Valley Center Pivot 7000 Series, Center Pivot 8000 Series, Center Pivot 8120 Series Owner's Manual

Center Pivot

7000, 8000, 8120 Series

Owner's Manual

0994464_M

© 2019 Valmont Industries, Inc., Valley, NE 68064 USA. All rights reserved.

www.valleyirrigation.com

2 Center Pivot 7000, 8000, 8120 Series

TABLE OF CONTENTS

CENTER PIVOT 7000, 8000, 8120 SERIES OWNER'S MANUAL .................................................................... 1

TABLE OF CONTENTS ..................................................................................................................................... 3

SERIES SPAN IDENTIFICATION ...................................................................................................................... 5

EC DECLARATION OF CONFORMITY............................................................................................................. 6

ELECTRICAL SAFETY STATEMENT ............................................................................................................... 7

ABOUT THIS MANUAL ..................................................................................................................................... 7

ANCILLARY EQUIPMENT WARRANTY ........................................................................................................... 7

SAFETY ............................................................................................................................................................. 8

Recognize Safety Information ..............................................................................................................................................8

Safety Messages ..............................................................................................................................................................8

Information Messages ......................................................................................................................................................8

Use of Personal Protective Equipment ................................................................................................................................9

Conductive Materials and Equipment ..................................................................................................................................9

Fall Protection ......................................................................................................................................................................9

Minimum Working Clearance .............................................................................................................................................10

Qualified Person ................................................................................................................................................................10

Irrigation Equipment near Airports and Crop Dusting Aircraft ...........................................................................................10

Overhead Power Lines ......................................................................................................................................................11

Minimal Lockout / Tagout Procedure ..................................................................................................................................12

Sequence of Lockout ......................................................................................................................................................12

Restoring Equipment to Service ..................................................................................................................................... 12

Operate Safely ...................................................................................................................................................................13

Safety Decals .....................................................................................................................................................................17

OVERVIEW....................................................................................................................................................... 21

Pivot ...................................................................................................................................................................................21

Collector Ring and J-Pipe ..................................................................................................................................................21

Pivot Flex ...........................................................................................................................................................................21

Spans ................................................................................................................................................................................22

Overhang (Option) .............................................................................................................................................................23

End Gun (Option) ..............................................................................................................................................................23

Drive Towers ......................................................................................................................................................................23

Water Application ...............................................................................................................................................................24

Span Cable ........................................................................................................................................................................24

Intermediate Tower Boxes..................................................................................................................................................24

Last Tower Box ..................................................................................................................................................................24

Safety Circuit .....................................................................................................................................................................24

Alignment ...........................................................................................................................................................................25

Over Watering Timer ..........................................................................................................................................................26

Stop In Slot Control - Mechanical (Option) ........................................................................................................................26

End Gun Control - Mechanical (Option) ............................................................................................................................26

End Gun and Stop In Slot Control - Electronic (Option) ....................................................................................................27

Public Power Towable (Option) ..........................................................................................................................................27

Drive Unit Mounted End of Field Stop/Auto Reverse (Option) ...........................................................................................28

Auto Reverse/Auto Stop Box (Option).............................................................................................................................28

Pivot Mounted Auto Reverse (Option) ...............................................................................................................................29

OPERATION .................................................................................................................................................... 31

Machine Operation ............................................................................................................................................................31

Part Circle Operation .........................................................................................................................................................31

Towable Pivots ...................................................................................................................................................................32

Towing Option ....................................................................................................................................................................33

Preparing Drive Units for Towing .....................................................................................................................................33

Preparing Drive Units for Operation ................................................................................................................................37

Towing the Skid Tow Pivot ...............................................................................................................................................41

Towing the 2 Wheel E-Z Tow Pivot ..................................................................................................................................47

Towing the 4 Wheel E-Z Tow Pivot - Fixed Tire ............................................................................................................... 53

Towing the 4 Wheel E-Z Tow Pivot - Swivel Tire .............................................................................................................57

Center Pivot 7000, 8000, 8120 Series 3

TABLE OF CONTENTS

MAINTENANCE ............................................................................................................................................... 63

Safety .................................................................................................................................................................................63

Wheel Gearbox 7000 Series..............................................................................................................................................64

Center Drive Gearmotor 7000 Series ................................................................................................................................ 65

Wheel Gearbox 8000/8120 Series.....................................................................................................................................66

Center Drive Gearmotors 8000/8120 Series .....................................................................................................................67

Helical Gearmotor ........................................................................................................................................................... 67

Worm Gearmotor ............................................................................................................................................................ 67

Tire and Wheel ..................................................................................................................................................................68

Towable Hub Lubrication .................................................................................................................................................68

Wheel Lug Nut Torque ....................................................................................................................................................68

Tire Pressures ................................................................................................................................................................68

Barricade ..........................................................................................................................................................................69

Wheel Tracks .....................................................................................................................................................................69

Engine/Generator ..............................................................................................................................................................69

Miscellaneous ....................................................................................................................................................................70

Flex Hose Replacement..................................................................................................................................................70

Bonding Ground Wire .....................................................................................................................................................70

Electrical and Grounding Conductors ............................................................................................................................. 70

Pivot Swivel Lubrication ..................................................................................................................................................70

2 Wheel E-Z Tow Pivot Swivel Bearing Lubrication.........................................................................................................71

Standard and 4 Wheel E-Z Tow Pivot .............................................................................................................................72

Pivot Mounted Auto Reverse Adjustment.....................................................................................................................72

Mechanical Stop In Slot Adjustment ............................................................................................................................73

Pivot Mounted Auto Reverse Adjustment.....................................................................................................................74

2 Wheel E-Z Tow Pivot ....................................................................................................................................................75

Mechanical End Gun Ramp Adjustment ......................................................................................................................75

Mechanical Stop In Slot Adjustment ............................................................................................................................76

Pivot Mounted Auto Reverse Adjustment.....................................................................................................................77

Actuator Bolt Adjustment .............................................................................................................................................77

Pivot Mounted Auto Reverse Example Settings...........................................................................................................78

End Gun Arc Setting Example ........................................................................................................................................79

Machine Alignment ............................................................................................................................................................80

Tower Alignment - Three Tower Method ..........................................................................................................................81

Standard Alignment Adjustment .....................................................................................................................................82

Modified Alignment Adjustment ......................................................................................................................................83

Pivot Floating Alignment Adjustment ..............................................................................................................................84

Setting Alignment Cable Tension ....................................................................................................................................... 85

2 Wheel E-Z Tow Power Supply Installation Example ........................................................................................................87

Span Flushing Procedure ..................................................................................................................................................88

Winterization ...................................................................................................................................................................... 91

Off Season Storage of Hose ...........................................................................................................................................91

Off Season Storage of Electric Cord ...............................................................................................................................91

Regular Maintenance ........................................................................................................................................................92

Pivot ................................................................................................................................................................................92

Span ...............................................................................................................................................................................92

Sprinkler ..........................................................................................................................................................................93

Alignment ........................................................................................................................................................................93

Drive Unit ........................................................................................................................................................................94

Critical Torque Applications .............................................................................................................................................95

Hardware Identification ...................................................................................................................................................95

Torque Chart ................................................................................................................................................................... 95

Annual Maintenance Logs .................................................................................................................................................96

TROUBLESHOOTING ................................................................................................................................... 103

Safety ...............................................................................................................................................................................103

In-Line Shut Down ...........................................................................................................................................................104

Tower Ahead Shut Down .................................................................................................................................................105

Tower Behind Shut Down ................................................................................................................................................106

4 Center Pivot 7000, 8000, 8120 Series

SERIES SPAN IDENTIFICATION

7000

7000

8000

8000

8120 (International Only) 5 ft (1524 mm)

8120 (INTERNATIONAL ONLY)

Center Pivot 7000, 8000, 8120 Series 5

5 ft (1524 mm)

Pipes

PIPES

EC DECLARATION OF CONFORMITY

We: Valmont Industries, Inc.

28800 Ida Street

Valley, NE 68064

+1 402.359.6312

+1 402.359.6143 (Facsimile)

declare under our sole responsibility that the product,

Crop Irrigation System

to which this documentation relates, is in conformity with the following documents:

Machinery Directive 2006/42/EC

Low Voltage Directive 2014/35/EU

Electromagnetic Compatibility Directive 2014/30/EU

The above-referenced equipment is in conformity with all safety-related clauses (Not all clauses reflecting commercial preference are met) of the following documents:

EN 60204-1:2006 Safety of Machinery – Electrical Equipment of Machines

EN 12100:2010 Safety of Machinery

EN 909:1998+A1 Irrigation Machines

Statement regarding Pressure Equipment Directive 97/23/EC:

Serial Number:

Purchase Order:

The Crop Irrigation System is excluded from the scope of the Pressure Equipment Directive, by the

language of Article 1, Sections 3.2, 3.6 & 3.10. This equipment is classified less than Category 1.

Statement regarding RoHS Directive 2011/65/EC:

The Crop Irrigation System is excluded from the scope of the RoHS Directive, by the language of Article

2, Section 4(e), being a “Large Scale Fixed Installation.”

Person Authorized to Compile the Technical File in Europe: Ruediger Claas

Relevant information will be transmitted via email Valmont Industries Inc.

in response to a reasoned request by national authorities Nordring 4

45894 Gelsenkirchen

Germany

+49(151)16716790

Ron Pollak Date of Issue: December 17, 2018

Senior Electrical Engineer Place of Issue: Valley, NE 68064

Valmont Industries, Inc.

6 Center Pivot 7000, 8000, 8120 Series

ELECTRICAL SAFETY STATEMENT

Installation Of The Valley Electric Irrigation Machine - European Union Only

Valmont Industries Inc. does not install a differential (ground fault) circuit breaker in the control panel of the

Valley electric irrigation machine because the standards of protection vary according to country of destination.

The distributor must provide and install a differential (ground fault) circuit breaker that meets the standards of

the country where the Valley irrigation machine is installed.

In the European Union, differential circuit breaker protection is fixed at a maximum of 24 volts.

Good grounding of the Valley irrigation machine is required.

• If resistance to ground is lower than 80 ohms, a differential (ground fault) circuit breaker of 300 mA will meet

requirements.

• If resistance to ground is between 80 and 800 ohms, a differential (ground fault) circuit breaker of 30 mA will

meet requirements.

The power supply installation and inspection of equipment protection components or systems are the responsibility of the installer. Valmont Industries, Inc. is not responsible for the failure of equipment protection components or systems not of their manufacture.

Valley pivot irrigation machines receiving power from a generator must have a cable connected from the irrigation machine structure to a ground rod and another cable from the irrigation machine structure to the ground

terminal on generator in order for the differential (ground fault) circuit breaker to work.

The linear irrigation machines equipped with a generator are not equipped with a ground rod but must have a

cable connected from the linear irrigation machine structure to the ground terminal of the generator in order for

the differential (ground fault) circuit breaker to work.

• The resistance between the irrigation machine and the generator must be substantially below 80 ohms.

About This Manual

Information contained in this manual applies to Valley Center Pivot and its use with the 7000, 8000 and 8120

Series of spans.

For proper operation of the Center Pivot machine, the Control Panel Owner’s Manual and Center Pivot Owner’s

Manual must be used together.

The Control Panel Owner’s Manual includes safety guidelines and explains the basic operation of the control

panel itself, including how to start/stop the machine, change running direction and change water application

amounts.

All Owner’s, operators and maintenance personnel MUST read and understand the Control Panel Owner’s

Manual and the Center Pivot Owner’s Manual.

All information in this manual is based on information available at the time of printing. Valmont Industries Inc.

reserves the right to make changes at any time without notice and without incurring any obligation. Specifications are applicable to equipment sold within the United States and may vary outside of the United States.

Ancillary Equipment Warranty

The owner is responsible for warranty registration of all ancillary equipment such as but not limited to engines,

pumps and generators with its respective manufacturer.

Center Pivot 7000, 8000, 8120 Series 7

SAFETY

Recognize Safety Information

This irrigation equipment may be powered by high voltage which can be extremely dangerous if used improperly. For maximum safety and optimum performance of the machine, all owner’s operator’s and maintenance

personnel must read and understand the owner/operator manual(s), all safety messages in this manual and

safety signs/decals on the machine before operating this equipment.

Anyone assembling, operating, servicing or maintaining this machine must read and understand all operation, maintenance, troubleshooting, testing, installation, assembly instructions and all safety messages in this

manual before operating the machine or beginning any maintenance, troubleshooting, testing, installation or

assembly of components.

These instructions alert you to certain things you should do carefully; if you don’t, you could hurt yourself or

others, hurt the next person who operates the equipment, or damage the equipment.

Safety Messages

Safety messages in this manual are preceded by the hazard symbol and one of three words, danger, warning

or caution. These messages alert you to potential hazards that could hurt you or others and or cause property

damage.

This HAZARD SYMBOL is used to alert you to information about unsafe actions or situations, and may

!

be followed by the word danger, warning, or caution.

!

DANGER

The HAZARD SYMBOL used with the word DANGER, will describe immediate hazards that may result in

severe personal injury or death.

!

WARNING

The HAZARD SYMBOL used with the word WARNING, will describe unsafe actions or situations that may

cause severe injury, death and/or major equipment or property damage.

!

CAUTION

The HAZARD SYMBOL used with the word CAUTION, will describe unsafe actions or situations that may cause

injury, and/or minor equipment or property damage.

Information Messages

Important information messages in this manual are preceded by the word NOTE.

NOTE

The word NOTE is used to alert you to information that describes procedures or tips to help you install, operate

or maintain your equipment properly.

8 Center Pivot 7000, 8000, 8120 Series

SAFETY

Use of Personal Protective Equipment

• People working in areas where there are potential electrical hazards must use, personal protective equipment

that is appropriate for the specific parts of the body to be protected and for the work to be performed. Refer to

U.S. Occupational Safety & Health Administration (OSHA) Regulations (Standards - 29 CFR) Safeguards for

personnel protection. - 1910.335, or applicable national, state or local regulations, for additional information.

• Personal protective equipment must be maintained in a safe, reliable condition and periodically inspected or

tested.

• Protective shields, protective barriers, or insulating materials must be used to protect each person from

shock, burns, or other electrically related injuries while that person is working near exposed energized parts

which might be accidentally contacted or where dangerous electric heating or arcing might occur. When normally enclosed live parts are exposed for maintenance or repair, they must be guarded to protect unqualified

persons from contact with the live parts.

• Safety signs and tags. Safety signs, safety symbols, or accident prevention tags must be used where necessary to warn people about electrical hazards which may endanger them.

Conductive Materials and Equipment

Materials and equipment that may conduct electricity must be handled in a way that will prevent them from

contacting energized power lines, exposed conductors or circuit parts.

• When handling long conductive objects (such as but not limited to truss rods, pipes, angles and ladders) in

areas with energized power lines, exposed conductors or circuit parts, work practices (such as the use of

insulation, guarding, and material handling techniques) must be used to minimize the hazard.

• Portable ladders must have non-conductive side rails.

• Do not wear conductive articles of jewelry and clothing (such as but not limited to watch bands, bracelets,

rings, key chains, necklaces, metalized aprons, cloth with conductive thread, or metal headgear) that could

come in contact with energized power lines, exposed conductors or circuit parts.

Fall Protection

Identify potential fall hazards and determine if fall protection equipment is appropriate for the task, before beginning the work. Pay attention to hazards associated with routine and non-routine tasks. Inspect fall protection

equipment (harnesses, lanyards) and devices (guardrails, tie-off points) before each use. Use fall protection

equipment if required for the job. Be sure the fall protection equipment is right for the task, fits properly, and is in

good condition. Refer to U.S. Occupational Safety & Health Administration (OSHA) Regulations Standards - 29

CFR 1926.500, 1926.501 and 1926.502, or applicable national, state or local regulations for more information.

• When using scaffolds, make sure there is proper access, full planking, stable footing, and guard railing.

• When using a boom lift, keep feet firmly on the platform of a boom lift, use fall protection equipment tied-off

at all times to the guardrail or tie-off point.

• When using a ladder, make sure the ladder is non-conductive and the correct size for the task. Read the

ladder user instructions and be sure the ladder is in good condition. Make sure ladder is set on stable footing

and at the correct angle.

Center Pivot 7000, 8000, 8120 Series 9

SAFETY

Minimum Working Clearance

To reduce the risk of injury, all persons require adequate working clearance around the electrical panel or other

electrical equipment. The table below identifies the minimum working clearance needed. Refer to U.S. Occupational Safety & Health Administration (OSHA) Regulations (Standards - 29 CFR) Safeguards for personnel protection. -1910.303(g)(1)(i), or any other applicable national, state or local regulations, for additional information.

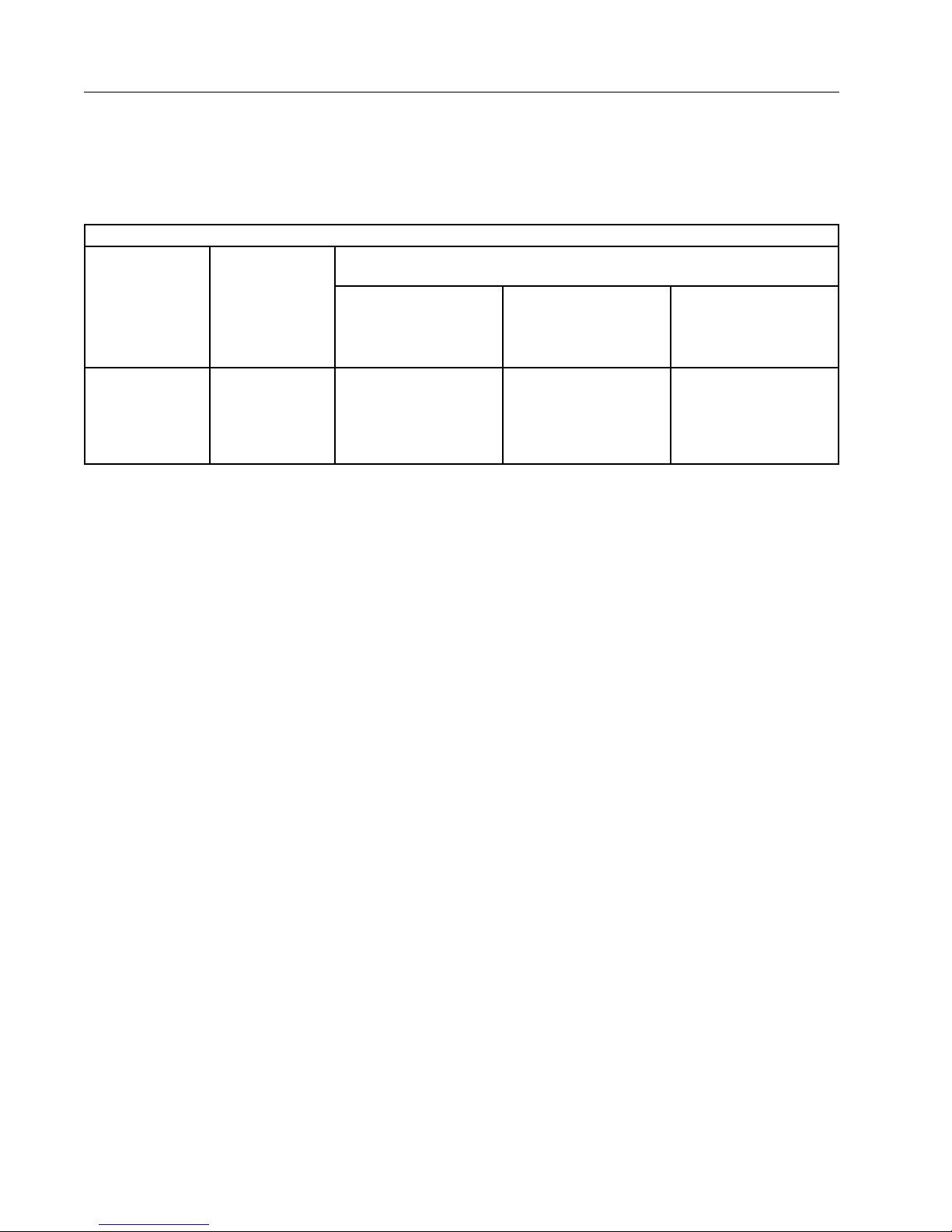

MINIMUM WORKING CLEARANCE 0-600 VOLTS

WIDTH

OF WORKING

CLEARANCE

AREA

30 in (76.2 cm)

MINIMUM OR

WIDTH OF

ENCLOSURE,

WHICH EVER IS

GREATER

Concrete, brick or tile walls shall be considered as grounded.

Qualified Person

A Qualified person is one who, by possession of a recognized degree, certificate, or professional standing, or

who by extensive knowledge, training, and experience, has successfully demonstrated his/her ability to solve or

resolve problems related to the subject matter, the work, or the project.

Only qualified persons may work on electric circuit parts or equipment that have not been de-energized.

Refer to U.S. Occupational Safety & Health Administration (OSHA) Regulations Standards - 29 CFR 1926.32(m)

and 1910.333, or applicable national, state or local regulations for additional information.

HEIGHT

OF WORKING

CLEARANCE

AREA

78 in (198.1 cm)

MINIMUM OR

HEIGHT OF

ENCLOSURE,

WHICH EVER IS

GREATER

MINIMUM WORKING CLEARANCE

IN FRONT OF ELECTRICAL PANEL/EQUIPMENT

EXPOSED LIVE PARTS

ON ONE SIDE OF WORK

SPACE AND NO LIVE

GROUNDED PARTS ON

THE OTHER SIDE.

36 in (91.4 cm) MINIMUM 42 in (107 cm) MINIMUM 48 in (122 cm) MINIMUM

EXPOSED LIVE PARTS

ON ONE SIDE OF WORK

SPACE AND LIVE

GROUNDED PARTS ON

THE OTHER SIDE.

EXPOSED LIVE PARTS

ON ONE SIDE OF WORK

SPACE AND EXPOSED

LIVE PARTS ON THE

OTHER SIDE.

Irrigation Equipment near Airports and Crop Dusting Aircraft

• If any part of the irrigation machine comes within 3200 ft (975 m) of an airport runway, especially the approach (ends) of the runway, additional warning markers may be required. In the United States, CFR Title 14,

Chapter I, Subchapter E, Part 77 – Safe, Efficient Use, and Preservation of the Navigable Airspace describes

when marking is needed.

This document is available at: www.ecfr.gov

• Marking requirements vary depending on the location of the irrigation equipment relative to the runway, the

type of airport (Civil, Military, or Heliport) and other factors. Contact the local airport authority for guidance

and specific recommendations. In the United States, guidelines for marking structures near airports are

published by the Federal Aviation Administration in Advisory Circular AC 70/7460-1L – Obstruction Marking

and Lighting.

Available here: www.faa.gov/regulations_policies/advisory_circulars

• For irrigation machines near private or unregulated airfields, including farm-based airstrips, Valley strongly

recommends complying with the same standards and requirements as Civil airports as shown in Part 77.

• Regulations vary by country, contact your local aviation authority for guidance.

Overhang cables, including overhang back cables are a particular danger. In locations where low-flying

aircraft are likely, such as within 1,500 ft (457 m) of an end of an airport runway, or where crop dusting aircraft

are common, Valley recommends adding obstruction markers to overhang cables to improve their visibility.

For large overhangs (36 ft / 10.97 m Heavy Duty and longer), five 12 in (300 mm) or 20 in (500 mm), aviation

orange marker balls are sufficient. One near the rabbit ears, two in the middle of the back cables and two in

the middle of the highest overhang cables. Refer to Section 3.5 in AC70/7460-1 for additional details. Aviation

marker balls are available online and from a variety of aviation and airport safety equipment providers.

10 Center Pivot 7000, 8000, 8120 Series

SAFETY

Overhead Power Lines

Assembling, towing or transporting irrigation machine components such as but not limited to the pivot point,

linear cart, span/drive unit assemblies, overhangs and/or corner assemblies underneath or near power lines is

extremely dangerous because of the risk of electrocution.

Operating equipment that elevates irrigation machine components, such as but not limited to an aerial lift or

crane, near power lines is extremely dangerous because of the risk of electrocution. Only qualified personnel

should operate this type of equipment. Before operating the equipment, qualified personnel must read the

equipment manufacturers’ operating and safety instructions.

Refer to U.S. Occupational Safety & Health Administration (OSHA) Regulations (Standards - 29 CFR) Cranes

and derricks. - 1926.550, or any other applicable national, state or local regulations for additional information.

• Always presume that any overhead power line is an energized line unless and until the person(s) owning

the line and/or the electrical utility authorities indicate that it is not an energized line and it has been visibly

grounded.

• Before operating any equipment near any power line make sure the line has been de-energized and

visibly grounded at the point of work.

• Electrocution can occur without touching an electrical power line. Electricity, depending on the magnitude,

can jump or become induced into equipment or conductive materials that come in close proximity to,

but do not touch a power line. High wind, lightening, wet ground and other environmental conditions will

increase the possibility of electrocution and require additional consideration.

• Transmitter towers can induce the equipment or materials being handled with an electrical charge. Before

working or operating equipment near transmitter towers make sure the transmitter is de-energized.

• Select the location where the span/drive unit will be assembled to ensure that neither the irrigation machine, or the equipment used during the assembly process, will violate the minimum clearance guidelines.

• Never operate equipment or allow the load, ropes or tag lines within 10 ft (3.05 m) of any power line rated

50 kV or lower whether it is energized or not. For lines rated over 50 kV, the minimum clearance shall be

10 ft plus 0.4 in (1.1 cm) for each kV over 50 kVs.

• Never assemble, tow, transport or allow irrigation machine components underneath or within 10 ft (3.05

m) of any power line rated 50 kV or lower whether it is energized or not. For lines rated over 50 kV, the

minimum clearance shall be 10 ft plus 0.4 in (1.1 cm) for each kV over 50 kVs. Overhang support angles,

cables and spinner drive components regularly extend 10 ft to 12 ft (3.1 m to 3.7 m) above the irrigation

pipeline (span).

• Use barricades to identify areas where interference with overhead power lines could occur. Keep the assembly, towing or transporting of irrigation machine components and the operation of equipment including

load, ropes or tag lines away from any power line, in the distances described above, whether the line is

energized or not.

• Always designate a person to observe clearance between the power line and all equipment being operated or moved in order to give timely warning for all operations to STOP if the minimum clearance is

violated.

Center Pivot 7000, 8000, 8120 Series 11

SAFETY

Minimal Lockout / Tagout Procedure

The following procedure establishes the minimum requirements for the lockout of energy isolating devices

whenever maintenance or servicing is done on machines or equipment. It is used to ensure that the machine

or equipment is stopped, isolated from all potentially hazardous energy sources and locked out before personnel perform any servicing or maintenance where the unexpectedly energized or start-up of the machine or

equipment or release of stored energy could cause injury. All personnel, upon observing a machine or piece of

equipment which is locked out to perform servicing or maintenance shall not attempt to start, energize, or use

that machine or equipment.

When the energy isolating devices are not lockable, tagout should be used and affected personnel must wear

full personal protection.

Refer to U.S. Occupational Safety & Health Administration (OSHA) Regulations (Standards - 29 CFR) Typical

minimal lockout procedures - 1910.147 App A, or applicable national, state or local regulations, for additional

information.

Sequence of Lockout

1. Notify all affected personnel that servicing or maintenance is required on a machine or equipment and that

the machine or equipment must be shut down and locked out to perform the servicing or maintenance.

2. The authorized personnel shall identify the type and magnitude of the energy that the machine or equipment utilizes, shall understand the hazards of the energy, and shall know the methods to control the energy.

3. If the machine or equipment is operating, shut it down by the normal stopping procedure (depress the stop

button, open switch, close valve, etc.).

4. De-activate the energy isolating device(s) so that the machine or equipment is isolated from the energy

source(s).

5. Lock out the energy isolating device(s) with assigned individual lock(s).

6. Stored or residual energy (such as that in capacitors, springs, elevated machine members, rotating flywheels, hydraulic systems, and air, gas, steam, or water pressure, etc.) must be dissipated or restrained by

methods such as grounding, repositioning, blocking, bleeding down, etc.

7. Ensure that the equipment is disconnected from the energy source(s) by first checking that no personnel

are exposed, then verify the isolation of the equipment by operating the push button or other normal operating control(s) or by testing to make certain the equipment will not operate.

!

CAUTION

• RETURN OPERATING CONTROL(S) TO NEUTRAL OR “OFF” POSITION AFTER VERIFYING THE

ISOLATION OF THE EQUIPMENT.

8. The machine or equipment is now locked out.

!

DANGER

• WHEN PERSONNEL WILL BE EXPOSED TO CIRCUIT ELEMENTS AND ELECTRICAL PARTS, A

QUALIFIED PERSON MUST USE TEST EQUIPMENT TO VERIFY THAT THE CIRCUIT ELEMENTS

AND EQUIPMENT PARTS OF THE EQUIPMENT ARE DE-ENERGIZED.

Restoring Equipment to Service

When the servicing or maintenance is completed and the machine or equipment is ready to return to normal

operating condition, the following steps shall be taken:

1. Check the machine or equipment and the immediate area around the machine to ensure that non-essential

items are removed and that the machine or equipment components are operationally intact.

2. Check the work area to ensure that all personnel are safely positioned or removed from the area.

3. Verify that the controls are in neutral.

4. Remove the lockout devices and re-energize the machine or equipment.

5. Notify affected personnel that the servicing or maintenance is completed and the machine or equipment is

ready to be used.

12 Center Pivot 7000, 8000, 8120 Series

SAFETY

Operate Safely

Valley Irrigation machines are designed with safety in mind. However, if this machine is operated incorrectly, it

may pose a safety threat to the operator. A good safety program is much like a chain, it is only as strong as its

weakest link. The manufacturer, dealer, and operator must maintain and improve all safety programs. Following

is a list of safety operating tips which you and all other persons servicing or operating the machine must read

and understand.

!

CAUTION

• DO NOT operate this machine without first reading the Owner’s Manuals for the machine.

• Read all safety messages in this manual and

safety signs on the machine.

• DO NOT let anyone operate this machine without proper instructions.

• Unauthorized modifications may impair the function and/or safety of the machine.

• If you do not understand any part of this manual,

contact your Valley dealer.

EMPLOYEE INSTRUCTION ON SAFETY

It is very important to instruct your employees on the

safe use of this equipment at the time of their initial

assignment to operate it. DO NOT let anyone operate this equipment without proper instructions.

Safety training should be presented annually and

the service manager should ensure employees fully

understand the safety messages and what to do in

case of emergencies.

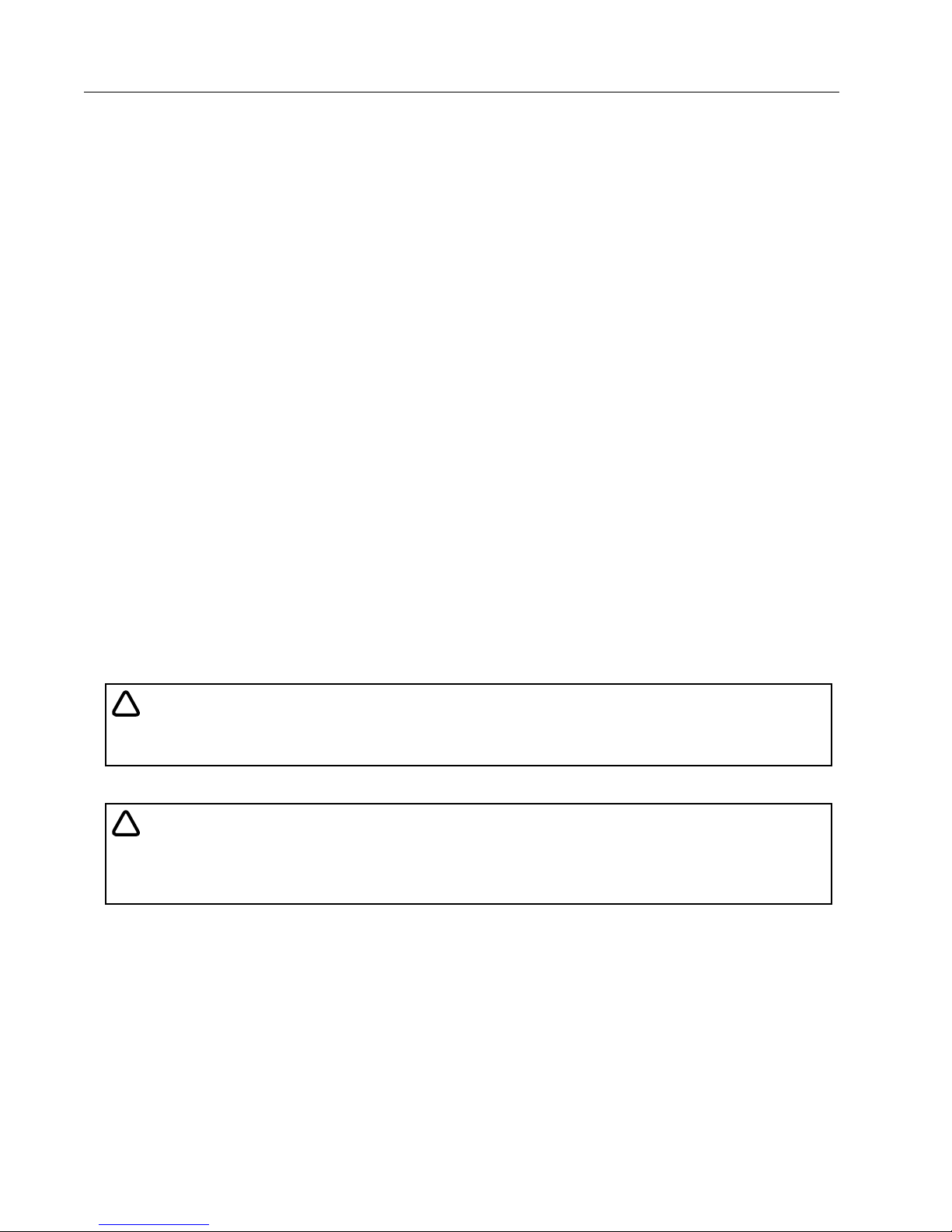

EMERGENCY STOPPING

The machine can be stopped at any time at any tower

by turning the disconnect switch, located underneath

the tower box, to the OFF position. See Figure 13-1.

!

WARNING

PROPER GROUNDING

DO NOT attempt to start the machine until the electrical service is properly installed and grounded by a

qualified electrician as per the electrical standards.

If the power supplied to the machine is not grounded

properly, severe injury or death can result should an

electrical malfunction occur.

It is your responsibility to ensure that your power

supplier and/or electrical contractor has grounded

the irrigation machine as required by the National

Electrical Code and by applicable local electrical

codes. If a machine is properly grounded and fuse

sizing is correct, there is extremely low probability of

an individual being injured by electrical shock.

5

4

3

Figure 13-1 1 . Disconnect Switch

2

1

Figure 13-2 1 . Ground Rod Installation

1

NOTE

• All 480 VAC, 60 Hz (380 VAC, 50 Hz) power supply services MUST be a 4 conductor service.

Three 480 VAC (380 VAC) power lines and one

ground conductor which is as large as the

power carrying conductors for that service.

2. Service Conductor

3. Copper Ground Rod

Center Pivot 7000, 8000, 8120 Series 13

4. Copper Ground Wire

5. Clamp

SAFETY

Operate Safely

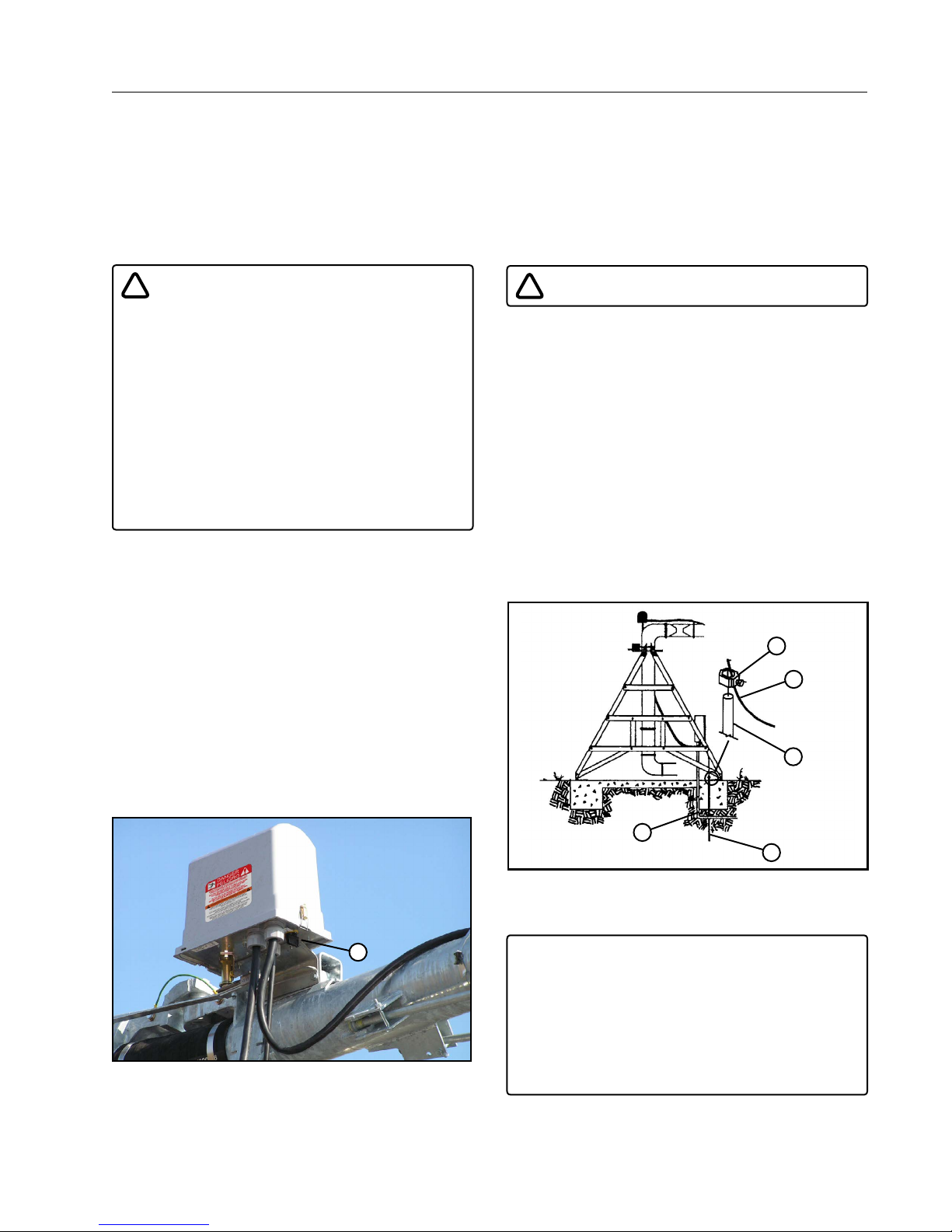

!

DANGER

DISCONNECT POWER WHEN SERVICING

ALWAYS disconnect electrical power before servicing or performing maintenance to the machine.

If you are going to perform maintenance on the machine, YOU MUST shut off and lock the main power

disconnect as shown below. See Figure 14-1.

1

2

Figure 14-1 1 . Main Power Disconnect

2. Lock

!

CAUTION

QUALIFIED SERVICE PERSONNEL

If you do not understand electricity or other parts of

the machine, have qualified service personnel perform any hazardous repairs or maintenance.

!

CAUTION

GUARD ALL POWER TAKE-OFF DRIVES

This includes all belt and power line drives.

Replace any guards and shields removed for maintenance.

!

WARNING

MARK AND GUARD ALL POWER LINES

Do NOT deep rip or chisel near the buried power

service wires.

Do NOT deep rip in a circle at the drive unit. The

deep chisel track will cause severe stresses on the

structure.

If you do deep rip your field, run the machine with the

percent timer at 100% for the first revolution.

!

WARNING

The blue (OSHA safety color code) tag shown below

should also be filled out and attached to the disconnect after locking. See Figure 14-2.

The tag should reveal the name of a person to contact before restoring power to the machine.

DANGER

DO NOT

OPERATE

SIGNED BY:

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

DATE:

Figure 14-2

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

0992009

FRONT

FRONT BACK

DANGER

DO NOT REMOVE

THIS TAG

REMARKS:

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

SEE OTHER SIDE

BACK

SUSPECTED SHORT CIRCUITS

DO NOT touch the machine if you suspect a shortcircuit situation. Call a qualified electrician or an

authorized Valley dealer immediately.

Circumstances which may cause you to suspect hazardous voltage situations may include:

• Physical damage to the machine or span cable

• Recent electrical storms (lightning)

• Unusual operating characteristics of the machine

If you suspect a short circuit due to feeling a rippling

tingle when touching the machine, DO NOT touch

the machine again. Call a qualified electrician or an

authorized Valley dealer immediately.

!

WARNING

LIGHTNING AND THE MACHINE

Stay away from the machine during an electrical

storm. An irrigation machine makes a good path to

earth. It is also probably the tallest object in the field,

which makes it a good lightning receptor!

14 Center Pivot 7000, 8000, 8120 Series

Operate Safely

SAFETY

!

CAUTION

DO NOT OVERSIZE FUSES

Fuses are sized for the protection of a specific machine.

Be certain you have the proper fuse sizes in place

before initial start-up and when replacing fuses.

!

CAUTION

PLUG - IN CONNECTORS

Disconnect power before connecting or disconnecting any plug-in connectors.

!

CAUTION

DO NOT OPERATE AT FREEZING TEMPERATURES

Spraying water has a cooling effect and water will

freeze even though the air temperature is slightly

above freezing.

Shut the machine down at 40 degrees Fahrenheit

(4.5 degrees Celsius). Do not operate machine when

temperature is below 40° F (4.5° C).

• DAMAGE TO EQUIPMENT RESULTING FROM

FREEZE-UP IS NOT COVERED UNDER WARRANTY.

• IT IS IMPORTANT TO MAKE SURE ALL PIPE

DRAINS FUNCTION PROPERLY TO PREVENT

PIPELINE FREEZE-UP DURING COLD WEATHER.

!

CAUTION

AVOID HIGH PRESSURE WATER STREAMS

Avoid body contact with high pressure water streams.

!

WARNING

AVOID CHEMICALS

Avoid exposure to sprinkler spray while chemicals

are being injected into the water. Read EPA Label

Improvement Program (PR Notice 87-1) and all instructions for chemical applications.

If you plan on chemigating, make certain you have

complied with state or local regulations in regard to

safety equipment, certification, operation and calibration of the injector pump. Make certain you have first

aid and fresh water available in case of an accident.

You must also be familiar with the correct cleanup

procedures in case of a spill.

• USE OF PROTECTIVE CLOTHING IS RECOMMENDED WHEN HANDLING CHEMICALS.

SAFETY GLASSES, GLOVES, AND PROTECTIVE OUTERWEAR SHOULD BE WORN WHEN

HANDLING CHEMICALS.

• CONTAMINATION OF THE WATER SUPPLY

MAY OCCUR IF EFFECTIVE SAFETY DEVICES

ARE NOT INSTALLED/USED IN CONNECTION WITH INJECTION EQUIPMENT FOR

CHEMIGATION.

!

DANGER

DRIVE SHAFTS START WITHOUT WARNING

An electric motor on each tower of the center pivot

powers two or more drive shafts connected to wheel

gear drives. These drive shafts start and stop without

warning.

• DO NOT touch rotating drive shalt or shield, Cloth-

ing or limbs may become entangled, resulting in

severe injury.

• DO NOT service the machine until the main dis-

connect is locked in the OFF position.

• ALWAYS replace drive shaft shields after servic-

ing.

• DRIVE SHAFT SHIELDS MUST ALWAYS BE IN

PLACE WHEN OPERATING THE MACHINE.

!

CAUTION

CHECK WHEEL TRACKS BEFORE STARTING

Make sure all objects, livestock or persons are clear

of the machine before starting. Drive trains are powerful and can climb over vehicles, equipment, etc.

Center Pivot 7000, 8000, 8120 Series 15

SAFETY

Operate Safely

!

CAUTION

KEEP CHILDREN AWAY

Irrigation Machines are NOT playground equipment.

Prevent children from playing or climbing around

on the machine. This can be extremely dangerous,

especially if the machine is operating.

!

CAUTION

CHECK MACHINE DIRECTION

DO NOT operate the machine if it moves in the direction opposite to that which was chosen.

Forward should be clockwise and reverse counterclockwise.

!

CAUTION

KEEP WATER OFF ROADWAYS

It is against the law in most states to allow water to

spray on state and county roadways. This is a serious hazard to passing motorists.

If end guns are used, make sure you read and understand the correct procedures for setting the on and

off positions to avoid watering the roadways.

If an end gun is watering a roadway, immediately

discontinue use and adjust the shutoff setting or

call your Valley dealer to repair the end gun shut off

mechanism.

!

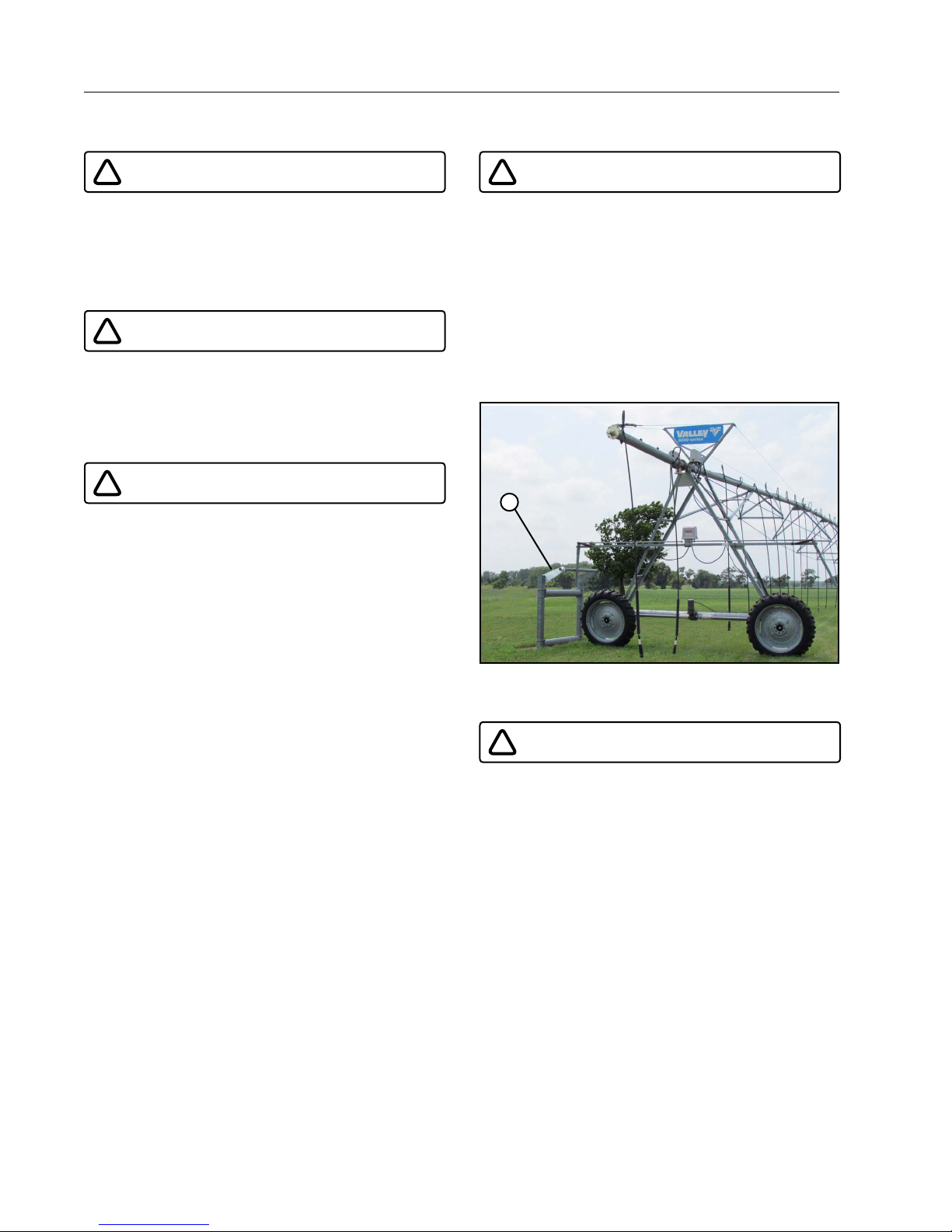

CAUTION

AUTO REVERSE OPERATION SAFETY

If the machine reverses direction at a roadway or a

physical object such as a building, tree line, power

pole, etc., then you MUST provide a backup device

to stop the machine if the reversing mechanism were

to fail. See Figure 16-1.

Contact your Valley dealer for more information

concerning physical barricades for machines under

these circumstances.

1

Figure 16-1 1 . Physical Barricade

16 Center Pivot 7000, 8000, 8120 Series

!

CAUTION

PROPER USE OF THE SAFETY OVERRIDE

Caution MUST be taken by the operator when using

the safety override function as it will bypass or disable all of the machine’s automatic safety shutdown

circuits.

NEVER depress and hold the START/STOP SAFETY OVERRIDE switch in the START position for

more than 3 to 5 seconds.

If the machine is not in full view by the operator, do

not use the Safety Override function.

The operator MUST inspect the entire machine between each safety override start attempt.

Repeated safety override start attempts can cause

severe structural damage.

Call your Valley dealer if the machine fails to start.

SAFETY

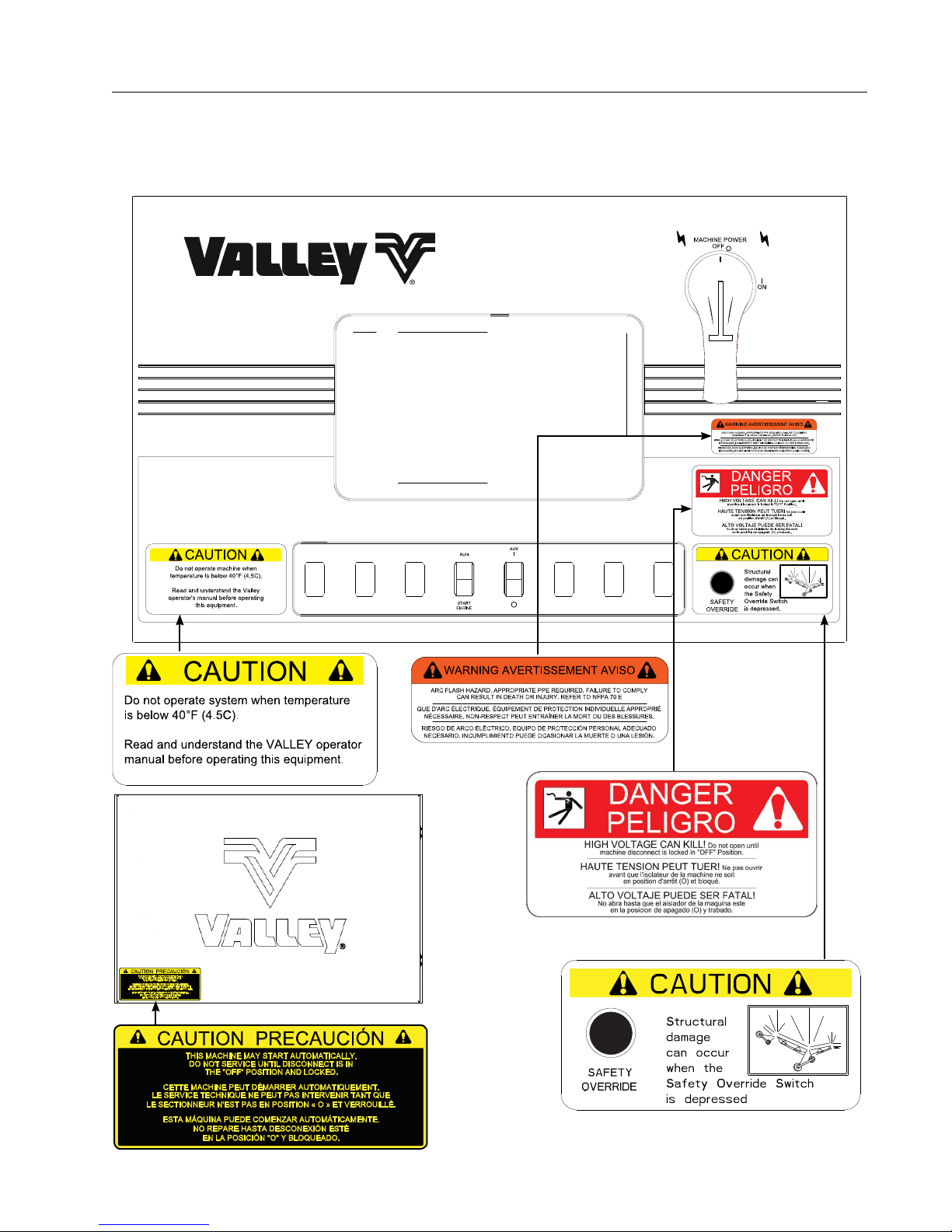

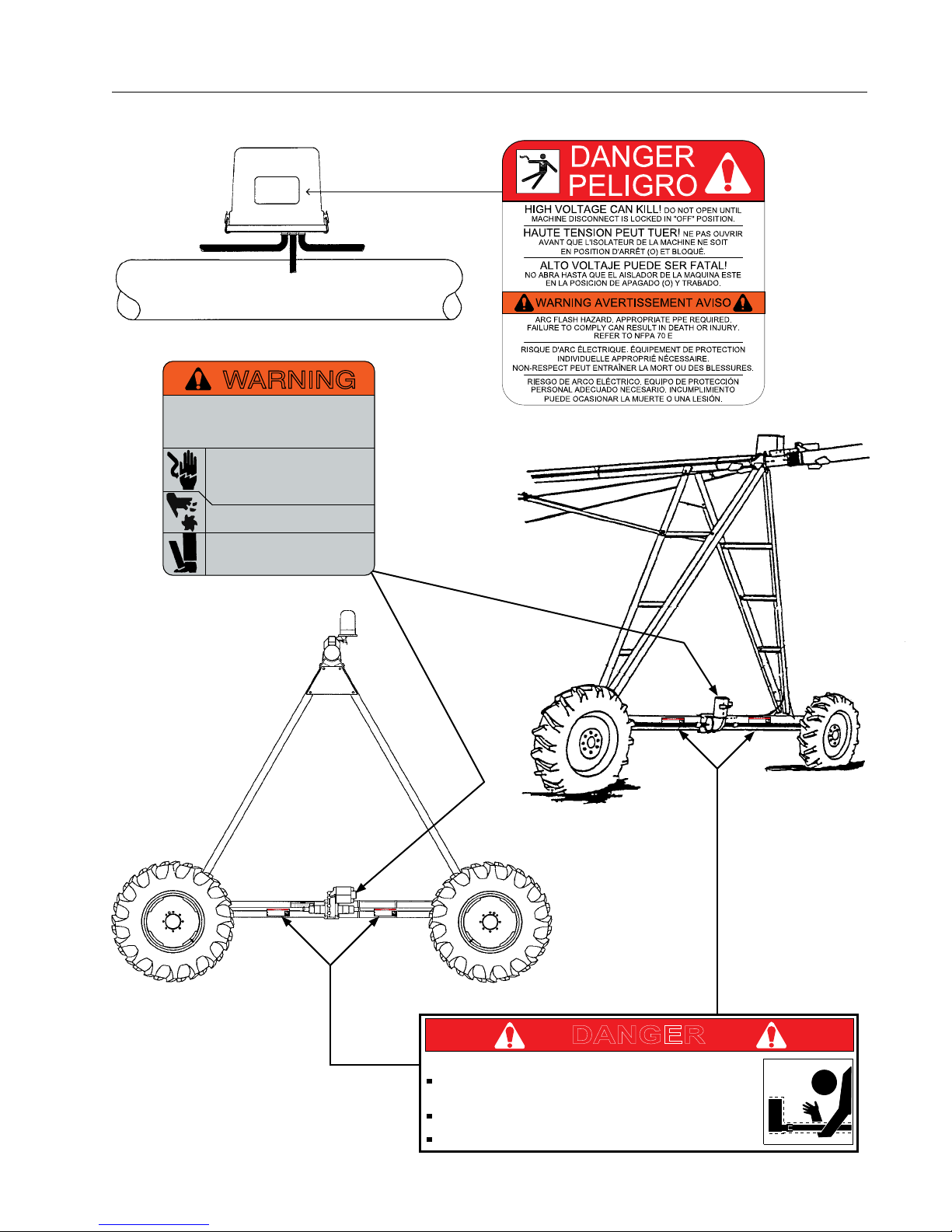

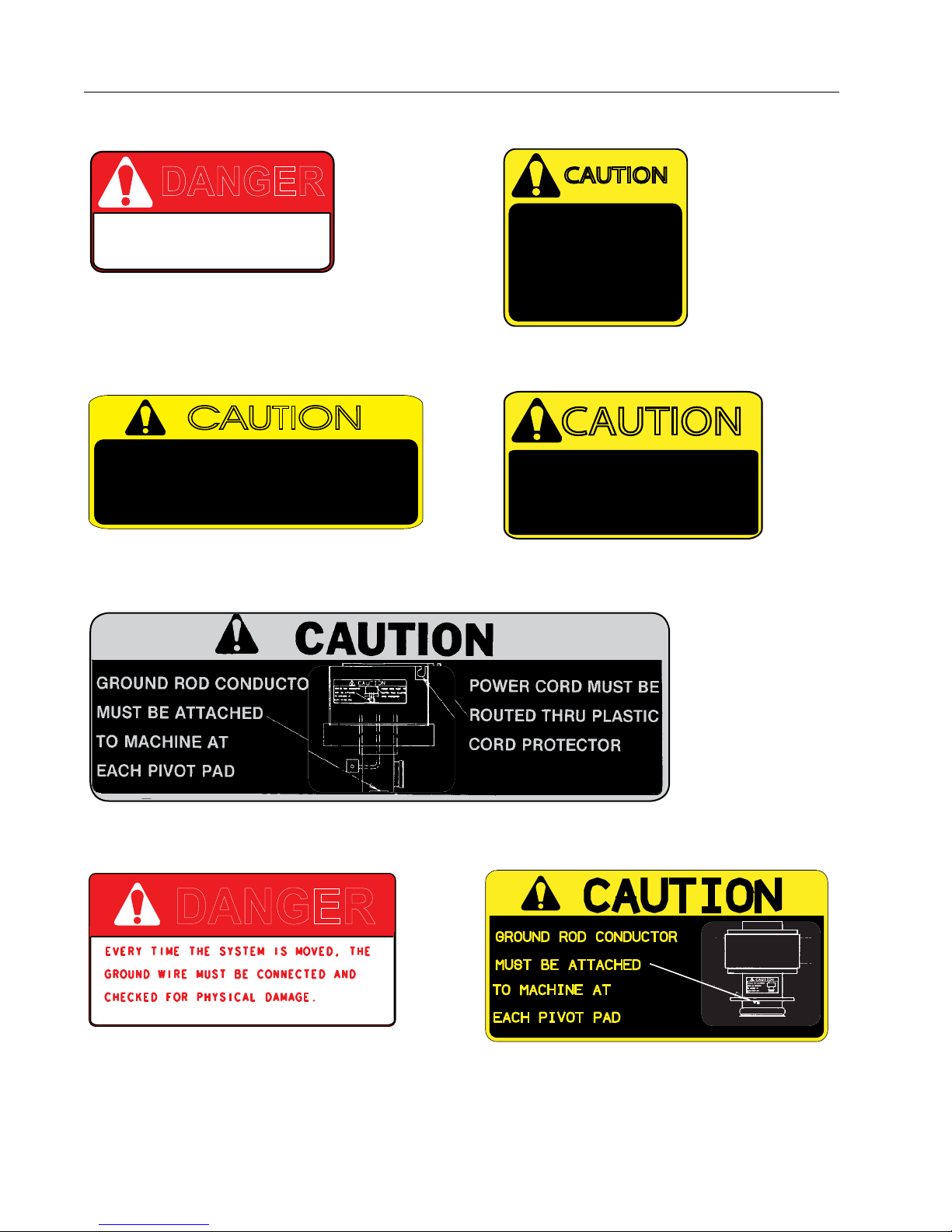

Safety Decals

These Danger, Warning, and Caution decals appear in various locations on a Valley irrigation machine. You

MUST familiarize yourself and other operators with these safety decals. For replacement of any decal, contact

your local Valley dealer.

Center Pivot 7000, 8000, 8120 Series 17

SAFETY

Safety Decals

WARNING

WARNING

WARNING

WARNING

18 Center Pivot 7000, 8000, 8120 Series

DANGER

DANGER

DANGER

Do not touch rotating drive shaft or shield. Clothing

or limbs may become entangled, resulting in severe

injury.

Do not service until machine is locked in the off

position.

Always replace drive shaft shield after servicing.

Drive Shaft Starts Without Warning!

DANGER

Safety Decals

WARNING

Improper installation of this motor may

result in fire, explosion, electrical shock or

other personal injuries. Read operating

instructions

Disconnect power before maintenance.

Open all circuits before removing conduit

box cover. Be sure motor is properly

grounded per local and national codes.

Do not place fingers or objects near

openings.

Do not use eye bolts or lifting hooks to

lift anything except the product.

SAFETY

Drive Shaft Starts Without Warning!

Do not touch rotating drive shaft or shield. Clothing

or limbs may become entangled, resulting in severe

injury.

Do not service until machine is locked in the off

position.

Always replace drive shaft shield after servicing.

Drive Shaft Starts Without Warning!

Do not touch rotating drive shaft or shield. Clothing

or limbs may become entangled, resulting in severe

injury.

Do not service until machine is locked in the off

position.

Always replace drive shaft shield after servicing.

Drive Shaft Starts Without Warning!

Do not touch rotating drive shaft or shield. Clothing

or limbs may become entangled, resulting in severe

injury.

Do not service until machine is locked in the off

position.

Always replace drive shaft shield after servicing.

DANGER

Drive Shaft Starts Without Warning!

Do not touch rotating drive shaft or shield. Clothing

or limbs may become entangled, resulting in severe

injury.

Do not service until machine is locked in the off

position.

Always replace drive shaft shield after servicing.

Center Pivot 7000, 8000, 8120 Series 19

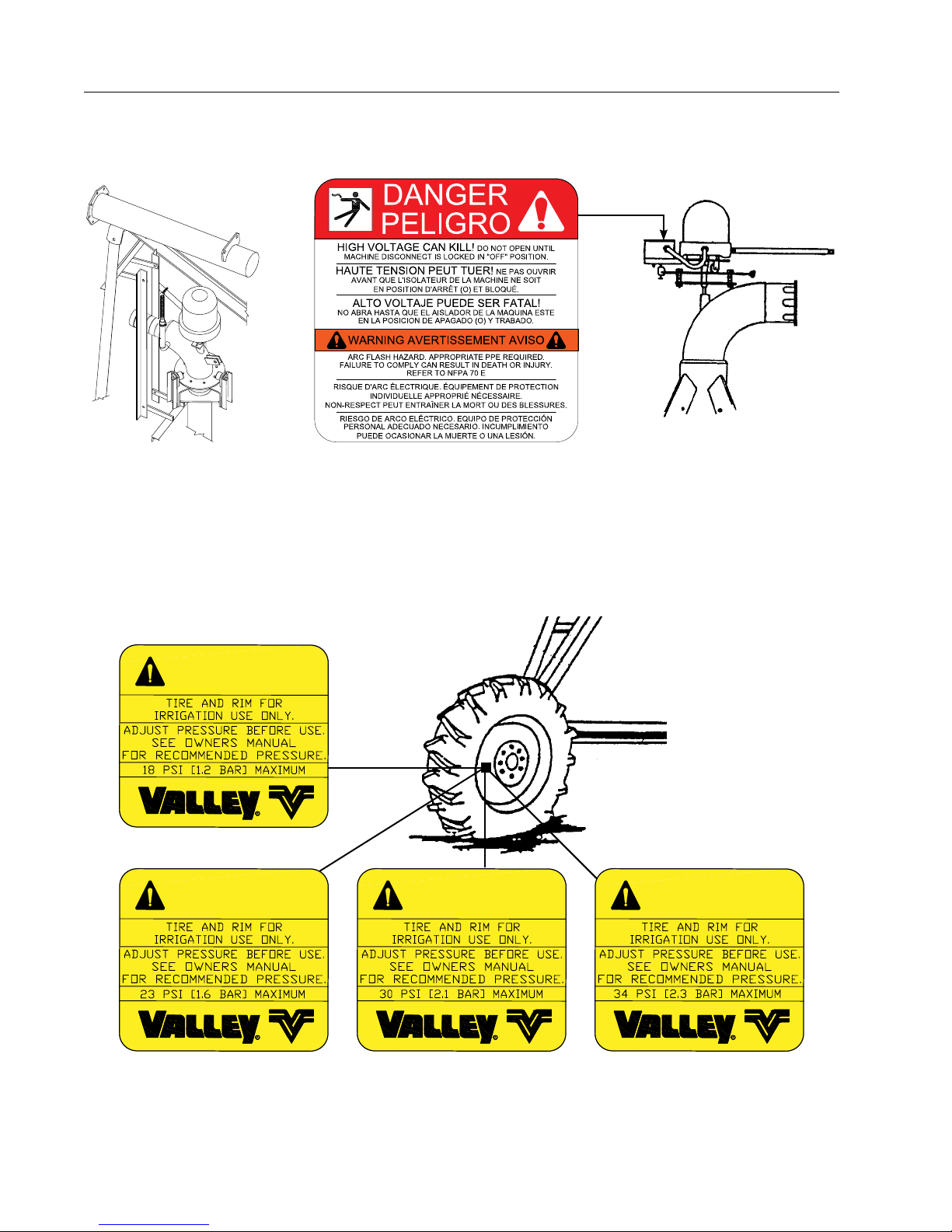

SAFETY

480 VOLTS

DANGER

Safety Decals

Location: Remote public power installations.

CAUTION

SAFETY SWITCH

MUST BE IN THE

"OFF" POSITION

WHEN HANDLING

PLUG OR CABLE

Location: Remote public power package.

CAUTION

INSPECT CABLE REGULARLY

TO ENSURE THAT IT IS IN

GOOD CONDITION

Location: Remote public power installations.

Location: Long E-Z Tow remote power package.

CAUTION

THIS MACHINE MAY START

AUTOMATICALLY. DO NOT

SERVICE UNTIL MACHINE

DISCONECT IS IN "OFF"

POSITION AND LOCKED.

Location: Automatic Restart Option.

480 VOLTS

Location: Ground Wire Towable Pivots.

DANGER

20 Center Pivot 7000, 8000, 8120 Series

Location: E-Z Tow Remote Power Hardware.

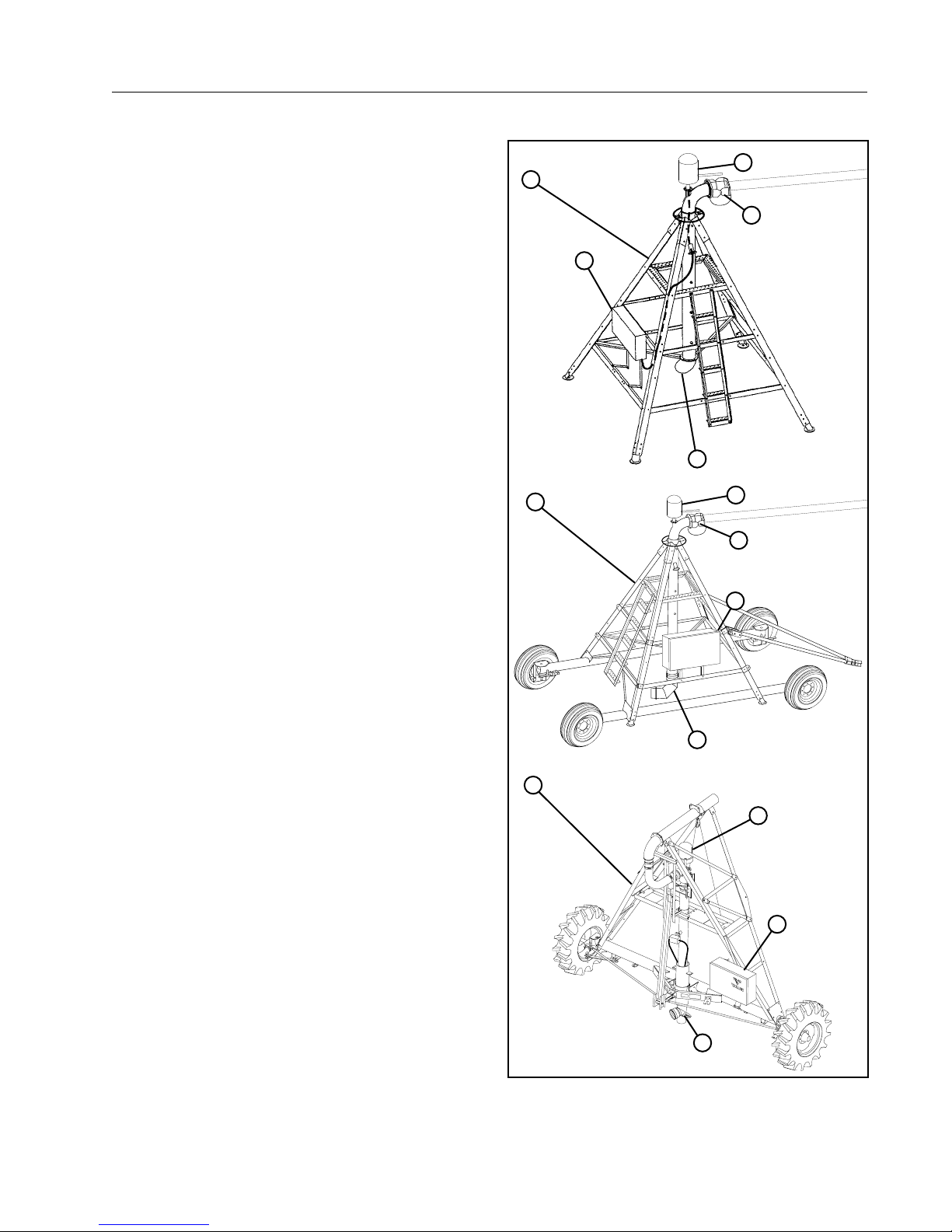

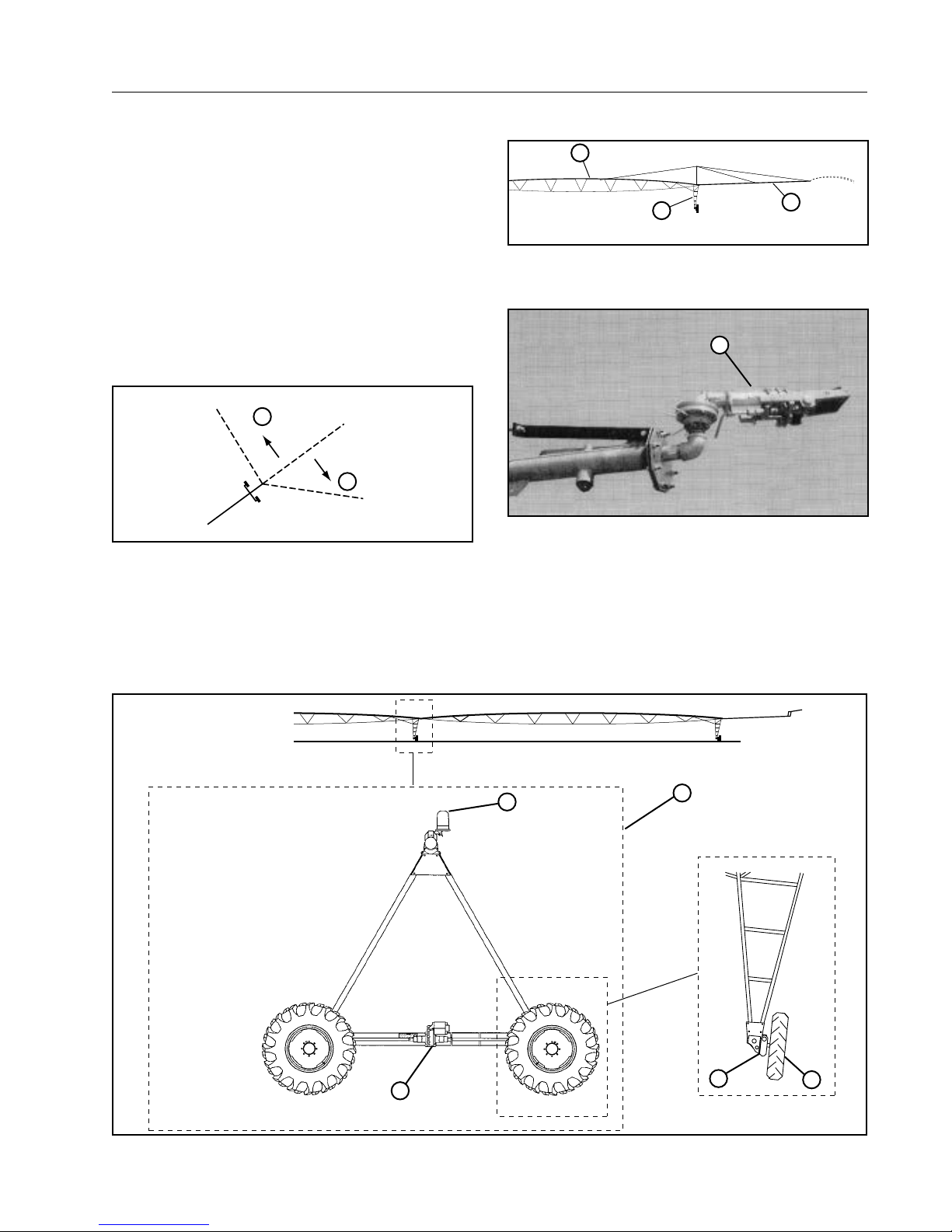

Pivot

Assembly / Part

Functional Area

4 Wheel EZ Tow

Overall Assembled View

Quality checked for better irrigation

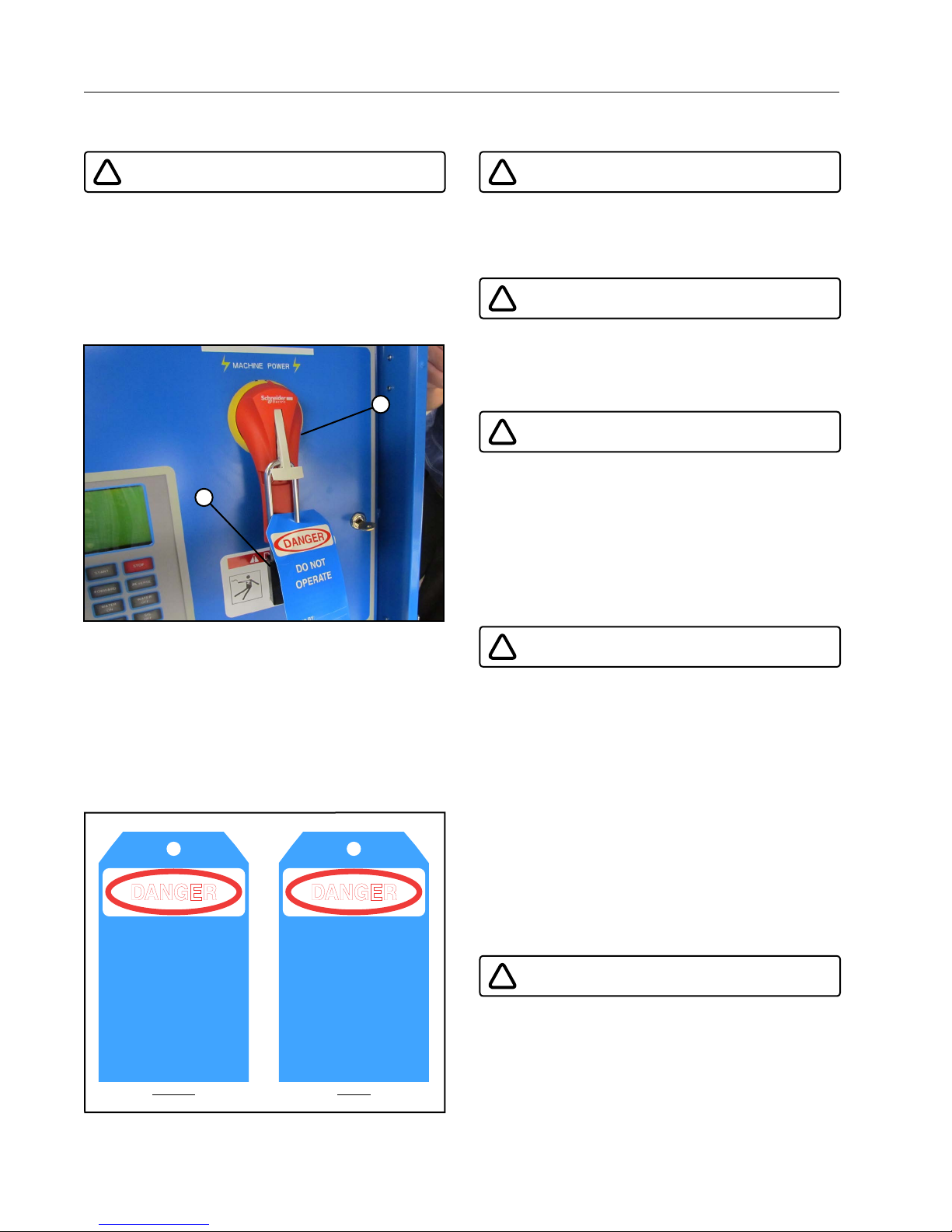

The center pivot is the structure which the entire machine rotates around. The water entry point for the

machine is at the riser pipe. See Figure 21-1.

The legs of a conventional center pivot are bolted

to a concrete foundation. Some pivots are towable

with a pivot point that is equipped with wheels so it

can easily be moved from one field to the other. See

Figure 21-1.

Collector Ring and J-Pipe

The collector ring allows the electric cable to rotate

with the pivot and is used with all public power options. See Figure 21-1.

The collector ring consists of brass rings in a stack

that remain stationary and are separated by insulators.

Contact brushes revolve around the brass rings providing continuous flow of current without twisting the

cable as the machine makes revolutions around the

field.

One electrical cable from the collector ring goes

down through the J-pipe, exiting near the bottom of

the riser and then is connected into the public power

panel.

The other electrical cable from the collector ring goes

out of the conduit and then connects into the control

panel.

OVERVIEW

4

1

5

6

7

2

4

5

6

Pivot Flex

A pivot flex allows for flexibility between the pivot

point and the first span. A Pivot Flex is required

where the first drive unit is 4% above or below the

level of the pivot pad. See Figure 21-1.

Grounding Jumper must be installed from the pivot

swivel flange to the span flange.

7

3

7

Figure 21-1 1 . Conventional Center Pivot

2. 4 Wheel E-Z Tow Pivot

3. 2 Wheel E-Z Tow Pivot

4. Collector Ring

4

6

5. Pivot Flex Coupling

6. Control Panel

7. Riser Pipe

Center Pivot 7000, 8000, 8120 Series 21

OVERVIEW

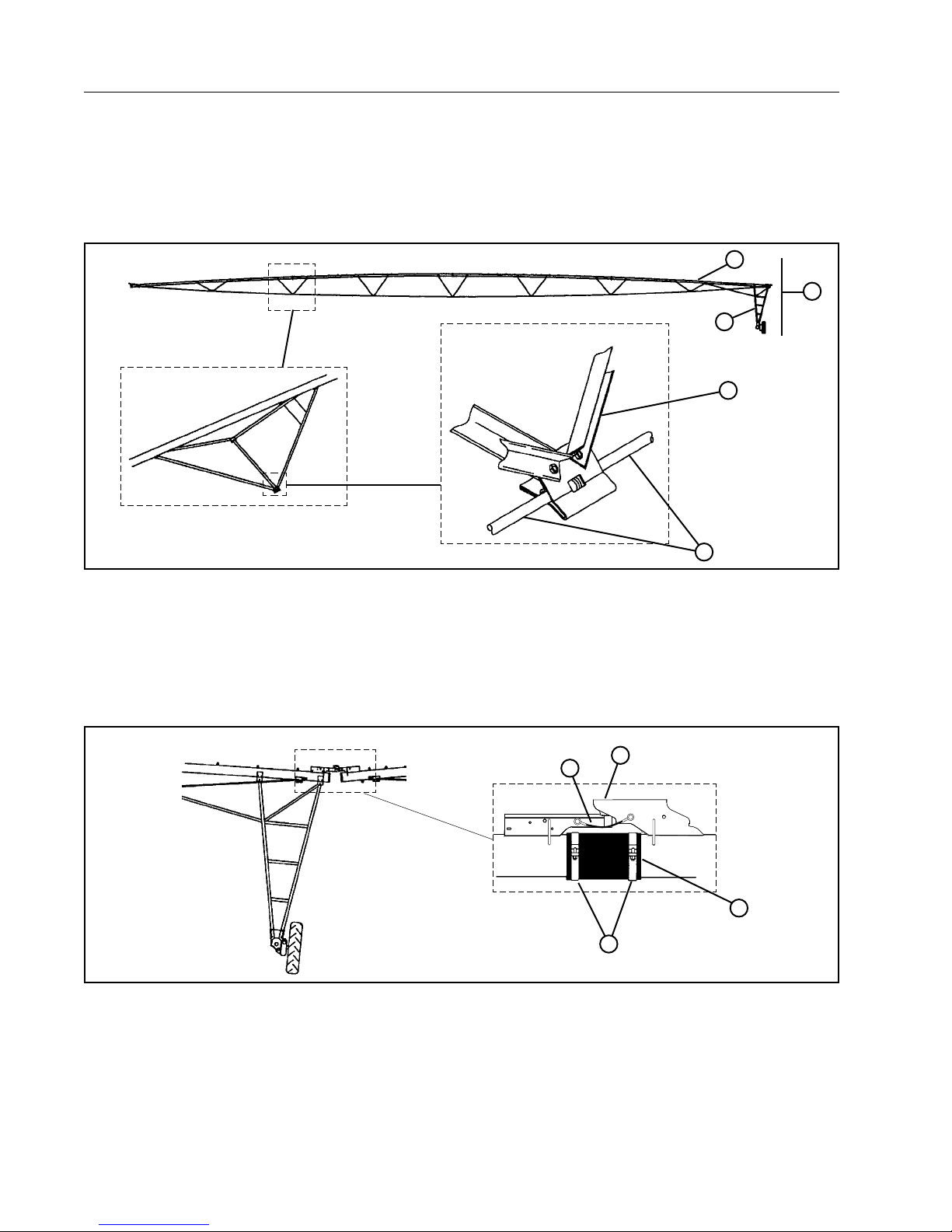

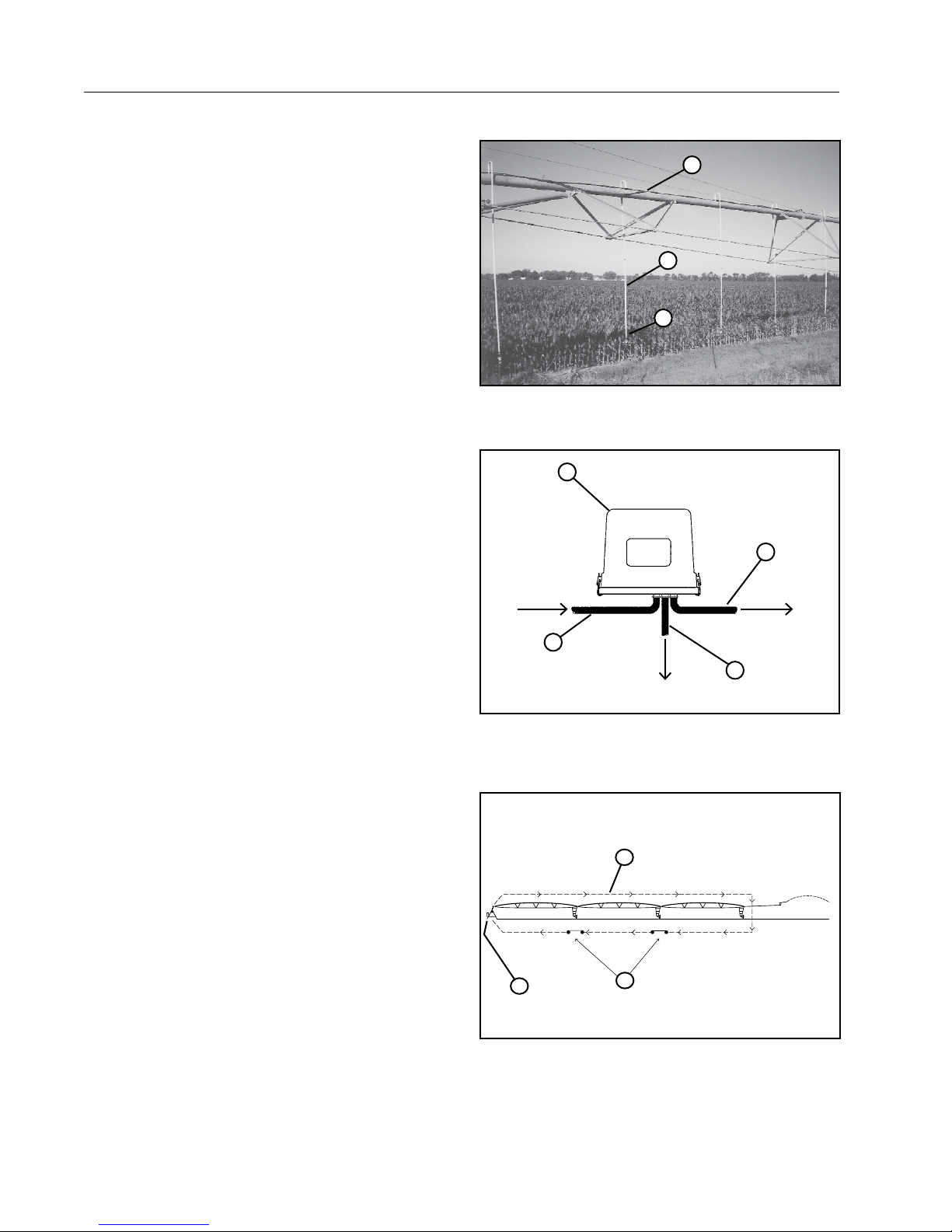

Spans

Water is transported to the irrigation machine through an underground pipe line. The water is then transported

across the field through a pipeline. The pipeline is made up of a series of spans which are connected together.

Each span also consists of a drive tower which moves the pipeline across the field. See Figure 22-1.

A span consists of a water pipeline supported with a bowstring under truss design. Truss rods are attached to

each truss assembly to support and strengthen the pipeline. See Figure 22-1.

1

2

3

5

4

Figure 22-1 1 . Pipeline

2. Span

3. Drive Tower

4. Truss Rod

5. Truss Assembly

The spans are attached to each other with a ball hitch and cup assembly which gives lateral, rotational, and

vertical flexibility between the spans. See Figure 22-2.

The pipelines in each span are connected together with a flexible hose that is held in place with band clamps.

See Figure 22-2.

1

2

3

Figure 22-2 1 . Hitch Ball and Cup Assembly

2. Flexible Hose

4

3. Band Clamp

4. Bonding Ground Wire

22 Center Pivot 7000, 8000, 8120 Series

Overhang (Option)

Typically an overhang is attached to the end of the

span pipe and used for irrigation beyond the span/

drive unit. Support ears and cables provide support

for the overhang. See Figure 23-1.

End Gun (Option)

Typically an end gun is attached at the end of the

overhang and used to increase the area irrigated

beyond the end of the machine. See Figure 23-2.

The end gun is set to cover a specified area. This

area is determined by the forward and backward

angles, which are referred to as the end gun arc settings. See Figure 23-3.

1

2

Figure 23-3 1 . Backward Angle

2. Forward Angle

1

Figure 23-1 1 . Span

2. Drive Tower

3. Overhang

Figure 23-2 1 . End Gun

OVERVIEW

2

1

3

Drive Towers

A drive tower is attached to the end of each span. The tower box acts as a junction box for the span cable and

supplies power to the electric motor on the center drive gearbox. The center drive gearbox drives the wheel

gearboxes. The wheel gearbox drives the tire and wheel. See Figure 23-4.

5

1

Figure 23-4 1 . Drive Tower

2. Center Drive Gearbox

2

3. Tower Box

4. Wheel Gearbox

3

5. Tire and Wheel Assembly

4

Center Pivot 7000, 8000, 8120 Series 23

OVERVIEW

Water Application

A sprinkler chart provides the operator with information about water application depths and pass times at

different percent timer settings.

Water is applied to the field through the sprinklers.

Sprinklers can be mounted on top of the pipeline

or on drop tubes that hang below the pipeline. See

Figure 24-1.

Span Cable

A cable with color coded wires enters and leaves

each tower box. The cable runs the entire length of

the machine and is referred to as span cable. See

Figure 24-2.

The span cable can carry multiple voltages including high voltage depending on control panel and the

country of use.

2

3

1

Figure 24-1 1 . Sprinkler

2. Pipeline

3. Drop Tube

Intermediate Tower Boxes

The intermediate tower control boxes provide power

to the center drive gear motors depending on the

tower box position in relationship to the next tower in

the system. See Figure 24-2.

Last Tower Box

The last tower control box provides power to the

center drive gear motor depending on the percent

timer setting at the control panel. It also completes

the safety circuit. See Figure 24-2.

Safety Circuit

The safety circuit is a 120 volt AC control circuit that

starts in the control panel and runs the entire length

of the machine. See Figure 24-3.

Each drive tower box contains a safety microswitch.

The safety microswitches must be closed to complete the safety circuit.

When the machine is in alignment, the safety

microswitches are closed. If the machine ever becomes too far out of alignment, a safety microswitch

opens, breaking the safety circuit. This stops the

machine to prevent structural damage.

1

3

2

4

Figure 24-2 1 . Tower Box

2. Span Cable Entering Tower Box

3. Span Cable Leaving Tower Box

4. Cable To Drive Motor

1

24 Center Pivot 7000, 8000, 8120 Series

2

Figure 24-3 1 . Safety Circuit

2. Control Panel

3. Safety Microswitch

3

Alignment

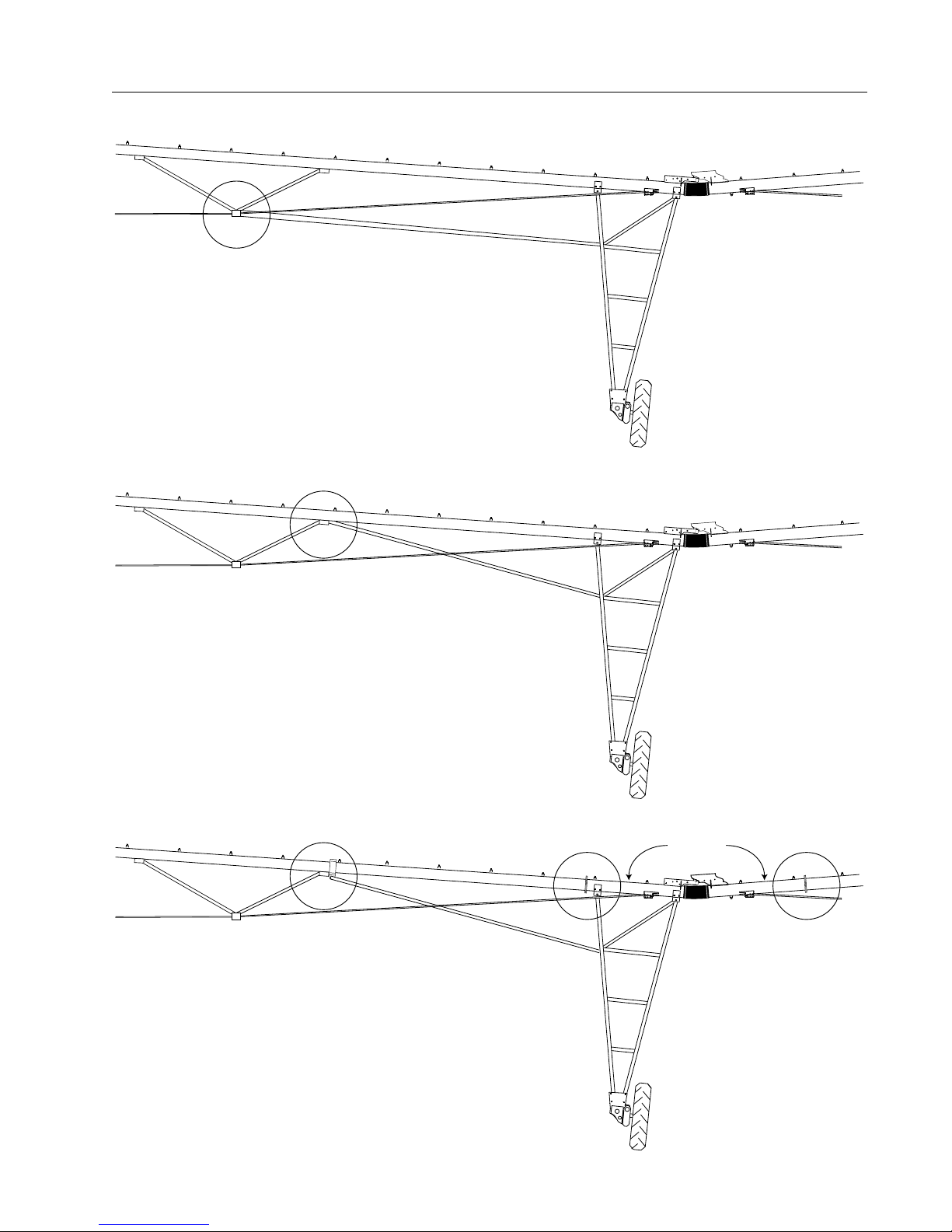

There are 3 types of span alignments available,

Standard, Modified and Pivot floating alignment. See

Figures 25-1, 25-2 and 25-3.

The type of alignment used varies depending on the

length of machine, type of field and other application

requirements.

General machine length guidelines are listed below:

• Standard alignment for machines up to 1500 ft

(457 m) long.

• Modified Alignment for machines 1500 ft to

2000 ft (457 m to 610 m) long.

• Pivot Floating Alignment for machines 2000 ft

to 2800 ft (610 m to 853 m) long.

The last tower is the controlling tower. As the end

tower moves, all of the other towers move to maintain

straight alignment.

When the last tower moves, it creates an angular deflection with the next intermediate tower, this closes

the run microswitches and causes the next intermediate tower to move.

This cycle repeats itself throughout the length of the

entire machine.

The result of these cycles is that any tower can be

moving at any time, depending on its relationship

with the next outer span.

OVERVIEW

Figure 25-1 Standard Alignment

Figure 25-2 Modified Alignment - Adjustable Sensitivity

Figure 25-3 Pivot Floating Alignment - Most Sensitive

Center Pivot 7000, 8000, 8120 Series 25

OVERVIEW

Over Watering Timer

The over watering timer is located in the time delay

watering box. See Figure 26-1.

The time delay watering box is normally located at

the next to last tower. It’s function is to act as a safety

device to shut the entire machine off should the end

tower fail to move due to mechanical/electrical failure

or wheel slippage. The timer can be set from 0-60

minutes and is factory set at 30 minutes.

At a setting of 30 minutes, the next to last tower must

cycle on and off before the 30 minute setting expires.

Each time the next to last tower runs, the timer is

reset.

1

Stop In Slot Control - Mechanical

(Option)

The Stop In Slot option stops the machine at a predetermined field location. The Valley Classic and

ClassicPlus Control Panel utilizes the same control

box as used for the end gun shut off. The stop in slot

micro switch is located on the outside of the ring. See

Figures 26-2 and 26-3.

The machine will be shut down when the stop in slot

micro switch contacts the stop in slot ramp.

End Gun Control - Mechanical

(Option)

The Valley Classic and ClassicPlus Control Panel

can turn the end gun on and off through a control box

near the top of the pivot. See Figure 26-3.

The end gun control ramps represent the locations

where the end gun will turn on and off.

Whenever the end gun micro switch rolls up on the

ramp, power is removed from the solenoid at the end

of the machine.

The solenoid controls a valve which shuts the water

supply to the end gun off when power is removed

from the solenoid. The end gun turns back on as the

micro switch rides off the ramp.

Figure 26-1 1 . Over Watering Timer

Figure 26-2 1 . Stop In Slot / End Gun Control Box

2

4

1

1

3

26 Center Pivot 7000, 8000, 8120 Series

Figure 26-3 1 . Stop In Slot Microswitch

2. End Gun Microswitch

3. Stop In Slot Ramp

4. End Gun Ramp

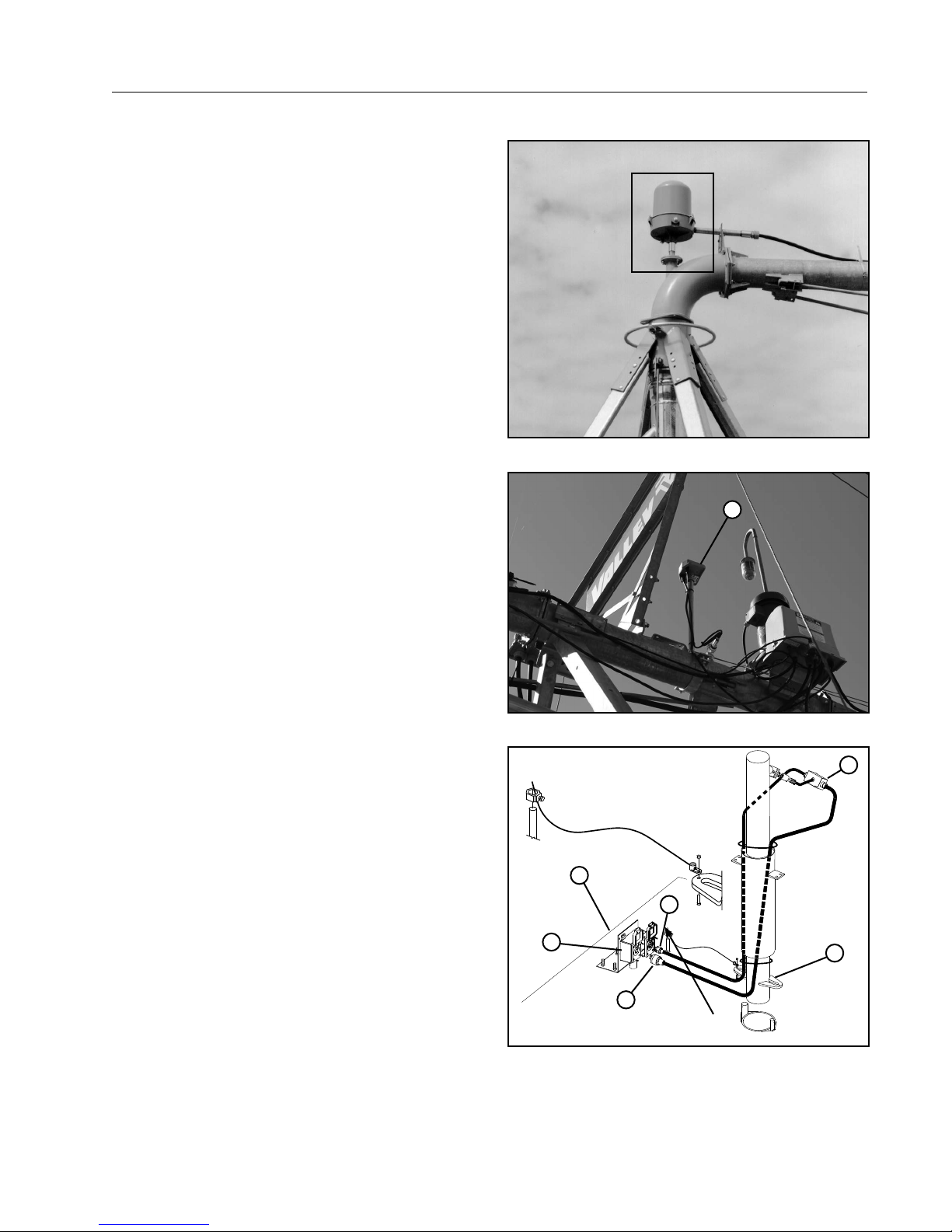

End Gun and Stop In Slot Control - Electronic (Option)

The Valley Control Panels use one of the following

options: encoder, a resolver or Valley GPS position

to determine the position of the pivot in the field. The

field position readings are used to turn the end gun

on and off or to stop at the stop in slot position.

Encoder or Resolver

The encoder and resolver options are installed in the

collector ring. See Figure 27-1.

As the pivot rotates, the collector ring turns which

also turns the shaft of the encoder or resolver. The

encoder or resolver send signals to the control panel.

The Control Panel uses the signal to determine field

position in degrees.

OVERVIEW

Valley GPS Position (Option)

The Valley GPS position option is usually installed at

or near the end of machine. See Figure 27-2.

When the machine is on, Valley GPS receives satellite position data and sends raw coordinates to the

control panel.

The control panel uses the raw coordinates to determine field position in degrees.

Public Power Towable (Option)

The public power towable option includes electrical

receptacles mounted on each pivot pad and electric

cords with plugs wired into an electrical box mounted

on the pivot point. See Figure 27-3.

Figure 27-1 Collector Ring

1

Figure 27-2 1 . Valley GPS Position

4

2

3

1

3

Figure 27-3 1. Electrical Receptacles

2. Pivot Pad

3. Electric Cord and Plug

Center Pivot 7000, 8000, 8120 Series 27

5

4. Electrical Box

5. 2 Wheel E-Z Tow Pivot

OVERVIEW

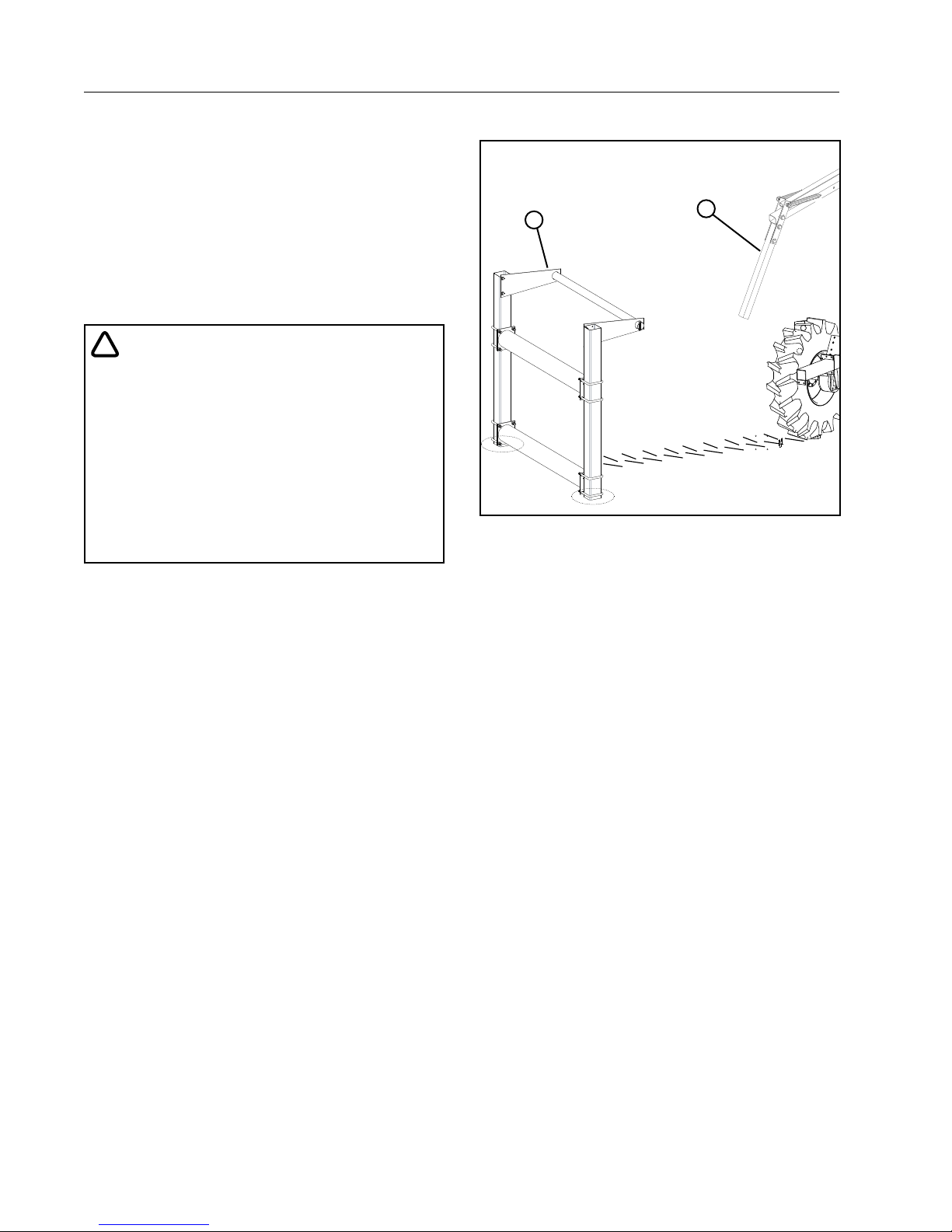

Drive Unit Mounted End of Field Stop/Auto Reverse (Option)

The drive unit mounted end of field stop is used with

both the end of field stop and end of field auto re-

verse option. See Figure 28-1.

This mechanism will stop the machine when the actuator arm contacts the barricade.

If the auto reverse option is installed, the operator

can choose to either have the machine stop or automatically reverse its direction of travel and continue

to run.

!

CAUTION

• NEVER USE THE SAFETY OVERRIDE BUTTON TO WALK THE MACHINE OFF OF THE

BARRICADE. STRUCTURAL DAMAGE MAY

RESULT.

• SOIL MAY BUILD UP IN THE WHEEL TRACK

RESULTING IN A RAMP EFFECT ALLOWING THE ACTUATOR ARM TO GO OVER THE

BARRICADES. REGULARLY MAINTAIN THE

WHEEL TRACK TO INSURE THE ACTUATOR

ARM ALWAYS CONTACTS THE BARRICADE.

Figure 28-1 1 . Actuator Arm

2

2. Barricade

1

Auto Reverse/Auto Stop Box (Option)

The Auto Reverse/Auto Stop box provides the machine the ability to Auto Reverse and Auto Stop when

the control panel also has the Auto Reverse option.

The Auto Reverse/Auto Stop Box is mounted on the

drive unit mounted end of field stop and is only used

with the Auto Reverse/Auto Stop option.

28 Center Pivot 7000, 8000, 8120 Series

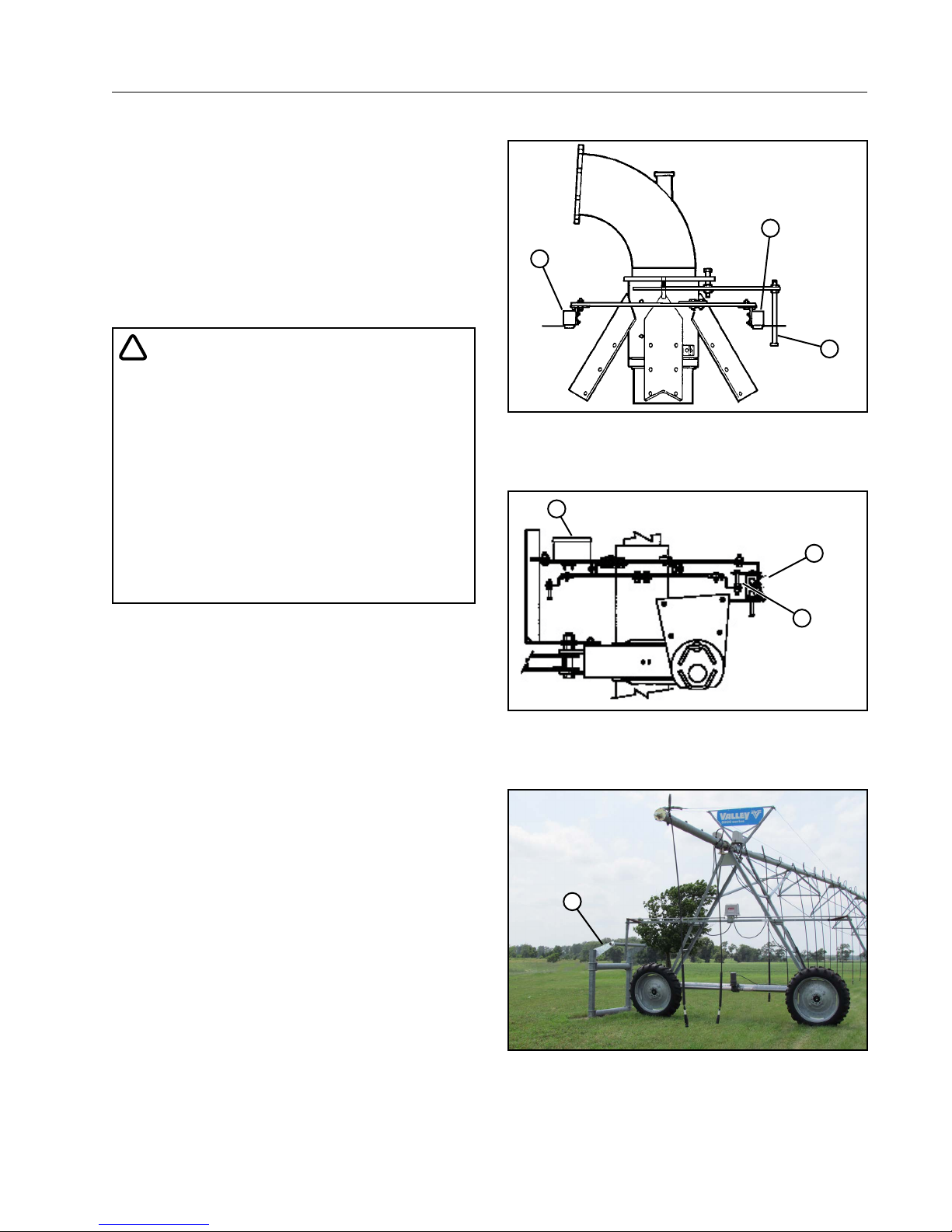

Pivot Mounted Auto Reverse (Option)

The pivot mounted auto reverse option is shown for

the Standard Center Pivot in Figure 29-1 and the 2

Wheel E-Z Tow Pivot in Figure 29-2.

Two heavy duty limit switches are mounted as shown

in the illustrations.

Each switch has a back-up safety contact designed

to stop the machine if the reversing contact or associated circuitry fails to achieve the planned direction

change.

OVERVIEW

2

1

!

CAUTION

• WHEN THE NEED FOR A PRECISE REVERSING POINT IS CRITICAL, SUCH AS AVOIDING

A BUILDING OR TREE LINE, THE DRIVE UNIT

MOUNTED AUTO REVERSE OPTION AND

THE PHYSICAL BARRICADE MUST BE USED.

• PHYSICAL END OF FIELD STOP BARRICADES MUST BE INSTALLED ON ALL PART

CIRCLE MACHINES. THE PHYSICAL BARRICADE SERVES AS A BACK UP IN CASE THE

CIRCUITRY OF THE PIVOT MOUNTED AUTO

REVERSE OPTION SHOULD EVER FAIL. SEE

FIGURE 29-3.

3

Figure 29-1 Standard Center Pivot Mounted Auto Reverse

1. Reversing Switch

2. Reversing Switch

3. Actuator Bolt

1

2

3

Figure 29-2 2 Wheel E-Z Tow Pivot Mounted Auto Reverse

1. E.G.S.O. and S.I.S. Control Box

2. Reversing Switch

3. Actuator Bolt

1

Figure 29-3 1 . End of Field Stop Barricade

Center Pivot 7000, 8000, 8120 Series 29

OVERVIEW

30 Center Pivot 7000, 8000, 8120 Series

Loading...

Loading...