Page 1

USER'S GUIDE

Vaisala HydroMet™ Data Collection Platform

Volume 1

M210784EN-E

Page 2

PUBLISHED BY

Vaisala Oyj Phone (int.): +358 9 8949 1

P.O. Box 26 Fax: +358 9 8949 2227

FIN-00421 Helsinki

Finland

Visit our Internet pages at http://www.vaisala.com/

© Vaisala 2010

No part of this manual may be reproduced in any form or by any means,

electronic or mechanical (including photocopying), nor may its contents

be communicated to a third party without prior written permission of the

copyright holder.

The contents are subject to change without prior notice.

Please observe that this manual does not create any legally binding

obligations for Vaisala towards the customer or end user. All legally

binding commitments and agreements are included exclusively in the

applicable supply contract or Conditions of Sale.

Page 3

________________________________________________________________________________

Table of Contents

CHAPTER 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Structure of the Data Collection Platform Documentation .10

Contents of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Version Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . .12

Product-Related Safety Precautions . . . . . . . . . . . . . . . . . . 13

ESD Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Regulatory Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

License Agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Redistribution License Agreement . . . . . . . . . . . . . . . . . . .16

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CHAPTER 2

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Data Collection Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . .19

QML Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

QML Logger Connector Block . . . . . . . . . . . . . . . . . . . . . . 22

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Sensor Multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Digital I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Transient Protection Devices . . . . . . . . . . . . . . . . . . . . 27

Communication Modules . . . . . . . . . . . . . . . . . . . . . . . . . .28

RS-232 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Isolated RS-485 Communication Module . . . . . . . . . . 28

Dual-Isolated RS-485 Communication Module . . . . . . 29

Fixed Line Modem Module. . . . . . . . . . . . . . . . . . . . . . 30

Ethernet Communication Module DSE101 . . . . . . . . . 31

Data Collection Software . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Operating Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

AWS Client Software . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setup Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Lizard Setup Software . . . . . . . . . . . . . . . . . . . . . . . . . 33

Updating QML Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

VAISALA________________________________________________________________________ 1

Page 4

User’s Guide ______________________________________________________________________

CHAPTER 3

AWS CLIENT SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Installing AWS Client . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Minimum System Requirements . . . . . . . . . . . . . . . . . . . .36

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Establishing Terminal Connection . . . . . . . . . . . . . . . . . . .41

Using AWS Client Software . . . . . . . . . . . . . . . . . . . . . . . . .43

Starting and Exiting AWS Client . . . . . . . . . . . . . . . . . . . . .43

AWS Client Main Window . . . . . . . . . . . . . . . . . . . . . . . . .44

Defining AWS Client Settings . . . . . . . . . . . . . . . . . . . . . . .45

Read Only Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Address Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Serial Line Connections . . . . . . . . . . . . . . . . . . . . . 46

TCP/IP Socket Connections . . . . . . . . . . . . . . . . . . 48

Server Socket with SMS . . . . . . . . . . . . . . . . . . . . . 50

Dial-Up Connections . . . . . . . . . . . . . . . . . . . . . . . . 53

Options Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Number Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Opening Service Connection . . . . . . . . . . . . . . . . . . . . . . .57

Giving Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Closing Service Connection . . . . . . . . . . . . . . . . . . . . . . . .60

Managing User Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Modifying Station Settings . . . . . . . . . . . . . . . . . . . . . . . . . .63

Setting the QML Logger Clock . . . . . . . . . . . . . . . . . . . . . .64

Setting Static Parameters . . . . . . . . . . . . . . . . . . . . . . . . .65

Station Parameter Backup and Restore. . . . . . . . . . . . 67

Calibrating Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Sensor Status List . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Manual Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Entering Values for Manual Sensors . . . . . . . . . . . . . . . . .76

Viewing Manual Sensors in AWS Client . . . . . . . . . . . 76

Entering Values for Manual Sensors . . . . . . . . . . . . . . 78

Setup File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Selecting Setup File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Uploading Setup File . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Secure Setup Upload . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Downloading Setup Files from QML Logger . . . . . . . . . . .83

AWS Settings Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Log Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Controlling Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Measurement Enable or Disable . . . . . . . . . . . . . . . . . . . .88

Freeing Up Logging Space . . . . . . . . . . . . . . . . . . . . . . . .90

Working with Data Log Files . . . . . . . . . . . . . . . . . . . . . . .90

Downloading Log Files. . . . . . . . . . . . . . . . . . . . . . . . . 91

Converting Downloaded Log Files to CSV Format . . . 94

Auto Downloading Log Files . . . . . . . . . . . . . . . . . . . . 96

Viewing the Status of Auto Downloads . . . . . . . . . . . 101

2 ____________________________________________________________________M210784EN-E

Page 5

________________________________________________________________________________

Using External Memory Card . . . . . . . . . . . . . . . . . . . . . . .102

Automatic Erase from External Memory Card . . . . . . . . . 103

Resetting the QML Logger . . . . . . . . . . . . . . . . . . . . . . . . .103

Reset Using the Reset Button . . . . . . . . . . . . . . . . . . . . . 104

Sleep Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Wakeup Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Command Reference for Terminal Connection . . . . . . . .106

CHAPTER 4

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . 111

Visual Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Determining QML Logger Operation Mode . . . . . . . . . . . .119

Establishing Terminal Connection for Troubleshooting . 119

Recording Terminal Connection Text . . . . . . . . . . . . . . . 119

Opening a Service Connection through QML Logger . . .

Connecti

on Problems

. . . . . . . . . . . . . . . . . . . . . . . . . . . .122

120

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Resetting QML Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Determining Sensor Status . . . . . . . . . . . . . . . . . . . . . . . .124

Using External Memory Card . . . . . . . . . . . . . . . . . . . . . . .128

Automatic Erase from External Memory Card . . . . . . . . . 129

Commands for Troubleshooting Purposes . . . . . . . . . . . 129

LASTVAL Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Warnings and Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Measurement Enable or Disable . . . . . . . . . . . . . . . . . . . 136

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

CHAPTER 5

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

RS-232 Module DSU232 . . . . . . . . . . . . . . . . . . . . . . . . .140

Isolated RS-485 Module DSI485 . . . . . . . . . . . . . . . . . . . 142

Dual RS-485 Module DSI486, Version A . . . . . . . . . . . . .143

Dual RS-485 Module DSI486, Version B . . . . . . . . . . . . .146

Digital I/O Module QMI118 . . . . . . . . . . . . . . . . . . . . . . . . 147

Fixed Line Modem DMX501 . . . . . . . . . . . . . . . . . . . . . . 148

Ethernet Communication Module DSE101 . . . . . . . . . . . .149

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

QML201 Logger, Version C . . . . . . . . . . . . . . . . . . . . . . . 150

APPENDIX A

GLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

VAISALA________________________________________________________________________ 3

Page 6

User’s Guide ______________________________________________________________________

4 ____________________________________________________________________M210784EN-E

Page 7

________________________________________________________________________________

List of Figures

Figure 1 QML Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2 QML Logger without Cover . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 3 CompactFlash Memory Card Reader . . . . . . . . . . . . . . . . . . .22

Figure 4 Connector Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 5 Sensor Multiplexer QMU101 . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 6 Digital I/O Module QMI118. . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Figure 7 Surge Protector for Serial Lines . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 8 RS-232 Communication Module DSU232 . . . . . . . . . . . . . . . . 28

Figure 9 Isolated RS-485 Communication Module DSI485 . . . . . . . . . .28

Figure 10 Dual-Isolated RS-485 Communication Module DSI486. . . . . .29

Figure 11 Fixed Line Modem Module DMX501 . . . . . . . . . . . . . . . . . . . . 30

Figure 12 Ethernet Communication Module DSE101 . . . . . . . . . . . . . . .31

Figure 13 Installation Wizard Welcome Window . . . . . . . . . . . . . . . . . . .37

Figure 14 License Agreement Window . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 15 Select Installation Folder Window . . . . . . . . . . . . . . . . . . . . . . 39

Figure 16 Ready to Install Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 17 Installation Complete Window . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 18 Connecting Terminal Cable . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 19 Terminal Connector COM0 Pins . . . . . . . . . . . . . . . . . . . . . . .42

Figure 20 Terminal Main Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 21 Terminal Showing Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 22 Address Book Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 23 Creating Serial Line Address Book Entry. . . . . . . . . . . . . . . . .47

Figure 24 Creating TCP/IP Socket Connection Address Book Entry. . . . 49

Figure 25 Creating Server Socket with SMS Address Book Entry. . . . . .51

Figure 26 Creating Dial-up Connection Address Book Entry . . . . . . . . . . 53

Figure 27 Options Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 28 Address Book Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 29 Common Parameters Window . . . . . . . . . . . . . . . . . . . . . . . . .63

Figure 30 Set Logger Time Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Figure 31 Static Parameters Window. . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Figure 32 Selecting File for Station Settings Backup . . . . . . . . . . . . . . . .67

Figure 33 Parameter Backup Completed. . . . . . . . . . . . . . . . . . . . . . . . .67

Figure 34 Selecting File for Station Settings Restore. . . . . . . . . . . . . . . .68

Figure 35 Parameter Restore Complete . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 36 Calibration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 37 Offset Calibration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 38 Manual Calibration Window . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 39 Manual Sensor Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 40 Entering Values for Manual Sensor . . . . . . . . . . . . . . . . . . . . . 78

Figure 41 Selecting an Upload Configuration File . . . . . . . . . . . . . . . . . . 81

Figure 42 Setup Uplodad in Progress . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Figure 43 Enabling Secure Setup Upload . . . . . . . . . . . . . . . . . . . . . . . .82

Figure 44 Setup File Download Progress View . . . . . . . . . . . . . . . . . . . . 84

Figure 45 Starting Logger Content Cleanup . . . . . . . . . . . . . . . . . . . . . .84

VAISALA________________________________________________________________________ 5

Page 8

User’s Guide ______________________________________________________________________

Figure 46 Output of Logshow Command . . . . . . . . . . . . . . . . . . . . . . . . .86

Figure 47 Output of the Logstatus Command . . . . . . . . . . . . . . . . . . . . .88

Figure 48 List of Log Files Available for Downloading . . . . . . . . . . . . . . .91

Figure 49 Log File Download Settings Window . . . . . . . . . . . . . . . . . . . .92

Figure 50 Log File Download Progress View . . . . . . . . . . . . . . . . . . . . . .94

Figure 51 List of Log Files Available for Conversion . . . . . . . . . . . . . . . .95

Figure 52 Log File Conversion Settings . . . . . . . . . . . . . . . . . . . . . . . . . .96

Figure 53 Auto Download Settings Window . . . . . . . . . . . . . . . . . . . . . . .97

Figure 54 Auto Download in Progress . . . . . . . . . . . . . . . . . . . . . . . . . .100

Figure 55 Auto Download Status Window . . . . . . . . . . . . . . . . . . . . . . .101

Figure 56 Delayed Reset Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Figure 57 Reset Button on QML Logger . . . . . . . . . . . . . . . . . . . . . . . .104

Figure 58 QML Logger without Cover . . . . . . . . . . . . . . . . . . . . . . . . . .118

Figure 59 Reset Button on QML Logger . . . . . . . . . . . . . . . . . . . . . . . .123

Figure 60 Settings Menu: Calibration Window . . . . . . . . . . . . . . . . . . . .125

Figure 61 RS-232 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Figure 62 Suggested T-Connection in Dual Port Mode . . . . . . . . . . . . .140

Figure 63 SDI-12 Jumper of DSU232-C. . . . . . . . . . . . . . . . . . . . . . . . .141

Figure 64 Isolated RS-485 Module Wiring Diagram. . . . . . . . . . . . . . . .142

Figure 65 Dual RS-485 Module Wiring Diagram . . . . . . . . . . . . . . . . . .143

Figure 66 Dual RS-485 Module Default Jumper Locations . . . . . . . . . .144

Figure 67 Dual RS-485 Wiring Diagram for RS-485 and RS-232 . . . . .144

Figure 68 Dual RS-485 Wiring Diagram for SDI-12 and 12 VDC

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Figure 69 RS-232 Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Figure 70 Digital I/O Module Wiring Diagram (Digital Outputs) . . . . . . .148

Figure 71 Fixed Line Modem Wiring Diagram . . . . . . . . . . . . . . . . . . . .148

Figure 72 Ethernet Communication Module DSE101 Wiring Diagram. .149

6 ____________________________________________________________________M210784EN-E

Page 9

________________________________________________________________________________

List of Tables

Table 1 Structure of the DCP Manual Set. . . . . . . . . . . . . . . . . . . . . . . . .10

Table 2 Manual Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Table 3 Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4 Analog Measurement Channels. . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 5 Power Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Table 6 Minimum System Requirements . . . . . . . . . . . . . . . . . . . . . . . . .36

Table 7 Toolbar Icons and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Table 8 Settings in AWS Client Options Window . . . . . . . . . . . . . . . . . . .55

Table 9 Interpreting Help Texts (the Correct Syntax) . . . . . . . . . . . . . . . . 59

Table 10 Accessible Commands in Different User Levels . . . . . . . . . . . . .62

Table 11 Common Parameters Window . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Table 12 Fields in the Calibration Windows . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 13 Sensor Status List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Table 14 Fields in Manual Sensors Window . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 15 Log Memory Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 16 Log Entry Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 17 Log File Download Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 18 Log File Conversion Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 19 Settings in Auto Download Settings Window . . . . . . . . . . . . . . . . 98

Table 20 Fields in Auto Download Status Window . . . . . . . . . . . . . . . . . . . 101

Table 21 LED Blinking Sequences and Card Status Options. . . . . . . . . . .102

Table 22 Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 23 Recommended Tools for Troubleshooting. . . . . . . . . . . . . . . . . . 112

Table 24 Test Commands for GSM Modems . . . . . . . . . . . . . . . . . . . . . . .116

Table 25 Determining Operation Mode by LED Flashing . . . . . . . . . . . . . .119

Table 26 Parameters for the Open Command . . . . . . . . . . . . . . . . . . . . . .121

Table 27 Some Common Connection Problems and Their Remedies . . . .122

Table 28 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

Table 29 Columns in the Sensor Calibration Tab . . . . . . . . . . . . . . . . . . . .126

Table 30 Sensor Status List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Table 31 LED Blinking Sequences and Card Status Options. . . . . . . . . . .128

Table 32 DSU232-C Jumper Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Table 33 Jumper Settings for Channel B in the RS-485 Mode . . . . . . . . . . 143

Table 34 Jumper Settings for Channel B in the RS-232 Mode . . . . . . . . . . 144

Table 35 Jumper Settings for DSI486-B . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Table 36 Technical Data QMI108/118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Table 37 Ethernet Communication Module DSE101 Specifications . . . . . . 149

Table 38 QML201C Logger General Specifications . . . . . . . . . . . . . . . . . .150

Table 39 QML201C Logger Accuracy Specifications . . . . . . . . . . . . . . . . .151

Table 40 QML201C Logger Regulatory Compliances . . . . . . . . . . . . . . . . 152

VAISALA________________________________________________________________________ 7

Page 10

User’s Guide ______________________________________________________________________

8 ____________________________________________________________________M210784EN-E

Page 11

Chapter 1 ________________________________________________________ General Information

CHAPTER 1

GENERAL INFORMATION

This chapter provides general notes for the product(s) and this manual.

About This Manual

This manual provides information on the basic data collection hardware

and software, namely, the QML logger and its accessories, and the

software applications that are used for operating the QML logger and

viewing the logged data.

This manual is applicable for data logger QML201C and AWS Client

software version 7.00.

For more detailed and advanced information on data collection software

and telemetry, refer to the supplementary user manuals Vaisala

HydroMet™ Data Collection Platform User’s Guide, Volumes 2 and 3.

VAISALA________________________________________________________________________ 9

Page 12

User's Guide ______________________________________________________________________

Structure of the Data Collection

Platform Documentation

The information in the Vaisala HydroMet™ Data Collection Platform

manual set is divided between the different manuals in the

documentation set as outlined in Table 1 on page 10.

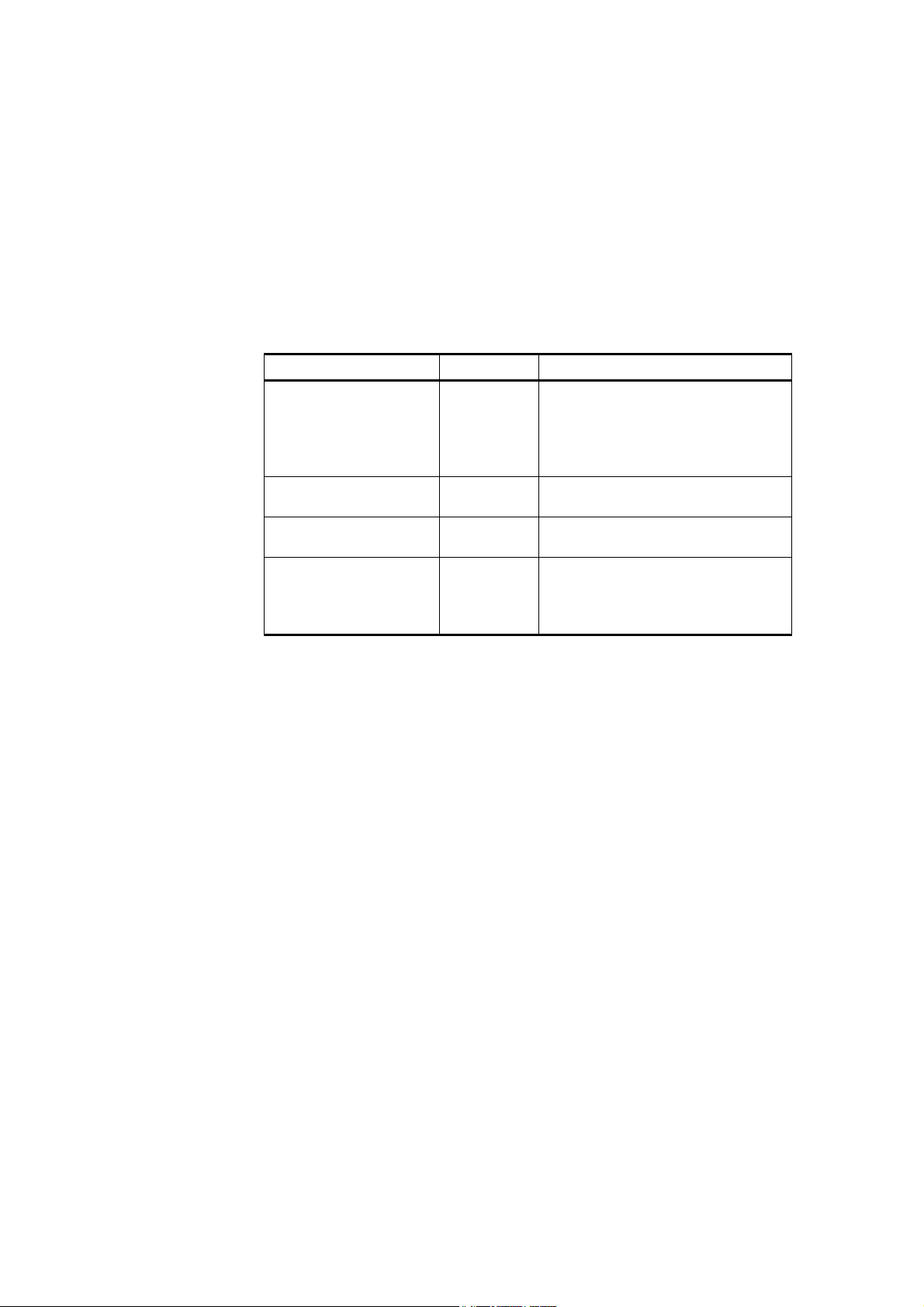

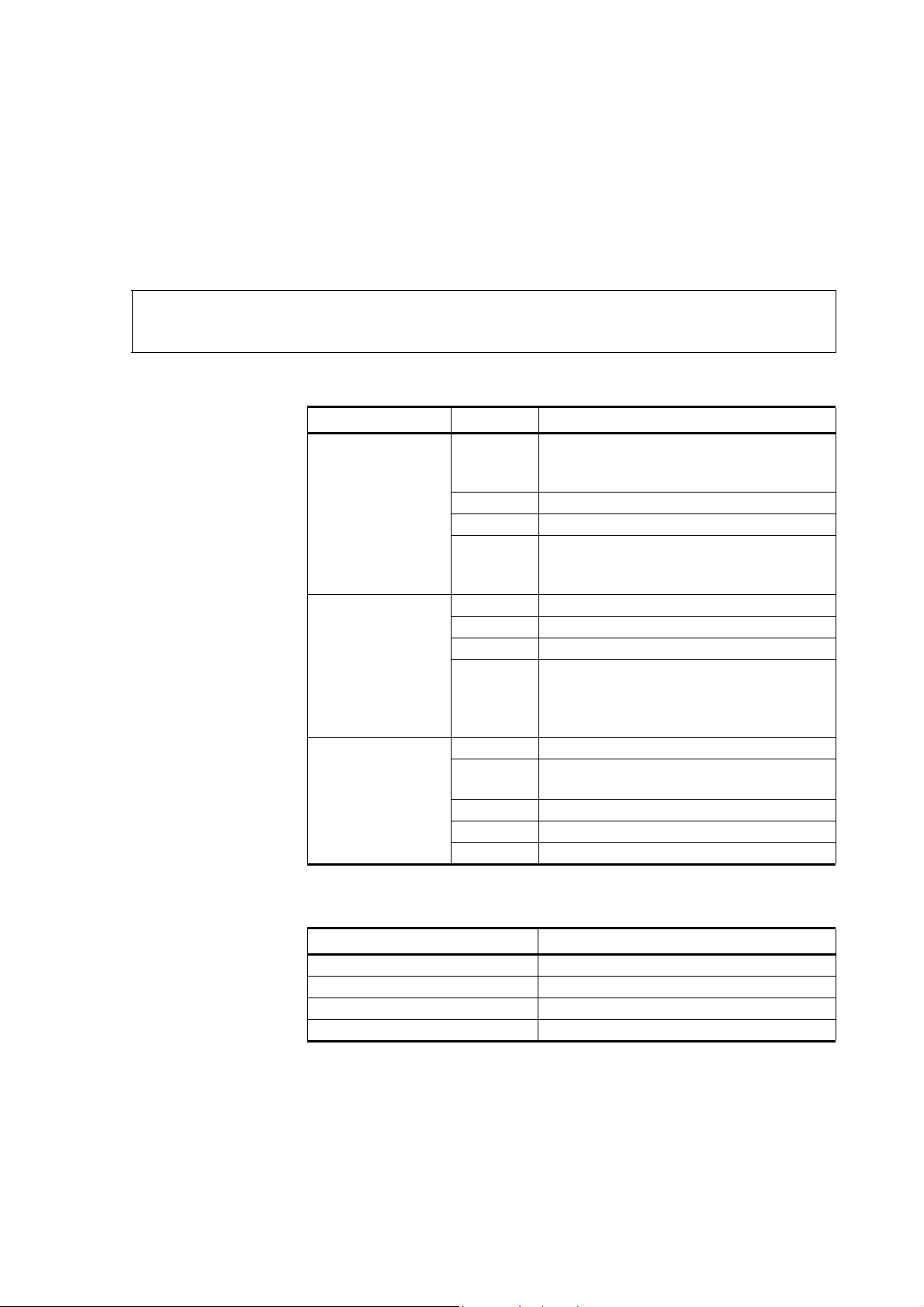

Table 1 Structure of the DCP Manual Set

Manual Code Content

User’s Guide, Volume 1 M210784EN Overview of the data collection

platform, the QML logger, and

related accessories. Operating

instructions for AWS Client

software.

User’s Guide, Volume 2 M210785EN Operating instructions for Lizard

Setup Software.

User’s Guide, Volume 3 M210933EN Telemetry and sensor configuration

in Lizard Setup Software.

Installation Manual

(Field Equipment)

M210786EN Installation information on the Data

Collection Platform with

meteorological and/or hydrological

sensors.

Contents of This Manual

This manual consists of the following chapters:

- Chapter 1, General Information: This chapter provides general

notes for the product(s) and this manual.

- Chapter 2, Product Overview: This chapter introduces the basic

data collection hardware and software.

- Chapter 3, AWS Client Software: This chapter provides

information on using Vaisala HydroMet™ Automatic Weather

Station Client, or AWS Client for short, for working with the QML

logger.

- Chapter 4, Troubleshooting: This chapter contains information on

some common problems, their probable causes and remedies.

- Chapter 5, Technical Data: This chapter provides the technical data

of the QML logger and accessory modules.

10 ___________________________________________________________________M210784EN-E

Page 13

Chapter 1 ________________________________________________________ General Information

- Appendix A, Glossary: This appendix contains a glossary with

explanations of some general meteorological and technical terms

and terms used in specifications.

Version Information

Table 2 Manual Versions

Manual Code Description

M210784EN-E This manual. For MAWS system release 8.00,

AWS Client 7.00, and data logger QML201C.

M210784EN-D Previous version. For MAWS system release

7.00, AWS Client 7.00, and data logger

QML201B.

M210784EN-C Previous version.

M210784EN-B Previous version.

M210784EN-A First version of this manual.

Related Manuals

Table 3 Related Manuals

Manual Code Manual Name

M210785EN Vaisala HydroMet™ Data Collection Platform

User's Guide, Volume 2

M210933EN Vaisala HydroMet™ Data Collection Platform

User's Guide, Volume 3

M210786EN Vaisala HydroMet™ Data Collection Platform

Installation Manual

M210629EN Automatic Weather Station MAWS101 User's

Guide

M210630EN Automatic Weather Station MAWS201 User's

Guide

M210681EN Real-time Display Software YourVIEW 2000

YVU2000 User’s Guide

M210743EN Voice Option for MAWS Technical Reference

M211022EN Configuring BUFR Reports MAWS Technical Note

VAISALA_______________________________________________________________________ 11

Page 14

User's Guide ______________________________________________________________________

Documentation Conventions

Throughout this manual, important safety considerations are

highlighted as follows:

WARNING

CAUTION

NOTE

Warning alerts you to a serious hazard. If you do not read and follow

instructions very carefully at this point, there is a risk of injury or even

death.

Caution warns you of a potential hazard. If you do not read and follow

instructions carefully at this point, the product could be damaged or

important data could be lost.

Note highlights important information on using the product.

12 ___________________________________________________________________M210784EN-E

Page 15

Chapter 1 ________________________________________________________ General Information

Product-Related Safety Precautions

The product has been tested for safety and approved as shipped from the

factory. The following safety precautions are not related to any specific

procedures and therefore do not appear elsewhere in this manual. They

are recommended precautions that personnel must understand and

apply during different phases of operation and maintenance.

WARNING

WARNING

WARNING

WARNING

Keep away from live circuits. Operating personnel must observe safety

regulations at all times. Component replacement or internal

adjustments must be made by qualified maintenance personnel. Do not

replace components with the power cable connected. Under certain

conditions, dangerous voltages may exist for some time even with the

power cable disconnected. To avoid injuries, disconnect power and

discharge circuits before touching them.

Do not service alone. Under no circumstances should any person reach

into parts and assemblies that are mains powered and alive, for the

purpose of servicing, except in the presence of someone who is

capable of rendering aid.

Personnel working with or near high voltages should be familiar with

modern methods of resuscitation.

Do not service a live system outdoors. Do not open units outdoors

when the enclosure used contains line voltage levels.

WARNING

WARNING

VAISALA_______________________________________________________________________ 13

Do not operate in an explosive atmosphere, for example, when

flammable gases or fumes are present. Operation of any electrical

instrument in such an environment constitutes a definite safety hazard.

Do not substitute parts or modify the instrument. Because of the

danger of introducing additional hazards, do not install unsuitable

parts in the instrument. Contact Vaisala or its authorized representative

for repairs to ensure that safety features are maintained.

Page 16

User's Guide ______________________________________________________________________

WARNING

CAUTION

CAUTION

Use only batteries of the same type as originally installed on the

system.

Do not make changes to the wiring. Incorrect wiring can damage the

device and prevent it from operating correctly.

Risk of damage to the equipment if the battery is replaced with an

incorrect type.

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Vaisala products are adequately protected against

ESD for their intended use. However, it is possible to damage the

product by delivering electrostatic discharges when touching,

removing, or inserting any objects inside the equipment housing.

To make sure you are not delivering high static voltages yourself:

- Handle ESD sensitive components on a properly grounded and

protected ESD workbench. When this is not possible, ground

yourself with a wrist strap and a resistive connection cord to the

equipment chassis before touching the boards. When neither of the

above is possible, at least touch a conductive part of the equipment

chassis with your other hand before touching the boards.

- Always hold the boards by the edges and avoid touching the

component contacts.

14 ___________________________________________________________________M210784EN-E

Page 17

Chapter 1 ________________________________________________________ General Information

Recycle all applicable material.

Dispose of batteries and the unit according to statutory regulations.

Do not dispose of with regular household refuse.

Recycling

Regulatory Compliances

The Vaisala HydroMet™ Data Collection Platform complies with the

following EU directives:

- Low Voltage Directive (2006/95/EC)

- EMC-Directive (2004/108/EC)

Trademarks

Vaisala HydroMet™ Data Collection Platform is a trademark of

Vaisala Oyj.

Windows® is a registered trademark of Microsoft Corporation in the

United States and/or other countries.

License Agreement

All rights to any software are held by Vaisala or third parties. The

customer is allowed to use the software only to the extent that is

provided by the applicable supply contract or Software License

Agreement.

VAISALA_______________________________________________________________________ 15

Page 18

User's Guide ______________________________________________________________________

Redistribution License Agreement

The QML logger software uses the TCP/IP stack produced by the "lwIP

Lightweight TCP/IP stack" -project with the following copyright and

license:

Copyright © 2001, 2002 Swedish Institute of Computer Science. All

rights reserved.

Redistribution and use in source and binary forms, with or without

modification, are permitted provided that the following conditions are

met:

1. Redistributions of source code must retain the above copyright

notice, this list of conditions and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright

notice, this list of conditions and the following disclaimer in the

documentation and/or other materials provided with the

distribution.

3. The name of the author may not be used to endorse or promote

products derived from this software without specific prior written

permission.

THIS SOFTWARE IS PROVIDED BY THE AUTHOR "AS IS" AND

ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE

AUTHOR BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL

DAMAGES (INCLUDING, BUT NOT LIMITED TO,

PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS

OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION)

HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

(INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY

WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF

ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

16 ___________________________________________________________________M210784EN-E

Page 19

Chapter 1 ________________________________________________________ General Information

Warranty

For certain products Vaisala normally gives a limited one-year

warranty. Please observe that any such warranty may not be valid in

case of damage due to normal wear and tear, exceptional operating

conditions, negligent handling or installation, or unauthorized

modifications. Please see the applicable supply contract or Conditions

of Sale for details of the warranty for each product.

VAISALA_______________________________________________________________________ 17

Page 20

User's Guide ______________________________________________________________________

18 ___________________________________________________________________M210784EN-E

Page 21

Chapter 2 __________________________________________________________ Product Overview

CHAPTER 2

PRODUCT OVERVIEW

This chapter introduces the basic data collection hardware and software.

Data Collection Hardware

QML Logger

1005-064

Figure 1 QML Logger

VAISALA_______________________________________________________________________ 19

Page 22

User's Guide ______________________________________________________________________

The QML logger is a complete AWS data logger designed on one

printed board only. This board contains a 32-bit Motorola CPU for data

processing and 10 differential (20 single-ended) analog sensor inputs

(these can also be used as digital inputs). Moreover, there are two

frequency sensor interfaces, a 24-bit A/D converter, 3.3 MB of secure

Flash memory for data logging, as well as an excitation power supply

for sensors and a charger for the internal backup battery. The last item

mentioned is not needed in systems where a backup battery with higher

capacity is used.

The board uses the latest SMD (Surface Mount Device) technology and

is conformal-coated for improved protection also in high humidity.

Each sensor input has a varistor (VDR) protection against induced

transients. The serial line connections, that is, RS-232 labeled as COM0

and RS-485 labeled as COM1, have two level ESD protection circuits

with VDRs directly at input pins.

The cover of the logger can be removed for installing the battery and for

resetting the weather station. In Figure 2 on page 21, the logger is shown

without the cover and the optional communication modules.

20 ___________________________________________________________________M210784EN-E

Page 23

Chapter 2 __________________________________________________________ Product Overview

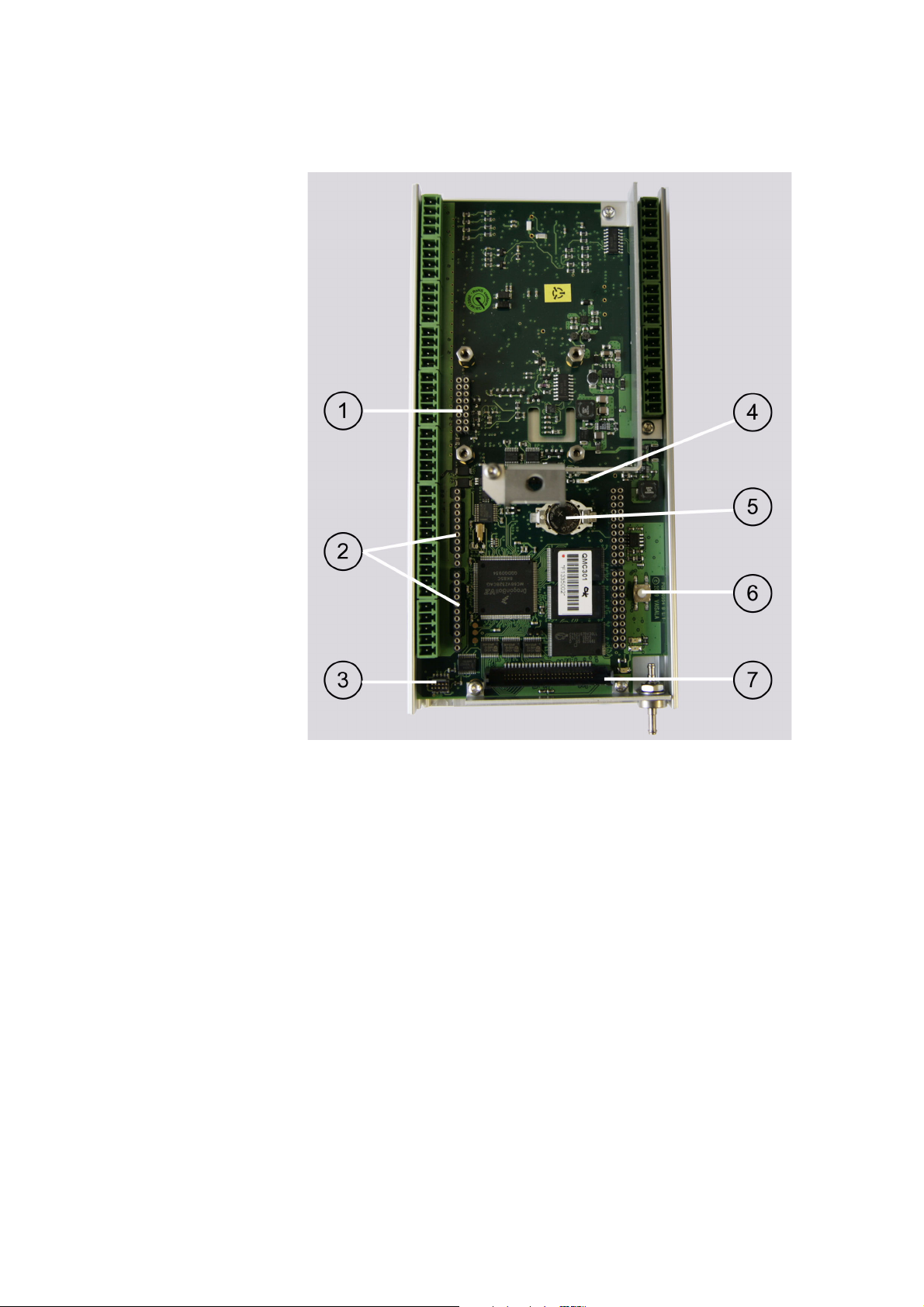

1004-120

Figure 2 QML Logger without Cover

The following numbers refer to Figure 2 on page 21:

1 = Pressure sensor connector

2 = Communication module places MOD1 and MOD2

3 = SPI connector

4 = Status LED (green)

5 = Lithium battery for RTC

6 = Reset button

7 = CF Card connector

VAISALA_______________________________________________________________________ 21

Page 24

User's Guide ______________________________________________________________________

When long signal cables are needed, these will be equipped with

optional surge voltage protection devices. These surge protectors

consist of a combination of VDRs, gas-filled discharge tubes, transzorb

diodes, and coils, thus providing excellent protection. These DIN-rail

mountable devices are easy to change without any special tools.

The QML logger is equipped with a CF card slot for logging a large

amount of data. The data is logged into daily files making it easy to

locate any particular data set for further analysis. The QML logger

supports CF cards of up to 2 GB. These cards can be read directly in the

PC. Several different types of readers are commercially available:

internal PCMCIA reader as well as external readers to be connected to

USB or parallel port of a PC. You are recommended to only use cards

purchased from Vaisala that have been tested to function in harsh

environments.

1004-042

Figure 3 CompactFlash Memory Card Reader

Optional modules include, for example, various communication

modules and a built-in pressure transducer.

QML Logger Connector Block

The QML logger includes:

1. Ten measurement channels and one internal channel for pressure

measurement.

2. One connector block for power supplies.

22 ___________________________________________________________________M210784EN-E

Page 25

Chapter 2 __________________________________________________________ Product Overview

3. One connector block for communication channels.

4. Two blocks for optional communication modules.

Single-ended (H-C or L-C) or differential (H-L) measurements can be

performed in the 10 measurement channels.

NOTE

Each sensor in a basic setup has its own dedicated channel. Table 4 on

page 23 is to be used for reference purposes only.

Table 4 Analog Measurement Channels

Channels Pin Name Description

CH0, CH1, CH2,

CH3 24-bit ADC

CH4, CH5, CH6,

CH7 24-bit ADC

CHA, CHB Suitable

for fast-changing

input signals 12-bit

ADC

E 12 V/25 mA voltage excitation ON/OFF,

voltage can be measured.

OR: 100 A/1mA current excitation.

H Analog input (High)

L Analog input (Low)

C The pin has been connected to ground

(GND) via a 10 resistor so that the

current can be measured.

E 100 A/1 mA current excitation

H Analog input (High)

L Analog input (Low)

C Common return and reference level for

voltage measurements via the channel's

own E-, H-, and L-pins. The pin has been

connected directly to ground.

F Frequency input

E 0 ... 12 V/20 mA adjustable excitation

voltage, can be measured.

H Fast analog input (High)

L Fast analog input (Low)

C Common return (Analog ground)

Table 5 Power Channels

Pin Name Description

GND Ground

SDI-12 SDI-12

GND Ground

+ExtDC 8 ... 30 VDC

VAISALA_______________________________________________________________________ 23

Page 26

User's Guide ______________________________________________________________________

1003-029

Figure 4 Connector Blocks

24 ___________________________________________________________________M210784EN-E

Page 27

Chapter 2 __________________________________________________________ Product Overview

Accessories

Sensor Multiplexer

NOTE

NOTE

0802-049

Figure 5 Sensor Multiplexer QMU101

The QML logger provides the possibility to extend the measuring

capacity with the optional QMU sensor multiplexer. It is designed to

increase the number of analog measurement channels with eight 16-bit

analog channels and two 12-bit analog channels. The unit increases the

measuring capacity with ten differential measurements or alternatively

with 20 single-ended measurements.

The unit interfaces to the logger via the RS-485 line, and is also located

inside the enclosure. The unit conforms to the same environmental

immunity and emission standards as the logger.

The multiplexer unit makes only analog measurements.

The multiplexer unit can only be connected to the QML201 logger or

newer. The type of the logger can be checked with the VER command.

VAISALA_______________________________________________________________________ 25

Page 28

User's Guide ______________________________________________________________________

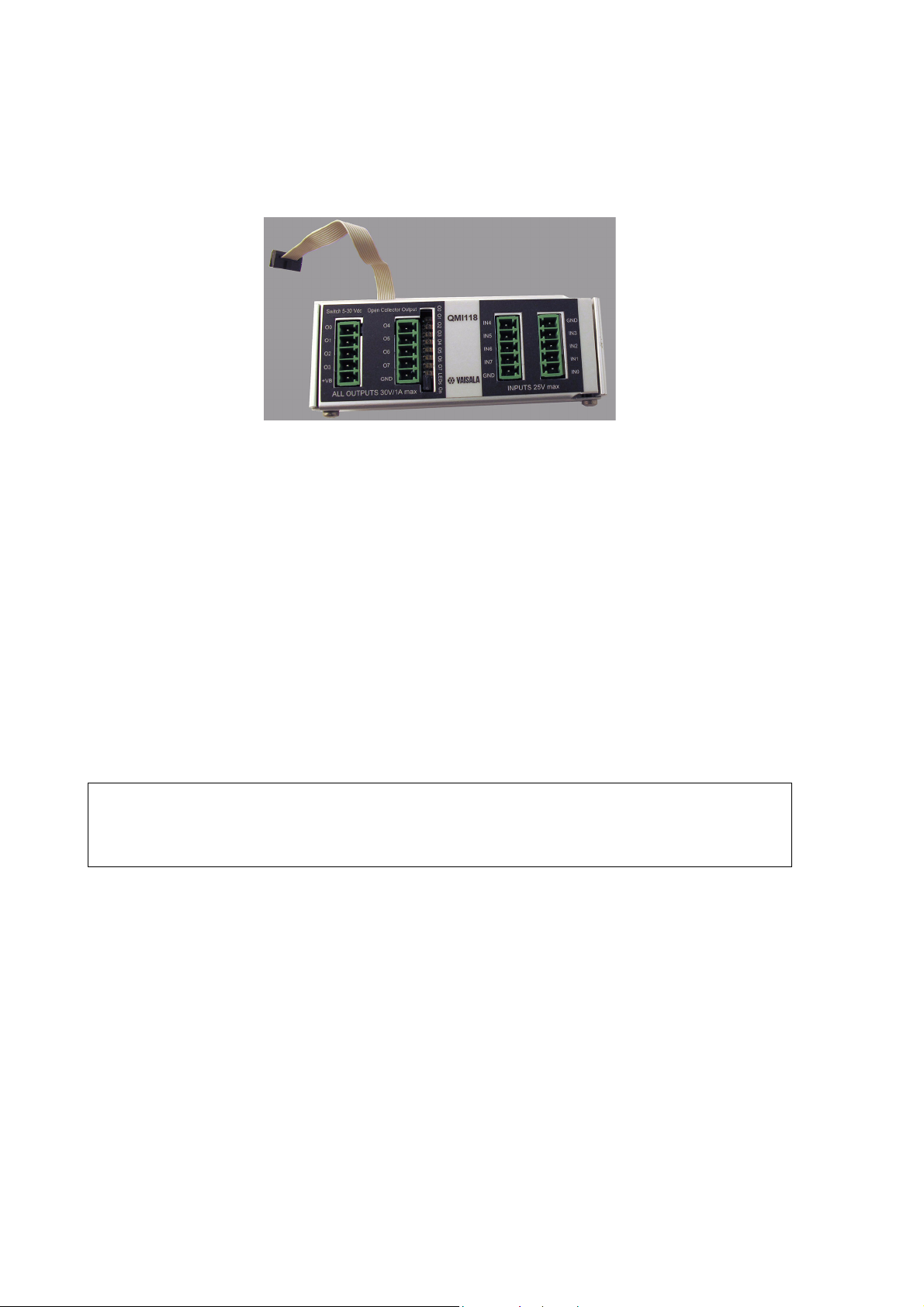

Digital I/O Module

1004-041

Figure 6 Digital I/O Module QMI118

The QML logger provides the possibility to extend the I/O capacity with

the optional digital I/O module (QMI) equipped with eight inputs and

eight outputs. The digital I/O module interfaces to the logger via the SPI

connector. The module is located inside the enclosure beside the logger

and it conforms to the same environmental immunity and emission

standards as the logger.

NOTE

The module has eight open collector outputs with 30 VDC/1 A

continuous drive capability and LED indicators. The eight inputs of the

module tolerate voltages from 0 to 25 VDC (the absolute maximum

30 VDC) and they have 40 ms (typical) contact debouncing circuitry.

The module allows connection of slow pulse inputs, for example, with

tipping bucket rain gauges.

The digital I/O module can only be connected to the QML201 logger

or newer. The type of the logger can be checked with the VER

command.

26 ___________________________________________________________________M210784EN-E

Page 29

Chapter 2 __________________________________________________________ Product Overview

Transient Protection Devices

Each sensor input in the logger has a varistor (VDR) protection against

induced transients. The maintenance terminal I/O ports have transzorb

diodes in their inputs.

In case of long signal cables, additional transient protectors can be

installed on the DIN rail. These surge protectors consist of a

combination of VDR, transzorb diodes, and coils, thus providing

excellent protection. These are easy to change in the field without tools.

0802-050

Figure 7 Surge Protector for Serial Lines

Optional coaxial surge protectors can be used for UHF and VHF

antennas as well as for the RF signal input when radio or satellite

equipment is used.

VAISALA_______________________________________________________________________ 27

Page 30

User's Guide ______________________________________________________________________

Communication Modules

RS-232 Module

The RS-232 communication module is unisolated, providing either a

double serial channel without handshaking (dual RS-232 module) or a

single RS-232 with handshaking (single RS-232 module). The power

consumption is less than 15 mA when communicating, less than 5 mA

at standby.

The later version of the module (DSU232C) adds a separate SDI-12

interface that can be taken into use by jumper selection. Wiring for the

SDI-12 is similar to the dual RS-485 module described in section Dual-

Isolated RS-485 Communication Module on page 29.

In other aspects, the later version is compatible with the old one and can

thus be used as a spare part without modifications to the system.

0403-106

Figure 8 RS-232 Communication Module DSU232

Isolated RS-485 Communication Module

0403-107

Figure 9 Isolated RS-485 Communication Module DSI485

28 ___________________________________________________________________M210784EN-E

Page 31

Chapter 2 __________________________________________________________ Product Overview

The RS-485 isolated communication module provides a 2-wire or 4wire RS-485-communication link between two devices with a similar

interface. This module is used, for example, for connecting displays and

terminals to the data logger when the distance is longer than 15 meters.

The maximum distance for the isolated RS-485 module is

approximately 1500 meters at full speed. The module must be

configured before use.

Dual-Isolated RS-485 Communication Module

0906-070

Figure 10 Dual-Isolated RS-485 Communication Module

DSI486

The RS-485 dual communication module is dual-isolated and can be

used in the RS-232, RS-485, or SDI-12 mode. The communication

mode is selected by the correct wiring of the I/O pins and with the

correct jumper settings on the board. The dual RS-485 communication

module is used, for example, for connecting displays, terminals, and the

data logger together when the distance is longer than 15 meters. The

maximum distance is approximately 1500 meters at full speed. The

module must be configured before use.

The RS-485/422 channels A and B are galvanically isolated from the

host board's electronics. The +5 VDC power supplies of channels A and

B are also isolated from each other with capacitors. Thus, it is possible

to wire these two channels to separate locations.

The RS-232 mode utilizes channel B. When channel B is used in the

RS-232 mode, it is possible to use channel A as a galvanically isolated

two-wire RS-485 channel. The RS-232 channel is galvanically

connected to the host board's GND potential.

VAISALA_______________________________________________________________________ 29

Page 32

User's Guide ______________________________________________________________________

The SDI-12 channel has its own connecting point on the board. It does

not use channel A or B for the communication. SDI-12 is galvanically

connected to the host board's GND potential.

There is a later version of this module, DSI486-B, that widens the

operating range and usable RS-485 line speed. The later version has the

same functionality as the original one and can be used as a drop-in

replacement without changes to the system configuration. Note that its

jumper locations and settings are slightly different.

Fixed Line Modem Module

The fixed line modem module is used for providing a long-distance

fixed line connection between two Vaisala devices with a similar

interface. It is used when the distance is up to 10 km, for example,

between the QML logger and a digital display, or between a ceilometer

and the logger. Through this I/O port, a remote location can send reports

and data or the host can poll them. The fixed line modem module must

be configured before use.

0306-013

Figure 11 Fixed Line Modem Module DMX501

The fixed line modem module supports the following communication

standards:

- V.21, 300 bps FSK

- V.23, 1200 / 75 bps FSK

- V.22, 1200 bps DPSK

30 ___________________________________________________________________M210784EN-E

Page 33

Chapter 2 __________________________________________________________ Product Overview

Ethernet Communication Module DSE101

1004-122

Figure 12 Ethernet Communication Module DSE101

Ethernet Communication Module DSE101 is a single, compact, printed

circuit board. It provides a 10Base-T Ethernet interface for the QML

logger, thus allowing the logger to be accessed, for instance, directly

from a LAN environment. DSE101 supports 10/100/1000 Mbps

switches and routers, full/half duplex operation, and autonegotiation.

Because DSE101 always transmits data at 10 Mbps, the connecting

switch or router must not be locked to 100 Mbps or faster speed.

DSE101 requires version 6.01 of MAWS software or higher to operate.

VAISALA_______________________________________________________________________ 31

Page 34

User's Guide ______________________________________________________________________

Data Collection Software

The QML logger works based on what is known as a setup. A setup is

a set of parameters that tells the logger what to measure, log, calculate,

and report. Measured data is stored in the daily log files that can be

downloaded to a PC and viewed using display software. The delivery/

project-specific data reports can be configured to collect data from

weather stations by data collection systems.

Usually, a delivery-specific setup has been loaded in the QML logger

program memory at the factory. Therefore you simply need to connect

the sensors, connect communication lines, and supply power. Your

station will then start operating, that is, making measurements, doing

calculations, and sending reports. Normally, the provided example

setups, such as the Basic setup, need to be modified according to

delivery-specific requirements. The setups are modified using Lizard

Setup Software.

On the delivery CD-ROM, you will find several setup examples. The

delivered setups will suit typical needs, but you may want to make

changes to them. For reconfiguring the setup files or making entirely

new ones, refer to Vaisala HydroMet™ Data Collection Platform

User’s Guide, Volumes 2 and 3.

The log files downloaded to a PC can be viewed using AWS Client

software. Alternatively, the data values can be viewed with YourVIEW

Basic Display Software or Vaisala Digital Displays.

Operating Software

The embedded operating software runs in the QML logger. Access to

the operating software commands can be gained using AWS Client

software.

AWS Client Software

Vaisala AWS Client software is used for downloading data log files,

issuing QML logger commands and setting its parameters, and

performing maintenance tasks on the QML logger. The supported

connection types to the QML logger are serial line, dial-up connections

using a modem, and TCP/IP socket connections. The logger measures

sensor data and stores it in log files. With AWS Client, you can

download these files to your PC and view them.

32 ___________________________________________________________________M210784EN-E

Page 35

Chapter 2 __________________________________________________________ Product Overview

When you start using the QML logger, the first thing you need to do is

to define what parameters you want to measure and at what frequency.

You can do this by creating the setup file using Lizard Setup Software.

With AWS Client, you can upload the setup file from your PC to the

logger.

AWS Client is also used for setting station-specific parameters such as

the station name, altitude, pressure sensor height, and sensor-specific

calibration coefficients. In addition, the QML logger date and time can

be either set manually or synchronized with the PC clock.

After you have uploaded the setup files to the QML logger, you can

browse the data files by downloading them from the logger to your PC.

With AWS Client, you can convert the data log files into CSV format

for viewing in other applications, such as Microsoft Excel. You can

define several download settings, such as an automatic download

schedule, where you want to save the downloaded files and what

operations the program performs automatically at each download.

For more detailed information, refer to Chapter 3, AWS Client

Software, on page 35.

Setup Software

Lizard Setup Software

Lizard Setup Software is used to configure the software parameters and

operation of the QML logger. With the Lizard Setup Software, you can

create or modify a QML logger setup file.

Creating a setup with Lizard Setup Software is divided into several

stages. First, you define an assembly for your system. Next, you define

the necessary measurements and the calculations derived from them.

Finally, you define reports and log groups from the measurement

results.

When your configuration is complete with Lizard Setup Software, use

the Generate functionality to create a setup file that contains all the

information. The setup file is then transferred into the logger using

AWS Client software.

For more detailed information, refer to Vaisala HydroMet™ Data

Collection Platform User’s Guide, Volumes 2 and 3.

VAISALA_______________________________________________________________________ 33

Page 36

User's Guide ______________________________________________________________________

Updating QML Software

The QML logger software may need to be updated in order for you to

utilize new features published by Vaisala.

CAUTION

Update the QML logger software only when requested by Vaisala.

Please contact Vaisala for further instructions.

34 ___________________________________________________________________M210784EN-E

Page 37

Chapter 3 _______________________________________________________ AWS Client Software

CHAPTER 3

AWS CLIENT SOFTWARE

This chapter provides information on using Vaisala HydroMet™

Automatic Weather Station Client, or AWS Client for short, for

working with the QML logger.

Product Overview

Vaisala AWS Client is used for downloading data log files, issuing

QML logger commands and setting its parameters, and performing

maintenance tasks on the QML logger. The supported connection types

to the QML logger are serial line, dial-up connections using a modem,

and TCP/IP socket connections. The logger measures sensor data and

stores it in log files. With AWS Client, you can download these files to

your PC and view them.

When you start using the QML logger, the first thing you need to do is

to define what parameters you want to measure and at what frequency.

You can do this by creating the setup file using Lizard Setup Software.

With AWS Client, you can upload the setup file from your PC to the

logger.

AWS Client is also used for setting station-specific parameters such as

the station name, altitude, pressure sensor height, and sensor-specific

calibration coefficients. In addition, the QML logger date and time can

be either set manually or synchronized with the PC clock.

After you have uploaded the setup files to the QML logger, you can

browse the data files by downloading them from the logger to your PC.

VAISALA_______________________________________________________________________ 35

Page 38

User's Guide ______________________________________________________________________

With AWS Client, you can convert the data log files into CSV format

for viewing in other applications, such as Microsoft Excel. You can

define several download settings, such as an automatic download

schedule, where you want to save the downloaded files, and what

operations the program performs automatically at each download.

Installing AWS Client

AWS Client is installed from the MAWS software CD using an

installation wizard.

Minimum System Requirements

Minimum system requirements for the AWS Client software are listed

in Table 6 on page 36.

Table 6 Minimum System Requirements

Component Minimum Requirement

PC 500 MHz

Operating System

Memory 256 MB RAM

Hard Disk Space 100 MB

Drives CD-ROM Drive

1. With Service Pack 1 or later

2. With Service Pack 4 or later

Windows® XP

1

or Windows® 2000

2

36 ___________________________________________________________________M210784EN-E

Page 39

Chapter 3 _______________________________________________________ AWS Client Software

Installation Procedure

NOTE

All installation procedures must be performed logged in as an

administrator.

AWS Client software is installed from the MAWS software installation

CD.

To install AWS Client, proceed as follows:

1. Insert the installation CD-ROM disc into your CD drive and select

setup.exe.

2. The AWS Client installation wizard starts, and the Welcome

window shown in Figure 13 on page 37 is displayed. Begin the

installation by selecting Next.

0802-043

Figure 13 Installation Wizard Welcome Window

3. The License Agreement window shown in Figure 14 on page 38

is displayed next. Read the license agreement and accept it. Select

Next to continue the installation.

VAISALA_______________________________________________________________________ 37

Page 40

User's Guide ______________________________________________________________________

0802-046

Figure 14 License Agreement Window

4. The Select Installation Folder window is displayed next as shown

in Figure 15 on page 39. To install the AWS Client software in the

default installation folder, select Next. You can also change the

installation folder on your desktop computer by selecting Browse

and then browsing for the folder you want or by entering the

installation folder path in the Folder field.

38 ___________________________________________________________________M210784EN-E

Page 41

Chapter 3 _______________________________________________________ AWS Client Software

0802-044

Figure 15 Select Installation Folder Window

5. The Ready to Install window is displayed as shown in Figure 16

on page 39. Start the installation by selecting Install.

0802-045

Figure 16 Ready to Install Window

VAISALA_______________________________________________________________________ 39

Page 42

User's Guide ______________________________________________________________________

6. Once the installation is complete, the Installation Complete

window presented in Figure 17 on page 40 is displayed. Exit the

installation wizard by selecting Finish.

0802-047

Figure 17 Installation Complete Window

7. After installation, you can access the AWS Client software via the

Vaisala program group in the All Programs list in the Windows

Start menu.

40 ___________________________________________________________________M210784EN-E

Page 43

Chapter 3 _______________________________________________________ AWS Client Software

Establishing Terminal Connection

To connect your computer to the QML logger serial port, proceed as

follows:

1. Connect the provided terminal cable to the Maintenance terminal

connector on the bottom flange of the enclosure and to an available

COM port on your PC, or, with an additional cable, to the USB port

on your PC. See Figure 18 on page 41.

0411-045

Figure 18 Connecting Terminal Cable

2. Start the AWS Client software on your PC, as instructed in section

Using AWS Client Software on page 43.

3. Set the communication parameters: 9600, N, 8, 1. For more

information, see section Opening Service Connection on page 57.

4. Open the service connection by selecting Terminal Connect on

the Maintenance menu or by clicking the Open command mode

button on the toolbar.

Figure 19 on page 42 shows the pin order for the terminal connector.

VAISALA_______________________________________________________________________ 41

Page 44

User's Guide ______________________________________________________________________

0304-025

Figure 19 Terminal Connector COM0 Pins

The following numbers refer to Figure 19 on page 42.

1 = Not connected

2=RxD

3=GND

4=TxD

5 = Not connected

42 ___________________________________________________________________M210784EN-E

Page 45

Chapter 3 _______________________________________________________ AWS Client Software

Using AWS Client Software

Starting and Exiting AWS Client

You can start AWS Client by clicking the Start button and then

selecting Programs - Vaisala - AWS Client. AWS Client is opened

with the terminal main window shown in Figure 20 on page 43.

0802-134

Figure 20 Terminal Main Window

When the service connection is closed, the messages and reports appear

on the main window as shown in Figure 21 on page 44. Some values are

shown as slashes because they will be calculated from the measured

values later.

VAISALA_______________________________________________________________________ 43

Page 46

User's Guide ______________________________________________________________________

NOTE

0802-135

Figure 21 Terminal Showing Report

The report type and appearance shown in Figure 21 on page 44 depend

on your setup.

You can exit AWS client by selecting the Exit option from the File

menu.

AWS Client Main Window

On top of the main window, you can find the AWS Client toolbar. The

toolbar is the quickest way to select functions.

Table 7 Toolbar Icons and Functions

Icon Function Description

Open connection Opens the address book for selecting the

weather station to connect to.

Close current

connection

Closes the connection to the QML logger.

Open command

mode

44 ___________________________________________________________________M210784EN-E

Opens the service connection for issuing

commands to the QML logger.

Page 47

Chapter 3 _______________________________________________________ AWS Client Software

Table 7 Toolbar Icons and Functions (Continued)

Icon Function Description

Close command

mode

Upload setup file Selects the new configuration (setup) file you

Closes the service connection. The terminal

window begins to show the messages and

reports configured in the QML logger.

want to upload and starts uploading.

Download log

files

Copy selected

text from terminal

window

Clear terminal

window

Set common

parameters

Set static

parameters

Set manual

sensor values

Show system

information

Selects the data log files you want to download

and starts downloading.

Copies the selected text from the terminal

window to Windows Clipboard.

Clears the commands and responses in the

terminal window.

Opens the Common Parameters window for

editing and viewing the parameter values.

Opens the Static Parameters window for

editing and viewing the parameter values.

Opens the Manual Sensors window for

viewing and setting manual sensor

measurements.

Displays information on the QML logger with

which the connection has been established.

Defining AWS Client Settings

When you start the software for the first time, you need to define the

settings to be used during download. Use the Settings menu options for

this purpose.

Read Only Mode

Multiple instances of AWS Client can be open simultaneously.

However, changes to the AWS Client settings can be permanently saved

only from the instance that was started first; all subsequent instances run

in read only mode, and cannot be used for changing settings.

Address Book

The AWS Client Address Book, shown in Figure 22 on page 46, is used

for storing and maintaining information on connections and their

VAISALA_______________________________________________________________________ 45

Page 48

User's Guide ______________________________________________________________________

parameters. The connection parameters to be configured depend on the

connection type: serial line, dial-up connection, or TCP/IP socket

connection. The following sections describe the parameters for each

connection type.

0802-136

Figure 22 Address Book Window

Serial Line Connections

To add an Address Book entry for a serial line connection, proceed as

follows:

1. On the Settings menu, select Address Book.

2. Select New. The fields for selecting new connection parameters are

displayed.

3. From the Type list, select the type of the connection; that is, select

Serial Port. The fields for selecting a serial port connection,

shown in Figure 23 on page 47, are displayed.

46 ___________________________________________________________________M210784EN-E

Page 49

Chapter 3 _______________________________________________________ AWS Client Software

0905-008

Figure 23 Creating Serial Line Address Book Entry

4. In the Name field, enter an alphanumeric string that uniquely

identifies the connection you are creating in the Address Book.

5. If you have multiple QML loggers on the same network, and you

are going to access them over the same serial connection, you will

need a unique identifier for each logger. To uniquely identify the

logger for which you are creating an Address Book entry, enter a

unique alphanumeric string in the Station id field. If you only have

a single logger on the network, you can leave the Station id entry

blank.

6. In the Command wait timeout (ms) field, enter a value in

milliseconds that specifies for how long AWS Client will wait for

the logger to respond when AWS Client sends a requests over the

serial line connection. If the request, for instance, a log file

download, succeeds within the timeout, a success message is

displayed. If the request fails, a failure message is displayed

instead, and you have the option to try again at a later time. Factors

such as the current load on the logger, delays in the connection, and

VAISALA_______________________________________________________________________ 47

Page 50

User's Guide ______________________________________________________________________

the response length affect whether or not the timeout will expire

during a request.

7. From the COM port field, select the serial port to be used on your

computer and the line parameters. The default line parameters for

the QML logger are 9600 bps, No parity bit, 8 data bits, 1 stop bit,

No flow control.

8. If you are using a modem to connect to the QML logger, enter also

the Telephone number to dial, the modem Initialization and Dial

commands, and the Hangup command. For instance, in the

Initialization command field, you could enter "ATE\rATX1";

that is, multiple AT commands separated by a "\r". Likewise, in the

Dial-up command field, you could enter ATDT123456; that is, an

AT command immediately followed by a phone number.

9. Save your settings and return to the Address Book window by

selecting Save.

TCP/IP Socket Connections

Using TCP/IP socket to connect to the QML logger requires that the

logger setup contains a virtual COM port with matching configuration:

- Service connection is enabled

- Incoming connection is enabled (client socket only)

- Port setting matches with AWS Client (client socket only)

- Target IP and port settings match with AWS Client (server socket

only)

For further information, see section Virtual COM Port in Vaisala

HydroMet™ Data Collection Platform User's Guide, Volume 3.

If QML logger with DSE101 Ethernet piggyback does not have a valid

setup but its IP address is known, it can be connected with a client

socket connection to port 50000.

To add an Address Book entry for a TCP/IP socket connection, proceed

as follows:

1. On the Settings menu, select Address Book.

2. Select New. The fields for selecting new connection parameters are

displayed.

48 ___________________________________________________________________M210784EN-E

Page 51

Chapter 3 _______________________________________________________ AWS Client Software

3. From the Type list, select Client socket or Server socket as the

connection type. The fields for selecting the TCP/IP connection

parameters, shown in Figure 24 on page 49, are displayed.

0905-009

Figure 24 Creating TCP/IP Socket Connection Address

Book Entry

4. In the Name field, enter an alphanumeric string that uniquely

identifies the connection you are creating in the Address Book.

5. If you have multiple QML loggers on the same network, and you

are going to access them over the same TCP/IP connection, you

will need a unique identifier for each logger. To uniquely identify

the logger for which you are creating an Address Book entry, enter

a unique alphanumeric string in the Station id field. However, if

you only have a single logger on the network, you can leave the

Station id entry blank.

6. In the Command wait timeout (ms) field, enter a value in

milliseconds that specifies for how long AWS Client will wait for

the logger to respond when AWS Client sends a requests over the

TCP/IP connection. If the request, for instance, a log file

download, succeeds within the timeout, a success message is

VAISALA_______________________________________________________________________ 49

Page 52

User's Guide ______________________________________________________________________

displayed. If the request fails, a failure message is displayed

instead, and you have the option to try again at a later time. Factors

such as the current load on the logger, delays in the connection, and

the response length affect whether or not the timeout will expire

during a request.

7. In the IP addr./DNS name field, enter the destination IP address

or DNS name.

NOTE

NOTE

In order to use the DNS name, must have access to a DNS server to be

able to resolve the DNS name to the IP address of the destination host.

For Server socket, the target IP addr./DNS name is not available in

the user interface.

8. Enter the port to be used in the Port field. Note that for Client

socket, this must match the port set for incoming connections in

the interface configuration in the QML logger. For Server socket,

Host address and port defined for virtual COM port must match the

AWS Client IP address and port.

9. If support for Telnet escape sequences for binary file transfer is

required, select the Telnet option.

10. Save your settings and return to the Address Book window by

selecting Save.

Server Socket with SMS

It is possible to trigger server socket connection open from logger to

AWS Client by sending an SMS to the logger. This mode of connection

requires advanced configuration on the logger and a GSM modem

connected to the PC running the AWS Client software. For further

information, see section IP Service Connectivity with GSM in Vaisala

HydroMet™ Data Collection Platform User's Guide, Volume 3.

To add an Address Book entry for a server socket connection with SMS,

proceed as follows:

1. On the Settings menu, select Address Book.

2. Select New. The fields for selecting new connection parameters are

displayed.

50 ___________________________________________________________________M210784EN-E

Page 53

Chapter 3 _______________________________________________________ AWS Client Software

3. From the Type list, select Server Socket with SMS as the

connection type. The fields for selecting the TCP/IP connection

parameters are displayed, as shown in Figure 25 on page 51.

0905-014

Figure 25 Creating Server Socket with SMS Address Book

Entry

4. In the Name field, enter an alphanumeric string that uniquely

identifies the connection you are creating in the Address Book.

5. If you have multiple QML loggers on the same network, and you

are going to access them over the same serial connection, you will

need a unique identifier for each logger. To uniquely identify the

logger for which you are creating an Address Book entry, enter a

unique alphanumeric string in the Station id field. If you only have

a single logger on the network, you can leave the Station id entry

blank.

6. In the Command wait timeout (ms) field, enter a value in

milliseconds that specifies for how long AWS Client will wait for

the logger to respond when AWS Client sends a requests over the

serial line connection. If the request, for instance, a log file

download, succeeds within the timeout, a success message is

VAISALA_______________________________________________________________________ 51

Page 54

User's Guide ______________________________________________________________________

displayed. If the request fails, a failure message is displayed

instead, and you have the option to try again at a later time. Factors

such as the current load on the logger, delays in the connection, and

the response length affect whether or not the timeout will expire

during a request.

7. In the Port field, enter the port where the logger is configured to

connect to. For further information, see section IP Service

Connectivity with GSM in Vaisala HydroMet™ Data Collection

Platform User's Guide, Volume 3.

8. In the GSM Modem COM Port field, select the PC COM port

where the GSM modem is connected to.

9. In the GSM Modem Baud rate field, select the baud rate for the

GSM modem.

10. In the GSM Modem Flow control field, select the flow control

mode for the GSM modem.

11. In the Telephone number field, enter the telephone number of the

logger's GSM modem.

12. In the Wake-up message field, enter open <connX>, where

<connX> refers to the logger SMS handler configuration. For

further information, see section IP Service Connectivity with GSM

in Vaisala HydroMet™ Data Collection Platform User's Guide,

Volume 3.

13. In the Optional initialization commands field, enter additional

initialization commands for the modem. For example:

AT+CPIN="XXXX"

AT+CSCA="<sms central number>"

14. Save your settings and return to the Address Book window by

clicking Save.

It is also possible to use an external program to execute the SMS

sending. In this case, select the Use external command option and

enter startup command and parameters for launching the external

program in the Program command line field. In this case, neither the

modem settings nor the wake-up message are used.

NOTE

Connecting to the logger with this method can involve significant

delays, which depend on how fast the SMS gets through and the logger

manages to establish a GSM connection for IP.

52 ___________________________________________________________________M210784EN-E

Page 55

Chapter 3 _______________________________________________________ AWS Client Software

Dial-Up Connections

The dial-up connections are based on Windows Dial-Up Networking

entries, so you first need to create the connection in Windows. For

information on creating Windows Dial-Up Networking connections,

please see the Windows online help. To add an Address Book entry for

the dial-up connection, proceed as follows:

1. On the Settings menu, select Address Book.

2. Select New. The fields for selecting new connection parameters are

displayed.

3. From the Type list, first select Socket. The field for selecting

Windows Dial-Up Networking entries is available in the window

shown in Figure 26 on page 53.

0802-139

Figure 26 Creating Dial-up Connection Address Book

Entry

4. In the Name field, enter an alphanumeric string that uniquely

identifies the connection you are creating in the Address Book.