User’s Guide

RapidVac™

Smoke Evacuator System

Foreword

This manual and the equipment it describes are for use only by qualified medical

professionals trained in the particular technique and surgical procedure to be performed.

It is intended as a guide for using the RapidVAc Smoke Evacuator only. Additional

users information is available in the RapidVac™ Smoke Evacuator Service

Manual.

Caution

Federal (USA) law restricts this device to sale by or on the order of a physician.

Equipment covered in this manual

RapidVac Smoke Evacuator—110 V and 220 V

Part Number: 1008878

Effective Date: May 2008

Trademark acknowledgements

RapidVac™ is a trademark of Valleylab. All trade names referenced are the

trademarks, registered trademarks, or products of their respective manufacturers.

Manufactured for:

Valleylab, a division of Tyco Healthcare Group LP

Boulder, Colorado 80301-3299 USA

European representative

Tyco Healthcare UK Ltd.

Gosport, PO13 0AS, UK

Device is compliant with the European Communities Council Directive 93/42/

EEC, Medical Device Directive.

Printed in USA

©2008 Valleylab. All rights reserved.

For information call

1-303-530-2300

Internet address

http://www.valleylab.com

ii RapidVac™ Smoke Evacuator User’s Guide

RapidVac™ Smoke Evacuator User’s Guide iii

Warranty

Valleylab, a division of Tyco Healthcare Group LP, warrants each product

manufactured by it to be free from defects in material and workmanship under

normal use and service for the period(s) set forth below. Valleylab’s obligation

under this warranty is limited to the repair or replacement, at its sole option, of

any product, or part thereof, which has been returned to it or its Distributor within

the applicable time period shown below after delivery of the product to the

original purchaser, and which examination discloses, to Valleylab’s satisfaction,

that the product is defective. This warranty does not apply to any product, or part

thereof, which has been repaired or altered outside Valleylab’s factory in a way so

as, in Valleylab’s judgment, to affect its stability or reliability, or which has been

subjected to misuse, neglect, or accident.

The warranty periods for Valleylab products are as follows:

Microwave Ablation Generator One year from date of shipment

Microwave Ablation Pump One year from date of shipment

Electrosurgical Generators One year from date of shipment

RFG-3C™ Plus Lesion Generator One year from date of shipment

LigaSure™ Vessel Sealing System One year from date of shipment

LigaSure™ Reusable Instruments One year from date of shipment

Mounting Fixtures (all models) One year from date of shipment

Footswitches (all models) One year from date of shipment

Force Argon™ Units One year from date of shipment

RapidVac Smoke Evacuator One year from date of shipment

LigaSure

Sterile Single Use Items Sterility only as stated on packaging

Patient Return Electrodes Shelf life only as stated on packaging

MWA Antennas Shelf life only as stated on packaging

™ Sterile Single Use Items

Sterility only as stated on packaging

This warranty is in lieu of all other warranties, express or implied, including

without limitation, the warranties of merchantability and fitness for a particular

purpose, and of all other obligations or liabilities on the part of Valleylab.

Valleylab neither assumes nor authorizes any other person to assume for it any

other liability in connection with the sale or use of any of Valleylab’s products.

Notwithstanding any other provision herein or in any other document or

communication, Valleylab’s liability with respect to this agreement and products

sold hereunder shall be limited to the aggregate purchase price for the goods sold

by Valleylab to the customer. There are no warranties which extend beyond the

terms hereof. Valleylab disclaims any liability hereunder or elsewhere in

connection with the sale of this product, for indirect or consequential damages.

iv RapidVac™ Smoke Evacuator User’s Guide

This warranty and the rights and obligations hereunder shall be construed under

and governed by the laws of the State of Colorado, USA. The sole forum for

resolving disputes arising under or relating in any way to this warranty is the

District Court of the County of Boulder, State of Colorado, USA.

Valleylab, its dealers, and representatives reserve the right to make changes in

equipment built and/or sold by them at any time without incurring any obligation

to make the same or similar changes on equipment previously built and/or sold by

them.

RapidVac™ Smoke Evacuator User’s Guide v

Conventions Used in this Guide

Warning

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Caution

Indicates a hazardous situation which, if not avoided, may result in minor or

moderate injury.

Notice

Indicates a hazard that may result in product damage.

Important

Indicates an operating tip or maintenance suggestion.

vi RapidVac™ Smoke Evacuator User’s Guide

Table of Contents

Foreword................................................................................................................................................................... ii

Warranty ..................................................................................................................................................................iv

Conventions Used in this Guide .......................................................................................................................... vi

Chapter 1. Introducing the RapidVac Smoke Evacuator

Parts Shipped with the Smoke Evacuator........................................................................................................ 1-2

About the RapidVac Smoke Evacuator ............................................................................................................ 1-2

Features ....................................................................................................................................................... 1-3

RapidVac+ System.....................................................................................................................................1-3

Operating Modes ........................................................................................................................................1-3

Power............................................................................................................................................................1-4

Operating Parameters................................................................................................................................1-4

Transport and Storage...............................................................................................................................1-4

Patient and Operating Room Safety .................................................................................................................1-4

General.........................................................................................................................................................1-4

Maintenance................................................................................................................................................1-7

Chapter 2. Controls, Indicators, and Receptacles

Front Panel............................................................................................................................................................2-2

Power On/Off Switch..................................................................................................................................2-3

Air Flow Controls ........................................................................................................................................2-3

Turbo Button................................................................................................................................................2-3

Filter Life Indicator ......................................................................................................................................2-4

RapidVac+ Button.......................................................................................................................................2-4

Footswitch Jack ..........................................................................................................................................2-4

Service Required Indicator........................................................................................................................2-4

Rear Panel ............................................................................................................................................................ 2-5

Power Cord Receptacle/Fuse Tray.......................................................................................................... 2-5

Remote Activator Jack...............................................................................................................................2-6

EPROM Jack (Covered) ............................................................................................................................ 2-6

Equipotential Grounding Lug ....................................................................................................................2-6

Chapter 3. Before Surgery

Periodic Inspection...............................................................................................................................................3-2

Initial Installation...................................................................................................................................................3-2

Checking the Smoke Evacuator ........................................................................................................................3-4

Checking the Remaining Filter Life.......................................................................................................... 3-4

Changing the Filter .....................................................................................................................................3-5

Testing the Airflow Controls...................................................................................................................... 3-5

Installing and Testing the Footswitch (optional) ....................................................................................3-6

Installing and Testing the Remote Switch Activator (optional)............................................................ 3-7

Installing and Testing the Generator Interlink Cable (optional)...........................................................3-8

Setting Up the Smoke Evacuator ......................................................................................................................3-9

After the initial installation, set up the smoke evacuator for use......................................................... 3-9

RapidVac Smoke Evacuator User’s Guide vii

Mounting the Smoke Evacuator...............................................................................................................3-9

Open Procedure—Evacuating Dry Smoke............................................................................................. 3-9

Open Procedure—Evacuating Smoke and Incidental Fluids............................................................ 3-10

Chapter 4. During Surgery

Initiating Airflow ....................................................................................................................................................4-2

Minimizing Noise.................................................................................................................................................. 4-2

Variables Affecting Airflow..................................................................................................................................4-3

Changing the Airflow ........................................................................................................................................... 4-3

Periodic Checks ...................................................................................................................................................4-3

Tubing .......................................................................................................................................................... 4-3

Sponge Guard.............................................................................................................................................4-3

Filter Life Indicator...................................................................................................................................... 4-3

Chapter 5. After Surgery

Preparing the RapidVac Smoke Evacuator for Reuse...................................................................................5-2

Removing the Tubing................................................................................................................................. 5-2

Cleaning the Smoke Evacuator......................................................................................................................... 5-2

Chapter 6. Troubleshooting

Inspecting the RapidVac Smoke Evacuator .................................................................................................... 6-2

Correcting Specific Malfunctions .......................................................................................................................6-2

Chapter 7. Maintenance and Repair

Routine Maintenance .......................................................................................................................................... 7-2

Checking the Power Cord ......................................................................................................................... 7-2

Removing the RapidVac Filter ................................................................................................................. 7-2

Responsibility of the Manufacturer....................................................................................................................7-2

Obtaining a Return Authorization Number....................................................................................................... 7-3

Returning the Smoke Evacuator for Service ................................................................................................... 7-3

Service Centers....................................................................................................................................................7-3

viii RapidVac Smoke Evacuator User’s Guide

Chapter

1Introducing the

RapidVac Smoke Evacuator

This section describes the clinical applications and features of the

RapidVac Smoke Evacuator.

1

Caution

Read all warnings, cautions, and instructions provided with this smoke evacuator

before using.

Read the instructions, warnings, and cautions provided with electrosurgical

accessories before using. Specific instructions are not included in this manual.

RapidVac™ Smoke Evacuator User’s Guide 1-1

Parts Shipped with the Smoke Evacuator

Parts Shipped with the Smoke Evacuator

When unpacking the smoke evacuator, verify that the following parts are

included:

• Power cord

• User’s guide and service manual

• Quick reference card

Upon initial receipt, inspect the smoke evacuator for dents, cracks, or damage that

may have occurred during shipment. If damage is present, notify the freight

carrier for assessment.

Additional items are available from Valleylab:

• Replacement RapidVac Filters

• RapidVac Footswitch

• RapidVac Remote Switch Activator

• Generator Interlink Cable

• Laparoscopic Smoke Evacuator Tubing Kit

• Hoses, tubing, adapters, wands and other accessories

About the RapidVac Smoke Evacuator

The RapidVac Smoke Evacuator captures particulates and adsorbs gases from

surgical smoke. The smoke evacuator is specifically designed to improve

visibility and reduce potential health hazards associated with surgical smoke. It

can be used in both open and laparoscopic procedures.

The RapidVac Smoke Evacuator is designed with a high suction, high flow rate

centrifugal action pump. The ultra-quiet motor is used to draw the smoke from the

surgical site through the vacuum tubing and into the system where it is processed

by a series of filters. A single disposable filter is used to simplify the installation

and removal during filter changes. The filter is completely enclosed to protect the

healthcare personnel from potential contamination during filter changes.

One SEA3700 Filter contains four filtration stages to capture the smoke plume:

• Stage 1 - A prefilter that traps and removes gross particulate and

incidental fluid.

• Stage 2 - An ULPA grade (Ultra Low Penetration Air) patented filter

captures particulates and micro-organisms down to 0.1 µm at 99.9995%

efficiency.

• Stage 3 - The highest grade virgin activated carbon, designed specifically

for Valleylab for the removal and adsorption of odors and toxic gases

produced by burning tissue. These harmful gases may constitute a health

hazard to healthcare professionals who are subjected to prolonged

exposure. The activated carbon used in the smoke evacuation system

preferentially removes toxic organic gases (rather than water vapor) and

provides optimal odor removal.

1-2 RapidVac™ Smoke Evacuator User’s Guide

About the RapidVac Smoke Evacuator

• Stage 4 - An expanded foam used to trap activated carbon fines from

migrating out of the filter.

Features

RapidVac Smoke Evacuator features include:

• Filter-life monitoring for its four-stage, 25-five hour filter

• Standby, RapidVac+, footswitch, or continuous operation modes

• Quiet operation

• Adjustable flow

• Compatibility with all Valleylab electrosurgery pencils and generators

RapidVac+ System

The RapidVac Smoke Evacuator incorporates The RapidVac+ mode which

controls the flow of the smoke evacuator when using a Valleylab electrosurgical

pencil. When the electrosurgical pencil is activated, the smoke evacuator operates

in the preselected flow setting. When the pencil is deactivated, the air flow

reduces to a low-flow purge setting.

Introducing the RapidVac

Smoke Evacuator

Two Valleylab accessories link the electrosurgical generator and smoke evacuator

to enable the RapidVac+ mode:

• RapidVac Remote Switch Activator

• Generator Interlink Cable

Operating Modes

Four operating modes are available: standby, footswitch, RapidVac+, and

continuous.

• Standby mode powers up the unit without activating the motor or vacuum

flow.

• Footswitch mode is used to turn the smoke evacuator on or off with the

optional footswitch pedal.

• RapidVac+ mode is used to control the vacuum flow simultaneously with

activation of an electrosurgical pencil. This mode is controlled with the

optional generator interlink or electrosurgery sensor.

• Continuous mode is used to operate the smoke evacuator using continuous

air flow.

RapidVac™ Smoke Evacuator User’s Guide 1-3

Patient and Operating Room Safety

Power

This unit is equipped from the factory with either a 110 VAC hospital grade

NEMA 5-15 power cord or a 220 VAC CEE7/7 power cord. Should the AC

power cord need replacing to match another plug configuration, the replacement

plug/cable/receptacle configuration must meet or exceed the following

specifications.

100-120 VAC

Cable - SJT16/3, IEC color code, maximum length 15 ft. (5m)

Plug - minimum 10A 125 VAC

Unit receptacle - IEC female, minimum 10A 125 VAC

220-240 VAC

Cable - H05VVF3G1.0 VDE, maximum length 15 ft. (5m)

Plug - minimum 6A 250 VAC

Unit receptacle - IEC female, minimum 6A 250 VAC

Operating Parameters

Ambient temperature range 10° C to 40° C (50° F to 104° F)

Relative humidity 30% to 75%, noncondensing

Transport and Storage

Ambient temperature range -34° C to 65° C (-29° F to 149° F)

Relative humidity 25% to 85%, noncondensing

Patient and Operating Room Safety

General

Warning

Only trained personnel are to operate the RapidVac Smoke Evacuator. Operators

should avail themselves of preclinical training, a review of pertinent literature, and

other appropriate education before attempting to use the RapidVac.

During initial set up, inspect the smoke evacuator for any damage that may have

been caused during shipping. If damaged, do not use or attempt to repair. Call

Valleylab for service assistance.

1-4 RapidVac™ Smoke Evacuator User’s Guide

Patient and Operating Room Safety

Warning

Inspect the smoke evacuator before each use. If there is evidence of damage, do

not use the smoke evacuator. Call Valleylab for service assistance.

The RapidVac Smoke Evacuator filter is a disposable component that captures

potentially hazardous particles. Handle used filters as you would any

biohazardous material. Dispose of used filters according to your local codes and

regulations, and follow your institutions procedures for disposal.

The smoke evacuation filter has a life of approximately 25 hours of use and

should not be used beyond the specified time. If the Replace Filter indicator

illuminates during operation, the smoke evacuator will continue to run until it is

turned off. Turning power off to the smoke evacuator will require replacement of

the filter before subsequent use.

Failure to change the filter accordingly may result in decreased efficiency in

smoke evacuation and contamination of the motor, vacuum pump, and sound

absorbing media within the smoke evacuator.

Do not operate this device in potentially explosive environments, such as in the

presence of flammable anesthetics.

Refer routine servicing to qualified biomedical technical personnel.

Use only with the power cord provided and always plug into a grounded outlet.

Introducing the RapidVac

Smoke Evacuator

Do not use two- or three-prong adapters with the smoke evacuator’s power

cords.

The power-cord assembly should be checked periodically for damaged insulation

or connectors. Do not use damaged cords.

Use of extension cords may result in fire hazards.

This device is not intended for the evacuation of fluid. If fluid is expected to be

aspirated to the smoke evacuation filter, a fluid collection device must be installed

with the vacuum hose assembly. Failure to install a fluid collection device could

cause filter blockage and electrical damage. Contact Valleylab Service for

additional information.

Do not connect a wet power cord to the wall receptacle.

If the smoke evacuator becomes wet, either from a leaking tube or from being

sprayed, unplug the smoke evacuator from the Mains outlet. Wipe dry or allow to

air dry before proceeding.

Connect the smoke evacuator power cord to a properly grounded receptacle.

Plug the power cord directly into the power receptacle without any adapter plugs.

Use of power plug adapters may result in electric shock.

Do not remove any covers or panels exposing the internal components of the

smoke evacuator. Refer to a Valleylab representative for service.

The smoke evacuator produces a strong vacuum. Adjust the airflow and the

position of the inlet end of the wand or tubing to prevent patient injury and to

prevent suction of surgical materials and surgical specimens.

RapidVac™ Smoke Evacuator User’s Guide 1-5

Patient and Operating Room Safety

Warning

If the smoke evacuator is activated while the airflow is set to a high speed, it may

produce a sudden, strong suction action. Check the airflow setting before

activating the smoke evacuator to prevent patient injury and to prevent suction of

surgical materials and surgical specimens.

Caution

Do not stack equipment on top of the smoke evacuator or place the smoke

evacuator on top of electrical equipment. These configurations are unstable and/

or do not allow for adequate cooling.

Use only Valleylab SEA3700 Filters in the RapidVac Smoke Evacuator. Filters

from other manufacturers may cause damage to the system, thereby voiding the

warranty.

Provide as much distance as possible between the smoke evacuator and other

electronic equipment (such as monitors). An activated smoke evacuator may

cause interference with them.

Read all warnings, cautions, and instructions provided with the RapidVac Smoke

Evacuator before using.

To maximize patient safety, the tubing or wand should not come in direct contact

with tissue. Otherwise, patient injury may result.

Do not block either the tubing or the filter. If either becomes occluded or

significantly restricted, the motor/blower may overheat and cause the unit to shut

down.

Care must be exercised in the installation of hoses, adapters and suction

canisters. Failure to follow the procedures outlined in this manual may result in

overheating of the motor and may void the unit warranty.

Notice

Using any unapproved filter or accessory with the smoke evacuator may cause

damage and will void the warranty.

The RapidVac Smoke Evacuator functions properly only when the ULPA filter is

correctly installed. If the filter is installed incorrectly, the amber Replace Filter

indicator flashes and the Service Required indicator is illuminated.

Fluids may damage the filters. When evacuating smoke and incidental fluids,

always use the appropriate tubing,

Connect the power cord to a wall receptacle having the correct voltage.

Otherwise, product damage will result.

Power line voltage below 100 VAC (110V SEA3690) and 200 VAC (220V

SEA3695) will significantly reduce airflow.

Connecting multiple lengths of tubing together may cause the smoke evacuator

to overheat.

1-6 RapidVac™ Smoke Evacuator User’s Guide

Patient and Operating Room Safety

Notice

The RapidVac Smoke Evacuator has been specially designed to fit on Valleylab

mounting carts only. Do not install the smoke evacuator on a cart other than a

Valleylab cart. Installing the smoke evacuator inside a cart with improper

ventilation may result in overheating or may adversely affect the stability of the

cart.

Periodically check the cart brackets that hold the smoke evacuator in place to

ensure that the screws are securely fastened.

Stacking the smoke evacuator on top of a generator may cause an unstable

condition and/or cause the smoke evacuator to overheat.

Do not use sterile accessory products if sterile packaging has been

compromised.

Maintenance

Warning

Always turn off and unplug the smoke evacuator before cleaning.

The ULPA filter captures potentially hazardous particles. Handle used filters as

you would any biohazardous material. Dispose of filters with other operative

waste materials according to the procedures for your institution.

Introducing the RapidVac

Smoke Evacuator

Do not reuse or resterilize any product labeled “DISPOSABLE” or “SINGLE

USE.” Doing so may result in cross contamination, injury to the patient or medical

staff, or equipment malfunction.

Caution

Inspect the smoke evacuator before each use. If there is evidence of damage, do

not use the smoke evacuator. Call Valleylab for service assistance.

Notice

Do not rub, touch, or clean the smoke evacuator with alcohol or caustic,

corrosive, or abrasive cleaning or disinfectant compounds, solvents, or other

materials that could scratch the control panel or damage the smoke evacuator.

Do not autoclave, pressure sterilize, or gas sterilize the smoke evacuator.

Keep the smoke evacuator away from liquids. Liquids that enter the smoke

evacuator will damage internal components.

RapidVac™ Smoke Evacuator User’s Guide 1-7

Patient and Operating Room Safety

1-8 RapidVac™ Smoke Evacuator User’s Guide

2Controls, Indicators, and

Receptacles

This chapter describes the front and rear panels on the smoke

evacuator, including all controls, indicators, receptacles, and ports.

Chapter

2

RapidVac™ Smoke Evacuator User’s Guide 2-1

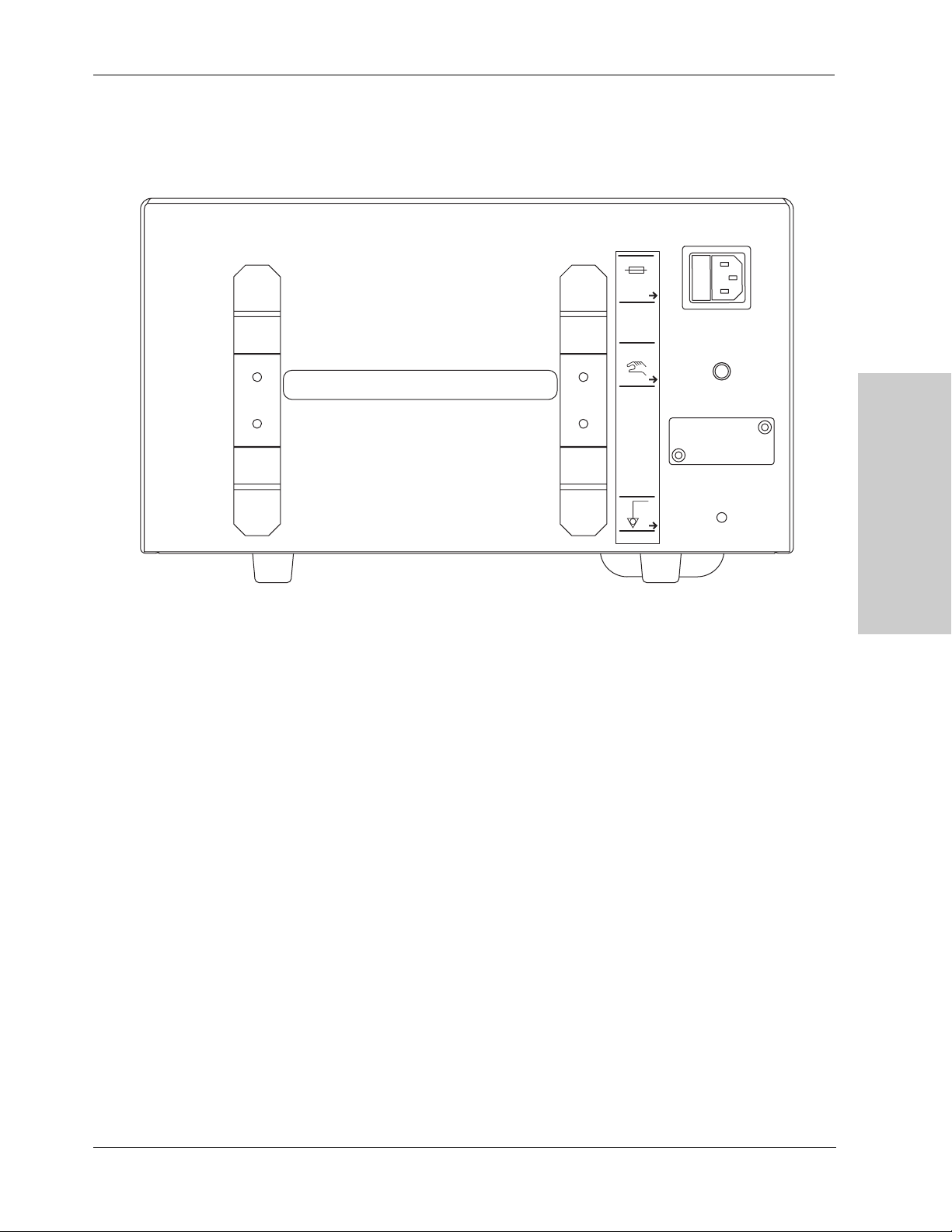

Front Panel

Front Panel

RapidVac

+

-

Smoke Evacuator

1 Power On/Off switch

2 Air-flow indicators (LED)

3 Turbo button

4 Air-flow controls

5 Power on indicator (LED centered in fan symbol)

6 Filter life indicators (LED)

7 RapidVac+ button

8 Service required indicator (LED)

9 Footswitch jack

Air filter with tubing connectors

RapidVac

1/4"

6 mm

3/8"

10 mm

7/8"

22 mm

Smoke Evacuator Filter

2-2 RapidVac™ Smoke Evacuator User’s Guide

Front Panel

Caution

Connect accessories to the proper receptacle type. Otherwise, the smoke

evacuator may not function properly.

Accessory equipment connected to interfaces must be certified according to

IEC 60601-1-1. All configurations shall comply with the system standard

IEC 60601-1-1. The user is responsible for verifying that accessory equipment

connections comply with the system requirements of IEC 60601-1-1. If in doubt,

contact Valleylab.

The electronic system controls on the RapidVac Smoke Evacuator are easy to

understand and simple to use. The control panel contains power and suction

controls, LED indicators, and connectors.

Notice

Please be sure to read all instructions before installing accessories or operating

this equipment. Failure to do so may result in damage to the unit and/or personal

injury.

Controls, Indicators, and

Receptacles

Power On/Off Switch

The power switch that controls power to the RapidVac Smoke Evacuator is

located in the lower-left corner of the front panel. To power up the smoke

evacuator, place the power switch in the ON position ( l ). The smoke evacuator

starts in standby (system power is on with no suction). When the smoke evacuator

is on in standby, the LED in the center of the fan symbol on the front panel will

blink continually until a fan speed is selected.

Turn the system power off by placing the power switch in the OFF position ( O ).

Air Flow Controls

The level of suction is controlled by the air-flow controls. up-arrow ( ) and

down-arrow ( ) buttons. To start the fan from standby mode, press the uparrow button. It starts in the lowest suction setting indicated by a single

illuminated air-flow indicator.

The suction control should be set at the lowest practical setting to completely

remove the surgical smoke from the operative site. Pressing either the up- or

down-arrow buttons changes the current suction level by 20%. The selected level

of suction is displayed by the air-flow indicator LEDs.

Turbo Button

When increased smoke removal is necessary, the Turbo button may be pressed at

anytime to increase suction. Turbo mode effectively increases the airflow to 100%

suction flow to quickly remove the smoke plume from the surgical site.

RapidVac™ Smoke Evacuator User’s Guide 2-3

Front Panel

Filter Life Indicator

The filter life indicator provides a visual indication of the status of the life of the

filter in use. Each illuminated LED represents five hours of remaining time on the

25-hour filter. The RapidVac Smoke Evacuator tracks the time each filter has

been used allowing for an accurate display of remaining use for new or previously

used filters.

Reading the Filter Life Indicator

Install an unused RapidVac filter into the system. When the smoke evacuator is

on, all five of the filter life indicator LEDs illuminate indicating the new filter has

100% filter life. The indicator will regress through subsequent LEDs until the

final LED is illuminated indicating less than 5 hours of filter life remaining. At

one hour remaining, the LED changes to amber. When the time remaining reaches

30 minutes, the amber LED flashes slowly.

RapidVac+ Button

When the smoke evacuator is connected to a generator using the Generator

Interlink Cable, pressing the RapidVac+ button synchronizes the smoke

evacuator with the use of an electrosurgical pencil. When a pencil is activated, the

smoke evacuator activates to a preselected air flow level.

Footswitch Jack

A RapidVac Footswitch (SEA3745) is available for use with the RapidVac

Smoke Evacuator.

A footswitch may be added to any system by simply plugging it into the

footswitch jack on the front panel. The unit may be turned on or off by depressing

the footswitch pedal once for each operation. For footswitching operation, the

smoke evacuator should be on and the suction level to be activated from the

footswitch should be selected on the control panel.

Service Required Indicator

The motor powering the RapidVac Smoke Evacuator has two motor brushes that

require regular maintenance every 500 hours. When the smoke evacuator has

been in use for 500 hours, the Service Required Indicator illuminates. Replace the

motor brushes and reset the Service Required Indicator as directed in the

RapidVac Smoke Evacuator Service Manual.

2-4 RapidVac™ Smoke Evacuator User’s Guide

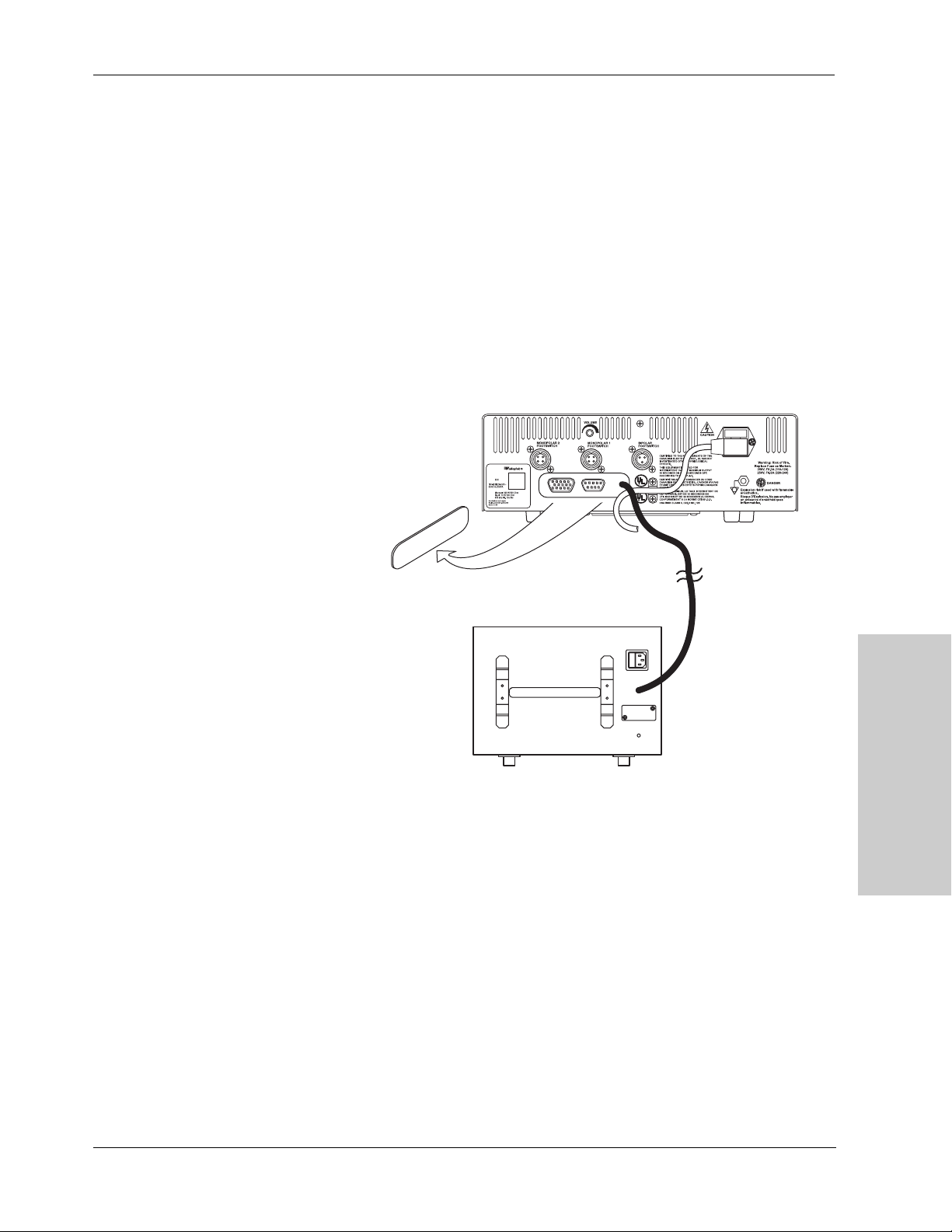

Rear Panel

250V, T10.0A-(100-120V)

250V, T8.0A-(220-240V)

Rear Panel

1 Cord brackets

2 Carrying handle

3 Power-cord receptacle/fuse tray

4 Remote Activator jack

5 EPROM jack

6 Equipotential grounding lug

Remote

Activator

Controls, Indicators, and

Receptacles

Power Cord Receptacle/Fuse Tray

The cord receptacle provides power to the smoke evacuator using a removable

cord appropriate for regional power supplies. Cord can be wound on the cord

brackets to store with the smoke evacuator.

Two 10 AMP fuses in the 110V model (8 AMP for 220V) are located in a

removable tray adjacent to the cord receptacle. Fuses electrically protect the

system from damage and the operator from injury. If the system is overheated or if

there is an electrical surge in the electrical system, fuses will open and the system

will not operate. To re-start the system, unplug the power cord and replace the

fuses.

RapidVac™ Smoke Evacuator User’s Guide 2-5

Rear Panel

Remote Activator Jack

A Generator Interlink Cable (SEA3730) and Remote Switch Activator

(SEA3740) are available for the automatic remote activation of the RapidVac

Smoke Evacuator.

The Generator Interlink Cable is compatible with the Valleylab Force FX™,

ForceEZ™, and ForceTriad™ generators. It attaches to a generator’s RF

activation port and to the smoke evacuator’s Remote Activator jack. When the

generator is activated, the smoke evacuator automatically initiates the pre-set

suction.

The Remote Switch Activator is a programmable switch that plugs into the smoke

evacuator jack and is attached to an electrosurgical generator. The remote switch

is programmed to recognize the audible tones used by the generator. When the

tone for cut or coag sounds, the remote switch automatically initiates the pre-set

suction.

EPROM Jack (Covered)

The EPROM jack located under the secured cover is to be used only by qualified

Valleylab service technicians to update the smoke evacuator’s software.

Equipotential Grounding Lug

The equipotential grounding lug provides an alternate rout for electrical energy

back to ground when attached to an earth-ground cable.

2-6 RapidVac™ Smoke Evacuator User’s Guide

3Before Surgery

This section contains procedures for:

• Periodic Inspection

Chapter

3

• Initial installation

• Checking and testing the smoke evacuator prior to use

• Preparing for evacuation of dry smoke (open procedure)

• Preparing for evacuation of smoke and incidental fluids

(open procedure)

Caution

Read all warnings, cautions, and instructions provided with this smoke evacuator

before using.

Read the instructions, warnings, and cautions provided with smoke evacuator

accessories before using. Specific instructions are not included in this manual.

RapidVac™ Smoke Evacuator User’s Guide 3-1

Periodic Inspection

Periodic Inspection

Initial Installation

The RapidVac Smoke Evacuator should be visually inspected at least every year.

This inspection should include checks for:

• Damage to the power cord.

• Damage to the power plug.

• Tightness of the power plug.

• Proper mating, cleanliness and absence of damage to the filter inlet.

• Obvious external or internal damage to the system.

To prepare the RapidVac Smoke Evacuator for use, you must verify that the filter

is installed, connect the appropriate tubing, and check the performance of the

smoke evacuator indicators and controls.

Notice

Stacking the smoke evacuator on top of a generator may cause an unstable

condition and/or cause the smoke evacuator to overheat.

1. Inspect the power cord for any signs of visible damage. If it is in good

condition, plug the power cord into a grounded wall receptacle.

Warning

Connect the smoke evacuator power cord to a properly grounded, hospital grade

receptacle of the correct voltage. Plug the power cord directly into the power

receptacle without any extension cords and/or adapter plugs.

2. Insert a RapidVac SEA3700 filter into the square opening on the right side of

the smoke evacuator. Slide the filter into place until it is fully seated and the

locking mechanism clicks into place.

RapidVac

S

mo

k

e

E

v

a

c

ua

t

o

r

+

-

1/4"

6 mm

3/8"

10 mm

7/8"

22 mm

3. Turn on power to the smoke evacuator by pressing the on switch ( l ) located

on the front panel.

3-2 RapidVac™ Smoke Evacuator User’s Guide

Initial Installation

4. The smoke evacuator performs a self test. Verify that all LEDs are illuminated

during the test. When the test is complete, the RapidVac is placed in standby

mode signified by an illuminated power on LED within the fan symbol and no

active suction.

5. (Optional) Connect the RapidVac Remote Switch Activator (SEA3740) to the

Remote Switch jack on the back panel of the smoke evacuator. Use only the

RapidVac Remote Switch Activator. Other remote units are not compatible.

6. (Optional) Connect the Generator Interlink Cable (SEA3730) to the Remote

Switch jack on the back panel of the smoke evacuator. and to the rear panel of

the compatible Valleylab generator. Use only the Valleylab Interlink Cable.

Other cables may not be compatible.

7. (Optional) Connect the RapidVac Footswitch to the front panel of the smoke

evacuator. Use only Valleylab footswitches with the RapidVac Smoke

Evacuator.

Before Surgery

RapidVac™ Smoke Evacuator User’s Guide 3-3

Checking the Smoke Evacuator

Checking the Smoke Evacuator

Before each use, test the following smoke evacuator components to verify

performance:

• RapidVac ULPA filter

•Airflow controls

• Footswitch (as applicable)

• Remote switch activator (as applicable)

• Generator interlink (as applicable)

If the system does not respond as indicated below, refer to Chapter 6,

Troubleshooting.

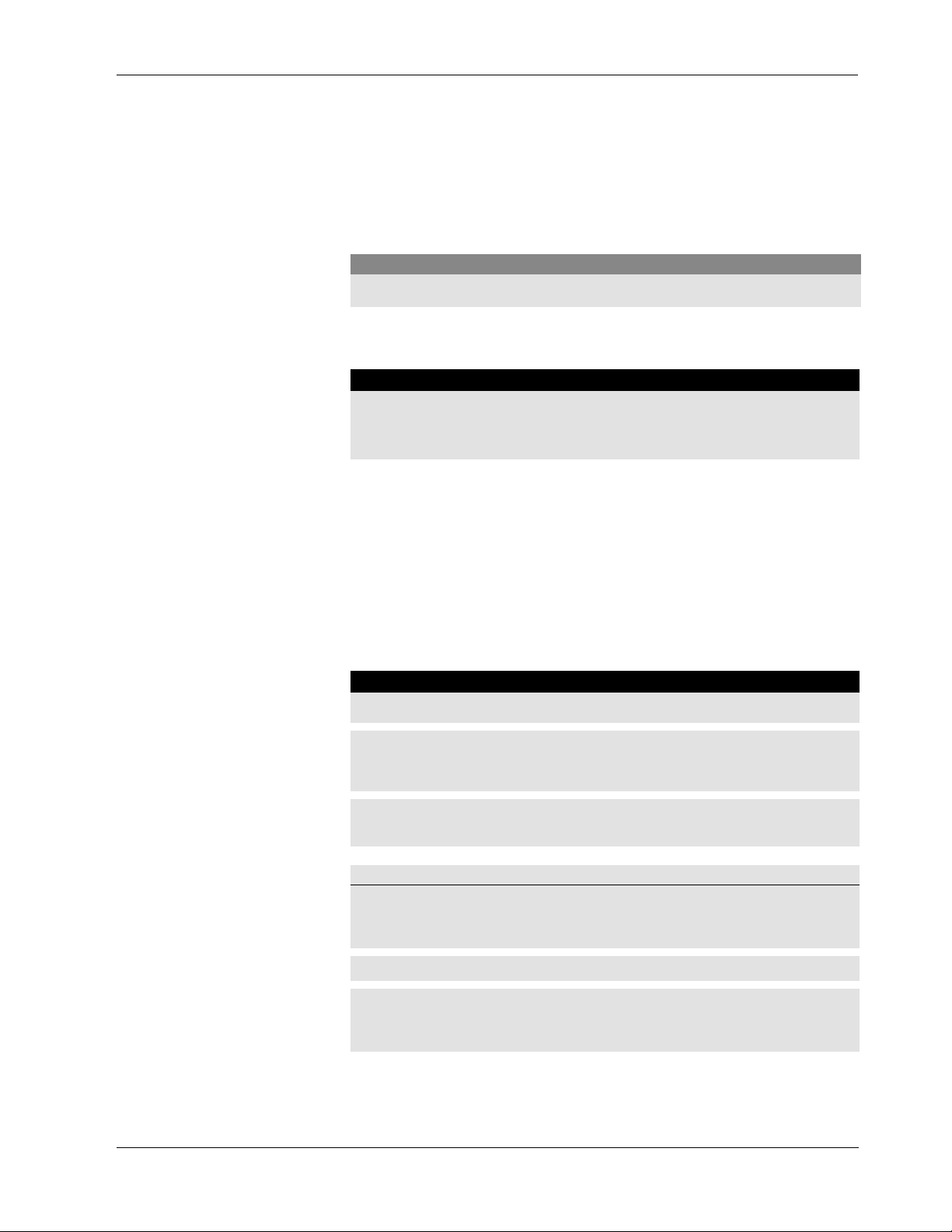

Checking the Remaining Filter Life

RapidVac Smoke Evacuator filters have a use duration of 25 hours. As a filter is

used, information about the amount of time the individual filter has been used is

stored on the filter’s RFID tag. Whenever a new or previously used filter is

inserted, the smoke evacuator reads the stored information from the tag. The

remaining filter life is visually displayed by the corresponding number of filter

life indicators on the smoke evacuator front panel.

1. Turn on the smoke evacuator and insert a filter.

2. Check the filter life indicators on the front panel to verify the filter has ample

remaining time to complete a procedure.

Illuminated Filter Life

Remaining Use

Indicators

All 25 to 20 hours

4 20 to 15 hours

3 15 to 10 hours

2 10 to 5 hours

1 (green) 5 hours to 1 hour

1 (amber) less than 1 hour

1 (flashing amber) less than 30 minutes

Important

Replace the filter when indicated. Failure to replace the filter may reduce airflow

and compromise the efficiency of the filter.

3-4 RapidVac™ Smoke Evacuator User’s Guide

Checking the Smoke Evacuator

Changing the Filter

Warning

The ULPA filter captures potentially hazardous particles. Handle used filters as

you would any biohazardous material. Dispose of filters with other operative

waste materials according to the procedures for your institution.

1. Remove the filter by depressing the locking tab on the top edge of the filter

while pulling the filter straight out of the opening.

2. Dispose of the filter with other operative waste according to the procedures

for your institution.

3. Install a new filter in the smoke evacuator as described earlier in this section.

Testing the Airflow Controls

Warning

The smoke evacuator produces a strong vacuum. Properly adjust the airflow and

the position of the inlet end of the wand or tubing to prevent patient injury and to

prevent suction of surgical materials and surgical specimens.

You can start, stop, and change the vacuum airflow rate when the smoke

evacuator is on. Illuminated LEDs display the airflow setting. Each pressing of

the up-arrow ( ) or down-arrow ( ) increases or decreases suction by 20%.

There are five suction flow indicator LEDs that light in succession. Turbo Mode

illuminates the sixth LED next to the Turbo button.

Suction Flow Illuminated Suction Flow

Indicators

No suction (Standby Mode) None (LED at the center of the fan

symbol blinks)

20% motor speed 1

40% motor speed 2

60% motor speed 3

80% motor speed 4

100% motor speed 5

Turbo Mode (100%) 6

Before Surgery

1. Verify that the filter is installed properly.

2. Ensure that the power cord is plugged into a hospital grade power receptacle.

RapidVac™ Smoke Evacuator User’s Guide 3-5

Checking the Smoke Evacuator

3. Turn on the smoke evacuator by pressing the power on switch ( | ) on the

lower left of the front panel. The smoke evacuator powers up with the fan

motor off (standby mode). The LED in the center of the fan symbol blinks

indicating power is on.

4. Press the up-arrow ( ) button once to start suction at the lowest air-flow

setting.

5. Press the up-arrow ( ) button and pause briefly to progress to the next level

of suction. Verify that the level of suction noticeably increases with each

progression.

6. When all suction flow LEDs are lit steadily (100% motor speed), press the

down-arrow ( ) button repeatedly to regress through the settings to the

lowest setting.

Installing and Testing the Footswitch (optional)

Only use the Valleylab Footswitch with the smoke evacuator. Other footswitches

are not compatible.

1. Turn on the smoke evacuator.

2. Connect the footswitch cord to the footswitch jack on the front panel.

3. Turn on the airflow to any setting.

4. Press the footswitch once to turn off the airflow.

5. Press the footswitch again to activate the airflow.

3-6 RapidVac™ Smoke Evacuator User’s Guide

Checking the Smoke Evacuator

Installing and Testing the Remote Switch Activator

(optional)

Use the Valleylab Remote Switch Activator with any of Valleylab’s

electrosurgical pencils and generators.

1. Select a location on the generator near the speaker where the Remote Switch

Activator is to be mounted.

2. Clean the surface of the selected area with alcohol. Allow the alcohol to

evaporate.

3. Remove the backing from the gasket on the RSA.

4. Affix the RSA to the generator.

5. Plug the RSA connector into the Remote Activator jack located on the back

panel of the smoke evacuator.

6. Turn on the smoke evacuator and press the up-arrow ( ) button twice to

illuminate the first two air flow indicators (40% motor speed).

7. Set up the surgical pencil and generator as instructed in their user

documentation. If the generator’s audible-tone volume can be adjusted, set it

at 50%.

8. Initiate programming the Remote Switch Activator by pressing the

Program/Reset button continually for 10 seconds.

9. Set the generator to cut mode.

10. Activate the generator in cut mode until the smoke evacuator motor starts.

Depending on the generator, this may take up to 40 seconds.

11. When the smoke evacuator motor starts, deactivate the generator in cut mode.

Important

Do not activate the generator in cut mode again until the Remote Switch Activator

has been programmed in coag mode.

12. Set the generator to coag mode.

13. Activate the generator in coag mode until the smoke evacuator motor starts.

Depending on the generator, this may take up to 40 seconds.

14. When the smoke evacuator motor starts, deactivate the generator in coag

mode.

Important

If the generator has only one tone, program this same tone into the Remote

Switch Activator memory.

If both the cut and coag tones are not activating the smoke evacuator reprogram

the Remote Switch Activator. Disconnect the Remote Switch Activator from the

smoke evacuator, then re-connect. Repeat the programming instructions

beginning with step 8.

Before Surgery

The Remote Switch Activator is now programmed. Powering on and off the

RapidVac Smoke Evacuator is now controlled by the generator and Remote

Switch Activator.

RapidVac™ Smoke Evacuator User’s Guide 3-7

Checking the Smoke Evacuator

Important

If the attached smoke evacuator is to be disconnected from the generator, unplug

the Remote Switch Activator from the smoke evacuator. The Remote Switch

Activator should remain affixed to the generator to which it was programmed. The

RapidVac Smoke Evacuator cannot be operated manually or with a footswitch

while the Remote Switch Activator is plugged into the smoke evacuator.

If the Remote Switch Activator is moved to another generator, it must be

reprogrammed using the steps in this section.

Installing and Testing the Generator Interlink Cable

(optional)

The Generator Interlink Cable attaches to a RapidVac Smoke Evacuator and a

compatible Valleylab generator to synchronize smoke evacuation with the

activation of the generator. The cable is compatible with the Valleylab generator

models Force FX™, ForceEZ™, and ForceTriad™.

1. Turn power off and unplug the smoke evacuator and generator from the power

source.

2. Remove the metal cover plate in the center of the generator back panel to

access optional ports.

3. Plug the interlink cable into the generator RF Activation port.

4. Plug the interlink cable into the Remote Activator jack on the back panel of

the smoke evacuator.

5. Plug the generator and smoke evacuator into outlets of proper voltage.

6. Turn power on to both devices.

7. When the generator and smoke evacuator have completed their self tests, set

the level of suction to be used when the smoke evacuator is activated.

8. Press press the up-arrow ( ) button until reaching the desired pre-setting.

9. Press the RapidVac+ button.

The pre-set suction level is now selected. The smoke evacuator continues to run

and suction reduces to a minimal level. Use of the surgical pencil will

automatically activate the RapidVac to the pre-set suction level. When the pencil

is deactivated, the smoke evacuator will return to minimal suction.

3-8 RapidVac™ Smoke Evacuator User’s Guide

Setting Up the Smoke Evacuator

Warning

Connect the smoke evacuator power cord to a properly grounded receptacle.

Plug the power cord directly into the power receptacle without any adapter plugs.

Use of power plug adapters may result in electric shock.

Use of extension cords may result in fire hazards.

After the initial installation, set up the smoke evacuator for use.

Mounting the Smoke Evacuator

The smoke evacuator may be mounted in the following locations:

• The Valleylab UC8009 Universal Mounting Cart—primary, secondary, or

suspended shelf

• ForceTriad Cart FT900

• Boom systems

Setting Up the Smoke Evacuator

• Stable, flat surfaces

This section describes how to set up for the following procedures:

• Open procedure—evacuating dry smoke

• Open procedure—evacuating smoke and incidental fluids

Open Procedure—Evacuating Dry Smoke

Notice

Connecting multiple lengths of tubing together may cause the smoke evacuator

to overheat.

1. Verify the installed filter has enough available filter life to complete the

procedure.

2. Connect your choice of tubing to the corresponding filter tubing connection.

Notice

Do not connect more than one set of tubing to the smoke evacuator filter at one

time. Suction levels and air flow will be adversely affected.

Before Surgery

RapidVac™ Smoke Evacuator User’s Guide 3-9

Setting Up the Smoke Evacuator

Open Procedure—Evacuating Smoke and Incidental

Fluids

The primary function of the smoke evacuator is to evacuate surgical smoke. A

fluid canister is recommended to prevent the filters from getting wet when

evacuating smoke that may contain incidental fluids.

Notice

Fluids may damage the filters. When evacuating smoke and incidental fluids,

always use the appropriate tubing and fluid canister.

Check the fluid level in the canister frequently during surgery. If the fluid canister

overfills, smoke evacuator damage will result.

Connecting multiple lengths of tubing together may cause the smoke evacuator

to overheat.

1. Verify the installed filter has enough available filter life to complete the

procedure.

2. Insert a fluid canister in-line with the smoke evacuator tubing.

3-10 RapidVac™ Smoke Evacuator User’s Guide

3During Surgery

Chapter

4

This chapter covers the following topics:

• Minimizing airflow noise

• Changing and adjusting airflow

• Checking the tubing

• Checking the prefilter

• Checking the sponge guard

RapidVac™ Smoke Evacuator User’s Guide 4-1

Initiating Airflow

Initiating Airflow

Warning

The smoke evacuator produces a strong vacuum. Adjust the airflow and the

position of the inlet end of the wand or tubing to prevent patient injury and to

prevent suction of surgical materials and surgical specimens.

If the smoke evacuator is activated while the airflow is set to a high speed, it may

produce a sudden, strong suction action. Check the airflow setting before

activating the smoke evacuator to prevent patient injury and to prevent suction of

surgical materials and surgical specimens.

The smoke evacuation filter has a life of approximately 25 hours of use and

should not be used beyond the specified time. If the Replace Filter indicator

illuminates during operation, the smoke evacuator will continue to run until it is

turned off. Turning power off to the smoke evacuator will require replacement of

the filter before subsequent use.

This device is not intended for the evacuation of fluid. If fluid is expected to be

aspirated to the smoke evacuation filter, a fluid collection device must be installed

with the vacuum hose assembly. Failure to install a fluid collection device could

cause filter blockage and electrical damage. Contact Valleylab Service for

additional information.

Minimizing Noise

Caution

To maximize patient safety, the tubing or wand should not come in direct contact

with tissue. Otherwise, patient injury may result.

1. Verify that all tubing is connected.

2. Turn on the smoke evacuator by pressing the power on switch ( | ) on the front

panel. The smoke evacuator powers up with the fan motor off. The smoke

evacuator is in standby mode which is indicated by a blinking LED in the

center of the fan symbol.

3. Press the up-arrow ( ) button once to start suction at the lowest air-flow

setting.

The higher the power setting, the greater the noise. Minimize noise by using a

lower power setting. Effectiveness of a lower power setting can be maximized by

using a larger diameter tubing and/or positioning the tubing closer to the source of

smoke.

4-2 RapidVac™ Smoke Evacuator User’s Guide

Variables Affecting Airflow

The following factors may affect airflow:

• Diameter of the tubing—with larger diameter tubing, airflow improves

• Airflow settings

• Attachments

Changing the Airflow

You can change the airflow while the smoke evacuator is in use.

1. Adjust the air flow by pressing the up-arrow ( ) to increase or the down-

arrow ( ) button to decrease.

2. Verify that the indicator illuminates for the speed setting you selected.

Periodic Checks

Variables Affecting Airflow

During surgery periodically check the accessories described below.

Tubing

Check for clogged, occluded, or kinked tubing during surgery.

Sponge Guard

If a sponge guard is in use, ensure it is fully attached to the sterile tubing to

prevent suction of surgical materials.

Filter Life Indicator

Monitor the remaining life of the filter by viewing the Filter Life Indicator LEDs

on the smoke evacuator front panel.

During Surgery

RapidVac™ Smoke Evacuator User’s Guide 4-3

Periodic Checks

4-4 RapidVac™ Smoke Evacuator User’s Guide

3After Surgery

This chapter covers the following topics:

• Preparing the smoke evacuator for reuse

• Cleaning the smoke evacuator

Chapter

5

RapidVac™ Smoke Evacuator User’s Guide 5-1

Preparing the RapidVac Smoke Evacuator for Reuse

Preparing the RapidVac Smoke Evacuator for Reuse

After surgery, prepare the smoke evacuator for reuse by performing the following

procedures:

• Remove the tubing

• Clean the smoke evacuator

Caution

Do not reuse or resterilize accessories labeled “disposable” or “single use only.”

Removing the Tubing

Warning

The tubing and filter capture potentially hazardous particles. When removed,

handle as you would any biohazardous material. Dispose of these items with

other operative waste materials according to the procedures for your institution.

1. Press the power switch (O) on the front panel to turn off the smoke evacuator.

2. If applicable, disconnect the tubing from any reusable instrument that will not

be discarded with the tubing.

3. Disconnect the tubing from the smoke evacuator.

Cleaning the Smoke Evacuator

Warning

Always turn off and unplug the smoke evacuator before cleaning.

The tubing and filter capture potentially hazardous particles. When removed,

handle as you would any biohazardous material. Dispose of these items with

other operative waste materials according to the procedures for your institution.

Wear appropriate protective gear when cleaning the filter ports and covering flap

to avoid coming in contact with incidental contaminants on these surfaces.

Notice

Do not rub, touch, or clean the smoke evacuator with alcohol or caustic, corrosive

or abrasive cleaning or disinfectant compounds, solvents, or other materials that

could scratch the control panel or damage the smoke evacuator.

Do not autoclave, pressure sterilize, or gas sterilize the smoke evacuator.

Keep the smoke evacuator away from liquids. Liquids that enter the smoke

evacuator will damage internal components. Do not spray liquid cleaner into the

filter ports.

1. Ensure that the power switch on the front panel is off (O).

2. Disconnect the power cord from the wall receptacle.

5-2 RapidVac™ Smoke Evacuator User’s Guide

Cleaning the Smoke Evacuator

3. Disconnect tubing as directed in the previous section.

4. Thoroughly wipe all external surfaces with a mild detergent or disinfectant.

5. Thoroughly clean both sides of the flap covering the filter ports. Do not spray

liquid cleaner into the filter ports.

6. Clean the surface around the filter ports. Do not spray liquid cleaner into the

filter ports. Follow procedures approved by your institution, or use a validated

infection-control procedure.

Warning

Wear protective gloves when cleaning around filter ports. Do not place fingers

into ports or touch the internal surface of the ULPA filter. Contaminants may be

present.

7. Ensure the smoke evacuator is completely dry before use.

8. Reconnect the power cord to the wall receptacle.

After Surgery

RapidVac™ Smoke Evacuator User’s Guide 5-3

Cleaning the Smoke Evacuator

5-4 RapidVac™ Smoke Evacuator User’s Guide

9Troubleshooting

This chapter describes solutions to problems that may occur when

operating the smoke evacuator.

If the smoke evacuator is not functioning properly, use the

information in this section to help identify and correct the

Chapter

6

malfunction.

RapidVac™ Smoke Evacuator User’s Guide 6-1

Inspecting the RapidVac Smoke Evacuator

Inspecting the RapidVac Smoke Evacuator

If there is a problem with the operation of the smoke evacuator, inspect the unit

for obvious conditions that can cause a malfunction:

• Check for visible signs of damage

• Verify the connections of all cables and tubing

• Verify proper filter installation

• Verify that the power switch is on and the power-on indicator LED in the

center of the fan symbol is blinking.

• Check the filter life indicators to ensure the filter has available filter time

remaining.

Correcting Specific Malfunctions

If a solution to the problem is not readily apparent, use the following table to help

identify and correct specific malfunctions. After you correct the malfunction,

verify that the smoke evacuator is in proper working order.

Situation Possible Cause Recommended Action

Smoke evacuator is on but there is

minimal or no vacuum or airflow at

the wand or tubing

Smoke evacuator does not adsorb

odors

Smoke evacuator does not

operate

Improperly installed ULPA filter Ensure the ULPA filter is properly

installed. Reposition if necessary.

Clogged tubing Unclog/replace the tubing.

Clogged ULPA filter Replace the filter.

Obstructed or malfunctioning motor

and/or blower

Charcoal component of the filter has

expired

Disconnected or faulty power cord Check and correct the power cord

No power from wall receptacle (power

cord is connected to wall receptacle,

but Mode Indicator is not illuminated)

Power switch on the front panel is off

(

O)

Contact Valleylab service for

assistance.

Replace the filter.

connections. Check the cord for

damage. Replace cord if needed.

Check the power at the wall

receptacle. Connect power cord to a

functional wall receptacle.

Turn the power switch on (|).

Fuses damaged Check the fuses to see if they have

burned through from being over

loaded or otherwise damaged.

Replace fuses if needed.

6-2 RapidVac™ Smoke Evacuator User’s Guide

Correcting Specific Malfunctions

Situation Possible Cause Recommended Action

Footswitch does not activate

smoke evacuator when Footswitch

mode is selected

Indicator LEDs do not illuminate No electrical power Refer to electrical utility maintenance.

Motor does not run, but Power On

LED illuminates

Improperly connected footswitch Check that the footswitch is securely

connected at the front of the smoke

evacuator.

Malfunctioning footswitch Replace the footswitch.

Incorrect footswitch connected to the

smoke evacuator

Filter incorrectly installed Reinstall the filter. Ensure that the

Malfunction in the smoke evacuator Contact Valleylab service.

Fuses damaged Check the fuses to see if they have

Malfunction in the smoke evacuator Contact Valleylab service.

Filter incorrectly installed Reinstall the filter. Ensure the filter is

Connect the RapidVac Footswitch

(SEA3745) to the smoke evacuator.

filter is fully seated in the smoke

evacuator and the securing tab locks

into place.

burned through from being over

loaded or otherwise damaged.

Replace fuses if needed.

fully seated in the smoke evacuator

and the securing tab locks into place.

Troubleshooting

ESU remote does not activate

when RapidVac mode is selected

Malfunction in smoke evacuator Contact Valleylab service.

Generator interlink cable incorrectly

installed

Remote Switch Activator incorrectly

installed

ULPA filter incorrectly installed Reinstall the filter. Ensure the filter is

Ensure the generator interlink is

properly connected to the rear panel

of the smoke evacuator and the

Valleylab generator.

Ensure the Remote Switch Activator

is connected to the rear of the smoke

evacuator.

or

Check the ESU pencil lead installation

on the electrosurgery sensor bobbin.

fully seated in the smoke evacuator

and the securing tab locks into place.

RapidVac™ Smoke Evacuator User’s Guide 6-3

Correcting Specific Malfunctions

6-4 RapidVac™ Smoke Evacuator User’s Guide

10Maintenance and Repair

Chapter

7

Refer to this chapter for information on:

• Routine maintenance

• The manufacturer’s responsibility

• Returning the smoke evacuator for service

• Service centers

RapidVac™ Smoke Evacuator User’s Guide 7-1

Routine Maintenance

Routine Maintenance

The RapidVac Smoke Evacuator requires very little maintenance. Periodically,

you must check the power cord and replace the filter. Periodic inspections and

performance tests are recommended by a qualified biomedical technician to

ensure safe and efficient operation.

Checking the Power Cord

Inspect the power cord each time you use the smoke evacuator, or at intervals

recommended by your institution. Make sure the power cord is in good working

condition, without exposed wires, cracks, or frayed areas.

Removing the RapidVac Filter

The filter removes odorous gases and submicron particles from surgical smoke.

Important

If the Replace Filter indicator illuminates, remove and replace the filter. Failure to

do so may reduce airflow and compromise the efficiency of the filter.

Warning

The ULPA filter captures potentially hazardous particles. Handle used filters as

you would any biohazardous material. Dispose of filters with other operative

waste materials according to the procedures for your institution.

1. Ensure that the smoke evacuator power switch on the front panel is off (O).

2. Depress the locking tab on the top edge of the filter and pull straight out of the

smoke evacuator.

3. Dispose of the filter with other operative waste materials according to the

procedures for your institution.

Responsibility of the Manufacturer

Valleylab is responsible for the safety, reliability, and performance of the smoke

evacuator only under the following circumstances:

• Installation and setup procedures in this manual are followed.

• Readjustments, modifications, or repairs to the unit are carried out by persons

authorized by Valleylab.

• The electrical installation of the relevant room complies with local codes and

regulatory requirements, such as UL.

• The accessories are used in accordance with the Valleylab instructions for

use.

For warranty information, refer to the Warranty at the beginning of this guide.

7-2 RapidVac™ Smoke Evacuator User’s Guide

Obtaining a Return Authorization Number

Obtaining a Return Authorization Number

Notice

For repairs, return the smoke evacuator to Valleylab.

Before you return the smoke evacuator, call the Valleylab Customer Service

Department (1-800-255-8522) for a Return Authorization Number or call your

Valleylab Representative for assistance.

Have the following information ready when you call:

• Hospital/clinic name/customer number

• Telephone number

• Department/address, city, state, and zip code

• Model number

• Serial number

• Description of the problem

Returning the Smoke Evacuator for Service

Follow this procedure when returning the smoke evacuator for service. Service

center information is provided below.

1. Remove the filter and any attached tubing and fluid container.

Warning

The ULPA filter captures potentially hazardous particles. Handle used filters as

you would any biohazardous material. Dispose of filters with other operative

waste materials according to the procedures for your institution.

2. Clean the smoke evacuator thoroughly. Follow the procedures approved by

your institution or use a validated infection control procedure.

3. Attach a tag to the smoke evacuator that includes the Return Authorization

Number and the information listed above (i.e., hospital, phone number, etc.).

4. Be sure the smoke evacuator is completely dry. Then, package the smoke

evacuator in its original shipping container, if available.

5. When you receive the Return Authorization Number, ship the smoke

evacuator prepaid according to Valleylab's instructions.

Maintenance and Repair

Service Centers

For a complete list of service centers worldwide, please refer to the Valleylab

website:

http://www.valleylab.com/valleylab/international/service-world.html

RapidVac™ Smoke Evacuator User’s Guide 7-3

Service Centers

7-4 RapidVac™ Smoke Evacuator User’s Guide

AAccessories

The accessories listed in this chapter are recommended for use

with the RapidVac Smoke Evacuator. Accessories can be ordered

through your Valleylab Sales Representative.

Product Catalog No

Chapter

8

RapidVac Filter SEA3700

Tubing, 6 mm x 3 m (1/4 in x 10 ft), sterile SEA3705

Tubing, 10 mm x 3 m (3/8 in x 10 ft), sterile SEA3710

Tubing with Sponge Guard, 2 cm x 3 m (7/8 in x 10 ft), sterile SEA3715

Laparoscopic Tubing Kit with Valve SEA3720

Wand, Laser Resistant, 2 cm x 20 cm (7/8 in x 8 in) SEA3725

Generator Interlink Cable SEA3730

AccuVac Attachment with Tubing, 10 mm x 3 m (3/8 in x 10 ft) SEA3735

RapidVac Remote Switch Activator SEA3740

RapidVac Footswitch SEA3745

RapidVac™ Smoke Evacuator User’s Guide 8-1

8-2 RapidVac™ Smoke Evacuator User’s Guide

Loading...

Loading...