Page 1

M212411EN-B

User Guide

Sanitary OEM Refractometer

PR-33-AC

Page 2

PUBLISHED BY

Vaisala Oyj

Vanha Nurmijärventie 21, FI-01670 Vantaa, Finland

P.O. Box 26, FI-00421 Helsinki, Finland

+358 9 8949 1

Visit our Internet pages at www.vaisala.com.

© Vaisala Oyj 2020

No part of this document may be

reproduced, published or publicly

displayed in any form or by any means,

electronic or mechanical (including

photocopying), nor may its contents be

modified, translated, adapted, sold or

disclosed to a third party without prior

written permission of the copyright holder.

Translated documents and translated

portions of multilingual documents are

based on the original English versions. In

ambiguous cases, the English versions are

applicable, not the translations.

The contents of this document are subject

to change without prior notice.

Local rules and regulations may vary and

they shall take precedence over the

information contained in this document.

Vaisala makes no representations on this

document’s compliance with the local

rules and regulations applicable at any

given time, and hereby disclaims any and

all responsibilities related thereto.

This document does not create any legally

binding obligations for Vaisala towards

customers or end users. All legally binding

obligations and agreements are included

exclusively in the applicable supply

contract or the General Conditions of Sale

and General Conditions of Service of

Vaisala.

This product contains software developed

by Vaisala or third parties. Use of the

software is governed by license terms and

conditions included in the applicable

supply contract or, in the absence of

separate license terms and conditions, by

the General License Conditions of Vaisala

Group.

This product may contain open source

software (OSS) components. In the event

this product contains OSS components,

then such OSS is governed by the terms

and conditions of the applicable OSS

licenses, and you are bound by the terms

and conditions of such licenses in

connection with your use and distribution

of the OSS in this product. Applicable OSS

licenses are included in the product itself

or provided to you on any other applicable

media, depending on each individual

product and the product items delivered

to you.

Page 3

Table of contents

Table of contents

1. About this document.....................................................................................5

1.1 Version information..........................................................................................5

1.2 Documentation conventions........................................................................... 5

1.3 Trademarks........................................................................................................ 6

2. Product overview............................................................................................ 7

2.1 Vaisala Sanitary OEM Refractometer PR-33-AC........................................... 7

2.2 Safety..................................................................................................................7

2.3 Regulatory compliances...................................................................................8

3. Instrument connections................................................................................9

3.1 Power supply.....................................................................................................9

3.2 mA output..........................................................................................................9

3.3 Ethernet connection.........................................................................................9

3.3.1 Ethernet specification...............................................................................9

3.3.2 IP settings for Sanitary OEM Refractometer..........................................11

3.3.3 IP settings for stand-alone computer....................................................12

3.3.4 Configuring refractometer network.......................................................13

3.3.5 Testing Ethernet connection...................................................................13

3.3.6 Troubleshooting connection...................................................................13

4. Refractometer mounting............................................................................ 15

4.1 Choosing refractometer mounting location.................................................15

4.2 Checklist for pipe mounting...........................................................................15

4.3 Refractometer wiring......................................................................................18

5. Startup and use.............................................................................................20

5.1 Startup.............................................................................................................20

5.1.1 Initial check..............................................................................................20

5.1.2 Calibration check.................................................................................... 20

5.2 Viewing refractometer status....................................................................... 20

6. Instrument homepage................................................................................. 21

6.1 Main page......................................................................................................... 21

6.2 Diagnostics......................................................................................................22

6.2.1 Measuring field samples.........................................................................23

6.2.2 Optical image...........................................................................................24

6.3 Parameters...................................................................................................... 25

6.4 Verification......................................................................................................26

7. Configuration and calibration..................................................................28

7.1 Configuring refractometer............................................................................ 28

7.1.1 Signal damping........................................................................................28

7.1.2 Skip count................................................................................................ 29

1

Page 4

PR-33-AC User Guide M212411EN-B

7.2 Calibrating concentration measurement..................................................... 29

7.2.1 Chemical curve......................................................................................... 31

7.2.2 Field calibration........................................................................................ 31

7.2.3 Direct BIAS adjustment.......................................................................... 32

7.3 Default mA output value............................................................................... 32

8. Instrument verification...............................................................................34

8.1 Refractometer verification............................................................................ 34

8.1.1 Handling R.I. liquids................................................................................ 34

8.2 Verification procedure................................................................................... 35

8.3 Verification report...........................................................................................37

8.4 Corrective action............................................................................................ 38

9. Maintenance....................................................................................................39

10. Troubleshooting............................................................................................40

10.1 Diagnostic message priorities...................................................................... 40

10.2 Hardware.........................................................................................................40

10.3 Measurement..................................................................................................40

11. Specifications.................................................................................................43

11.1 PR-33-AC model code................................................................................... 43

11.2 Mounting specifics for EHEDG certified PR-33-AC configuration............46

12. Ethernet protocol specification..............................................................47

12.1 Communication protocol...............................................................................47

12.1.1 Request format........................................................................................47

12.1.2 Response format..................................................................................... 47

12.1.3 Request and response errors.................................................................48

12.2 Request-response pair specification...........................................................49

12.3 Error message specification......................................................................... 50

13. Principle of measurement.......................................................................... 51

Appendix A:

EU declaration of conformity..............................................53

Appendix B: Refractometer field calibration form.................................54

Warranty............................................................................................................ 55

Technical support............................................................................................ 55

Recycling...........................................................................................................55

2

Page 5

List of figures

Figure 1 Sanitary OEM Refractometer PR‑33‑AC......................................................7

Figure 2 Simple network configuration......................................................................10

Figure 3 Three refractometers in the same network..............................................10

Figure 4 Connecting refractometer(s) via wireless..................................................11

Figure 5 Using fiber link to connect refractometer(s).............................................11

Figure 6 Typical stand-alone IP configuration..........................................................12

Figure 7 A network of Sanitary OEM Refractometers............................................13

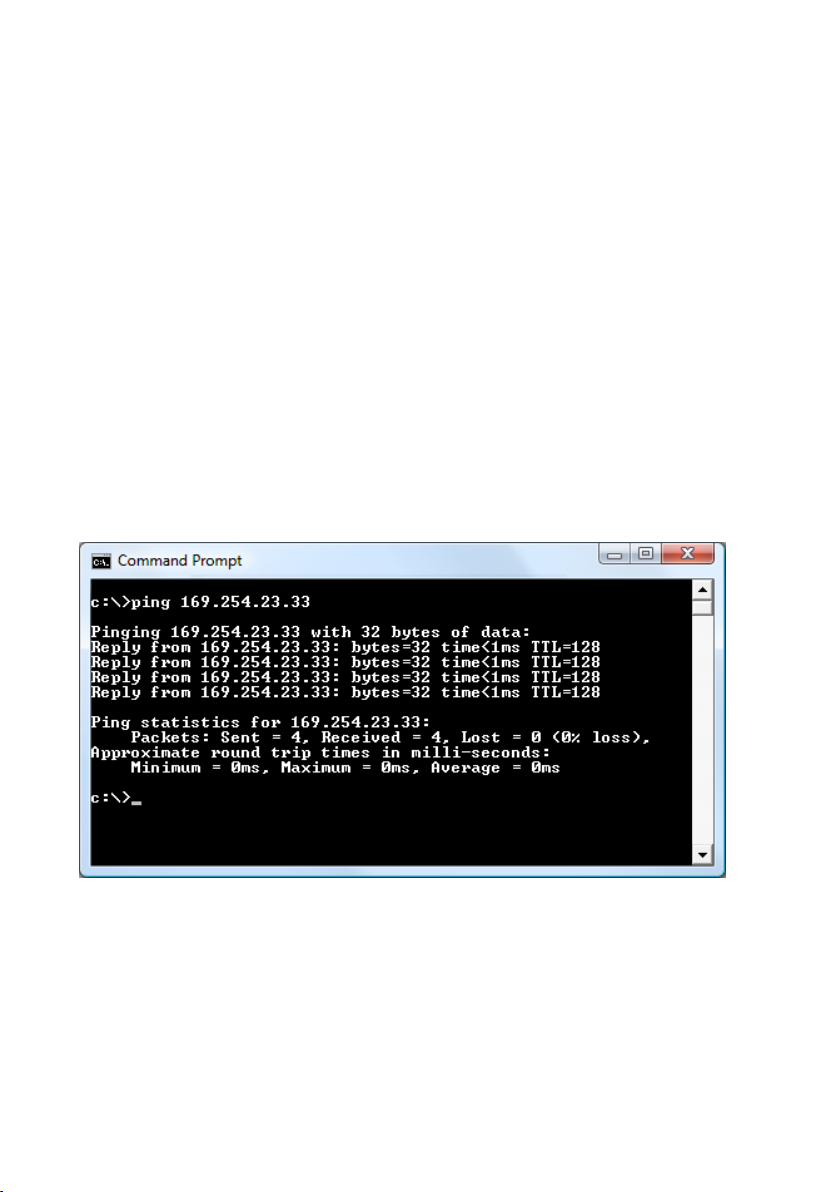

Figure 8 Pinging address 169.254.23.33.....................................................................14

Figure 9 Sensor configuration.......................................................................................17

Figure 10 Output options..................................................................................................17

Figure 11 Sanitary OEM Refractometer connectors................................................. 18

Figure 12 Wiring drawing.................................................................................................19

Figure 13 Main page.......................................................................................................... 22

Figure 14 Diagnostics page.............................................................................................23

Figure 15 Measuring field samples................................................................................24

Figure 16 Optical image................................................................................................... 25

Figure 17 Parameters page.............................................................................................26

Figure 18 Verification page............................................................................................. 27

Figure 19 Eect of damping time on measurement with linear damping.........28

Figure 20 Calibration layers............................................................................................30

Figure 21 NAMUR NE 43 signal ranges........................................................................33

Figure 22 Verification page.............................................................................................36

Figure 23 Universal sample holder PR-1012................................................................37

Figure 24 Verification report...........................................................................................38

Figure 25 Refractometer principle................................................................................. 51

Figure 26 Optical images................................................................................................. 52

Figure 27 Optical image detection................................................................................52

List of figures

3

Page 6

PR-33-AC User Guide M212411EN-B

List of tables

Table 1 Document versions (English)............................................................................5

Table 2 Chemical curve parameters..............................................................................31

Table 3 Hardware messages..........................................................................................40

Table 4 Measurement messages....................................................................................41

Table 5 SANITARY OEM REFRACTOMETER for pipelines (3-A

Sanitary Standard 46-04 Certified)..............................................................43

Table 6 SANITARY OEM REFRACTOMETER for pipelines (3-A

Sanitary Certified and EHEDG certified)..................................................... 43

Table 7 Elbow Flow Cells for PR-33-AC......................................................................44

Table 8 EHEDG Certified Elbow Flow Cells, connection Sanitary

3A-clamp 2½ inch.............................................................................................. 45

Table 9 Mounting hardware for PR-33-AC.................................................................46

Table 10 Request-response pair specification............................................................49

4

Page 7

Chapter 1 – About this document

1. About this document

1.1 Version information

This document provides instructions for installing, using and maintaining the Vaisala

K‑PATENTS® Sanitary OEM Refractometer PR‑33‑AC.

Table 1 Document versions (English)

Document Code Date Description

M212411EN-B February 2020 Manual updated to new format, template, and document code.

IM-EN-PR33AC-ASeptember

2019

1.2 Documentation conventions

Minor changes to content.

First version.

WARNING!

follow instructions carefully at this point, there is a risk of injury or even death.

CAUTION!

follow instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

Tip gives information for using the product more eciently.

Lists tools needed to perform the task.

Warning alerts you to a serious hazard. If you do not read and

Caution warns you of a potential hazard. If you do not read and

5

Page 8

PR-33-AC User Guide M212411EN-B

Indicates that you need to take some notes during the task.

1.3 Trademarks

Vaisalaâ and K-PATENTS® are registered trademarks of Vaisala Oyj.

Linuxâ is a registered trademark of Linus Torvalds.

Windowsâ is either a registered trademark or trademark of Microsoft Corporation in the

United States and other countries.

Varivent® is a registered trademark of GEA Tuchenhagen GMBH.

All other product or company names that may be mentioned in this publication are trade

names, trademarks, or registered trademarks of their respective owners.

6

Page 9

Chapter 2 – Product overview

2. Product overview

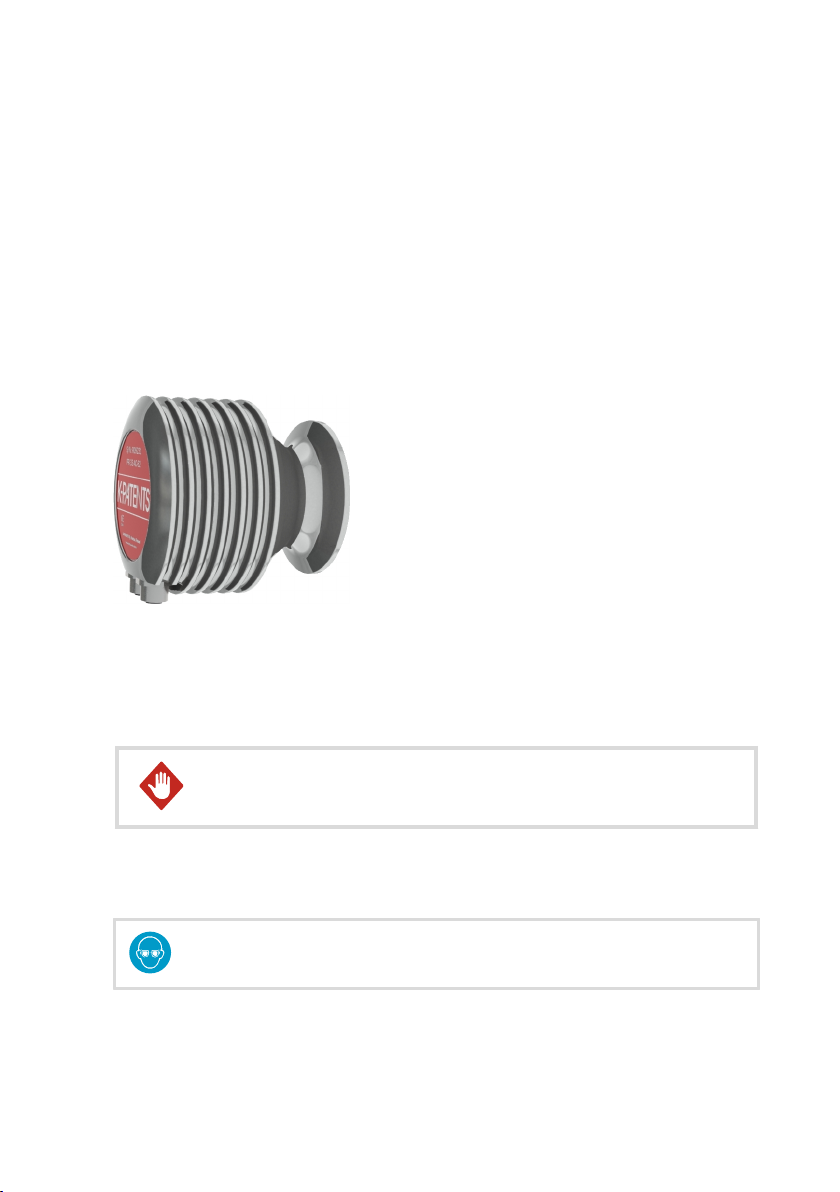

2.1 Vaisala Sanitary OEM Refractometer PR-33-AC

The inline Sanitary OEM Refractometer PR–33–AC measures the refractive index nD and the

temperature of the process medium. The concentration of the process liquid is calculated from

these values when the main components of the process medium are known.

The output values of the sensor are transmitted through a 4 … 20 mA output and an Ethernet

connection by using a UDP/IP protocol. For more information, see Ethernet protocol

specification (page 47). An optional mA output unit is also available, if more than one current

output is required.

Figure 1 Sanitary OEM Refractometer PR‑33‑AC

2.2

Safety

This product has been tested for safety. Note the following precautions:

WARNING!

must adhere to local and state legislation and regulations.

The process medium may be hot or otherwise hazardous. Use shields and protective clothing

adequate for the process medium. Do not rely on avoidance of contact with the process

medium.

Wear protective eyewear.

Only licensed experts may install electrical components. They

7

Page 10

PR-33-AC User Guide M212411EN-B

Wear protective gloves.

Precautions when removing a sensor from the process line :

• Check that the process line is depressurized and drained

• Loosen the flowcell screws cautiously; be prepared to tighten again

• Ensure you are clear of any possible spillage and you have a clear emergency escape path

2.3 Regulatory compliances

This product complies with the following performance and environmental test standards:

• 3-A

• EHEDG

8

Page 11

Chapter 3 – Instrument connections

3. Instrument connections

The instrument has three dierent connections: power supply (+24 Vdc), 4 … 20 mA current

output, and an Ethernet connection for digital data acquisition and configuration.

These connections are grouped into two connectors so that one of the connectors carries both

the power supply and the current output. The other connector is an Ethernet connection.

Both connections use the industrial M12 connector. The Ethernet connector has the industry

standard M12-Ethernet pin-out. The power supply and current output use an A-coded M12

male on the instrument side. The Ethernet connection uses a D-coded female connector on the

instrument side.

For the wiring details, see Refractometer wiring (page 18).

3.1 Power supply

The Sanitary OEM Refractometer requires a 24 V DC power supply (allowable tolerance is

±10 %). The current consumption of the refractometer is less than 100 mA. Shield the power

supply from external voltage surges.

3.2

mA output

The mA output of the refractometer supplies voltage and it is galvanically isolated. The

compliance (maximum resistive load) for the output is 1000 Ω.

3.3

Ethernet connection

The Ethernet connection enables data download from a Sanitary OEM Refractometer to a

computer. Any type of computer (PC, Mac, PDA, mainframe) with a compatible network

connection can be configured to view and download data from the refractometer.

The Sanitary OEM Refractometer can be configured and monitored without any special

software by using a standard web browser. Ethernet protocol specification (page 47) gives

all the specifications necessary to write a data acquisition program.

3.3.1 Ethernet specification

The Sanitary OEM Refractometer is designed to be connected to a network with a standard

Ethernet cable. The cable supplied with the instrument has an industrial M12 connector in the

instrument and a RJ-45 connector in the other end. The maximum communication speed of

the refractometer is 100 Mbit/s (Ethernet 100BASE-T). In the simplest form the network

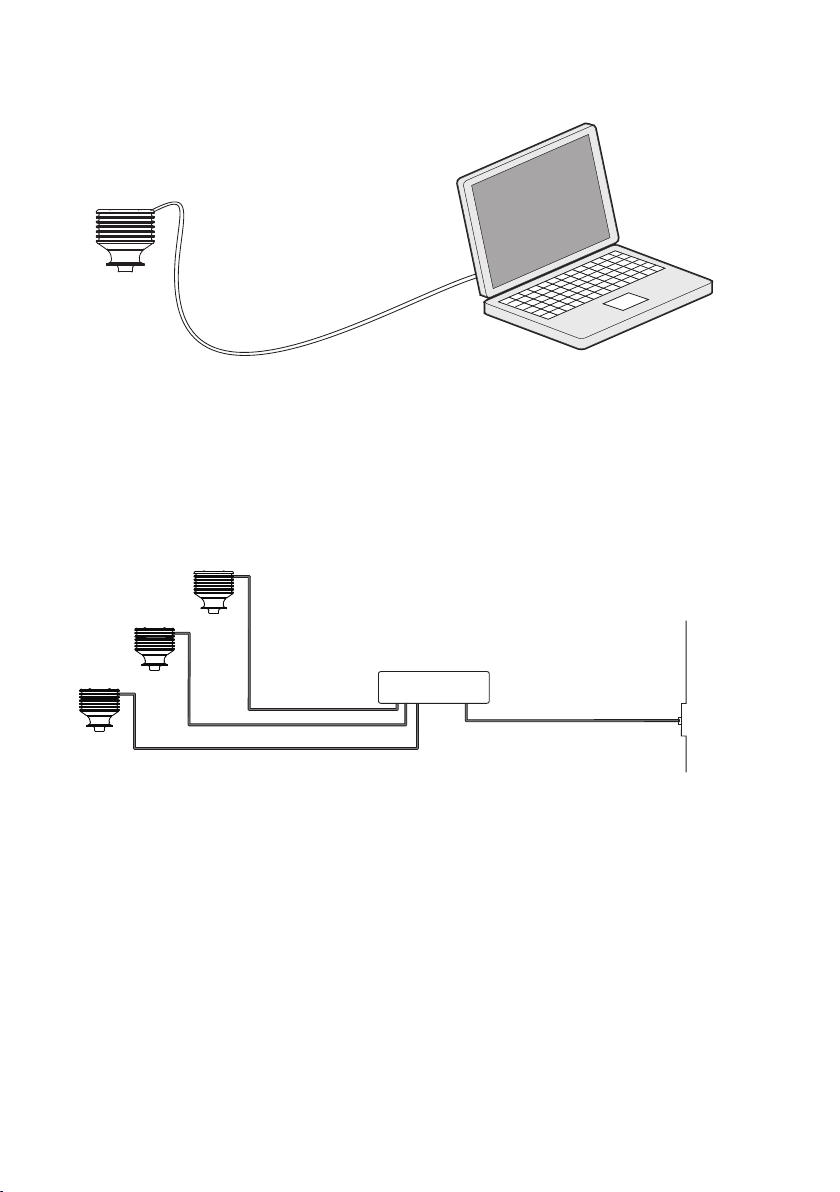

consists of one refractometer and one computer. The following figure shows the configuration.

9

Page 12

Ethernet

cable

Hub/Switch

LAN

Ethernet

cable

Ethernet

cable

PR-33-AC User Guide M212411EN-B

Figure 2 Simple network configuration

Several refractometers can be connected to the same Ethernet network. The Sanitary OEM

Refractometer also has an automatic function (known as Auto MDI/MDIX) to detect the

polarity of the network so that the network may utilize either cross-over or straight

interconnecting cables.

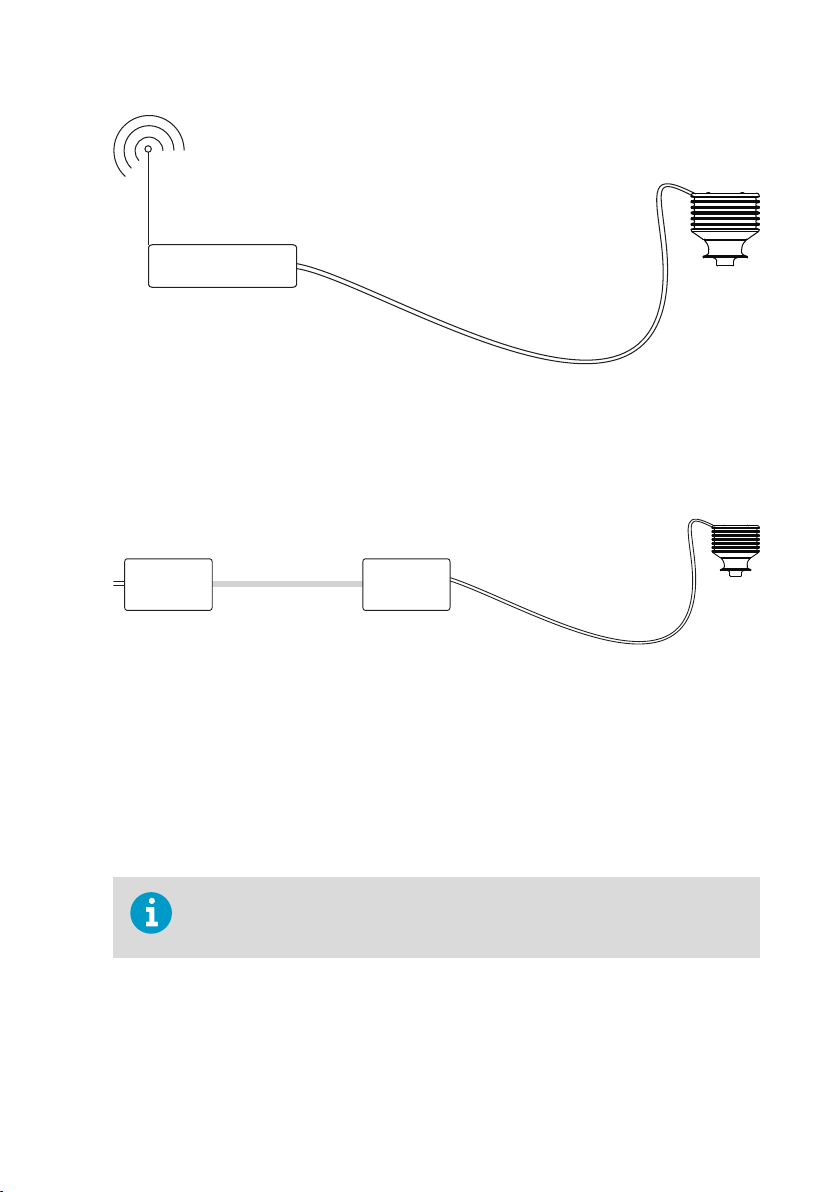

The following figure shows an example of how to connect three refractometers to an existing

LAN with a switch.

Figure 3 Three refractometers in the same network

It is possible to use a WLAN access point to decrease the number of cables.

10

Page 13

WLAN

Access

point

Ethernet

cable

Fiber

Media

converter

Media

converter

Ethernet

cable

Chapter 3 – Instrument connections

Figure 4 Connecting refractometer(s) via wireless

The maximum distance of a single Ethernet connection is 100 m (incl. one joint adapter/

coupler), but if longer distances are required, a fiber link may be used to extend the range as

shown in the followinf figure. The range may be up to several kilometers with a suitable fiber

connection.

Figure 5 Using fiber link to connect refractometer(s)

3.3.2 IP settings for Sanitary OEM Refractometer

All Sanitary OEM Refractometers are shipped with the factory default IP address of

169.254.23.33. This address belongs to the Zeroconf addresses (as defined in IETF standard

RFC 3927) so that it can easily be reached from a stand-alone computer, usually without

changing the network settings of the computer.

This address remains in the instrument even after a dierent IP address has been set. The

sensor answers in the address that is first called up after startup.

If there is more than one Sanitary OEM Refractometer in the same network, this

address cannot be used. For more information, see Configuring refractometer

network (page 13).

Change the IP address of the instrument through the instrument homepage. For more

information, see Instrument homepage (page 21).

11

Page 14

PR-33-AC User Guide M212411EN-B

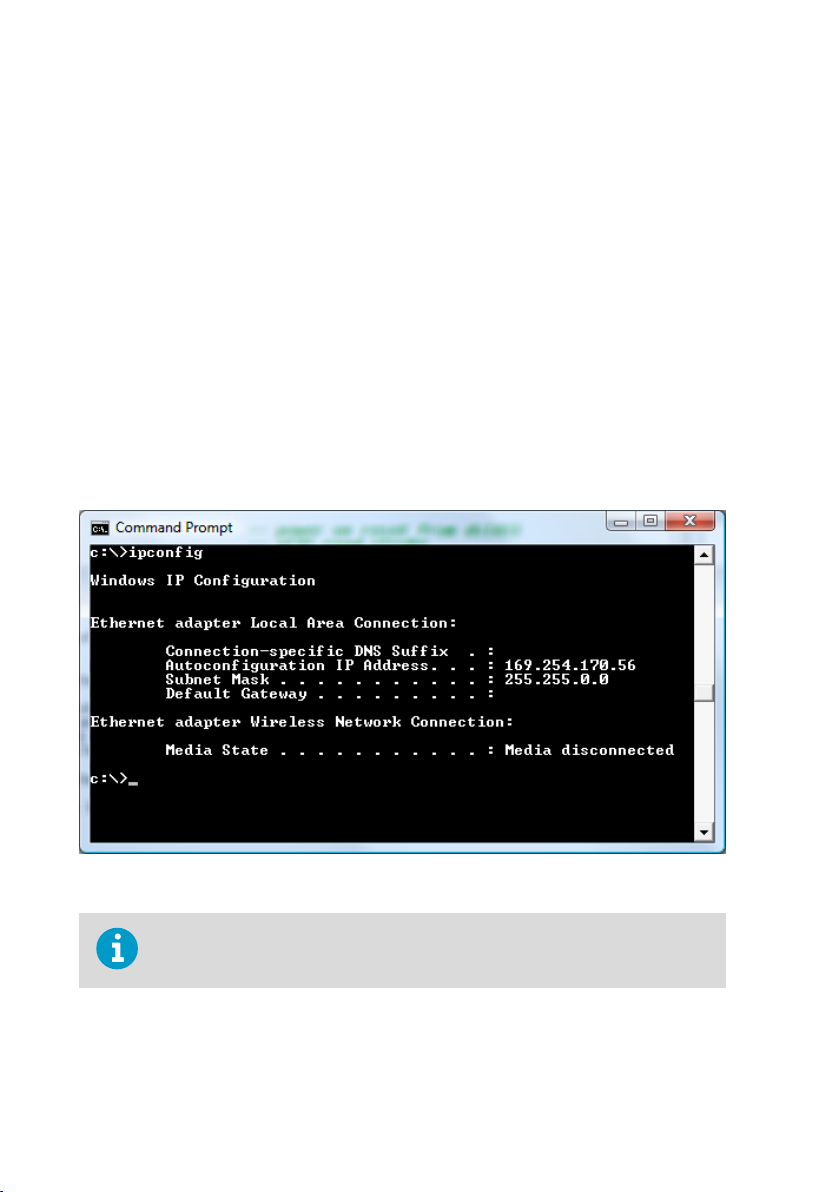

3.3.3 IP settings for stand-alone computer

When a computer with automatic IP settings (DHCP enabled) is turned on in a network with

only the refractometer, the computer automatically obtains the IP address 169.254.x.x. In this

case the factory default address of the refractometer can be used for connecting without any

further changes in settings. If this does not work, make sure that the WLAN (Wireless network

connection) is not active on the computer that is connected to the refractometer. If the WLAN

is active, the computer’s Ethernet connection may not function as expected. Obtaining the

169.254.x.x. address may take up to a minute.

If you still have diculties connecting to the refractometer, check the computer’s IP address by

opening the command window (command prompt) and by typing the command ipconfig

(press ENTER to give the command). In Mac OS X and Linux the same command is called

ifconfig. The information given includes the computer’s IP address. If the address does not

start with 169.254, configure the IP address of the computer manually to 169.254.23.34,

netmask 255.255.0.0.

For further troubleshooting, see Troubleshooting connection (page 13).

The following figure shows an example IP configuration for a stand-alone laptop when

connected to the refractometer. The laptop wireless (WLAN) is turned o.

Figure 6 Typical stand-alone IP configuration

The connection does not work if the computer and the refractometer have exactly

the same IP address.

When the network settings of the instrument (and/or the computer) have been configured

according to the instructions above, the next step is to test the connection as instructed in

Testing Ethernet connection (page 13).

12

Page 15

Hub/Switch

IP = 192.168.33.1

IP = 192.168.33.2

IP = 192.168.33.3

IP = 192.168.33.100

netmask = 255.255.255.0

Chapter 3 – Instrument connections

3.3.4 Configuring refractometer network

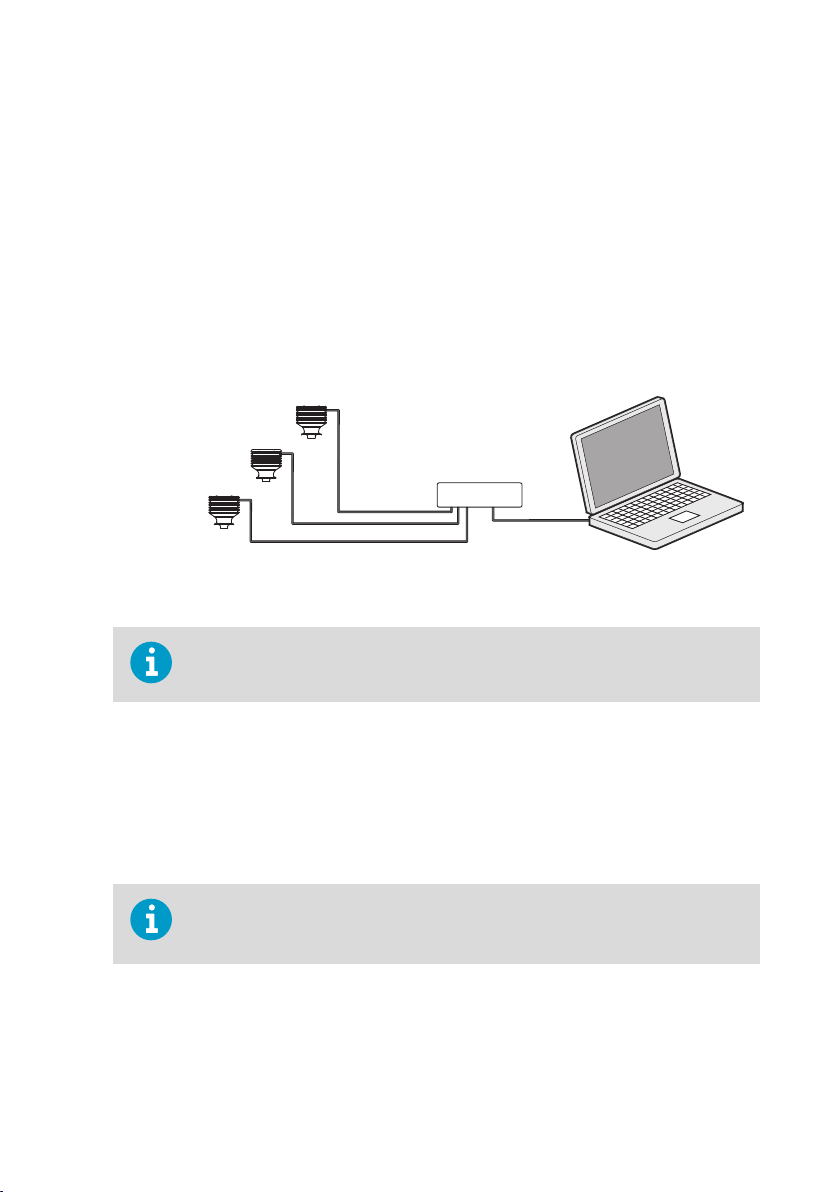

If there is more than one Sanitary OEM Refractometer in a network, configure their IP

addresses manually as the factory defaults do not work.

If the Sanitary OEM Refractometer is to be connected to a factory network, consult the

network administrator for the correct settings.

If the network is a stand-alone network with only one Sanitary OEM Refractometer and one or

more computers with no connection to any other network, then the IP addresses can be

chosen rather freely. One possibility is to number the instruments so that they all have

192.168.33.x addresses so that every computer and instrument has a dierent number x

between 1. 254. The subnet mask (or netmask) is in this case 255.255.255.0.

Figure 7 A network of Sanitary OEM Refractometers

There are no settings for subnet mask, default gateway or name servers in the

Sanitary OEM Refractometer, as these settings are not required.

3.3.5 Testing Ethernet connection

When the Sanitary OEM Refractometer is connected to a switch, the corresponding link light

illuminates in the switch.

Once the refractometer is powered up, it is reachable from any correctly configured computer.

Typing the IP address of the instrument to the address bar of a web browser should bring up

the instrument homepage. For more information, see Instrument homepage (page 21).

The factory-default IP address of the Sanitary OEM Refractometer is

169.254.23.33. This address always responds. For more information, see IP

settings for Sanitary OEM Refractometer (page 11).

3.3.6 Troubleshooting connection

If the instrument cannot be reached through the network, check the following:

• The instrument receives power; the ethernet switch link light is lit.

13

Page 16

PR-33-AC User Guide M212411EN-B

• The network settings of the computer are compatible with those of the instrument; for

more information, see IP settings for stand-alone computer (page 12).

• If the instrument should be at IP address 169.254.23.33, but cannot be reached, check that

there is only one Sanitary OEM Refractometer in the same network, as otherwise there is

an address conflict.

• Check that the software firewall of the computer does not block the connections.

A useful test to determine whether the problem is in network settings is to set up a small

network. Perform the following steps:

• Set up a network of only one Sanitary OEM Refractometer and one computer.

• Check that the computer has suitable network settings and that its WLAN connection is

turned o; for more information, see IP settings for stand-alone computer (page 12).

• Use the ping utility of the computer to try and reach the refractometer.

The ping utility is available in Windows systems by using the Command Prompt (usually found

in the Accessories; or open Run, type cmd in the empty line and press ENTER to open

Command Prompt).

To use ping go to the command interface, type the name of the command and the IP address

you want to check and press ENTER. If the Ethernet connection is physically working and the

address given to ping is correct, the refractometer answers the ping and returns any data

packets sent to it.

Figure 8 Pinging address 169.254.23.33

14

Page 17

Chapter 4 – Refractometer mounting

4. Refractometer mounting

Choose the Sanitary OEM Refractometer mounting location with care to ensure reliable

readings from the process.

4.1 Choosing refractometer mounting location

The mounting location must be such that sediments or gas bubbles cannot accumulate by the

refractometer. Good flow velocity is essential in keeping the prism clean.

CAUTION!

damage the in-line refractometer mounted on it.

The refractometer cover should not be exposed to high temperature radiation. In most cases,

draft and natural convection provide sucient air cooling if the air gets to flow freely around

the refractometer head.

CAUTION!

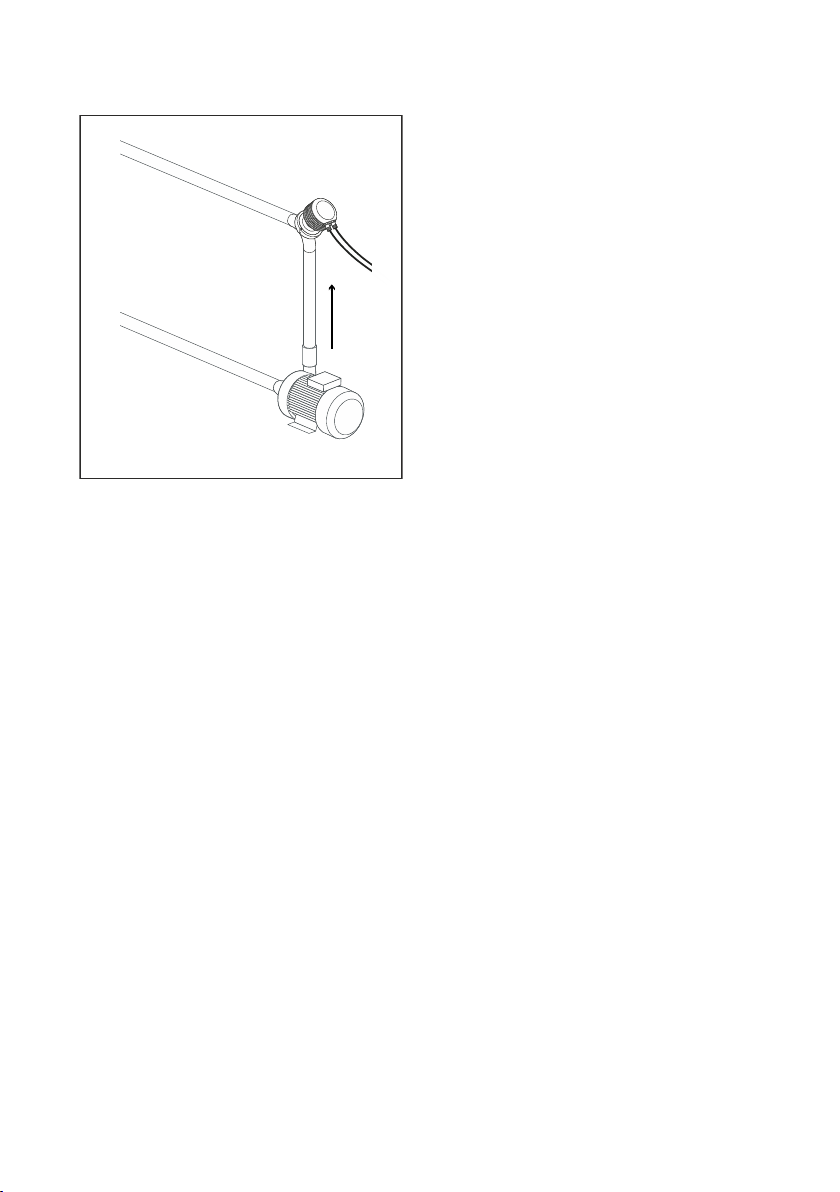

points downwards from the refractometer head.

If the process pipe vibrates, support the pipe. A vibrating pipe can

Always mount the refractometer so that the interconnecting cable

4.2 Checklist for pipe mounting

Most Sanitary OEM Refractometers are mounted in a pipe. The recommended flow velocity is

between 1 and 3 m/s (3 … 10 ft/s). If the flow velocity exceeds 6 m/s (20 ft/s), there is a risk of

cavitation. Cavitation may damage the sensor and the piping. Too slow a flow velocity may

cause erroneous measurement readings due to coating of stratification (layering) of the

sample on the prism.

15

Page 18

PR-33-AC User Guide M212411EN-B

- Upper pipe bend

- Cable downwards

- High velocity (>1.5 m/s [5 ft/s])

- High temperature

- High pressure

- Easy access

The diameter and form of the pipe and the process temperature all aect the measurement

and need to be taken into account.

16

Page 19

1 2 3

4

5

6

Figure 9 Sensor configuration

1 IP: 169.254.23.33

2 Ethernet

3 Computer with Ethernet and browser

4 4 … 20 mA

5 24 VDC

6 PLC

Chapter 4 – Refractometer mounting

Figure 10 Output options

1. If the process pipe diameter varies, select the position with the smallest diameter (and

accordingly highest velocity) to ensure the prism stays clean better.

17

Page 20

PR-33-AC User Guide M212411EN-B

2. If the refractometer is used in a feedback control loop, make the time lag short. For

example, when a dilution valve is controlled, mount the refractometer close to the dilution

point. However, make sure complete mixing has occurred at mounting location.

3. If the temperature varies along the process pipe, select the position with the highest

process temperature. That minimizes the risk of coating, because higher temperature

means higher solubility and also lower viscosity.

4. Often the position with the highest process pressure (= after pump + before valve) has

favorable flow conditions without sedimentation or air trapping risks.

5. Position the refractometer so it is conveniently accessible for service.

4.3 Refractometer wiring

The Sanitary OEM Refractometer sensor has two M12 connectors. The A-coded male sensor is

for power supply and milliamp output signals. The D-coded female connector is for the

Ethernet connection.

Figure 11 Sanitary OEM Refractometer connectors

The following figure shows the wiring layout.

18

Page 21

Chapter 4 – Refractometer mounting

Figure 12 Wiring drawing

19

Page 22

PR-33-AC User Guide M212411EN-B

5. Startup and use

5.1 Startup

Startup of the Sanitary OEM Refractometer consists of the following checks:

• Initial check

• Calibration check

5.1.1 Initial check

Connect the Sanitary OEM Refractometer to a 24 V DC supply. For more information, see

Power supply (page 9) and Refractometer wiring (page 18).

Check that the instrument powers up properly. This is easiest to check by measuring the

milliamp output, which should be at 4 mA after the first startup. It is also possible to see a faint

blinking amber light when viewing the prism at an oblique angle.

Connect the instrument to a computer with an Ethernet cable (RJ‑45 to M12 type). After the

instrument has powered up, use a web browser to open the instrument homepage. For more

information, see Ethernet connection (page 9).

On the homepage, check that the serial number of the page corresponds to that on the

instrument nameplate. If you have diculties connecting to the instrument, see

Troubleshooting connection (page 13).

5.1.2 Calibration check

Wait until normal process conditions occur. The concentration reading is precalibrated at

delivery and a copy of the calibration certificate is delivered with the refractometer. If the

diagnostic message is Normal operation but the concentration reading does not agree with

the laboratory results, see Calibrating concentration measurement (page 29).

5.2

Viewing refractometer status

The basic information on the measurements is shown on the Main page of the instrument. For

more information, see Main page (page 21). More information is shown on the Diagnostics

page. For more information, see Parameters (page 25).

The measurement result is calculated from the refractive index (nD) and process temperature

(T) values. Both of these values are available on the main page.

In addition to these measurements, the refractometer monitors its internal temperature and

humidity, which both are available on the Diagnostics page. The internal temperature should

not be above 65 °C, and the humidity should be below 60 %. High humidity is an indication of

leaking seals, and high temperature may deteriorate the measurement performance and/or

shorten the lifetime of the unit.

20

Page 23

Chapter 6 – Instrument homepage

6. Instrument homepage

Every Sanitary OEM Refractometer has a built-in web server with an instrument homepage.

The homepage oers facilities to configure, monitor, verify and diagnose the instrument.

Once there is a functional Ethernet connection between the instrument and the computer,

access the instrument’s homepage by entering the instrument’s IP address into the address

bar of the computer’s web browser.

The recommended browsers are Firefox 15.0 (or later) or Internet Explorer 8.0 (or later), but

most functionality is accessible using any modern web browser.

Opening the instrument homepage:

1. Establish a functioning Ethernet connection to the instrument. For more information, see

Ethernet connection (page 9).

2. Open your preferred web browser (for example Mozilla Firefox, Internet Explorer, Safari,

Chrome or Opera).

3. The address (URL) to access the instrument’s homepage is the refractometer’s IP address,

which for a factory default set Sanitary OEM Refractometer is http://

169.254.23.33/. Insert this address into the browser address bar, then ENTER, just as

you would enter any other web address.

4. Wait until the homepage is loaded, this may take a few seconds.

The page looks approximately as shown in Main page (page 21); the exact appearance of

the page depends on the browser and screen settings you are using.

5. Access more extensive instrument information using the links in the link bar at the left

side of the page.

The JavaScript support must be enabled in the browser, in order for the web

pages to function as intended.

6.1 Main page

Once the instrument homepage has loaded, it displays all the essential information regarding

the instrument.

21

Page 24

PR-33-AC User Guide M212411EN-B

Figure 13 Main page

This page shows the measurement values, serial number and the tag for the instrument. The

small numeric display in the top left-hand corner of the page indicates the number of

measurement cycles (one per second) since the last login to the sensor.

6.2

Diagnostics

The Diagnostics page displays the diagnostic values produced by the refractometer. In

addition to the measurement results, the page shows several intermediate results and other

diagnostic values.

The optical images produced by the refractometer can be seen on this page. Both the images

and the diagnostic values are live values, updated with an interval of a few seconds.

22

Page 25

Chapter 6 – Instrument homepage

Figure 14 Diagnostics page

6.2.1 Measuring field samples

The Diagnostics page oers a possibility to measure samples for field calibration purposes.

For more information, see Field calibration (page 31).

Measure a sample by clicking the Field point button on the page. After clicking the button the

instrument measures ten measurement results and shows the average and deviation of the

measurements. The measurement status is also shown, and if the status is not Normal

operation, the point is not accepted.

Several points may be measured, and all the points display on the page until the page is

reloaded. After measuring a sucient amount of points, you can print the page.

23

Page 26

PR-33-AC User Guide M212411EN-B

Figure 15 Measuring field samples

6.2.2 Optical image

View the raw optical image, which contains all optical information, by clicking on the Optical

image link on the left panel on the Diagnostics page.

Download the optical image as a file by clicking on the caption (Raw optical image) of the

image. This file can be used by Vaisala for troubleshooting purposes.

24

Page 27

Chapter 6 – Instrument homepage

Figure 16 Optical image

6.3

Parameters

All the instrument’s functional parameters can be changed using the Parameters page. The

link to which is located in the menu displayed on the left-hand side of the computer display.

25

Page 28

PR-33-AC User Guide M212411EN-B

Figure 17 Parameters page

New parameters can be entered into the input fields. Once parameter editing is complete,

clicking on the Submit changes button applies the designated parameters following their

confirmation. The parameter update may take a few seconds to apply.

6.4

Verification

Perform instrument verification on the Verification page. For more information on the

verification procedure, see Refractometer verification (page 34).

26

Page 29

Figure 18 Verification page

Chapter 6 – Instrument homepage

27

Page 30

40

41

42

43

44

45

46

47

48

0 10 20 30 40 50 60 70 80 90 100 110 120

Time [s]

CONC [%]

30 s

15 s

7 s

PR-33-AC User Guide M212411EN-B

7. Configuration and calibration

7.1 Configuring refractometer

In PR-33, all parameter changes are made with a web browser through the Parameters page.

For more information, see Parameters (page 25).

7.1.1 Signal damping

The system provides the possibility to enter signal damping to diminish the influence of

process noise. The damping is applied to the CONC value (and thus the output signal).

Figure 19 Eect of damping time on measurement with linear damping

There are three dierent damping types available in the Sanitary OEM Refractometer:

• Linear damping

• Exponential damping

• Slew rate limit damping

Linear damping is a sliding average, and it is recommended for most cases. The damping time

represents the averaging time. For fast damping, use 0–2 s damping, for minimal noise, use a

value of 10 s or more.

Exponential damping is a single time constant (one pole) low-pass filter. If this option is

chosen, the damping time represents the half-time of the filter. The damping time

recommendation is the same as for the linear damping.

28

Page 31

Chapter 7 – Configuration and calibration

With both linear and exponential damping the residual random noise is inversely proportional

to the square root of the damping time. In practice, using a damping time of more than 30

seconds does not improve the noise performance. It should also be noted that increasing the

damping time will deteriorate the response speed of the instrument.

If the process signal has short erroneous high or low peaks, slew rate limit damping can be

used to cut their eects. Slew rate limit damping limits the maximum change for the output

signal in one second. Slew rate limit damping is recommended for random noise suppression

as it is non-linear.

The slew rate parameter is presented in output units. For example when the concentration is

measured in percentages, typical slew rate value is 0.05

7.1.2 Skip count

When the sample is removed, the refractometer goes to NO SAMPLE state. However, if skip

count is greater than 0, the CONC is frozen to its last value for the number of measurement

cycles (one per second) indicated by skip count. Typically skip count is used when there are

large voids in the process liquid. For example a setting of 10 measurement cycles ensures that

any NO SAMPLE state shorter than 10 seconds will not make a dip in the output signal.

Skip count is set in the Output settings section of the parameter page.

7.2

Calibrating concentration measurement

The concentration calibration of the inline refractometer PR-33 is organized in six layers.

29

Page 32

TEMP

Pt-1000

ETHERNET

FIELD CALIBRATION

CHEMICAL CURVE

n

D

CCD

CONC

CALC

1.

2.

3.

4.

5.

6.

DAMPING

PR-33-AC User Guide M212411EN-B

Figure 20 Calibration layers

1 The information from the CCD element

and the Pt- 1000 temperature

element. The position of the shadow

edge is described by a number called

CCD and scaled from 0 to 100 %.

2 The refractometer calibration: The

actual refractive index nD is calculated

from the CCD value. The process

temperature is calculated from the

Pt‑1000 resistance. The refractometer

output is nD and temperature TEMP in

Centigrade. The calibrations of all

PR-33 refractometers are identical,

which makes the refractometers

interchangeable. The calibration of

each refractometer can be verified

using standard refractive index liquids.

3 The chemical curve: The refractometer

calculates the Brix value based on n

D

and TEMP. The result is a temperature

compensated calculated concentration

value CALC.

4 Field calibration: Adjustment of the

calculated concentration value CALC

may be required to compensate for

some process conditions or to fit the

measurement to the laboratory results.

5 Damping.

6 Output signal: The output signal is

transmitted through the Ethernet

connection.

The calibration of each refractometer can be verified using standard refractive index liquids,

see Refractometer verification (page 34).

Field calibration (page 31) determines the appropriate adjustment to CALC. The adjusted

concentration is called CONC. If there is no adjustment, CALC and CONC are equal. Thus the

chemical curve is kept intact as a firm base for the calculation, the adjustment is merely

additional terms.

For more information on damping, see Signal damping (page 28).

30

The output signal can also be transmitted over the 4 … 20 mA current output.

Page 33

Chapter 7 – Configuration and calibration

7.2.1 Chemical curve

The chemical curve is a model of the refractive index behavior of the process medium. It is

used in calculating the Brix value from the measured nD and TEMP. The curve is defined by a

set of 16 parameters.

Table 2 Chemical curve parameters

C

00

C

10

C

20

C

30

C

01

C

11

C

21

C

31

C

02

C

12

C

22

C

32

C

03

C

13

C

23

C

33

The Sanitary OEM Refractometer is shipped with a chemical curve to show the temperature

compensated Brix value of the process medium. The set of parameters is given by Vaisala and

should not be altered, except in case of changing to another process medium.

7.2.2 Field calibration

Vaisala provides a field calibration service that adapts the calibration to the factory laboratory

determinations based on the data supplied. This field calibration corrects the instrument

reading to show the same values as the laboratory measurements.

Perform the field calibration procedure under normal process conditions only, using standard

laboratory determinations of sample concentration.

Measure the calibrating data by using the Field point functionality on the on the Sanitary OEM

Refractometer homepage. For more information, see Measuring field samples (page 23).

Record the data either on the Refractometer field calibration form (page 54), or print out the

field points on the web page.

If you have a constant oset, you can perform a bias adjustment, see Direct BIAS adjustment

(page 32). For a more detailed field calibration, send the completed calibration form to either

helpdesk@vaisala.com or your local representative. A computer analysis of the data will be

made at Vaisala and optimal calibration parameters will be sent to be entered in the system.

For a complete report, 10 ‑ 15 valid data points (see below) are needed. A data point is of use

for calibration only when the diagnostic message is Normal operation. Each data point

consists of:

• LAB%: Sample concentration determined by the user

• CALC: Calculated concentration value

• T: Process temperature measurement in Centigrade

• nD: Actual refractive index n

• CONC: Measurement in concentration units, the large size number

In addition to the calibration data, write down the refractometer serial number.

Accurate calibration is only achieved if the sample is taken correctly. Pay special attention to

following details:

D

31

Page 34

PR-33-AC User Guide M212411EN-B

• The sampling valve and the refractometer should be installed close to each other in the

process

WARNING!

operating the sampling valve and handling the sample.

• Run the sample before starting to collect data points to avoid sampling old process liquid

that has remained in the sampling valve

• Read the values CALC, T(emp), nD and CONC at exactly the same time with sampling

• Use a tight container for the sample to avoid evaporation

CAUTION!

reliable results, as problems are caused by:

Calibration using the process liquid must always be made inline.

Wear protective clothing appropriate to your process when

Oine calibration using process liquid very seldom gives

• Low flow which makes sample to form an unrepresentative film on

the prism

• Sample evaporation at high temperature or undissolved solids at

low temperature giving deviations from laboratory determinations

• An ageing sample which is not representative

• Outside light reaching the prism

7.2.3 Direct BIAS adjustment

The concentration measurement value can also be directly adjusted by changing the field

adjustment parameter f00. The bias adjustment is well-suited to situations where the

dierence between the refractometer and the laboratory readings is small, and where there is

no clear temperature or concentration dependence of the correction.

Also, if the field calibration points are from a narrow concentration and temperature range, the

bias adjustment is usually the best option.

The value of the bias parameter f00 is added to the concentration value:

NEW CONC = OLD CONC + f00.

7.3

Default mA output value

Since sensor program version 2.05, it is possible to set in the mA output settings a mA default

output value that the instrument returns to in certain malfunction situations. The value can be

set to a low or high mA value, e.g. 3.0 mA or 22 mA. The mA measurement always returns to

the mA default output value when error message is SHORT-CIRCUIT, NO SIGNAL, TEMP

MEASUREMENT FAULT or NO SENSOR. When mA output source is configured to

concentration, also NO OPTICAL IMAGE, NO SAMPLE and PRISM COATED cause the mA

measurement to return to the default mA output value.

32

Page 35

0.5

4

20

mA

failure OK

Measurement Data

failure

24

Chapter 7 – Configuration and calibration

NAMUR is an international association of users of automation in process industries. The

association recommendation NE 43 promotes a standardization of the signal level for failure

information. The goal of NE 43 is to set a basis for proactively using transmitter failure signals

in process control strategies. Using these failure signals, instrument faults are separated from

process measurements.

NAMUR NE 43 uses the 3.8 ‑ 20.5 mA signal range for measurement information, with ≥21 mA

or ≤3.6 mA to indicate diagnostic failures. For more information, see the figure below. With

that information, it is easier to detect a failure condition on a refractometer, for example, it

clearly tells you whether you have an empty pipe or a failed instrument.

Figure 21 NAMUR NE 43 signal ranges

An optional secondary mA output default can be set for the NO SAMPLE state to dierentiate

it from the other messages that cause the measurement to revert to default mA.

The factory setting for secondary mA default is Disable. To implement secondary mA default,

go to the mA output calibration section on the parameter page and set secondary default

mode to NO SAMPLE and then set the mA output value desired. For more information, see

Parameters (page 25).

33

Page 36

PR-33-AC User Guide M212411EN-B

8. Instrument verification

8.1 Refractometer verification

The refractometer calibration is verified using a set of standard refractive index liquids. In

order to perform a valid verification, at least three liquids need to be used. The verification is

valid only within the refractive index range defined by these three liquids.

The instrument automatically recognizes the following refractive index standard liquids (the

values are stated at +25 °C):

• 1.3200

• 1.3300

• 1.3400

• 1.3500

• 1.3600

• 1.3700

• 1.3800

• 1.3900

• 1.4000

• 1.4100

• 1.4200

• 1.4300

• 1.4400

• 1.4500

• 1.4600

• 1.4700

• 1.4800

• 1.4900

• 1.5000

• 1.5100

• 1.5200

The accuracy of the certified standard refractive index liquids is ± 0.0002 and they can be

traced back to NIST standards #1823 and #1823 II. As the specified accuracy of the

refractometer is ± 0.0002, then the representative level is the sum of the two accuracy

specifications, that is ± 0.0004.

Vaisala provides a set of standard R.I. liquids, PR‑2300, containing five selected liquids (1.3300,

1.3700, 1.4200, 1.4700, 1.5200). The set can be ordered from Vaisala. Other liquids are available

on request.

8.1.1 Handling R.I. liquids

Use gloves and safety glasses or goggles. Make sure the ventilation is good, local ventilation is

preferable. Review the safety instructions and the MSDS shipped with the liquids (valid inside

R.I. range 1.30-1.57, safety markings valid in EU/EEA areas). Do not put tissues or liquid bottles

in household waste, dispose of waste according to local regulations for chemical waste.

34

Page 37

Chapter 8 – Instrument verification

8.2 Verification procedure

Perform instrument verification using the web interface. On the instrument homepage, go to

the Verification page. The standard liquids are placed on the prism as instructed by the

instructions on the screen. Once the liquid has settled, sample is measured by clicking the

New verification point button.

The liquids are automatically detected, and the quality of the measurement is constantly

monitored throughout the process. If the same liquid is measured several times, the new result

replaces the older one. To remove a single measurement point, click the Remove button.

The verification result displays on the page. Reloading the page removes all points. After

measuring a sucient number of points the verification can be saved by clicking the Save

verification button.

In order to avoid verification errors, please make sure:

• The temperature has settled, i.e., the refractometer is in the ambient temperature

• The temperature of the refractometer is between 20 °C and 30 °C

• The prism is cleaned properly before placing the sample

• The test liquid wets the prism properly

Check the temperature of the refractometer by following the temperature measurement on

the Verification page. The temperature should be constant.

35

Page 38

PR-33-AC User Guide M212411EN-B

Figure 22 Verification page

The sample holder keeps the sample on the prism surface and also blocks the ambient light

from reaching the prism. Universal sample holder PR-1012 can be used with any Vaisala

K‑PATENTS® refractometer.

The optical image displayed on the page helps determining whether the prism is wetted

completely. The image should have a sharp corner as in the figure above. The position of the

corner depends on the refractive index. A soft image may indicate improper cleaning of the

prism. If there is not enough liquid on the prism, the image tends to flatten. If the image

changes its shape during the measurement of a single liquid, redo the measurement. The most

likely reason is that the liquid leaks from the sample holder.

36

Page 39

Chapter 8 – Instrument verification

Figure 23 Universal sample holder PR-1012

After measuring a sample, remove the sample and clean the prism and the sample holder. The

prism can be cleaned by soft tissue and ethanol or other suitable solvent. Repeat the

procedure (cleaning, replacing the sample, measuring) for each nD liquid. In case you perform

the procedure more than once for a single sample, the latest measurement will replace earlier

measurements.

The table on the verification page keeps a real time record of the points measured and the

status (pass/fail) of the verification. If you have a failed point, either remove it or remeasure it.

Once all liquids have been measured, save the verification by clicking the Save verification

button. The button is only available after a sucient number of points has been measured.

The limit for acceptance is that all measurements must be within ± 0.0004 of the nominal

values.

The refractometer verification concerns only the refractive index nD measurement.

The calculation of concentration from nD and process temperature TEMP is not

included.

8.3 Verification report

The last saved verification data can be accessed by clicking the Verification report link on the

left panel. This verification report includes all measurement data and the PASS/FAIL status of

the verification. The report can be printed out or saved as a reference for the quality system.

37

Page 40

PR-33-AC User Guide M212411EN-B

Figure 24 Verification report

8.4

Corrective action

If the verification is not passed, first check that both the prism and the sample holder are

absolutely clean and the sample holder sits tightly on the refractometer tip before a standard

liquid is applied. Make sure the standard liquids are in good condition and not past their

expiration date. Also, inspect the prism surface, checking that it is flat and shiny without any

scratches, digs or deposition on it.

Repeat the verification procedure. If the verification still fails, print out the verification report,

send the data to helpdesk@vaisala.com or your nearest representative, and wait for further

instructions.

38

Page 41

Chapter 9 – Maintenance

9. Maintenance

Ensure that the refractometer is not a source of contamination to product due to damaged or

worn product contact surfaces. Such surfaces may not stay clean in processing and so do not

fulfill 3‑A requirements. Vaisala oers 3‑A Standard Accepted repair and maintenance

package, performed by a 3‑A authorized service center. In the repair process all wetted parts,

prism, gaskets and dryer are replaced and the sensor is calibrated, all according to 3‑A

Sanitary standards.

If a sensor is repaired by using old wetted metal parts (replacing only prism and

gaskets), the repair may result in a non-sanitary condition of the surfaces.

39

Page 42

PR-33-AC User Guide M212411EN-B

10. Troubleshooting

10.1 Diagnostic message priorities

The messages are listed in descending order of priority. For example, if both NO

OPTICAL IMAGE and TEMP MEASUREMENT FAULT are activated, only NO

OPTICAL IMAGE displays.

• OUTSIDE LIGHT ERROR

• NO OPTICAL IMAGE

• TEMP MEASUREMENT FAULT

• HIGH SENSOR HUMIDITY

• HIGH SENSOR TEMP

• NO SAMPLE

• PRISM COATED

• OUTSIDE LIGHT TO PRISM

• LOW IMAGE QUALITY

• Normal operation

The following sections list the diagnostic messages, their causes and corrective actions.

10.2

Hardware

The following table describes the hardware messages and their related actions.

Table 3 Hardware messages

Message Description Corrective action

HIGH SENSOR

HUMIDITY

HIGH SENSOR

TEMP

Tells that humidity measured inside

the instrument exceeds 60 % relative

humidity. The reason may be moisture

leaking in through prism seal or the

cover being open.

The temperature inside the instrument

exceeds 65 °C (150 °F). To read this

temperature, go to the diagnostics

page. For more information, see

Diagnostics (page 22).

Contact Vaisala.

See Choosing refractometer mounting

location (page 15).

10.3 Measurement

The following table describes the measurement messages and their related actions.

40

Page 43

Chapter 10 – Troubleshooting

Table 4 Measurement messages

Message Description Corrective action

OUTSIDE LIGHT

ERROR or

OUTSIDE LIGHT

TO PRISM

NO OPTICAL

IMAGE

PRISM COATED The optical surface of the prism is

LOW IMAGE

QUALITY

NO SAMPLE The operation of the equipment is OK

The measurement is not possible or is

disturbed because outside light

reaches the camera.

The prism is heavily coated. Remove sensor from line and clean

There is moisture condensation in the

sensor.

The sensor temperature is too high.

The light source is faulty. When the

sensor is removed from the process,

the yellow flashing light can be seen

through the prism.

The light is only visible

at an oblique angle.

There are negative spikes in the

optical image. The probable cause is

dust or fingerprints on the CCD

window.

The CCD card in the sensor is faulty.

coated by the process medium or

impurities in the process medium.

The most likely cause for this message

is coating on the prism. There still is

an optical image available, but the

measurement quality may not be

optimal.

but there is no process liquid on the

prism. In some cases this message

may also be caused by coating on the

prism.

Identify the light source and block the

light from getting to the prism at the

sensor tip. The amount of outside

light can be seen at BGlight on the

Diagnostics page.

prism manually.

See Hardware (page 40).

Check the LED value on the

Diagnostics page. For more

information, see Diagnostics

(page 22).

If the value is clearly below 100, LED

fault is not likely.

If the value is above 100, contact

Vaisala.

Contact Vaisala.

Remove sensor from line and clean

prism manually.

If the problem is recurrent, consider

improving the flow conditions. For

more information, see Choosing

refractometer mounting location

(page 15).

41

Page 44

PR-33-AC User Guide M212411EN-B

Message Description Corrective action

TEMP

MEASUREMENT

FAULT

Indicates faulty temperature element. Contact Vaisala.

A dierence to some

other process

temperature

measurement is not a

fault. The Sanitary

OEM Refractometer

shows the true

temperature of the

prism surface.

Concentration

drift during

Normal operation

For drift upward or downwards to

zero, cause is likely the prism coating.

Remove sensor from line and clean

prism manually.

If the problem is recurrent, consider

improving the flow conditions. For

more information, see Choosing

refractometer mounting location

(page 15).

42

Page 45

Chapter 11 – Specifications

11. Specifications

11.1 PR-33-AC model code

Table 5 SANITARY OEM REFRACTOMETER for pipelines (3-A Sanitary Standard 46-04 Certified)

Model and description Model

PR-33 = Refractometer PR-33

Refractometer type

-AC = Compact type for pipeline installation, 3‑A certified -AC

Refractive Index range limits

-73 = R.I. 1.320-1.530 nD (0-100 Brix) Sapphire prism -73

Process connection

-H = for Sanitary 3A-clamp, 2½ inch

-E = for Varivent® in-line access unit clamp DN65

Wetted parts material

SS = AISI 316 L SS

Electrical classification

-GP = General purpose -GP

Housing material

-RS = Stainless steel AISI 304 -RS

Electrical connections

-A = 1 x 4–20 mA, 1 x Ethernet UDP/IP, power supply +24 VDC -A

Sensor wetted parts surface treatment option

-EP = Electropolished sensor wetted parts (Ra 0.38 µm, 15 µ inch) -EP

1)

1)

-H

-E

1) Sensor only without clamp, gasket and ferrule.

Example: PR-33-AC-73-HSS-GP-RS-A-EP

Table 6 SANITARY OEM REFRACTOMETER for pipelines (3-A Sanitary Certified and EHEDG

certified)

Model and description Model

PR-33 = Refractometer PR-33

43

Page 46

PR-33-AC User Guide M212411EN-B

Model and description Model

Refractometer type

-AC = Compact type for pipeline installation, 3‑A certified -AC

Refractive Index range limits

-73 = R.I. 1.320-1.530 nD (0-100 Brix) Sapphire prism -73

Process connection

-H = for Sanitary 3A-clamp, 2½ inch

1)

-H

-E = for Varivent® in-line access unit clamp DN65 -E

Wetted parts material

SS = AISI 316 L SS

Electrical classification

-GP = General purpose -GP

Housing material

-RS = Stainless steel AISI 304 -RS

Electrical connections

-A = 1 x 4–20 mA, 1 x Ethernet UDP/IP, power supply +24 VDC -A

EHEDG

-EH = EHEDG Type EL Class I Certified model -EH

Sensor wetted parts surface treatment option

-EP = Electropolished sensor wetted parts (Ra 0.38 µm, 15 µ inch) -EP

1) Complete with clamp, gasket and ferrule.

Example: PR-33-AC-73-HSS-GP-RS-A-EH

Table 7 Elbow Flow Cells for PR-33-AC

Model and description Model

AFC = Elbow flow cell AFC

Sensor connection

-H = Sanitary 3A‑clamp, 2½ inch -H

Material of construction

SS = AISI 316 L SS

Process connection

44

Page 47

Chapter 11 – Specifications

Model and description Model

-H = Sanitary 3A clamp -H

Pipe section diameter

10 = 25 mm (1 inch) 10

15 = 40 mm (1½ inch) 15

20 = 50 mm (2 inch) 20

25 = 65 mm (2½ inch)

1)

25

Flow cell inlet type

-SI = Straight pipe -SI

-RI = Reduced pipe (cone) -RI

1) With -SI option only.

Table 8 EHEDG Certified Elbow Flow Cells, connection Sanitary 3A-clamp 2½ inch

Model and description Model

AFC = Elbow flow cell AFC

Sensor connection

-H = Sanitary 3A-clamp, 2½ inch -H

Material of construction

SS = AISI 316 L SS

Process connection

-H = Sanitary 3A clamp -H

Pipe section diameter

20 = 50 mm (2 inch) 20

Flow cell inlet type

-SI = Straight pipe -SI

EHEDG

-EH = EHEDG Type EL Class I Certified Model

Polishing option

-EP = Electropolished process wetted parts (Ra 0.38 µm, 15 µ inch) -EP

45

Page 48

PR-33-AC User Guide M212411EN-B

Table 9 Mounting hardware for PR-33-AC

Model and description Model

MFC = Mini Flow Cell MFC

Sensor connection

-H = Sanitary 3A-clamp, 2½ inch -H

Material of construction

SS = AISI 316 L SS

Process connection

-H = Sanitary 3A clamp -H

Pipe section diameter

05 = 15 mm (½ inch) 05

11.2 Mounting specifics for EHEDG certified

PR-33-AC configuration

Vaisala oers certain PR-33-AC configurations which have been certified to fulfill the sanitary

requirements published by EHEDG (European Hygienic Engineering & Design Group)

organization. During this certification the hygienic characteristics of both the refractometer

and the process connection were evaluated against the applicable requirements.

To ensure EHEDG compliant installation, follow the mounting specifics provided on the

mounting drawing supplied by Vaisala with each PR-33-AC refractometer sensor ordered with

the -EH option.

46

Page 49

Chapter 12 – Ethernet protocol specification

12. Ethernet protocol specification

The main purpose of the Ethernet connection is to collect measurement data from the

instrument. For this data acquisition, you need suitable software on your computer. You can

program a data acquisition program yourself following the specifications listed in the following

sections.

For examples and ready-made applications, contact Vaisala.

12.1 Communication protocol

The communications protocol is based on UDP/IP to port 50023. It is a client/server protocol,

where the sensor is the server and thus only sends information when the client (i.e. your

computer) requests it. The server should answer to all requests within 100 ms.

12.1.1 Request format

The client to server communication, i.e. the requests sent from your computer to the

refractometer, is in binary format. The request packets contain the following binary data (all

integers are in the network order, MSB first):

• 32-bit integer: packet number

• 32-bit integer: request ID

• (any): request data (depends on the request)

• (any): fill-in data

The maximum size of the message is 1472 octets (bytes).

The packet number is echoed back by the refractometer, but not processed in any way. The

packet numbers do not have to be sequential, any 32-bit value is valid.

The request ID is a 32-bit value that identifies the requested function, for example

refractometer information. See Request-response pair specification (page 49) for request IDs.

The request data consists of 0 to 1464 octets of additional data associated with the request.

The fill-in data can be used to increase the number of octets in a message. Any number of

NULL characters (0x00) may be added to the end of the request as long as the total size of

the message does not exceed the maximum of 1472 octets. This may be useful, for example, if

the client implementation uses fixed-length packets.

12.1.2 Response format

The response data sent by the instrument is in ASCII format. With the exception of the packet

number, the data is human-readable. The data structure is very simple:

47

Page 50

PR-33-AC User Guide M212411EN-B

• Packet number (32-bit integer)

• Zero or more lines of ASCII (text) keys and values associated with these keys (for example

temperature key and process temperature in Celsius)

The packet number is echoed back without change. The client (software on computer) can

use the packet number to check the response against the packet number of the request.

The message text consists of lines of text, each line a single key (of one word) and its value or

values. The values are separated from the key by an equal sign ( = ) and multiple values are

separated by a comma. White space (space or tabulator) is allowed anywhere except within a

single value or key name.

If the response consists of a character string, it is enclosed in double quotes ("). For example,

all these are valid message text lines:

ok

temp = 23.45

headhum = 13.32

LEDcnt = 8341

ChemCurve = 1.234, 3.21, 0.00, 4.37, 1.11, 0.00002, 2.1345

StatusMessage = "Normal Operation"

All the key identifiers are case-insensitive. For more information, see Request-

response pair specification (page 49). However, the recommendation is that

they are written as in this specification.

The server (refractometer) may send the response keys in any order. It sends the mandatory

keys of the specific request, but may omit any other keys. The mandatory keys are marked

with an asterisk in Request-response pair specification (page 49).

The server may also send keys that are not specified in this document, but the client

(computer) may ignore them.

12.1.3 Request and response errors

When the server (refractometer) detects an error, it responds with an error message. For more

information, see Error message specification (page 50).

An error message can be caused, for example, by an unknown request or inability to collect

data for the mandatory keys of a response.

48

Page 51

Chapter 12 – Ethernet protocol specification

12.2 Request-response pair specification

The following table describes the query messages, i.e. request-response pairs, used for data

collection using the Ethernet connection.

Those response keys that are always sent are preceded by an asterisk (*).

Table 10 Request-response pair specification

Specification Description Request ID Request data Response key

NULL

message

Protocol

version

Refractomete

r information

Included in query messages

for debugging purposes as it

can be used to check

whether the server is

listening. The message gives

a high-level 'ping'

functionality.

Responded to with a value

representing the server

(refractometer) protocol

version.

Gives the basic information

of the refractometer.

0x00000000(none) • IP: IP address

0x00000001 (none) *Version: integer, the

0x000000030x0000000

0: always

zero

• MAC: Ethernet

MAC address

server protocol

version (currently 3)

• *SensorSerial:

string,

refractometer

serial number

• *SProcSerial:

string, processor

card serial number

• *SensorVersion:

string, version

number of the

refractometer

software

49

Page 52

PR-33-AC User Guide M212411EN-B

Specification Description Request ID Request data Response key

Measurement

results

Gives the measured and

calculated measurement

values from the

refractometer.

0x000000040x0000000

0: always

zero

• Status: string,

refractometer

status message

• PTraw: integer,

PT1000 value

• LED: float, LED

value

• RHsens: float,

internal humidity

• nD: float,

calculated nD value

• CONC: float, final

concentration

value

• Tsens: float,

internal

temperature

• T: float, process

temperature

• CCD: float, image

shadow edge

• CALC: float,

calculated

concentration

value

• QF: float, quality

factor

• BGlight: integer,

background light

12.3

Error message specification

If the server (refractometer) does not recognize the request or cannot fulfill it, it responds with

an error message. The error message has the following keys:

• *Error: integer, error code 0x00000000: Unknown request

• *Error: integer, error code 0x00000001: Invalid request (request recognized, invalid

request data)

• *Error: integer, error code 0x00000002: Invalid sensor number

• ErrorMsg: string, error details

There may also be error-dependent extra keys. Other error codes may be returned.

0x00000003 is handled as an unknown request. Codes with higher numbers refer to internal

errors; contact Vaisala for more information.

50

Page 53

L

P

MM

S

A C B

Chapter 13 – Principle of measurement

13. Principle of measurement

The Vaisala K-PATENTS® inline refractometer determines the refractive index nD of the process

solution. It measures the critical angle of refraction using a yellow LED light source with the

same wavelength (589 nm) as the sodium D line (hence nD). Light from the light source (L) in

the figure below is directed to the interface between the prism (P) and the process medium

(S). Two of the prism surfaces (M) act as mirrors bending the light rays so that they meet the

interface at dierent angles.

Figure 25 Refractometer principle

The reflected rays of light form an image (ACB), where (C) is the position of the critical angle

ray. The rays at (A) are totally internally reflected at the process interface, the rays at (B) are

partially reflected and partially refracted into the process solution. In this way the optical

image is divided into a light area (A) and a dark area (B). The position of the shadow edge (C)

indicates the value of the critical angle. The refractive index nD can then be determined from

this position.

51

Page 54

B B

C

C

A A

Low concentration High concentration

a. Optical image

b. CCD element

c. CCD output

V

PR-33-AC User Guide M212411EN-B

The refractive index nD changes with the process solution concentration and temperature. For

most solutions the refractive index increases when the concentration increases. At higher

temperatures the refractive index is smaller than at lower temperatures. From this follows that

the optical image changes with the process solution concentration as shown in the figure

below. The color of the solution, gas bubbles or undissolved particles do not aect the

position of the shadow edge (C).

Figure 26 Optical images

The position of the shadow edge is measured digitally using a CCD element and is converted

to a refractive index value nD by a processor inside the instrument. This value is used together

with the measured process temperature to calculate the concentration.

Figure 27 Optical image detection

52

Page 55

2019-09-01H/JAMO

1 (1)

Vaisala Oyj | PO Box 26, FI-00421 Helsinki, Finland

Phone +358 9 894 91 | Fax +358 9 8949 2227

Email firstname.lastname@vaisala.com | www.vaisala.com

Domicile Vantaa, Finland | VAT FI01244162 | Business ID 0124416-2

EU DECLARATION OF CONFORMITY

Manufacturer: Vaisala Oyj

Mail address: P.O. Box 26, FI-00421 Helsinki, Finland

Street Address: Vanha Nurmijärventie 21, Vantaa, Finland

This declaration of conformity is issued under the sole responsibility of the manufacturer.

Object of the declaration:

K-Patents Process Refractometer PR-33 series

The object of the declaration described above is in conformity with Directives:

RoHS Directive (2011/65/EU)

EMC Directive (2014/30/EU)

The conformi

ty is declared using the following standards:

EN 50581:2012

Technical documentation for the assessment of electrical and

electronic products with respect to the restriction of hazardous subs tances

EN 61010-1:2010

Safety requirements for electrical equipment for measurement,