Page 1

IM-EN-PR23AC-VACC-A

Appendix

to PR-23 Instruction Manual for Vaisala K-PATENTS®

Products Intended for Use in Vaccine Production

Vaisala K-PATENTS® Pharma Refractometer PR-23-AC

Page 2

Appendix to the Instructions Manual PR-23

Do not underestimate or neglect the laboratory and factory safety rules:

●

Before you start, assess the workplace to determine if hazards are present, or are

likely to be present, which necessitate the use of personal protective equipment, e.g.:

●

protective clothing and shoes

●

safety goggles

●

protective gloves

●

respiratory shields and devices

●

Locate the nearest safety equipment, extinguishers, eyewash, and emergency shower

2

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 3

Contents

Section 1 Vaisala K-PATENTS® products for vaccine production and sucrose gradient

ultracentrifugation ............................................................................................................... 5

1.1 Designqualication........................................................................................................ 6

Section 2 The Pharma Refractometer PR-23-AC ................................................................................ 7

2.1 System description ........................................................................................................ 7

2.2 System components ...................................................................................................... 8

2.2.1 Checklist of components .................................................................................... 8

2.3 Pharma Refractometer Sensor PR-23-AC- 62-HSS-SC ............................................. 10

2.3.1 Sensor model code .......................................................................................... 10

2.3.2 Pharma Mini Flow Cell model code ................................................................. 10

2.4 Indicating Transmitter DTR-GP-SC ............................................................................. 12

2.4.1 Indicating Transmitter model code ................................................................... 12

2.5 Pharma vaccines accessories ..................................................................................... 13

Section 3 Installation of PR-23 Pharma Refractometer ................................................................... 15

3.1 Hardware and software requirements ......................................................................... 15

3.2 Mechanical and electrical requirements ...................................................................... 15

3.3 Sensor installation for use in pharmaceutical batch manufacturing ............................ 15

3.4 Indicating Transmitter installation for use in table top ................................................. 19

3.5 Wiring transmitter connections to sensor, power cable and computer ....................... 20

3.6 Refractometerinstrumentverication .......................................................................... 21

Section 4 Electronic data capture and storage ................................................................................ 23

4.1 Ethernet connection ..................................................................................................... 23

Section 5 Complying with documentation and validation regulations ......................................... 25

5.1 Documentation ............................................................................................................. 25

5.2 Qualication ................................................................................................................. 25

5.3 Protocol acceptance by customer and list of tests performed .................................... 25

5.4 Electronic data management and data storage ........................................................... 26

5.5 Electronic signatures/audit trail .................................................................................... 26

5.6 Record keeping ............................................................................................................ 26

5.7 Security ........................................................................................................................ 26

5.8 System validation ......................................................................................................... 26

5.9 Vaisala K-PATENTS

Section 6 Onsitequalicationprotocolsandrecords:InstallationQualication ....................... 29

6.1 Authorization and responsibilities ................................................................................ 29

6.1.1 Documents and procedures ............................................................................ 29

6.1.2 Authorizedofciator ......................................................................................... 30

6.1.3 Execution ......................................................................................................... 30

6.2 System ......................................................................................................................... 30

®

refractometer system adherence to Part 11 ............................. 27

© Copyright Vaisala 2020. All rights reserved.

3

Page 4

Appendix to the Instructions Manual PR-23

6.2.1 Qualifying the system ...................................................................................... 30

6.2.2 Manufacturers and suppliers ........................................................................... 31

6.3 IQ protocol ................................................................................................................... 31

6.3.1 Scope of delivery ............................................................................................. 31

6.3.2 Damage ............................................................................................................ 32

6.4 Documentation ............................................................................................................. 32

6.5 Operating environment ................................................................................................ 33

6.6 Installation .................................................................................................................... 33

6.7 Setting up the system components and devices ......................................................... 34

6.8 Electrical connections and wiring ................................................................................ 35

6.9 Ethernet connection ..................................................................................................... 36

6.10 Initial check and switching the device on ................................................................... 36

6.11 InstallationQualicationsummaryreport .................................................................... 37

Section 7 Onsitequalicationprotocolsandrecords:OperationalQualication ...................... 39

7.1 Individual module and system components check ...................................................... 39

7.2 InstallationQualicationhasbeenperformedsuccessfully ........................................ 39

7.3 Test procedure ............................................................................................................. 40

7.4 Authorizedofciator ..................................................................................................... 40

7.5 Systemqualication ..................................................................................................... 41

7.6 Setting up the system components and devices ......................................................... 41

7.7 Instrumentvericationwithsampleholderandrefractiveindexliquids ...................... 42

7.8 OperationalQualicationsummaryreport .................................................................. 43

Section 8 Routine operation phase ................................................................................................... 45

Section 9 Preventive maintenance .................................................................................................... 47

Section 10 Other documentation ......................................................................................................... 49

4

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 5

Vaisala K-PATENTS® products for

1

vaccine production and sucrose

gradient ultracentrifugation

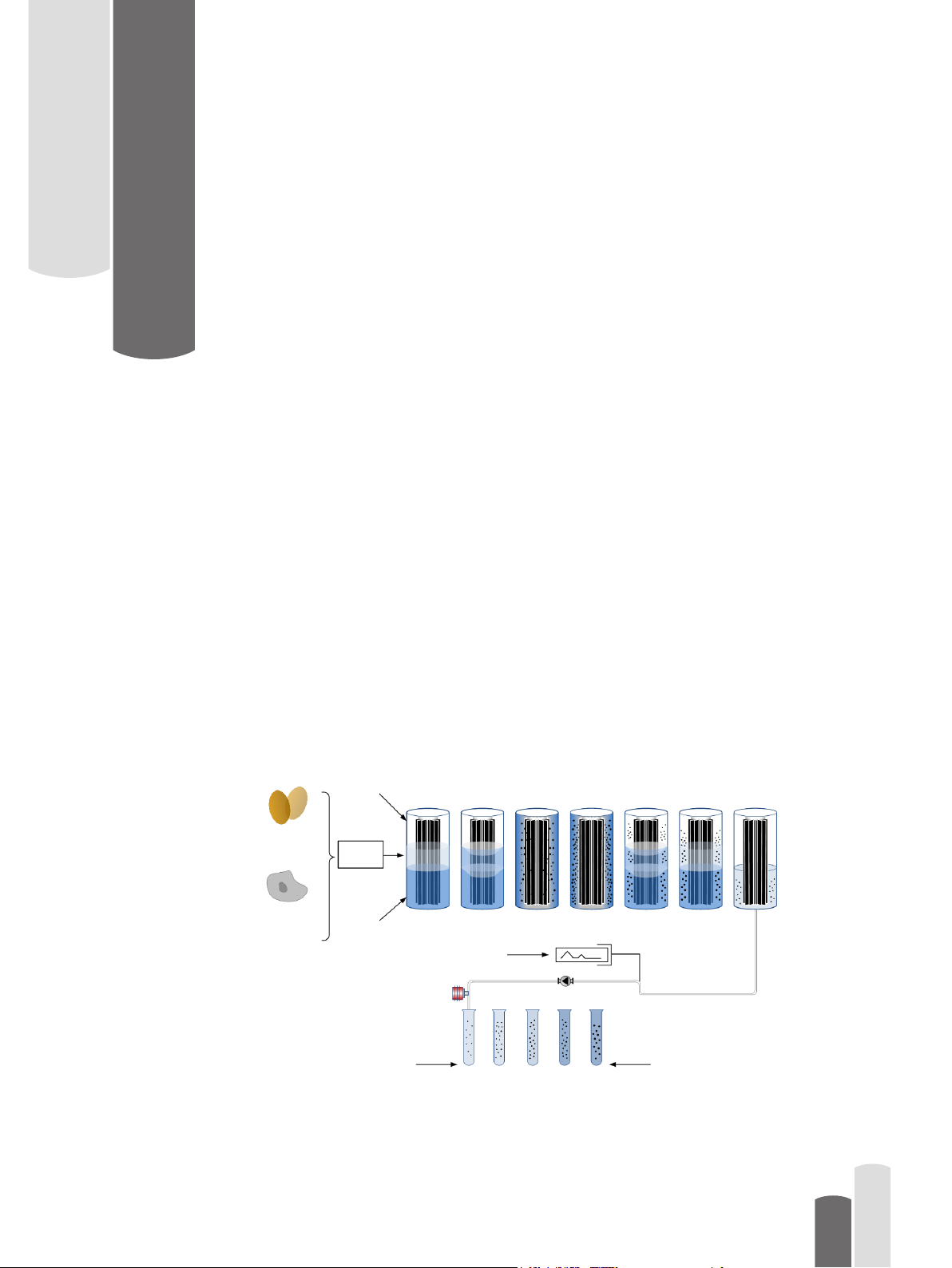

This instruction manual appendix covers Vaisala K-PATENTS® Pharma Refractometer

PR-23-AC when used in the production of viral vaccines. The vaccines are either produced

by inoculating viruses into specic pathogen-free eggs or in animal cell culture based

process. The allantoic uid of these processes is harvested and puried by centrifugation

and stabilised with buffer containing sucrose. The centrifugation process typically uses

density gradient continuous ow ultracentrifuge for the purication of the virus particles.

The internal subviral core of the virus is separated and fractionated on the basis of its’

sedimentation rate, and the buoyant sucrose density. Pharma Refractometer PR-23-AC is

used for accurate measurement of these sucrose densities. The measurement signal is used

for reliable and timely determination of the product peak in the density gradient (0 to 60%

w/w sucrose), and the subsequent collection of the virus rich fraction (Figure 1.1.).

Pharma Refractometer PR-23-AC can be installed in the vaccines fractionation unit for

in-line process control. The output of the transmitter is a 4 to 20mA DC output signal

proportional to sucrose solution density or Brix. Process data can also be downloaded to a

computer via an Ethernet cable.

High Density

Solution

• Inoculation egg

with virus

• Incubation

• Inoculation

preparation

• Cell expansion

• Virus propagation

Figure 1.1 Ultracentrifugation density gradient purication process steps.

© Copyright Vaisala 2020. All rights reserved.

Inactivation

of virus

Low Density

Solution

Sucrose gradient purication by zonal centrifugation

Fractionation and separation

Chart Recorder

Filling

Low Density High Density

Rotor unloading

5

Page 6

Appendix to the Instructions Manual PR-23

1.1 Design qualication

Design Qualication (DQ) typically consists of manufacturer’s documentation to verify

that the proposed design of the Vaisala K-PATENTS

intended purpose.

Pharma Refractometer PR-23-AC is an in-line real-time instrument that is designed to meet

the pharmaceutical industry standards and guidelines including PAT, GMP, CIP/SIP and

validation. Pharma Refractometer PR-23-AC wetted parts materials comply with the contactcompatibility of a substance with pharmaceutical materials. Gasket materials conform to the

FDA requirements 21 CFR 177.2600 and to biocompatibility standards according to USP

Class VI. Meeting the FDA and USP criteria guarantees that the seal material is acceptable

for sanitary process applications and the material, or extracts from the material will not

be harmful to human health. No animal derived ingredients (ADI) have been used in the

machining and polishing processes. The PR-23-AC also meets the 3-A Sanitary Standard

and is tested for in-place-cleanability according to the Euopean Hygienic Engineering Design

Group (EHEDG) test.

The refractometer has an Ethernet communications solution. The transmitter uses the

IP protocol to communicate over the Ethernet to any type of computer. This eliminates

human error and allows for easy capture of the refractometer generated measurement

and diagnostic data for storage, analysis and reporting. Access to the refractometer

and the generated data can be restricted to authorized personnel using password and

padlock protection.

®

Refractometer is suitable for the

Vaisala K-PATENTS refractometers are designed, manufactured and serviced under

ISO 9001 quality system and procedures that guarantee the accuracy and repeatability

of the measurement results. Each refractometer sensor is provided with a calibration

certicate comparing a set of standard liquids to the actual sensor output. Vaisala veries

the calibration of all delivered instruments according to the procedure similar to the

one described in the PROCESS REFRACTOMETER PR-23 INSTRUCTION MANUAL,

Section 13.

The quality system is ISO 9001 certied by Det Norske Veritas. The quality performance

is improved by critical self-assessment, internal auditing and feedback system. The chain

of quality starts from the subcontractors with whom Vaisala maintains a quality contracting

and regular auditing system. The internal quality functions, from verication of incoming

products to packing and delivery, are based on dened procedures. Vaisala provides full

traceability of the wetted parts materials. Certicates of Origin, and any other required

quality documentation is available upon request at time of order.

Vaisala K-PATENTS process refractometers and support services are available to customers

anywhere in the world. Application, installation and technical assistance are provided both

locally by the representatives and by the headquarters in Finland and a branch in the U.S.

Vaisala warrants that all products made by Vaisala shall be free of defects in material and

workmanship. Vaisala agrees either to replace or repair free of charge any such product or

part thereof which shall be returned to the nearest authorized Vaisala K-PATENTS repair

facility within two (2) years from the date of delivery.

6

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 7

2

The Pharma Refractometer

PR-23-AC

2.1 System description

The recommended system for the vaccines production process comprises of a

Pharma Refractometer PR-23-AC unit and a Pharma Mini Flow Cell PMFC-HSS

that allows the sensor connection to the zonal ultracentrifuge rotor unloading and

fractionation phase.

The standard Ethernet communication solution allows for simultaneous data

logging and continuous monitoring of the measurement values and diagnostic

data from the Indicating Transmitter DTR to a computer via an Ethernet connection.

© Copyright Vaisala 2020. All rights reserved.

7

Page 8

Appendix to the Instructions Manual PR-23

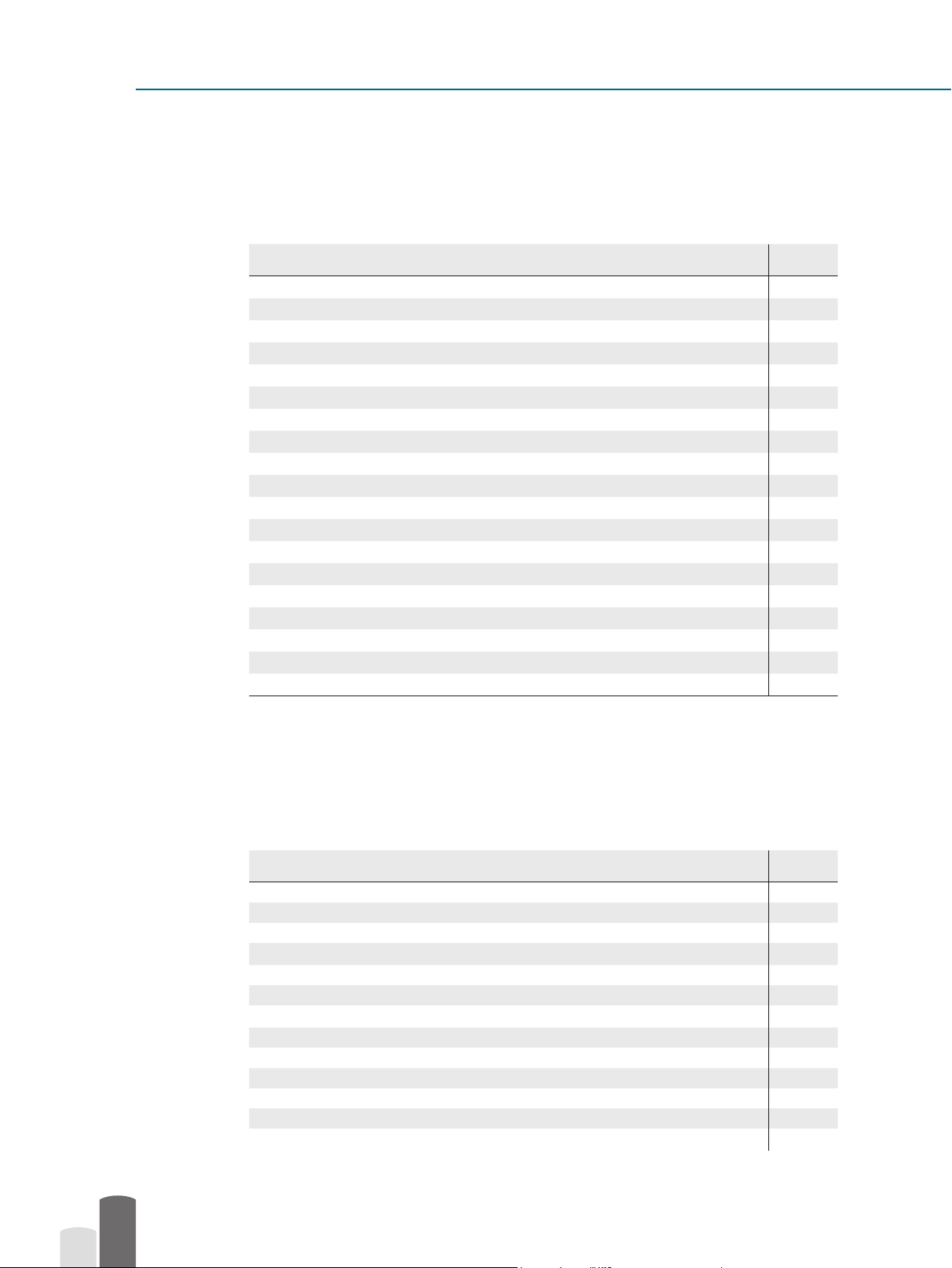

2.2 System components

2.2.1 Checklist of components

Pharma Refractometer Sensor PR-23-AC-62-HSS-SC- EP calibrated with raw

1

measurement data refractive index (n

Indicating Transmitter DTR-M/U-GP-SC that calculates and displays the process liquid

2

concentration based on the refractive index and temperature, installed in a stainless steel

2a

enclosure that contains a key

Table top stand PR-7603-SS for Indicating Transmitter,

3

contains a set of two M5x10 A2 DIN 912 screws

3a

Wall mounting screws kit for mounting the Indicating Transmitter DTR on the wall

4

Interconnecting cable between transmitter and sensor PR-8230

5

PR-8820 Crossover cable for Ethernet connection between Indicating Transmitter and

6

computer, length 5 m (16 inch), contains cable gland for enclosure connection

Table top stand PR-7605 -SS with an integral support rod and

7

2.5” Sanitary Clamp for the Pharma Refractometer Sensor PR-23-AC-62-HSS

7a

contains a M5x16 A4 DIN 912 screw

7b

Pharma Mini Flow Cell PMFC-HSS

8

PR-9244-USP O-ring for the Pharma Mini Flow Cell, 22.2x3.0 EPDM

9

Two sets of PR-9235 0.5” Sanitary Clamp for the Pharma Mini Flow Cell connection

10

Two sets of PR-9236 -USP Sanitary gasket EPDM for the 0.5” Sanitary Clamps

11

Two sets of PR-9237 0.5” Sanitary ferrule (lenght 1.5 cm) for the inlet and outlet hose

12

connections and Pharma Mini Flow Cell

Universal sample holder PR-1012

13

R.I. Liquid set PR-2300, consists of Cargille Cer ticate for the liquids

14

) and temperature (T)

D

8

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 9

The Pharma Refractometer PR-23-AC

1

13

2

11

8

9

10

7b

7a

5

3

3a

14

2a

7

12

6

4

2

Figure 2.1 System components provided by Vaisala.

© Copyright Vaisala 2020. All rights reserved.

9

Page 10

Appendix to the Instructions Manual PR-23

2.3 Pharma Refractometer Sensor PR-23-AC-62-HSS-SC

2.3.1 Sensor model code

Model and Description Model

PR-23 = Sensor PR-23

Sensor model

-A = 3A approved -A

Sensor type

C = Compact type for pipe line installation C

Refractive Index range limits

-62 = R.I. 1.320....1.530 ( 0-100 Brix ) -62

Process connection -SC

-H = Sanitary 3A-clamp, 2 ½ inch -H

Sensor wetted parts material

SS = AISI 316 L SS

Electrical classication

-GP = General purpose -GP

-AX = ATEX certied EX II 3 G Eex nA II T4 (up to Zone 2) -AX

-IA = ATEX and IECEx certied EX II 1 G Ex ia II C T4 Ga (up to Zone 0) (A) -IA

Sensor housing

-SC = Stainless steel -SC

Sensor wetted parts surface treatment option

-EP = Electropolished process wetted parts (Ra 0.4µm, 15 µ inch ) -EP

(A) Available with STR- Indicating Transmitter and IS Isolator only

10

2.3.2 Pharma Mini Flow Cell model code

The wetted parts materials for the Pharma Mini Flow Cell are AISI 316 stainless

steel standard Ra 0.4µm, 15 µ inch and EPDM (ethylene propylene diene

monomer) for the O-ring sealing.

Model and Description Model

PMFC = Pharma Mini Flow Cell PMFC

Sensor connection

-H = Sanitary 3A-clamp, 2 ½ inch -H

Material of Construction

SS = AISI 316 SS

Process connection

-H = Sanitary mini tting -H

Pipe section diameter

04 = 4 mm 04

05 = 5 mm 05

06 = 6 mm 06

Options

-EP = Electropolished process wetted parts (Ra 0.4µm, 15 µ inch ) -EP

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 11

The Pharma Refractometer PR-23-AC

2

Figure 2.2 Pharma Refractometer PR-23-AC-62-HSS-EP sensor and Pharma Mini Flow Cell

Figure 2.3 Pharma Mini Flow Cell PMFC-HSS-EP.

PMFC-HSS-EP with PR-7605 -SS table top stand.

© Copyright Vaisala 2020. All rights reserved.

11

Page 12

Appendix to the Instructions Manual PR-23

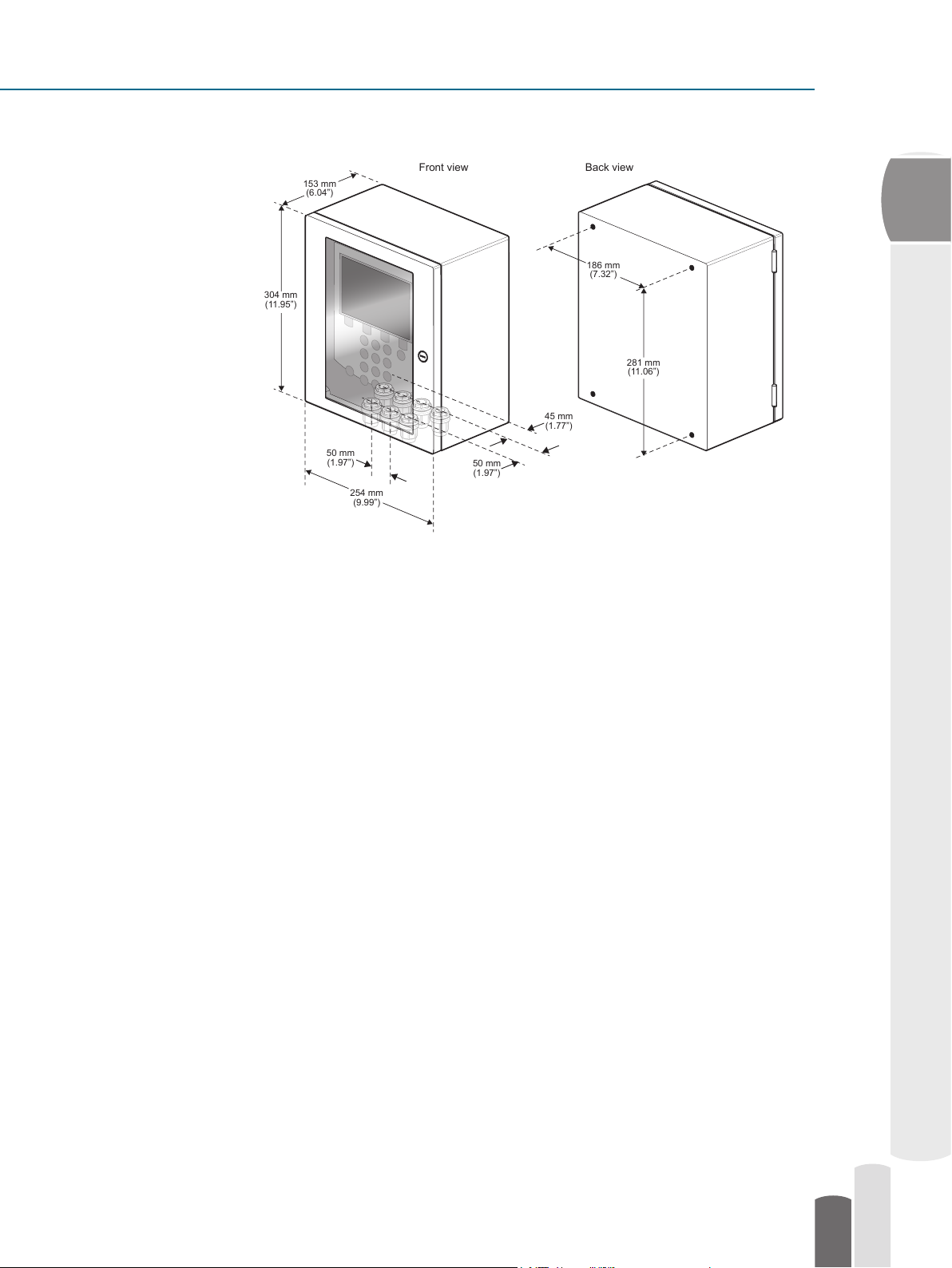

2.4 Indicating Transmitter DTR-GP-SC

Indicating Transmitter DTR is a specialized computer designed to process data

received from the refractometer sensor. Indicating Transmitter (Figure 2.4) contains

a front panel with a backlit Liquid Crystal Display (LCD) and a keyboard. A lock and

a key are included in the enclosure’s door to prevent unauthorized access. Please

note that neither any power cables nor any external power switches are included in

the standard delivery.

Materials for the Pharma Indicating Transmitter Enclosure DTR-M/U-GP-SC are:

Stainless steel enclosure and polycarbonate window.

2.4.1 Indicating Transmitter model code

Model and Description Model

DTR = Indicating Transmitter (connectivity for two sensors)

STR = Indicating Transmitter (connectivity for one –IA/-IE sensor)

Cable connection

-U = ½ inch NPT-type conduit hubs -U

-M = M20x1,5 metric cable glands -M

Electrical classication

-GP = General purpose -GP

Enclosure

-SC = Stainless Steel enclosure with window -SC

Transmitter options (A) (leave this section blank, if AC supply is specied)

-AC = Power supply 100-240 VAC 50/60 Hz -AC

-DC = Power supply 24 V DC -DC

(A) Note standard power supply is 100-240 VAC 50/60 Hz

DTR

STR

12

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 13

The Pharma Refractometer PR-23-AC

Front view Back view

186 mm

(7.32”)

281 mm

(11.06”)

153 mm

(6.04”)

304 mm

(11.95”)

254 mm

(9.99”)

50 mm

(1.97”)

50 mm

(1.97”)

45 mm

(1.77”)

2

Figure 2.4 Indicating Transmitter DTR-GP-SC with Stainless steel enclosure; dimensions (mm/in).

2.5 Pharma vaccines accessories

Vaisala recommended accessories for the vaccines production application contain

Ethernet crossover cable, IQ and OQ documentation (this document) and parts for

verication and usage of Pharma Refractometer sensor and Indicating Transmitter

mounted on a table top or a trolley via metal support stands. The recommended

accessories and corresponding part numbers are:

●

PR-7603-SS Table top stand for Indicating Transmitter (contains a set of two M5x10

A2 DIN screws)

●

PR-7605-SS Table top stand with the intregral support rod and 2.5” Sanitary Clamp

for the Pharma Refractometer Sensor PR-23-AC (contains a screw)

●

PR-8820 Crossover cable for Ethernet connection between Indicating Transmitter

and computer, length 5 m (16 feet)

●

Parts for off-line instrument verification:

PR-1012 Sample holder

PR-2300 R.I. liquid set 5 x ¼ .oz.; Including: 1.33; 1.37; 1.42; 1.47; 1.52

●

IM-EN-PR23AC-VACC IQ and OQ Documentation for Equipment qualification

© Copyright Vaisala 2020. All rights reserved.

13

Page 14

Appendix to the Instructions Manual PR-23

14

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 15

3

Installation of PR-23 Pharma

Refractometer

3.1 Hardware and software requirements

PR-23 software is included in the Indicating Transmitter DTR and it comprises the

following functions:

●

Automatic temperature compensation

●

Ethernet connection for data download

●

Sensor diagnostics and verication

3.2 Mechanical and electrical requirements

Power supply for the refractometer is AC input 100-240 VAC/50-60 Hz, optional 24 VDC,

30 VA.

3.3 Sensor installation for use in pharmaceutical batch

manufacturing

Laboratory table top or trolley installation and key considerations for the site

preparation

1. Physical dimensions of the instrument and accessories: make sure there is enough

space to accommodate them.

2. Suitable recommended operational environment for the instrument and for the Cargille

Refractive Index Liquids should be maintained between 20 – 30 °C (68 – 86°F).

3. Utilities: 100-240 VAC/50-60 Hz (optional 24 VDC, 30 VA) electrical power supply and

computer network connection.

© Copyright Vaisala 2020. All rights reserved.

15

Page 16

Appendix to the Instructions Manual PR-23

Attaching table top stand PR-7605-SS for Sensor and Mini Flow cell

Attach the 2.5” Sanitary clamp and the support rod to the base plate. The supplied screw

(M5x16 A4 DIN 912) for attaching the stand is inserted from the bottom of the base plate

through the bottom hole (Figure 3.1). To assemble the Pharma Mini Flow Cell rst locate the

PR-9244-USP O-ring 22.2x3.0 EPDM inside the Mini Flow Cell (Figure 3.2). Then insert the

2.5” Sanitary clamp for the sensor and Mini Flow Cell.

Finally insert the two PR-9236-USP Sanitary EPDM gaskets and the two PR-9237

0.5” Sanitary ferrules for the inlet and outlet connectios using the two PR-9235 0.5”

Sanitary Clamps.

Sensor can now be connected to exible hoses and used as a free standing tabletop unit,

see Figure 3.3.

1

Sanitary clamp

and support

Base plate

Retaining screw

Sensor stand assembly

Figure 3.1 Sensor stand assembly: Attaching the clamp and support rod to the base plate.

16

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 17

Installation of PR-23 Pharma Refractometer

2

3

Figure 3.2 Sensor stand assembly: Installing the sensor and Mini Flow Cell to the stand.

3

PR-9236-USP Sanitary gasket

EPDM for the 0.5”

PR-9237-USP

0.5” Sanitary ferrule

PR-9235 0.5” Sanitary Clamp

Figure 3.3 Sensor assembly: Attaching the ferrules for the feed pipes.

© Copyright Vaisala 2020. All rights reserved.

17

Page 18

Appendix to the Instructions Manual PR-23

Figure 3.4 Sensor stand assembled.

4

18

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 19

Installation of PR-23 Pharma Refractometer

3.4 Indicating Transmitter installation for use

in table top

Attaching table top stand PR-7603- SS for Indicating Transmitter

Unlock and open the transmitter cabinet door, then unscrew the retaining screw for the keypad

panel and open the panel. The supplied screws (M5x10 A2 DIN 912) for attaching the stand

are inserted from the inside through the top two holes located at the back of the cabinet. These

are aligned and screwed into the threaded attachment points located at the top of the stand.

The enclosure can now be used as a free standing tabletop unit, see Figure 3.2.

3

1

Figure 3.5 Attaching the laboratory table top stand to the Transmitter for use in the laboratory.

© Copyright Vaisala 2020. All rights reserved.

19

Page 20

Appendix to the Instructions Manual PR-23

3.5 Wiring transmitter connections to sensor,

power cable and computer

For Indicating Transmitter DTR wiring and Ethernet connections instructions see PROCESS

REFRACTOMETER PR-23 INSTRUCTION MANUAL, Section 3 and Section 12. When the

wiring connections have been made sensor calibration and verication can commence.

Indicating Transmitter

DTR-M-GP-SC

Pharma Mini Flow Cell

PMFC-HSS-EP

Pharma Refractometer

PR-23-AC-62-HSS-EP

Interconnecting cable

PR-8230

PC -Windows

(not supplied by Vaisala)

Figure 3.6 Connection diagram

Power Supply

Cable (not supplied

by Vaisala)

Crossover Cable

20

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 21

Installation of PR-23 Pharma Refractometer

3.6 Refractometer instrument verication

The operational procedure checking the refractometer calibration accuracy, linearity and

short-term repeatability and reproducibility consists of verication tests using Cargille

standard refractive index n

The verication of the refractometer calibration is performed whenever a new Vaisala

laboratory refractometer is qualied as a part of the validation process, and also if any of the

following occurs:

●

There is a replacement of optical parts (prism and prism gasket).

●

Refractometer readings reect an unusual shift, or are outside of the acceptable limits,

and other means of assessing and correcting unacceptable control values fail to

identify and correct the problem.

Verication is recommended to be performed once every 12 months (or more frequently if

specied in the client’s own quality system) as a routine quality control check. Verication

is carried out using the Sample Holder PR-1012 and the set of Cargille standard refractive

index n

PR-1012 consists of a sample receptacle with O-ring seal around the bottom aperture.

Before commencing the verication process make sure that your refractometer and sample

holder are at normal room temperature. Preferably take all components to the laboratory

already one day prior to the verication. Check the condition and expiry date of your

standard refractive index liquids and that you also have the required cleaning solution

(e.g. Isopropyl alcohol) and cleaning tissue to clean the sensor wetted surfaces and the

sample holder.

liquids. A set (R.I. Liquid Set PR-2300) is supplied by Vaisala. The Sample Holder

D

liquids.

D

3

For full Sensor verication instructions see PROCESS REFRACTOMETER PR-23,

INSTRUCTION MANUAL Section 13.

After verication of the PR-23 sensor, further verication of the Laboratory Test Cuvette and

Sensor combination can be carried out.

© Copyright Vaisala 2020. All rights reserved.

21

Page 22

Appendix to the Instructions Manual PR-23

22

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 23

4

Electronic data capture and storage

4.1 Ethernet connection

In addition to software operation via the hardware, the DTR can be considered as a web

server and is accessible via a web-browser (e.g. Internet Explorer, Firefox, Chrome etc.).

The Ethernet connection enables data download from an Indicating Transmitter DTR to a

computer and replaces the traditional paper-based data collection methods and streamlines

data collection. The connection works both directly between the DTR and a computer, or via

a hub or a switch, local area network (LAN), wireless network (WLAN) or ber Ethernet.

Any type of computer (PC, Mac, PDA, mainframe…) with a compatible network connection

can be congured to download data from the DTR.

For connecting and operating instructions of the Ethernet connection see PROCESS

REFRACTOMETER PR-23 INSTRUCTION MANUAL Section 12.

© Copyright Vaisala 2020. All rights reserved.

23

Page 24

Appendix to the Instructions Manual PR-23

24

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 25

5

Complying with documentation

and validation regulations

5.1 Documentation

When a pharmaceutical company purchases new measuring instruments, they must take

into account the documentation requirements covered by national and international laws

and directives, for example, the US Food and Drug Authority’s Code of Federal Regulations

(CFR). FDA’s validation requirements leave it up to the manufacturer to determine what

data is essential to prove control over their processes. Therefore, the requirements vary

from company to company, and each pharmaceutical company is responsible for dening

and maintaining its own documentation requirements list. Some areas to consider and their

Vaisala K-PATENTS solutions are presented in the sections below.

5.2 Qualication

The qualication action consists of proving and documenting that the equipment and

ancillary systems are properly installed, operating correctly, and producing veried results.

Qualication is a part of the validation process, but the individual qualication stages alone

do not constitute process validation.

Installation Qualication, Operational Qualication and Performance Qualication protocols

are normally required to document that the correct refractometer model and parts have been

ordered, delivered and installed according to Vaisala’s recommendations, and also to check

that the refractometer meets its performance specication and is able to reliably measure

typical samples using the selected measurement method. Users are able to create their

own protocols using the relevant information from this manual appendix and the product

manual, and/or using their own templates. The complete qualication process must be

fully documented.

5.3 Protocol acceptance by customer and list of

tests performed

A qualication protocol which provides details about the system, the scope and constraints

of the qualication, the qualication tests, test procedures and acceptance criteria should

be available for review and approval before the qualication begins. The protocol should

also contain an exception log to record any out of the specication results, investigation and

problem resolution. After the qualication, the test results must be reviewed and approved

before the instrument can be put into routine use.

© Copyright Vaisala 2020. All rights reserved.

25

Page 26

Appendix to the Instructions Manual PR-23

5.4 Electronic data management and data storage

The Code of Federal Regulations (CFR) FDA 21, Part 11 requires that pharmaceutical

companies use electronic (i.e. software-maintained) data recording and storage, rather

than paperwork. In case of instrument measurements, the code requires that every reading

taken with the instrument must be logged and permanently stored electronically, and the

data is password-protected ensuring alteration accountability (i.e. which operator makes

an alteration) and tracking.

Part 11 describes four basic system elements that must be addressed. They are:

●

Electronic signatures and tracking

●

Data storage and logs

●

Security

●

System validation.

5.5 Electronic signatures/audit trail

Data records must be linked to the relevant electronic signatures so that when accessed,

either electronically or through printout, the signatures will be openly displayed along with

the date and time of execution.

5.6 Record keeping

Data records must be stored in a format that the FDA can reasonably expect to be able to

read. These records must be retained for the length of time required by the predicate rule.

5.7 Security

System access can be restricted to authorized individuals using the lock on the Indicating

Transmitter door and password protected access to the transmitter and to the computer.

There are also four input switches behind the front panel of Indicating Transmitter. An input

switch can be congured to seal the calibration and to prevent access to the calibration

and to conguration, see PROCESS REFRACTOMETER PR-23 INSTRUCTION MANUAL,

Section 6.4.

The actions of these authorized individuals in relation to the data must be openly accounted

for throughout the audit trail.

5.8 System validation

The system must be validated to prove that it complies with the technical requirements of

Part 11. The Installation Qualication, Operation Qualication, and Performance Qualication

(IQ/OQ/PQ) should also be performed.

26

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 27

Complying with documentation and validation regulations

5.9 Vaisala K-PATENTS® refractometer system

adherence to Part 11

It is not possible to supply a system readily in compliance with Part 11. This is because the

requirements of Part 11 fall into two categories: those that are handled technically (through

software features), and those that are handled procedurally (such as through system

validation, SOPs, policies, etc.).

Part 11 applies to all computerized systems that create, modify, maintain, archive, or

retrieve records required by the FDA. Pharma Refractometer generates electronic records

via Ethernet connection. These records can be stored as digital les and printed out for

signature or led and maintained as hard copies. The computer les are subject to Part 11

regulation. The instrument parameter and conguration changes also fall into this category.

These computer les may be used in either of the two ways:

1. as a non-subject system by printing results, signing by hand, and maintaining

hard copies

2. as an electronic record-keeping system subject to Part 11 regulation.

Systems described by number 1 would be subject only to predicate rules, not Part 11.

Systems described by number 2 must comply with Part 11.

Please note: While Vaisala has taken account of the FDA Part 11 rules during development of

the Pharma Refractometer package and in the compilation of the instructions and guidelines

contained in this Instruction manual appendix, the system described has not been approved

or mandated by the FDA or any other government agencies. So all compliance responsibility

lies with the end user and Vaisala makes no claims that the completion of all the procedures

described here will exempt these companies or individuals from FDA sanctions.

5

© Copyright Vaisala 2020. All rights reserved.

27

Page 28

Appendix to the Instructions Manual PR-23

28

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 29

6

Onsite qualication protocols and

records: Installation Qualication

This Installation Qualication (IQ) involves documented verication of the complete

system: Pharma Refractometer PR-23-AC and Pharma Mini Flow Cell PMFC-HSS with

Ethernet connection, as installed and connected to a fractionation unit and a computer,

and in compliance with the approved design, the manufacturer’s recommendations and

user requirements.

6.1 Authorization and responsibilities

6.1.1 Documents and procedures

The following documents and procedures are inspected:

●

Scope and Procedure for Qualication

●

Report on Installation Qualication

●

Protocol for Installation Qualification

The authorized ofcial (client) hereby declares that the execution of the Installation

Qualication (IQ) for the Pharma Refractometer and Pharma Mini Flow Cell have been

approved in accordance with this document/log. The authorized ofcial is responsible for all

relevant matters in regard to the installation qualification.

Release by superior department:

Name:

Function:

Date:

Signature:

Initials:

Authorization by a higher-level authority is a prerequisite for carrying out the

qualication procedure. If no valid written authorization is available, terminate the

Installation Qualification.

© Copyright Vaisala 2020. All rights reserved.

29

Page 30

Appendix to the Instructions Manual PR-23

6.1.2 Authorized ofciator

Selection of the individual authorized to carry out the Installation Qualication of the Pharma

Refractometer system should be in accordance to their relevant ability to undertake the

procedure. The authorized ofciator’s signature is required for the next stage to validate

Date/Initials in the Installation Qualication log and reports.

Name:

Function:

Date:

Signature:

Initials:

6.1.3 Execution

As it is executed, each described step of the Installation Qualication requires initialing

and dating. If any deviations occur, the qualication must either be aborted or a detailed

explanation of the deviations must be entered in the subsequent “Deviation, evaluation,

corrective actions” logs and must be documented appropriately.

6.2 System

6.2.1 Qualifying the system

Location of the Pharma Refractometer Sensor and Pharma Mini Flow Cell:

Location of the Indicating Transmitter:

Device Serial Number Supplier Manufacturer

Pharma Refractometer:

Sensor PR-23-AC-62-HSS

Pharma Refractometer: Indicating

Transmitter DTR-M/U-GP-SC

Computer

Vaisala Oyj

Vaisala Oyj

30

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 31

Onsite qualication protocols and records: Installation Qualication

6.2.2 Manufacturers and suppliers

Full address of the manufacturers and suppliers:

Manufacturer: Supplier:

Vaisala Oyj

Postal address: P.O. Box 26,

FI-00421 Helsinki, Finland

Street address:

Vanha Nurmijärventie 21,

FI-01670 Vantaa, Finland

Tel. Int.+358 9 89491

Fax Int.+358 9 8949 2227

www.vaisala.com

6.3 IQ protocol

6.3.1 Scope of delivery

Description of requirements

Check that the delivery is complete and that all the listed instrument components and

accessories are included in the delivery.

6

Requirement acceptance values

Compliance with the component checklist “System components provided by Vaisala”,

included in the Manual Appendix (this document) Section 2.2.

Failure to meet delivery values

If any essential component is missing terminate the installation qualication and call your

support, otherwise check conditional pass and move with the IQ, inform your support.

Terminate the IQ.

*

Date Signature Pass

*Conditional pass:

Conditional Pass Fail

© Copyright Vaisala 2020. All rights reserved.

31

Page 32

Appendix to the Instructions Manual PR-23

6.3.2 Damage

Description of requirements

Inspection of all components and devices to check they are undamaged and functional.

Damage or malfunction detected

Terminate the IQ.

Report to:

*

Date Signature Pass

*Conditional pass:

6.4 Documentation

Description of requirements

Make sure that the Operating Instructions and all other required documentation are complete

and accessible.

Type of document Document/Revision No.

Instruction Manual for Inline

Refractometer

PR-23(-...-AX/FM/CS/IA/IF)

Appendix to Instruction

Manual

Operating Manual for:

Material Safety Data Sheet

for Cargille Refractive Index

Liquids

Conditional Pass Fail

Requested

Present Missing Not requested

IM-EN-PR23

IM- EN- PR23AC-VACC- A

32

Date Signature Pass

*Conditional pass:

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

*

Conditional Pass Fail

Page 33

Onsite qualication protocols and records: Installation Qualication

6.5 Operating environment

Description of requirements

Ensuring that the appropriate power supply and power switch are available.

Requirement acceptance values

An electrical power supply with a voltage and frequency of 100-230 VAC/50-60 Hz (Optional

24 VDC). A computer (PC, Mac, PDA or mainframe).

Failure to meet any of the acceptance values

A new environment must be established and the qualication performed again from Section

6.3.1 (of this document) onwards.

Date Signature Pass

*Conditional pass:

6.6 Installation

Requirement description

The authorized operator who in accordance with Section 6.2 (of this document), must read

the installation instructions in Section 3 (of this document).

6

*

Conditional Pass Fail

Requirement acceptance values

The relevant sections have been read.

Date Signature Pass

*Conditional pass:

*

Conditional Pass Fail

© Copyright Vaisala 2020. All rights reserved.

33

Page 34

Appendix to the Instructions Manual PR-23

6.7 Setting up the system components and devices

Description of requirements

The Pharma Refractometer system with Refractometer sensor, Pharma Mini Flow Cell and

Indicating Transmitter, are assembled and mounted correctly as described in the Section

3 (this document). Also the ancillary sample system is connected in accordance with the

Section 3 (this document). The ancillary equipment is switched on in accordance with the

corresponding operating manuals.

Requirement acceptance values

The system and devices are complete and have been set up in compliance with

the instructions.

Failure to meet the acceptance values

Terminate the IQ.

*

Date Signature Pass

*Conditional pass:

Conditional Pass Fail

34

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 35

Onsite qualication protocols and records: Installation Qualication

6.8 Electrical connections and wiring

Description of requirements

The frequency of the power supply must match the frequency indicated on the instrument’s

rating plate. The electrical wiring connections have been connected in accordance with

the instructions laid down in the PROCESS REFRACTOMETER PR-23 INSTRUCTION

MANUAL Section 12.

Requirement acceptance values

All electrical wiring connections have been connected in compliance with the instructions laid

down in the PROCESS REFRACTOMETER PR-23 INSTRUCTION MANUAL Section 12.

*

Date Signature Pass

*Conditional pass:

Description of requirements

Ethernet connections and wiring have been connected and set up in accordance with the

PROCESS REFRACTOMETER PR-23 INSTRUCTION MANUAL Section 12.

Conditional Pass Fail

6

Requirement acceptance values

The Ethernet connections comply with the PROCESS REFRACTOMETER PR-23

INSTRUCTION MANUAL Section 12.

*

Date Signature Pass

*Conditional pass:

Conditional Pass Fail

© Copyright Vaisala 2020. All rights reserved.

35

Page 36

Appendix to the Instructions Manual PR-23

6.9 Ethernet connection

Description of requirements

Ethernet connections and wiring have been connected and set up in accordance with the

PROCESS REFRACTOMETER PR-23 INSTRUCTION MANUAL Section 12.

Requirement acceptance values

The Ethernet connections comply with the PROCESS REFRACTOMETER PR-23

INSTRUCTION MANUAL Section 12.

*

Date Signature Pass

*Conditional pass:

Conditional Pass Fail

6.10 Initial check and switching the device on

Description of requirements

The initial check has been performed and the electrical power has been connected in

accordance with the PROCESS REFRACTOMETER PR-23 INSTRUCTION MANUAL

Section 5.1.1.

Requirement values

The corresponding screen displays occur in accordance with the PROCESS

REFRACTOMETER PR-23 INSTRUCTION MANUAL Section 5.1.1.

Failure to meet acceptance values

Terminate the IQ.

*

36

Date Signature Pass

*Conditional pass:

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Conditional Pass

Fail

Page 37

Onsite qualication protocols and records: Installation Qualication

6.11 Installation Qualication summary report

Successful completion of the preceding activities and checks indicates that this instrument

has been satisfactorily delivered and installed. This instrument has passed the Installation

Qualication and may now be submitted for Operational Qualification.

IQ completed by

Name:

Function:

Date:

Signature:

Signature:

IQ deviations approved by

Name:

Function:

Date:

Signature:

Signature:

6

IQ approved by

Name:

Function:

Date:

Signature:

Signature:

© Copyright Vaisala 2020. All rights reserved.

37

Page 38

Appendix to the Instructions Manual PR-23

Comments (including discrepancies)

38

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 39

7

Onsite qualication protocols and

records: Operational Qualication

Operational Qualication (OQ) is documented verication stating that the equipment and

systems, as installed for the rst time or after repairs and major incidents, perform as

intended throughout the required operating ranges. The OQ is to ensure that the Pharma

Refractometer meets predened specications, and all system components function

correctly and according to specications within a specic environment.

7.1 Individual module and system components check

Checking the operation of the refractometer as an individual module, and as a system that

comprises also of the Pharma Mini Flow Cell, the computer, the Ethernet connection and

Ancillary equipment such as fractionation unit.

●

Operational check on the refractometer consists of refractive index n

linearity and short-term repeatability and reproducibility verication tests with Cargille

standard refractive index n

●

In addition to the system components, testing functional challenge, testing the system

software operation, should be conducted.

●

Stage by stage operational procedure checking. A pre-determined set of instructions

can be input stage by stage into the system. The system responses are then

compared to the expected outcome of the instructions to determine any problems in

their fulfillment.

●

Sign off when successfully completed.

liquids.

D

accuracy,

D

7.2 Installation Qualication has been performed

successfully

Description of Requirement

An Installation Qualication has been performed for the system.

Requirement Acceptance values

The Installation Qualication has been carried out successfully with the required approval.

Date of Installation Qualification:

Performed by:

Do not proceed with the Operational Qualication until a valid Installation Qualication has

been successfully completed and signed off.

© Copyright Vaisala 2020. All rights reserved.

39

Page 40

Appendix to the Instructions Manual PR-23

7.3 Test procedure

The Operational Qualication of the system is performed in accordance with a set plan in

which the following points are tested and documented sequentially:

●

The required documents, measuring instruments, refractive index liquids, and required

cleaning materials are available

●

Functional checks and verication of the refractometer performance

●

Functional checks have been made for the ancillary equipment.

The authorized ofcial (client) hereby declares that the performance of the Operational

Qualication (OQ) for the Pharma Refractometer and Pharma Mini Flow Cell has been

approved in accordance with this document/protocol. The authorized ofcial is responsible

for all relevant matters in regard to the operational qualification.

Release by superior department:

Name:

Function:

Date:

Signature:

Initials:

Authorization by a higher-level authority is a prerequisite for carrying out the

qualication procedure. If no valid written authorization is available, terminate the

Operational Qualification.

7.4 Authorized ofciator

Selection of the individuals authorized to carry out the Operational Qualication of the

Pharma Refractometer system should be in accordance with their relevant ability to

undertake the procedure. The authorized ofciator’s signature is required for the next stage

to validate Date/Initials in the Operational Qualication log and reports.

Name:

Function:

40

Date:

Signature:

Initials:

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 41

7.5 System qualication

Onsite qualication protocols and records: Operational Qualication

Check that the system is the same as dened in the IQ, with no changes.

Denition of requirements

All system equipment remains the same as for the IQ and the ancillary equipment IQ is valid.

Date Signature Pass Conditional Pass Fail

Conditional pass:

7.6 Setting up the system components and devices

Description of requirements

The Pharma Refractometer system comprised of refractometer sensor, Pharma Mini Flow

Cell and Indicating Transmitter, is assembled and mounted correctly as described in the

Section 3 (this document). Initial startup checks for the Refractometer have been made

according to PROCESS REFRACTOMETER PR-23 INSTRUCTION MANUAL, Section 5.

Also the ancillary fractionation unit and the sample delivery system (if required) are

connected and the ancillary equipment is switched on and functional checks are made in

accordance with the corresponding operating manuals.

7

Requirement acceptance values

The system and devices are complete and have been set up in compliance with

the instructions.

Failure to meet any of the acceptance values

Terminate the OQ.

Date Signature Pass Conditional Pass Fail

Conditional pass:

© Copyright Vaisala 2020. All rights reserved.

41

Page 42

Appendix to the Instructions Manual PR-23

7.7 Instrument verication with sample holder and

refractive index liquids

Description of requirements

Refractometer, Sample Holder PR-1012 and a set of ve standard refractive index

liquids PR-2300 with Cargille Certication are allowed to be settled to laboratory

ambient temperature (between 20-30 °C, 77-86°F) 24 hours prior to commencement of

the qualification.

Requirement acceptance values

Refractometer, sample holder and Refractive index liquids positioned in the laboratory 24

hours prior to verication with the ambient temperature at between 20-30 °C (77-86°F).

Date Signature Pass Conditional Pass Fail

Conditional pass:

Description of requirements

The procedure is done with all ve liquids using a sample holder and verication instructions

at PROCESS REFRACTOMETER PR-23 INSTRUCTION MANUAL, Section 13.

Nominal R.I. values:

●

1.330

●

1.370

●

1.42 0

●

1.470

●

1.520

Requirement values

The verication results are OK for all samples and acceptance / deviation values (not

more than + 0.0004 of the nominal values) are received for each sample. The Instrument

Verication page in the browser for the complete verication test procedure shows

Verication result: pass.

Failure to meet acceptance values

Terminate the OQ.

Date Signature Pass Conditional Pass Fail

42

Conditional pass:

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 43

Onsite qualication protocols and records: Operational Qualication

7.8 Operational Qualication summary report

Successful completion of the preceding activities and checks indicates that this instrument

performs satisfactorily. The Operational Qualication has been accepted.

OQ completed by

Name:

Function:

Date:

Signature:

Signature:

OQ deviations approved by

Name:

Function:

Date:

Signature:

Signature:

7

OQ approved by

Name:

Function:

Date:

Signature:

Signature:

© Copyright Vaisala 2020. All rights reserved.

43

Page 44

Appendix to the Instructions Manual PR-23

Comments (including discrepancies)

44

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 45

8

Routine operation phase

After the instrument is qualied, it can be used to measure analytical data. A Standard

Operating Procedure (SOP) has to be written for the new instrument. Operational

instructions, maintenance and calibration should be included in the SOP. It is unnecessary

to copy the complete operation manual into the SOP. Writing down simple instructions

referencing the related manual sections is more effective. The particular tasks and the

frequency they should be performed during maintenance should be clearly stated in the

maintenance section. Tests required to verify the instrument, the acceptance criteria and the

frequency for each test should be covered in the calibration section of the SOP.

Denitions of major and minor repairs, which necessitate partial or full system re-qualication,

should be included as well. For example, the replacement of a Teon pad in the sample mixer

does not require a full re-qualication. Replacement of optical parts (prism) will warrant full

re-qualication.

Good system maintenance starts with the users. Proper care, which can be as simple as

a good system rinsing and clean up after use, will reduce the possibility of system failure

during runs and will extend the useful life of the instrument.

Maintain good usage and service records for the instrument for Good Manufacturing

Practice (GMP) purposes. Records of usage allow the users to be alerted to any system or

instrument calibration failure. The user may have to do an impact assessment to determine

whether the failure would have affected the reliability of the results generated by the system.

The service records will also provide useful information about the system, which may

simplify trouble shooting in some cases.

The GMP requirements dictate that the refractometer calibration verication (see Section

3.1) should be performed at suitable intervals in accordance with an established schedule.

Any instrument failing to meet established specications shall not be used. Each Pharma

Refractometer is recommended to have a calibration verication label applied with the

relevant status information on the system, date of the last calibration verication, who carried

out the verication and the scheduled date for the next verification.

© Copyright Vaisala 2020. All rights reserved.

45

Page 46

Appendix to the Instructions Manual PR-23

46

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 47

9

Preventive maintenance

The need for Pharma Refractometer regular maintenance is minimal, due to the construction

with no moving parts, no mechanical adjustments, no trimpots and with a solid-state light

source, see Section 7, PROCESS REFRACTOMETER PR-23 INSTRUCTION MANUAL.

The following checks should be performed for Mini Flow Cell at suitable intervals in

accordance with an established schedule:

●

Check the condition of the O-ring (PR-9244-USP O-ring 22.2x3.0 EPDM) of the

Pharma Mini Flow Cell

●

Check the condition of the two sanitary gaskets (PR-9236-USP EPDM) of the 0.5”

sanitary clamps

© Copyright Vaisala 2020. All rights reserved.

47

Page 48

Appendix to the Instructions Manual PR-23

48

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 49

10

Other documentation

You may want to include the following documents in your les concerning this Vaisala

K-PATENTS

●

●

●

●

®

instrument:

Delivery Data Sheet (supplied with the instrument)

Certicate of Traceability for Standard Refractive Index liquids

(supplied with the liquids PR-230 0)

Material Traceability Certicate of Compliance in accordance with EN 1024-3.1b.

Note: This document is delivered on request and it must be specied when ordering.

Vaisala ISO 9001 certificate

© Copyright Vaisala 2020. All rights reserved.

49

Page 50

Appendix to the Instructions Manual PR-23

Notes

50

Document/Revision No. IM-EN-PR23AC-VACC/A Effective: March 1, 2020

Page 51

Page 52

www.vaisala.com

Loading...

Loading...