Page 1

Service Manual

Valleylab™

Argon Gas Delivery Unit II

1012506

Valleylab Argon Gas Delivery Unit II Service Manual i

Page 2

Preface

This manual and the equipment it describes are for use only by qualified medical

professionals trained in the particular technique and surgical procedure to be performed.

It is intended as a guide for servicing the Force FX Electrosurgical Generator C only.

Additional users information is available in the Valleylab Argon Gas Delivery Unit II User’s

Guide.

Equipment covered in this manual:

Valleylab Argon Gas Delivery Unit II (Force Argon II-20)

120 VAC nominal, 50–60 Hz

The Valleylab Argon Gas Delivery Unit II Service Manual consists of two parts: the text

(part 1 of 2) and a Schematics Supplement (part 2 of 2) which contains the schematics.

Conventions Used in this Guide

Warning

Indicates a potentially hazardous situation, which if not avoided, could result in death or serious

injury.

Caution

Indicates a hazardous situation, which if not avoided, may result in minor or moderate injury.

Notice

Indicates a hazard which may result in product damage.

Important

Indicates an operating tip or maintenance suggestion.

ii Valleylab Argon Gas Delivery Unit II Service Manual

Page 3

Limited Warranty

Covidien warrants each covered product listed below to be free from defects in material

and workmanship for normal use and service for the period(s) set forth below. Covidien’s

obligation under this warranty is limited to the repair or replacement, at its sole option,

of any product, or part thereof, which has been returned to it (or its authorized

distributor) within the applicable time period shown below after delivery of the product

to the original purchaser, and which examination discloses, to Covidien’s satisfaction, that

the product is defective. This limited warranty does not apply to any product, or part

thereof, which has been repaired or altered in a way so as, in Covidien’s judgment, to

affect its stability or reliability, or which has been subjected to misuse, neglect, or

accident.

The warranty periods for Covidien products are as follows:

ForceTriadTM Energy Platform One year from date of shipment

Electrosurgical Generators One year from date of shipment

TM

Cool-tip

EvidentTM MWA Generator One year from date of shipment

RFG-3C

LigaSure

RFA Generator One year from date of shipment

TM

Plus Lesion Generator One year from date of shipment

TM

Vessel Sealing System One year from date of shipment

LigaSureTM Reusable Instruments One year from date of shipment

Mounting Fixtures (all models) One year from date of shipment

Footswitches (all models) One year from date of shipment

TM

Valleylab

RapidVac

LigaSure

Argon Gas Delivery Unit II One year from date of shipment

TM

Smoke Evacuator One year from date of shipment

TM

Sterile Single Use Items Sterility only as stated on packaging

Cool-tipTM Sterile Single Use Items Sterility only as stated on packaging

Sterile Single Use Items Sterility only as stated on packaging

Patient Return Electrodes Shelf life only as stated on packaging

Notwithstanding any other provision herein or in any other document or communication,

Covidien’s liability with respect to this limited warranty and the products sold hereunder

shall be limited to the aggregate purchase price for the products sold to the customer.

This limited warranty is non-transferable and runs only to the original purchaser of the

Valleylab Argon Gas Delivery Unit II Service Manual iii

Page 4

covered product(s). There are no warranties which extend beyond the terms hereof.

Covidien disclaims any liability hereunder or elsewhere in connection with the sale of

products and for any form of indirect, tort, or consequential damages.

This limited warranty and the rights and obligations hereunder shall be construed under

and governed by the laws of the State of Colorado, USA. The sole forum for resolving

disputes arising under or relating in any way to this limited warranty is the District Court

of the County of Boulder, State of Colorado, USA.

Covidien reserves the right to make changes in covered products built or sold by it at any

time without incurring any obligation to make the same or similar changes to equipment

previously built or sold by it.

THE OBLICATION TO REPAIR OR REPLACE A DEFECTIVE OR NONPERFORMING PRODUCT

IS THE SOLE REMEDY OF THE CUSTOMER UNDER THIS LIMITED WARRANTY. EXCEPT AS

EXPRESSLY PROVIDED HEREIN, COVIDIEN DISCLAIMS ALL OTHER WARRANTIES,

WHETHER EXPRESS OR IMPLIED, ORAL OR WRITTEN, WITH RESPECT TO

PRODUCTS, INCLUDING WITHOUT LIMITATION ALL IMPLIED WARRANTIES,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

iv Valleylab Argon Gas Delivery Unit II Service Manual

Page 5

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Conventions Used in this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Chapter 1. Introduction

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

List of Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Service Personnel Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General Service Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Fire/Explosion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Electric Shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

High Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Argon Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2. Controls, Indicators, and Receptacles

Valleylab Argon Gas Delivery Unit II

Front Panel Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Overpressure System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

System Purge Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Gas Flow Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Gas Tank Indicators and Controls . . . . . . . . . . . . . . . . . . . . . 2-3

Gas Lines and Receptacles. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Chapter 3. Technical Specifications

Performance Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Standard Conditions of Measurement . . . . . . . . . . . . . . . . . 3-2

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Storage and Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Input Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Low Frequency Leakage (50Hz – 60 Hz). . . . . . . . . . . . . . . . 3-2

Gas Flow Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Audio Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Approximate Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Gas Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Power Cord Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Standards and IEC Classifications . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Type CF Equipment (IEC 60601-1) /Defibrillator Proof . . . . 3-4

Liquid Spillage (IEC 60601-2-2 Clause 44.3) . . . . . . . . . . . . . 3-4

Valleylab Argon Gas Delivery Unit II Service Manual v

Page 6

EMC Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Electromagnetic Compatibility (IEC 60601-1-2 and

IEC 60601-2-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Chapter 4. Principles of Operation

Functional Descriptive Overview . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Circuit Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Main Microprocessor (Control Board, sheet 2 of 8). . . . . . . 4-2

RS-232 Interface (Control Board, sheet 2 of 8). . . . . . . . . . . 4-2

Address Latches and I/O Decoders (Control Board,

sheet 2 of 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Solenoid Drivers (Control Board, sheet 3 of 8). . . . . . . . . . . 4-3

Audio Amplifier (Control Board, sheet 3 of 8). . . . . . . . . . . 4-3

Solenoid Master Power Switch (Control Board,

sheet 3 of 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Watchdog Circuitry (Control Board, sheet 4 of 8) . . . . . . . . 4-3

Malfunction Microprocessor (Control Board, sheet 4 of 8). 4-4

Argon Gas Tank Pressure Scale (Control Board,

sheet 4 of 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Display Interface and Lamp Drivers (Control Board,

sheet 4 of 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Argon Gas Tank Detection and Measurement (Control Board,

sheet 5 of 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Pressure Transducers (Control Board, sheet 6 of 8 and

sheet 7 of 8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Overvoltage Monitors (Control Board, sheet 6 of 8). . . . . . 4-5

A-D Converter (Control Board, sheet 6 of 8) . . . . . . . . . . . . 4-5

DC Power Connector (Control Board, sheet 6 of 8). . . . . . . 4-5

IsoBloc Circuit Modules (Control Board, sheet 8 of 8) . . . . . 4-5

Lamps and LEDs (Display Board, sheet 2 of 4) . . . . . . . . . . . 4-5

Switch Read Buffer (Display Board, sheet 2 of 4) . . . . . . . . 4-6

Bar Graph Display Driver (Display Board, sheet 3 of 4) . . . . 4-6

Seven Segment Display Driver (Display Board,

sheet 4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

ESU Interface Connector (Footswitch Board, sheet 1 of 1) . 4-6

Footswitch Connector (Footswitch Board, sheet 1 of 1) . . . 4-6

Speaker (Footswitch Board, sheet 1 of 1). . . . . . . . . . . . . . . 4-6

Software Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

vi Valleylab Argon Gas Delivery Unit II Service Manual

Page 7

Chapter 5. Setup, Tests, and Adjustments

Setting up the Valleylab Argon Gas Delivery Unit II . . . . . . . . . 5-2

Unpacking and Installing the Unit . . . . . . . . . . . . . . . . . . . . 5-2

Connecting the Argon Gas Tank(s). . . . . . . . . . . . . . . . . . . . 5-2

Constructing an Extended Length Argon Gas Supply Hose 5-3

Removing the argon gas supply hose from the Valleylab Argon

Gas Delivery Unit II System . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Connecting the Electrosurgical Generator and Accessories 5-5

General Test Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Mechanical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Rear Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Initialization Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Functional Test with Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Chapter 6. Troubleshooting

Inspecting the Valleylab Argon Gas Delivery Unit II . . . . . . . . . 6-2

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Nonfatal Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Fatal Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Error Code Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Power Supply Board Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Cable Connection Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Footswitch Board Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Footswitch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

ESU Interface Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Front Panel Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Argon Control Assembly Test . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Description of Valve Operation . . . . . . . . . . . . . . . . . . . . . 6-14

Test Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Testing Tanks 1 and 2, and the Release Solenoid Valves . 6-15

Testing the Orifice and Flow Control Solenoid Valves . . . 6-15

Testing the Peritoneal Directional Solenoid Valve . . . . . . 6-16

Chapter 7. Replacement Procedures

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Valleylab Argon Gas Delivery Unit II Spare Components . . . . . 7-2

Front Bezel and Display Board Replacement . . . . . . . . . . . . . . . 7-3

Valleylab Argon Gas Delivery Unit II Service Manual vii

Page 8

Power Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Power Supply Board Replacement . . . . . . . . . . . . . . . . . . . . . . . 7-5

Footswitch Board Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

AC Inline Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Internal Argon Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . 7-9

Argon Control Valve Assembly/Second Stage Regulator

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Control Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Argon Gas Tank Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Chapter 8. Repair Policy and Procedures

Responsibility of the Manufacturer . . . . . . . . . . . . . . . . . . . . . . 8-2

Obtaining a Return Authorization Number . . . . . . . . . . . . . . . . 8-2

Returning Circuit Boards and Other Subassemblies. . . . . . . . . . 8-2

Returning the Valleylab Argon Gas Delivery Unit II for Service 8-3

Cleaning the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Shipping the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Disposing of the Valleylab Argon Gas Delivery Unit II. . . . . . . . 8-4

Service Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Chapter 9. Service Parts

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Valleylab Argon Gas Delivery Unit II Assembly . . . . . . . . . . . . . 9-3

Argon Gas Delivery Unit II Parts List . . . . . . . . . . . . . . . . . . . 9-4

Footswitch Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Display Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Control Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

viii Valleylab Argon Gas Delivery Unit II Service Manual

Page 9

Chapter 1

Introduction

This manual provides instructions for servicing the Valleylab Argon Gas Delivery

Unit II. This chapter introduces the features and components of the unit and

reviews the precautions associated with repair.

Introduction

Valleylab Argon Gas Delivery Unit II Service Manual 1-1

Page 10

General Description

General Description

The Valleylab Argon Gas Delivery Unit II System is designed to provide a controlled flow

of argon (an inert, nonreactive gas) over the active electrode of an electrosurgical

accessory which is powered by a Force series electrosurgical generator. A variety of

handsets provide argon-enhanced electrosurgery as well as standard electrosurgery.

Argon-enhanced coag permits the coagulation of certain tissue in a more controlled

manner than with standard electrosurgical coagulation.

In argon-enhanced coag, activating the handset creates an argon gas plasma between

the electrode and the tissue. The presence of inert gas at the surgical site inhibits

combustion with other gases (e.g., oxygen, nitrogen, etc.) and pushes residual smoke,

water vapor, or fluids away from the surgical site, thereby improving visibility.

The Valleylab Argon Gas Delivery Unit II has an overpressure system that continuously

measures peritoneal cavity pressure in real-time. This system operates when the unit is in

the low flow range for argon gas (0.5 - 4 LPM), i.e. the gas flow range for laparoscopic

procedures. Use the overpressure system in conjunction with a carbon dioxide insufflator

monitor.

The overpressure system senses when the peritoneal cavity pressure meets or exceeds the

user selectable setpoint (between 5 and 30 mm Hg). As the peritoneal cavity pressure

approaches the setpoint, the Overpressure indicator on the front panel illuminates, and

an intermittent alarm sounds. When the peritoneal cavity pressure meets or exceeds the

setpoint, the Overpressure indicator on the front panel illuminates, and a continuous

alarm sounds.

List of Components

The Valleylab Argon Gas Delivery Unit II is shipped with the following components:

• Valleylab Argon Gas Delivery Unit II

• ESU Interface Cable

• E0502-12 Active Adapter

• Argon Gas Tank Regulator Assembly for Tank 1

•Power Cord

• Power cord retaining clip

• User’s Guide, Service Manual, Reference Card

1-2 Valleylab Argon Gas Delivery Unit II Service Manual

Page 11

Service Personnel Safety

Service Personnel Safety

Before servicing the Valleylab Argon Gas Delivery Unit II, it is important that you read,

understand, and follow the instructions supplied with the unit and with any other

equipment used to install, test, adjust, or repair the unit.

General Service Precautions

Caution

The unit contains electrostatic sensitive components. When repairing the unit, work at a static

control workstation. Wear a grounding strap when handling electrostatic sensitive components.

Handle the circuit boards by their nonconductive edges. Use an antistatic container for transport

of electrostatic sensitive components and circuit boards.

Introduction

Notice

Connect the power cord to a wall receptacle having the correct voltage. Otherwise, product

damage may result.

If required by local codes, connect the unit to the hospital equalization connector with an

equipotential cable.

Fire/Explosion

Warning

Do not install the Valleylab Argon Gas Delivery Unit II System in the presence of flammable

anesthetics, gases, liquids, or objects.

Always use high purity grade (99.998% pure or better) argon gas. Do not use oxygen for any

adjustments. Oxygen regulation values differ from argon regulation values, and incorrect

adjustments result.

For continued protection against fire hazard, replace fuses only with those having the same type

and rating as the original fuse.

Fire Hazard Do not place active accessories near or in contact with flammable materials (such as

gauze or surgical drapes). Electrosurgical accessories that are activated or hot from use can cause

a fire. Use a holster to hold electrosurgical accessories safely away from personnel and flammable

materials.

Valleylab Argon Gas Delivery Unit II Service Manual 1-3

Page 12

Service Personnel Safety

Electric Shock

Warning

Disconnect the power cord before replacing parts.

Always unplug the Valleylab Argon Gas Delivery Unit II before cleaning.

Do not connect a wet power cord assembly to the unit or a wall receptacle.

Ensure that all accessories and adapters are correctly connected and that no metal is exposed.

The interface cable must be connected to the Valleylab Argon Gas Delivery Unit II and the

electrosurgical generator for operation. If the Valleylab Argon Gas Delivery Unit II is not being

used, disconnect the power cord from the wall receptacle.

Do not touch any exposed wiring or conductive surface while the unit is disassembled and

energized. Never wear a grounding strap when working on an energized unit. Otherwise,

damage to circuit board components may result.

Take appropriate precautions (such as use of isolated tools and equipment; use of the “one hand

rule,” etc.) when taking measurements or troubleshooting the unit.

The front heatsink on the power supply is at an elevated voltage. Do not come in contact with it.

Do not use it for ground. Otherwise, burns to service personnel may result. Damage to circuit

board components may result.

Caution

When attaching the Argon Handset, ensure that the RF jumper cable is disconnected from the RF

Input receptacle on the Valleylab Argon Gas Delivery Unit II front panel.

High Pressure

Warning

Ensure that argon gas tanks and fittings used with the Valleylab Argon Gas Delivery Unit II have

been pressure tested, certified, and filled according to applicable standards and local codes. In

filling the tanks, ensure your supplier meets all local and national codes. Do not over pressurize

the tanks. Do not exceed 3,000 psig.

Use only the high pressure regulator supplied with the Valleylab Argon Gas Delivery Unit II. Order

replacement regulators from Valleylab. Argon gas pressure should not exceed 434 KPa (63 psig) ±

5% at the regulator hose connection to the receptacle on the rear panel.

Always ensure that the regulator tank fitting is properly connected to the tank valve outlet.

Caution

Improperly secured gas tanks and/or improper connection of gas lines may result in injury.

1-4 Valleylab Argon Gas Delivery Unit II Service Manual

Page 13

Service Personnel Safety

Argon Gas

Warning

Use only high purity grade (99.998% pure or better) argon gas. Patient safety may be

compromised by using low purity gas.

The regulator coupling in this unit is compatible with many common gas tanks (e.g., Freon,

helium, krypton, neon, nitrogen, and xenon). Only connect argon gas to the Valleylab Argon Gas

Delivery Unit II. Using other gases may affect gas flow, create phosgene or other harmful gases,

or create an explosion hazard.

Cleaning

Notice

Do not clean the unit with abrasive cleaning or disinfectant compounds, solvents, or other

materials that could scratch the panels or damage the generator.

Introduction

Valleylab Argon Gas Delivery Unit II Service Manual 1-5

Page 14

Page 15

Chapter 2

Controls, Indicators, and Receptacles

The controls, indicators and receptacles for accessories are located on the front

and rear panels of the Valleylab Argon Gas Delivery Unit II. This chapter describes

each component of the unit and its function.

Controls, Indicators, and

Detailed specifications for the unit are in Chapter 3, Technical Specifications.

Receptacles

Valleylab Argon Gas Delivery Unit II Service Manual 2-1

Page 16

Valleylab Argon Gas Delivery Unit II Front Panel Descriptions

Valleylab Argon Gas Delivery Unit II

Front Panel Descriptions

Overpressure System

This system operates only when the Valleylab Argon Gas Delivery Unit II System is in the

low gas flow range. Use only this range for laparoscopic procedures.

Overpressure Setpoint Display - The display shows the overpressure setpoint (available

only when using the low flow range).

Overpressure Indicator - As the peritoneal cavity pressure approaches the overpressure

setpoint, this indicator illuminates and an intermittent alarm sounds. When the

peritoneal cavity pressure meets or exceeds the setpoint, this indicator remains

illuminated and a continuous alarm sounds.

Peritoneal Pressure Display - The display indicates the peritoneal cavity pressure

(available only when using the low flow range). The display flashes when the pressure is

below 1 mm Hg.

Overpressure On/Off Switch - Press this button to turn peritoneal cavity pressure

monitoring on or off (available only when using the low flow range).

Overpressure Control Knob - To increase (+) the alarm setting, turn the knob

clockwise. To decrease (-) the alarm setting, turn the knob counterclockwise.

Setpoint Symbol

System Purge Control

Handset Tubing or Peritoneal Pressure Tubing Obstruction Indicator - When a gas

tubing obstruction occurs, the indicator illuminates and an alarm sounds. The Gas Flow

indicator or the Overpressure indicator will also be flashing.

Gas Line Purge Button - Pressing this button removes air and causes a brief discharge

of argon gas through the handset tubing at a gas flow of 3.0 LPM.

Gas Flow Controls

Gas On/Gas Off Button - Press this button to select gas on or gas off.

Gas On Indicator - When you turn on the gas, the indicator illuminates and gas is

available to the handset.

Gas Off Indicator - When you turn off the gas, the indicator illuminates and gas is not

available to the handset.

Gas Flow Indicator - This indicator illuminates when you activate argon-enhanced coag

or argon-shrouded cut or when you press the Gas Line Purge button.

Flow Rate Display - The display shows gas flow on a scale from 0.5 to 12 LPM. The

2-2 Valleylab Argon Gas Delivery Unit II Service Manual

Page 17

Valleylab Argon Gas Delivery Unit II Front Panel Descriptions

default gas flow setting is 0.5 LPM.

Standard Gas Flow Indicator - This green LED illuminates when you select the standard

gas flow range.

Gas Flow Range Selector - Press this switch to the top position for standard flow range

(0.5 - 12 LPM) or bottom position for low gas flow (0.5 - 4 LPM).

Low Gas Flow Indicator - This green LED illuminates when you select the low gas flow

range.

Flow Control Knob - To increase (+) the argon gas flow, turn the knob clockwise. To

decrease (-) the argon gas flow, turn the knob counterclockwise.

Controls, Indicators, and

Gas Tank Indicators and Controls

Tank Select Button, Tank 1 - Press this button to select tank 1.

Tan k I n di cat or, Tan k 1 - The indicator illuminates when you select tank 1.

Low Pressure Alarm, Tank 1 - The indicator illuminates when the tank pressure is

below 10% of full tank pressure. The indicator flashes and a brief alarm sounds when all

available tanks are low.

% Argon in Tank 1 - The bar graph indicates percent of argon gas remaining in tank 1.

Tank Select Button, Tank 2 - Press this button to select tank 2.

Tan k I n di cat or, Tan k 2 - The indicator illuminates when you select tank 2.

Low Pressure Alarm, Tank 2 - The indicator illuminates when the tank pressure is

below 10% of full tank pressure. The indicator flashes and a brief alarm sounds when all

available tanks are low.

% Argon in Tank 2 - The bar graph indicates percent of argon gas remaining in tank 2.

Gas Lines and Receptacles

On/Off Switch - This switch supplies power to the unit.

Peritoneal Pressure Tubing Receptacle - Connect the peritoneal pressure tubing filter

to this luer receptacle.

Receptacles

Gas Line Receptacle - Connect the handset particle filter to this luer receptacle.

RF Input Receptacle - Connect the RF jumper cable to this receptacle when using the

Valleylab Argon Accessory.

Handset Receptacle - Connect the handset three-pin connector to this receptacle.

Valleylab Argon Gas Delivery Unit II Service Manual 2-3

Page 18

Valleylab Argon Gas Delivery Unit II Front Panel Descriptions

Front panel

Overpressure Setpoint Display

Obstruction Indicator (Handset

Tubing or Peritoneal Pressure Tubing)

Overpressure

Indicator

Gas On/Gas Off Button

Standard Gas

Flow Indicator

Tan k S el ec t

Button, Tank 1

Peritoneal

Pressure

Display

Overpressure

On/Off Switch

On/Off

Switch

Peritoneal Pressure

Tubing Receptacle

Overpressure Control

Knob

Gas On Indicator

Gas Line

Purge Button

Flow Rate

Display

Gas Flow

Indicator

Flow Control

Knob

Gas Off

Indicator

% Argon in Tank 1

Gas Flow

Range

Selector

Low Gas

Flow

Indicator

Gas Line

Receptacle

Ta nk

Indicator,

Tan k 1

Low Pressure

Alarm, Tank 2

RF Input

Receptacle

Tank Indicator,

Tank 2

% Argon in

Tank 2

Handset

Receptacle

Tank Select

Button, Tank 2

Low Pressure

Alarm, Tank 1

2-4 Valleylab Argon Gas Delivery Unit II Service Manual

Page 19

Rear panel

Tank 1 Receptacle

Connect the tank 1

regulator hose to this

receptacle.

Connect the tank 2 regulator

hose to this receptacle.

The Valleylab Argon Gas Delivery Unit II may

be adjusted through this serial port to stop

argon gas delivery when the peritoneal

cavity pressure meets or exceeds the

selected setpoint. Contact your Valleylab

representative for further information.

Tank 2 Receptacle

Valleylab Argon Gas Delivery Unit II Front Panel Descriptions

RS-232 Serial Port

Power Entry Module

Connect a power cord with a

three-prong hospital grade

connector to this receptacle.

There are two entry module fuses

in this receptacle.

Controls, Indicators, and

Receptacles

Tank 2 Transducer Receptacle

Connect the tank 2 transducer cable

to this receptacle.

Tank 1 Transducer Receptacle

Connect the tank 1 transducer cable to

this receptacle.

Connect a Valleylab electrosurgical footswitch to this receptacle. Use

only a Valleylab footswitch with the Valleylab Argon Gas Delivery Unit

II. Use of an incompatible footswitch may case unexpected output.

Do not plug the footswitch into the electrosurgical generator.

Equipotential Grounding Lug

Use an equipotential grounding

cable to connect the generator to

protective earth ground.

ESU Interface Cable Receptacle

Connect a Valleylab electrosurgical

generator to this receptacle using the ESU

interface cable provided by Valleylab.

Footswitch Receptacle

Valleylab Argon Gas Delivery Unit II Service Manual 2-5

Page 20

Page 21

Chapter 3

Technical Specifications

Specifications subject to change without notice.

Technical Specifications

Valleylab Argon Gas Delivery Unit II Service Manual 3-1

Page 22

Performance Characteristics

Performance Characteristics

Standard Conditions of Measurement

Unless otherwise specified, all measurements are specified at an ambient temperature of

70° F (21° C) and 760 torr.

Operating Parameters

Temperature Range: 50° F – 104° F (10° C – 40° C)

Humidity Range: 15% – 85%, noncondensing

Atmospheric Pressure: 10 psia - 15.4 psia (70 KPa – 106 KPa)

Storage and Shipping

Temperature Range: -40° F – 158° F (-40° C – 70° C)

Humidity Range: 10% – 85%, noncondensing

Atmospheric Pressure: 10 psia - 15.4 psia (70 KPa – 106 KPa)

Input Power Source

Operating Range: 100V – 120 V ~

Line frequency: 50 Hz – 60 Hz

Current: 0.5 ampere

Power consumption: 100 VA – 120 VA

Low Frequency Leakage (50Hz – 60 Hz)

All patient connected terminals tied together:

Source current normal polarity, intact chassis ground< 10 μA

Source current normal polarity, ground open< 50 μA

Source current reverse polarity, ground open< 50 μA

Sink current, all inputs < 20 μA

3-2 Valleylab Argon Gas Delivery Unit II Service Manual

Page 23

Performance Characteristics

Gas Flow Ranges

Low Gas Flow: 0.5 - 4 standard liters/minute ± 15% of the flow rate shown on the Flow

display.

Standard Gas Flow: 0.5 - 12 standard liters/minute ± 15% of the flow rate shown on the

Flow display.

Audio Volume

The alarm tones are set to a level of > 65 dBA at 1 m and are not adjustable.

Approximate Weight

24 lb. (10.9 kg)

Size

17.8 in. x 16.0 in. x 5.6 in. (45.2 cm x 40.6 cm x 14.2 cm)

Gas Tanks

Maximum Pressure: 2000 psi (13790 kPa) (138 bar)

Power Cord Specification

This unit was equipped from the factory with a 110 NEMA 5-15 power cord. Should the

AC power cord need to be replaced to match another plug configuration, the

replacement plug/cable/receptacle configuration must meet or exceed the following

specifications:

100 - 120 VAC

Cable - SJT16/3, IEC color code, maximum length 15 ft. (5 m)

Plug - minimum 10 A - 125 VAC

Unit receptacle - IEC female, minimum 10 A - 125 VAC

Technical Specifications

Valleylab Argon Gas Delivery Unit II Service Manual 3-3

Page 24

Standards and IEC Classifications

Standards and IEC Classifications

The Valleylab Argon Gas Delivery Unit II meets all pertinent clauses of the IEC 60601-1

second edition and IEC 60601-2-2 third edition.

ATTENTION: Consult accompanying documents.

Danger: Explosion risk if used with flammable anesthetics.

To reduce the risk of electrical shock, do not remove the cover. Refer servicing to qualified

service personnel.

Classified with respect to electrical shock, fire, mechanical, and other specified hazards

only in accordance with UL60601-1 and CAN/CSA C22.2 No. 601.1.

Type CF Equipment (IEC 60601-1) /Defibrillator Proof

The Valleylab Argon Gas Delivery Unit II unit provides a high degree of protection against

electric shock, particularly regarding allowable leakage currents. It is type CF isolated

(floating) output and may be used for procedures involving the heart.

This generator complies with the ANSI/AAMI HF18 specifications for “defibrillator proof”

designation and IEC 60601-2-2.

Liquid Spillage (IEC 60601-2-2 Clause 44.3)

The Valleylab Argon Gas Delivery Unit II is constructed so that liquid spillage in normal

use des not wet electrical insulation or other components which when wetted are likely

to adversely affect the safety of the equipment.

3-4 Valleylab Argon Gas Delivery Unit II Service Manual

Page 25

EMC Compatibility

Electromagnetic Compatibility (IEC 60601-1-2 and IEC 60601-2-2)

The Valleylab Argon Gas Delivery Unit II unit complies with the appropriate IEC 60601-12 and IEC 60601-2-2 specifications regarding electromagnetic compatibility.

Notice

The Valleylab Argon Gas Delivery Unit II should not be used adjacent to or stacked with operating

room equipment, unless otherwise specified in the Valleylab Argon Gas Delivery Unit II User’s

Guide and Service Manual. The Valleylab Argon Gas Delivery Unit II should be used only in the

intended configuration.

The electrosurgical generator used with the Valleylab Argon Gas Delivery Unit II delivers RF energy

during activation. Observe other electronic medical equipment during activation of the Valleylab

Argon Gas Delivery Unit II for any possible adverse electromagnetic effects. Provide adequate

separation of this equipment to minimize the risk of adverse effects.

EMC Compatibility

The use of accessories, other than specified in the Valleylab Argon Gas Delivery Unit II User’s

Guide and Service Manual, may increase emissions or decrease immunity of the Valleylab Argon

Gas Delivery Unit II.

Technical Specifications

Valleylab Argon Gas Delivery Unit II Service Manual 3-5

Page 26

EMC Compatibility

Guidance and manufacturer's declaration - electromagnetic emissions

The Valleylab Argon Gas Delivery Unit II is intended for use in the electromagnetic environment

specified below. The customer or the user of the Valleylab Argon Gas Delivery Unit II should

ensure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment -

guidance

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations/

flicker emissions

IEC61000-3-3

Group 1 The Valleylab Argon Gas Delivery Unit II

uses RF energy only for its internal

function. Therefore, its RF emissions are

very low and are not likely to cause any

interference in nearby electronic

equipment.

Class A The Valleylab Argon Gas Delivery Unit II

is suitable for use in all establishments

other than domestic and those directly

Class A

Complies

connected to the public low-voltage

power supply network that supplies

buildings used for domestic purposes.

3-6 Valleylab Argon Gas Delivery Unit II Service Manual

Page 27

Guidance and manufacturer's declaration - electromagnetic immunity

The Valleylab Argon Gas Delivery Unit II is intended for use in the electromagnetic environment

specified below. The customer or the user of the Valleylab Argon Gas Delivery Unit II should

assure that it is used in such an environment.

EMC Compatibility

Immunity test IEC 60601 test

level

Electrostatic

discharge (ESD)

IEC 61000-4-2

Electrical fast

transient/burst IEC

61000-4-4

Surge

IEC 61000-4-5

Voltage dips, short

interruptions and

voltage variations on

power supply input

lines

IEC 61000-4-11

+/-6 kV contact

+/-8 kV air

+/-2 kV for power

supply lines

+/-1 kV for input/

output lines

+/-1 kV

differential mode

+/-2 kV common

mode

< 5% U t

(>95% dip in Ut)

for 0,5 cycle

4 0% Ut

(>60% dip in Ut)

for 5 cycles

7 0% Ut

(>30% dip in Ut)

for 25 cycles

< 5% U t

(>95% dip in Ut)

for 5 sec

Compliance

level

+/-6 kV contact

+/-8 kV air

+/-2 kV for power

supply lines

+/-1 kV for input/

output lines

+/-1 kV

differential mode

+/-2 kV common

mode

< 5% U t

( > 9 5 % d i p i n U t )

for 0,5 cycle

4 0% U t

( > 6 0 % d i p i n U t )

for 5 cycles

7 0% U t

( > 3 0 % d i p i n U t )

for 25 cycles

< 5% U t

( > 9 5 % d i p i n U t )

for 5 sec

Electromagnetic

environment - guidance

Floors should be wood,

concrete or ceramic tile. If

floors are covered with

synthetic material, the

relative humidity should be

at least 30%.

Mains power quality should

be that of a typical

commercial or hospital

environment.

Mains power quality should

be that of a typical

commercial or hospital

environment.

Mains power quality should

be that of a typical

commercial or hospital

environment. If the user of

the Valleylab Argon Gas

Delivery Unit II requires

continued operation during

power mains interruptions,

it is recommended that the

Valleylab Argon Gas

Delivery Unit II be powered

from an uninterruptible

power supply or a battery.

Technical Specifications

Power frequency (50/

60 Hz) magnetic field

IEC 61000-4-8

NOTE: Ut is the a.c. mains voltage prior to the application of the test level.

3 A/m 3 A/m Power frequency magnetic

fields should be at levels

characteristic of a typical

location in a typical

commercial or hospital

environment.

Valleylab Argon Gas Delivery Unit II Service Manual 3-7

Page 28

EMC Compatibility

Guidance and manufacturer's declaration - electromagnetic immunity

The Valleylab Argon Gas Delivery Unit II is intended for use in the electromagnetic environment

specified below. The customer or the user of the Valleylab Argon Gas Delivery Unit II should

assure that it is used in such an environment.

Immunity

test

Conducted

RF IEC

61000-4-6

Radiated RF

IEC 61000-

4-3

IEC 60601

test level

3 Vrms

150KHz to

80MHz

3 V/m

80MHz to

2.5GHz

Compliance

level

3 V

7 V/m

Electromagnetic environment - guidance

Portable and mobile RF communications

equipment should be used no closer to any part

of the Valleylab Argon Gas Delivery Unit II,

including cables, than the recommended

separation distance calculated from the

equation applicable to the frequency of the

transmitter.

Recommended separation distance

√P

d=1.2

d=0.5

√P 80MHz to 800MHz

d=√P 800MHz to 2.5GHz

Where P is the maximum output power

rating of the transmitter in watts (W) according

to the transmitter manufacturer and d is the

recommended separation distance in meters (m).

Field strengths from fixed RF transmitters, as determined by an

electromagnetic site survey, should be less than the

compliance level in each frequency range

Interference may occur in the vicinity of

equipment marked with the following symbol:

NOTE 1 At a 80MHz and 800MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected

by absorption and reflection from structures, objects and people.

a. Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless)

telephones and land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast

cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due

to fixed RF transmitters, an electromagnetic site survey should be considered. If the measured

field strength in the location in which the Valleylab Argon Gas Delivery Unit II is used exceeds the

applicable RF compliance level above, the Valleylab Argon Gas Delivery Unit II should be observed

to verify normal operation. If abnormal performance is observed, additional measures may be

necessary, such as reorienting or relocating the

Valleylab Argon Gas Delivery Unit II.

b. Over the frequency range 150kHz to 80MHz, field strengths should be less than 3V/m.

3-8 Valleylab Argon Gas Delivery Unit II Service Manual

Page 29

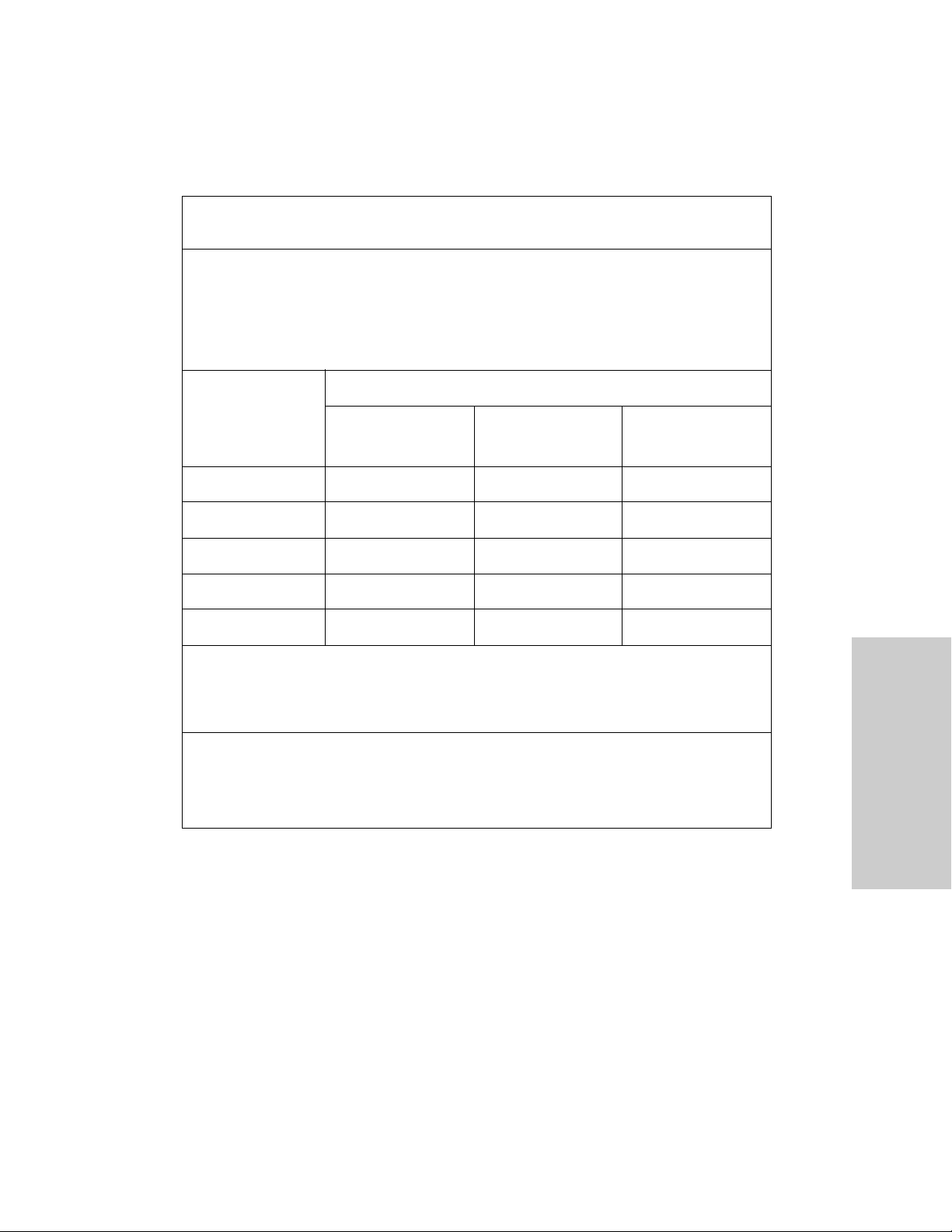

Recommended separation distances between portable and mobile RF communication

equipment and the Valleylab Argon Gas Delivery Unit II

The Valleylab Argon Gas Delivery Unit II is intended for use in an electromagnetic environment in

which radiated RF disturbances are controlled. The Customer or the user of the Valleylab Argon

Gas Delivery Unit II can help prevent electromagnetic interferences by maintaining a minimum

distance between portable and mobile RF communications equipment (transmitters) and the

Valleylab Argon Gas Delivery Unit II as recommended below, according to the maximum output

power of the communications equipment.

Separation distance according to frequency of transmitter (m)

Rated maximum

output power of

transmitter (W)

0.01 .12 m 0.05 m 0.1 m

150 kHz to 80MHz

√P

d=1.2

80MHz to 800MHz

d=0.5√P

800MHz to 2.5GHz

d=√P

EMC Compatibility

0.1 .38 m 0.16 m 0.32 m

1 1.2 m 0.5 m 1 m

10 3.8 m 1.6 m 3.2 m

100 12 m 5 m 10 m

For transmitters rated at a maximum output power not listed above, the recommended

separation distance d in meters (m) can be estimated using the equation applicable to the

frequency of the transmitter, where P is the maximum output power rating of the transmitter in

watts (W) according to the transmitter manufacturer.

NOTE 1 At a 80MHz and 800MHz, the separation distance for the higher frequency range

applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected

by absorption and reflection from structures, objects and people.

Technical Specifications

Valleylab Argon Gas Delivery Unit II Service Manual 3-9

Page 30

Page 31

Chapter 4

Principles of Operation

This chapter provides the basic circuit theory for the Valleylab Argon Gas Delivery

Unit II. A functional block diagram appears at the end of this chapter. Refer to

the Schematics Supplement for schematics of the Control Board, Display Board,

and Footswitch Board.

Valleylab Argon Gas Delivery Unit II Service Manual 4-1

Principles of Operation

Page 32

Functional Descriptive Overview

Functional Descriptive Overview

The electronics of the Valleylab Argon Gas Delivery Unit II perform a variety of functions:

• Direct interface signals from the Valleylab Argon Gas Delivery Unit II to the associated

electrosurgical unit (ESU).

• Control argon gas delivery at digitally preset flow rates.

• Monitor error conditions: (gas line obstructions, low tank pressures for each tank,

dosage error, power supply voltage, proper clock signals, software errors)

• A special error routine for line obstruction to exhaust the pressurized gas line.

• Automatic selection or switching of argon gas tank lines.

• Allows the surgeon to select argon enhanced or standard electrosurgery using the

Valleylab Argon Handset.

• Allows the selection of low or standard gas flow.

• Allows the purging of the attached gas tubing.

• Allows control and monitoring of the argon gas tanks.

• Bar graphs display the % volume available in each argon gas tank.

• Has isolation electronics to prevent dielectric breakdown between the RF electrical

signal and the electronics.

• Allows the unit to operate from 120 Vac – 240 Vac nominal, 50 Hz – 60 Hz.

• Provides safe shutdown in case of power failure.

• Monitors peritoneal cavity pressure in low flow mode.

Circuit Descriptions

Refer to the circuit descriptions in the Schematic Supplement for the designated sheet

number of the schematic.

Main Microprocessor (Control Board, sheet 2 of 8)

An 80C31 single chip microprocessor (U40) controls the Valleylab Argon Gas Delivery

Unit II. The microprocessor controls all the functions of the unit. It provides direct

communication between the Control Board, front panel, rear panel, memory, and the

malfunction microprocessor.

RS-232 Interface (Control Board, sheet 2 of 8)

The RS-232 interface (U5) allows service personnel to communicate with a Valleylab

Argon Gas Delivery Unit II by a computer. This allows for troubleshooting of the unit.

4-2 Valleylab Argon Gas Delivery Unit II Service Manual

Page 33

Circuit Descriptions

Address Latches and I/O Decoders (Control Board, sheet 2 of 8)

The address latches (U33 and U49) and I/O decoders (U28 and U29) work with the main

microprocessor to deliver to and receive information from the rest of the circuits.

Solenoid Drivers (Control Board, sheet 3 of 8)

The argon gas control system is a collection of five fixed orifices capable of producing gas

flows of 0.5, 1.0, 2.0, 4.0, and 8.0 liters per minute (LPM) in parallel and individually

selectable. The pneumatic portion of the Valleylab Argon Gas Delivery Unit II consists of

one or two cylinders of compressed argon pressurized to a maximum of 2000 psig (not

supplied), a high pressure transducer and regulator, HEPA filter, argon gas control valve

with dual inlet tank selector valve and a delivery pressure relief valve. Argon passes from

the gas tanks to the high pressure regulators where it acts on the high pressure

transducers and leaves the regulators at a pressure of 60 psig. The gas then goes through

a tank selector valve that controls which tank is to be used as the gas source. From the

tank selector valve the gas travels through a HEPA filter, a second stage regulator, and the

argon control valve.

The microprocessor causes solenoid drivers (U7, U10, U11, U16, U17, U23, and U24) to

open the appropriate fixed-sized orifice(s) based on the argon flow rate selected on the

Valleylab Argon Gas Delivery Unit II front panel. The front panel is a direct readout in

LPM.

Audio Amplifier (Control Board, sheet 3 of 8)

An error or a change in setting on the front panel enables the audio annunciator (U4).

The speaker is on the Footswitch Board.

Solenoid Master Power Switch (Control Board, sheet 3 of 8)

This circuit controls the power to the solenoid drivers and is under the control of the main

microprocessor. The power to the solenoid drivers is terminated under fatal error

conditions.

Watchdog Circuitry (Control Board, sheet 4 of 8)

A two stage reset circuit (U20) ensures that the microcontroller is held reset for a short

time after AC power is applied. During this time, the remainder of the circuitry stabilizes

before the microcontroller starts to exercise power.

Principles of Operation

Valleylab Argon Gas Delivery Unit II Service Manual 4-3

Page 34

Circuit Descriptions

Malfunction Microprocessor (Control Board, sheet 4 of 8)

The malfunction microprocessor (U12) checks for any errors caused and/or not reported

by the microprocessor during operation. During initialization, the malfunction

microprocessor (PIC) checks the main microprocessor and the circuitry for integrity. A

major function of the PIC is to monitor the argon gas valve control system for dosage

error. The dosage error circuit determines whether the delivered gas flow rate lies within

specified limits or is out of range. When a dosage error is detected, the PIC immediately

inhibits gas flow, sounds an alarm, and flashes an error code on the front panel. To clear

the dosage error, turn off and then turn on the power to the unit.

To allow the Valleylab Argon Gas Delivery Unit II to enter the test mode, the PIC can be

disabled. To disable the PIC, connect pins 1 and 2 to JP2. To return the unit to normal

function, connect pins 2 and 3 to JP2.

Argon Gas Tank Pressure Scale (Control Board, sheet 4 of 8)

The % Argon in Tank 1 and 2 displays on the front panel indicate the gas remaining in

each tank. To properly display this information relative to the tank size, adjust the

connections at JP1. For full scale display when using a 2000 psig tank, connect pins 2 and

3.

Display Interface and Lamp Drivers (Control Board, sheet 4 of 8)

The LEDs and lamps on the front panel indicate the mode of operation of the Valleylab

Argon Gas Delivery Unit II. The keyboard and knobs allow the user to interface with the

unit. A ribbon cable provides communication between the front panel and the Control

Board. The Control Board lamp drivers (U14, U18, U19, and U43) and lamp latches

control the lamps on the front panel.

Argon Gas Tank Detection and Measurement (Control Board, sheet 5 of 8)

The two separate tank detection circuits (U3, U6, and U9) determine whether a pressure

transducer is connected to the Valleylab Argon Gas Delivery Unit II. There is a separate

circuit for each of the two argon gas tank connectors. Two additional separate circuits

(U1-U3, U6, and U8) measure the pressure within each tank. The tank detection circuits

are identical.

A 10 V excitation is provided to the transducer bridge circuit. The sense voltage is then

amplified and filtered. The A-D Converter changes this measurement from an analog to a

digital value.

4-4 Valleylab Argon Gas Delivery Unit II Service Manual

Page 35

Circuit Descriptions

Pressure Transducers (Control Board, sheet 6 of 8 and sheet 7 of 8)

Two of the pressure transducer circuits (PS1-PS3, U25-U27, U30-U32, U35, and U36)

measure the pressure seen by the orifice assembly at the argon gas inlet chamber and the

argon gas outlet chamber. The third pressure transducer circuit monitors the peritoneal

cavity pressure. The analog pressure measurement is filtered and amplified before it is

converted by the A-D Converter.

Overvoltage Monitors (Control Board, sheet 6 of 8)

Two overvoltage monitoring circuits (U41) continuously check the +5V and +12V lines to

ensure they are within specification of the manufacturer. If either of the voltage lines

becomes out of specification, the overvoltage monitor trips and shuts down the Valleylab

Argon Gas Delivery Unit II. To clear this condition, turn off and then turn on the power to

the unit.

A-D Converter (Control Board, sheet 6 of 8)

The A-D Converter (U39) receives analog inputs from the pressure transducers,

overvoltage monitors, and tank measurement circuits. These inputs are converted to a

digital format to be processed by the main microprocessor.

DC Power Connector (Control Board, sheet 6 of 8)

The DC power connector establishes the connection between the power supply and the

Valleylab Argon Gas Delivery Unit II. A 45 watt universal input power supply is used in the

unit. The unit can accept 85-264 Vac at 47-63 Hz without input range switching or other

adjustment. The power supply provides +5V at 3 amps and +12V at 2 amps to the

Valleylab Argon Gas Delivery Unit II.

IsoBloc Circuit Modules (Control Board, sheet 8 of 8)

The microcontroller responds to inputs from the front panel and from a handset and/or

footswitch. The handset and footswitch connectors are isolated from the rest of the

Valleylab Argon Gas Delivery Unit II with two completely separate IsoBloc circuits (U34,

U50, and U51). This is necessary because the handswitch leads, in particular, may be

elevated to relatively high RF voltages. To maintain isolation within the unit, these leads

must not be coupled to ground.

Principles of Operation

Lamps and LEDs (Display Board, sheet 2 of 4)

The lamps for the Gas Flow, Overpressure, Tank 1, Tank 2, Low Gas Flow, Standard

Gas Flow, and Obstruction indicators are controlled by the Control Board through the

ribbon cable connector. The LEDs for Gas On, Gas Off, and Low Pressure Alarm Tank

Valleylab Argon Gas Delivery Unit II Service Manual 4-5

Page 36

Circuit Descriptions

1 and Tank 2 are controlled by an LED latch (U6) with commands from the main

microprocessor. These commands are active low.

Switch Read Buffer (Display Board, sheet 2 of 4)

The switch read buffer (U3) receives inputs from the two rotary knobs and the six push

buttons on the front panel. The buffer returns this information to the main

microprocessor to change the state of the Valleylab Argon Gas Delivery Unit II according

to input from the front panel.

Bar Graph Display Driver (Display Board, sheet 3 of 4)

When the tank transducer is connected, the bar graph display driver (U7) receives inputs

from the main microprocessor to indicate the % argon gas available in each tank. The bar

graph display driver, in conjunction with a digit driver (U4), also displays the user

adjustable overpressure setpoint.

Seven Segment Display Driver (Display Board, sheet 4 of 4)

The seven segment display driver (U5) controls the flow and overpressure readings as

indicated by the main microprocessor.

ESU Interface Connector (Footswitch Board, sheet 1 of 1)

When the user activates the handset or footswitch (K1-K4) in the cut or coag mode, the

ESU interface connector sends signals to the associated electrosurgical generator through

an external cable.

Footswitch Connector (Footswitch Board, sheet 1 of 1)

When connected to a footswitch, the footswitch connector activates the Valleylab Argon

Gas Delivery Unit II.

Speaker (Footswitch Board, sheet 1 of 1)

The speaker (SP1) for the alarm enunciator (located on the Control Board) is located on

the Footswitch Board.

4-6 Valleylab Argon Gas Delivery Unit II Service Manual

Page 37

Circuit Descriptions

Software Initialization

Each time the Valleylab Argon Gas Delivery Unit II is turned on, the main microprocessor

must initialize and the circuitry must warm up and stabilize. Hardware initialization takes

a fraction of a second. Then the microcontroller starts the software initialization. All LEDs

on the front panel illuminate for three seconds.

Valleylab Argon Gas Delivery Unit II Block Diagram

Valleylab Argon Gas Delivery Unit II Service Manual 4-7

Principles of Operation

Page 38

Page 39

Chapter 5

Setup, Tests, and Adjustments

This chapter provides setup and test procedures to verify that the Valleylab

Argon Gas Delivery Unit II System is functioning properly. Some test procedures

require partial disassembly of the unit. Refer to Chapter 7 Replacement

Procedures for disassembly instructions.

Setup, Tests, and Adjustments

Valleylab Argon Gas Delivery Unit II Service Manual 5-1

Page 40

Setting up the Valleylab Argon Gas Delivery Unit II

Setting up the Valleylab Argon Gas Delivery Unit II

Unpacking and Installing the Unit

1. Carefully remove the Valleylab Argon Gas Delivery Unit II and all accessories from the

shipping packages. Save cartons and packing materials for use if the unit is returned

for service.

2. Place the unit on any stable flat surface, such as a table, platform, or Valleylab cart.

Carts with conductive wheels are recommended. Refer to the procedures for your

institution or to local codes for details.

3. According to the procedures used by your institution, connect an equipotential

grounding cable to the grounding lug on the rear panel of the unit. Then, connect the

cable to earth ground.

4. Plug the unit power cord into the rear panel receptacle. Secure the cord to the rear

panel using the screw and C clamp provided.

Warning

Electric Shock Hazard: Connect the unit power cord to a properly grounded receptacle. Do not

use power plug adapters.

Fire Hazard: Do not use extension cords.

Notice

Connect the power cord to a wall receptacle having the correct voltage. Otherwise, product

damage may result.

5. Plug the unit power cord into a grounded receptacle. Grasp the plug, not the power

cord. Do not pull on the cord itself.

Connecting the Argon Gas Tank(s)

Refer to Chapter 7 Replacement Procedures for instructions on connecting the argon

gas tanks to the Valleylab Argon Gas Delivery Unit II. Verify that the regulator to tank

fitting has been installed into the high pressure regulator.

Warning

Use only the high pressure regulator supplied with the Valleylab Argon Gas Delivery Unit II.

Replacement regulators should be ordered from Valleylab. Argon gas pressure should not exceed

434 KPa (63 psig) ± 5% at the regulator hose connection to the receptacle on the rear panel.

5-2 Valleylab Argon Gas Delivery Unit II Service Manual

Page 41

Setting up the Valleylab Argon Gas Delivery Unit II

Constructing an Extended Length Argon Gas Supply Hose

An extended supply hose may be required to access a remote argon gas supply source.

Warning

Use only high purity grade (99.998% pure or better) argon gas. Patient safety may be

compromised by using low purity gas.

High Pressure Hazard: Ensure that argon gas tanks and fittings used with the Valleylab Argon

Gas Delivery Unit II have been pressure tested, certified, and filled according to applicable

standards and local codes. In filling the tanks, ensure your supplier meets all local and national

codes. Do not over pressurize the tanks. Do not exceed 2,000 psig.

The regulator coupling in this unit is compatible with many common gas tanks (e.g., Freon®,

helium, krypton, neon, nitrogen, and xenon). Only connect argon gas to the Valleylab Argon Gas

Delivery Unit II. Using other gases may affect gas flow, create phosgene or other harmful gases, or

create an explosion hazard.

Setup, Tests, and Adjustments

Removing the argon gas supply hose from the Valleylab Argon Gas Delivery Unit II System

Equipment:

• Wire brush for cleaning threads.

• Two wrenches to fit applicable hose fittings.

1. Disconnect the Valleylab Argon Gas Delivery Unit II high pressure regulator assembly

from the argon gas tank.

– Follow the appropriate safety precautions for handling high pressure gas tanks. If

applicable, obtain the tank safety cap before proceeding.

– Make sure the Valleylab Argon Gas Delivery Unit II is off, the electrosurgical

generator is off or in standby, and the valves on both argon gas tanks are

completely closed.

– It is normal for a small amount of argon to escape during this procedure. To

disconnect the high pressure regulator assembly from the tank, hold the regulator

assembly stationary while you loosen the regulator coupling with a wrench. If

applicable, attach the safety cap to the top of the unused tank.

2. Disconnect the argon gas supply hose at the quick connect fitting on the rear panel of

the Valleylab Argon Gas Delivery Unit II.

3. Disconnect the Valleylab Argon Gas Delivery Unit II argon gas supply hose from the

outlet port of the high pressure regulator.

4. Remove the 1/4 in. NPT street elbow from the outlet port of the high pressure

regulator. If reusing the 1/4 in. NPT street elbow, clean all threads of old thread

sealant.

5. Clean old thread sealant from the 1/4 in. NPT hose fitting and the 1/4 in. FNPT

regulator threads.

Valleylab Argon Gas Delivery Unit II Service Manual 5-3

Page 42

Setting up the Valleylab Argon Gas Delivery Unit II

Removing the argon gas supply hose

Argon gas

supply hose

1/4 in. NPT

street elbow

1/4 in. NPT

outlet port

High pressure

transducer

Handwheel

Nipple

High pressure

regulator

5-4 Valleylab Argon Gas Delivery Unit II Service Manual

Page 43

Setting up the Valleylab Argon Gas Delivery Unit II

Connecting the Electrosurgical Generator and Accessories

A Force series electrosurgical generator should be used with the Valleylab Argon Gas

Delivery Unit II. Refer to the electrosurgical generator’s user’s guide or instruction manual

for detailed setup information. The electrosurgical generator may be stacked on top of

the Valleylab Argon Gas Delivery Unit II.

Important

When using the Force FX generator, connect the ESU interface cable to either the Monopolar 1 or

2 footswitch receptacle on the generator rear panel. The connected footswitch activates

monopolar output for the instrument connected to the corresponding numbered receptacle on

the front panel. Use only a Valleylab footswitch with the Force Argon-II. Use of an incompatible

footswitch may cause unexpected output.

1. Plug the electrosurgical generator into a hospital grade power receptacle.

2. Connect the ESU interface cable to the Valleylab Argon Gas Delivery Unit II and the

electrosurgical generator rear panels.

Setup, Tests, and Adjustments

Connecting the Valleylab Argon Gas Delivery Unit II and electrosurgical generator

Force FX Electrosurgical Generator

Valleylab Argon Gas

ESU Interface Cable

Delivery Unit II

Valleylab Footswitch

Valleylab Argon Gas Delivery Unit II Service Manual 5-5

Page 44

Setting up the Valleylab Argon Gas Delivery Unit II

Connect a handset to the system. The graphic below illustrates how to connect the

Argon Handset.

Important

Argon-enhanced coag will not function properly in low voltage Desiccate coag. Before using

argon-enhanced coag, be sure that the generator is set in the correct coag mode.

Force EZ – Fulgurate coag

Force FX – Spray coag

Connecting the Argon Plus Handset

Force FX Electrosurgical Generator

Valleylab Argon

Gas Delivery Unit II

5-6 Valleylab Argon Gas Delivery Unit II Service Manual

Page 45

General Test Information

General Test Information

Valleylab recommends that the Valleylab Argon Gas Delivery Unit II be inspected and

functionally checked once a year.

Warning

Electric Shock Hazard: The front heatsink on the power supply is at an elevated voltage. Do not

come in contact with it. Do not use it for ground.

Take appropriate precautions (such as use of isolated tools and equipment; use of the “one hand

rule,” etc.) when taking measurements or troubleshooting the unit.

Electric Shock Hazard: Do not touch any exposed wiring or conductive surface while the unit is

disassembled and energized.

Caution

The unit contains electrostatic sensitive components. When repairing the unit, work at a static

control workstation. Wear a grounding strap when handling electrostatic sensitive components.

Handle the circuit boards by their nonconductive edges. Use an antistatic container for transport

of electrostatic sensitive components and circuit boards.

Setup, Tests, and Adjustments

When testing, follow proper testing procedures in order to duplicate manufacturer test

data. Keep test leads as short as possible. Lead inductance and stray capacitance can

affect meter readings adversely. Use of uncompensated scope probes may cause large

errors in measurements. When measuring microampere leakage currents, accidental

capacitive or inductive coupling may cause order-of-magnitude error in the observed

values.

Valleylab Argon Gas Delivery Unit II Service Manual 5-7

Page 46

Recommended Test Equipment

Recommended Test Equipment

You will need the following equipment to perform the checks described in this chapter. If

substitute equipment is used, it must meet or exceed the specifications of the

recommended equipment.

Description Specifications

Electrosurgical generator Force EZ or Force FX Generator

Two bottles of argon With known gas pressures (within 100 psig)

Cylinder pressure 0 - 2000 psi cylinder pressure, 57 - 75 psi delivery

pressure gauge/regulator

Gas pressure gauge 0 - 100 (min.) psig

ESU interface cable

Argon Handset

Valleylab Argon Accessory

Banana plug

5-8 Valleylab Argon Gas Delivery Unit II Service Manual

Page 47

Mechanical Inspection

Mechanical Inspection

The following inspection assumes that you are familiar with the unit’s controls, indicators,

and receptacles.

Front Panel Controls

1. Ensure that the unit is not connected to power.

2. Check the following receptacles for damage or corrosion:

– AR Gas (male luer lock)

– Peritoneal Pressure Tubing (female luer lock)

– RF Input

– Handset

Setup, Tests, and Adjustments

3. Using a banana plug, check the RF Input and Handset receptacles for obstructions

and secure fit.

4. Check the On/Off switch for damage or corrosion.

Rear Panel Connectors

Verify that all connectors are properly and securely tightened.

Power Cord

The Valleylab Argon Gas Delivery Unit II is supplied with a hospital grade power

connector. The Valleylab representative in your country will equip your unit with the

proper connector for your operating room. The power connector meets all requirements

for safe grounding. Its purpose should not be defeated by using extension cords or threeprong to two-prong adapters.

Periodically check the power cord assembly for damaged insulation or connectors.

Always grasp cords by the connector. Do not pull on the cord itself.

Clean the power cord with a damp cloth and mild detergent. Let the power cord dry

completely, and install the power cord assembly.

Warning

Electric Shock Hazard Do not install a wet power cord assembly into the unit or

into a wall receptacle.

Valleylab Argon Gas Delivery Unit II Service Manual 5-9

Page 48

Initialization Sequence

Initialization Sequence

This test verifies that the Valleylab Argon Gas Delivery Unit II turns on and performs the

initialization sequence (self-test) properly. Before beginning this test, verify that:

• The Valleylab Argon Gas Delivery Unit II is connected to the electrosurgical generator

• At least one argon gas tank is attached to the unit (pressure must be greater than 300

• A handset is connected to the system.

1. Open the argon gas tank valve.

2. Press the unit power switch to the on position.

3. The unit conducts the initialization sequence. Check the following:

and both are plugged into hospital grade grounded receptacles.

psig). Valleylab recommends attaching two argon gas tanks to complete all test steps.

– All LED indicators and lamps illuminate for approximately three seconds.

– The Valleylab Argon Gas Delivery Unit II will purge the handset at 3 LPM.

4. After the initialization sequence, verify that:

– A single tone sounds.

–The Flow Rate display is dashed (– –).

–The Gas Off indicator illuminates.

–The Low Gas Flow indicator illuminates.

–The Peritoneal Pressure display flashes 0.

–The Overpressure Setpoint display indicates 5.

Functional Test with Gas

This test verifies that the Valleylab Argon Gas Delivery Unit II System functions properly

when it is turned on and used with gas. Test the Valleylab Argon Gas Delivery Unit II with

a Valleylab Argon Handset. If the unit does not perform as described in this test, refer to

Chapter 6 Troubleshooting for further information. For complete instructions regarding

use of the Force electrosurgical generator, refer to the appropriate user’s guide. Before

beginning this test, verify that:

• The Valleylab Argon Gas Delivery Unit II is connected to the electrosurgical generator

and both are plugged into hospital grade grounded receptacles.

• At least one argon gas tank is attached to the unit (pressure must be greater than 300

psig). Valleylab recommends attaching two argon gas tanks to complete all test steps.

• A handset is connected to the system.

5-10 Valleylab Argon Gas Delivery Unit II Service Manual

Page 49

Step 1 –Turn on the electrosurgical generator and place it in the

ready mode.

1. Press the electrosurgical generator power switch to the on position.

2. After the generator performs a self-test, short the generator Patient receptacle.

3. Press the generator Ready button (if applicable).

4. Ensure that all generator power levels are set at 1.

Step 2 –Turn on the Valleylab Argon Gas Delivery Unit II.

Refer to Initialization Sequence on page 5-10.

Step 3 –Verify that the unit controls function properly in the

standard gas flow mode.

Functional Test with Gas

Setup, Tests, and Adjustments

1. To select standard gas flow, press the Gas Range Flow selector on the front panel.

Verify that the Standard Gas Flow indicator illuminates. The Valleylab Argon Gas

Delivery Unit II sounds one tone.

2. To turn the gas on, press the Gas On/Gas Off button. Verify that the Gas On

indicator illuminates.

3. Tur n the Flow Control knob. Verify that the display changes from 0.5 to 12 and from

12 to 0.5. Set the gas flow to 1.

4. Ensure that both gas tank valves are open. Press the Tank Select 1 button and then

the Tan k S ele ct 2 button. Verify that both tanks have sufficient pressure. Verify that

the unit toggles between tank 1 and tank 2.

5. Press and release the Gas Line Purge button. Verify that the Gas Flow indicator

illuminates for one to two seconds, and that the unit discharges argon through the

gas tubing.

6. Turn the gas off by pressing the Gas On/Gas Off button. Verify that the Gas Off

indicator illuminates.

Step 4 –Verify gas flow and electrosurgical generator control.

1. Turn on the gas at the handset. Verify that the Gas On indicator illuminates and that

a single tone sounds.

2. Using the Flow Control knob, set the gas flow to 5.

3. Press the yellow cut and blue coag buttons. Verify that the generator activates, and

that gas flows to the handset when activating cut and coag.

4. Turn off the gas at the handset. Verify that the Gas Off indicator illuminates, and that

a tone sounds. Press the yellow cut and blue coag buttons, and verify that no gas

flows to the handset.

Valleylab Argon Gas Delivery Unit II Service Manual 5-11

Page 50

Functional Test with Gas

Step 5 –Verify that the gas line obstruction alarm functions

properly.

1. Turn on the gas at the handset. Verify that the Gas On indicator illuminates and that

a tone sounds.

2. Verify that the gas flow is still set at 5.

3. Press the yellow cut button or the blue coag button on the handset. While gas flows

to the handset, pinch the gas line to obstruct the gas flow. Verify the following:

–The Obstruction indicator illuminates.

–The Gas Flow indicator flashes.

– An alarm sounds until you release the cut or coag button.

– The gas line depressurizes (may be hard to detect).

4. With the gas line still pinched, press the yellow cut button or the blue coag button on

the handset. Verify that the alarm recurs. Release the pinched gas line.

Step 6 –Verify that the low pressure alarms operate properly.

1. Close both tank valves. Turn the Flow Control knob to set the gas flow to 12. Press

the yellow cut button on the handset.

2. Observe an apparent decrease in the pressure of the tank being used. Verify that the

Low Pressure Alarm indicator illuminates for the tank below 10%.

3. Observe a tank switch when the pressure is below 5% and the Low Pressure Alarm

indicator flashes.

4. Continue to press the yellow cut button on the handset. Verify that the Low Pressure

Alarm indicator illuminates for the second tank below 10%.

5. Verify that both Low Pressure Alarm indicators flash and that an alarm sounds

when both tanks are shown as being below 5%.

6. Turn off the gas at the handset.

7. Press the yellow cut button on the handset. Verify that the generator’s yellow Cut

indicator illuminates.

8. Press the blue coag button on the handset. Verify that the generator’s blue Coag

indicator illuminates.

9. Open both tank valves; the alarm should clear.

Step 7 –Verify that the footswitch operates properly.

1. Connect the footswitch to the Valleylab Argon Gas Delivery Unit II. Do not plug the

footswitch connector into the electrosurgical generator.

2. Turn the gas back on with the Gas On/Gas Off button. Verify that the Gas On

indicator illuminates.

5-12 Valleylab Argon Gas Delivery Unit II Service Manual

Page 51

Functional Test with Gas

3. Press the left pedal. Verify that the handset operates in cut.

4. Press the right pedal. Verify that the handset operates in coag.

Step 8 –Verify that the unit controls function properly in the low