Page 1

Nacelle-mounted lidar:

New advances in Power Performance Testing,

optimization, and financial outcomes in wind energy

Page 2

As wind energy continues to evolve, so do the financial stakes in

maximizing power output and profit.

Today, even a minor difference between estimated

and actual energy output creates substantial

financial impacts. While developers and operators

expect to get the energy output promised by

manufacturers, they can’t know if they are

succeeding without accurate Power Performance

Testing (PPT) data. They are also unable to identify

and take corrective actions that can extend the life

of the turbine and reduce annualized cost of energy.

Enter nacelle-mounted lidar. With its exceptional

accuracy and range, economical design and small

footprint, nacelle-mounted lidar is one of the most

reliable and affordable ways to assess a turbine and

enable IEC-compliant PPT. Recent advances in the

lidar itself and the software that interprets its data

are revolutionizing wind farm operations.

This eBook explains how nacelle-mounted lidar

works, how it is changing PPT, and why it is such

a powerful solution for today’s ever-growing wind

turbines and farms.

$500,000

Revenue loss from a 1% decrease in annual production (100 two-megawatt turbines)1.

© Vaisala 2021

Page 3

Contents

How does nacelle-mounted lidar work? 4

Power Performance Testing in detail 6

Leosphere, a Vaisala company's, Windcube suite 10

Case study: Offshore PPT 12

Further applications for nacelle-mounted lidar 13

© Vaisala 2021

Page 4

How does nacelle-mounted lidar work?

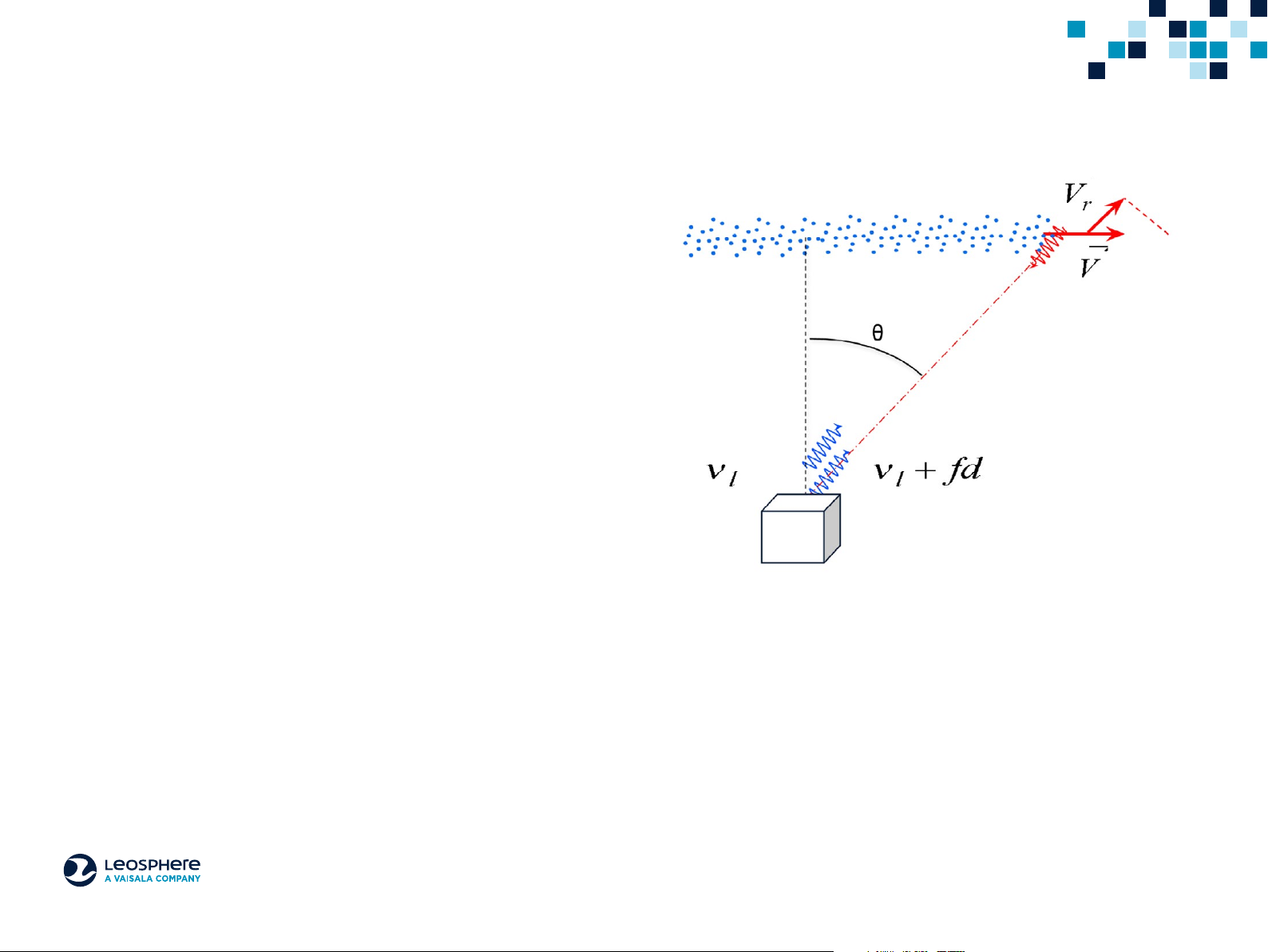

Wind speed measurement and the Doppler effect

Lidar emits light pulses at a very high frequency, and these light pulses are

reflected back by aerosols in the atmosphere. The Doppler effect allows the

lidar to accurately compute the speed of those particles — and, thus, the speed

of the wind carrying them through the atmosphere. Today, wind lidar is used for

a wide range of applications in wind energy, aviation, and meteorology.

Notably, WindCube© Nacelle operates on a pulsed lidar principle, which provides

several important advantages over other lidar types. Pulsed lidar maintains

constant accuracy over the entire measurement range, and it offers the highest

accuracy, data availability, and sample rates regardless of weather conditions.

Nacelle-mounted lidar has evolved substantially in recent years. For example, earlier generations of WindCube Nacelle (formerly called Wind Iris) measured up to 450

meters at 10 measurement distances. This was extremely useful, but today’s version covers a measurement range from 50 to 700 meters at 20 separate distances,

dramatically increasing PPT quality and making it suitable for even the largest turbines likely to be deployed now or in the future.

WindCube Nacelle measures from 50 to 700 meters at 20 separate distances, dramatically increasing PPT

quality and making it suitable for even the largest turbines likely to be deployed now or in the future.

© Vaisala 2021

Page 5

The best technology for the job

Once a wind turbine is deployed, its operators

depend on its performance to match manufacturer

expectations. Underperformance can be extremely

costly — and without good wind data, it can go

unobserved for months or years.

Back when turbines were smaller, this was less of

a problem. But now that the scale of wind turbines

has increased so much, so has the scale of the

financial losses when they aren’t operating at

maximum capacity. Even slight underperformances

are no longer acceptable.

Traditionally, the way to assess power performance

was to use a met mast. But because of their costs

and logistical challenges, many wind operators

simply skipped using them. One reason why is

that you need to have both the met mast and the

turbine aligned with the wind direction — meaning

that frequent changes in wind direction can

invalidate the measurements. Another is that the

costs and logistical constraints are often too high for

such a short measurement period. Nacelle-mounted

anemometers are cheaper to use, but they are not

accurate enough for reliable PPT.

Nacelle-mounted lidar, on the other hand, is

much quicker and easier to deploy, and it collects

data much faster. It is always aligned with the

wind turbine because it moves with it, and it is

typically half the cost (or less) of using a met mast,

particularly for taller and offshore wind turbines.

Lidar also uses multiple laser beams to cover the

whole rotor area, creating more representative

wind data that accounts for shear values and

other influences acting in three dimensions. (This

data, while not mandatory, can now be included

in PPT for improved accuracy and higher certainty

following IEC rules.)

Expert groups from IEC and independent consultants

are also preparing guidelines for using nacellemounted lidar in complex terrain for the next

revision of IEC standards.

The bottom line is that nacelle-mounted lidar

is here to stay. It is the best solution for PPT —

both onshore and offshore — and its continual

improvements are making wind farms more

profitable, reliable, and efficient.

© Vaisala 2021

Page 6

Power Performance Testing in detail

PPT is the most critical application for nacelle lidar,

since it provides operators and other stakeholders

the power curve data they need to verify the

performance of a wind farm project. Enormous

financial resources are at stake in any PPT project.

Critical factors in PPT include:

•

Ability to accurately verify turbine

power performance

•

Comparison of actual power curves with

warranted power curves

•

Reduced logistics for setting-up and operating

the measurement system

•

Optimized OPEX

•

Rapid data completion

•

Presentation and analysis of power curve data in

an IEC-compliant format

•

Ensuring measurement traceability

© Vaisala 2021

Page 7

Power Performance Testing planning and key steps

Four steps to success

A correctly managed PPT campaign is broken down into four stages.

2. Verification

Check the quality of the

in the campaign

3. Operation

Install, operate, and

monitor throughout the

campaign duration

1. Design

Plan the campaign as much as

possible in advance

system for every device used

4. Analysis

Extract data and act on it

Step 1: Design

The first decision in campaign planning is choosing which turbine(s) to measure. Operators can typically help minimize the length of the PPT campaign by selecting the

one with the biggest opening sector.

Process

•

Decide on the needed applications: contractual or operational PPT, checking

production increases after turbine upgrades, yaw alignment and nacelle-transfer

function verification, research and turbine prototyping. (One data set can be

used for multiple applications.)

•

Select the wind turbine to test: Maximize open sector following various rules

•

Anticipate installation steps including OEM authorizations and network access

•

Key documents:

◦

IEC - 61400-12-1

◦

IEC - 61400-50-3 – CDV (available as draft, and expected to be released

from mid 2021)

◦

Lidar manufacturer installation and safety guidelines

◦

Various precursor project report – EUDP procedure (established by DTU,

Orsted, Siemens-Gamesa and Leosphere)

© Vaisala 2021

Page 8

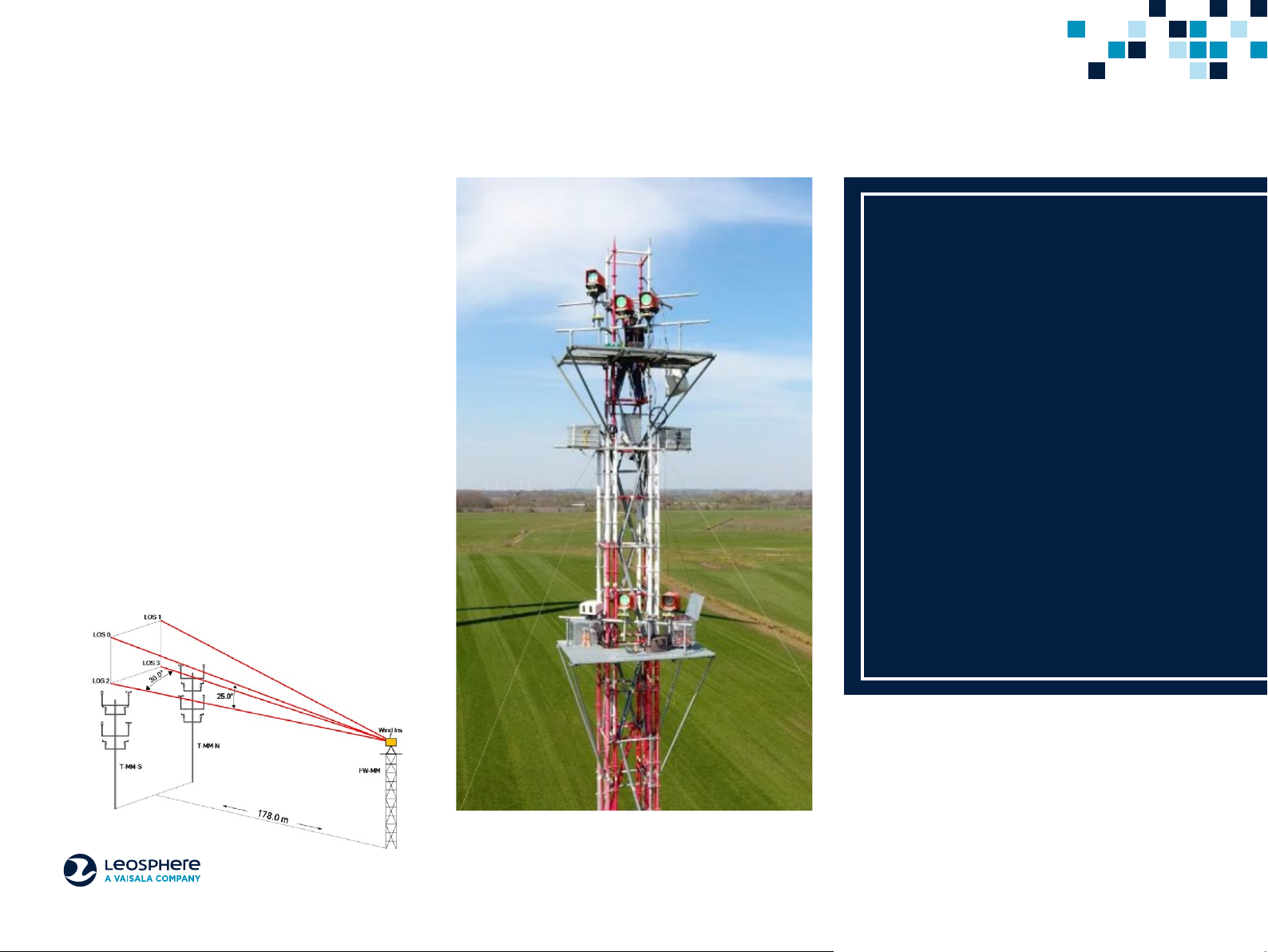

Step 2: Verification and calibration

Verification ensures performance of the lidar.

Much of the verification process can be done in

parallel with design, and usually takes about two

months at a certification site.

Process

Leosphere

certification and

verification standards

•

Verification at Leosphere: Leosphere calibrates

lidar units throughout the manufacturing process,

then verifies it against a calibrated lidar of the

same type.

•

Third-party calibration: This is a contractual

step for PPT, conducted at an independent test

site. The analyst uses this data to calculate the

uncertainty on the power curve. Key documents

for the verification process:

◦

EUDP and UniTTe reports

◦

IEC: IEC 61400-50-3 – CDV (expected

to be published in 2021)

Leosphere products meet the latest

and most rigorous international

verification standards, including

ISO9001. All WindCube products

are compliant to the latest IEC

standards (when applicable), and

they are recognized and verified by

the world’s leading independent

certifying bodies, including DNV

GL, DTU Wind Energy, UL, and

Deutsche WindGuard.

DNV GL calibration site in Germany

© Vaisala 2021

Page 9

Step 3: Operation

Operation is a busy and important phase.

It requires training, foresight, and effective

project management.

Process

•

Installation: Training is provided. Documentation

includes checklist and health/safety precautions.

Complete alignment on nacelle roof.

•

Time synchronization: Use either NTP or GPS.

All sensors should be synchronized, or the offset

should be reported.

•

Monitoring: Conduct daily or weekly checks on

all related equipment and sensors along with any

automatic alerts.

•

Data collection: Choose automatic, FTP, or

manual. Regularly check if data set is completed

(see step 4).

Measured wind speeds

Step 4: Analysis

After a few weeks of operation, there will be

enough information in the dataset to extract and

analyze. This can overlap the monitoring phase.

•

Synchronization: This is a crucial, sometimes

difficult, step in preparing for data extraction.

(WindCube Insights—Analytics includes a

simple-to-use synchronization function).

•

Filtering: Isolate a time period when everything

was working nominally and proper data was

being returned.

•

Data completion: The IEC provides guidance that

will help you determine whether your dataset is

complete. Key indicators include:

◦

180h of valid measurement

◦

At least three measurements per bin

(0.5m/s)

◦

Range of wind speed according to turbine

nominal power

•

Complete analyses according to IEC procedures.

◦

PC, Cp, AEP

◦

And associated uncertainty

◦

Terrain assessment

◦

Obstacles & topo

Power curve

© Vaisala 2021

Page 10

WindCube Nacelle:

The industry's most trusted and deployed nacelle-mounted lidar

WindCube Nacelle is one of the most accepted and widely deployed nacelle-mounted lidar systems in

the world.

It is the only long range nacelle-mounted lidar that enables PPT on any wind turbine — onshore or

offshore. Its accuracy and versatility have made Leosphere a contributing expert to industry guidelines

and standards for PPT.

Key benefits

Enables quick, accurate, compliant PPT

Rapid data completion with continuous wind direction alignment

Reliable contractual and operational PPT

Based on industry best practices and upcoming IEC standards

Accurate data from 50 to 700 meters

Captures wind data simultaneously at 20 measurement distances

Extremely high correlation with IEC met mast measurements

Gives wind industry stakeholders the reliable data needed to make better decisions

WindCube Nacelle

also provides a wide

range of supporting

data, including shear,

veer, turbulence, and is

ready for REWS (Rotor

Equivalent Wind Speed)

Universal compatibility and ease of use

Compatible with all current and future turbine types

Simple installation and system integration and configuration

Outstanding reliability under even the most demanding conditions

Permits a 3-year warranty period and limited maintenance

© Vaisala 2021

Page 11

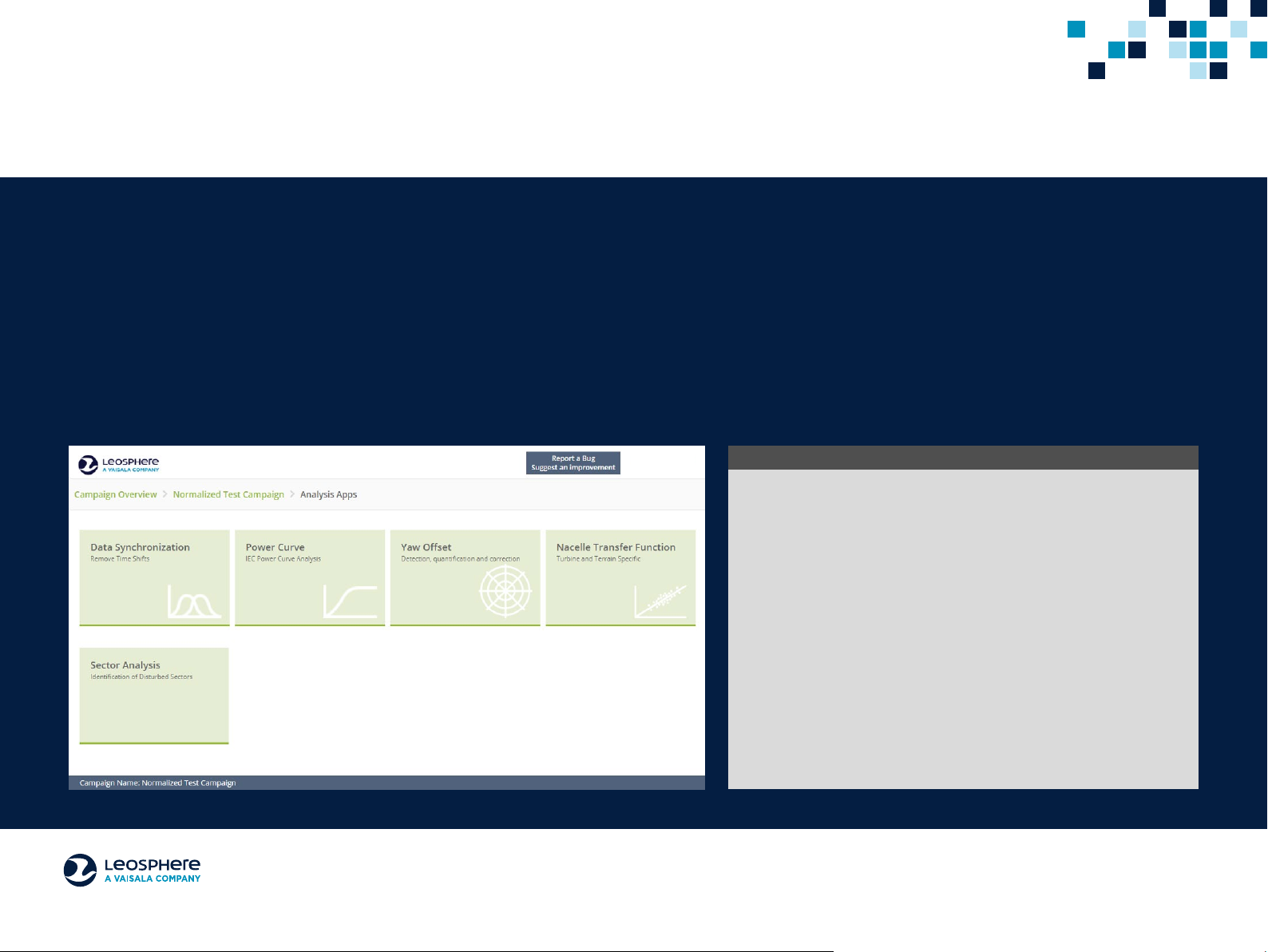

WindCube Insights — Analytics:

Revolutionary software enabling IEC-compliant PPT

No other lidar provider offers a solution like it.

WindCube Insights — Analytics software completes the PPT process by analyzing, interpreting, and displaying the data obtained from WindCube Nacelle.

Operators can perform quick, simple, and transparent PPT with IEC-compliant filtering, AEP calculation, and uncertainties reporting. Simplifying data handling activities

frees users to focus on the most essential performance analysis and optimization work.

Since PPT is a very strict process, this tool provides transparent validations and even lists which IEC standards are relevant while in use. It allows for the upload

of WindCube Nacelle and SCADA data with a simplified data synchronization process, and provides a variety of standardized lidar and turbine data filters that are

available and fully configurable to prepare the data set.

Key benefits

Easy-to-use, fully compliant, affordable PPT analytics

Eliminates time-consuming and expensive processes developed

in-house

Provides powerful performance calculations and data integrations

Adheres to accepted industry best practices

Backed by rigorous, transparent validations

Proactively displays which IEC paragraph/standard it is referring to

while in use

Improved data visibility and value for the whole wind farm

Gives users outstanding awareness of their systems

Simple interface, efficient analyses, and easy report table exporting

Enables data-driven decision-making and better-functioning

wind farms

© Vaisala 2021

Page 12

Case study: Offshore PPT

Siemens Gamesa Renewable Energy

Siemens Gamesa Renewable Energy, one of

the world's largest wind turbine manufacturers,

provides offshore and onshore wind services and is

well-known as a renewable energy industry leader.

The company has been using nacelle-mounted lidar

in place of met masts for several years because

many of the limitations of using met masts are

compounded offshore. Met masts offshore are

prohibitively expensive and, between permitting

and the building process itself, can take years

to implement.

Siemens Gamesa has adopted nacelle-mounted lidar

in offshore applications for several primary reasons:

•

Reduced cost

•

Wider measurement sector in most cases

•

Faster power curve calculations due to the wider

measurement sector

•

Ability to collect both short-range (inside

the induction zone) and long-range

data simultaneously

•

WindCube Nacelle measures up to 700m to cover

their largest offshore wind turbines

As an early adopter of nacelle-mounted lidar

for offshore applications, Siemens Gamesa is

leading its field and routinely proving the value of

WindCube Nacelle.

© Vaisala 2021

Page 13

Further applications for nacelle-mounted lidar

Although nacelle-mounted lidar’s primary purpose is PPT, it is a multi-use tool that creates impressive efficiencies and cost savings throughout a wind farm’s lifespan.

Any of these secondary applications can be compelling enough on their own to deploy nacelle-mounted lidar. They include:

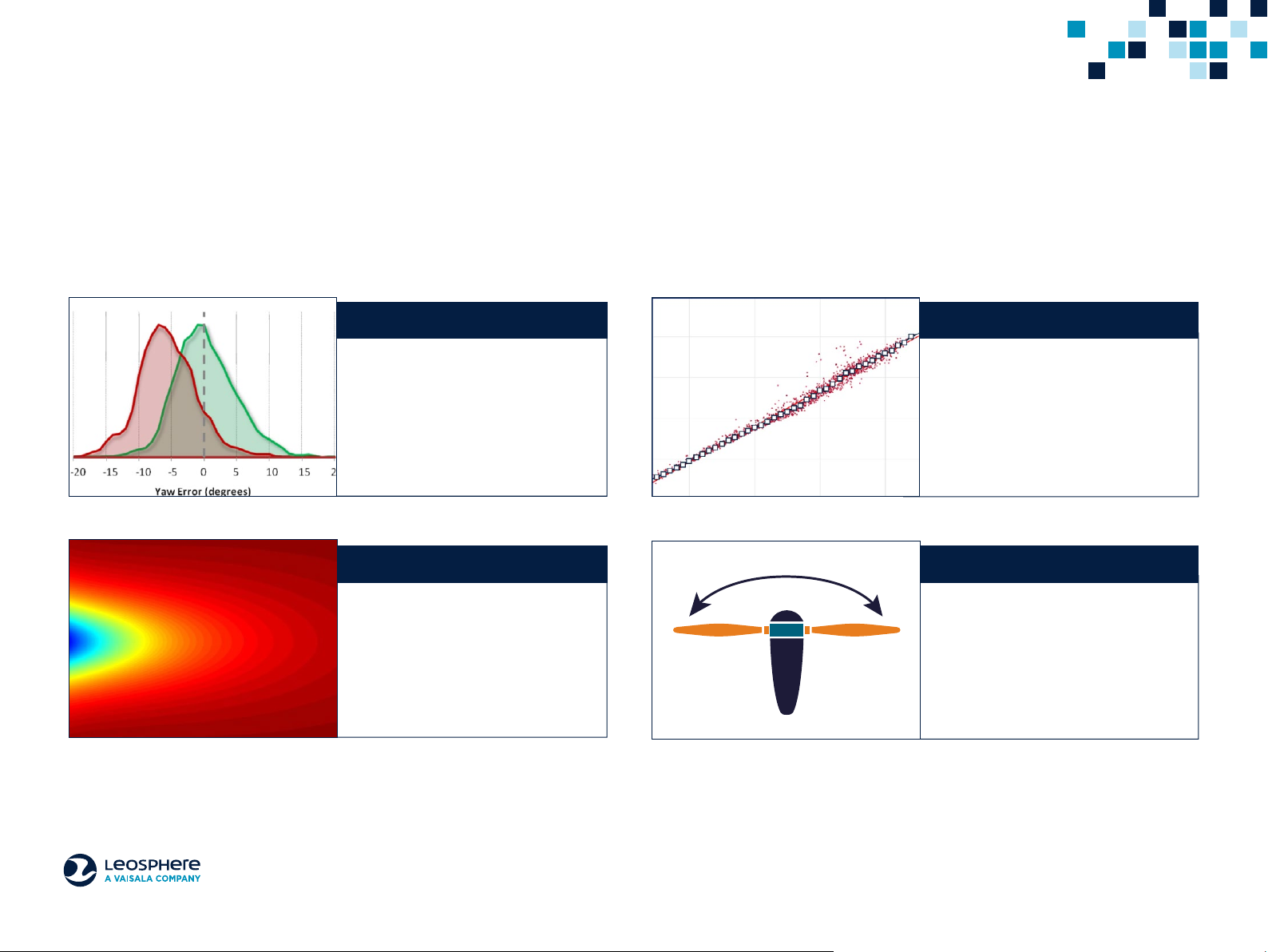

Turbine yaw misalignment

Nacelle-mounted lidar allows

operators to identify and correct any

misalignment between the turbine

and wind direction — maximizing

performance and reducing structural

loads. Nacelle-mounted lidar is the

only proven technology for this cost-

saving assessment.

Research Project

Many agencies and companies rely

on highly detailed wind field data for

studies and product development.

Nacelle-mounted lidar can provide

previously unavailable detail and

precision, leading to accelerated

innovation and new insights.

Nacelle transfer function

Nacelle transfer function, which

describes how the turbine and nacelle

structures influence wind speed, is

an important assessment to improve

turbine performance monitoring.

Nacelle-mounted lidar assesses this

accurately even after a wind campaign

is complete.

Lidar assisted control

Lidar-assisted control (LAC) allows for anticipatory

adjustments to blade and turbine alignment to

better handle incoming weather or storms. LAC can

substantially reduce turbine cost, reduce loads on

the turbine and nacelle, improve longevity, and

reduce risk. It can also increase energy capture and

lower the levelized cost of energy (LCOE). WindCube

Nacelle for Turbine Control is the ideal, custom-

made solution for this purpose. Learn more about it

at windcubelidar.com.

© Vaisala 2021

Page 14

Why Leosphere, a Vaisala company?

We are modern innovators, scientists, and discoverers who enable our customers to harness the power of wind energy in new ways. We are driven by passion,

relentless curiosity, and the desire to create a better world, as evidenced in our commitment to four guiding principles:

Trustworthy, superior metrology

Our solutions are backed by the best science and metrology, and

validated by the most demanding testing and certifications in the

industry. Our contributions make wind energy smarter.

Unrivaled thought leadership

Our years of experience, impressive global client roster, and

plethora of industry breakthroughs demonstrate that we are the

iconic gold standard in wind energy.

As a result, Leosphere, a Vaisala company, is the iconic and trusted gold standard in wind lidar. Our turnkey WindCube product suite offers innovative, reliable, and

highly accurate solutions for thousands of customers across the globe. All of this has enabled us to be catalysts for change and ambassadors for wind energy, always

advancing the field and those we serve.

Our innovation story, like the wind energy story, continues.

Innovative lidars from a one-stop shop

Customers know we have the right suite of solutions for their

needs in wind energy — taking them ever higher by adding value

at each step of the project lifecycle.

Easy, reliable global solution

We make our clients’ lives easier. Our easy to use, turnkey

WindCube product suite enables customers to harness the power

of wind energy efficiently and affordably.

windcubelidar.com

Ref. B211919EN-C ©Vaisala 2021

This material is subject to copyright protection, with all copyrights retained by Vaisala and its individual

partners. All rights reserved. Any logos and/or product names are trademarks of Vaisala or its individual

partners. The reproduction, transfer, distribution or storage of information contained in this ebook in any

form without the prior written consent of Vaisala is strictly prohibited. All specifications — technical included

— are subject to change without notice.

Loading...

Loading...