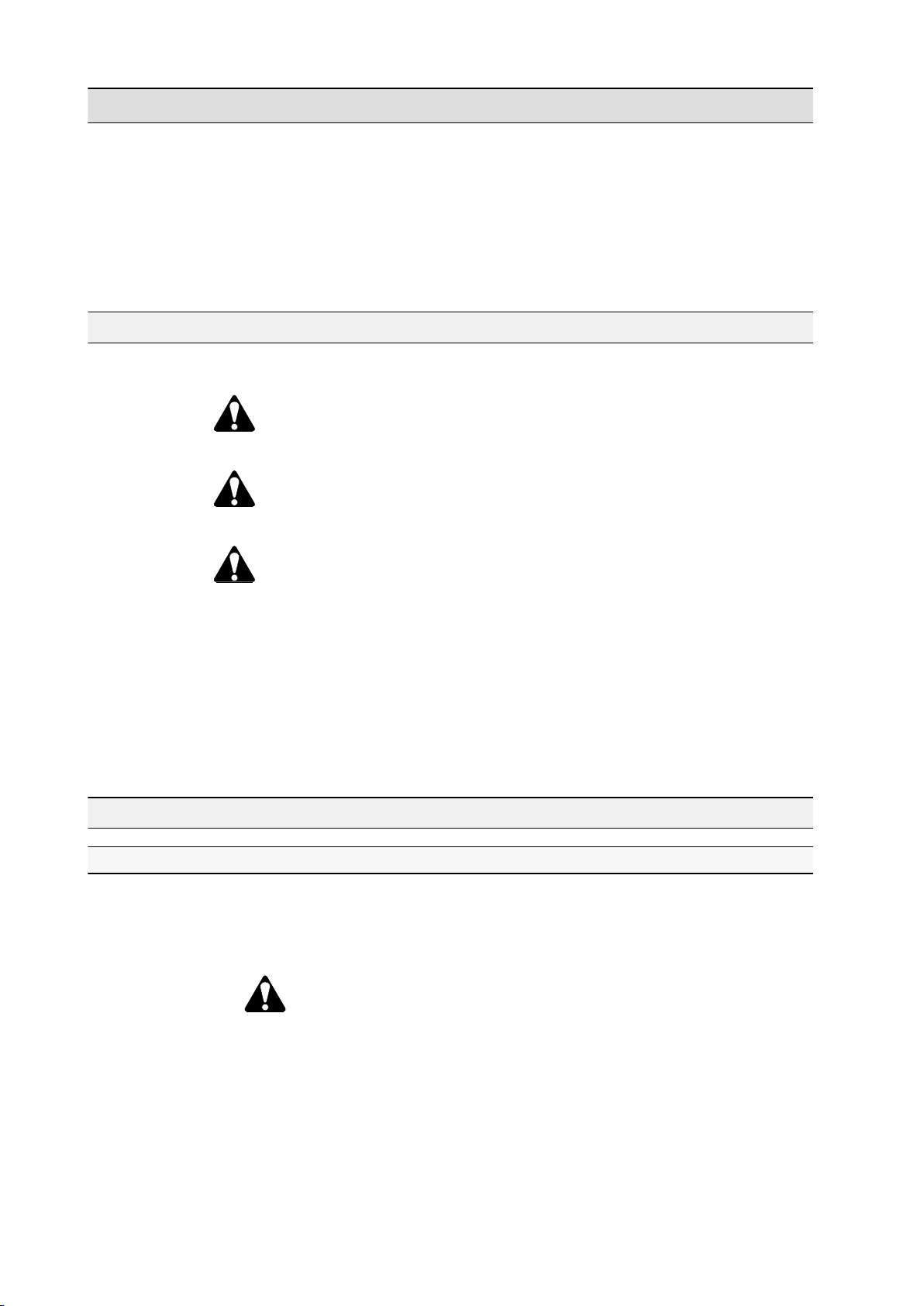

Tractor serial numbers

2

1

6

63

7

A83 h AC17.2

W15308

4

5

When ordering spare parts or service, give the model indication and serial

numbers and, in some cases, the engine, front axle, cab and transmission numbers.

GUID-F00AFDCA-F0D2-4B46-8B11-514781803E50

1. Type plate EEC

• Model = model indication used by service/spare part department

• Identification number = tractor serial number

2. Cab number

3. Transmission Identification number

4. Engine number

5. Tractor serial number

6. Front axle number

7. Power take-off identification number

- 2 -

Page 5

Contents

Contents

About this manual........................................................................................1

Tractor serial numbers.................................................................................2

1 Safety precautions................................................................................10

1.1 Hazard statements.............................................................................................10

1.2 Safety rules........................................................................................................10

1.2.1 Replacing safety and information signs............................................................10

1.2.2 Maintaining hardware safety............................................................................11

1.2.3 Using tractor safety features............................................................................12

1.2.4 Safe operation..................................................................................................13

1.2.4.1 Following safe operating practices.............................................13

1.2.4.2 Getting into and out of the cab....................................................14

1.2.4.3 Driving on public roads...............................................................15

1.2.4.4 Controlling the driving speed......................................................15

1.2.4.5 Driving downhill...........................................................................15

1.2.4.6 Operating with implements.........................................................16

1.2.4.7 Running with power take-off driven implements or

machines....................................................................................17

1.2.4.8 Using ballast weights..................................................................17

1.2.4.9 Towing........................................................................................18

1.2.4.10 Ensuring personal safety of other people...................................18

1.2.4.11 Fire hazards................................................................................19

1.2.4.12 Handling viton seals subjected to high temperatures.................19

2 Instruments and controls......................................................................20

2.1 Pedals................................................................................................................20

2.2 Dashboard.........................................................................................................21

2.2.1 Infoline instrument panel..................................................................................22

2.2.2 Proline instrument panel ..................................................................................22

2.2.2.1 Symbols on the Proline instrument panel display.......................23

2.2.3 Indicator lights on the left side of the display....................................................24

2.2.4 Indicator lights on the right side of the display.................................................25

2.3 Controls on the right-hand side..........................................................................27

2.3.1 Driving controls.................................................................................................27

2.3.2 Linkage.............................................................................................................28

2.3.3 Power take-off..................................................................................................29

2.3.4 Auxiliary hydraulics...........................................................................................30

2.3.5 Other controls...................................................................................................31

2.4 Controls on the rear side....................................................................................32

2.4.1 Rear window opening device...........................................................................32

2.5 Controls on the left-hand side............................................................................32

2.6 Controls on the front roof console......................................................................33

2.7 Air conditioning controls.....................................................................................33

2.7.1 Manual air conditioning controls ......................................................................33

2.8 Driver's seat.......................................................................................................34

2.9 Air suspended driver's seat ...............................................................................35

2.10 Controls on the rear mudguard..........................................................................36

2.11 Rear controls and connections outside the cab.................................................37

3 Operation..............................................................................................38

3.1 Running the tractor in.........................................................................................38

3.2 Preparing for use...............................................................................................38

3.2.1 Adjusting the driver's seat................................................................................38

3.2.2 Adjusting the air-suspended driver's seat........................................................40

3.2.3 Adjusting the armrest.......................................................................................43

3.2.4 Adjusting the steering wheel............................................................................44

- 3 -

Page 6

Contents

3.2.5 Adjusting mirrors..............................................................................................45

3.2.6 Using the windscreen wiper and washer..........................................................45

3.2.7 Using the rear window wiper............................................................................46

3.2.8 Using the rear window washer.........................................................................46

3.2.9 Power shuttle lever...........................................................................................47

3.2.10 Using the main switch......................................................................................47

3.2.11 Control stop......................................................................................................48

3.2.12 Using the control stop.......................................................................................49

3.2.13 Using the ignition switch...................................................................................49

3.2.14 Using the roof hatch.........................................................................................51

3.3 Starting the tractor.............................................................................................51

3.3.1 Starting under normal conditions......................................................................51

3.3.2 Starting under cold conditions..........................................................................53

3.3.3 Starting with an auxiliary battery......................................................................53

3.4 Using lights........................................................................................................54

3.4.1 Using headlights...............................................................................................54

3.4.2 Using upper headlights.....................................................................................55

3.4.3 Using working lights.........................................................................................55

3.4.4 Using the cab light............................................................................................56

3.5 Using notification devices..................................................................................56

3.5.1 Using the direction indicators...........................................................................56

3.5.2 Using the horn..................................................................................................57

3.5.3 Using the rotating warning light........................................................................57

3.5.4 Using hazard warning flashers ........................................................................58

3.6 Heating and ventilation......................................................................................58

3.6.1 Using the heater...............................................................................................58

3.6.2 Using the extra heater......................................................................................59

3.6.3 Controlling ventilation nozzles..........................................................................60

3.6.4 Using the manual air conditioning....................................................................60

3.7 Power outlets.....................................................................................................62

3.7.1 Lighter..............................................................................................................62

3.7.2 Two-pin power socket......................................................................................62

3.7.3 Three-pin power socket....................................................................................63

3.7.4 Trailer socket....................................................................................................64

3.7.5 Two-pin power socket on the bonnet...............................................................64

3.8 Driving the tractor...............................................................................................65

3.8.1 Steering............................................................................................................65

3.8.2 Power shuttle....................................................................................................65

3.8.3 Using the power shuttle lever...........................................................................66

3.8.4 Using the parking brake...................................................................................66

3.8.5 Using the clutch pedal......................................................................................68

3.8.6 Braking.............................................................................................................69

3.8.7 Starting to drive................................................................................................69

3.8.8 Transmission system........................................................................................70

3.8.8.1 Selecting the range gear.............................................................71

3.8.8.2 Selecting the speed gear............................................................72

3.8.9 Parking the tractor............................................................................................72

3.8.10 Cruise control...................................................................................................73

3.8.10.1 Cruise control switches...............................................................73

3.8.10.2 Programming the driving speed cruise control...........................74

3.8.10.3 Activating and deactivating the driving speed cruise

control ........................................................................................74

3.8.10.4 Programming the engine speed cruise control...........................76

3.8.10.5 Activating and deactivating the engine speed cruise

control.........................................................................................77

3.8.10.6 Decreasing the cruise control setting..........................................77

3.8.10.7 Increasing the cruise control setting...........................................78

3.8.11 Automatic traction control.................................................................................79

3.8.12 Using the automatic traction control.................................................................80

3.8.13 Differential lock.................................................................................................81

- 4 -

Page 7

Contents

3.8.14 Engaging and disengaging the differential lock................................................81

3.8.15 Four-wheel drive...............................................................................................82

3.8.16 Engaging and disengaging the four-wheel drive..............................................82

3.8.17 Engaging and disengaging the four-wheel drive automatic function................83

3.8.18 Driving start automatics....................................................................................83

3.8.19 Activating and deactivating the driving start automatics...................................84

3.8.20 Permitted driving inclinations for driving the tractor on a slope........................84

3.9 Proline instrument panel display........................................................................85

3.9.1 Fixed views.......................................................................................................85

3.9.2 Selecting a view...............................................................................................86

3.9.3 Top and middle row views................................................................................86

3.9.3.1 Working time view.......................................................................87

3.9.3.2 Cruise control view.....................................................................88

3.9.3.3 Driving speed view......................................................................88

3.9.3.4 Rear power take-off speed view.................................................88

3.9.3.5 Front power take-off speed view.................................................89

3.9.3.6 Engine speed view......................................................................89

3.9.3.7 Fuel consumption views.............................................................89

3.9.3.8 Rear lower links' position view....................................................91

3.9.3.9 Front lower links' position view...................................................91

3.9.3.10 Gearbox temperature view.........................................................92

3.9.3.11 Travel distance view...................................................................92

3.9.3.12 Surface area view.......................................................................93

3.9.4 Periodical maintenance view............................................................................93

3.9.4.1 Clearing the periodical maintenance view..................................93

3.9.5 Resetting views................................................................................................94

3.9.6 Enlarging the middle row..................................................................................95

3.9.7 Changing parameters.......................................................................................96

3.9.7.1 Activating and exiting the setting mode......................................96

3.9.7.2 Changing the parameter value...................................................97

3.9.7.3 Setting the display backlight level...............................................97

3.9.7.4 Setting the implement width........................................................98

3.9.7.5 Changing the hour display..........................................................98

3.9.7.6 Changing the minute display......................................................98

3.9.7.7 Changing the clock mode...........................................................99

3.9.7.8 Activating the direction indicator buzzer.....................................99

3.9.7.9 Changing the temperature unit...................................................99

3.9.7.10 Changing the length unit...........................................................100

3.9.7.11 Changing the volume unit.........................................................100

3.9.7.12 Activating and deactivating the front power take-off speed

view...........................................................................................101

3.9.7.13 Activating and deactivating the front lower links' position

view...........................................................................................101

3.9.7.14 Adjusting the display contrast...................................................101

3.10 Rear linkage.....................................................................................................102

3.10.1 Diagnose light.................................................................................................102

3.10.2 Lift/lower indicator lights ................................................................................103

3.10.3 Activating the linkage.....................................................................................103

3.10.4 Using the lift/stop/lower switch.......................................................................104

3.10.5 Using the position control knob......................................................................105

3.10.6 Using the linkage floating position..................................................................105

3.10.7 Using the lift/lower switch and lift/lower push buttons....................................107

3.10.8 Setting the lowering speed.............................................................................107

3.10.9 Limiting the lifting height.................................................................................108

3.10.10 Draft control....................................................................................................109

3.10.11 Activating and deactivating the draft control...................................................110

3.10.12 Passing the position set by the position control knob....................................110

3.10.13 Passing the height set by the lifting height selector.......................................111

3.10.14 Using the drive balance control .....................................................................112

3.11 Three-point linkage..........................................................................................114

- 5 -

Page 8

Contents

3.11.1 Attaching implements.....................................................................................115

3.11.2 Using telescopic lower links...........................................................................117

3.11.3 Using quick couplings for lower links .............................................................117

3.11.3.1 Setting the release cable for lower link quick couplings ..........118

3.11.4 Adjusting lifting links ......................................................................................120

3.11.5 Adjusting lower links.......................................................................................120

3.11.6 Adjusting the check links' length....................................................................121

3.12 Auxiliary hydraulics..........................................................................................122

3.12.1 Controlling the auxiliary hydraulics rear valves 1 and 2.................................123

3.12.2 Controlling the auxiliary hydraulics rear valves 3 and 4.................................124

3.12.3 Setting valves for single-action or double-action............................................125

3.12.4 Using quick-action couplings .........................................................................126

3.12.5 Connecting an external hydraulic motor to the auxiliary hydraulics...............126

3.13 Using the front linkage.....................................................................................127

3.13.1 Setting front linkage lifting link positions.........................................................128

3.14 Using the Valtra front loader............................................................................129

3.14.1 Softdrive.........................................................................................................131

3.14.2 Locking the equipment...................................................................................131

3.14.3 Using the continuous floating position............................................................132

3.14.4 Using the floating position with joystick buttons.............................................133

3.14.5 Controlling the extra cylinder with the change valve......................................134

3.15 Power take-off..................................................................................................135

3.15.1 Attaching implements to the power take-off...................................................135

3.15.2 Rear power take-off........................................................................................137

3.15.2.1 Activating rear power take-off...................................................138

3.15.2.2 Starting rear power take-off......................................................139

3.15.2.3 Stopping rear power take-off temporarily..................................140

3.15.2.4 Deactivating rear power take-off...............................................141

3.15.2.5 Stopping the rear power take-off in emergency........................142

3.15.2.6 Using the rear power take-off automatic stop...........................143

3.15.3 Front power take-off.......................................................................................144

3.15.3.1 Using the front power take-off...................................................144

3.16 Towing devices................................................................................................145

3.16.1 Pick-up hitch...................................................................................................145

3.16.1.1 Unlatching the pick-up hitch .....................................................145

3.16.1.2 Latching the pick-up hitch.........................................................146

3.16.2 Agricultural drawbar devices..........................................................................147

3.16.3 Towing device frames ...................................................................................148

3.16.3.1 Adjusting the jaw height............................................................149

3.16.3.2 Attaching to the mechanical jaw...............................................151

3.16.3.3 Attaching to the automatic jaw..................................................151

3.17 Air pressure system.........................................................................................153

3.18 Trailer...............................................................................................................155

3.18.1 Trailer air pressure brakes.............................................................................155

3.18.2 Trailer fluid brake valve..................................................................................156

4 Maintenance.......................................................................................158

4.1 Maintenance schedule.....................................................................................158

4.2 Service inspection............................................................................................158

4.3 Performing maintenance tasks........................................................................159

4.3.1 Cleaning the tractor........................................................................................160

4.3.1.1 Cleaning the engine compartment............................................161

4.3.2 Greasing lubricating points fitted with grease nipples....................................161

4.3.3 Supporting the tractor.....................................................................................161

4.4 Recommended fuel and lubricants..................................................................163

4.4.1 Fuel................................................................................................................163

4.4.1.1 Quality requirements for engine fuel.........................................163

4.4.1.2 Storing fuel................................................................................163

4.4.1.3 Biodiesel fuel............................................................................164

4.4.2 Grease............................................................................................................164

- 6 -

Page 9

Contents

4.4.2.1 Universal Grease - NLGI2 universal grease.............................164

4.4.2.2 Calsium LF - NLGI2 calsium grease LF....................................164

4.4.2.3 Grease Moly - NLGI2 moly grease...........................................165

4.5 Storing the tractor............................................................................................165

4.5.1 Storing the tractor for a period shorter than two months................................165

4.5.2 Storing the tractor for a period longer than two months.................................165

4.6 Running the tractor in after storage.................................................................166

4.6.1 Running the tractor in after a storing period shorter than two months...........166

4.6.2 Running the tractor in after a storing period longer than two months............166

4.7 Periodical maintenance....................................................................................167

4.7.1 Periodical maintenance chart.........................................................................167

4.7.2 Daily maintenance..........................................................................................169

4.7.2.1 Checking the engine oil level....................................................169

4.7.2.2 Checking the oil level in the transmission system....................170

4.7.2.3 Checking the coolant level........................................................171

4.7.2.4 Cleaning radiators.....................................................................172

4.7.2.5 Draining the water from the air pressure system......................173

4.7.3 Weekly maintenance......................................................................................173

4.7.3.1 Greasing the three-point linkage...............................................173

4.7.3.2 Checking the pick-up hitch........................................................174

4.7.3.3 Greasing the pick-up hitch........................................................174

4.7.3.4 Maintaining the front linkage.....................................................175

4.7.3.5 Checking the front power take-off.............................................176

4.7.3.6 Greasing front axle mounting bearings.....................................176

4.7.3.7 Checking belts' tension.............................................................177

4.7.3.8 Adjusting the air conditioning compressor belt.........................177

4.7.3.9 Adjusting the air compressor belt.............................................178

4.7.3.10 Changing the belts....................................................................178

4.7.3.11 Checking the fuel system prefilter and sediment bowl..............181

4.7.3.12 Checking the tyre pressure.......................................................183

4.7.3.13 Checking wheel nuts' tightness................................................183

4.7.3.14 Windscreen washer fluid reservoir............................................183

4.7.4 Maintenance every 500 hours........................................................................183

4.7.4.1 Greasing door hinges...............................................................183

4.7.4.2 Changing the engine oil and the oil filter...................................184

4.7.4.3 Checking the breather pipe.......................................................185

4.7.4.4 Checking the brake fluid level...................................................186

4.7.4.5 Cleaning the cab ventilation air filter.........................................186

4.7.4.6 Cleaning the extra heater's air filter..........................................187

4.7.4.7 Checking the brake pedal free travel........................................188

4.7.4.8 Adjusting brake pedals' travel...................................................188

4.7.4.9 Checking the parking brake......................................................190

4.7.4.10 Adjusting the parking brake......................................................190

4.7.4.11 Changing transmission oil filters...............................................193

4.7.4.12 Changing hydraulic system oil filters........................................194

4.7.4.13 Checking the oil level in the front axle differential.....................195

4.7.4.14 Checking the oil level in front axle hubs...................................195

4.7.4.15 Changing front PTO housing oil and washing oil filter..............196

4.7.4.16 Checking front PTO rubber couplings.......................................197

4.7.4.17 Checking and greasing the trailer air-pressure brake

system......................................................................................197

4.7.4.18 Adjusting engine valves............................................................198

4.7.5 Maintenance every 1000 hours or yearly.......................................................198

4.7.5.1 Changing oil in the transmission system..................................198

4.7.5.2 Cleaning the suction strainer....................................................199

4.7.5.3 Changing the transmission breather.........................................200

4.7.5.4 Changing oil in the front axle differential...................................201

4.7.5.5 Changing oil in the front axle hubs...........................................201

4.7.5.6 Changing the cab ventilation air filter........................................202

4.7.5.7 Changing the extra heater's air filter.........................................202

- 7 -

Page 10

Contents

4.7.5.8 Changing engine air filters........................................................204

4.7.5.9 Cleaning the cyclone block.......................................................206

4.7.5.10 Greasing the flywheel ring gear................................................207

4.7.5.11 Checking the front wheel toe-in................................................207

4.7.5.12 Adjusting toe-in of front wheels.................................................208

4.7.5.13 Checking the power shuttle operation......................................209

4.7.5.14 Tightening frame nuts and bolts...............................................209

4.7.6 Maintenance every 2000 hours or every other year.......................................209

4.7.6.1 Changing the brake fluid...........................................................209

4.7.6.2 Bleeding the brake system ......................................................210

4.7.6.3 Cleaning the cooling system.....................................................212

4.7.6.4 Maintaining the air conditioning................................................215

4.8 Checks and adjustments..................................................................................216

4.8.1 Changing tyres...............................................................................................216

4.8.2 Track widths...................................................................................................216

4.8.2.1 Front axle track widths..............................................................217

4.8.2.2 Rear axle track widths..............................................................217

4.8.3 Using chains...................................................................................................218

4.8.4 Using twin-mounted wheels...........................................................................218

4.8.5 Engine............................................................................................................218

4.8.5.1 Bleeding the fuel system...........................................................218

4.8.6 Electrical system............................................................................................219

4.8.6.1 Safety precautions for the electrical system.............................219

4.8.6.2 Checking the battery.................................................................220

4.8.6.3 Alternator..................................................................................220

4.8.6.4 Protecting the electrical system before welding........................220

4.8.6.5 Fuses and relays......................................................................221

4.8.6.6 Fuses and relays in the electric centre.....................................222

4.8.6.7 Engine induction air preheater fuse..........................................224

4.8.6.8 Cab power supply fuse.............................................................224

4.8.6.9 Engine control unit fuse............................................................225

4.8.6.10 Adjusting headlights..................................................................225

4.8.7 Steering system..............................................................................................226

4.8.7.1 Adjusting the steering angle.....................................................226

4.8.8 Cab and shields..............................................................................................227

4.8.8.1 Limiting the door opening.........................................................227

4.8.8.2 Checking and adjusting front mudguards.................................227

4.8.9 Hydraulic system............................................................................................228

4.8.9.1 Adjusting lifting links of the pick-up hitch..................................228

4.8.9.2 Maintaining the automatic jaw of the wagon towing device......229

5 Faults and remedial actions...............................................................230

5.1 Handling error situations..................................................................................230

5.2 Errors indicated by the indicator lights.............................................................230

5.2.1 Cleaning the main engine air filter..................................................................231

5.2.2 Identifying a blocked transmission or hydraulic system filter..........................232

5.3 Warning symbols on the Proline instrument panel display..............................234

5.3.1 Low fuel pressure warning.............................................................................234

5.3.2 Fuel level sensor open circuit warning...........................................................234

5.3.3 Fuel level sensor short circuit warning...........................................................235

5.4 Steering system malfunctions..........................................................................235

5.5 Towing the tractor............................................................................................236

5.5.1 Towing the tractor when the engine is running..............................................236

5.5.2 Towing the tractor when the engine is not running........................................236

6 Technical specifications.....................................................................237

6.1 Dimensions......................................................................................................237

6.2 Weights............................................................................................................237

6.3 Maximum permissible axle loading..................................................................237

6.4 Tyres................................................................................................................237

- 8 -

Page 11

Contents

6.4.1 Wheel nuts tightening torque..........................................................................238

6.4.2 Wheel stud dimensions..................................................................................238

6.4.3 Front axle tyre loadings and pressures..........................................................238

6.4.4 Rear axle tyre loadings and pressures...........................................................238

6.5 Spacing for wheel discs...................................................................................239

6.6 Track widths.....................................................................................................239

6.6.1 Rear track widths............................................................................................239

6.6.2 Front track widths...........................................................................................239

6.7 Engine..............................................................................................................240

6.7.1 Engine lubrication system..............................................................................240

6.7.2 Fuel system....................................................................................................240

6.7.3 Air cleaner......................................................................................................240

6.7.4 Cooling system...............................................................................................241

6.8 Electrical system..............................................................................................241

6.9 Power transmission..........................................................................................241

6.9.1 Power shuttle..................................................................................................241

6.9.2 Clutch.............................................................................................................242

6.9.3 Gearbox..........................................................................................................242

6.9.4 Rear axle differential lock...............................................................................242

6.9.5 Rear power take-off........................................................................................242

6.9.5.1 Rear power take-off alternatives...............................................242

6.9.5.2 Rear power take-off ratios........................................................242

6.9.5.3 Rear power take-off shafts........................................................243

6.9.5.4 Lower link end distance from rear power take-off shaft............243

6.9.5.5 Maximum power take-off output...............................................243

6.9.6 Front power take-off.......................................................................................243

6.9.6.1 Front power take-off ratios........................................................243

6.9.6.2 Front power take-off shafts.......................................................243

6.10 Brake system...................................................................................................244

6.11 Steering system...............................................................................................244

6.11.1 Front axle.......................................................................................................244

6.11.2 Turning circle radius.......................................................................................245

6.12 Cab and shields...............................................................................................245

6.12.1 Cab filter capacity...........................................................................................245

6.12.2 Windscreen washer........................................................................................245

6.12.3 Air conditioning system..................................................................................245

6.12.4 Noise level......................................................................................................246

6.12.5 Exposure to vibration......................................................................................246

6.13 Hydraulic system..............................................................................................246

6.13.1 Low pressure circuit.......................................................................................246

6.13.2 High pressure circuit.......................................................................................246

6.13.3 Auxiliary hydraulics.........................................................................................246

6.13.3.1 Valves for auxiliary hydraulics..................................................246

6.13.3.2 Counter pressure when using the return connection for

auxiliary hydraulics...................................................................247

6.13.4 Rear linkage...................................................................................................247

6.13.4.1 Maximum lifting force on the whole lifting area ........................247

6.13.4.2 Lifting range at the end of the lower links.................................247

6.13.5 Front linkage...................................................................................................247

6.13.6 Trailer hitches and towing devices.................................................................248

6.13.6.1 Pick-up hitch.............................................................................248

6.13.6.2 Agricultural towing device.........................................................248

6.13.6.3 Towing device frames...............................................................249

6.13.6.4 Drawbar eye.............................................................................249

Alphabetical index...................................................................................250

- 9 -

Page 12

1. Safety precautions

1 Safety precautions

Always follow the safety precautions given when working with the tractor.

The regulations given do not release the operator from statutory and other

national regulations as regards traffic safety and occupational health and safety.

In addition to the precautions given in this manual, always follow the safety

regulations applicable to different types of working sites and existing road traffic

laws.

1.1 Hazard statements

Five symbols are used in the documentation.

DANGER: Indicates an imminently hazardous situation that, if not

avoided, results in death or very serious injury.

WARNING: Indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation that, if not

avoided, may result in minor injury.

IMPORTANT: Indicates special instructions or procedures which, if not strictly

observed, could result in damage to, or destruction of the machine, process or its

surroundings.

NOTE: Indicates points of particular interest for more efficient and convenient

repair or operation.

1.2 Safety rules

1.2.1 Replacing safety and information signs

Replacement signs are available from your dealer in the event of loss or damage.

• Replace any danger, warning, caution or instruction signs that are not

readable or are missing.

WARNING: Do not remove or obscure danger, warning, caution or

instruction signs.

- 10 -

Page 13

1.2.2 Maintaining hardware safety

To ensure maximum safety for the operator, maintain tractor hardware safety.

The owner is responsible for repairing any damage or wear which might

endanger the safety of the tractor.

• Cab

Damages on the cab must be repaired without delay to ensure the cab's

protective capability.

WARNING: If damage occurs to the cab, replace all parts affected

with new ones. Do not attempt any repair work (welding, drilling,

cutting, or grinding) without first consulting the manufacturer.

• Tractor construction

Do not change the tractor construction, such as maximum driving speed or

maximum power.

The tractor is type approved to comply with construction and use regulations.

Any changes to the tractor construction may reduce safety and durability and

affect the warranty terms.

1. Safety precautions

• Brakes

• Always check that the brakes are working before driving.

• Lock the brake pedals together whenever individual wheel brakes are not

required and always when driving on the road.

• Extensive repairs to the braking system should be undertaken only by an

authorised Valtra workshop.

• When implements or ballast weights are front-end mounted, the rear axle

loading is decreased:

• Check that the rear brakes are still effective.

• Use appropriate ballast weights at rear as required.

• Cleaning

Keep the tractor clean to minimise risk of fire.

• Lights

• Make sure that lights and reflectors are clean and in working order.

• Make sure that the headlights are correctly adjusted.

• Steps

Keep the steps clean. Dirty steps can lead to falls and personal injury.

• Quick couplings

DANGER: Clean the quick couplings and ball joints before

attaching an implement. There is risk that the implement is not

attached properly.

- 11 -

Page 14

1

2

1. Safety precautions

• Maintenance

• Follow the maintenance instructions and safety precautions applicable to

the tractor.

• Stop the engine and lower the implement before carrying out any

maintenance work on the tractor or implement.

• Support the tractor from the correct support points on the frame and use

suitable blocks or stands when carrying out maintenance tasks that

require supporting the tractor.

1.2.3 Using tractor safety features

The tractor has several features that contribute to the operator's safety.

• Steering wheel and safety handles

WARNING: Hold on to the steering wheel or safety handles in the

cab if the tractor tips over. Never try to jump out.

• Safety belt

Always use the safety belt when using the tractor.

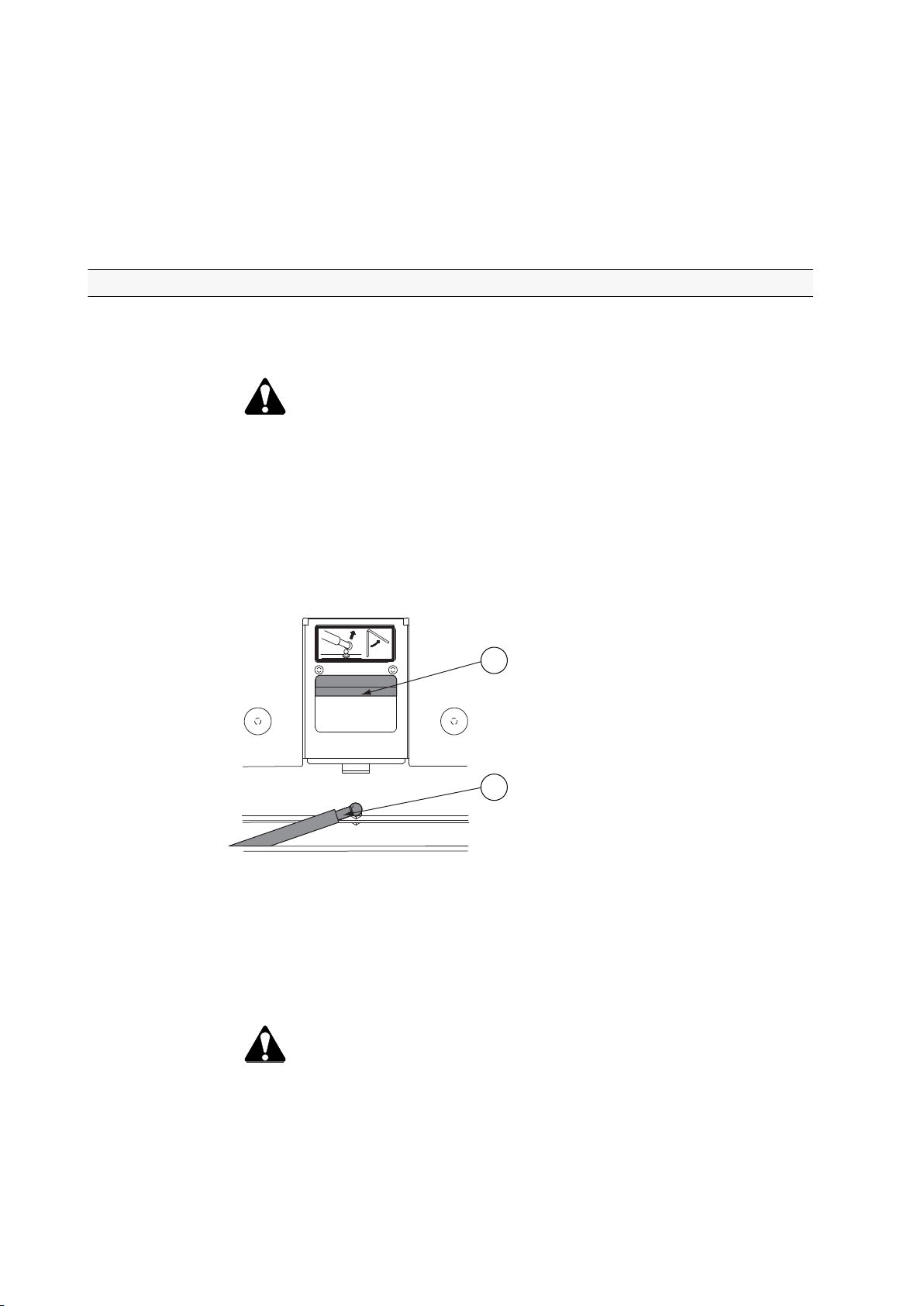

• Emergency exits

Familiarise yourself with the four emergency exits of the tractor cab, that is,

the doors, the rear window and the roof hatch (extra equipment).

• Roof hatch (extra equipment)

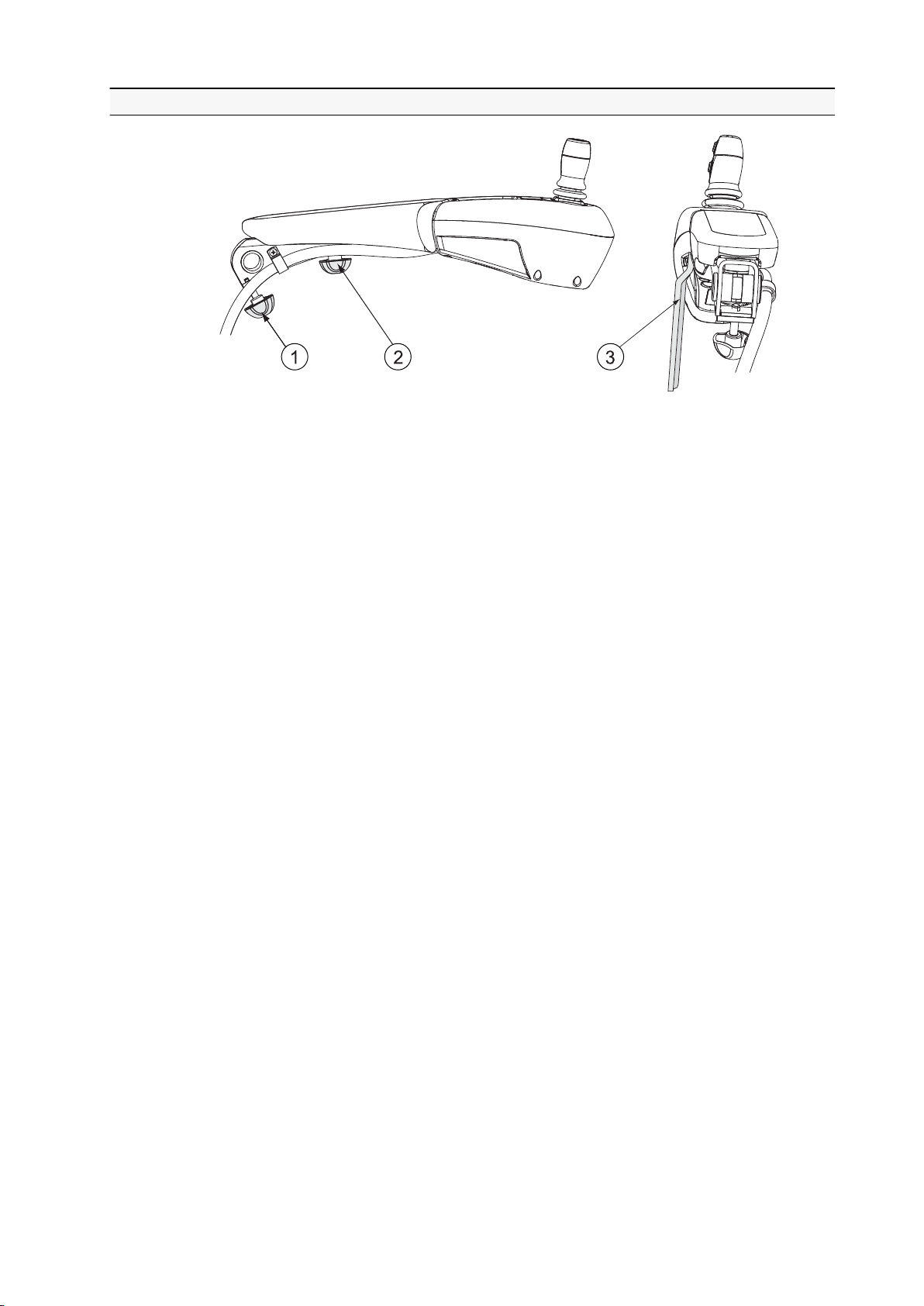

GUID-E522C473-E223-48DF-BC14-03DCD1490CD2

1. Handle

2. Gas spring

• Open the hatch by pushing the handle forward and pushing the hatch

upward.

• To open the hatch fully (for emergency exit), detach the upper end of the

gas spring from its fastener and push the hatch fully open.

WARNING: When driving on ice, keep the roof hatch open.

- 12 -

Page 15

1.2.4 Safe operation

1.2.4.1 Following safe operating practices

To operate the tractor safely, follow all the safety precautions and instructions.

• Avoid operating the tractor near ditches, embankments and holes.

• Stay off slopes too steep for safe operation.

• When using chemicals, carefully follow the chemical manufacturer’s

instructions for use, storage and disposal.

Also follow the chemical application equipment manufacturer’s instructions.

• Protect yourself against motor noise.

Use hearing protectors to avoid noise injuries when you are working outside

the cab near the engine.

• Avoid carbon monoxide poisoning.

WARNING: To avoid carbon monoxide poisoning, do not start the

engine or run it indoors with the doors closed unless the exhaust is

vented to the outside.

1. Safety precautions

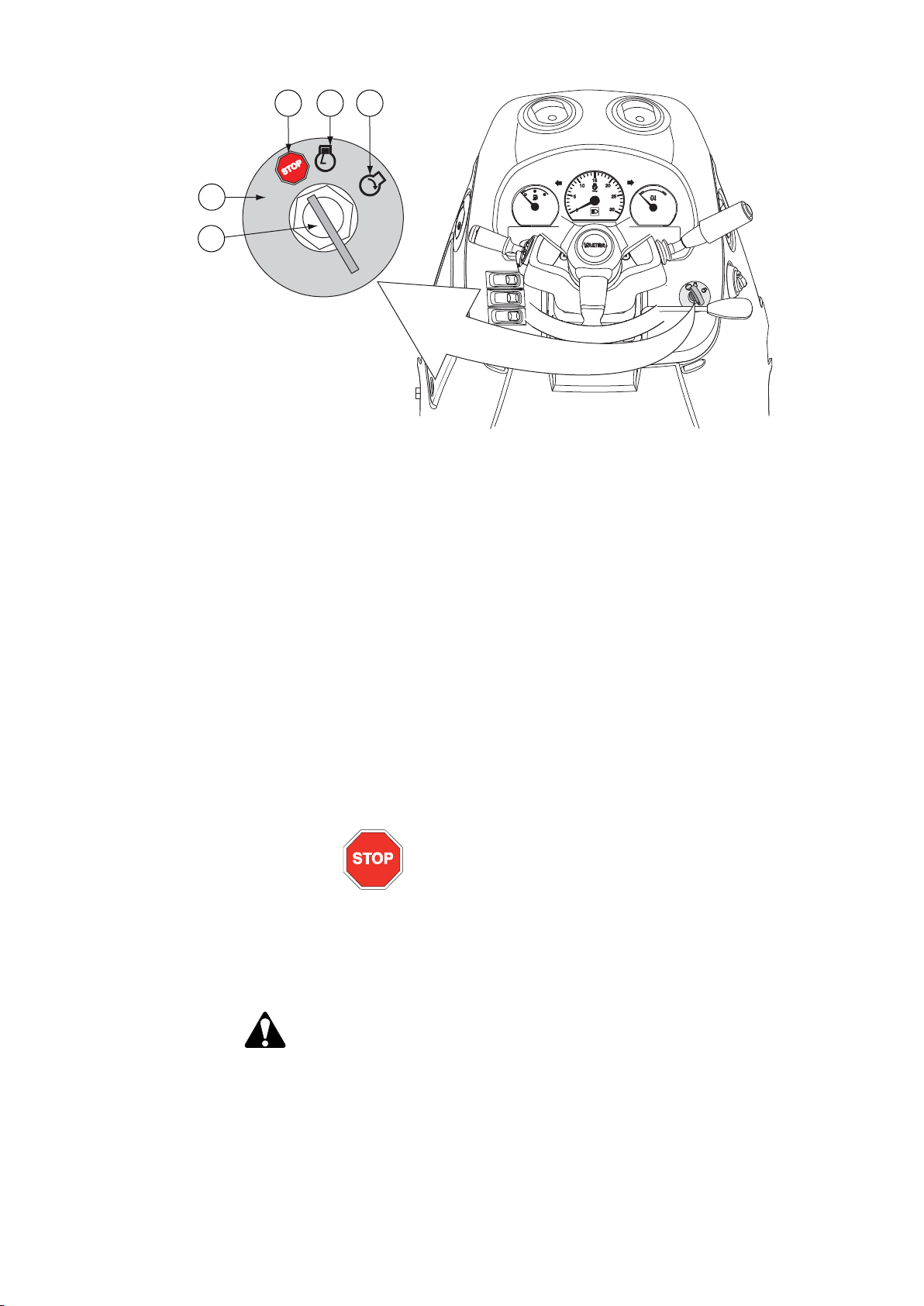

• Restarting after engine stop

• If the engine has stalled, for example due to too heavy loading, turn the

ignition key to the STOP position.

• Restart the engine.

Keep an eye on the indicator lights on the instrument panel.

• Front loader

• Ensure that no one is in the working area when you are working with a

front loader.

• Lower the front loader to the down position before leaving the tractor.

• Observe any special instructions issued by the loader manufacturer.

WARNING: The risk of overturn increases as the loader is raised.

Be extra careful on slopes when operating the loader. Always

carry the loader as low as practical for the conditions.

WARNING: Always look at the implement. Objects can fall or roll

backwards onto the driver when the loader is raised. Only lift loads

which can be contained in, and are intended for, the specific

implement.

• Differential lock

Use the differential lock only when running on loose or slippery ground.

- 13 -

Page 16

1. Safety precautions

• Overturning

• Always consider the way in which the tractor is to be used and the fact

• Adapt the tractor speed according to visibility, weather conditions and the

• Hydraulic/fuel pressure

Do not attempt to locate a leak in the hydraulic system or attempt to close a

leak using any part of your body.

• Hot surfaces

that the centre of gravity of the tractor/implement assembly changes

according to the load being transported or towed.

type of terrain.

WARNING: The instructions concerning overturning in this manual

are not exhaustive.

CAUTION: Oil/fuel under high pressure easily penetrates through

clothing and skin and can cause serious injury.

CAUTION: Be careful of hot surfaces during operation and service

work, in particular the engine and hydraulics components.

• Falling Object Protection Structure (FOPS)

DANGER: The cab structure is not designed for protection against

falling objects (no FOPS).

• Operator Protection Structure (OPS)

DANGER: Protection against penetrating objects is not provided

(no OPS available).

• Hazardous substances EN 15695-1:2009

DANGER: The cab is classified as category 1 according to the

draft of EN15695-1:2009. Protection against dust or hazardous

substances (agricultural chemicals, etc.) is not provided. Personal

protective equipment must be used according to the chemical

manufacturer's recommendations.

• Forest work

• When working in forest, pay special attention to safety issues. The

specific dangers related to forest work are overturning, falling objects and

penetrating objects.

1.2.4.2 Getting into and out of the cab

When getting into and out of the cab, pay special attention to safety issues.

• Always use three-point contact with the tractor and face the tractor when

getting in and out.

• Use handrails, grab handles and steps when getting in and out.

• Do not use the control levers as a handhold.

• Do not step on pedals when getting in and out.

- 14 -

Page 17

• Never attempt to get into or out from a moving tractor.

1

• Never jump off a tractor.

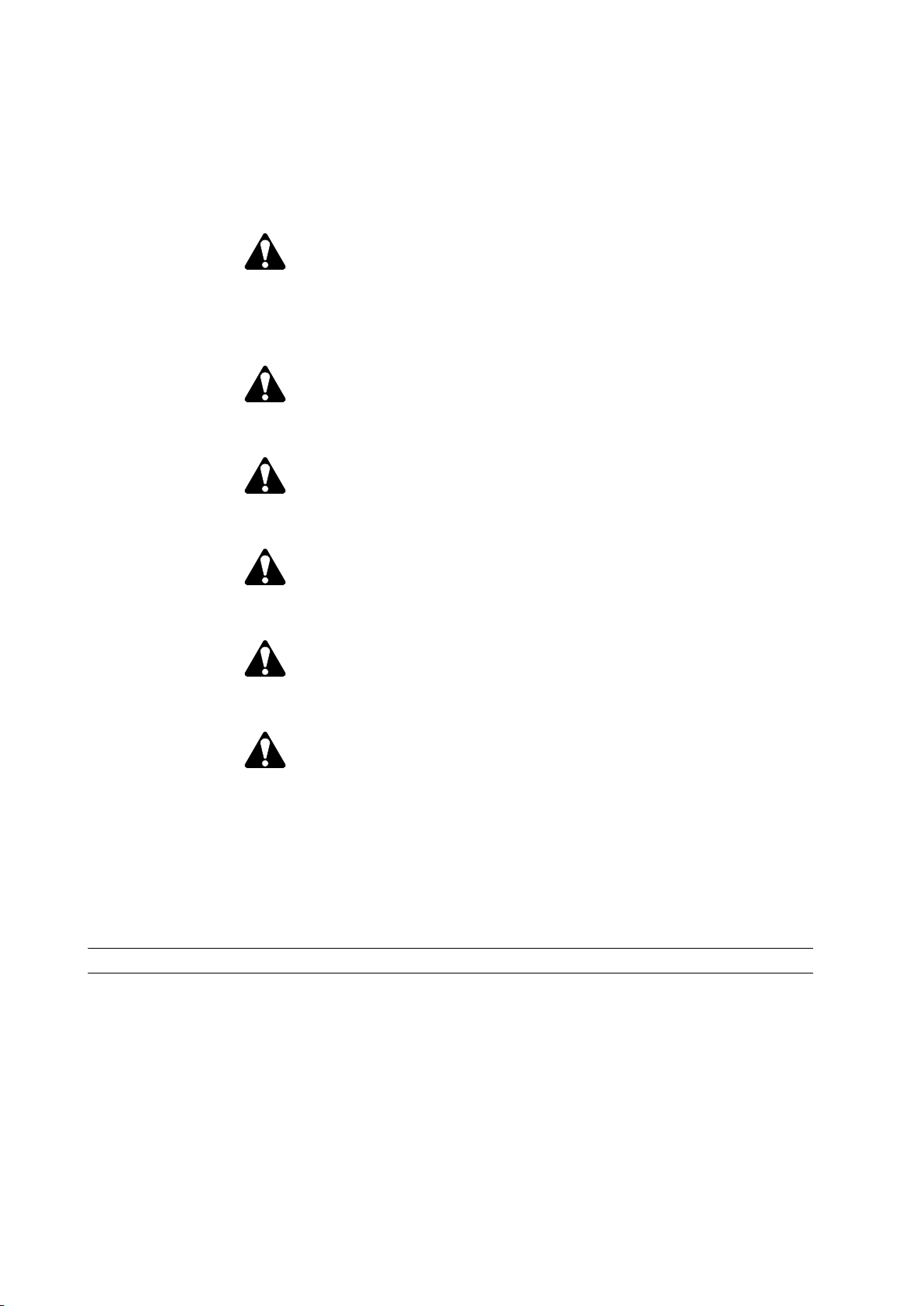

1.2.4.3 Driving on public roads

When driving the tractor on public roads, pay special attention to the safety issues.

• Before driving

• Check that the tractor is safe for driving on the road.

• Adjust the rear view mirrors to give the correct viewing angle.

• Lock the check links with pins when transporting implements using threepoint linkage.

• When driving the tractor on public roads

WARNING: Do not transport anything on the auxiliary hydraulic

valves while driving on the road. The load, trailer link steering and

such have to be locked (for example mechanically).

• Use the slow moving vehicle emblem on the rear end of the tractor if

allowed by law.

1. Safety precautions

GUID-1CEA41C8-DCE5-4D4C-ACAD-50A81837A945

1. Slow moving vehicle emblem

1.2.4.4 Controlling the driving speed

Adjust the driving speed to suit the driving surface, visibility and load.

IMPORTANT: Do not alter the maximum driving speed of the tractor. The

maximum reverse driving speed is 20 km/h.

• Avoid any sudden increase or reduction (braking) in the driving speed.

• Avoid tight turns at high driving speed.

• When driving the tractor with an attached implement which centre of gravity

is far from the tractor, the tractor may sway considerably during cornering.

If care is not taken, the tractor may tip over or the load may be displaced.

1.2.4.5 Driving downhill

Be careful when driving downhill.

• Check the brakes often.

- 15 -

Page 18

1. Safety precautions

• Change to a lower gear before driving down a steep incline.

IMPORTANT: Do not brake continuously as the brakes may overheat.

IMPORTANT: Do not let the engine overrun to avoid damage to the engine.

NOTE: If the speed is too high, a speed warning is shown on the instrument

panel display and a buzzer goes off.

1.2.4.6 Operating with implements

Read and follow the instructions to avoid unnecessary risks when operating with

implements and attachments.

WARNING: Always follow carefully the instructions given in the

implement's user documentation. It is not allowed to use an implement

without reading and understanding all the precautions and regulations.

WARNING: Before entering between the tractor and the implement,

prevent the tractor from moving by applying the parking brake or

blocking the wheels. There is risk of accidents if the tractor or

implement should move.

WARNING: Implements attached to the linkage or the auxiliary

hydraulic system must be lowered to the ground while parking and

during maintenance.

WARNING: When installing an implement, air in hydraulic hoses and

cylinders can cause erratic operation.Run the engine at low speed and

make slow movements with the joystick to purge any air from the

hydraulic system.

WARNING: When installing an implement, keep hands and feet away

from moving components.Do not use your fingers to check the

alignment of holes or pins — use a mandrel or a steel rod.

WARNING: When disconnecting, the implement may fall downwards.

IMPORTANT: When attaching a trailer or implement, be sure not to exceed the

maximum weight of the rear axle. See the technical specifications in this manual

for the maximum permissible axle loading.

• Make sure to allow sufficient clearance for turning.

Three-point hitch and side-mounted implements make a much larger arc

when turning than towed equipment. Use only Valtra approved attachments

and implements.

• Familiarise yourself with the working area and terrain.

Pay attention to vertical clearance and limitations that arise due to the

increased reach.

- 16 -

Page 19

1. Safety precautions

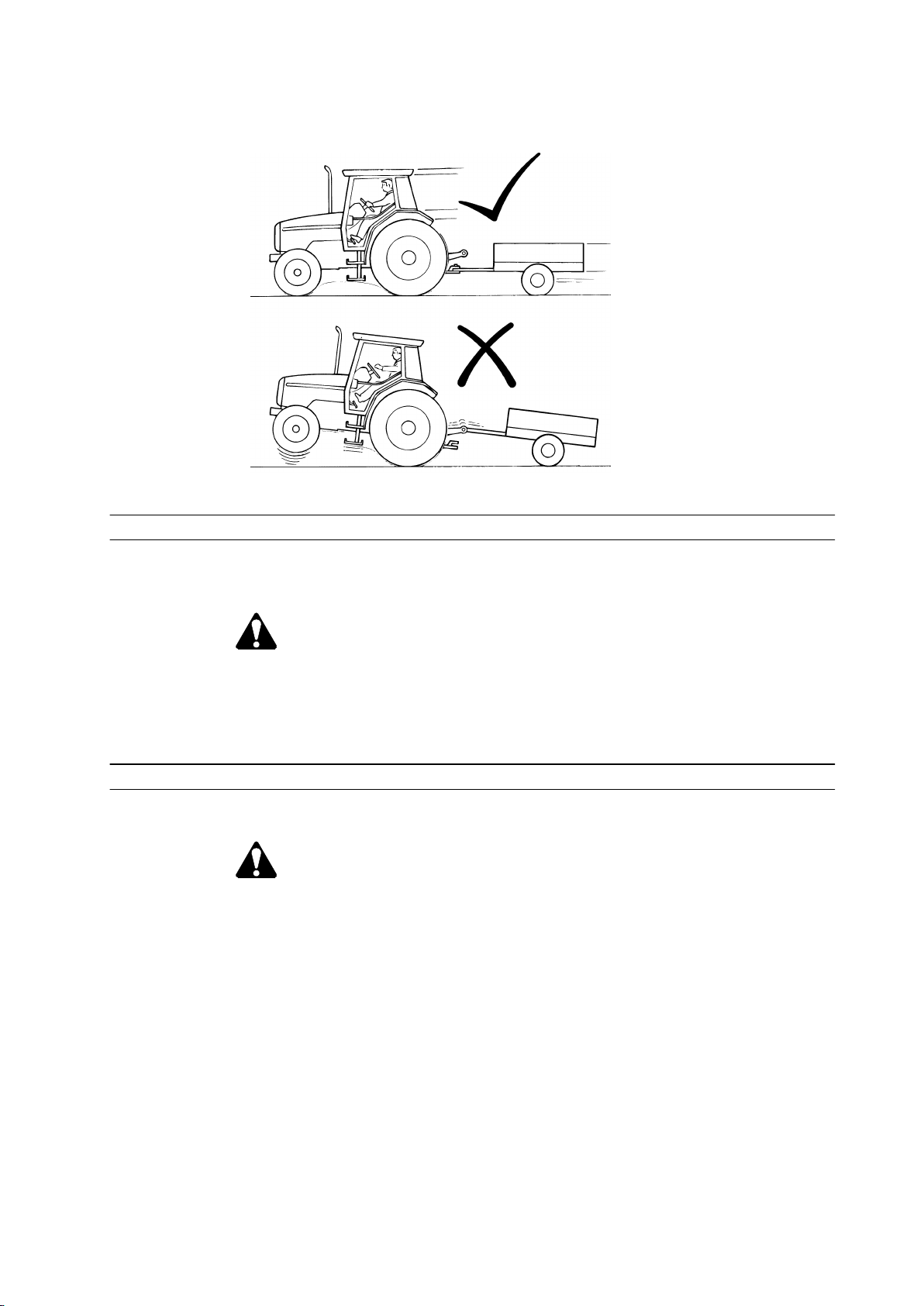

• Pull only from the approved drawbar.

Towing or attaching to other locations may cause the tractor to overturn.

GUID-B824BDA5-67EA-4CC6-AB40-7D1D42AD9627

1.2.4.7 Running with power take-off driven implements or machines

Read and follow the given instructions to use power take-off (PTO) driven

implements and machines safely.

DANGER: Serious accidents may occur due to failure to use the

prescribed safety devices.

• Use the prescribed safety devices and ensure that they are in good condition.

• Follow the directions given by the implement or machine manufacturer.

1.2.4.8 Using ballast weights

Use ballast weights according to the instructions when needed.

WARNING: When driving on the road, at least 20% of the gross weight

of the tractor must be on the front axle. When lifting an implement, the

weight on the front end of the tractor is reduced, and the steering

ability of the tractor is impaired or sometimes lost.

IMPORTANT: When using salt liquid as ballast weight in the wheels, the

manufacturer does not take the responsibility for the damages caused by salt.

• Use sufficient ballast weights.

• Mount ballast weights only at the points intended for this purpose.

- 17 -

Page 20

1. Safety precautions

1.2.4.9 Towing

Read and follow the given instructions to tow a trailer or an implement safely.

WARNING: When the tractor is towing a trailer, the brake pedals must

be locked together. The brakes are not to be used individually for

steering.

WARNING: When using a trailer, make sure that the hitch latch is locked.

WARNING: When using a trailer, always use the trailer brakes if

required by law.

WARNING: Be sure no one is standing between tractor and implement.

IMPORTANT: When attaching a trailer or implement, be sure not to exceed the

maximum weight of the rear axle. See the technical specifications in this manual

for the maximum permissible axle loading.

IMPORTANT: When attaching a trailer or implement, be sure not to exceed the

maximum load of the tyre type. See the technical specifications for maximum rear

axle tyre loadings.

• Couple a trailer to the drawbar using an approved trailer coupling.

• Always lower a loaded drawbar with the hydraulic lift.

• Check that trailer brakes are operating properly and observe any special

instructions issued by the trailer manufacturer.

• Secure the trailer load properly.

WARNING: On tractors with trailers, the load must be properly

secured. The load must not obstruct the operator’s vision, or cover

lights and reflectors. Loads which project more than 1 m behind

the vehicle train must be suitably marked. During daytime, this

should be done with a flag, and during darkness, with a red light

and a reflector arrangement.

1.2.4.10 Ensuring personal safety of other people

Avoid hazards for other people when using the tractor.

DANGER: Do not allow children in the cab or near the tractor or an

attached implement while the engine is running.

- 18 -

Page 21

1. Safety precautions

DANGER: If the tractor engine is running, do not leave anybody in the

cab without supervision, as the push buttons are easily operated.

Always apply the parking brake.

• Stop the engine and lower the implement to the ground when leaving the tractor.

• Do not let passengers ride in the tractor unless it is provided with a special

seat.

Other personal transport, for example on front-mounted loaders, is not

permissible.

• Do not let passengers ride on the platform inside the tractor.

• Never lend the tractor to a person who is not used to driving it.

DANGER: You may be held responsible for any resulting accidents.

• Do not allow children, untrained or unqualified persons to operate your tractor.

They could injure themselves or someone else.

1.2.4.11 Fire hazards

WARNING: Open fire, smoking and sparks are prohibited near the fuel

system and batteries. Especially when charging batteries, explosive

gases are present.

1.2.4.12 Handling viton seals subjected to high temperatures

At temperatures over 300°C, the viton seals of the engine produce highly

corrosive hydrofluoric acid.

• Do not touch viton seals subjected to abnormally high temperatures with your

bare hands.

Use neoprene rubber or heavy duty gloves and safety glasses when

decontaminating.

• Wash seals and the contaminated area with 10% calcium hydroxide or other

alkali solution.

• Put all the removed material in sealed plastic bags and deliver them to the

point stated by the authorities concerned.

WARNING: Never burn viton seals.

- 19 -

Page 22

1 3 42

2. Instruments and controls

2 Instruments and controls

2.1 Pedals

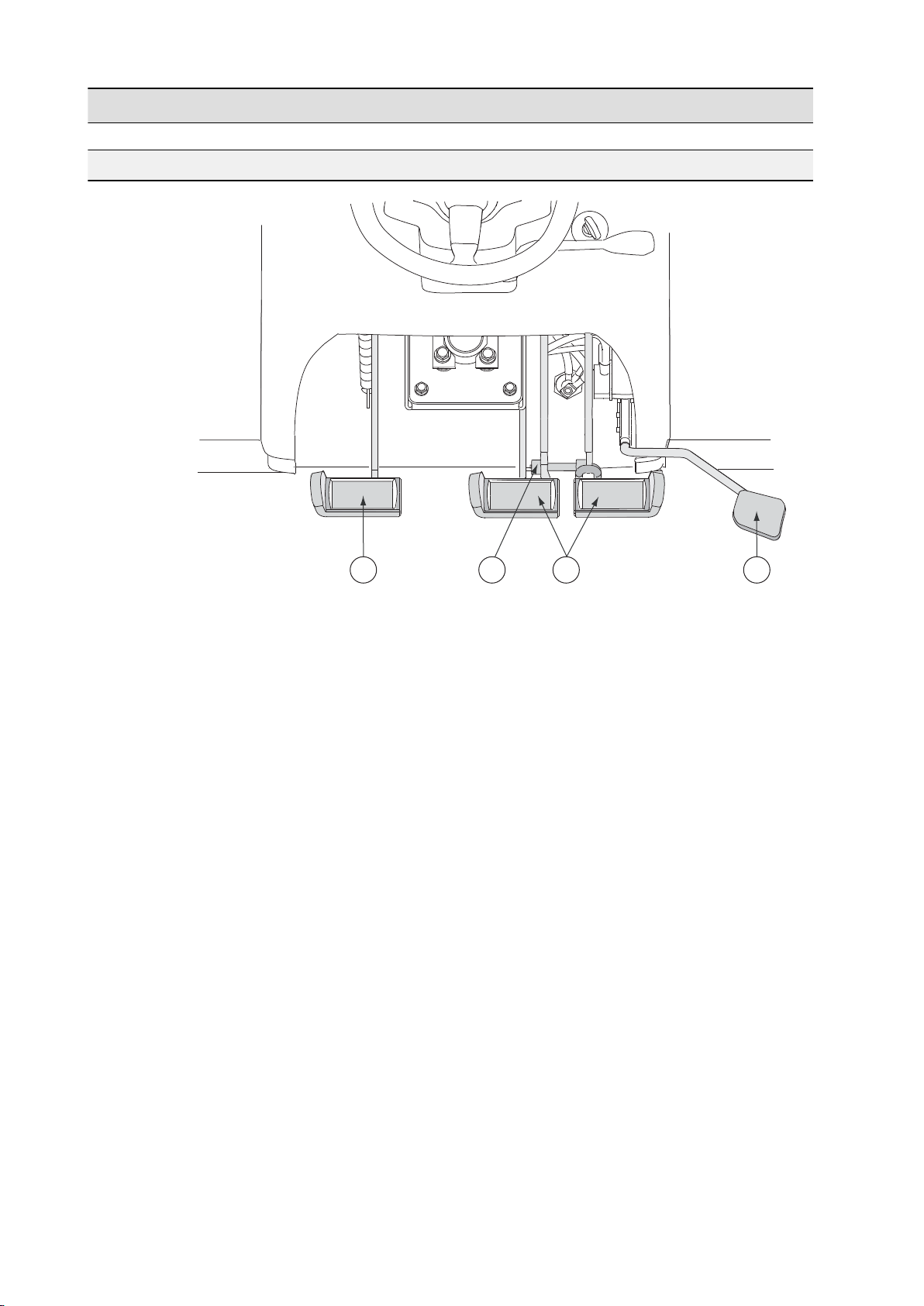

GUID-CE4B8BB7-F624-4395-8927-43A39CAC9E48

1. Clutch pedal

2. Latch for brake pedals

3. Brake pedals

4. Accelerator pedal

- 20 -

Page 23

2.2 Dashboard

4

1

5

6

8

9

10

11

12

7

2

3

2. Instruments and controls

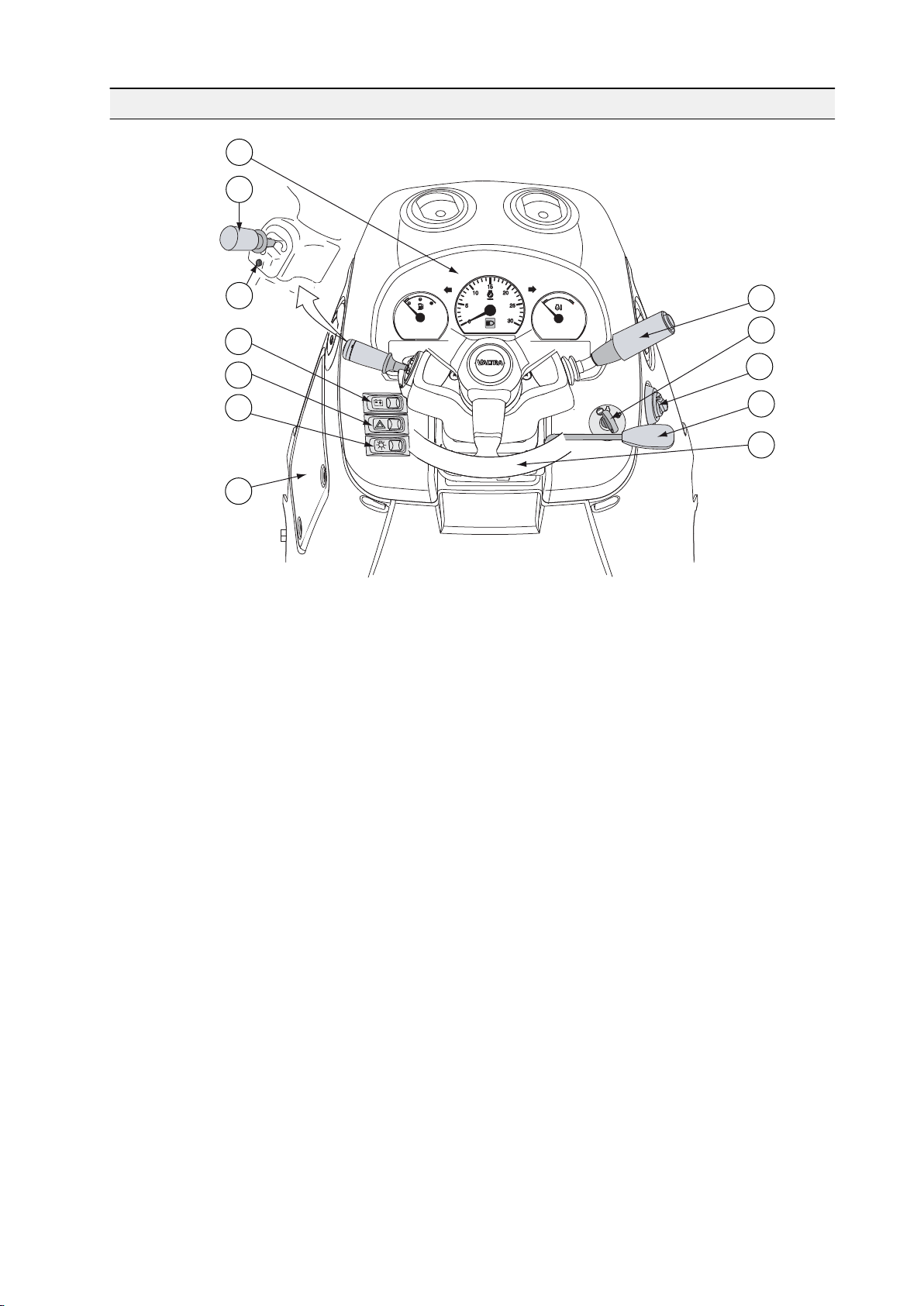

GUID-3F6336F5-9354-4B02-A85F-7134D8877C3B

1. Instrument panel

2. Power shuttle lever

3. Preprogramming push button

4. Main switch (extra equipment)

5. Hazard warning flasher switch

6. Light switch

7. Electric centre

8. Multifunctional lever

9. Ignition switch

10. Heater adjustment knob

11. Lever for adjusting steering wheel position

12. Steering wheel

- 21 -

Page 24

5

1

2 3

2

4

6

2. Instruments and controls

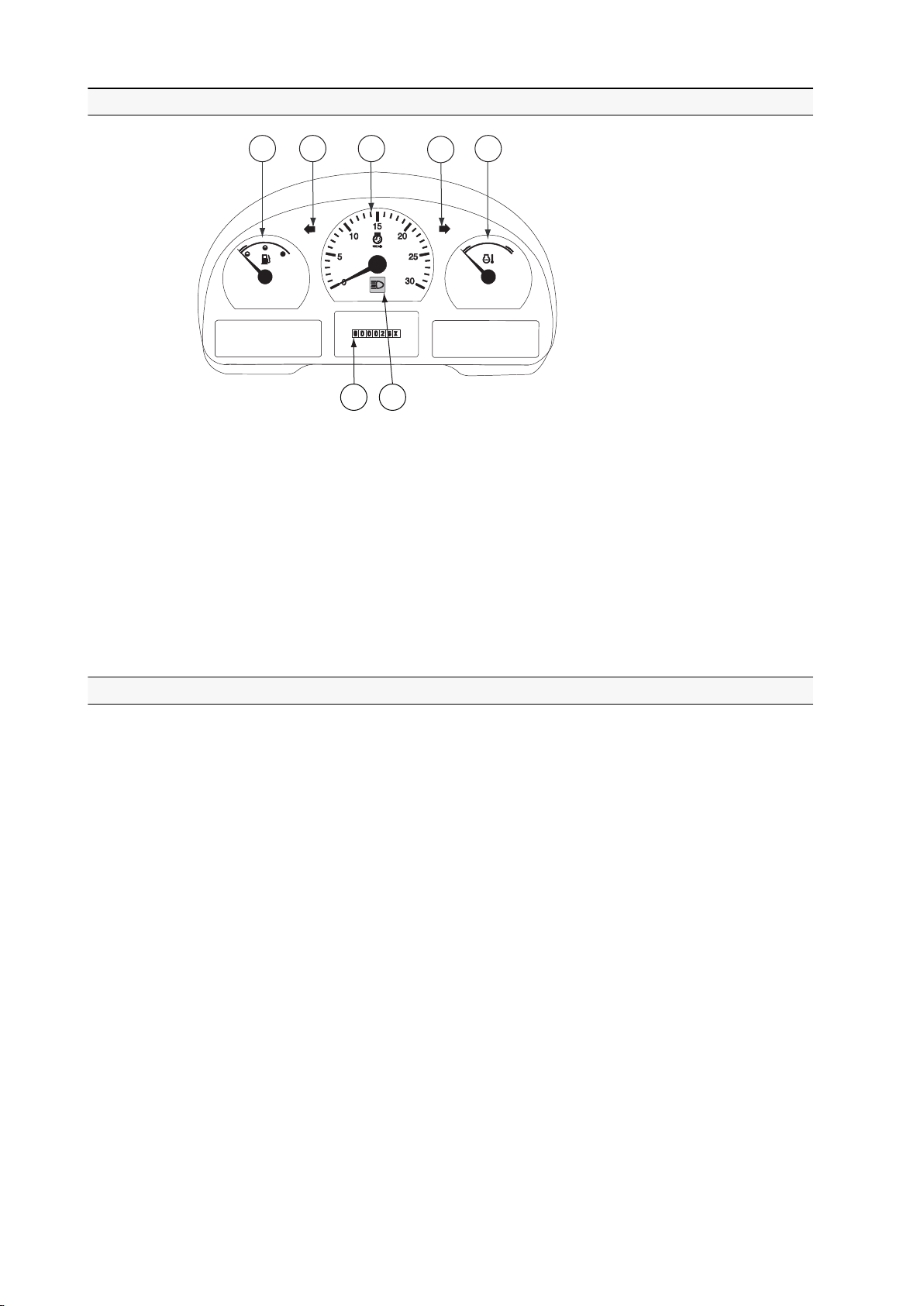

2.2.1 Infoline instrument panel

GUID-4034DDEC-F3C6-485F-BBB5-07446F964E91

1. Fuel gauge

2. Indicator lights for direction indicator

3. Tachometer

4. Coolant thermometer

5. Operating hour meter

6. Indicator light for the main beam

The fuel gauge shows the amount of fuel left in the tank.

The coolant thermometer indicates the engine temperature. The zone between

blue (cold) and red (hot) is the normal operating temperature.

2.2.2 Proline instrument panel

The operator receives information from the gauges, coolant thermometer,

tachometer, speedometer and indicator lights. All this can be seen on the Proline

instrument panel. The Proline instrument panel is an alternative equipment.

- 22 -

Page 25

1 2

4

5

3

3

6 7

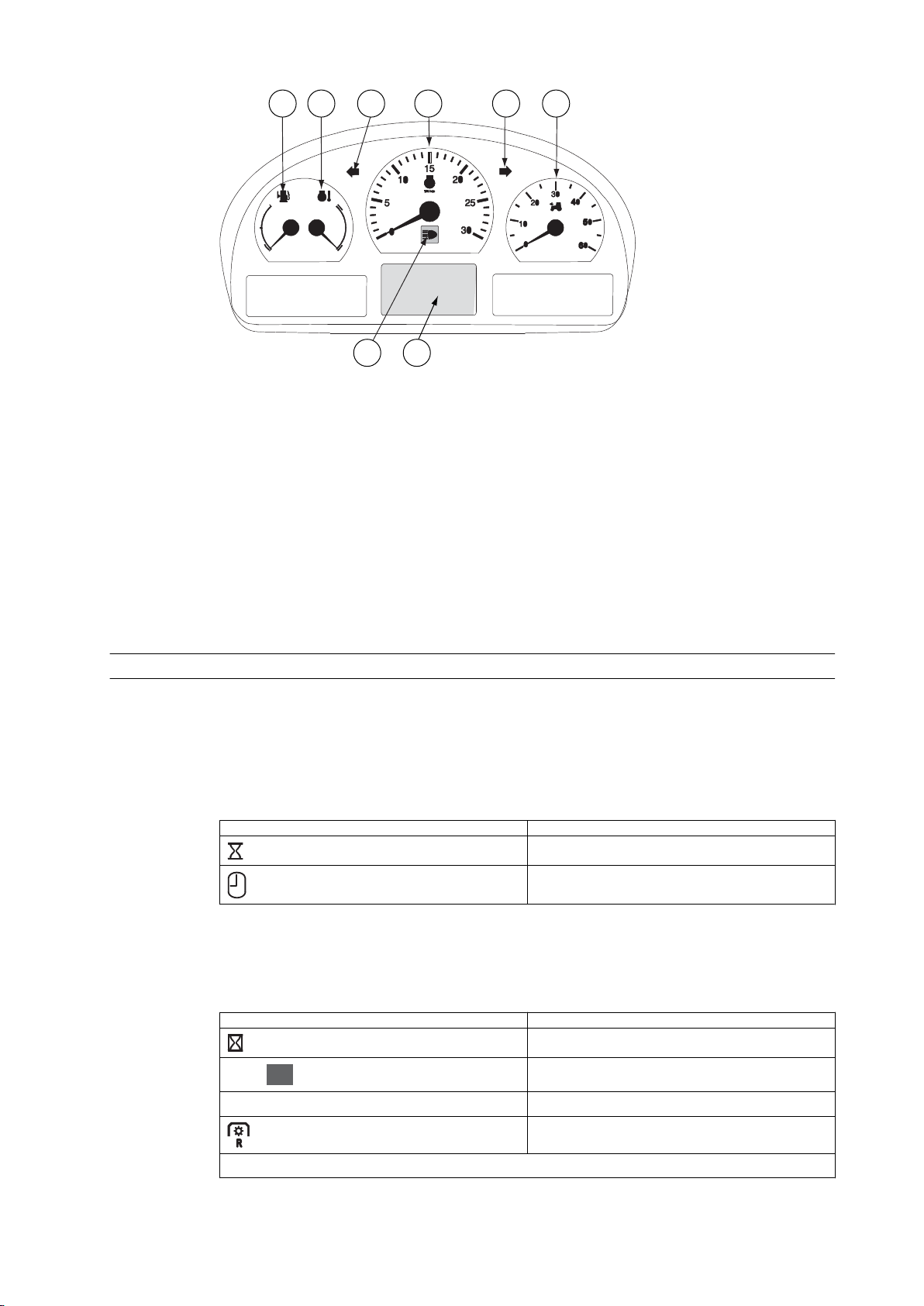

GUID-FC2CD6B7-89CF-4206-B450-F2A852212AB7

cruise

cruise

RPM

RPM

cruise

cruise

KMH

KMH

1. Fuel gauge

2. Coolant thermometer

3. Indicator lights for direction indicator

4. Tachometer

5. Speedometer

6. Indicator light for the main beam

7. Proline instrument panel display

2. Instruments and controls

The fuel gauge shows the amount of fuel left in the tank.

The coolant thermometer indicates the engine temperature. The zone between

blue (cold) and red (hot) is the normal operating temperature.

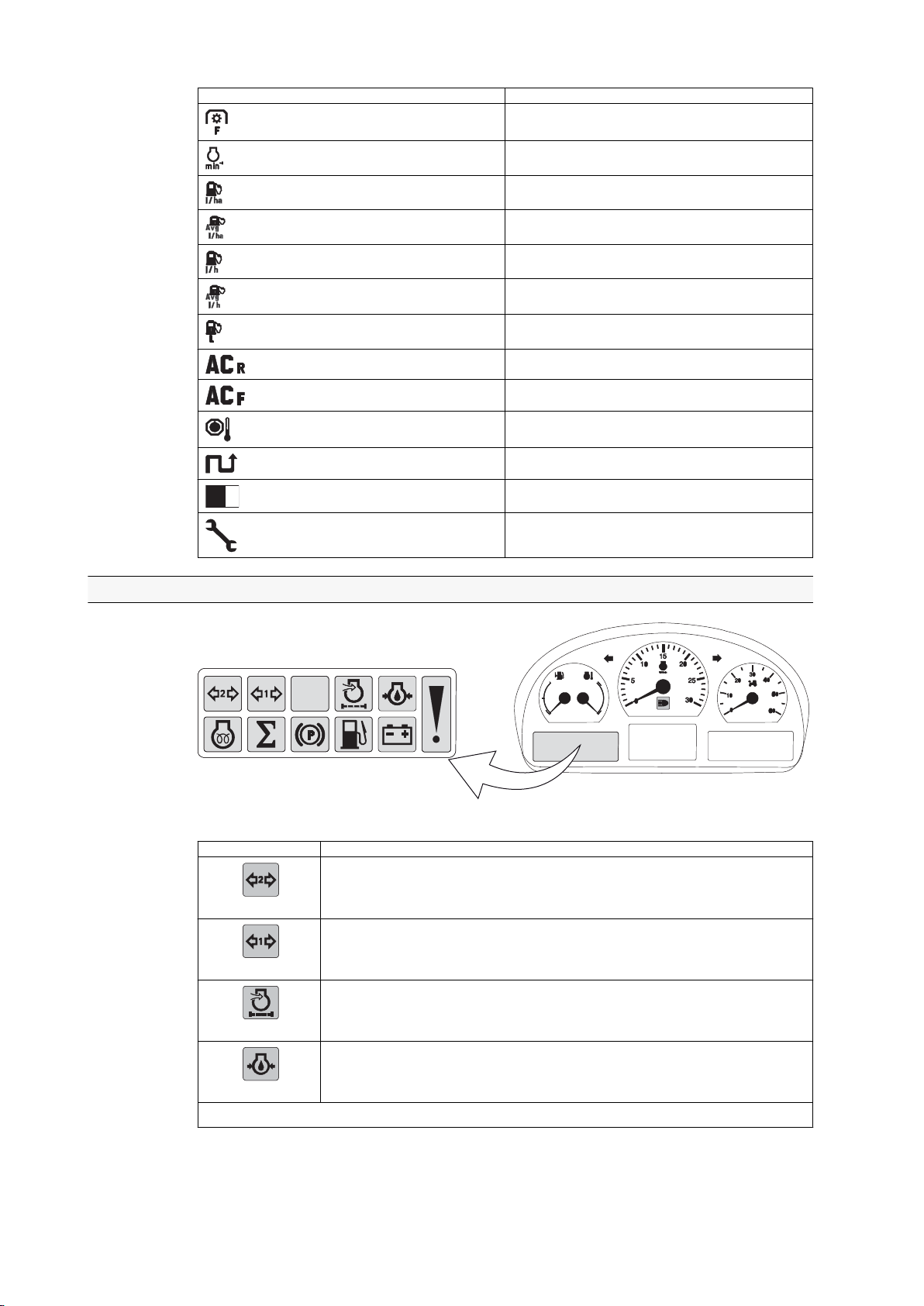

2.2.2.1 Symbols on the Proline instrument panel display

The Proline instrument panel display has fixed views and views that can be

selected by the operator.

Fixed view symbols

The fixed views are the two functions shown on the bottom row of the display:

Symbol

Selectable view symbols

The selectable views are the functions shown on the top and centre row of the

display:

Symbol

Function

Operating hours (hhhh.h)

Clock (hh:mm)

Function

Working time (h:mm)

Cruise control

km/h/mph Driving speed (km/h/mph)

Rear power take-off (PTO) speed (rpm)

Table continued on next page

- 23 -

Page 26

2. Instruments and controls

Symbol Function

Front power take-off (PTO) speed (rpm)

Engine speed (rpm)

Immediate fuel consumption (ha, acre)

Average fuel consumption (ha, acre)

Immediate fuel consumption

Average fuel consumption

Fuel consumption

Lower link position (%, 0-100)

Lifting link position of front linkage (%, 0-100)

Gearbox temperature (C/F)

Travel distance (m/km/miles)

Square area (ha)

Periodical maintenance

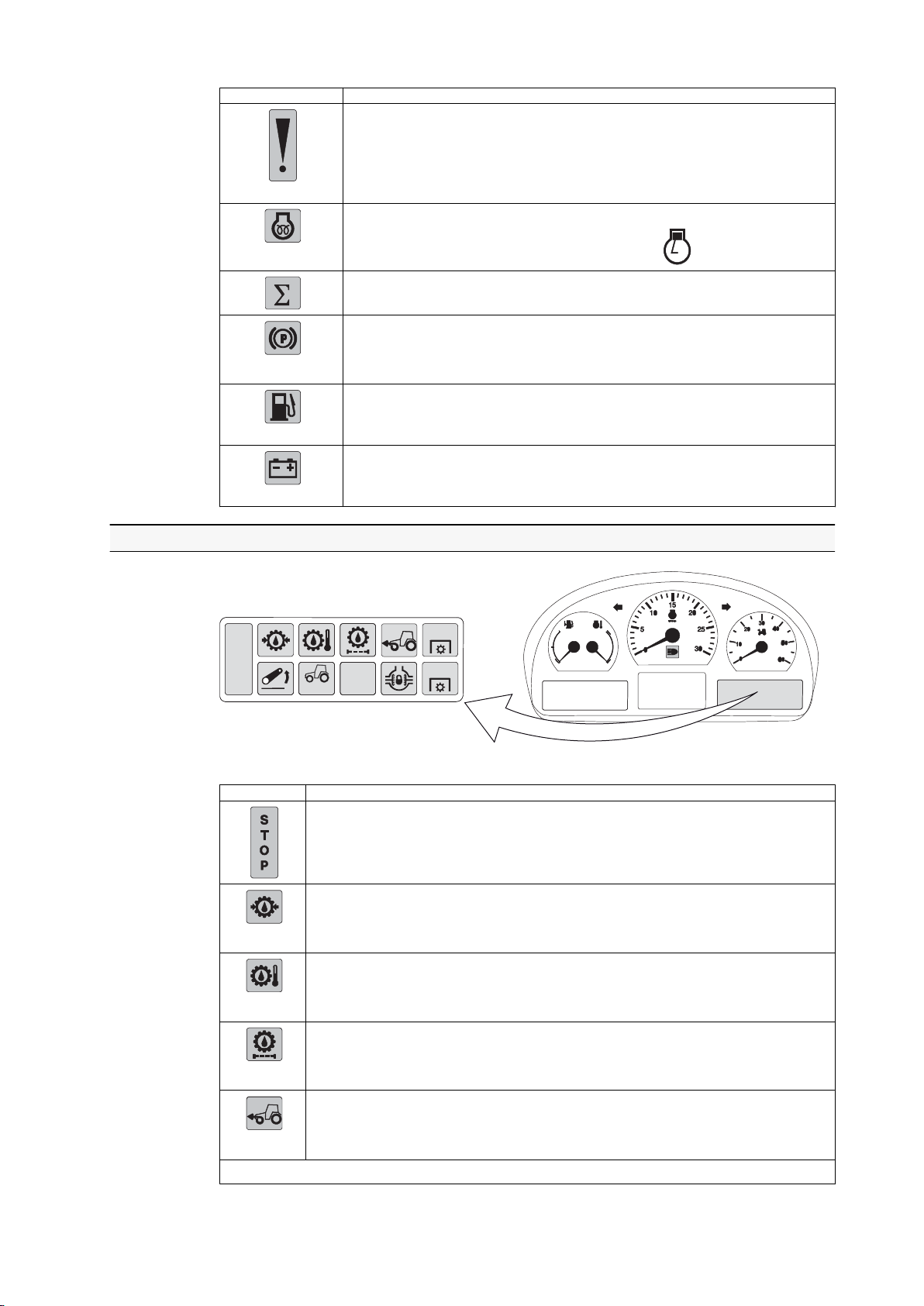

2.2.3 Indicator lights on the left side of the display

GUID-1802E922-D2FC-42D2-8690-6D5D6974D412

Indicator light

GUID-32CAE5D4-C71C-4D8B-

A41F-2E1DE50F1ED4

GUID-16CF17A4-

D96E-4592-8DF3-1D4A100F090E

Indication

Direction indicator light for second trailer (green).

If one of the bulbs on the combination has failed, this light is not lit.

Direction indicator light for first trailer (green).

If one of the bulbs on the combination has failed, this light is not lit.

Engine air cleaner clogging indicator light.

GUID-06E4C986-88C7-44BA-9897-211

781955328

Engine oil pressure light

GUID-A1E9566C-86CE-4AD3-A512-

D772AE266E1E

Table continued on next page

- 24 -

Page 27

Indicator light Indication

CRUISE

F

R

S

T

O

P

The exclamation mark is lit together with other indicator lights (yellow).

GUID-8D5CD1CF-666F-46C9-9211-2B

B777A73D4E

Glow indicator light

GUID-9DD75249-0CC3-461D-84EC-

C9937C947DB9

The light (yellow) is lit when the ignition key is in position

Ʃ-indicator light is used as a service code indicator light (flashing)

Parking brake indicator light

GUID-

F0C90BFB-3126-404D-8C49-3FA955C

C4FD2

The light (red) is lit to indicate that the power shuttle lever is in the parking brake position.

Low fuel level indicator light

GUID-714DD8B7-ED71-4AA7-

BFAA-31C5E3693067

The light is lit (yellow) and a buzzer sounds once to indicate that about 50 litres of fuel

is left.

Battery charging indicator light

GUID-CD4C4C77-7CDB-4FB5-AF3A-

BEFDF3417EB1

2. Instruments and controls

and the engine is cold.

2.2.4 Indicator lights on the right side of the display

GUID-A05FB324-D33C-419E-8E65-DDDFBDC37FCD

Indicator light

GUID-9B9A9C87-

BB4C-43A1-9A88-789929

9F22D0

Indication

STOP indicator light (red)

Gearbox oil pressure light

Gearbox oil temperature light

GUID-

AC890C72-21FE-4056-89

5A-DB34A4CE9357

Pressure oil filter clogging indicator light

GUID-9B16B673-

D692-4975-

A9F9-5D6DBAFC4177

Four-wheel drive (4WD) indicator light

GUID-1E59203D-

F3B7-420D-ABC9-

F7433B7A6C19

The light is lit (yellow) to indicate that 4WD is engaged.

Table continued on next page

- 25 -

Page 28

2. Instruments and controls

Indicator light Indication

Front power take-off (PTO) indicator light

GUID-9AA1D60E-5812-4

B9F-

BDB0-44D48BEA8941

GUID-39523C54-

CBE4-40C9-98E5-3128D0

E9D502

GUID-4A174D51-0D8F-49

D5-A784-8C0B31037162

GUID-533CED2D-

D3E0-4488-8590-

A1E859BA91C5

GUID-70C6E3BDC691-4819-BA77-

BA56A2A6A231

The light (yellow) is continuously on and indicates that the front PTO (extra equipment) is

engaged.

Rear linkage indicator light

The light is on (yellow) to indicate that the lift/stop/lower switch is in lift (transport) position.

Cruise control indicator light

The light is on (yellow) to indicate that cruise control is engaged (constant driving speed/

constant engine speed chosen).

Differential lock indicator light

The light is lit (yellow) to indicate that the differential lock is engaged.

Rear PTO indicator light

The light blinks (yellow) when the rear PTO has been activated and is ready to operate. The

light is on continuously when the rear PTO is engaged.

- 26 -

Page 29

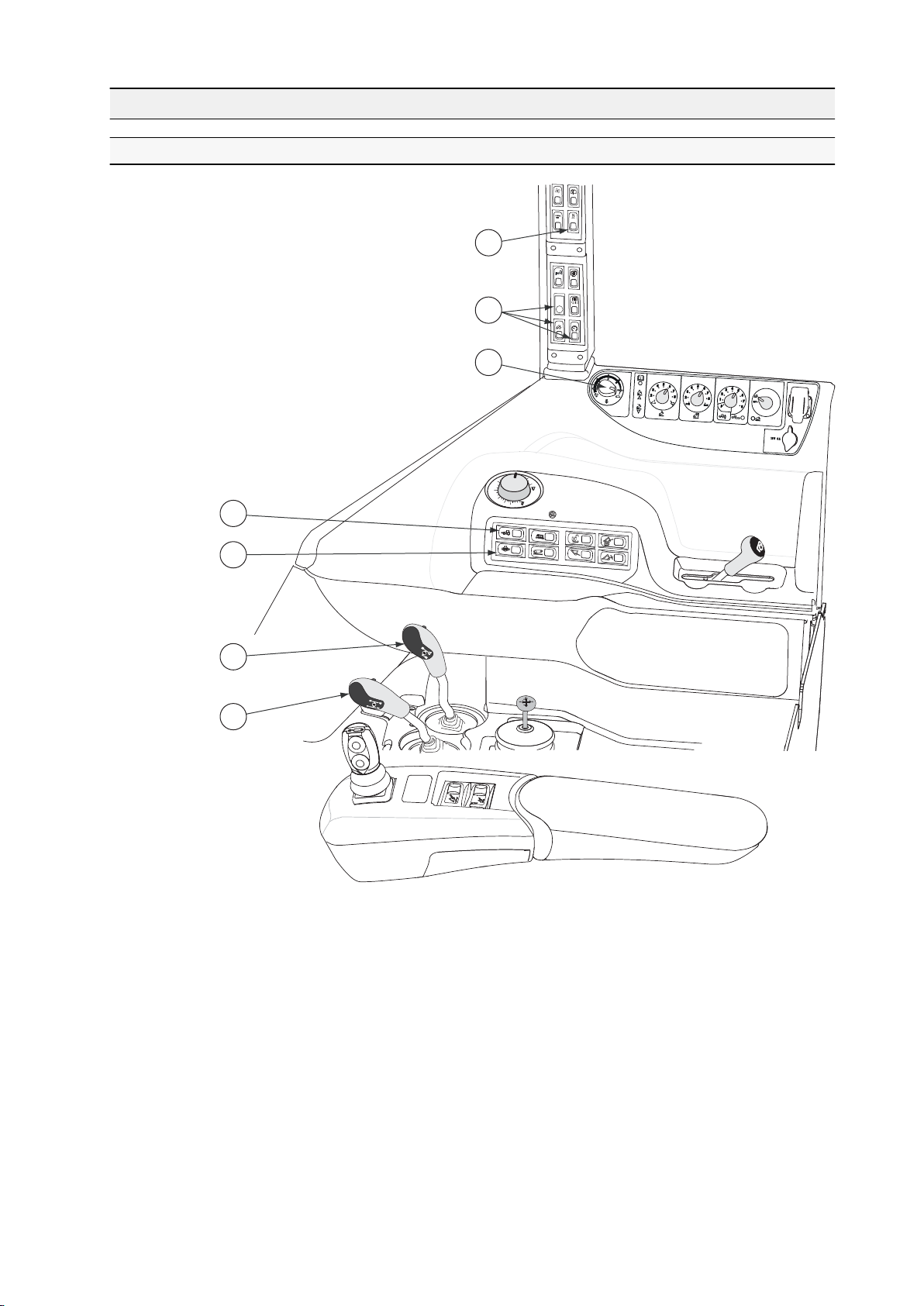

2.3 Controls on the right-hand side

2

1

1

cruise

+

_

4

5

6

7

2

3

4

5

8

9

1

ON/OFF

3

CRUISE

OFF

2.3.1 Driving controls

2. Instruments and controls

GUID-71A12285-8768-4EF9-AF3B-C2CBC7BB1249

1. Switch for automatic traction control

2. Switches for cruise control (extra equipment)

3. Hand throttle

4. Switch for four-wheel drive (4WD)

5. Switch for differential lock

6. Range gear lever

7. Speed gear lever

- 27 -

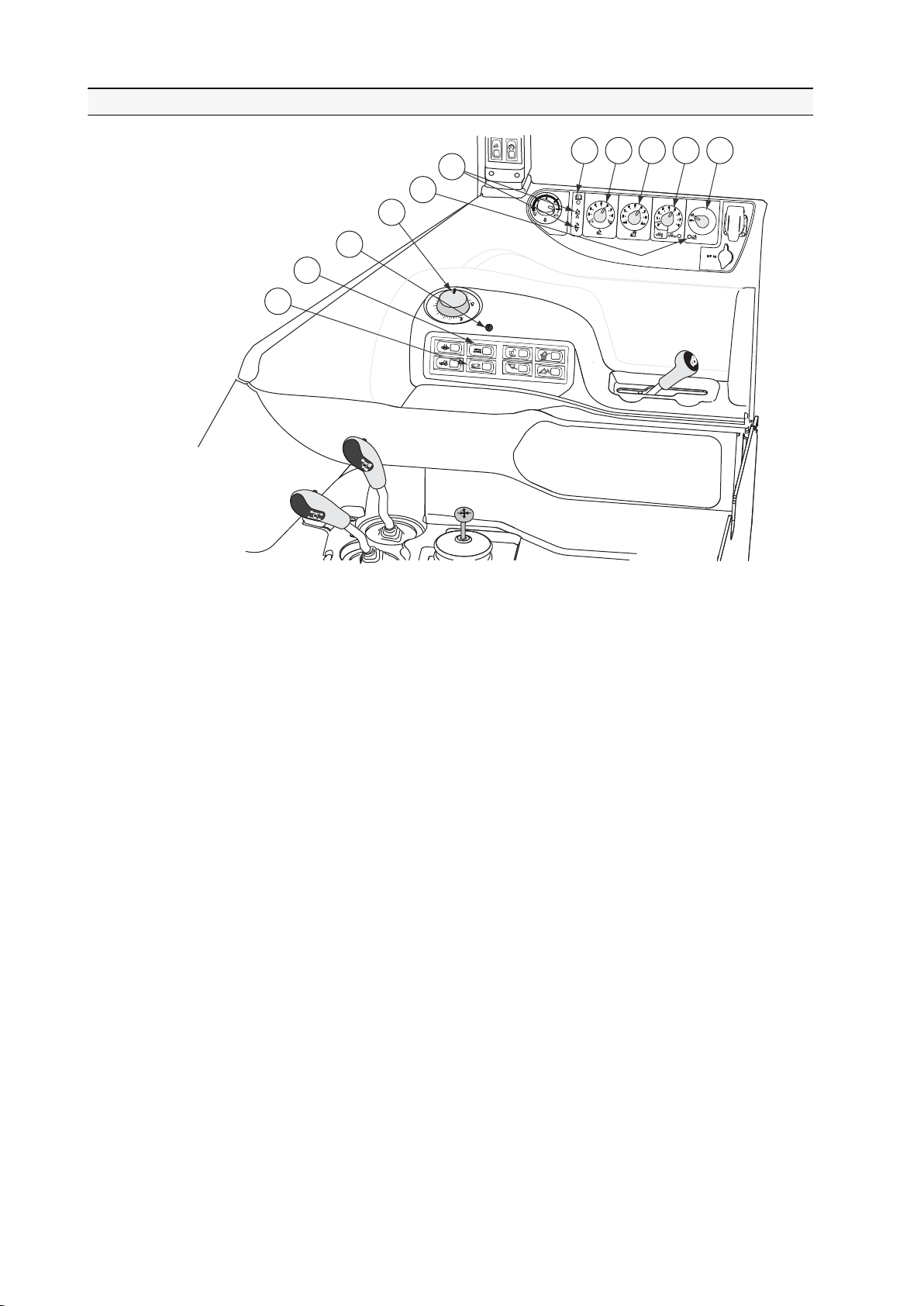

Page 30

8

9

10

11

1

cruise

+

_

2

3

4

5

8

9

1

ON/OFF

397 161 00

397 161 00

1

2

3 4 5

6

7

2. Instruments and controls

2.3.2 Linkage

GUID-4049B706-B451-4FCF-8CF7-11B4C4626E69

1. Diagnose light

2. Lowering speed selector

3. Lifting height selector

4. Draft control selector

5. Drive balance control

6. Lift/lower indicator lights

7. Drive balance control light

8. Position control knob

9. Passing switch for position control knob

10. Lift/stop/lower switch

11. Lift/lower switch

- 28 -

Page 31

2.3.3 Power take-off

3

1

cruise

1

cruise

+

_

2

3

4

5

8

9

1

ON/OFF

397 161 00

3

9

7

1

6

1

0

0

2

1

cruise

1

cruise

+

_

2

3

4

5

8

9

1

ON/OFF

397 161 00

397 161

00

Rear power take-off

2. Instruments and controls

GUID-85E225E3-4C10-4D43-BC28-6E3916454FF8

1. Switch for rear power take-off (PTO)

The rear PTO push buttons on the mudguards are extra equipment.

2. Switch for the rear PTO automatic stop (extra equipment)

3. Speed control lever for the rear PTO

Front power take-off

Front power take-off (PTO) is extra equipment.

GUID-3EADB628-222B-49CE-9790-D5BE86BA4A9E

1. Switch for front PTO

- 29 -

Page 32

1

2

6

7

3

4

5

2

3

4

5

8

9

1

ON/OFF

8

9

2. Instruments and controls

2.3.4 Auxiliary hydraulics

GUID-DF8BDC4D-F38B-41EA-966B-2C95D2DF19E3

1. Front loader hydraulics On/Off switch

The armrest with front loader hydraulics controls is extra equipment.

2. Joystick

3. Joystick push buttons

4. Switch for continuous floating position

5. Switch for floating position activation

6. Switch for Softdrive (extra equipment)

7. Switch for equipment locking (extra equipment)

8. Control levers for the auxiliary hydraulics rear valves 3 and 4 (extra equipment)

9. Control lever for the auxiliary hydraulics rear valves 1 and 2

- 30 -

Page 33

2.3.5 Other controls

1

2

3

4

5

6

7

8

9

cruise

1

cruise

+

_

2

3

4

5

8

9

1

ON/OFF

10

11

2. Instruments and controls

GUID-026248F1-0062-470F-94D7-4BADED0B7630

1. Switch for upper headlights (extra equipment)

2. Switch for front working lights (extra equipment)

3. Proline instrument panel display change-over switch (extra equipment)

4. Switch for heater fan

5. Switch for control stop (extra equipment)

6. Switch for rotating warning light (extra equipment)

7. Switch for rear working lights

8. Proline instrument panel display setting switch (extra equipment)

9. Switch for rear window wiper and washer (extra equipment)

10. Three-pin power socket

11. Two-pin power socket (extra equipment)

- 31 -

Page 34

1

1

2

3

2. Instruments and controls

2.4 Controls on the rear side

2.4.1 Rear window opening device

GUID-EBC23273-EEF6-432D-A529-D4891EEB953B

1. Rear window opening device

2.5 Controls on the left-hand side

GUID-2D3C9DB7-78E0-43DE-883C-33B1411DEBC7

1. Storage compartment

2. Lighter

3. Cup holder

- 32 -

Page 35

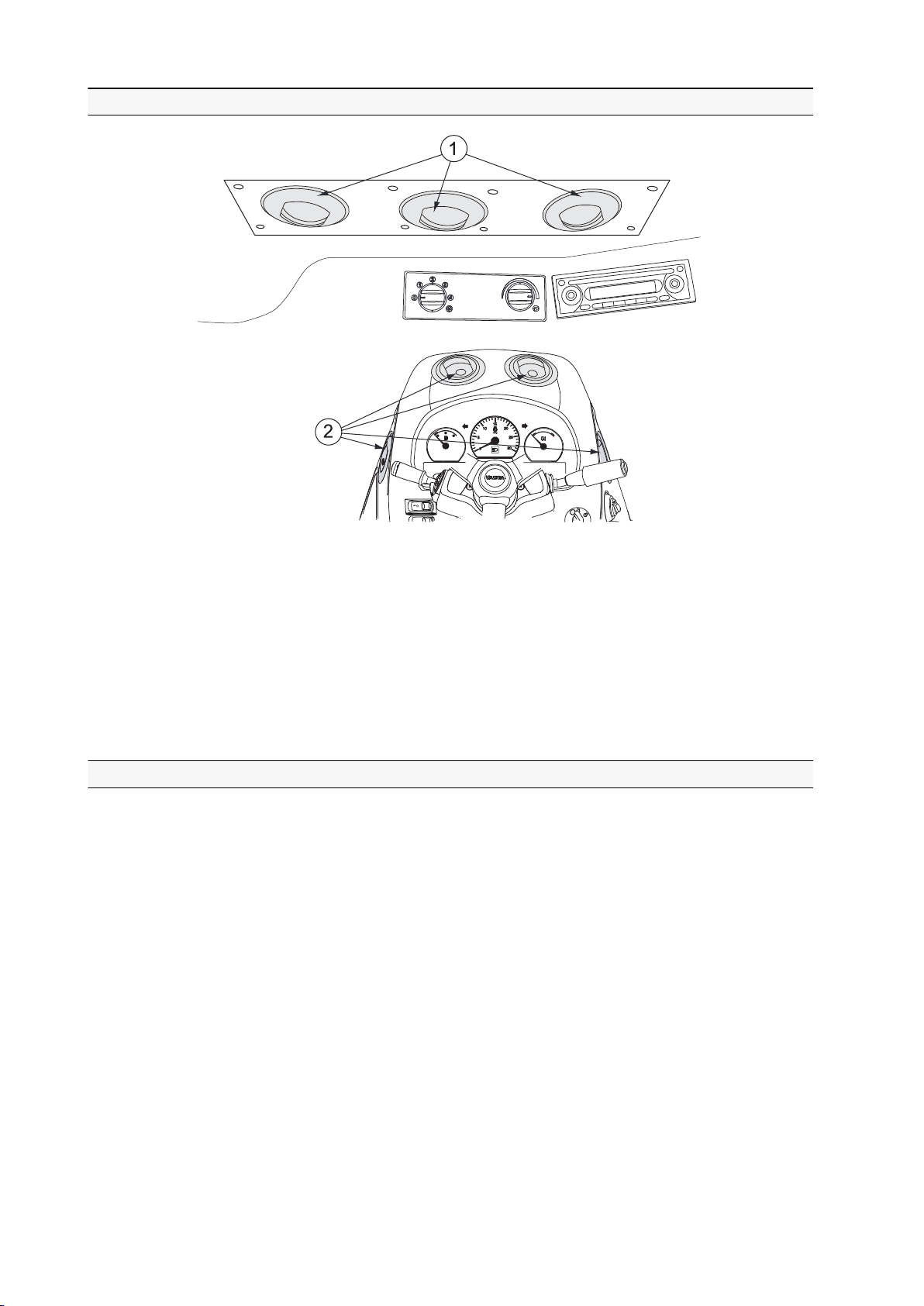

2.6 Controls on the front roof console

5

6

4

3

1

2

3

2

1

2. Instruments and controls

GUID-4ED84FEF-AFCF-4238-92E9-48434AD7C168

1. Ventilation nozzles (extra equipment)

2. Fan control knob (extra equipment)

3. Cab light

4. Sun visor down

5. Radio (extra equipment)

6. Sun visor up

2.7 Air conditioning controls

2.7.1 Manual air conditioning controls

The manual air conditioning system is extra equipment.

GUID-B5D7DDF2-AB47-4140-BDAA-339CDFED704A

1. Fan control knob

2. Air conditioning control knob

3. Recirculation control knob

- 33 -

Page 36

3

2

1

4

4

5

6

7

2. Instruments and controls

2.8 Driver's seat

GUID-570C8583-9948-4E8D-B41F-63B06BDC44E1

1. Backrest inclination adjustment

2. Seat belt anchor point

3. Seat turning lock/release

4. Height adjustment

5. Forward/backward adjustment

6. Suspension adjustment

7. Operator weight display

- 34 -

Page 37

2.9 Air suspended driver's seat

2

3

off

on

4

5

7

1

8

9

11

10

6

Air suspended driver's seat is extra equipment.

2. Instruments and controls

GUID-549B2B80-8D42-4968-9E9C-DE807B7EBCFF

1. Seat depth and cushion angle adjustment

2. Storage compartment for manuals

3. Headrest height adjustment and removal

4. Seat heating

5. Lumbar support adjustment

6. Armrest adjustment

7. Forward/backward adjustment

8. Backrest inclination adjustment

9. Longitudinal suspension adjustment

10. Height and vertical suspension adjustment